Patents

Literature

149results about How to "Low toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

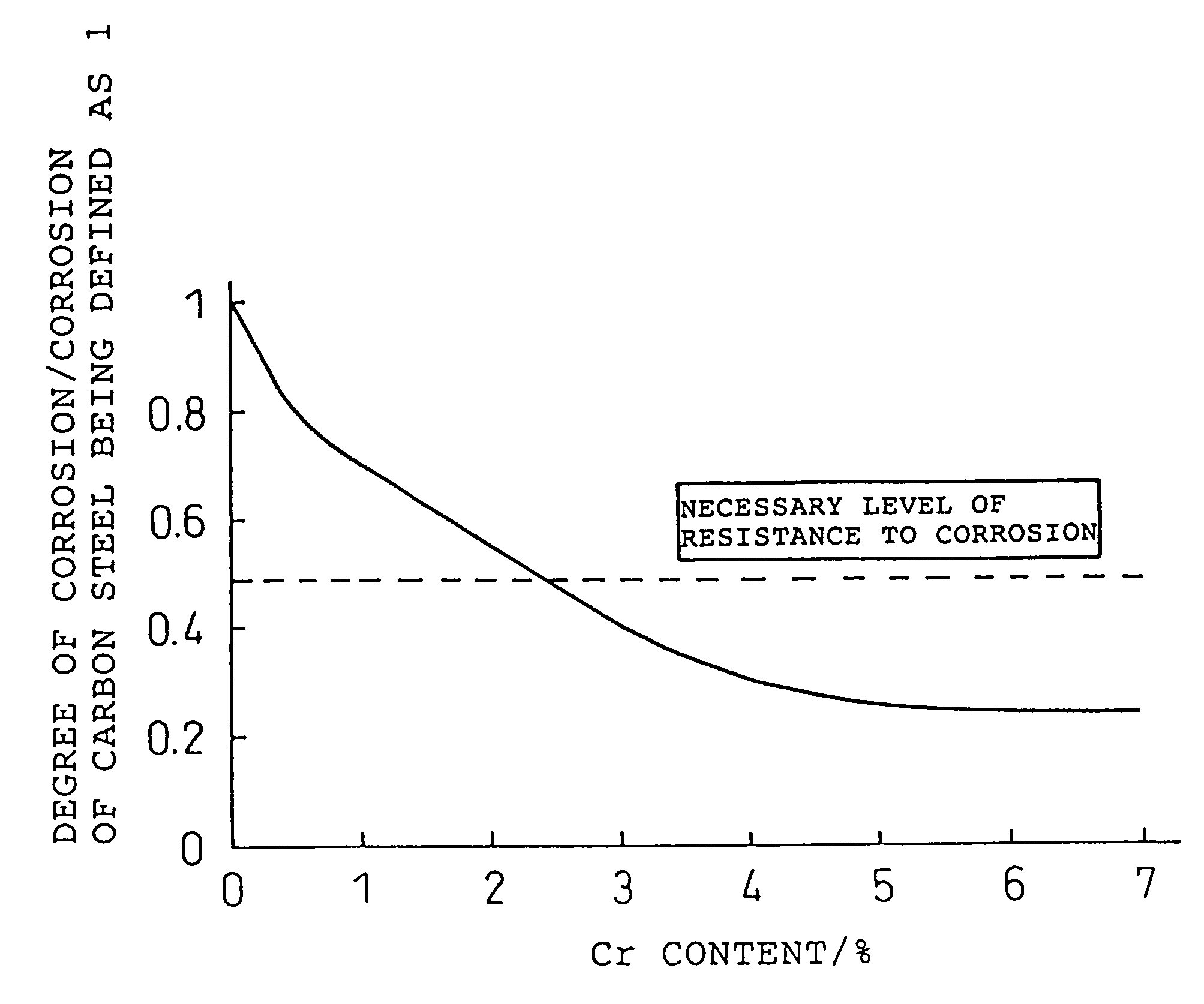

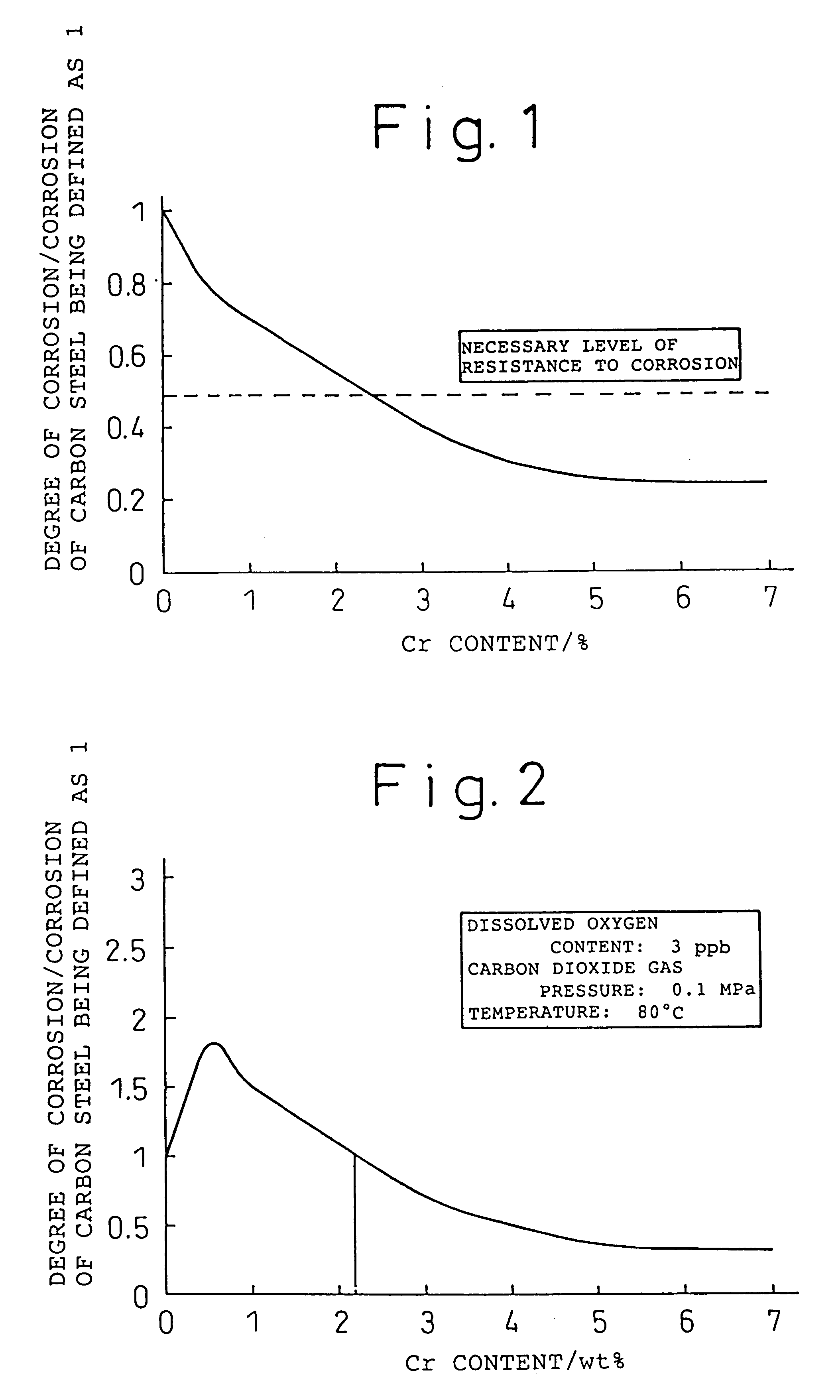

Corrosion resisting steel and corrosion resisting oil well pipe having high corrosion resistance to carbon dioxide gas

InactiveUS6248187B1Excellent in resistance to corrosionHigh strengthMartensiteUltimate tensile strength

An object of the present invention is to provide a corrosion resistant steel excellent in strength and low temperature toughness as well as resistance to corrosion by carbon dioxide and seawater, and most suitable for oil well steel pipes and line pipes for production and transportation of gas, petroleum, etc. used in the field of energy, or a steel for plants, and corrosion resistant oil well steel pipes. The corrosion resistant steel and the corrosion resistant oil well steel pipes comprise, based on weight, up to 0.30% of C, up to 1.0% of Si, 0.2 to 2.0% of Mn, 2.1 to less than 5.0% of Cr, up to 0.03% of P, up to 0.02% of S, up to 0.10% of Al, up to 0.015% of N, optionally containing Cu, Ni, Mo, Ti, Nb and B, and the balance of Fe and unavoidable impurities, and have a martensitic structure as their metallic structure.

Owner:NIPPON STEEL CORP

Flux-cored wire for stainless steel arc welding

ActiveUS20110139761A1Guaranteed Low Temperature ToughnessImprove corrosion resistanceWelding/cutting media/materialsWelding/soldering/cutting articlesRare-earth elementMetallurgy

A flux-cored wire for stainless steel arc welding including an outer sheath made of stainless steel and flux filled up in the outer sheath contains, as percentage to the total mass of the wire, Cr: 22.0-30.0 mass %, Ni: 6.0-12.0 mass %, Mo: 2.0-5.0 mass %, N: 0.20-0.35 mass %, TiO2: 4.0-9.0 mass %, SiO2: 0.1-2.0 mass %, ZrO2: 0.5-4.0 mass %, total of Li2O, Na2O and K2O: 0.50-1.50 mass %, metal fluoride in terms of fluorine amount: 0.10-0.90 mass %, and rare earth element component: 0.10-1.00 mass %, limits C to 0.04 mass % or below, W to 4.0 mass % or below, Cu to 2.0 mass % or below, Bi2O3 to 0.01 mass % or below, and limits oxides other than the above to 3.0 mass % or below. With such a composition, it is possible to obtain a weld bead which is excellent in the weldability in welding in all attitudes and is more excellent in the low temperature toughness while keeping excellent pitting corrosion resistance in arc welding of duplex stainless steel and the like.

Owner:KOBE STEEL LTD

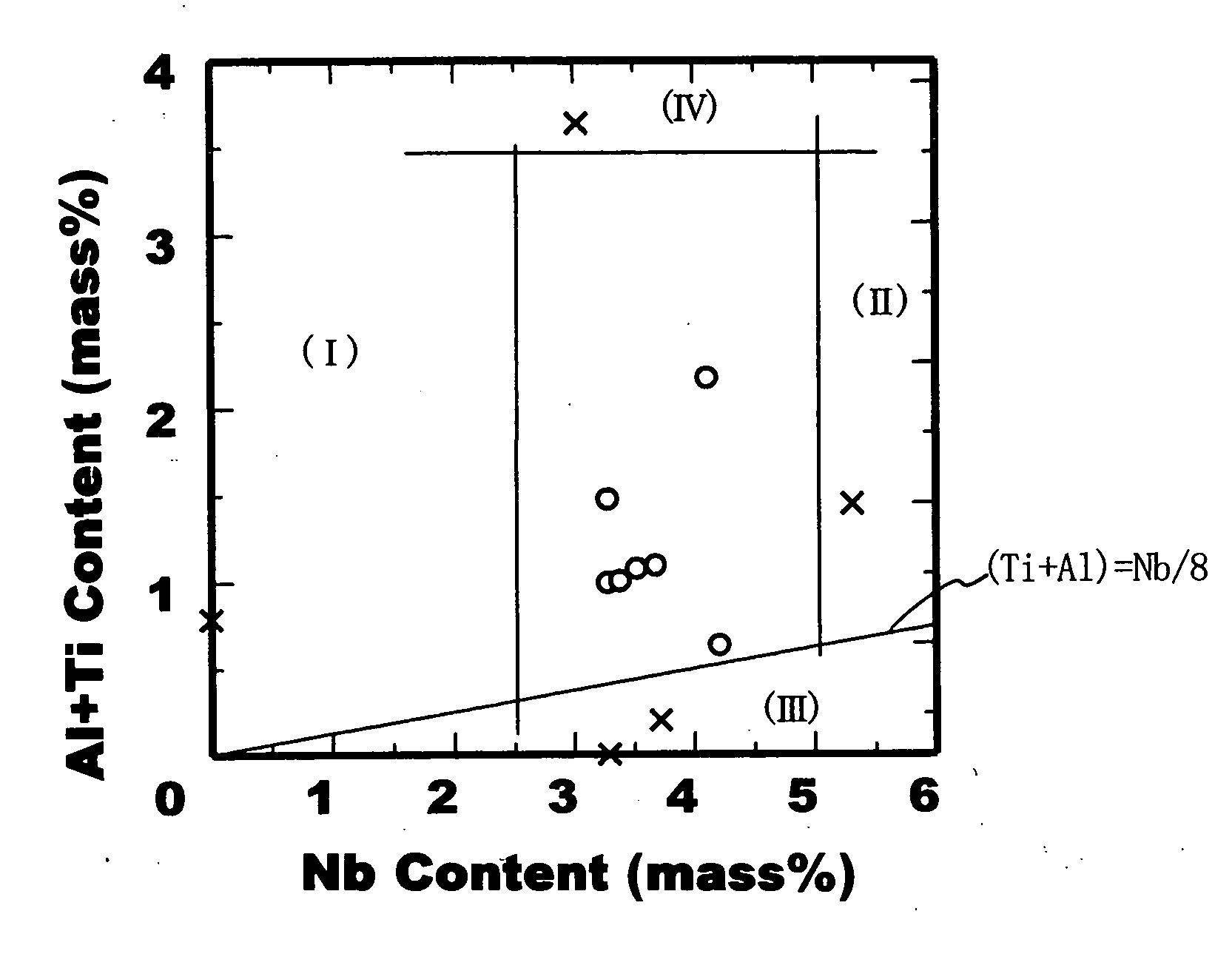

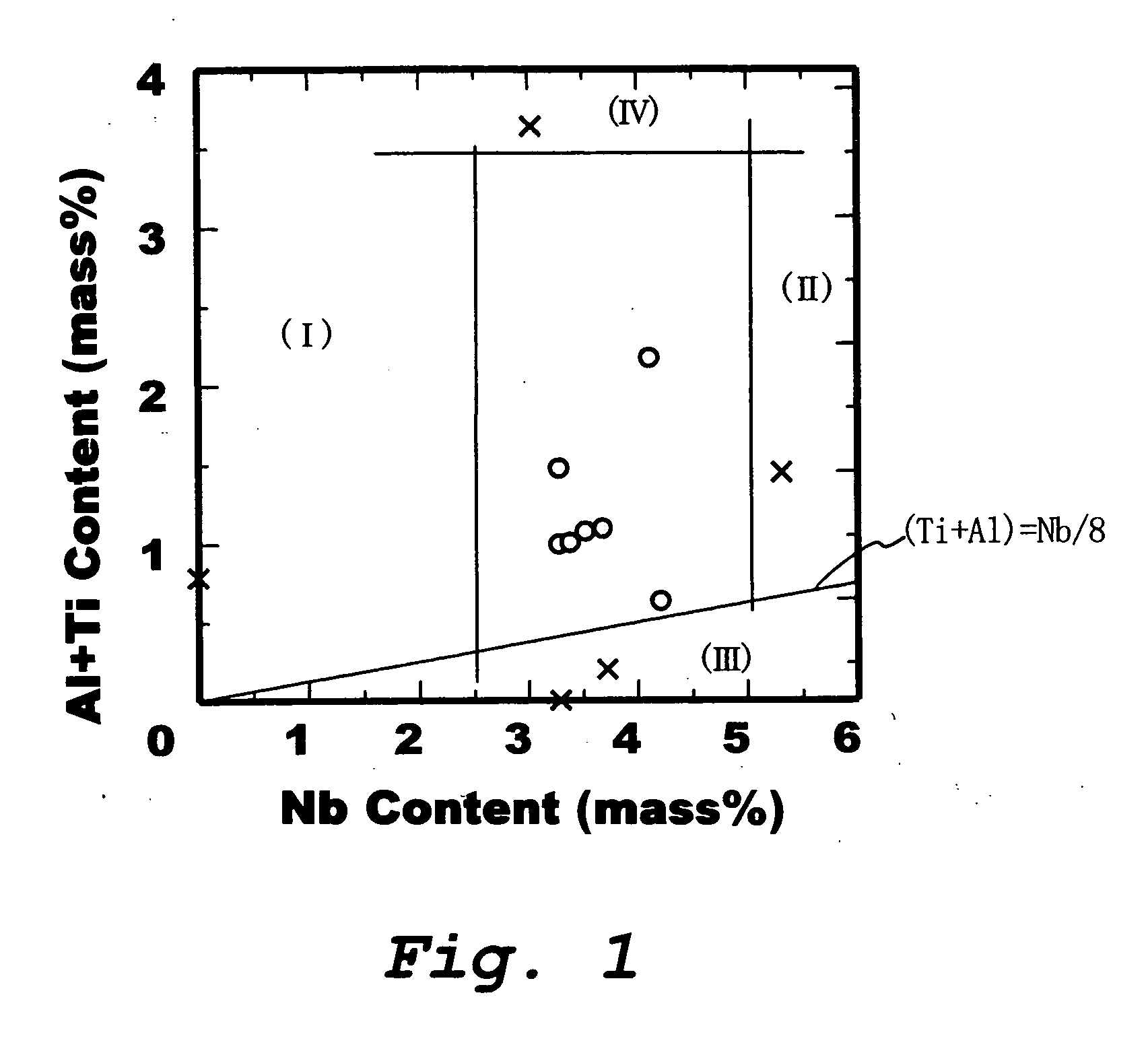

Welded joint made of an austenitic steel

InactiveUS20060191606A1High strengthIncrease resistanceArc welding apparatusMachines/enginesChemical compositionHigh pressure hydrogen

A weld joint having a base material and a weld metal both of an austenitic steel, wherein the weld metal has a chemical composition, in mass %, that C: 0.04% or less, Si: 1.0% or less, Mn: 3% or less, P: 0.02% or less, S: 0.005% or less, Cr: 15 to 25%, Ni: 30% or more, Mo: 10% or less, Nb: 2.5 to 5%, Al: 3.0% or less, Ti: 0.5% or less, and the balance: Fe and inevitable impurities, the contents of Al and Ti satisfying the following: (Ti+Al)>Nb / 8. The weld joint is a high strength austenitic steel weld joint which exhibits excellent toughness at a low temperature and excellent resistance to hydrogen embrittlement, which are required for a piping and a vessel for high pressure hydrogen, particularly also in a welded zone.

Owner:NIPPON STEEL CORP

Basic flux cored wire with excellent weldability

InactiveUS20030116550A1Improve crack resistanceLow toughnessWelding/cutting media/materialsSoldering mediaMn oxideAlloy steel

Disclosed is a basic flux cored wire having a mild steel or an alloy steel sheath filled with flux, characterized in that the flux essentially consists of, with respect to the total weight of the wire: 0.3 to 3.0% Ti and Ti oxide (TiO2-converted value); 1.0 to 2.5% Si and Si oxide (SiO2-converted value); 0.1 to 1.5% Mg and Mg oxide (MgO-converted value); 1.5 to 4.0% Mn and Mn oxide (MnO-converted value); 0.2 to 1.5% Al and Al oxide (Al2O3-converted value); 0.1 to 1.0% Zr and Zr oxide (ZrO2-converted value); 0.2 to 3.5% CaF2; and 0.01 to 0.5% K2O, with the proviso that the components satisfy the basicity of 0.5 to 4.5 in the basicity equation (1) defined as B=(CaF2+MgO+MnO+K2O) / (TiO2+SiO2+Al2O3+ZrO2). The basic flux cored wire of the present invention is excellent in crack resistance and low temperature toughness, and exhibits excellent welding workability in all welding positions, ensuring an improvement in the efficiency of welding work. Furthermore, the basic flux cored wire according to the present invention exhibits excellent welding workability even under a shield gas of 100% CO2.

Owner:KISWEL LTD

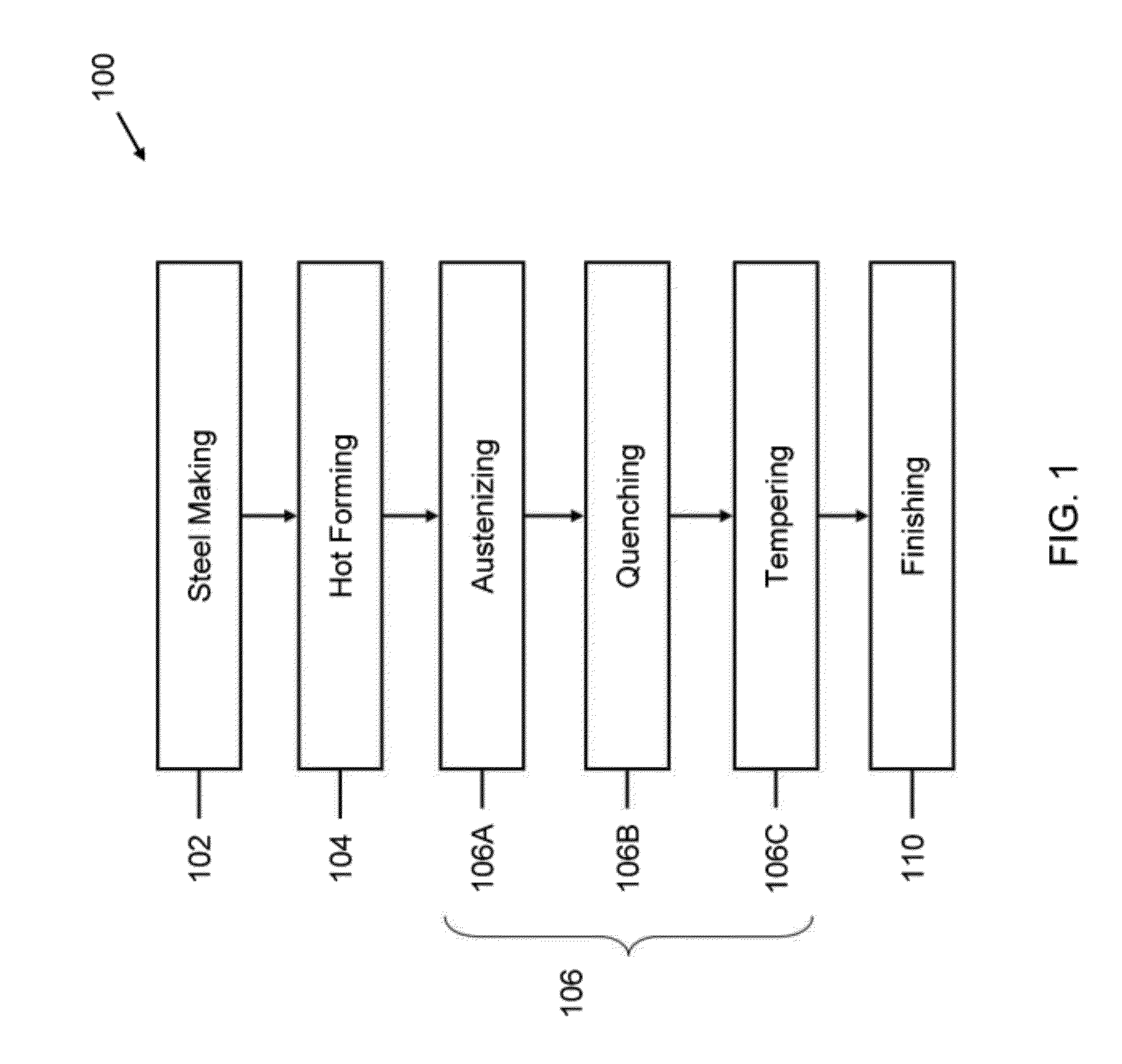

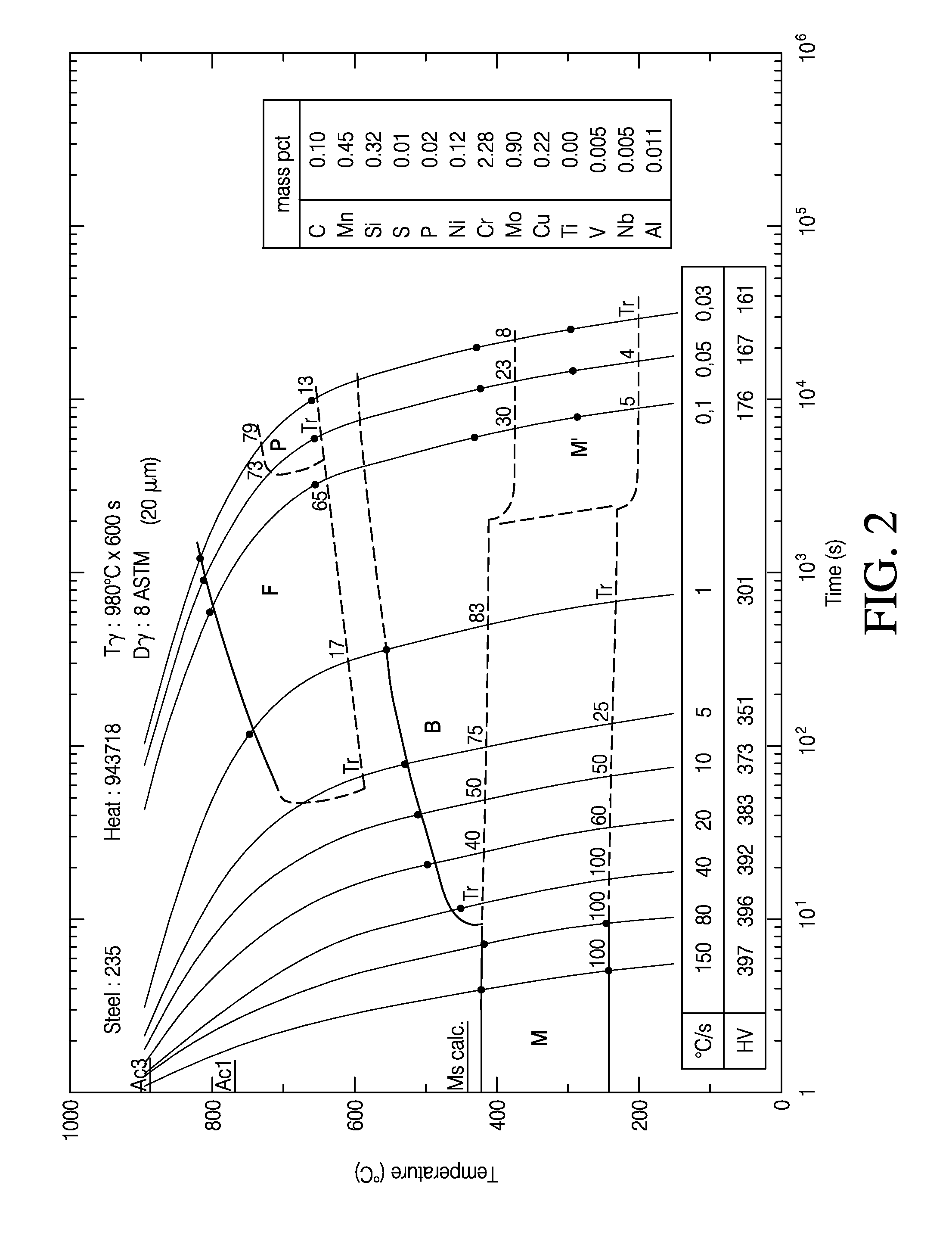

High strength steel pipes with excellent toughness at low temperature and sulfide stress corrosion cracking resistance

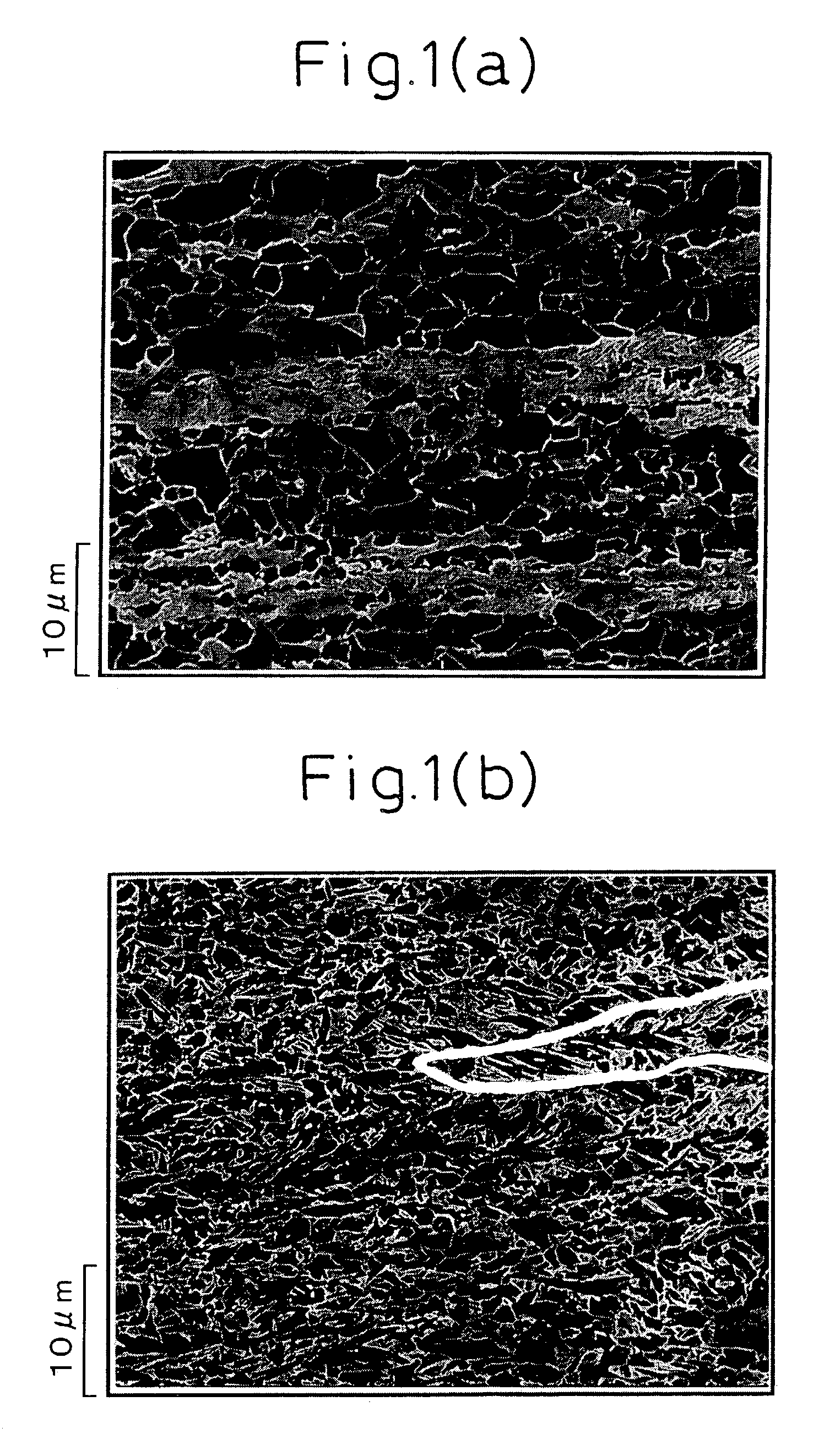

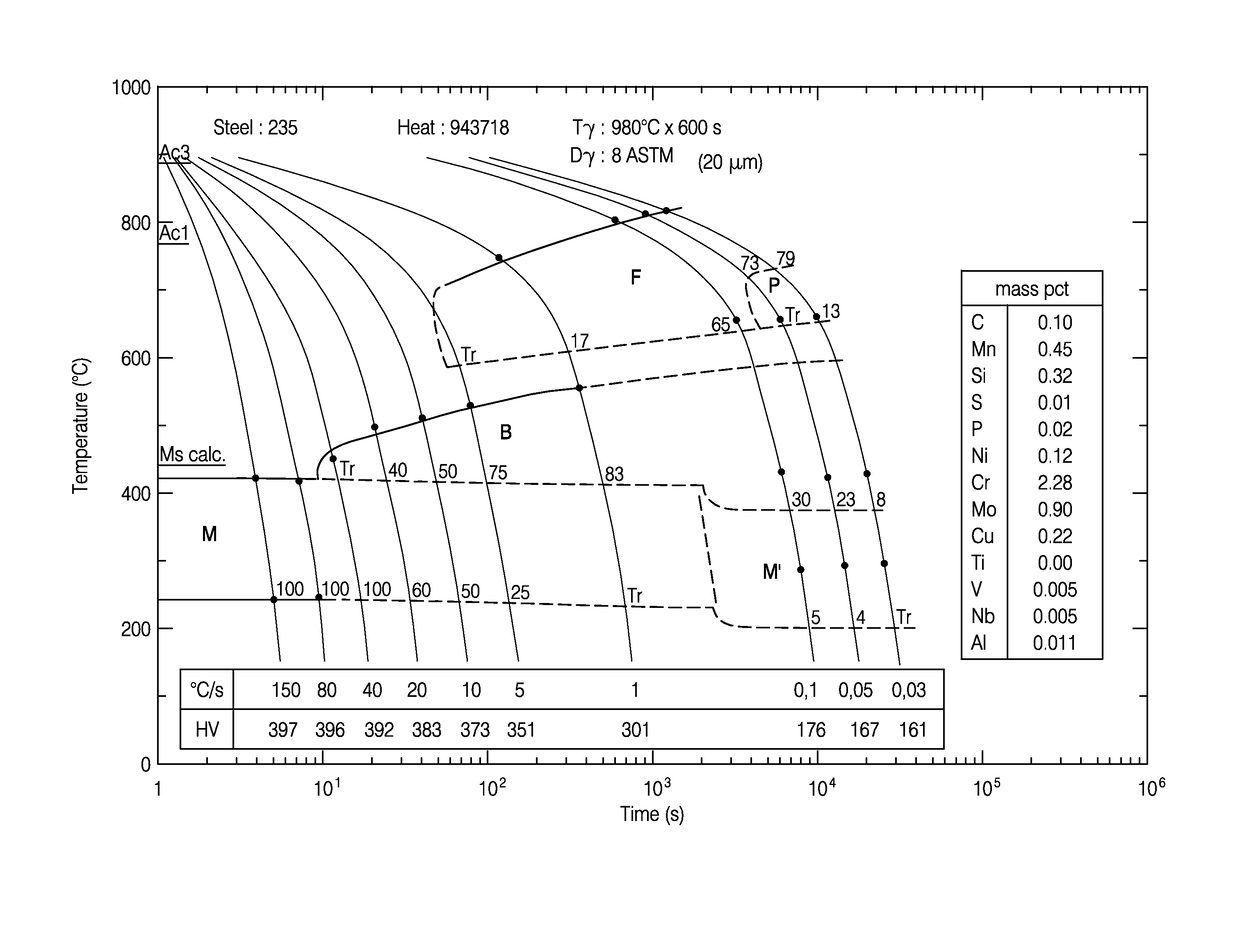

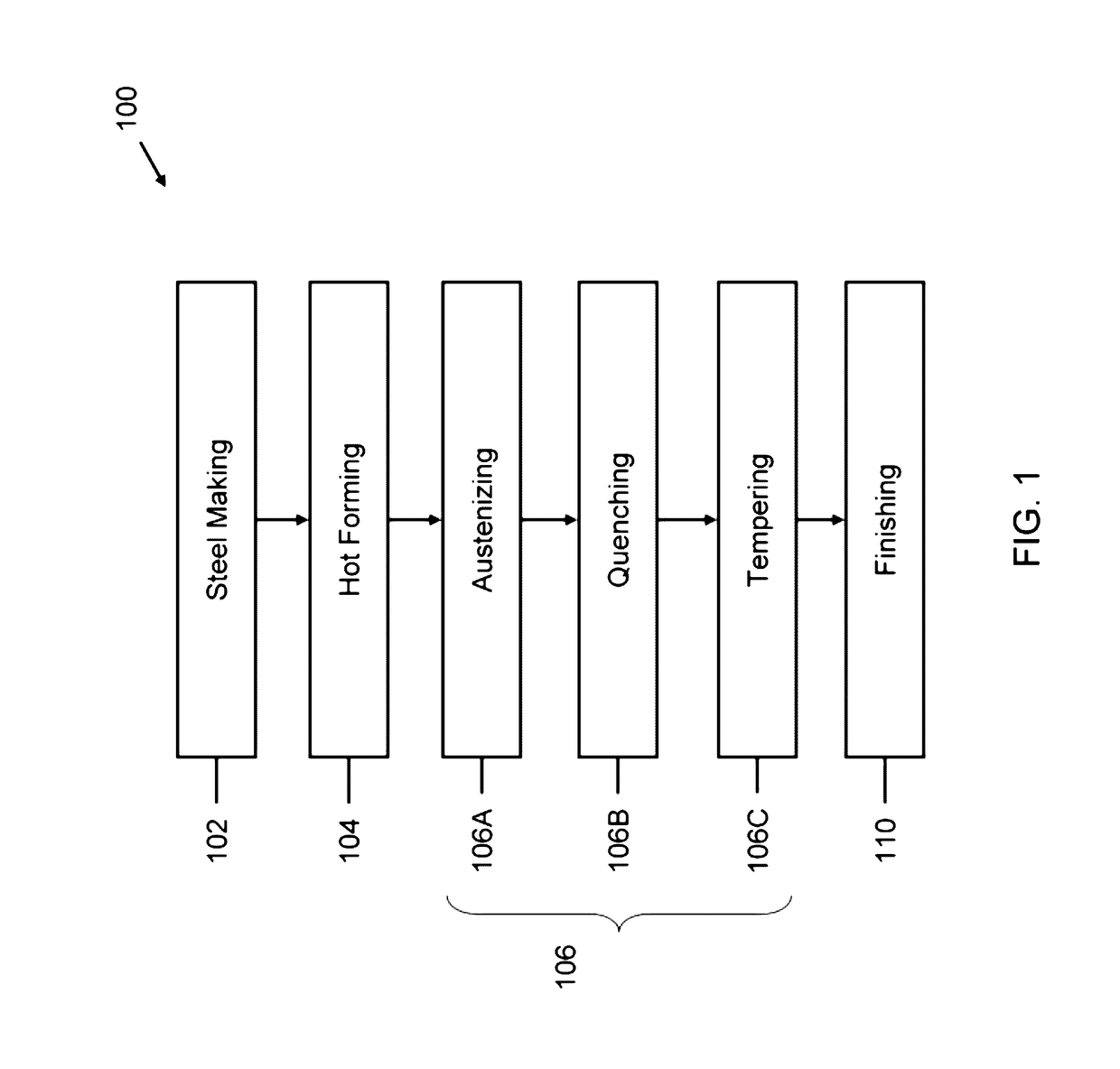

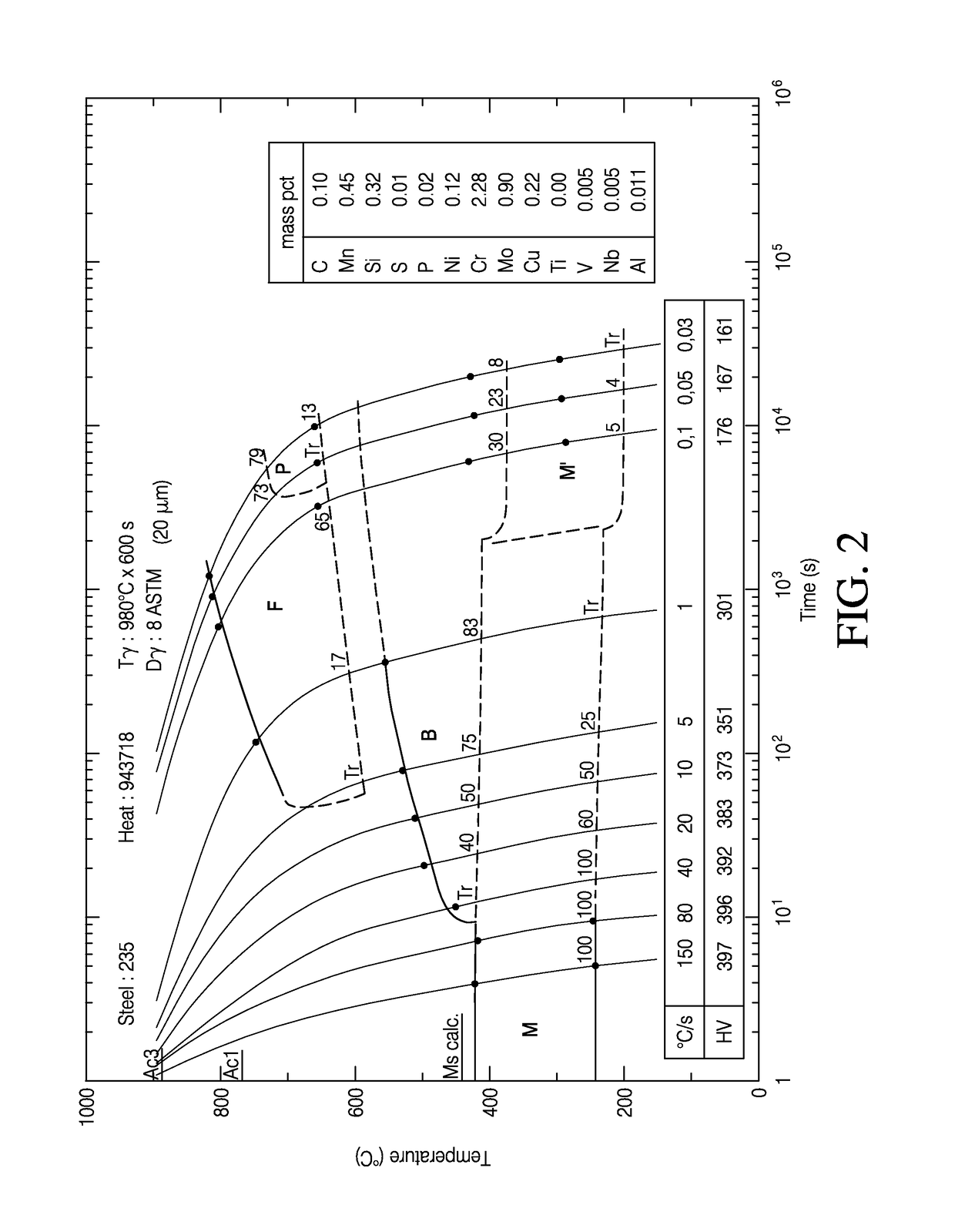

ActiveUS20120199255A1Improve low temperature toughnessImprove corrosion resistanceFurnace typesHeat treatment furnacesAustenite grainStress corrosion cracking

Low-alloy steels and methods of manufacturing pipes having a wall thickness greater than or equal to about 8 mm and less than or equal to about 35 mm therefrom are provided. In one embodiment, a steel composition is processed that yields an average prior austenite grain size greater than about 15 or 20 μm and smaller than about 100 μm. A quenching sequence has been determined that yields a microstructure of greater than or equal to about 60% martensite by volume, and less than or equal to about 40% by volume lower bainite, without substantial formation of ferrite, upper bainite, or granular bainite. The yield strength of the quenched and tempered pipes may be greater than about 70 ksi, 80 ksi, or 90 ksi. The quenched and tempered pipes are suitable for 70 ksi, 80 ksi, and 90 ksi grades and resistant to sulfide stress corrosion cracking.

Owner:DALMINE SPA

Low-temperature X80HD (High Density) large-deformation pipeline steel with great wall thickness and production method thereof

The invention discloses low-temperature X80HD (High Density) large-deformation pipeline steel with great wall thickness and a production method thereof, belonging to the technical field of medium-thickness plate production and longitudinal submerged arc welded tube production. A steel plate comprises the following chemical components in percentage by mass: not less than 0.04% and not greater than 0.09% of C, not greater than 0.35% of Si, not less than 1.5% and not greater than 1.85% of Mn, not greater than 0.012% of P, not greater than 0.004% of S, not less than 0.02% and not greater than 0.05% of Nb, not less than 0.008% and not greater than 0.025% of Ti, not less than 0.10% and not greater than 0.50% of Ni, not less than 0.10% and not greater than 0.45% of Cr, not less than 0.10% and not greater than 0.30% of Cu, not less than 0.10% and not greater than 0.35% of Mo, not less than 0.020% and not greater than 0.070% of Alt, not greater than 0.0005% of B, not greater than 0.0050% of Ca, and the balance of Fe and inevitable impurities. A preparation method of the steel plate comprises the processes such as converter smelting, external refining, continuous casting, heating, controlled rolling, relaxation phase change control and quick cooling; a texture of the rolled steel plate is ferrite, bainite and a little M / A (Martensite / Austenite), wherein ferrite content is 60%-85%, and bainite and M / A content is 15%-40%. The obtained X80HD large-deformation pipeline steel has high strength and toughness, a high work-hardening index, high uniform ductility, a low yield ratio and good deformation resistance.

Owner:SHOUGANG CORPORATION

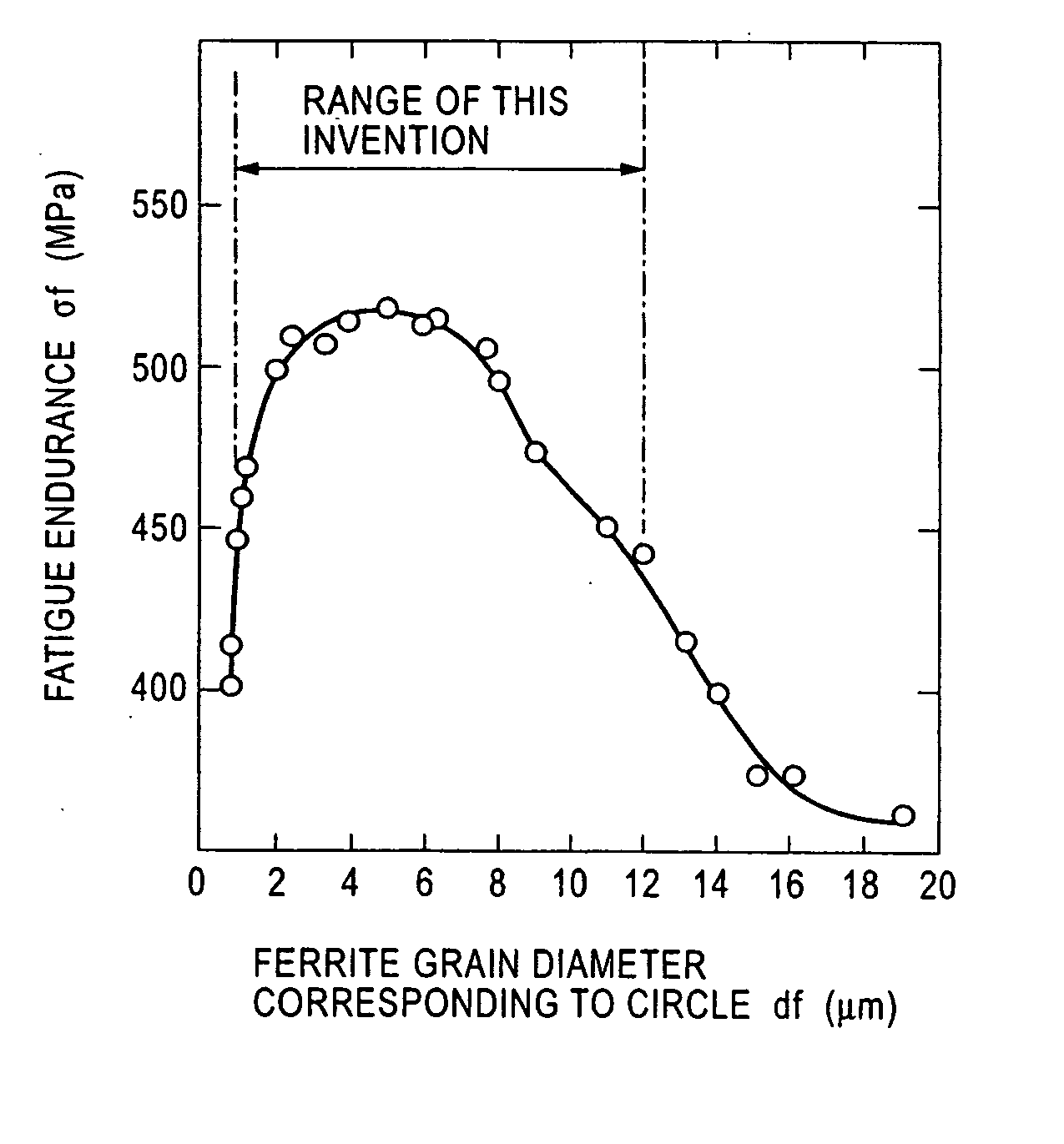

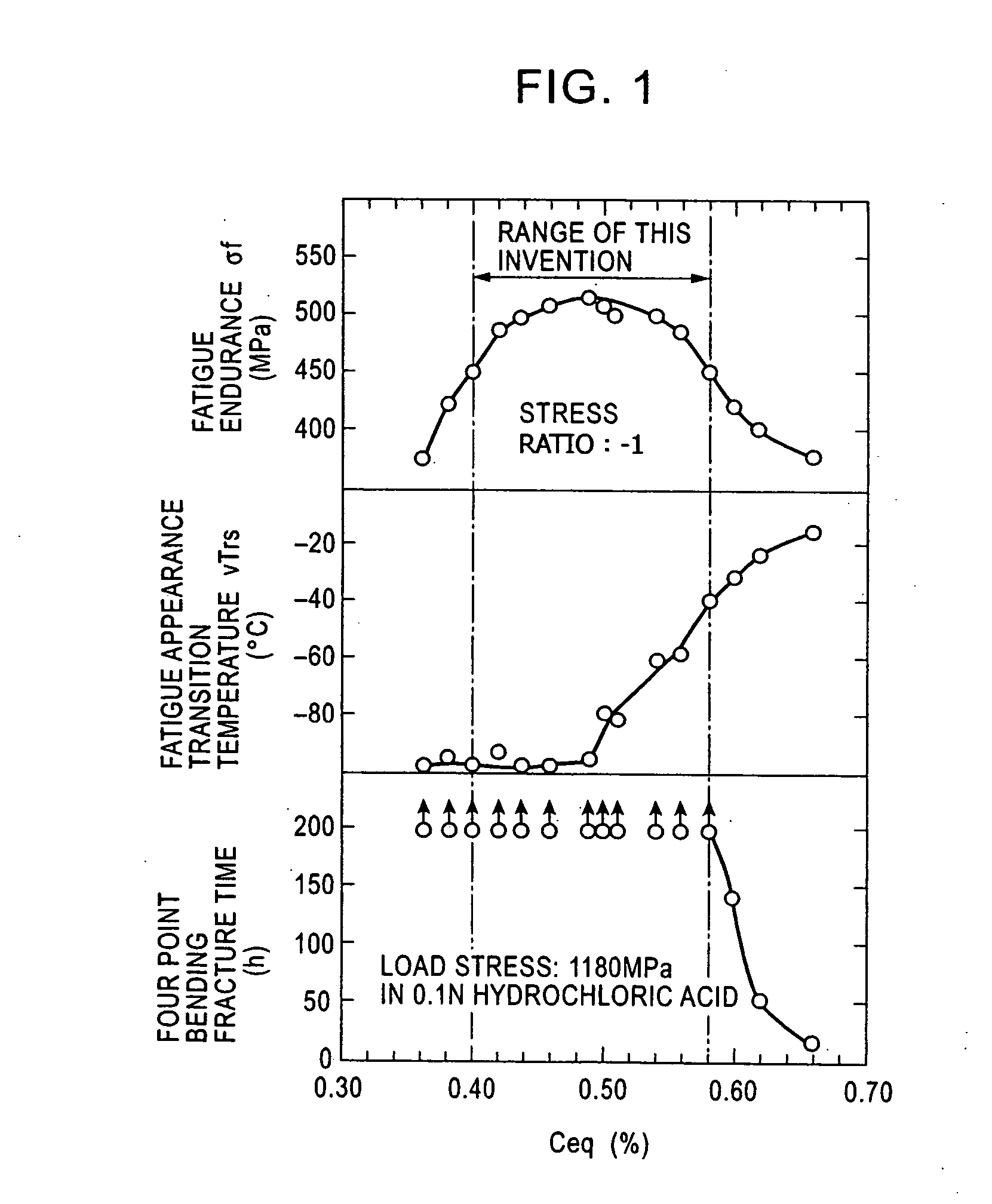

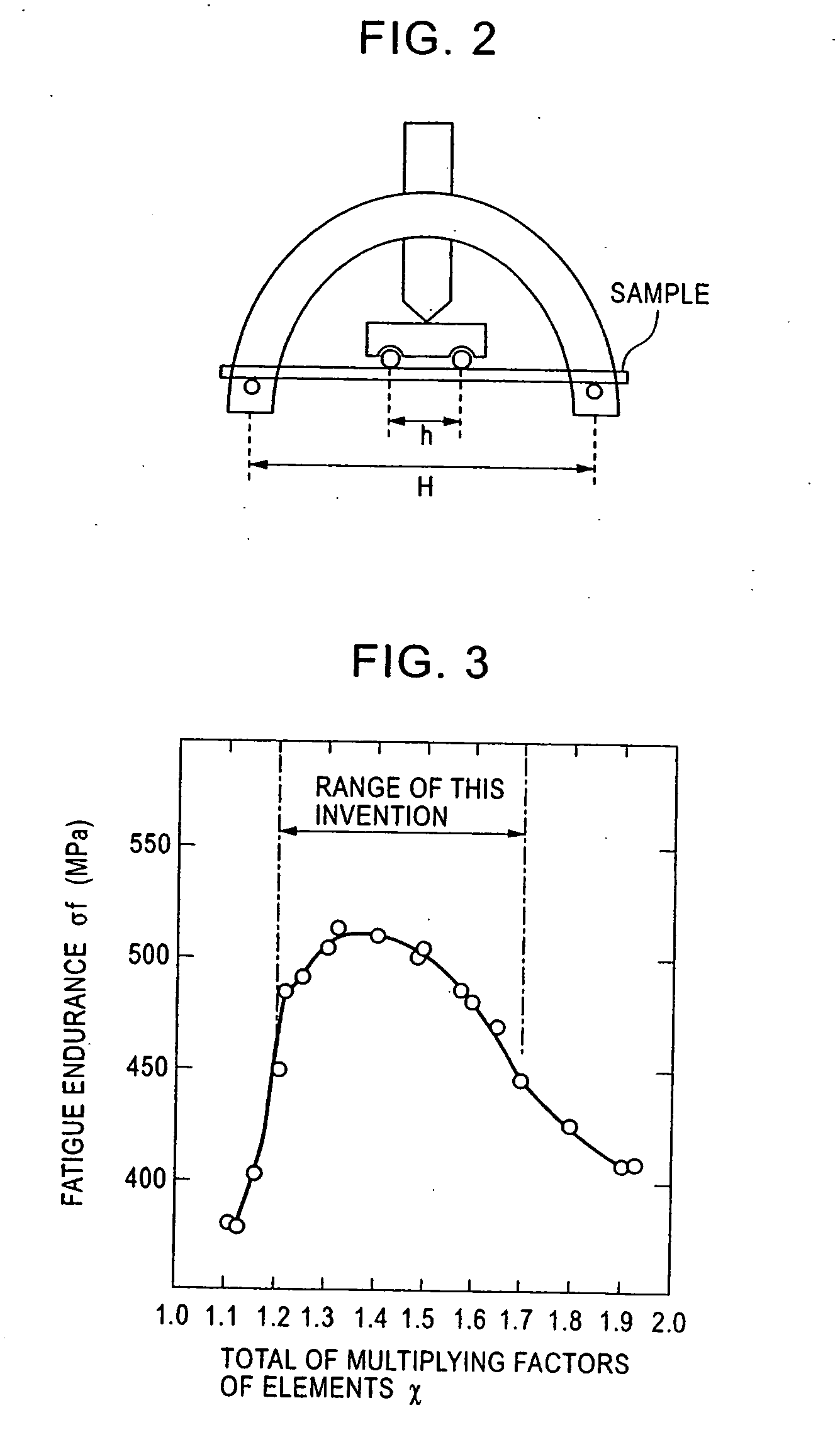

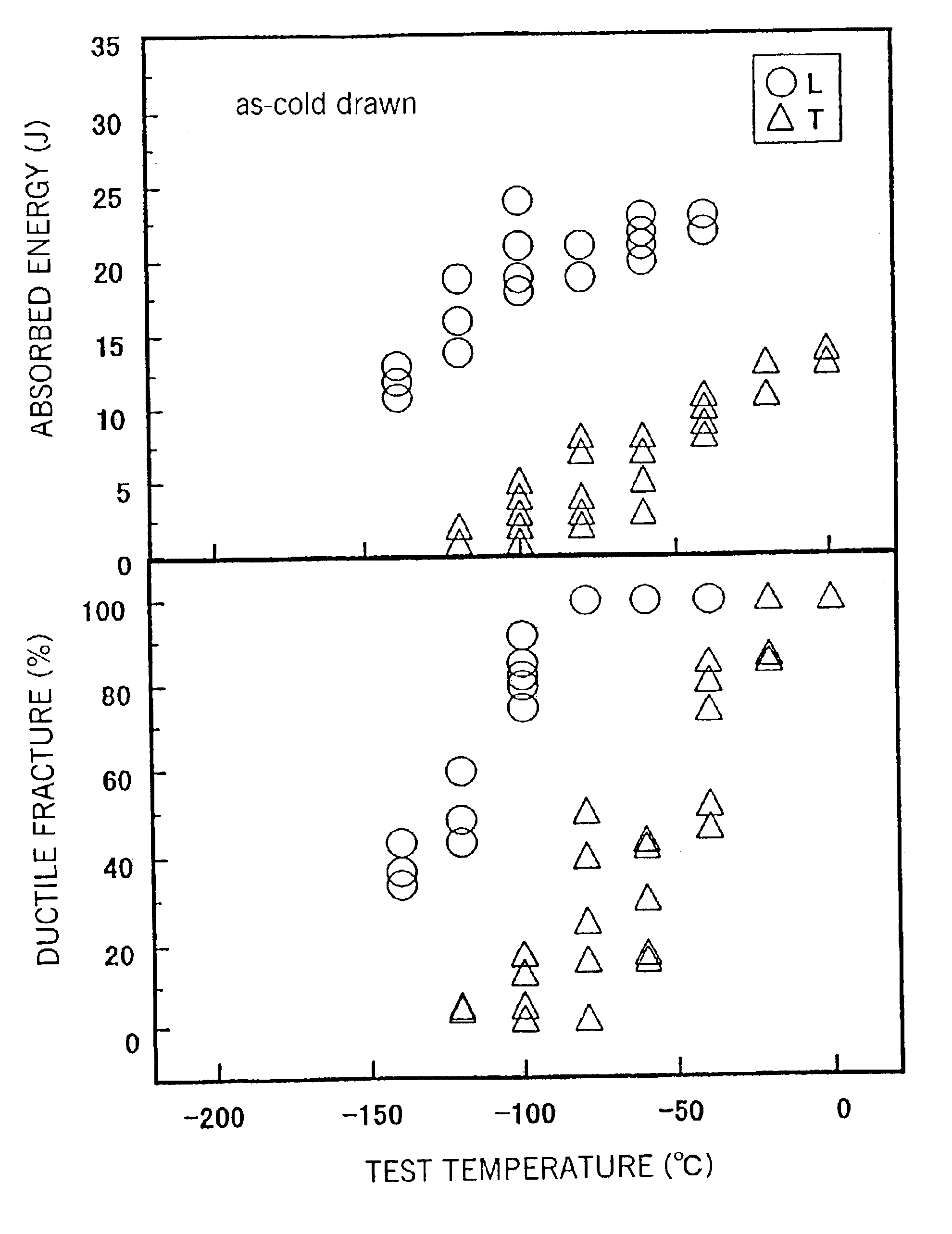

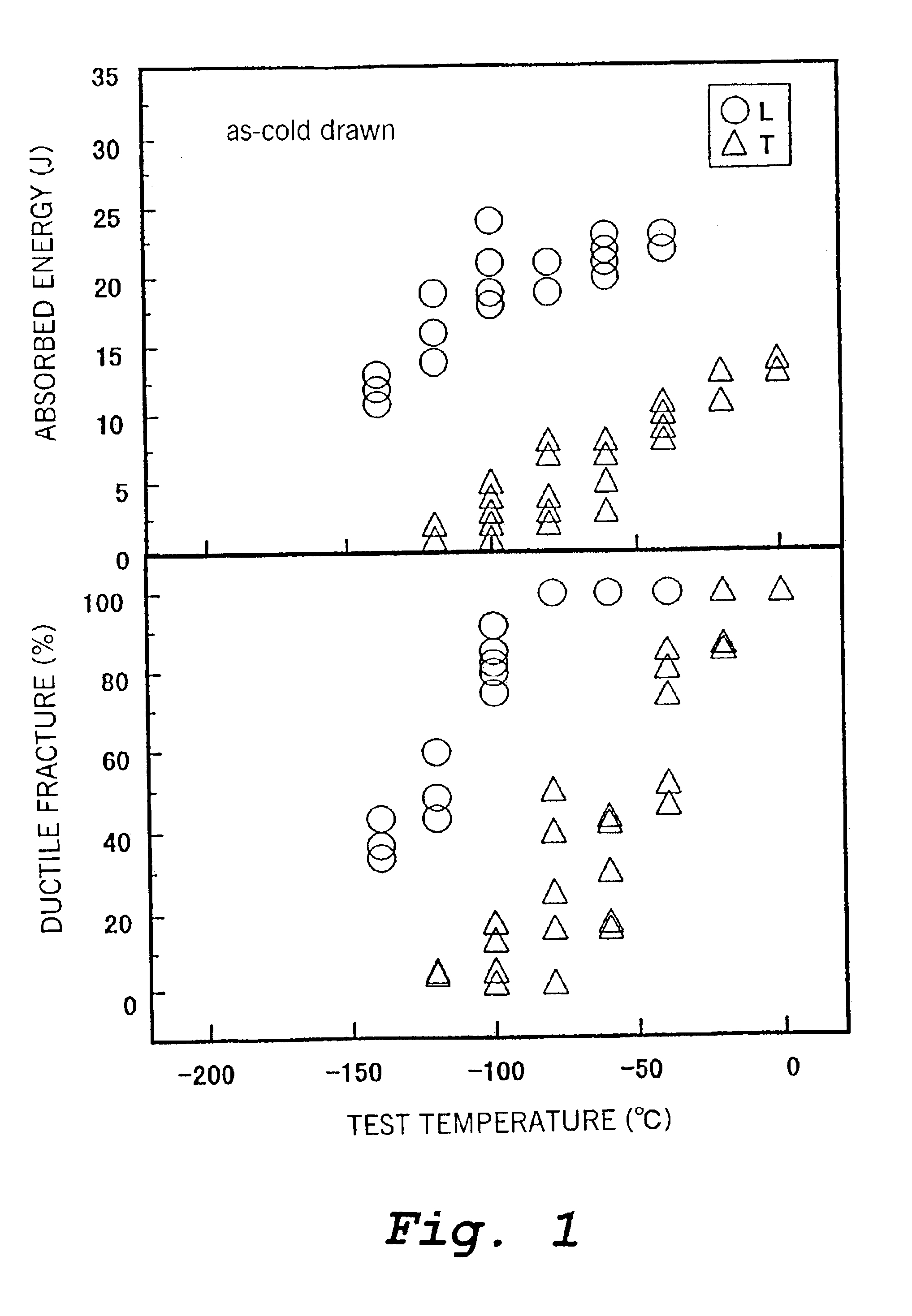

Steel for structural part of automobile and method for producing the same

InactiveUS20070144632A1Improve fatigueGood formabilityFurnace typesIncreasing energy efficiencySlow coolingCorrosion fatigue

A steel having excellent formability, fatigue endurance after quenching, low temperature toughness, resistance for hydrogen embrittlement, and corrosion fatigue endurance. A method includes heating a steel slab at 1160° C. to 1320° C., hot-finish-rolling the steel slab at a finisher delivery temperature of 750° C. to 980° C., and then coiling the hot-rolled steel at a coiling temperature of 560° C. to 740° C. after slow cooling for a time of 2 seconds or more to produce a hot-rolled steel strip having a structure in which the ferrite grain diameter df corresponding to a circle is 1.1 μm to less than 1.2 μm and the ferrite volume fraction Vf is 30% to 98%, the steel slab containing 0.18 to 0.29% of C, 0.06 to 0.45% of Si, 0.91 to 1.85% of Mn, 0.019% or less of P, 0.0029% or less of S, 0.015 to 0.075% of sol. Al, 0.0049% or less of N, 0.0049% or less of O, 0.0001 to 0.0029% of B, 0.001 to 0.019% of Nb, 0.001 to 0.029% of Ti, 0.001 to 0.195% of Cr, and 0.001 to 0.195% of Mo so that the carbon equivalent Ceq satisfies a value of 0.4 to less than 0.58, and the total x of multiplying factors including that for B according to Grossmann satisfies a value of 1.2 to less than 1.7.

Owner:JFE STEEL CORP +1

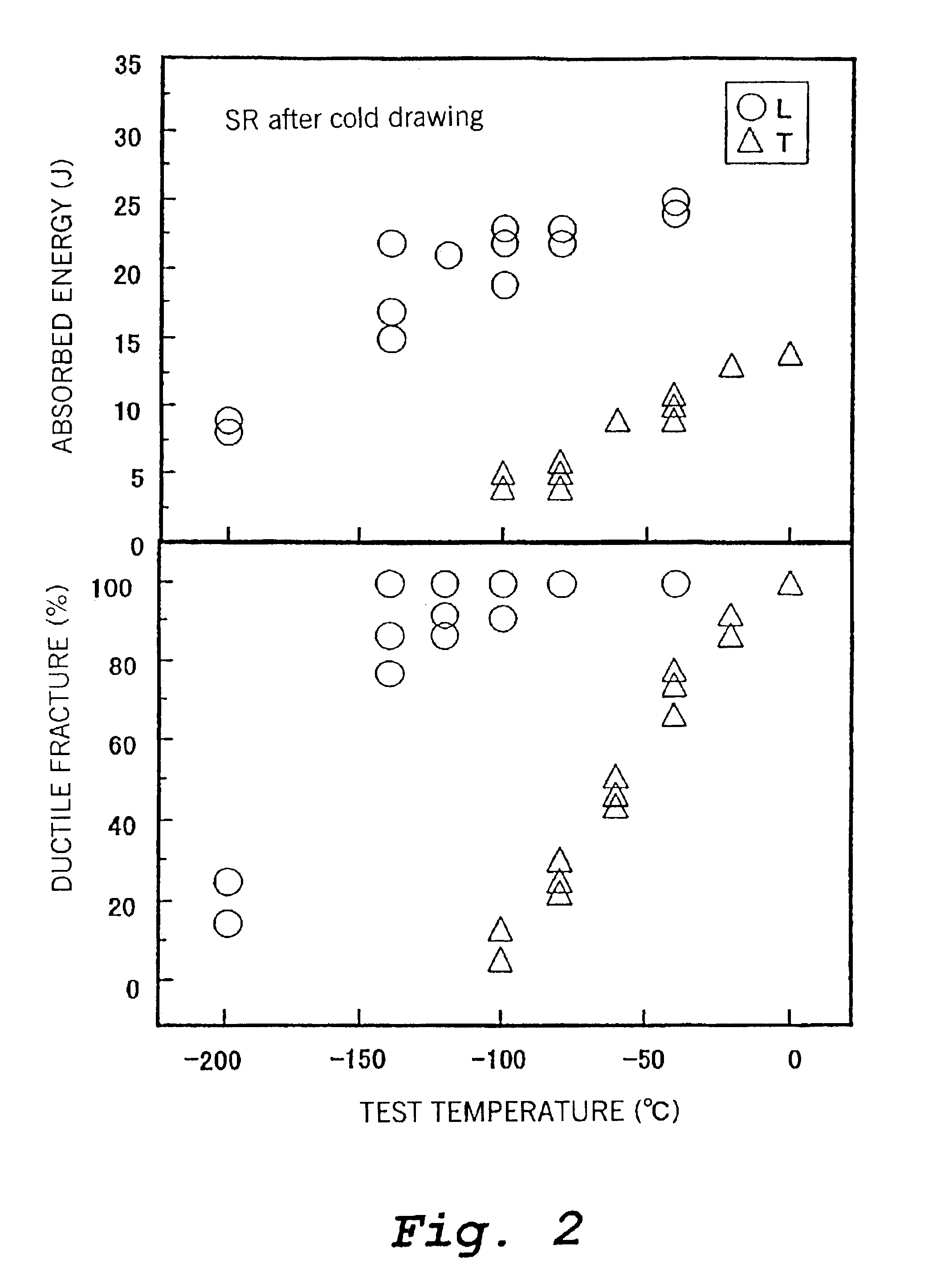

High strength steel pipe for an air bag and a process for its manufacture

InactiveUS6878219B2High strengthGood weldabilityPedestrian/occupant safety arrangementFurnace typesRare-earth elementHigh intensity

In order to manufacture a steel pipe for an air bag which can cope with increase in the pressure of gas blown into an air bag and decreases in the wall thickness of an accumulator, a steel having a composition, mass %, of:C: 0.05-0.20%,Si: 0.1-1.0%,Mn: 0.20-2.0%,P: at most 0.025%,S: at most 0.010%,Cr: 0.05-1.0%,Al: at most 0.10%,if necessary at least one of Mo: at most 0.50%, Ni: at most 1.5%, Cu: at most 0.5%, V: at most 0.2%, Ti: at most 0.1%, Nb: at most 0.1%, and B: at most 0.005%, andalso if necessary, at least one of Ca: at most 0.01%, Mg: at most 0.01%, and REM (rare earth elements): at most 0.01%,and a remainder of Fe and impurities is used to produce a steel pipe, and the pipe is then subjected to cold working to predetermined dimensions, then to heating to a temperature of at least the Ac1 transformation temperature followed by quenching, and then to tempering at a temperature no higher than the Ac1 transformation temperature.

Owner:NIPPON STEEL CORP

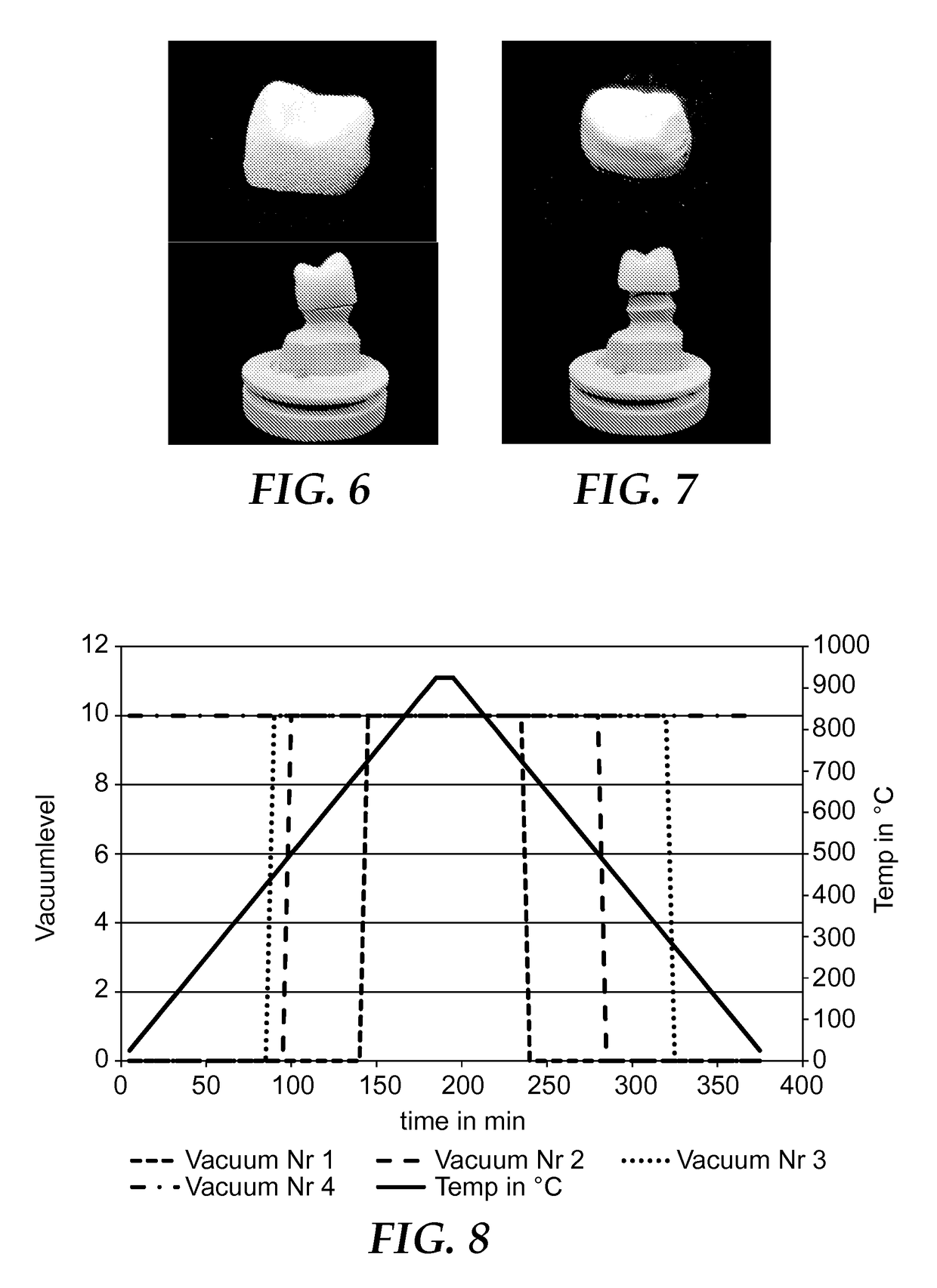

Process for producing a sintered lithium disilicate glass ceramic dental restoration and kit of parts

InactiveUS20170128174A1Easily be individualizedLow strengthAdditive manufacturing apparatusImpression capsMetallurgyAtmospheric pressure

The present invention is directed to a process for producing a sintered lithium disilicate glass ceramic dental restoration out of a porous 3-dim article, the process comprising the step of sintering the porous 3-dim article having the shape of a dental restoration with an outer and inner surface to obtain a sintered lithium disilicate ceramic dental restoration, the sintered lithium disilicate glass ceramic dental restoration comprising—Si oxide calculated as SiO2 from 55 to 80 wt.-%, —Li oxide calculated as Li2O from 7 to 16 wt.-%, —Al oxide calculated as Al2O3 from 1 to 5 wt.-%, and—P oxide calculated as P2O5 from 1 to 5 wt.-%, wt.-% with respect to the weight of the dental restoration, the sintering being done under reduced atmospheric pressure conditions, the reduced atmospheric pressure conditions being applied at a temperature above 600° C. The present invention is also directed to a kit of parts comprising a porous 3-dim article having the shape of a dental milling block and a respective instruction of use.

Owner:3M INNOVATIVE PROPERTIES CO

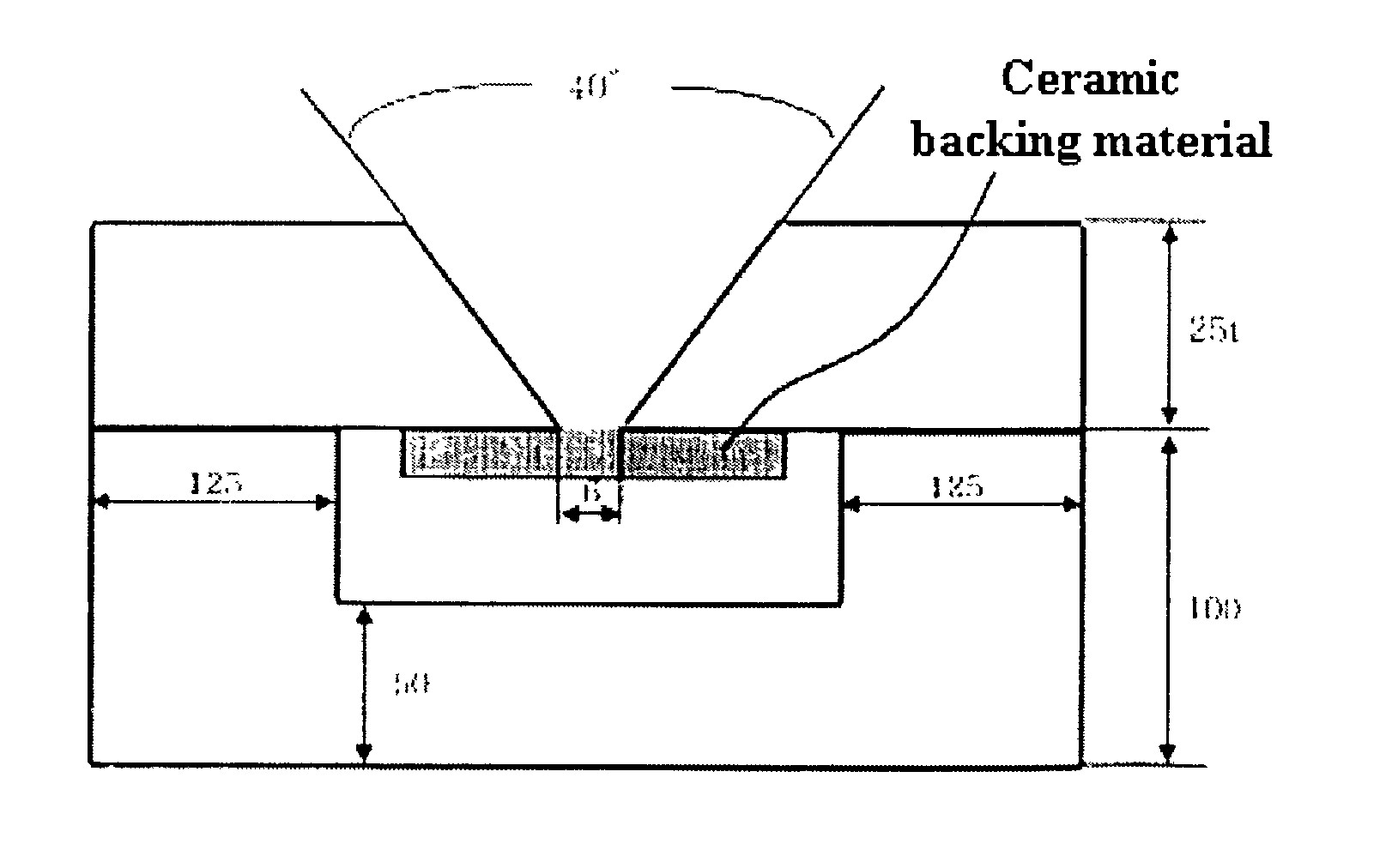

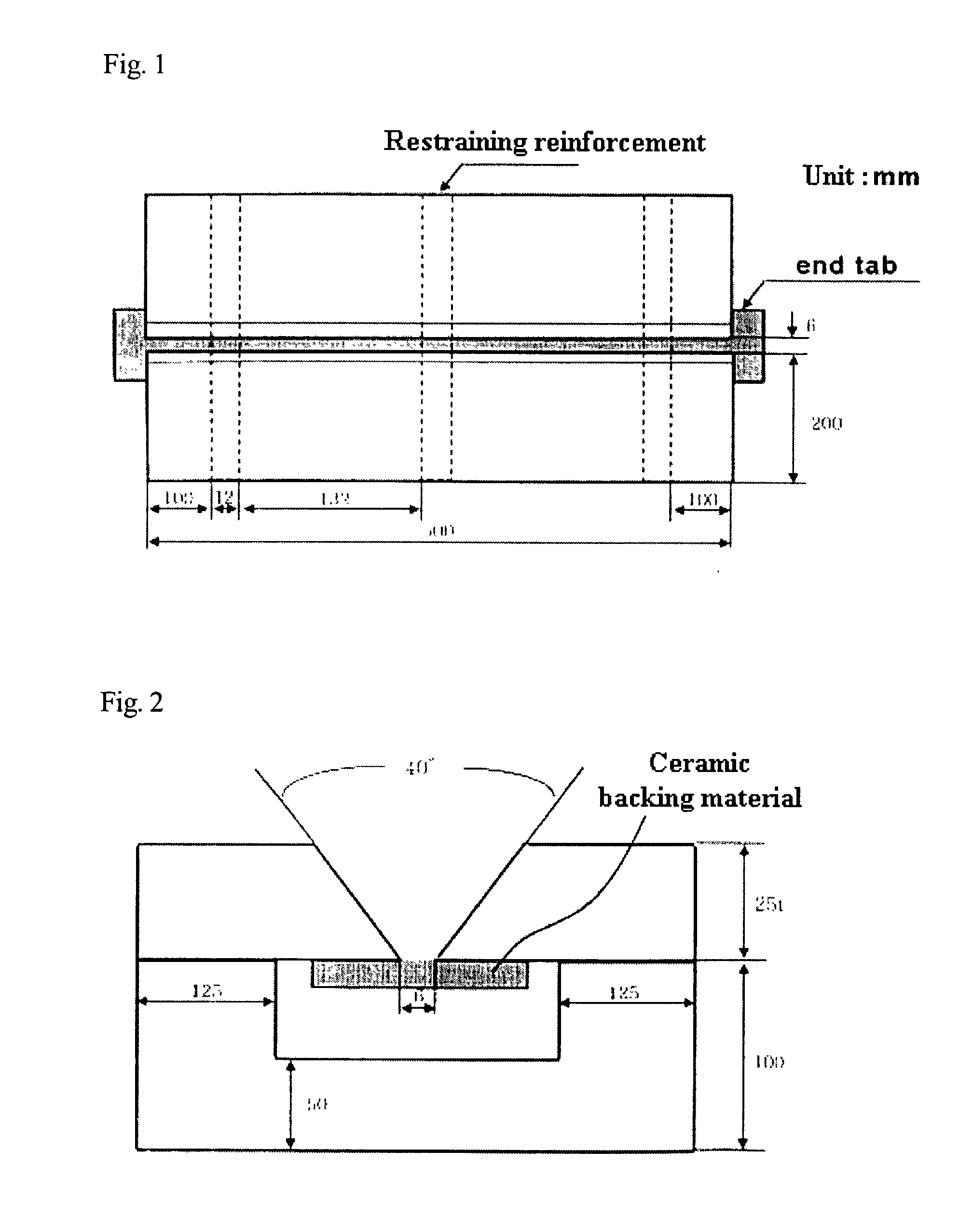

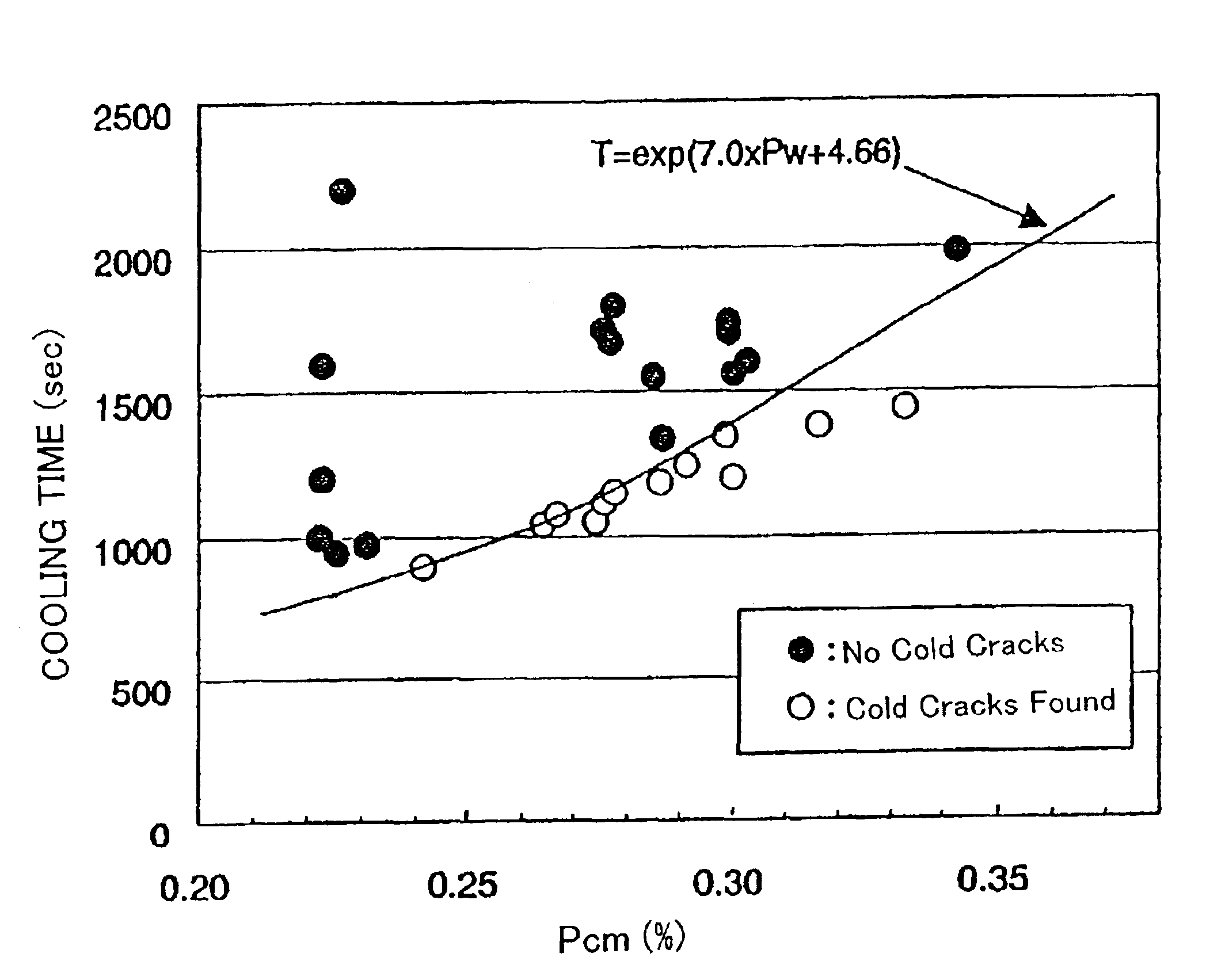

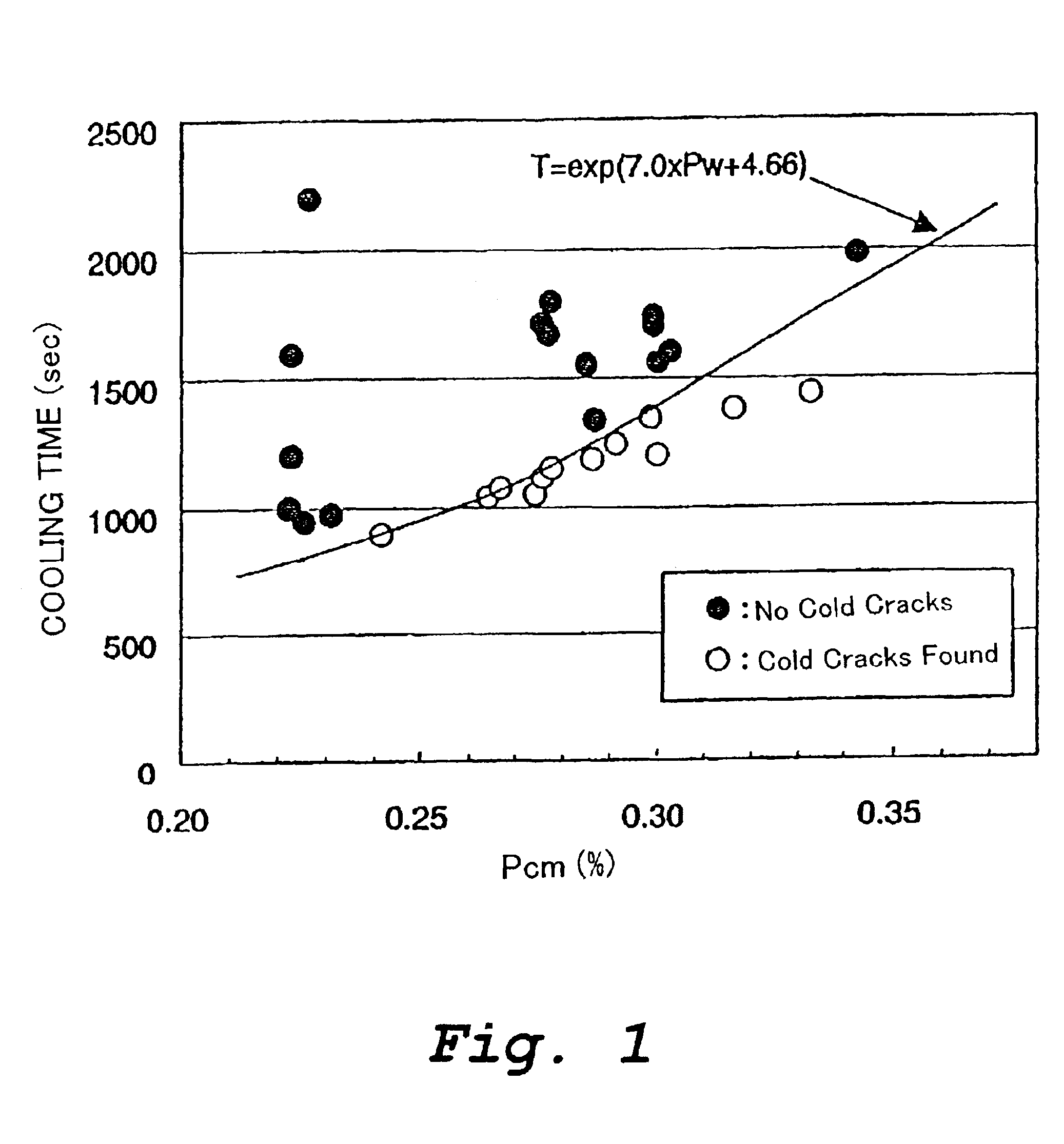

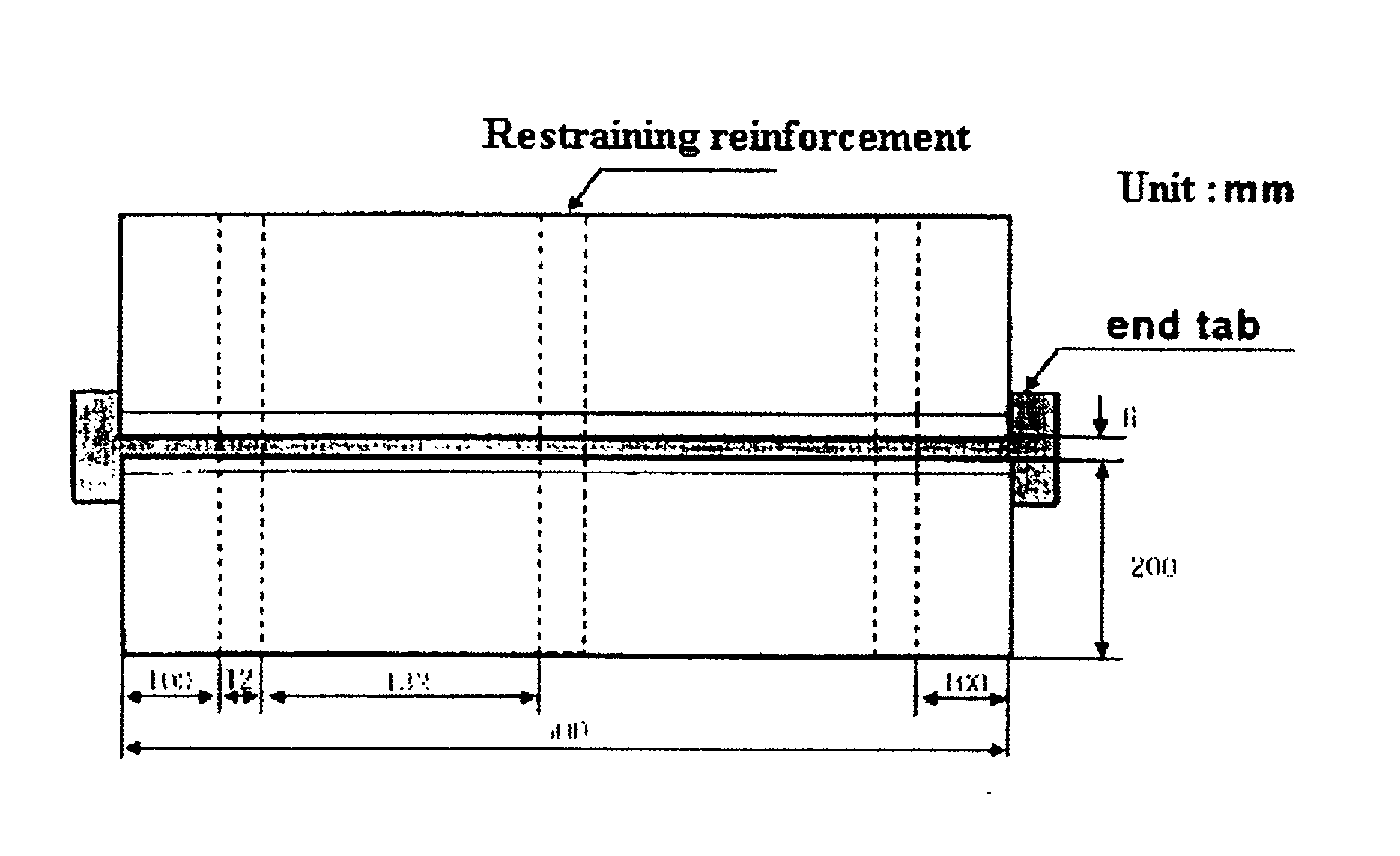

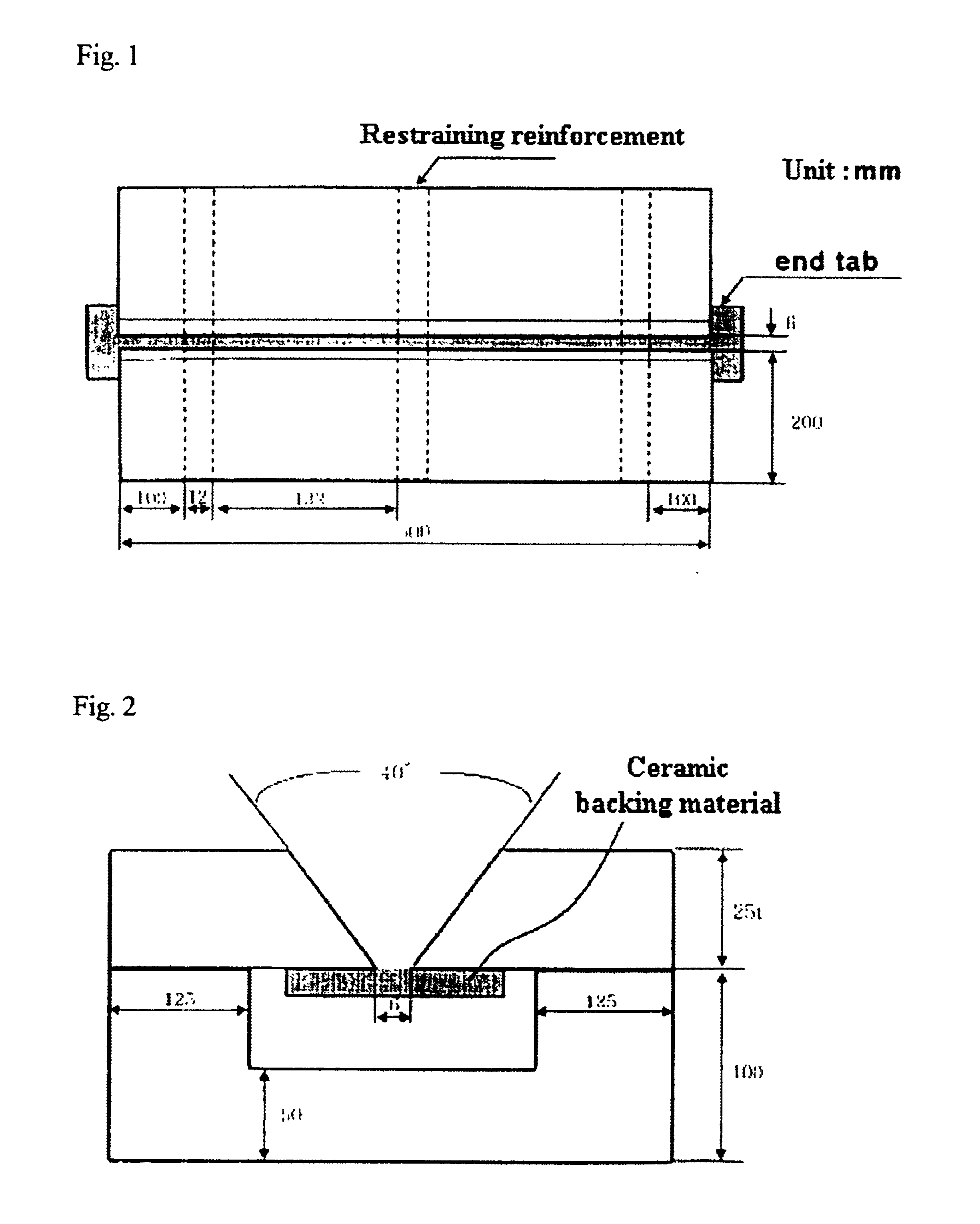

High strength steel weld having improved resistance to cold cracking and a welding method

InactiveUS6953508B2High strengthHigh tensile strengthArc welding apparatusFurnace typesHydrogenHigh intensity

A welding method includes performing welding to form a weld metal consisting essentially of, in mass %,C: 0.01-0.15%,Si: 0.02-0.6%,Mn: 0.6-3.0%,Al: 0.004-0.08%,Ti: 0.003-0.03%,B: at most 0.005%,Cu: 0-1.2%,Ni: 0-3%,Cr: 0-1.2%,Mo: 0-2%,V: 0-0.05%,Nb: 0-0.05%,and a remainder of Fe and unavoidable impurities. The amounts of impurities are P: at most 0.03%, S: at most 0.03%, N: at most 0.01%, Ca or Mg: at most 0.005%. The value of Pcm expressed by the following Equation (3) is in the range of 0.23-0.35%, and the time T until the weld metal is cooled to 100° C. after welding satisfies the following Equation (1):T(seconds)≧exp(7.0×Pw+4.66) Equation (1)Pw=Pcm+HD / 60 Equation (2)Pcm(mass %)=C+Si / 30+Mn / 20+Cu / 20+Ni / 60+Cr / 20+Mo / 15+V / 10+5B Equation (3)HD [ml / 100 g]: amount of hydrogen in the weld metal immediately after welding.

Owner:NIPPON STEEL CORP

High-strength hot-rolled steel sheet having excellent baking hardenability and low temperature toughness with maximum tensile strength of 980 mpa or more

ActiveUS20150329950A1Excellent bake hardenabilityGuaranteed Low Temperature ToughnessHot-dipping/immersion processesFurnace typesCarbideHigh intensity

Provided is a high-strength hot-rolled steel sheet consisting of, in mass %, C: 0.01% to 0.2%, Si: 0% to 2.5%, Mn: 0% to 4.0%, Al: 0% to 2.0%, N: 0% to 0.01%, Cu: 0% to 2.0%, Ni: 0% to 2.0%, Mo: 0% to 1.0%, V: 0% to 0.3%, Cr: 0% to 2.0%, Mg: 0% to 0.01%, Ca: 0% to 0.01%, REM: 0% to 0.1%, B: 0% to 0.01%, P: less than or equal to 0.10%, S: less than or equal to 0.03%, O: less than or equal to 0.01%, one or both of Ti and Nb: 0.01% to 0.30% in total, and the balance being Fe and inevitable impurities. The steel sheet has a structure in which a total volume fraction of tempered martensite or lower bainite is 90% or more, a dislocation density thereof is greater than or equal to 5×1013 (1 / m2) and less than or equal to 1×1016 (1 / m2) and 1×106 (numbers / mm2) or more iron-based carbides are included therein.

Owner:NIPPON STEEL CORP

Basic flux cored wire with excellent weldability

InactiveUS6713723B2Improve crack resistanceLow toughnessWelding/cutting media/materialsSoldering mediaCrack resistanceShielding gas

Disclosed is a basic flux cored wire having a mild steel or an alloy steel sheath filled with flux, characterized in that the flux essentially consists of, with respect to the total weight of the wire: 0.3 to 3.0% Ti and Ti oxide (TiO2-converted value); 1.0 to 2.5% Si and Si oxide (SiO2-converted value); 0.1 to 1.5% Mg and Mg oxide (MgO-converted value); 1.5 to 4.0% Mn and Mn oxide (MnO-converted value); 0.2 to 1.5% Al and Al oxide (Al2O3-converted value); 0.1 to 1.0% Zr and Zr oxide (ZrO2-converted value); 0.2 to 3.5% CaF2; and 0.01 to 0.5% K2O, with the proviso that the components satisfy the basicity of 0.5 to 4.5 in the basicity equation (1) defined as B=(CaF2+MgO+MnO+K2O) / (TiO2+SiO2+Al2O3+ZrO2). The basic flux cored wire of the present invention is excellent in crack resistance and low temperature toughness, and exhibits excellent welding workability in all welding positions, ensuring an improvement in the efficiency of welding work. Furthermore, the basic flux cored wire according to the present invention exhibits excellent welding workability even under a shield gas of 100% CO2.

Owner:KISWEL LTD

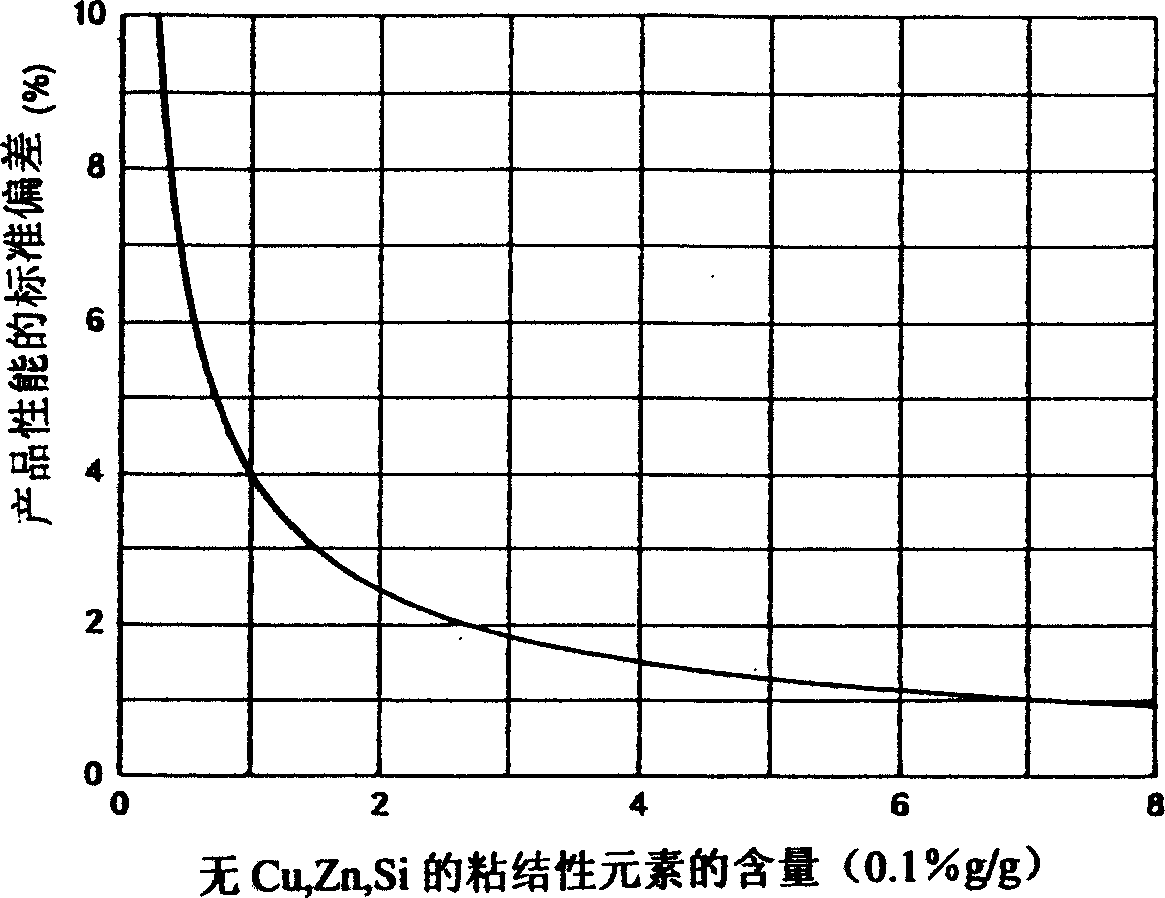

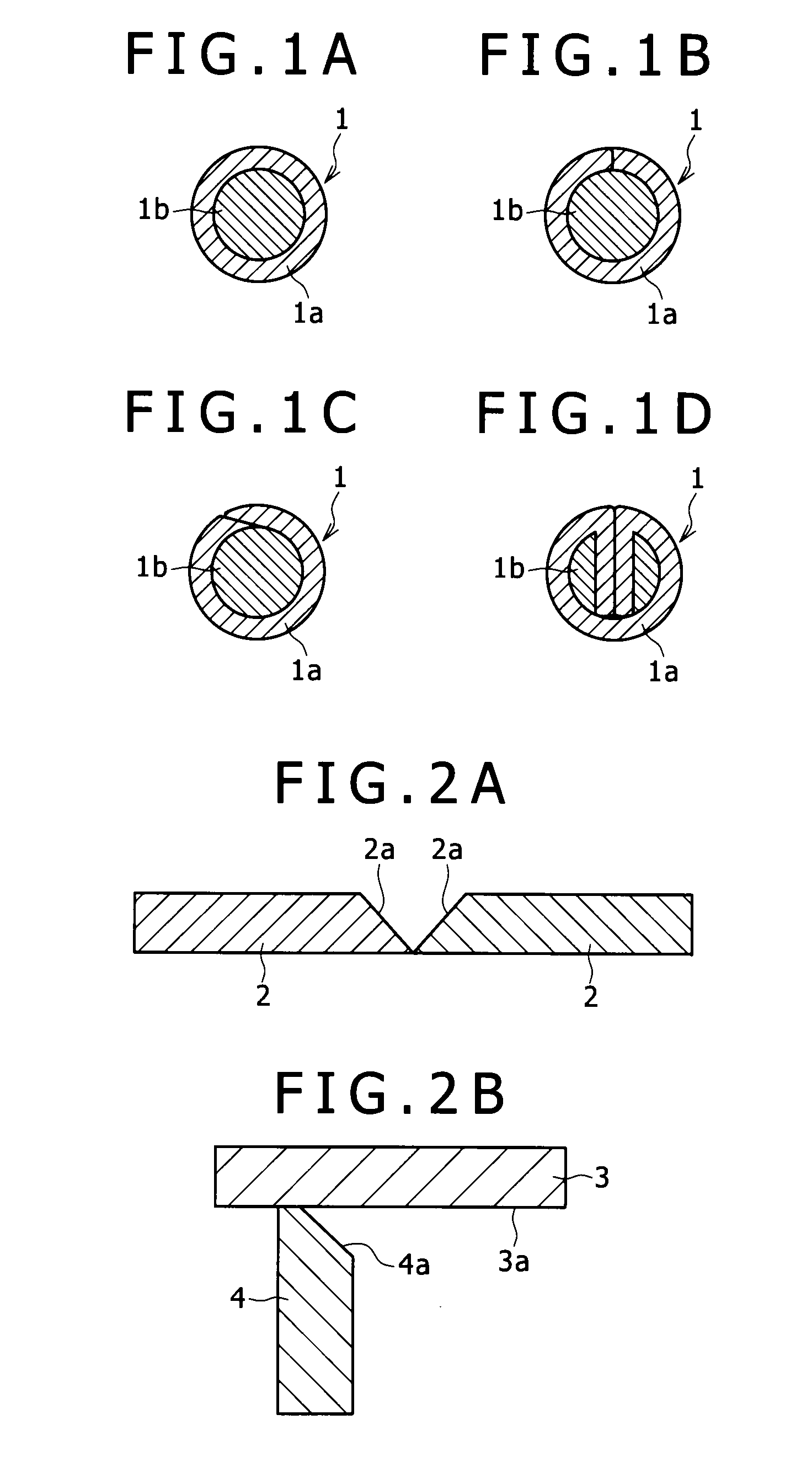

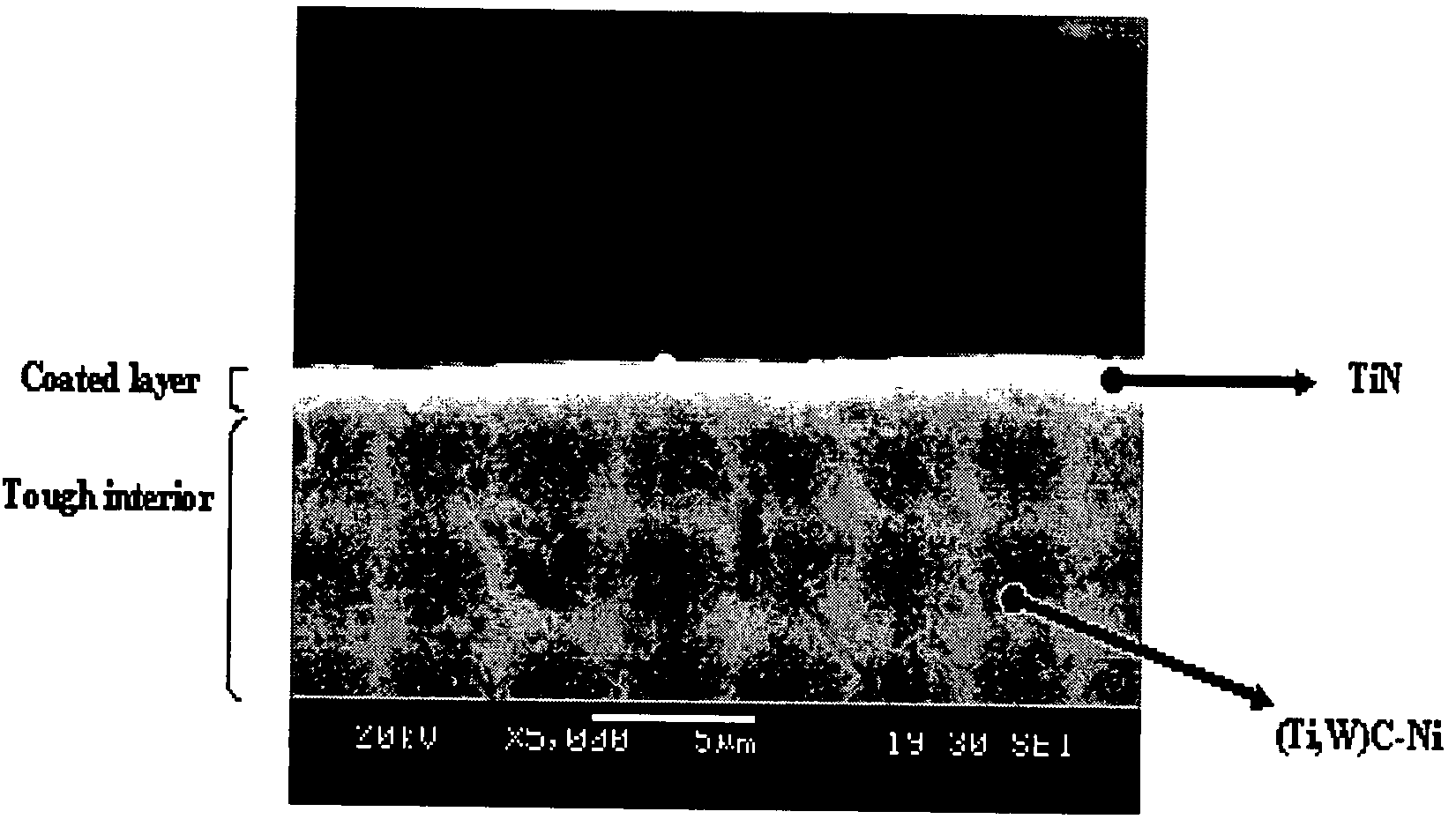

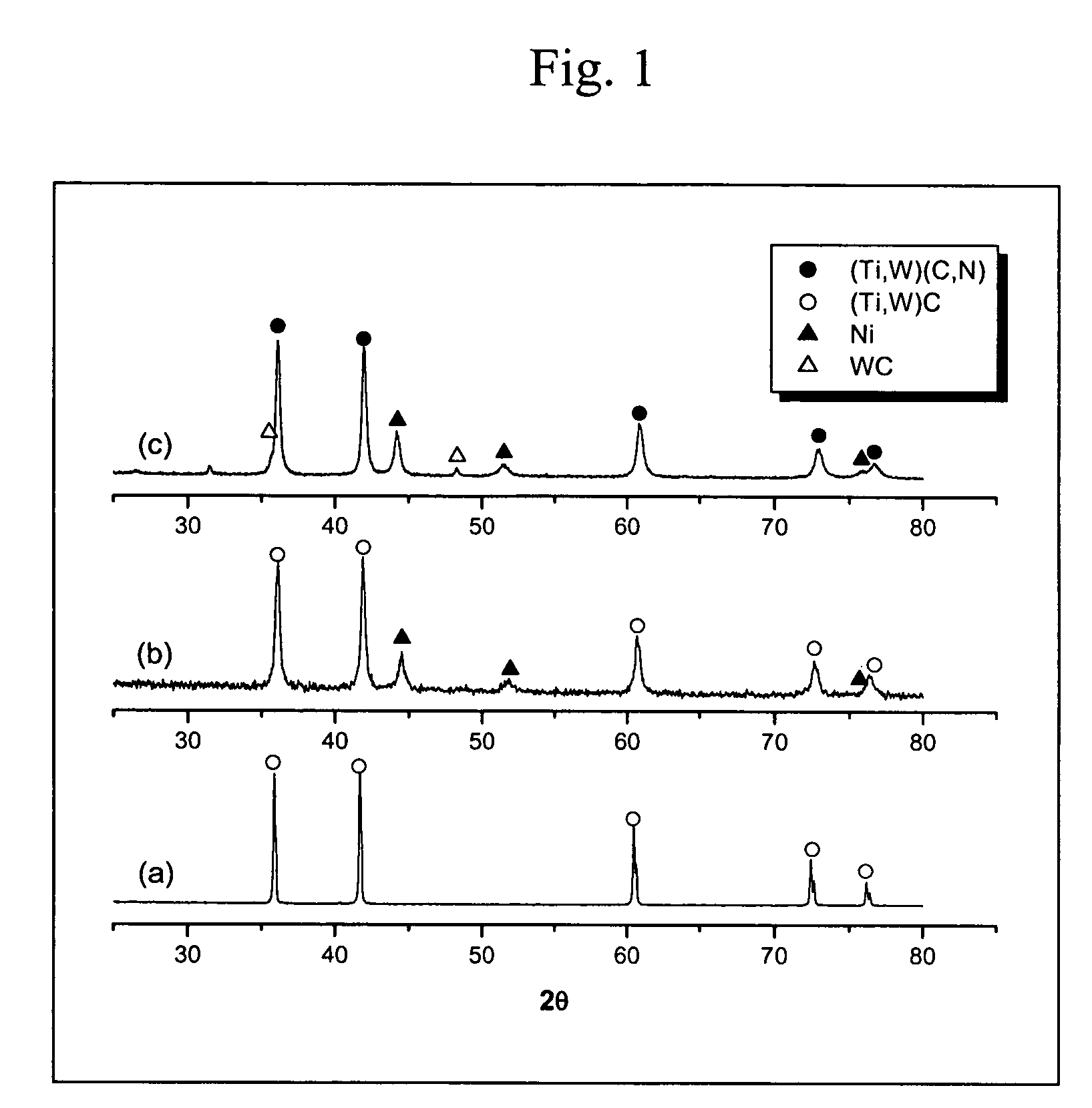

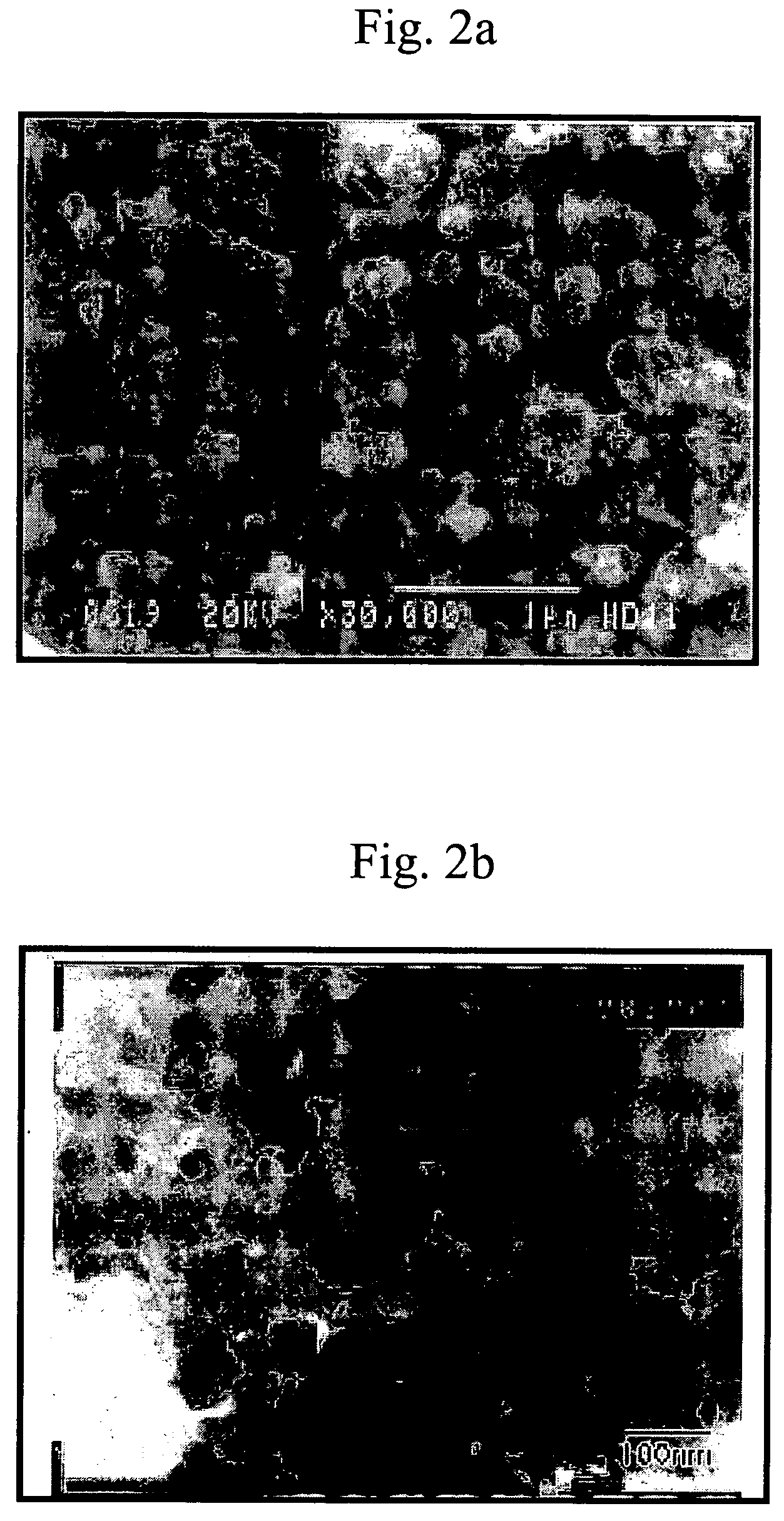

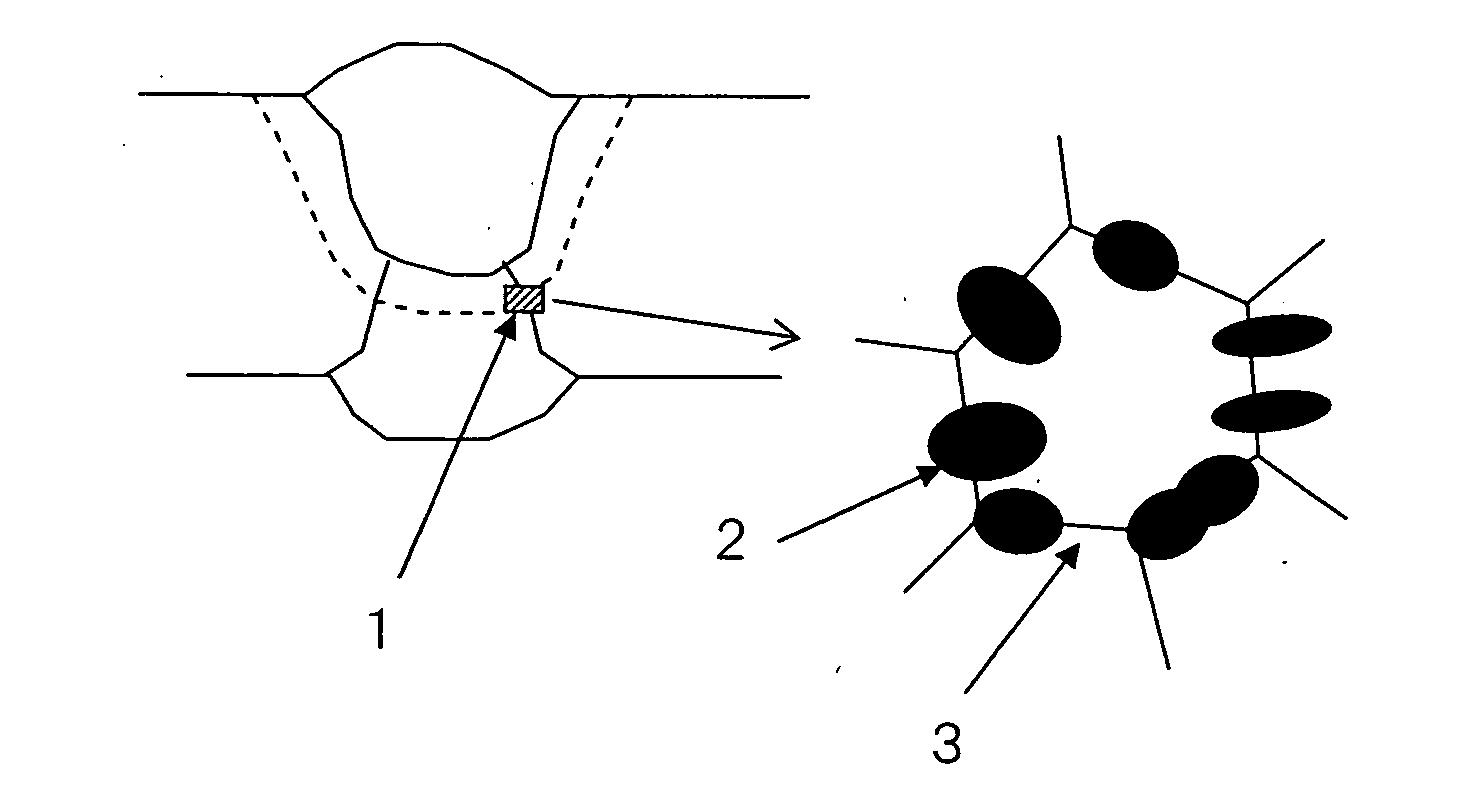

Solid-solution powder, method to prepare the solid-solution powder, cermet powder including the solid-solution powder, method to prepare the cermet powder, cermet using the cermet powder and method to prepare the cermet

ActiveUS20050180875A1Low toughnessHigh hardnessMaterial nanotechnologyTitanium carbideMicrostructureCermet

Disclosed are a solid-solution powder, a method for preparing the solid-solution powder, a cermet powder including the solid-solution powder, a method for preparing the cermet powder, a cermet using the cermet powder and a method to prepare the cermet. According to the present invention, the problem of low toughness due to high hardness that conventional cermets (especially TiC or Ti(CN) based cermet) have is resolved because a complete solid-solution phase without core / rim structure is provided to the cermets as a micro structure thereof, and in which further increased the hardness as well as the toughness, thereby substantially and considerably increasing general mechanical properties of materials using the cermet, and thus substituting WC—Co Hard material and allowing manufacturing of cutting tools with high hardness and toughness.

Owner:SEOUL NAT UNIV R&DB FOUND

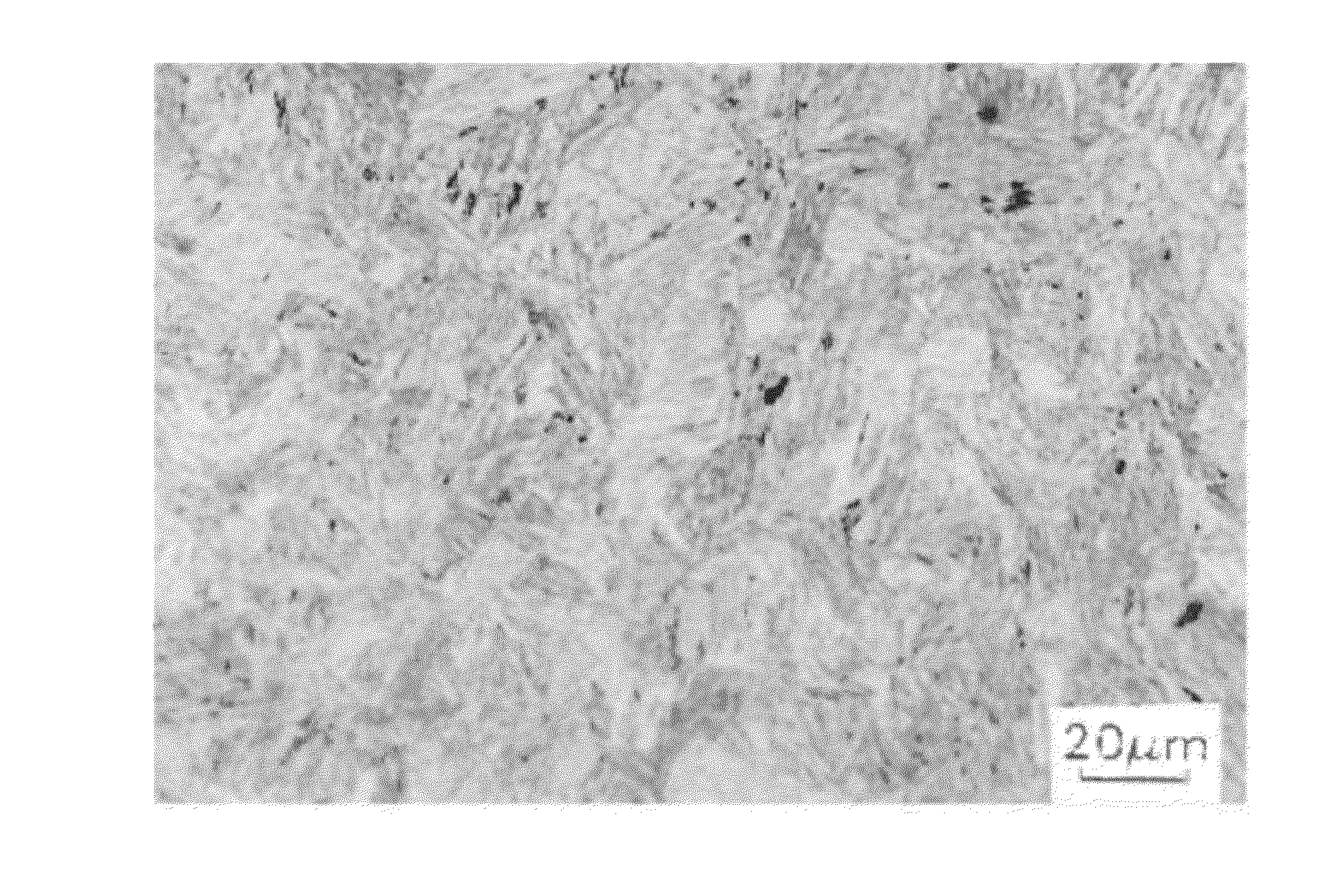

High strength steel pipe for line pipe superior in low temperature toughness and high strength steel plate for line pipe and methods of production of the same

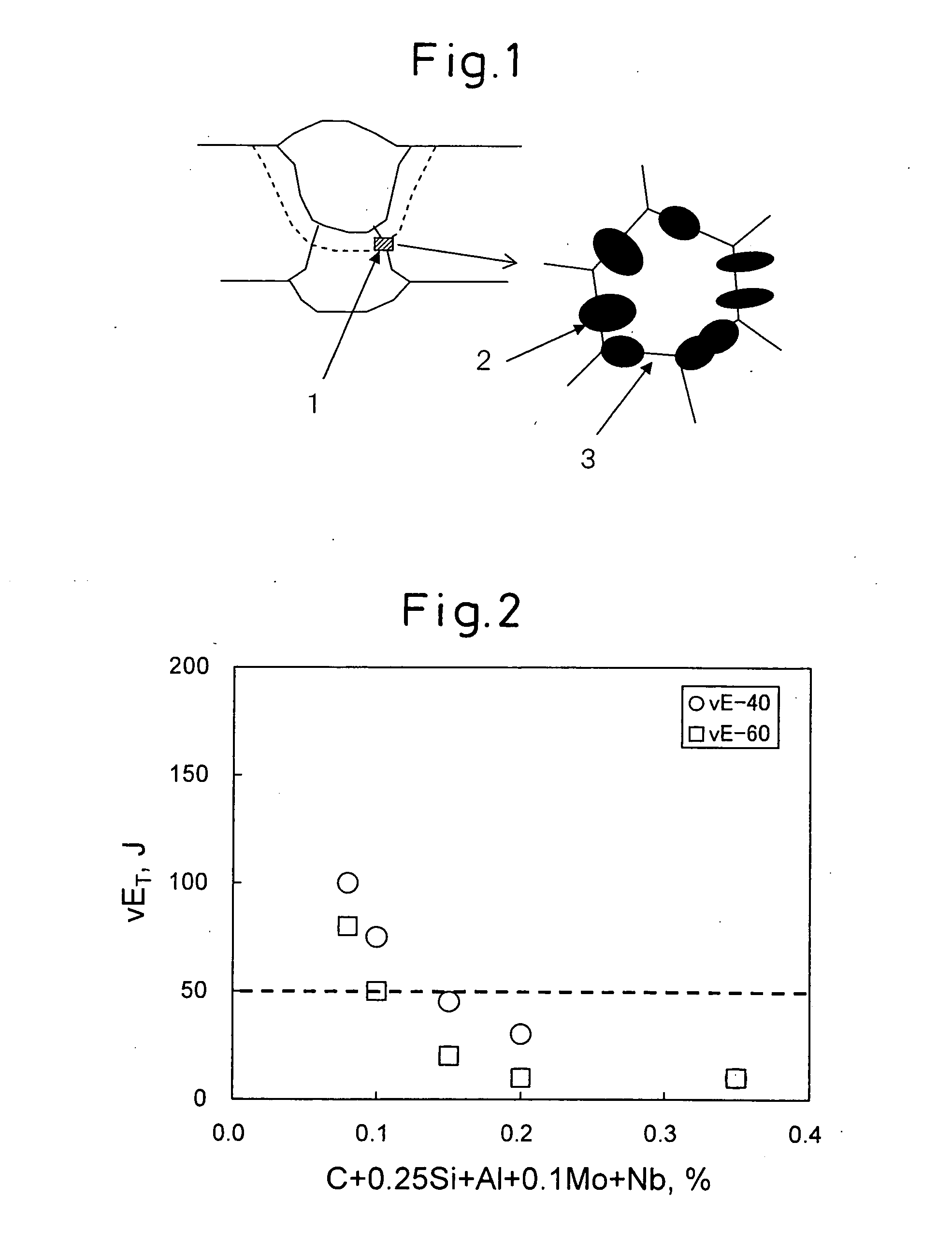

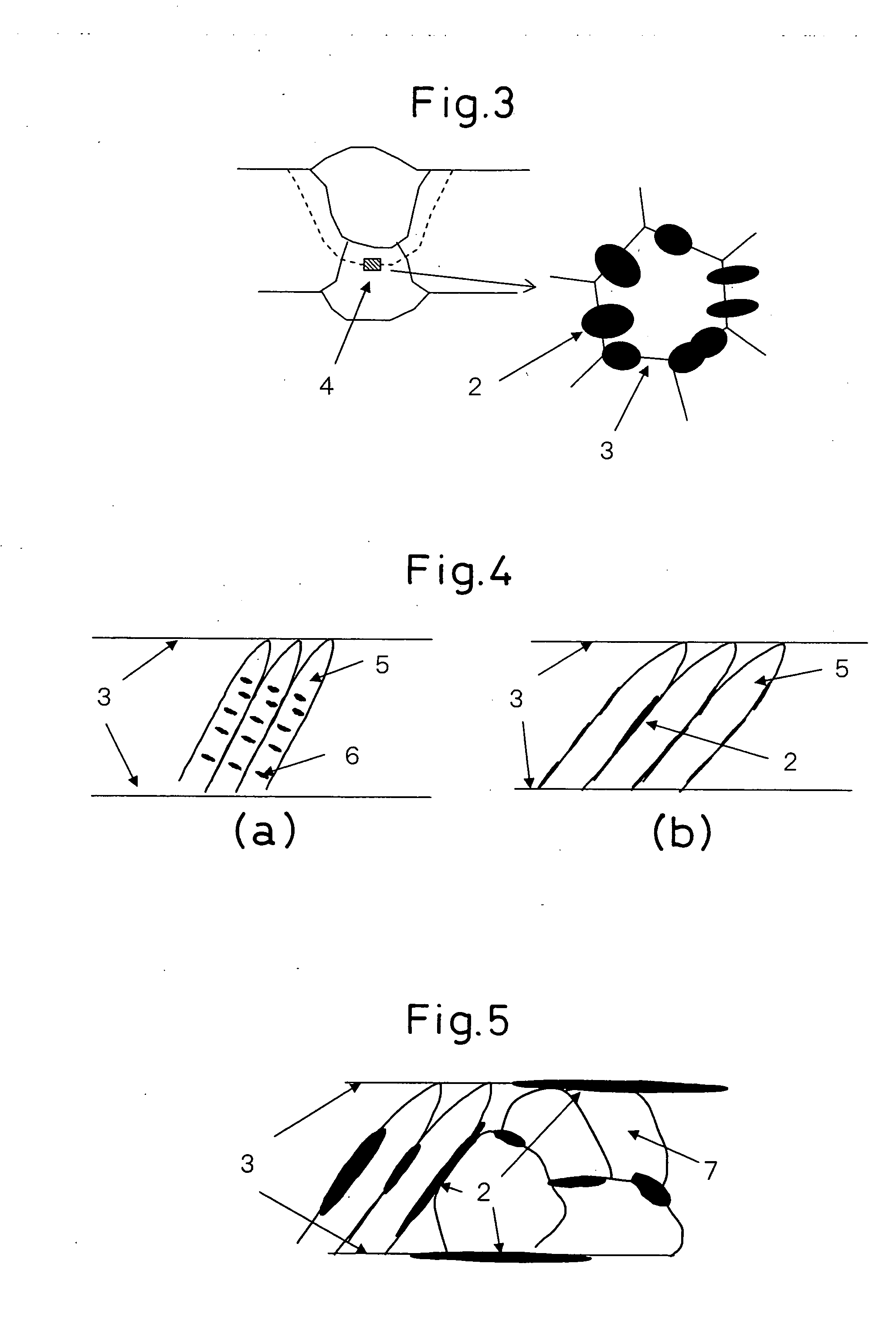

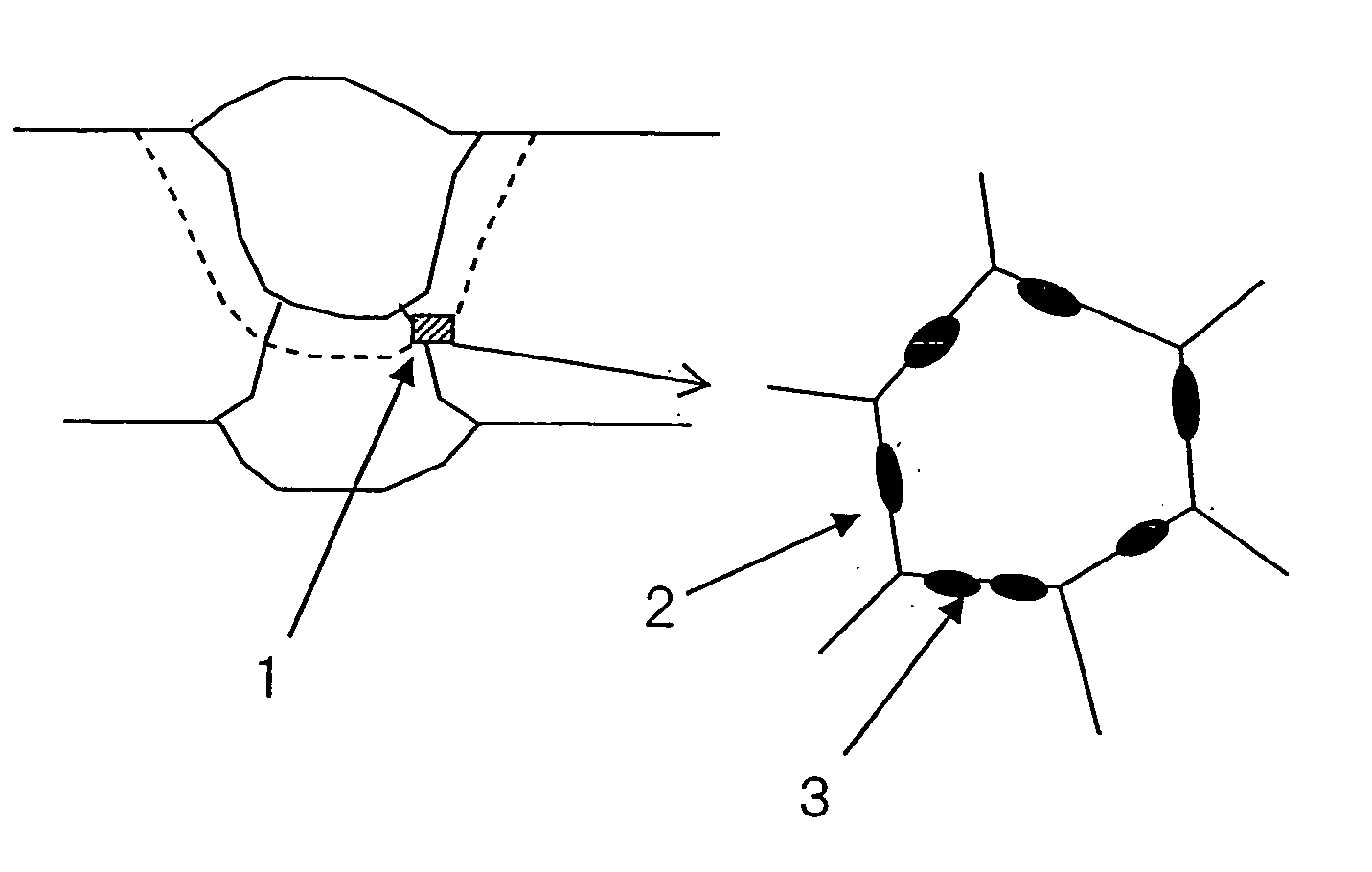

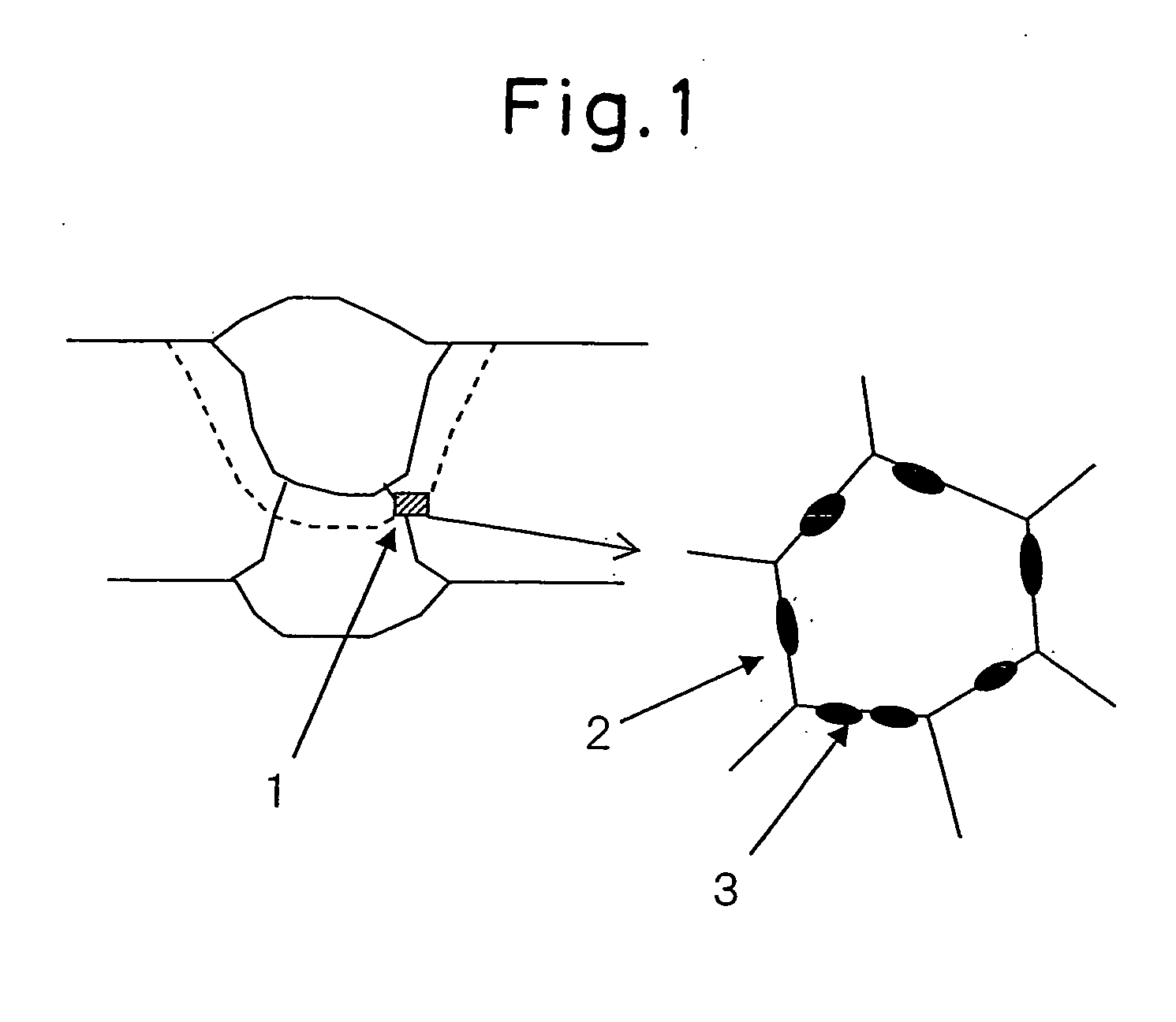

InactiveUS20100236668A1Suppressing drop of toughnessImprove low temperature toughnessFurnace typesWelding/cutting media/materialsHeat-affected zoneAustenite grain

The present invention provides high strength steel pipe for line pipe superior in low temperature toughness suppressed in drop of toughness of the HAZ and a method of production of the same, more particularly high strength steel plate for line pipe used as a material for high strength steel pipe for line pipe and a method of production of the same, in particular high strength steel pipe for line pipe superior in low temperature toughness characterized in that the chemical compositions of the base metal is, by mass %, C: 0.020 to 0.080%, Si: 0.01 to 0.50%, Mo: 0.01 to 0.15%, Al: 0.0005 to 0.030%, and Nb: 0.0001 to 0.030% contained in a range of C+0.25Si+0.1Mo+Al+Nb: 0.100% or less and the mixture of austenite and martensite present along prior austenite grain boundaries of the reheated part of the heat affected zone has a width of 10 μm or less and a length of 50 μm or less.

Owner:NIPPON STEEL CORP

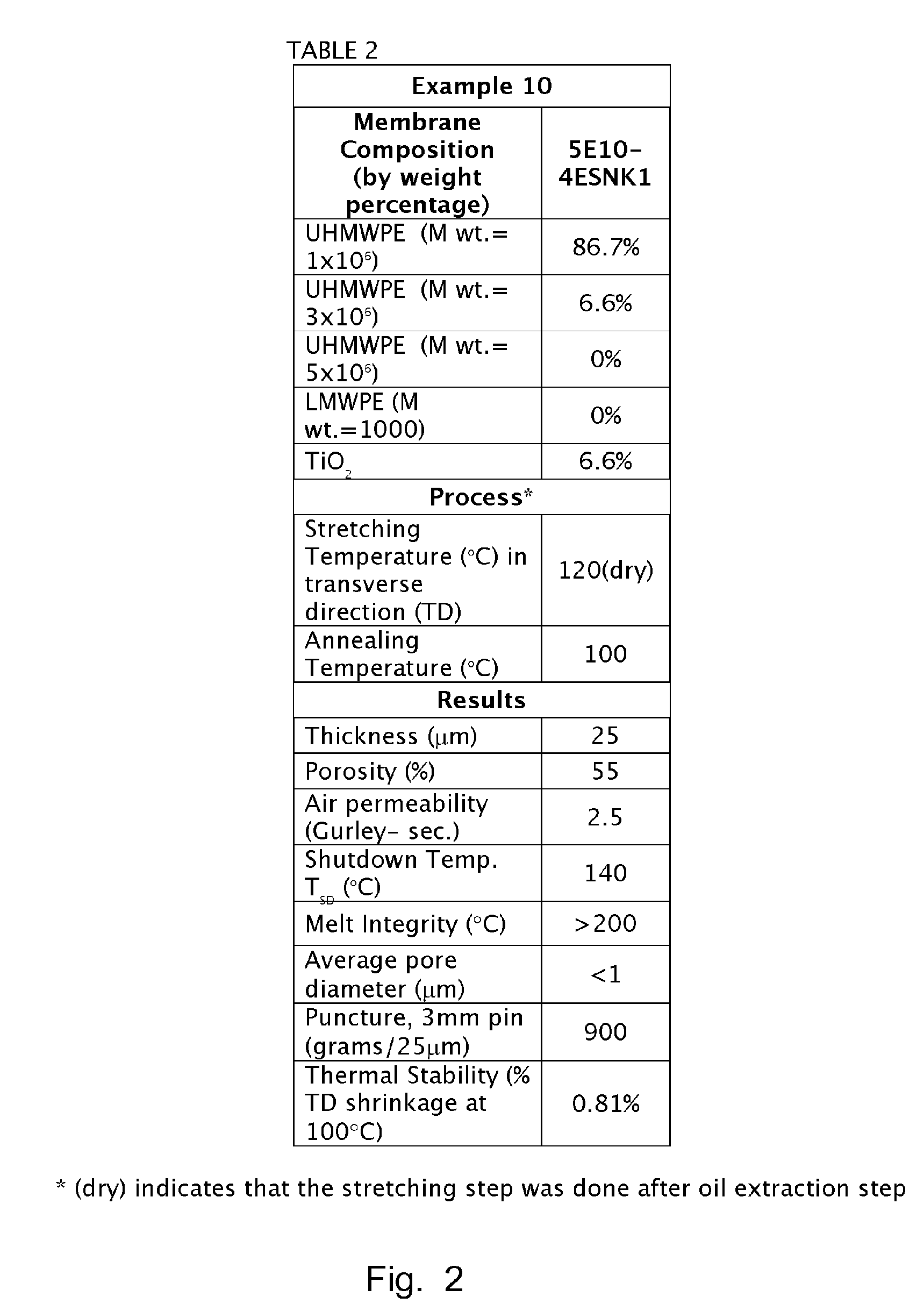

Shutdown separators with improved properties

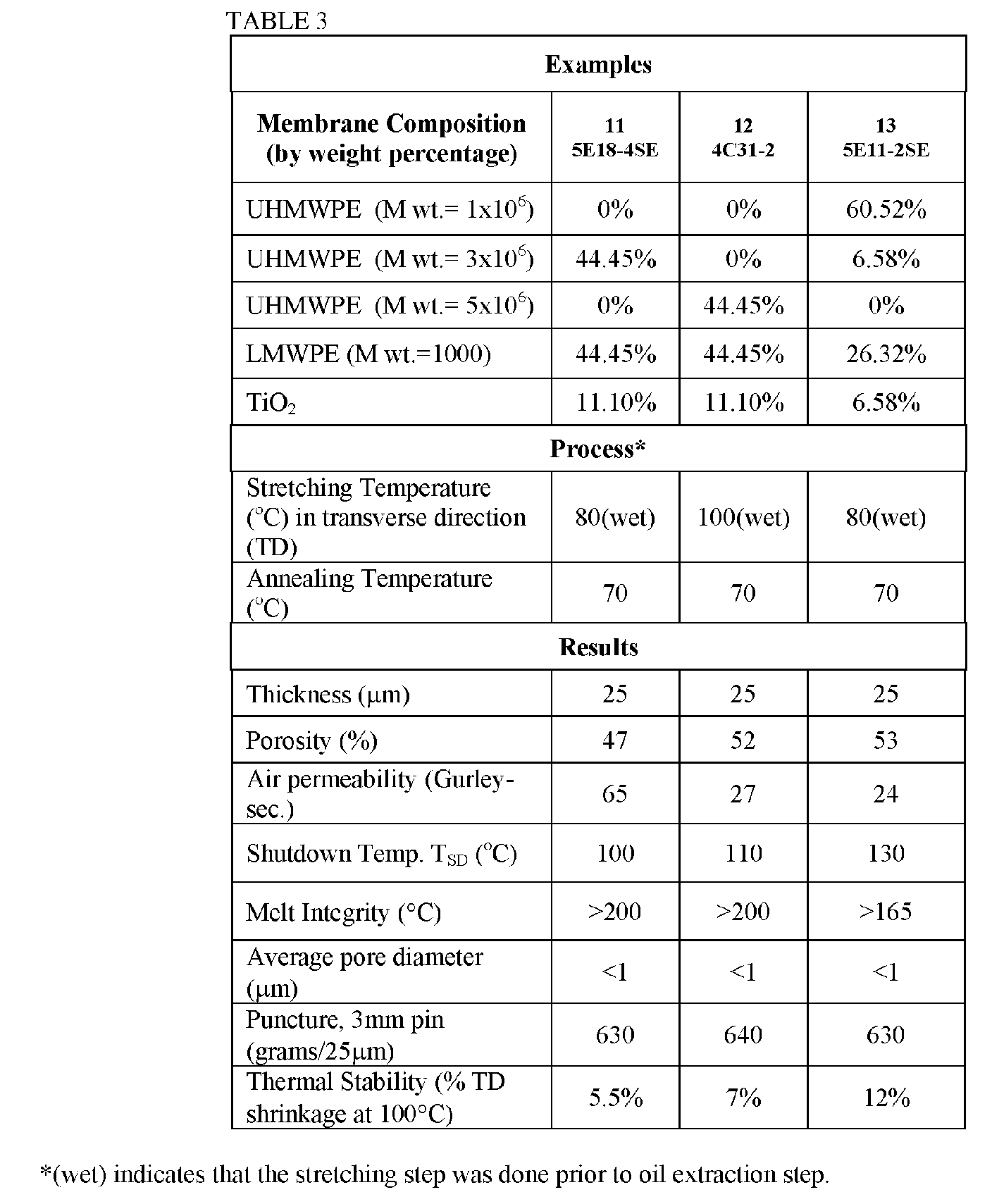

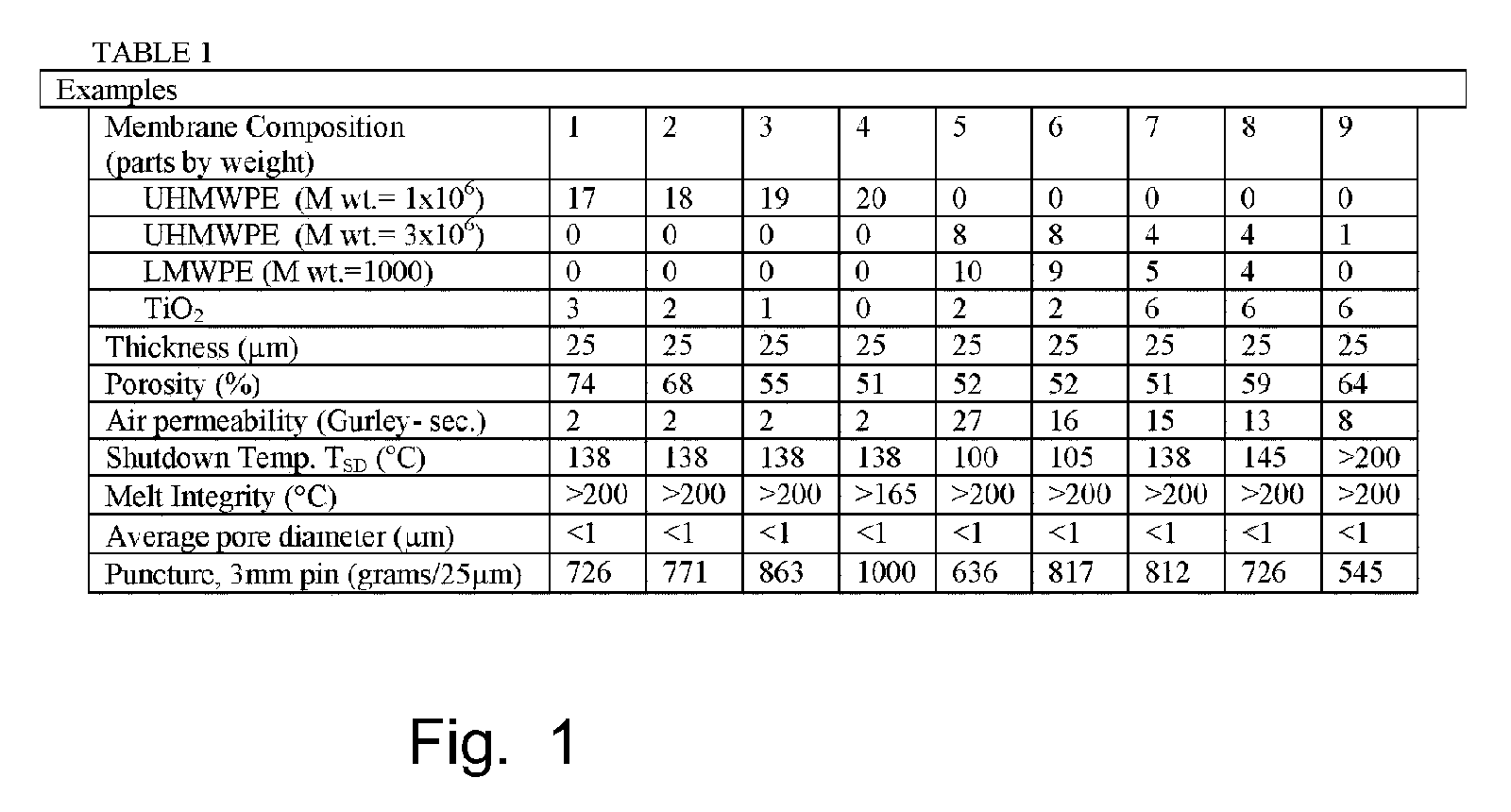

InactiveUS7323274B1Improve propertiesReduced flexibilitySemi-permeable membranesMembranesPolymer sciencePolyolefin

A microporous polyolefin battery separator membrane is extremely high in porosity, high in puncture strength, very low in shrinkage and with shutdown temperature of 130-140 degrees C. and melt integrity greater than 165 degrees C. It is made of UHMWPE having a weight-average molecular weight of 1×106 or more and an inert filler. A second microporous polyolefin battery separator has a shutdown temperature of between 95 and 110 degrees C. and a melt integrity of more than 165 degrees C. It is made from an UHMWPE having a weight-average molecular weight of 1×106 or more, a shutdown (LMWPE) having a weight-average molecular weight of 4500 or less and an inert filler. Both membranes have a thickness of 5-75 microns, a porosity of 30-95%, an air permeability of 1-200 sec / 10 cc, an average pore diameter of 0.001 to 1 micron and puncture strength of more than 300 grams / 25 μm.

Owner:ADVANCED MEMBRANE SYST INC

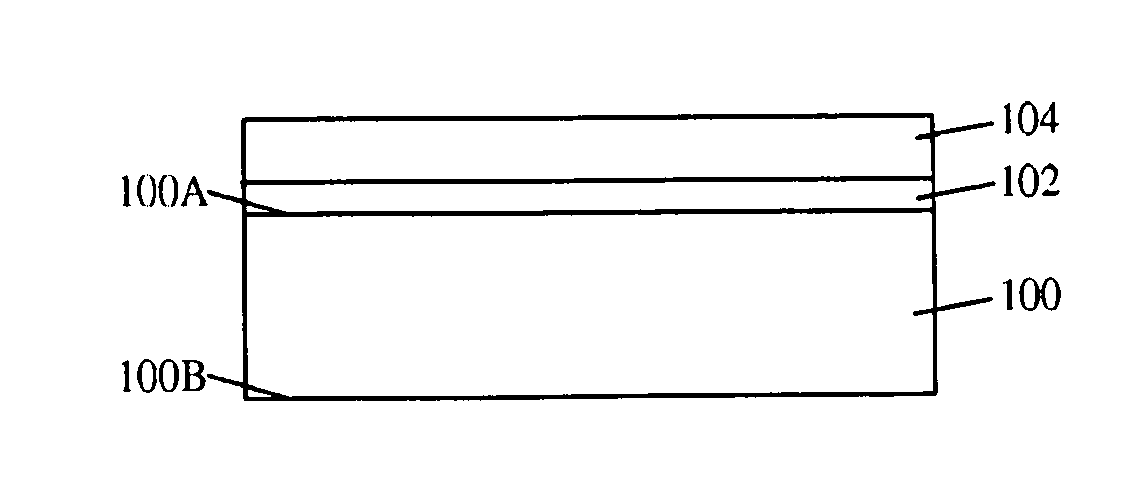

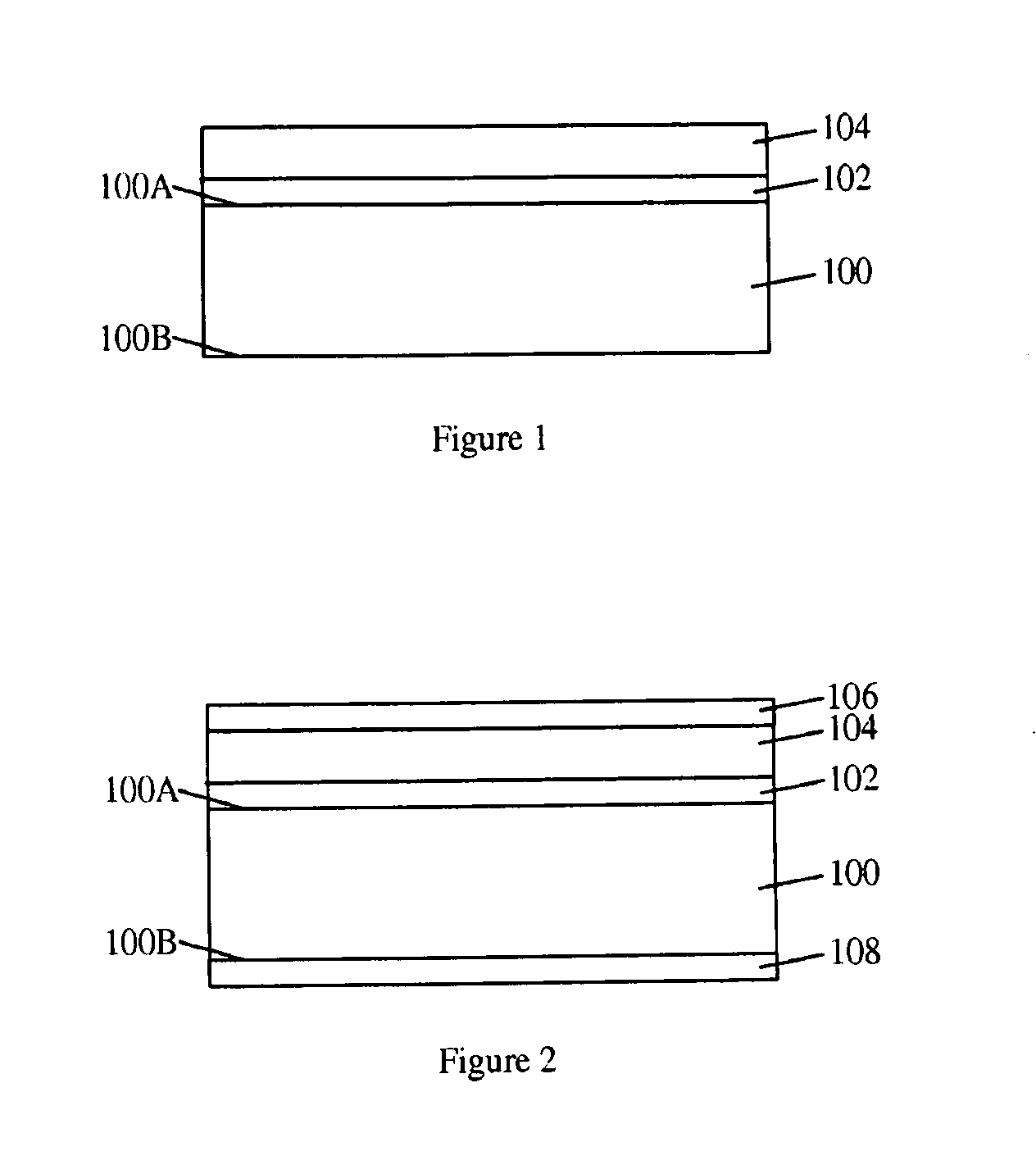

Asymmetric multi-layer composites and processes for producing the same

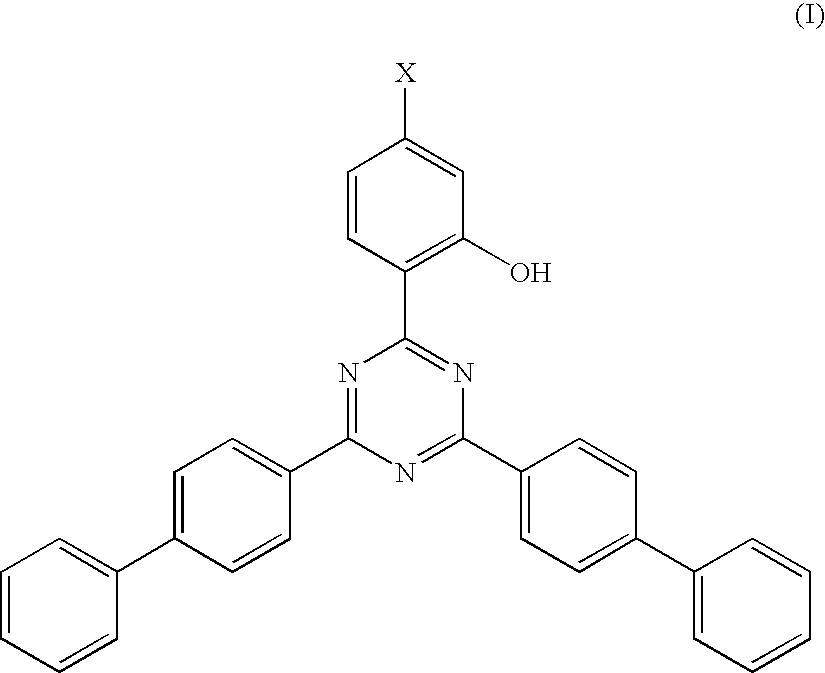

ActiveUS8455105B2Desired weathering and scratch resistance propertiesLow toughnessLiquid surface applicatorsSynthetic resin layered productsCoating

Multi-layer composites comprising: (a) a first scratch-resistant coating layer comprising a first coating (primer); (b) a thermoplastic layer; and (c) a second scratch-resistant coating layer comprising a second coating (primer); wherein the first scratch-resistant coating layer and the second scratch-resistant coating layer are disposed on opposing sides of the thermoplastic layer; wherein the first coating and the second coating are not the same; and wherein the first scratch-resistant coating layer and the second scratch-resistant coating layer are selected such that a multi-layer composite having the first scratch-resistant layer disposed on both sides of the thermoplastic layer has a lower critical impact speed for tough / brittle transition at −30° C. according to DIN EN ISO 6603-1 than a multi-layer composite having the second scratch-resistant layer disposed on both sides of the thermoplastic layer; processes for producing the same; and uses therefor.

Owner:COVESTRO DEUTSCHLAND AG

Silicone Composition, Silicone Adhesive, Coated and Laminated Substrates

InactiveUS20140194019A1Optimize working timeHigh transparencySynthetic resin layered productsAnimal housingHydrogenHalogen

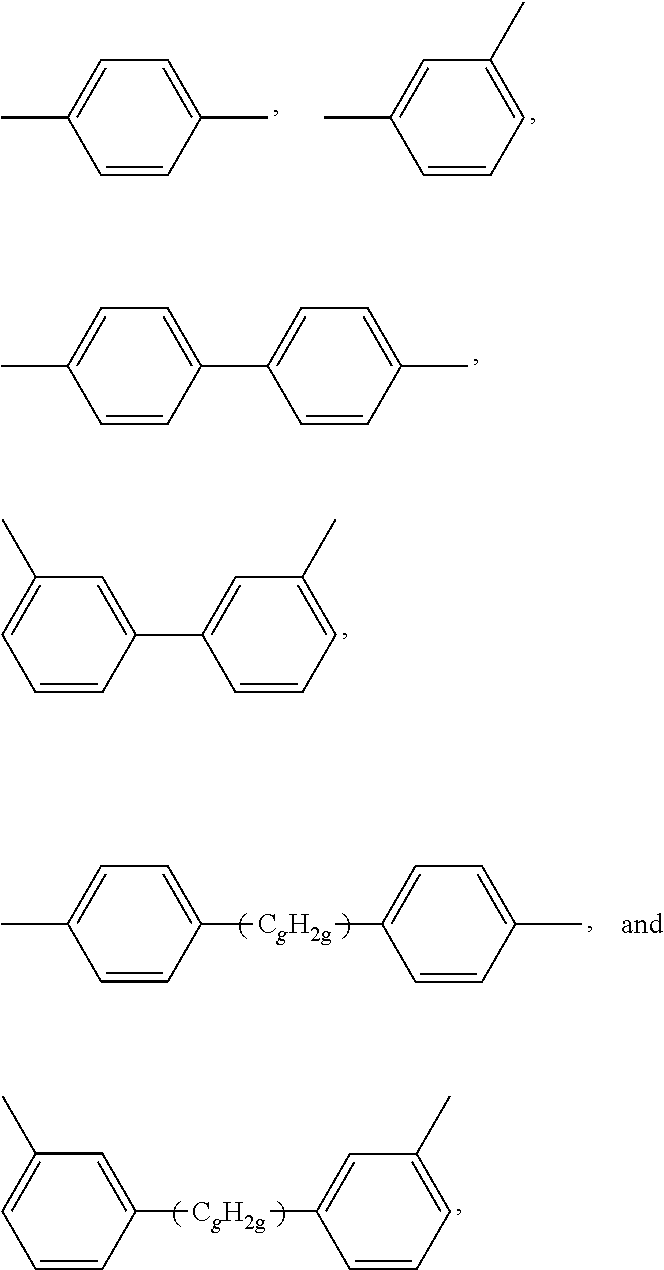

A silicone composition and more particularly to a silicone composition comprising at least one organosilicon compound having an average of at least two silicon-bonded hydrogen atoms per molecule, at least one silicone resin having the formula (R1R4R5SiO1 / 2)w(R12SiO2 / 2)x(R4SiO3 / 2)y(SiO4 / 2)z (II), wherein R1 is C1 to C10 hydrocarbyl or C1 to C10 halogen-substituted hydrocarbyl, both free of aliphatic unsaturation, R4 is C2 to C4 alkenyl, R5 is R1 or R4, w is from 0.01 to 0.6, x is from 0 to 0.5, y is from 0.1 to 0.95, z is from 0 to 0.4, and w+x+y+z)=1, and a hydrosilylation catalyst; a silicone adhesive comprising a cured product of the silicone composition, and a coated substrate and a laminated substrate, each comprising the silicone adhesive.

Owner:DOW CORNING CORP

Welded steel pipe for high strength line pipe superior in low temperature toughness and method of production of the same

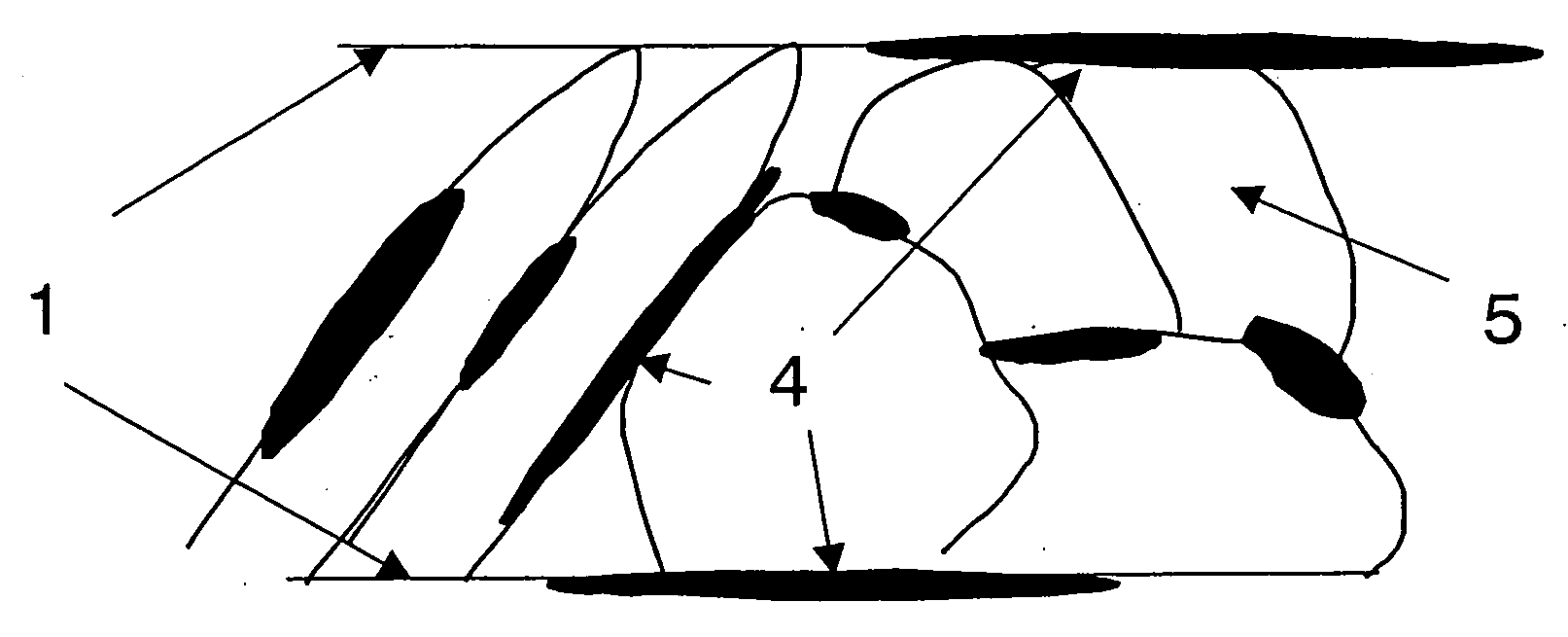

ActiveUS20100330388A1Improve low temperature toughnessHigh strengthSoldering apparatusArc welding apparatusHeat-affected zoneSheet steel

The present invention provides high strength welded steel pipe for line pipe inexpensive in cost and superior in low temperature toughness, and a method of production of the same, produced by forming a base material steel plate containing, by mass %, C: 0.010 to 0.050%, Si: 0.01 to 0.50%, Mn: 0.50 to 2.00%, S: 0.0001 to 0.0050%, and Ti: 0.003 to 0.030%, limiting Al to 0.020% or less and Mo to less than 0.10%, having a carbon equivalent Ceq of 0.30 to 0.53 and a crack susceptibility parameter Pcm of 0.10 to 0.20, comprised of polygonal ferrite and residual bainite of an area rate of 20% or less, and having an effective crystal grain size of 20 μm or less, into a pipe shape, then seam welding it and making the effective crystal grain size of the heat affected zone 150 μm or less.

Owner:NIPPON STEEL CORP

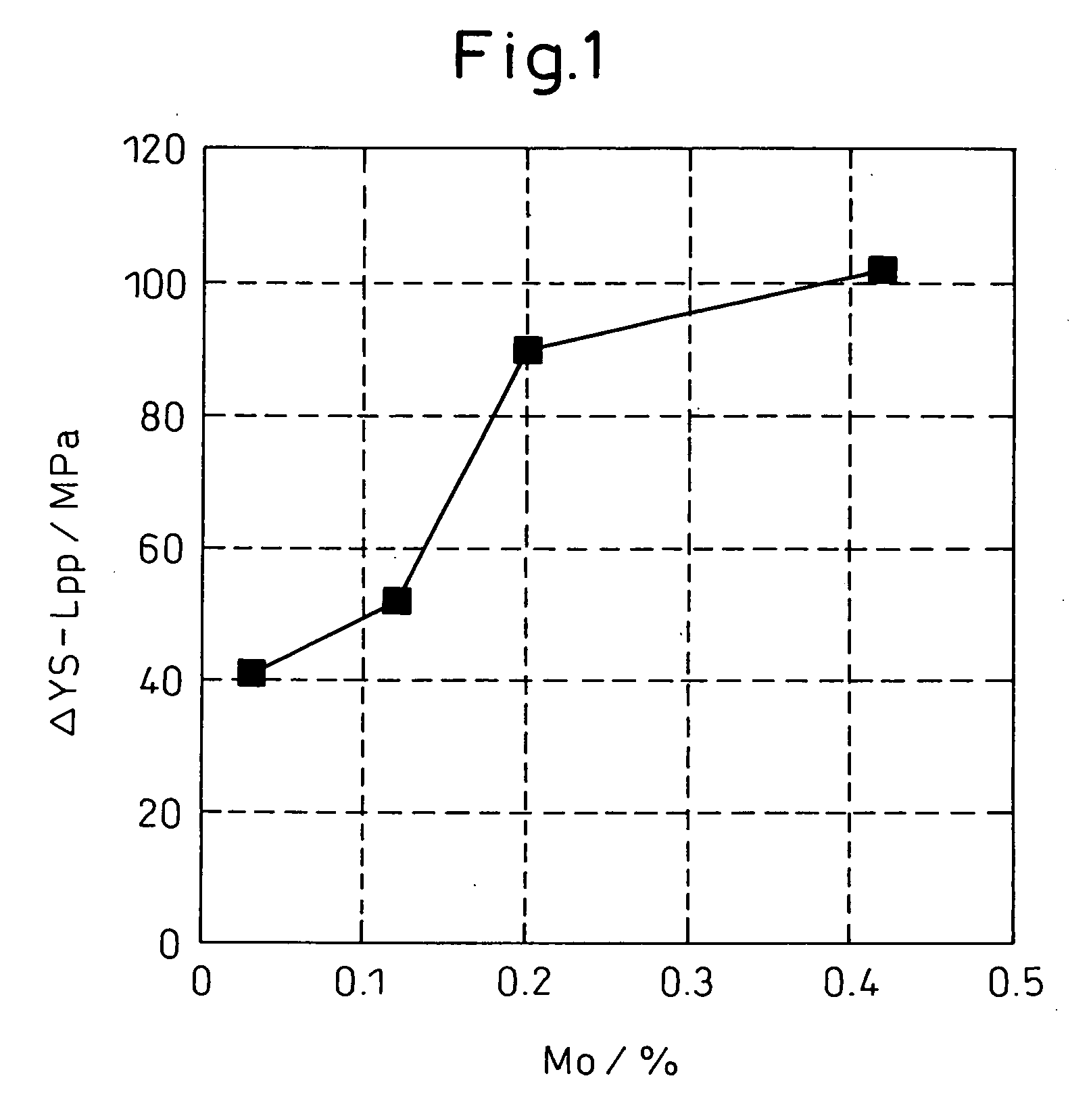

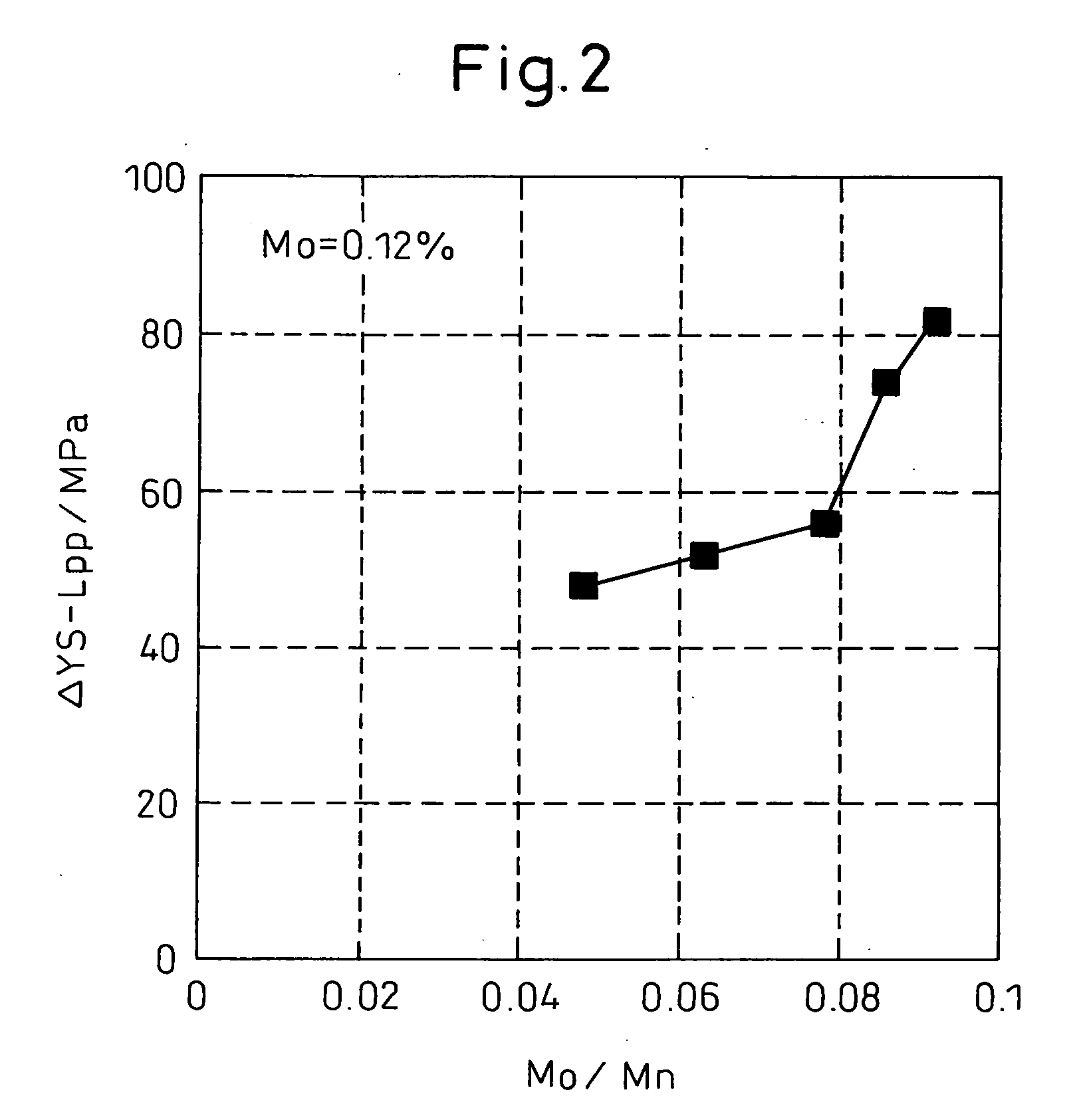

Steel pipe for high strength line pipe superior in strain aging resistance and steel plate for high strength line pipe and methods of production of the same

InactiveUS20090092514A1Superior strain aging resistanceHigh strengthArc welding apparatusFurnace typesLine tubingSheet steel

The present invention provides steel plate for high strength line pipe suppressing the rise in yield strength in the longitudinal direction of expanded steel pipe due to the heating at the time of coating to prevent corrosion and superior in strain aging resistance and steel pipe for the material for the same, that is, high strength steel pipe for line pipe superior in strain aging resistance characterized in that a base material having a composition of chemical elements containing, by mass %, Mo: over 0% to less than 0.15% and Mn: 1.7 to 2.5%, satisfying Mo / Mn: over 0 to 0.08, containing C, Si, P, S, Al, Ti, N, and B, furthermore containing one or more of Ni, Cu, and Cr, having a balance of iron and unavoidable impurities, having a P value of 2.5 to 4.0 in range, and having a metallurgical structure comprised of bainite and martensite:P value=2.7C+0.4Si+Mn+0.8Cr+0.45(Ni+Cu)+2Mo.Furthermore, it may contain one or more of Nb, V, Ca, REM, and Mg.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

Release film, laminate and method for manufacturing same, and method for manufacturing fuel cell

ActiveUS20160276689A1Increase productionPrevents and reduces and breakageCell electrodesFinal product manufactureFuel cellsSide chain

A release layer of a release film for producing a membrane electrode assembly of a polymer electrolyte fuel cell comprises a cyclic olefin polymer comprising an olefin unit having a C3-10alkyl group as a side chain thereof. The release layer may have a glass transition temperature of about 210 to 350° C. The release layer may have a transition point of a dynamic storage modulus E′ in a range from −50 to 100° C. An ion exchange layer comprising an ion exchange polymer may be laminated on the release layer of the release film by a roll-to-roll processing to produce a laminate. The release film may be separated from the laminate to give the membrane electrode assembly. The release film achieves improved production of a membrane electrode assembly (an electrolyte membrane and / or an electrode membrane) of a polymer electrolyte fuel cell.

Owner:DAICEL CHEM IND LTD +1

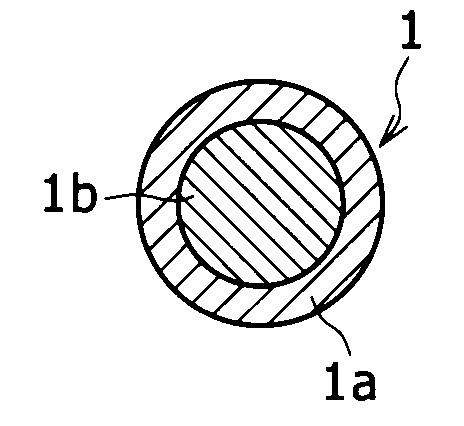

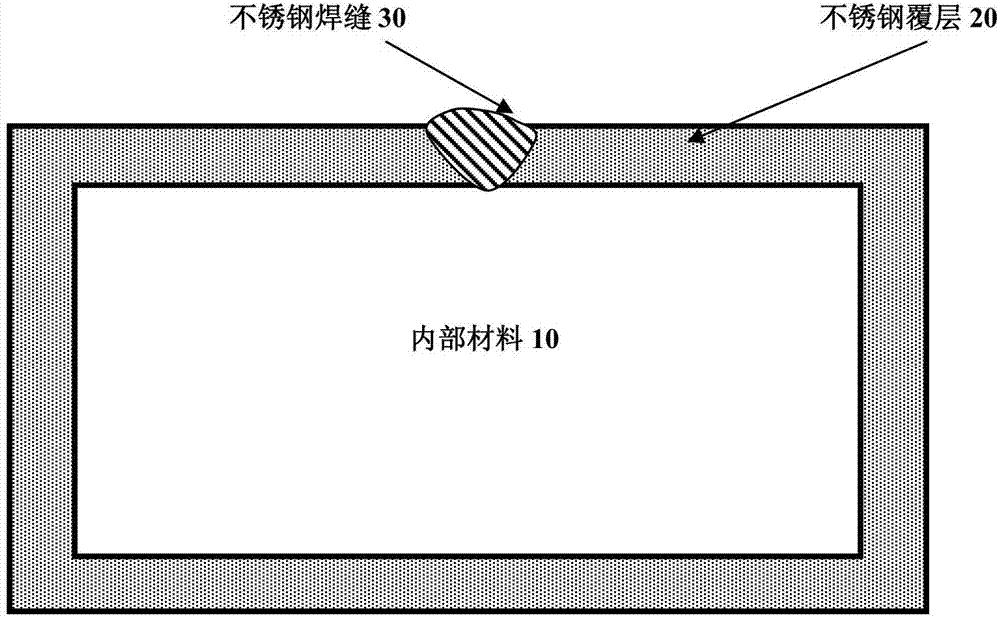

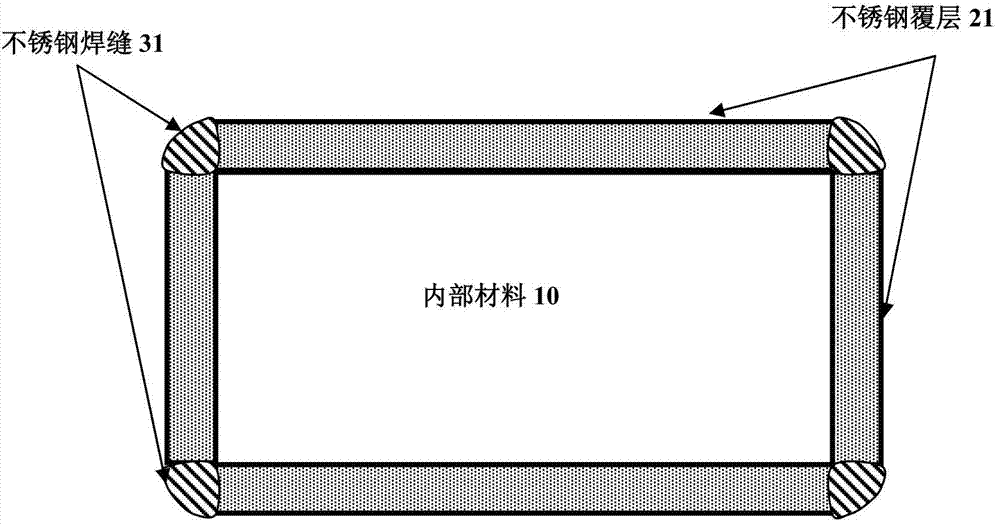

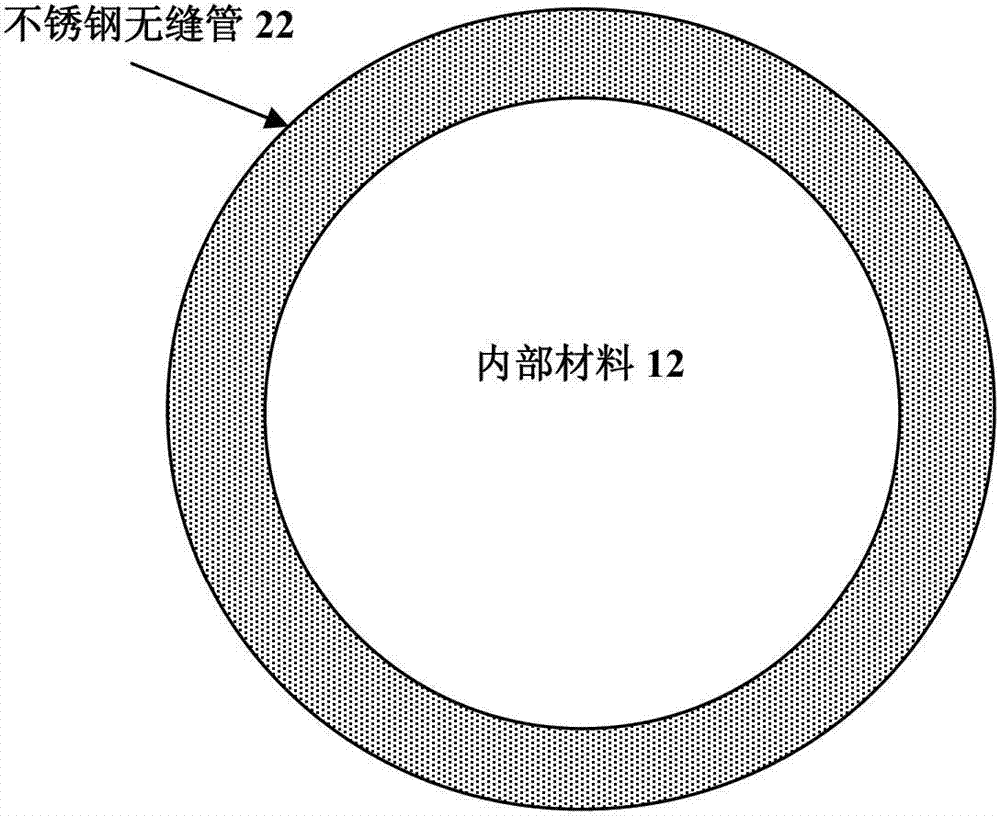

Corrosion-resistant composite section bar and preparation method thereof

ActiveCN104329560ALow costReduced corrosion resistanceConstructions elementsSocial benefitsMetallurgy

The invention discloses a corrosion-resistant composite section bar and a preparation method thereof. The corrosion-resistant composite section bar consists of an internal material, an external cladding layer and a chemical transition region, wherein the external cladding layer is attached to the internal material; the chemical transition region is sandwiched between the internal material and the external cladding layer; the internal material is a carbon steel material, a low alloy steel material or a micro alloy steel material; the external cladding layer is a stainless steel cladding layer; the chemical transition region is an element diffusion transition region between the internal material and the external cladding layer. According to the corrosion-resistant composite section bar, the manufacturing cost is low, the process is simple, and important social benefit and economic benefit are realized in development of low carbon and green economy.

Owner:CENT IRON & STEEL RES INST +1

High tensile strength steel and marine structure having excellent weld toughness

In order to provide a high tensile strength steel having excellent low temperature toughness and which can withstand large heat input welding, a steel comprises, in mass percent, C: 0.01-0.10%, Si: at most 0.5%, Mn: 0.8-1.8%, P: at most 0.020%, S: at most 0.01%, Cu: 0.8-1.5%, Ni: 0.2-1.5%, Al: 0.001-0.05%, N: 0.0030-0.0080%, O: 0.0005-0.0035%, if necessary at least one of Ti: 0.005-0.03%, Nb: 0.003-0.03%, and Mo: 0.1-0.8%, and a remainder of Fe and impurities, and the N / Al ratio is 0.3-3.0.

Owner:SUMITOMO METAL IND LTD

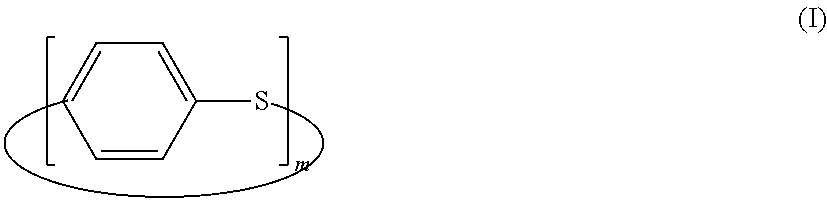

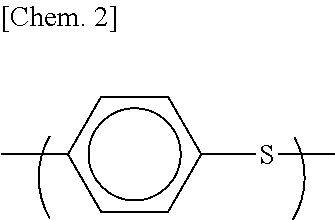

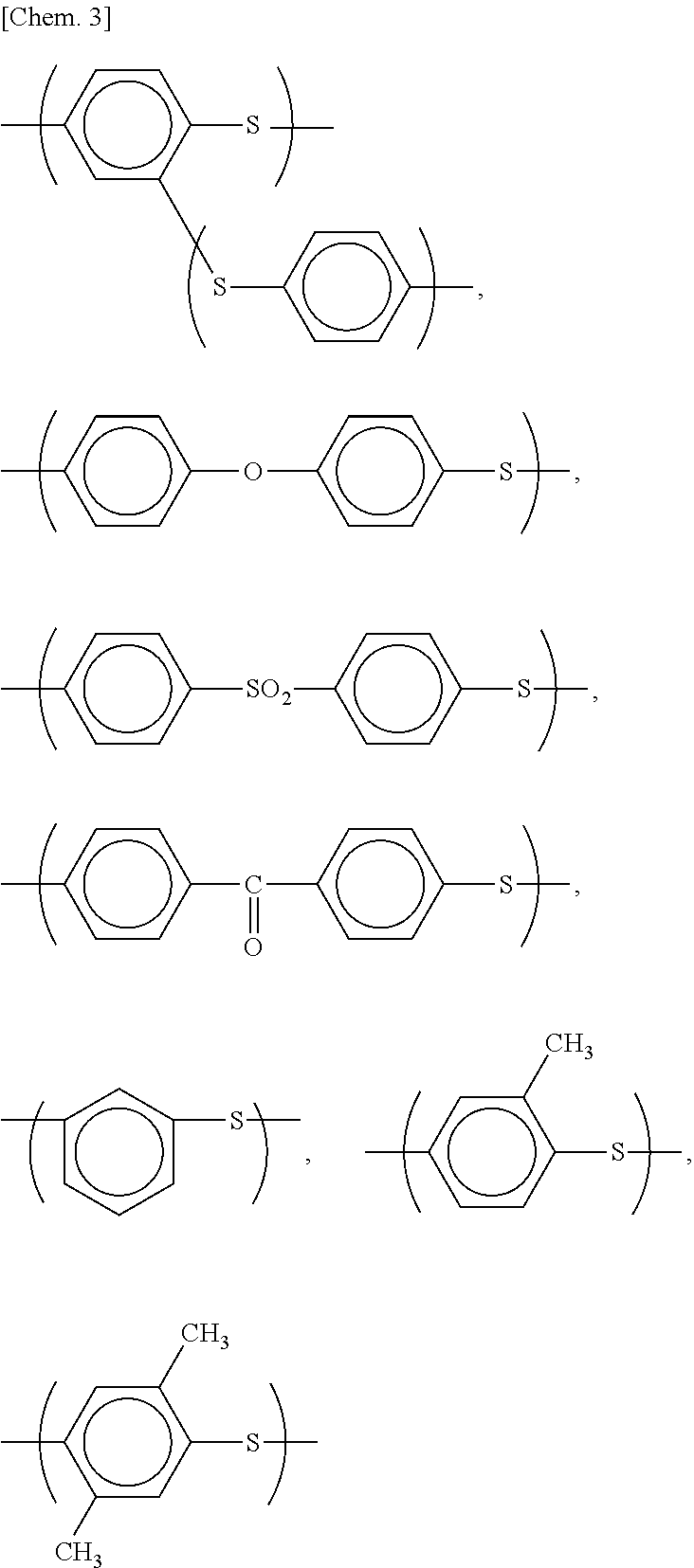

Polyphenylene sulfide resin composition, molded product of polyphenylene sulfide resin composition and production method of polyphenylene sulfide resin composition

There is provided a polyphenylene sulfide resin composition, comprising 5 to 95% by weight of a component (B) which is a polyphenylene sulfide resin having a weight-average molecular weight of not less than 10,000 and a weight loss percentage ΔWr of not greater than 0.18% under heating, relative to 95 to 5% by weight of a component (A) which is a polyphenylene sulfide resin having the weight loss percentage ΔWr of greater than 0.18%, wherein a total of the component (A) and the component (B) is equal to 100% by weight.

Owner:TORAY IND INC

Asymmetric Multi-Layer Composites and Processes for Producing the Same

ActiveUS20090212587A1Desired weathering and scratch resistance propertiesLow toughnessWindowsWindscreensCoating

Multi-layer composites comprising: (a) a first scratch-resistant coating layer comprising a first coating (primer); (b) a thermoplastic layer; and (c) a second scratch-resistant coating layer comprising a second coating (primer); wherein the first scratch-resistant coating layer and the second scratch-resistant coating layer are disposed on opposing sides of the thermoplastic layer; wherein the first coating and the second coating are not the same; and wherein the first scratch-resistant coating layer and the second scratch-resistant coating layer are selected such that a multi-layer composite having the first scratch-resistant layer disposed on both sides of the thermoplastic layer has a lower critical impact speed for tough / brittle transition at −30° C. according to DIN EN ISO 6603-1 than a multi-layer composite having the second scratch-resistant layer disposed on both sides of the thermoplastic layer; processes for producing the same; and uses therefor.

Owner:COVESTRO DEUTSCHLAND AG

High-strength steel sheet and high-strength steel pipe excellent in deformability and method for producing the same

ActiveUS8070887B2Good deformabilityLow toughnessArc welding apparatusFurnace typesProduction rateSheet steel

The present invention provides a line pipe of, e.g., the API standard X60 to X100 class. The line pipe has an excellent deformability, as well as excellent low temperature toughness and high productivity, a steel plate used as the material of the steel pipe. Methods for producing the steel pipe and the steel plate are also provided. In particular, a high-strength steel plate excellent in the deformability has a ferrite phase is dispersed finely, and accounts for 5% to 40% in area percentage in a low temperature transformation structure mainly composed of a bainite phase. For example, most grain sizes of the ferrite phase are smaller than the average grain size of the bainite phase. A high-strength steel pipe excellent in deformability is also provided, in which a large diameter steel pipe is produced through forming the steel plate into a pipe shape. The steel pipe has the above-referenced structure, and satisfies the conditions that YS / TS is 0.95 or less and YS×uEL is 5,000 or more. Methods for producing such steel plate and steel pipe are also provided.

Owner:NIPPON STEEL CORP

High strength steel pipes with excellent toughness at low temperature and sulfide stress corrosion cracking resistance

ActiveUS9598746B2Lower resistanceLow toughnessFurnace typesHeat treatment furnacesAustenite grainStress corrosion cracking

Owner:DALMINE SPA

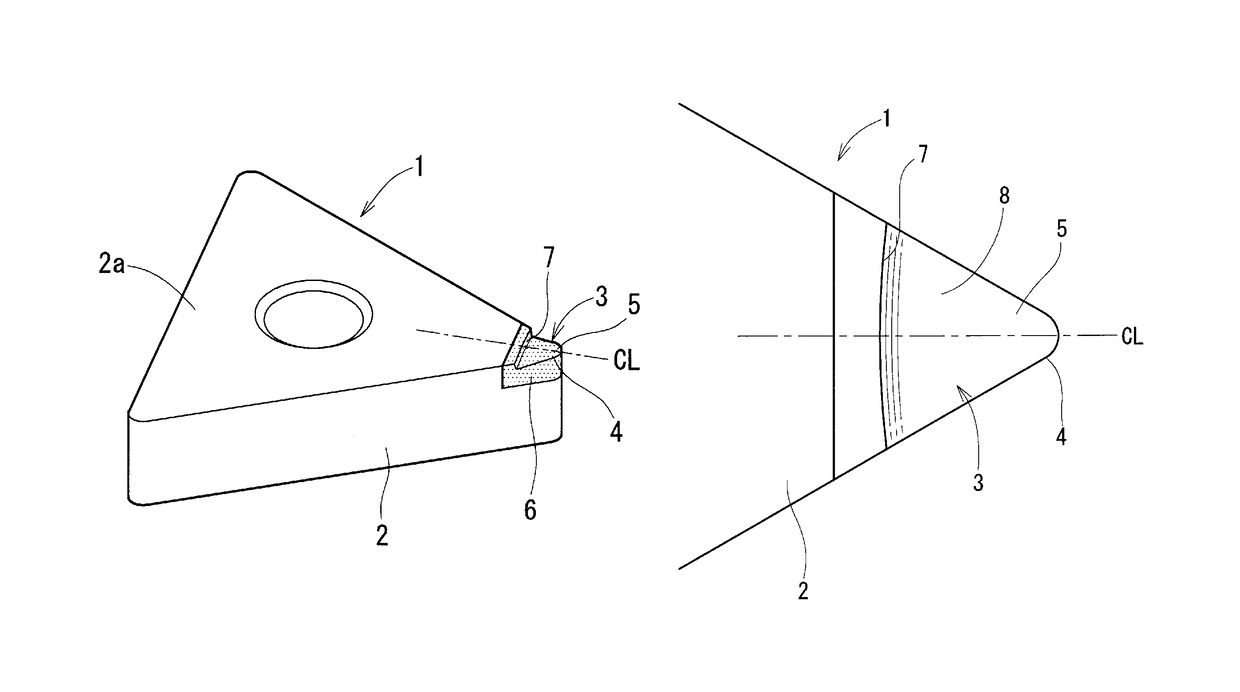

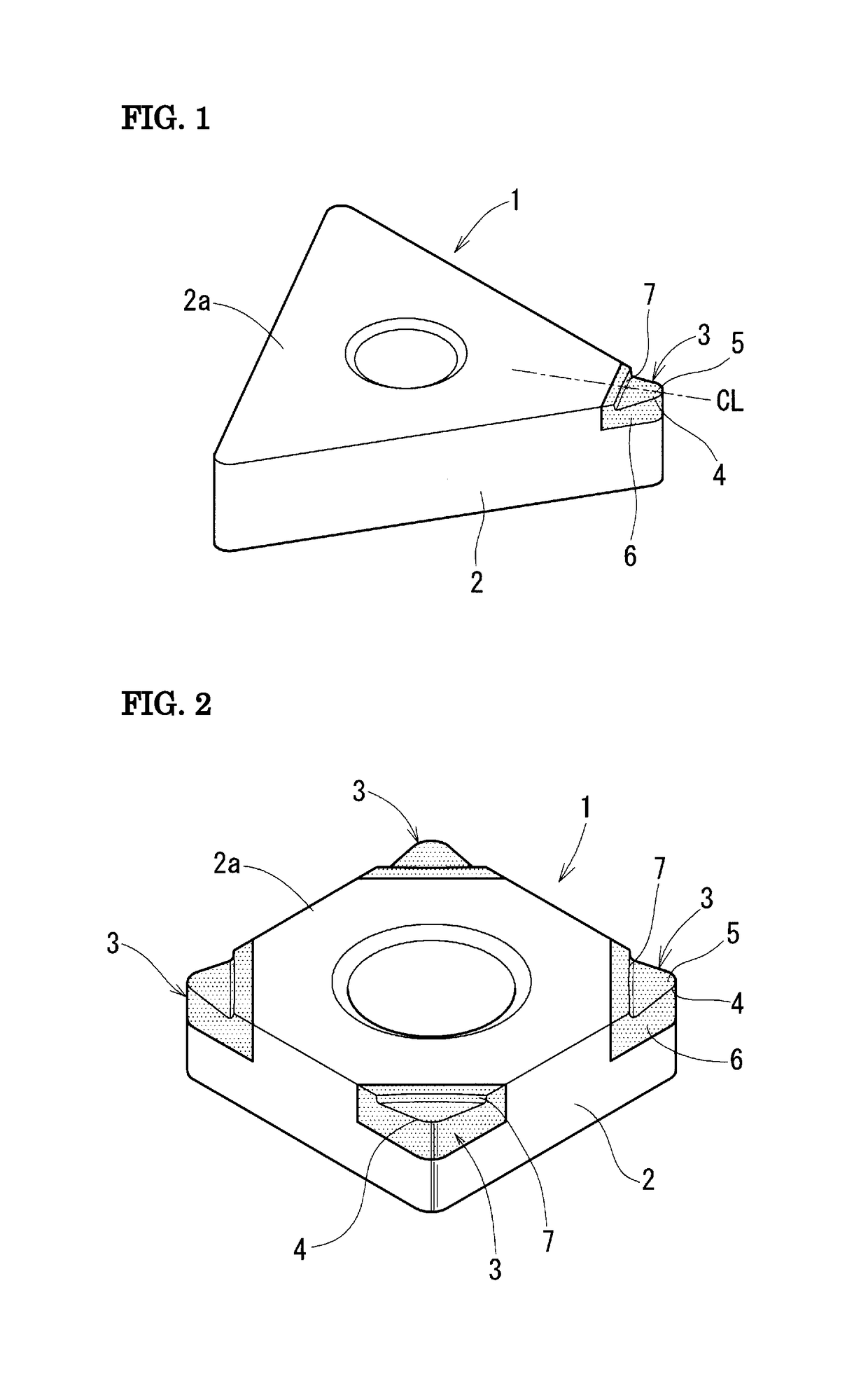

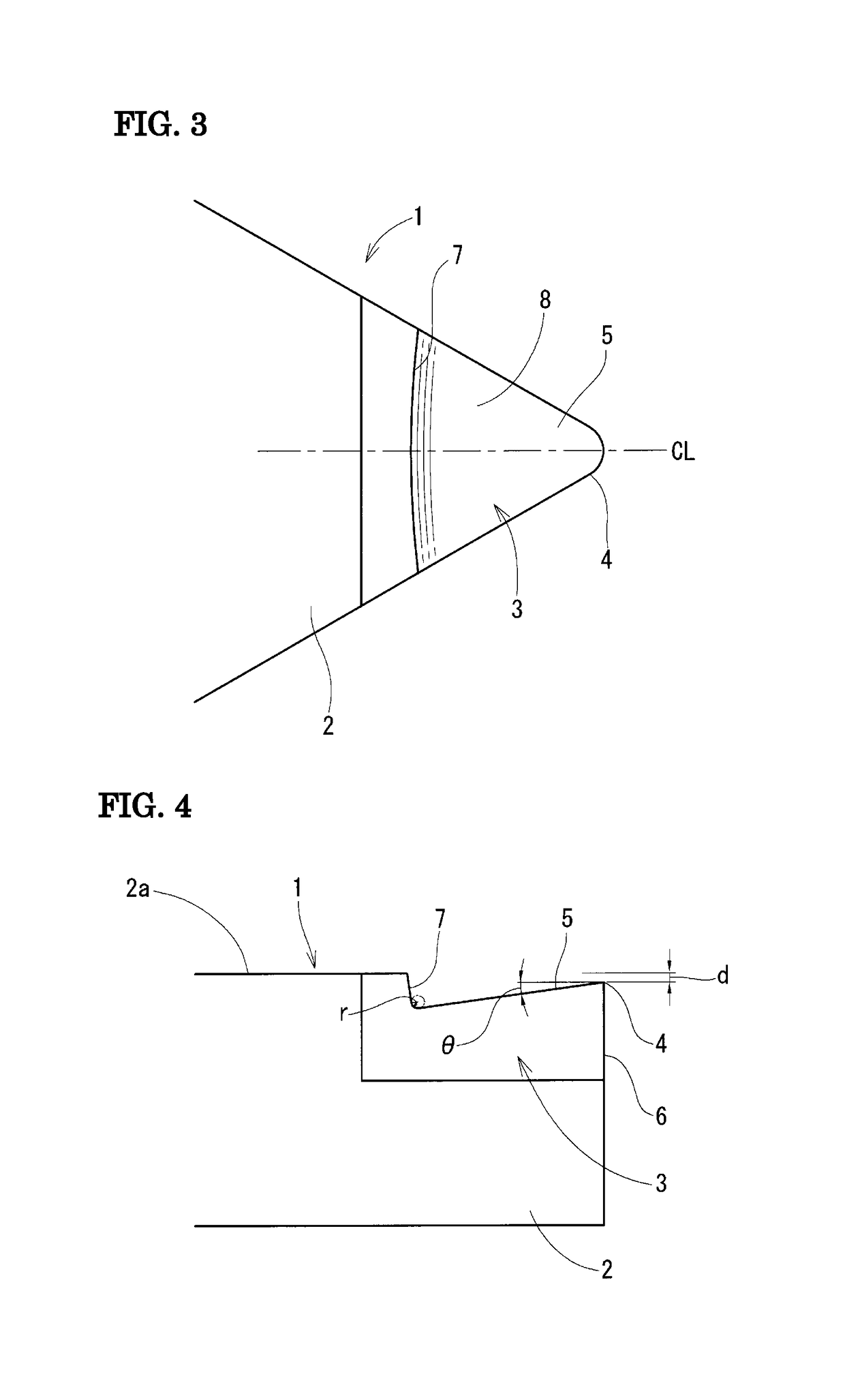

Cubic boron nitride cutting tool

An object is to prolong the life of a cubic boron nitride cutting tool used for cutting a heat-resistant alloy. A cubic boron nitride cutting tool includes an edge tip made of a sintered cubic boron nitride compact having a thermal conductivity within the range of 20 to 70 W / m·K and including cubic boron nitride particles having an average particle diameter within the range of 0.5 μm to 2 μm; and a base metal that holds the edge tip at a corner portion of the base metal, wherein a cutting edge formed on the edge tip of the tool has a positive rake angle.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Welded steel pipe for high strength line pipe superior in low temperature toughness and method of production of the same

ActiveUS8039118B2Improve low temperature toughnessHigh strengthSoldering apparatusArc welding apparatusSheet steelHeat-affected zone

The present invention provides high strength welded steel pipe for line pipe inexpensive in cost and superior in low temperature toughness, and a method of production of the same, produced by forming a base material steel plate containing, by mass %, C: 0.010 to 0.050%, Si: 0.01 to 0.50%, Mn: 0.50 to 2.00%, S: 0.0001 to 0.0050%, and Ti: 0.003 to 0.030%, limiting Al to 0.020% or less and Mo to less than 0.10%, having a carbon equivalent Ceq of 0.30 to 0.53 and a crack susceptibility parameter Pcm of 0.10 to 0.20, comprised of polygonal ferrite and residual bainite of an area rate of 20% or less, and having an effective crystal grain size of 20 μm or less, into a pipe shape, then seam welding it and making the effective crystal grain size of the heat affected zone 150 μm or less.

Owner:NIPPON STEEL CORP

Low yield ratio and high toughness thick steel plate and manufacturing method thereof

The invention discloses a low yield ratio and high toughness thick steel plate which comprises the following chemical components, by mass percent, 0.060-0.080% of C, 5.5-6.0% of Mn, 0.10-0.30% of Si, 0.015-0.040% of Al, 0.15-0.30% of Mo, 0.20-0.40% of Cr, 0.15-0.40% of Ni, 0.01-0.03% of Ti, less than or equal to 0.006% of S, less than or equal to 0.010% of P, and the balance Fe and unavoidable impurity elements. The steel plate has high yield strength, low yield ratio, and good low temperature impact toughness. The invention further discloses a manufacturing method of the steel plate. The manufacturing method comprises the steps of heating, rolling and carrying out heat treatment. The manufacturing method simply requires once heat treatment, is simple in process and facilitates production and implementation.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com