Process for producing a sintered lithium disilicate glass ceramic dental restoration and kit of parts

a technology of lithium disilicate glass ceramic and dental restoration, which is applied in glass making apparatus, manufacturing tools, impression caps, etc., can solve the problems of limited possibilities, limited productivity of current process, and inability to apply dry milling process to produce dental restorations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1 (

Non-Colored Lithium Disilicate Ceramic Disc)

[0258]The following amounts of powder were mixed in a bottle: 72.1 wt.-% SiO2, 15.1 wt.-% Li2CO3, 3.4 wt.-% Li3PO4, 3.5 wt.-% Al(OH)3, 3.2 wt.-% K2CO3 and 2.7 wt.-% ZrO2.

In a next step the powder mixture was melted in a platinum crucible at 1500° C. and fitted in water. This was repeated three times. Afterwards the frit was milled. The resulting glass powder had the following particle size distribution: d50: 13.5 μm (d10: 2.5 μm, d90: 49.6 μm).

[0259]The powder was mixed with 10 wt.-% water and pressed to discs (dimensions: 20 mm×1.5 mm) or blocks (dimensions: 12 mm×14 mm×18 mm) by applying a pressure of 7.5 MPa).

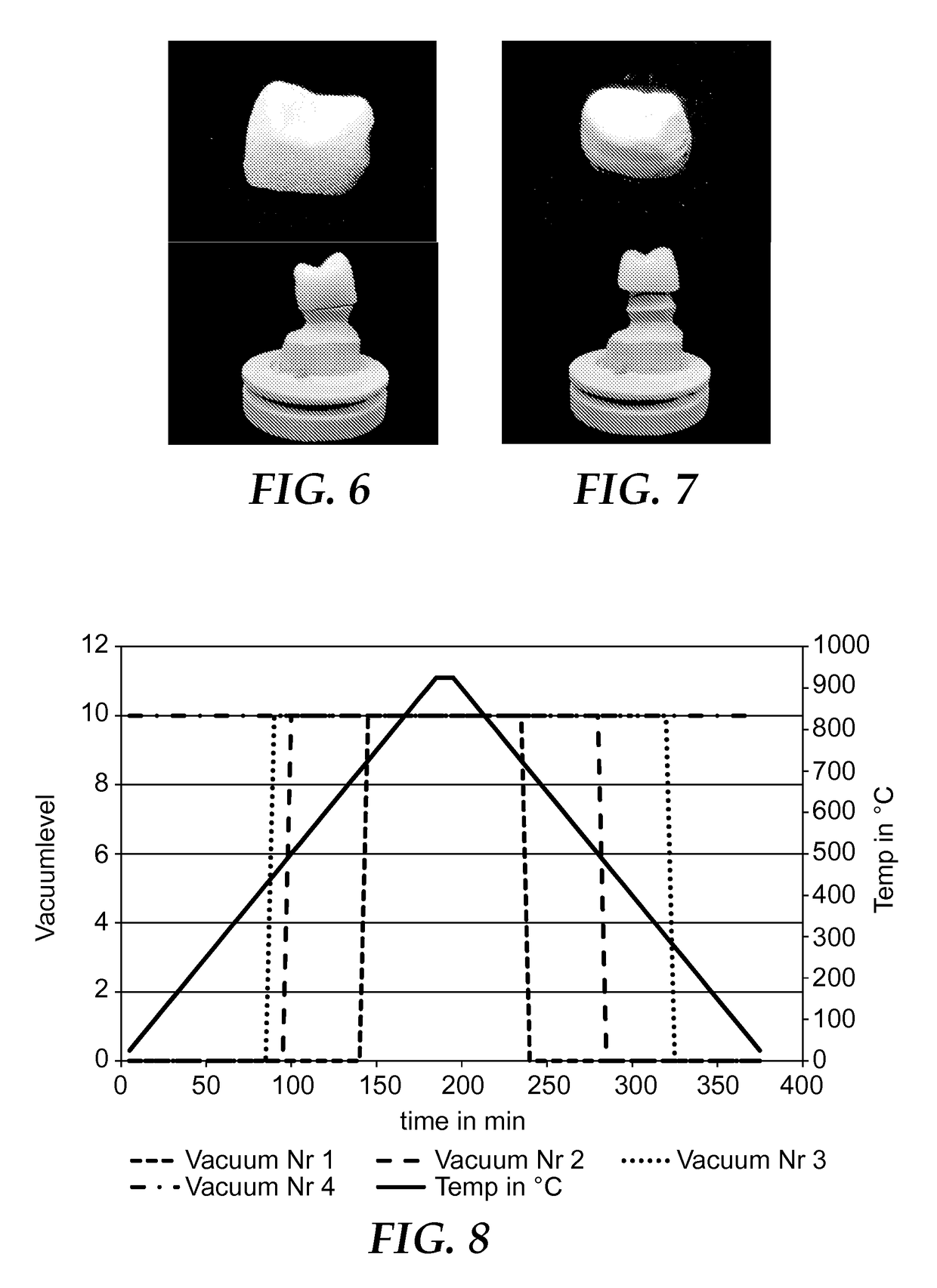

[0260]Glass ceramic bodies with 98-100% theoretical density were achieved with the following one step crystallization and sintering program:[0261]Heating with 5 K / min to 730° C.;[0262]Holding at 730° C. till Vacuum on;[0263]Heating with 10 K / min to 930° C.;[0264]Holding time 10 min;[0265]Cooling with 10 K / min to 730° C.;[0266]Holdi...

example 2 (

Colored Lithium Disilicate Ceramic Disc)

[0274]A disc as described in Example 1 was prepared. The disc was pre-sintered at 550 to 650° C. to obtain a porous body.

[0275]The porous body was colored by immersing it in commercially available coloring liquids or by applying commercially available coloring liquids with a brush to its surface (Lava™ Plus Coloring Liquids and / or Lava™ Plus Effect Shades; 3M ESPE).

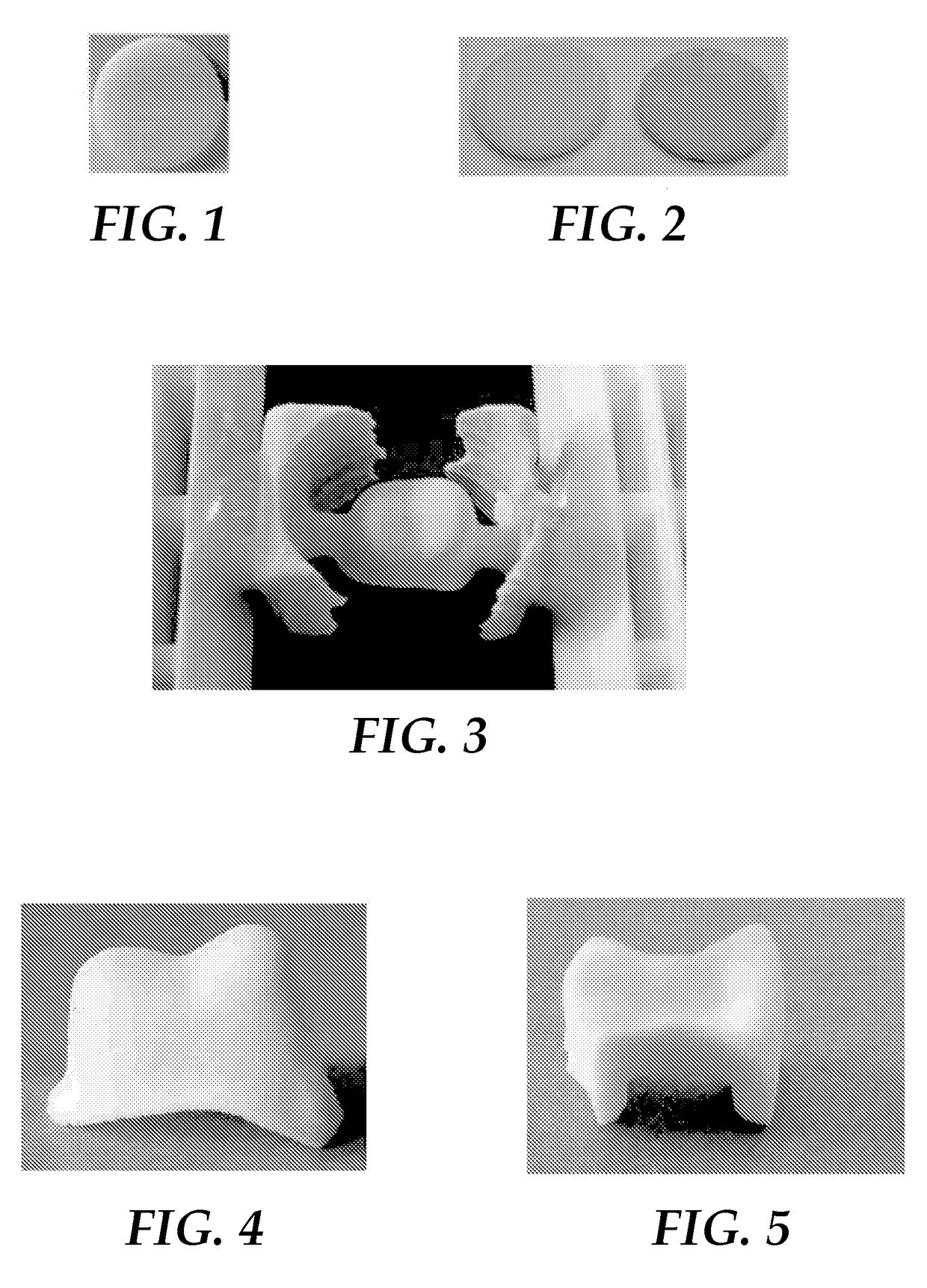

[0276]After sintering, a colored lithium disilicate glass ceramic was obtained, which has been colored in the amorphous and porous state (i.e. before sintering). The sample obtained is shown in FIG. 2 on the right side. For comparison, the left disc is non-colored.

example 3 (

Dental Restorations)

[0277]A crown was machined out of a pre-sintered dental milling block obtained as described in Example 1 using a Lava™ CNC 500 milling machine (3M ESPE). A picture of the crown machined from a dental milling block made of a pre-sintered lithium silicate material is shown in FIG. 3.

[0278]Similarly, an inlay was machined out of a pre-sintered block obtained as described in Example 1 using a Sirona CEREC™ inLab.

[0279]In FIG. 4 a sintered lithium disilicate crown is shown. The crown was produced by machining it out of a pre-sintered block, coloring the obtained crown in a pre-sintered stage as described in Example 2 and sintering the crown in one step applying the conditions described in Example 1.

[0280]The crown was sintered without using a sintering support. The obtained sintered dental restoration did not show any relevant distortion.

[0281]FIG. 5 shows an inlay produced in the same manner as the crown above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com