Patents

Literature

156 results about "Lithium disilicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass ceramics are categorized according to their major crystalline structure and/or application. 2 Lithium disilicate is among the best known and most widely used types of glass ceramics. The IPS e. max lithium disilicate, for example, is composed of quartz, lithium dioxide, phosphor oxide, alumina, potassium oxide, and other components.

High-strength dental restorations

InactiveUS20050127544A1Improve adhesionHigh strengthHair accessoriesImpression capsDental ProductHigh intensity

Lithium disilicate based glass-ceramics contain high strength ceramic components for use in the manufacture of dental products. The glass-ceramics have good pressability, i.e., the ability to be formed into dental products by heat-pressing using commercially available equipment. The strength of the dental articles is increased with the inclusion of the high strength ceramic components.

Owner:ARDENT

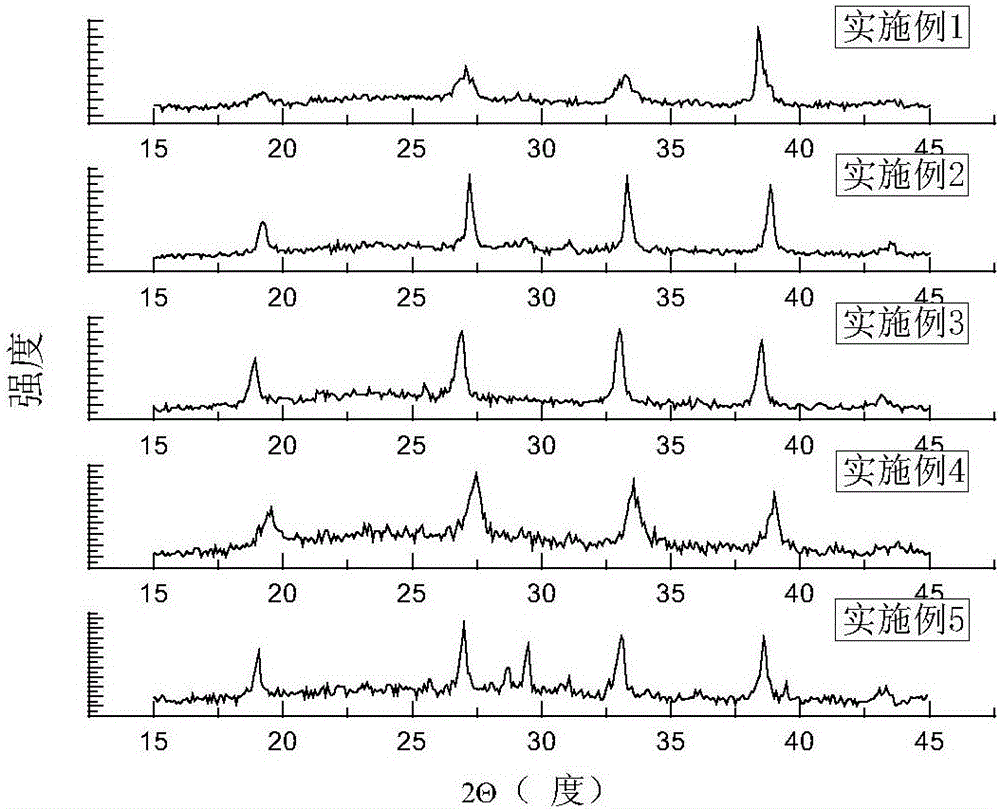

High-strength lithium disilicate glass ceramic and preparation method thereof

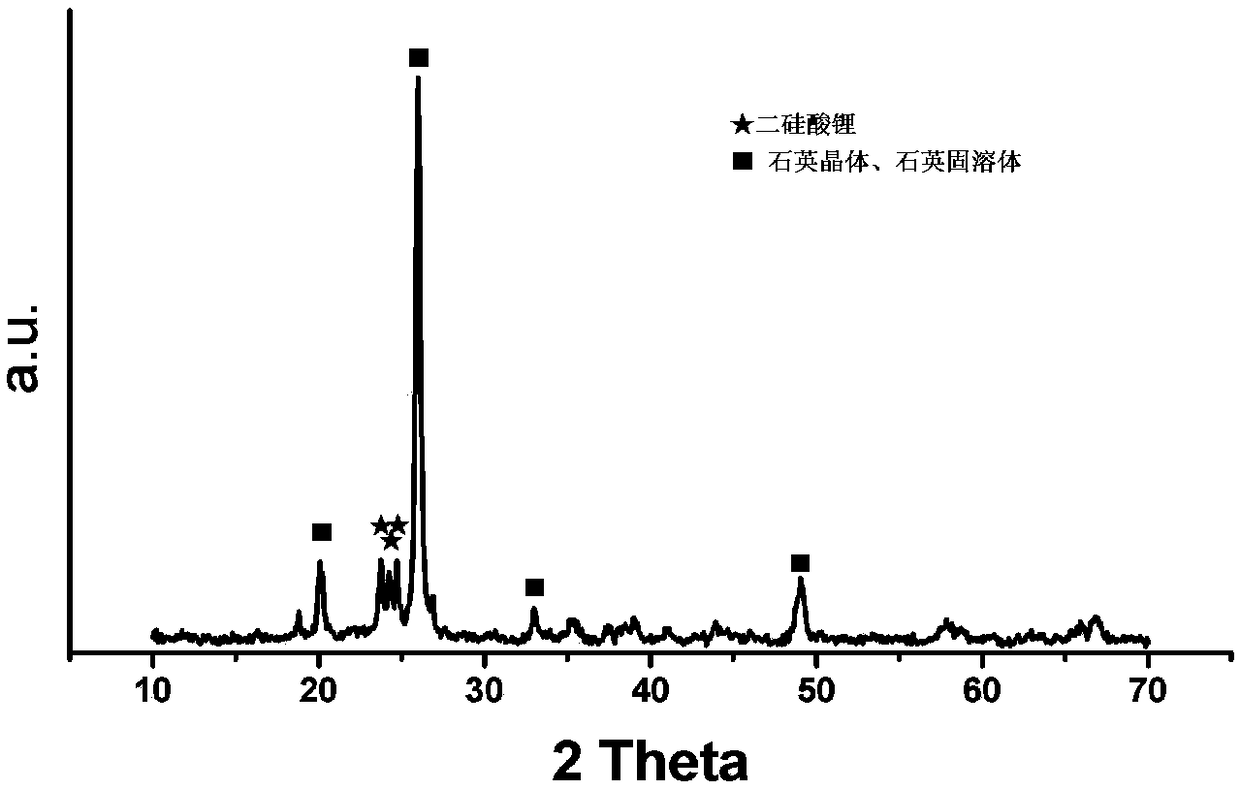

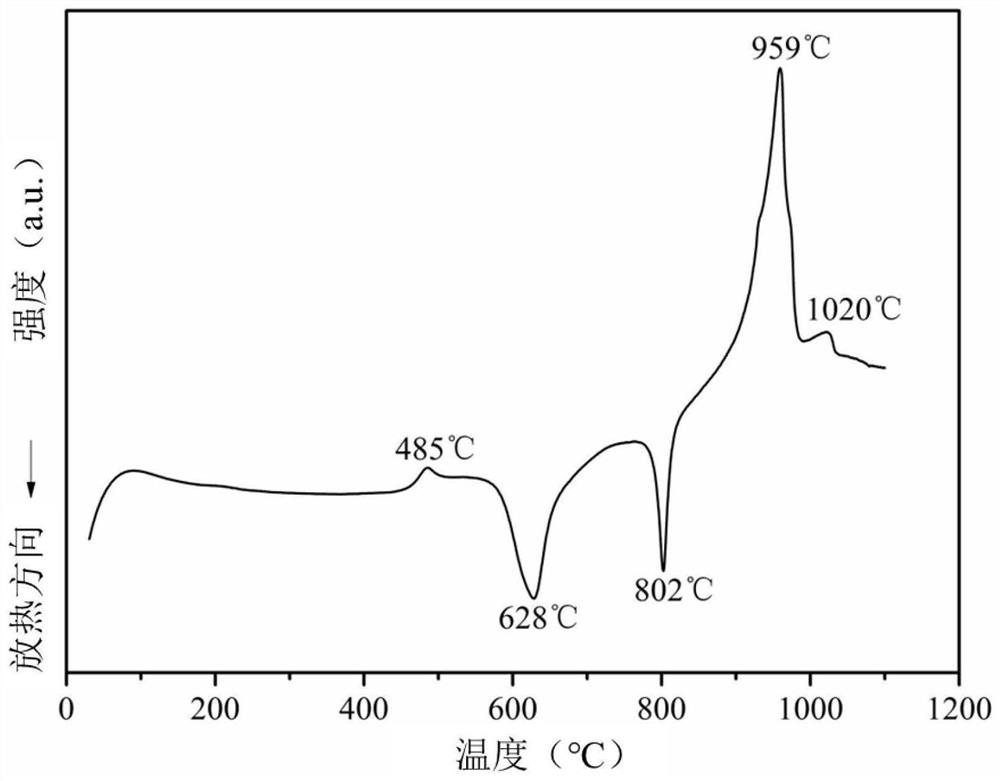

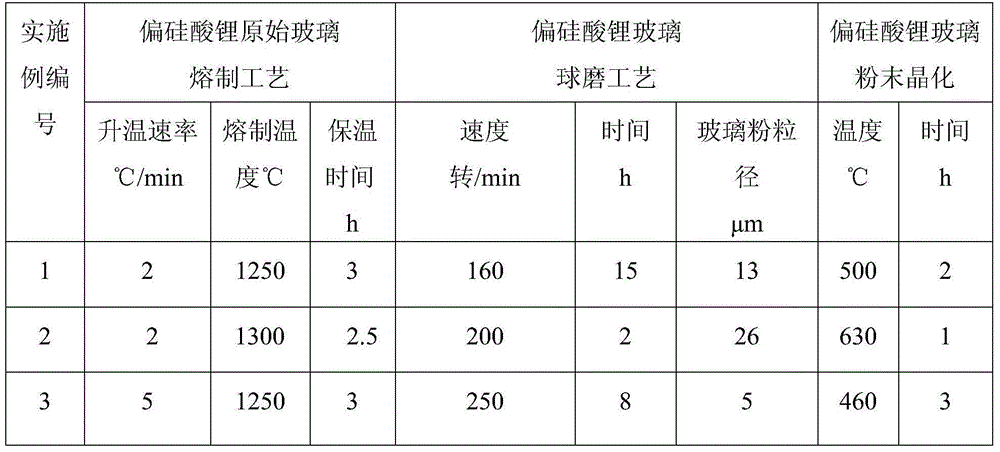

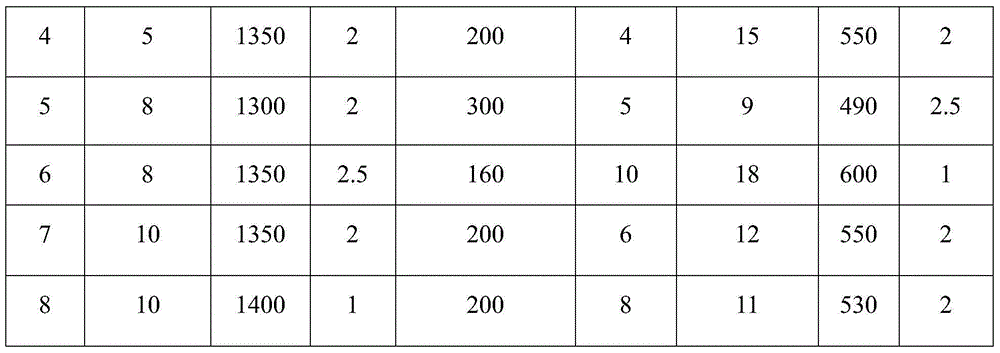

The invention discloses high-strength lithium disilicate glass ceramic and a preparation method thereof. The glass ceramic comprises the following chemical components in percentage by weight: 59-80% of SiO2, 10-18% of Li2O, 0.1-14% of MgO, 0-15% of Al2O3, 1-8% of P2O5, 0-5% of Na2O, 0-7% of CaO, 0-9% of K2O, 0.5-8% of stabilizer and 0-10% of colorant, wherein the stabilizer is selected from one or more of ZrO2, SrO, BaO and Y2O3, and the colorant is selected from one or more of Eu2O3, CeO<+>, Tb4O7, La2O3, Ta2O5, MnO2 and Fe2O3. The lithium disilicate glass ceramic is a material which contains a residual glass phase, a Li2Si2O5 principal crystalline phase and a small quantity of Li3PO1, quartz, cristobalite, zirconium oxide or magnesium-aluminum silicate phase and is prepared by controlling nucleation and crystallization processes after carrying out heat treatment on lithium disilicate matrix glass. The lithium disilicate glass ceramic is very high in bending strength and fracture toughness and favorable in translucence and chemical stability and can serve as a full-ceramic dental material applied to the field of dental restoration.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Glass-ceramics and method for manufacturing the same

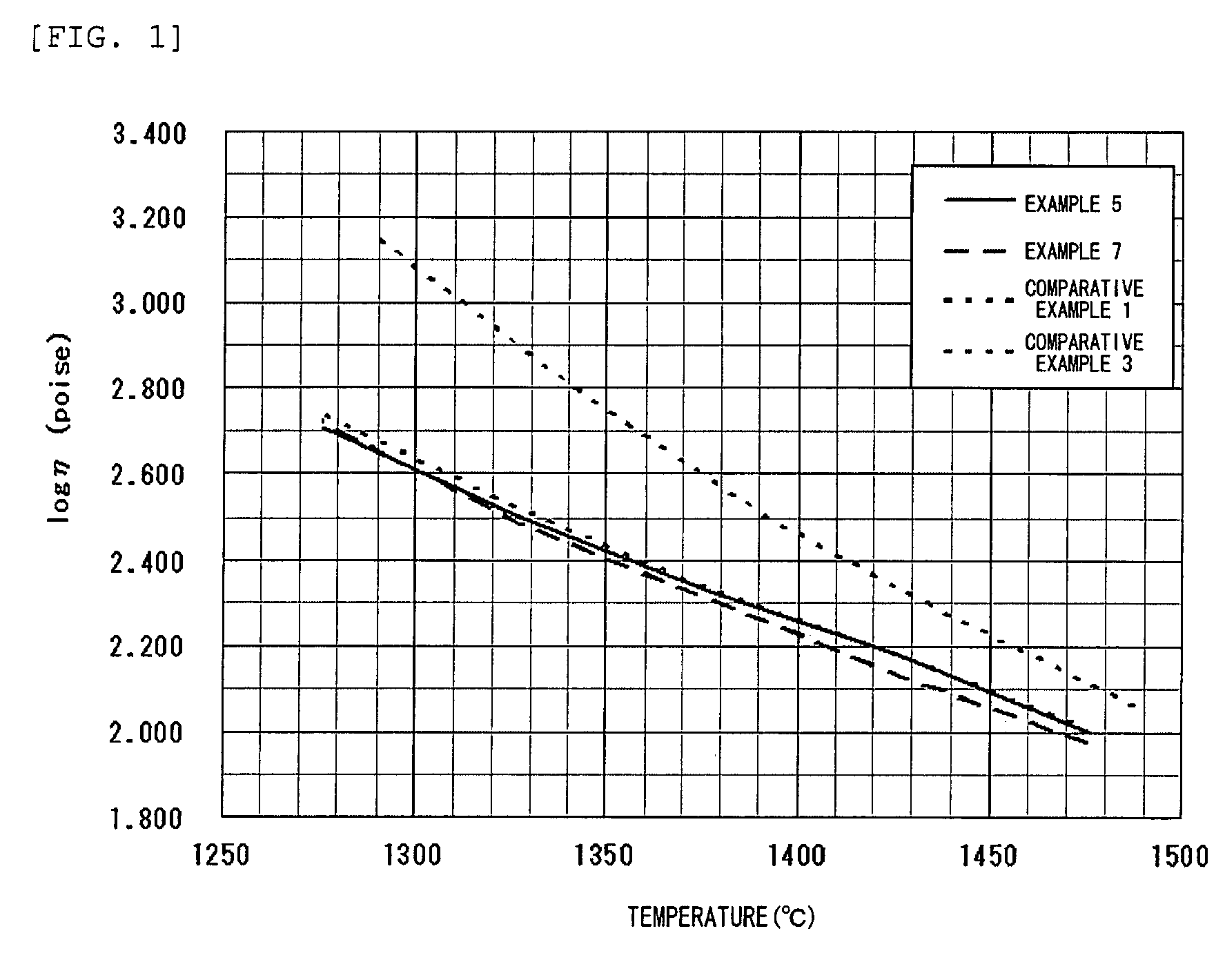

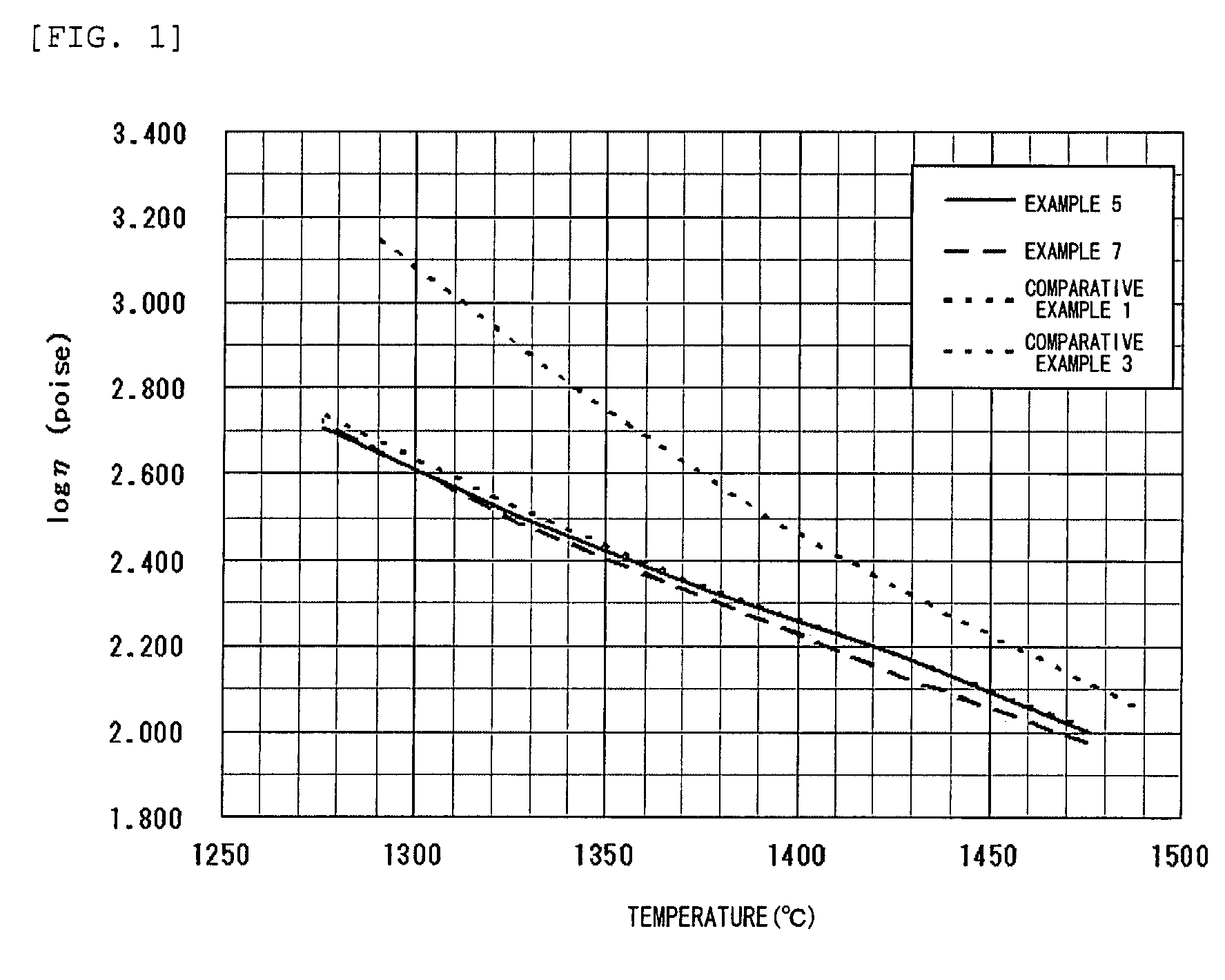

InactiveUS20090162608A1Suitability for press formingImprove productivityMagnetic materials for record carriersBase layers for recording layersGlass-ceramicAntimony

For providing glass-ceramics having properties suitable for use as a substrate of an information storage medium of next generation such as one for the perpendicular magnetic recording system without employing arsenic and antimony components which adversely affect human beings and the environment, there are provided glass-ceramics comprising SiO2, Li2O and Al2O3 on oxide basis, comprising lithium disilicate as a crystal phase, and comprising one or more elements selected from the group consisting of Sn, Ce, Mn, W, Ta, Bi, Nb, S, Cl and F.

Owner:OHARA

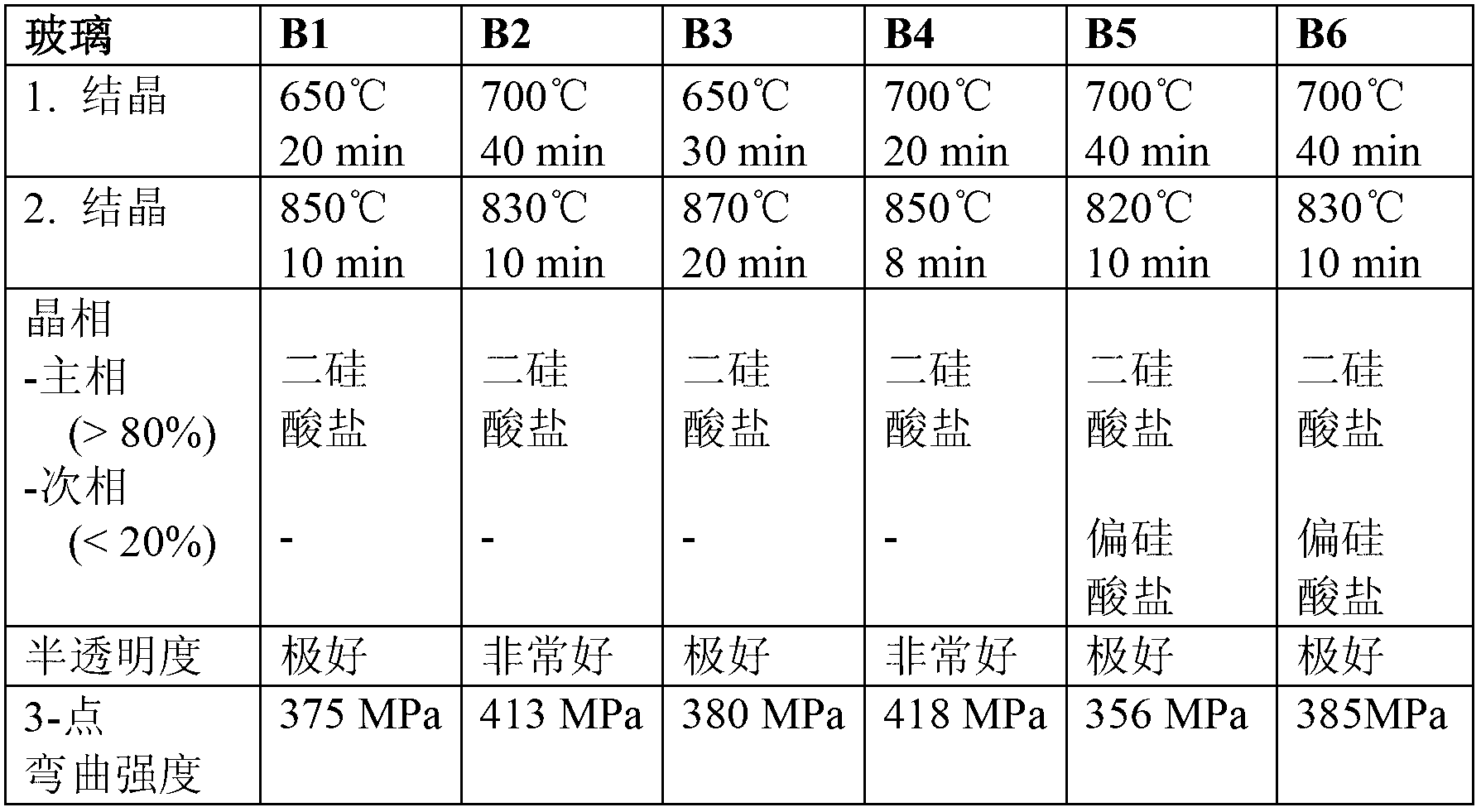

Lithium disilicate glass ceramics, method for the production thereof and use thereof

ActiveCN102741186AEasy to processHigh strengthTooth crownsArtificial teethHigh intensityIntermediate stage

The invention relates to glass ceramics on the basis of the lithium disilicate system, which can be easily mechanically machined in an intermediate stage of the crystallization and which represent high-strength, highly translucent and chemically stable glass ceramics after complete crystallization. Furthermore, the invention relates to a method for producing said glass ceramics. The glass ceramics according to the invention are used as dental material.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +2

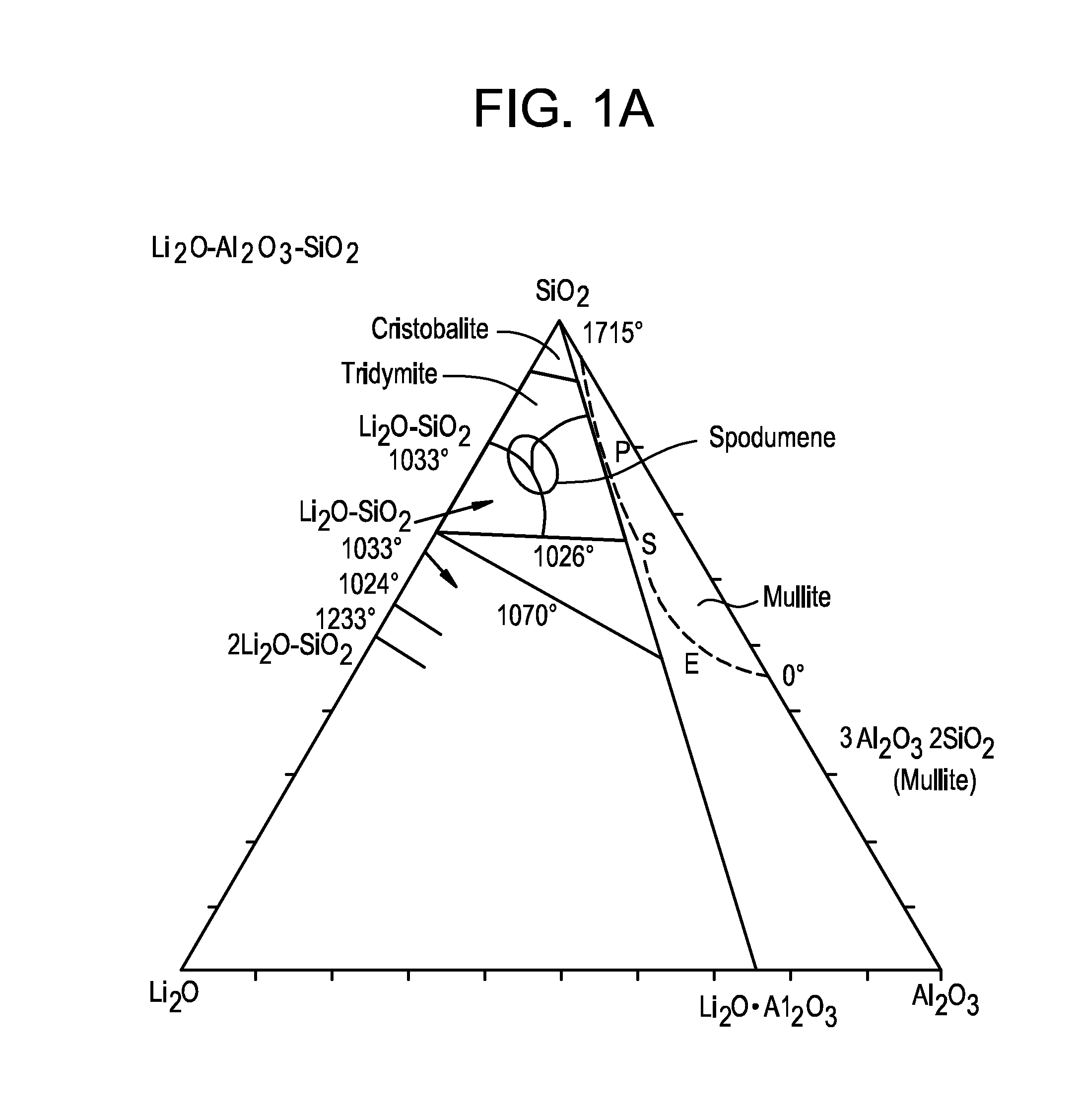

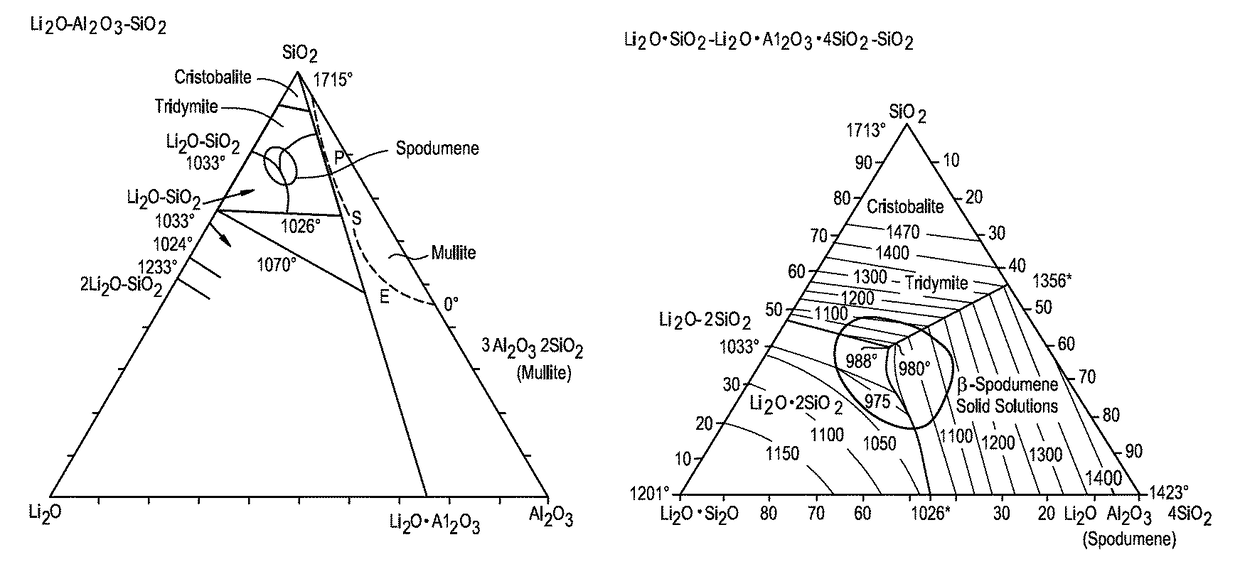

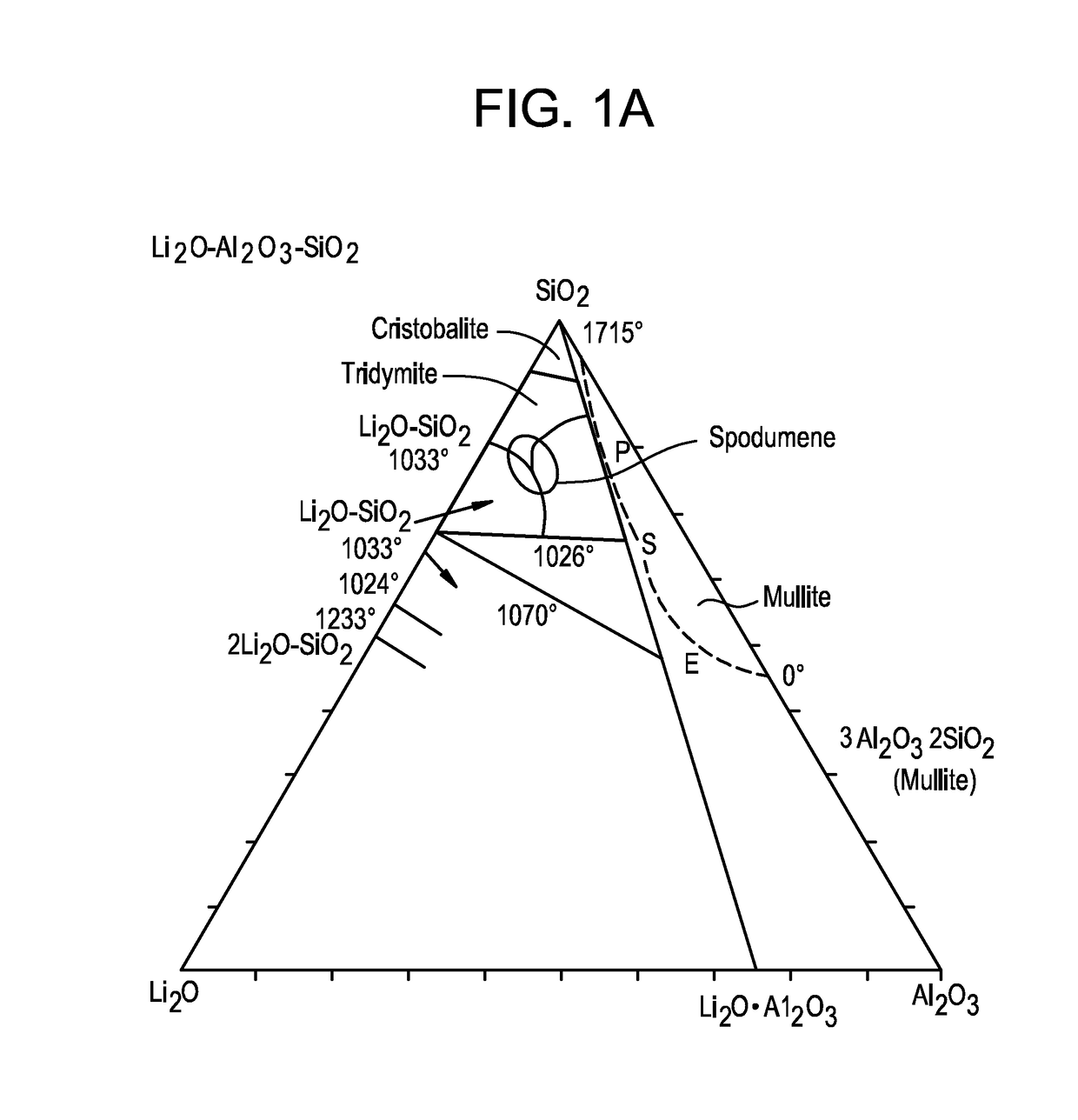

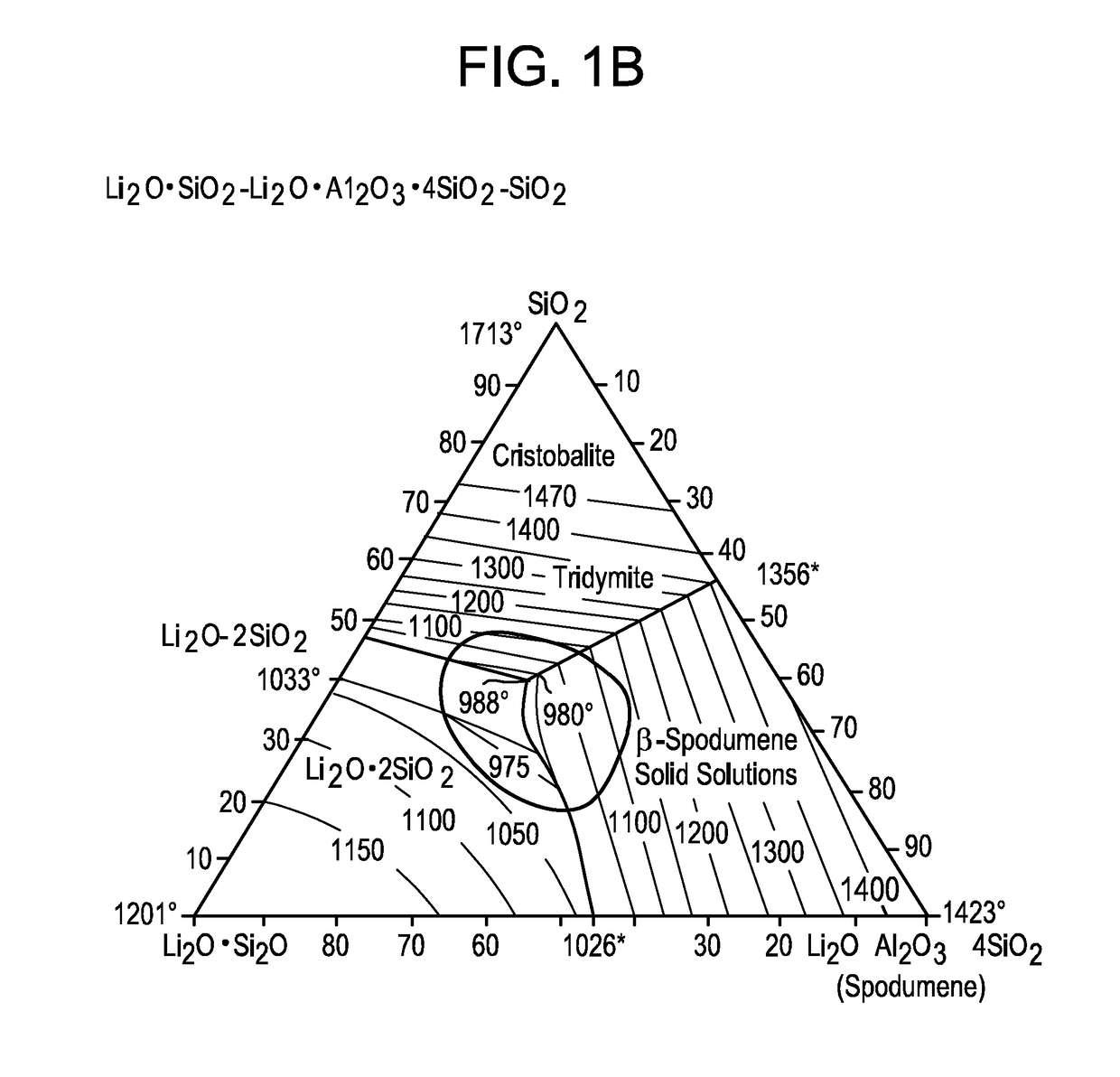

High strength glass-ceramics having lithium disilicate and beta-spodumene structures

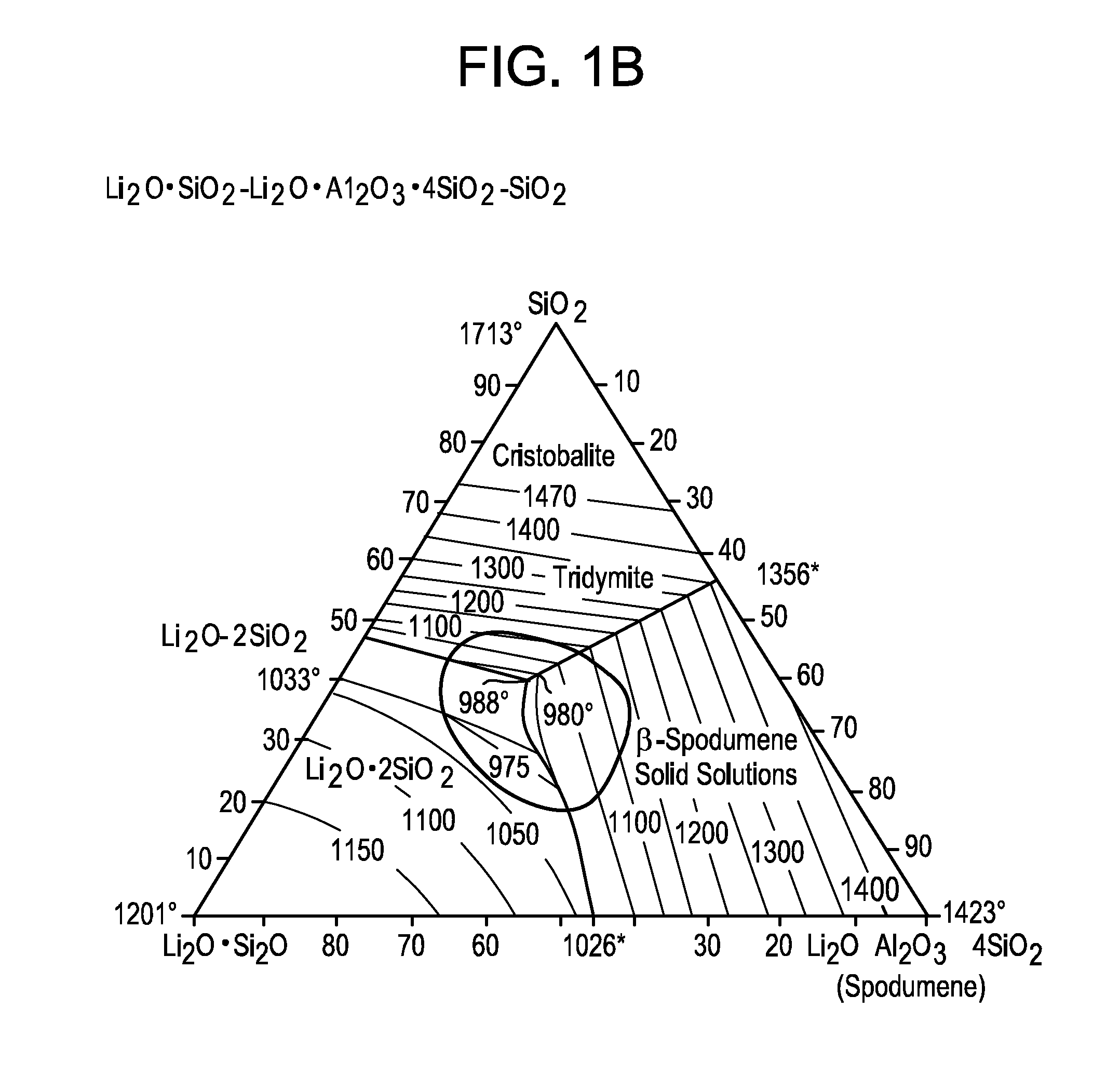

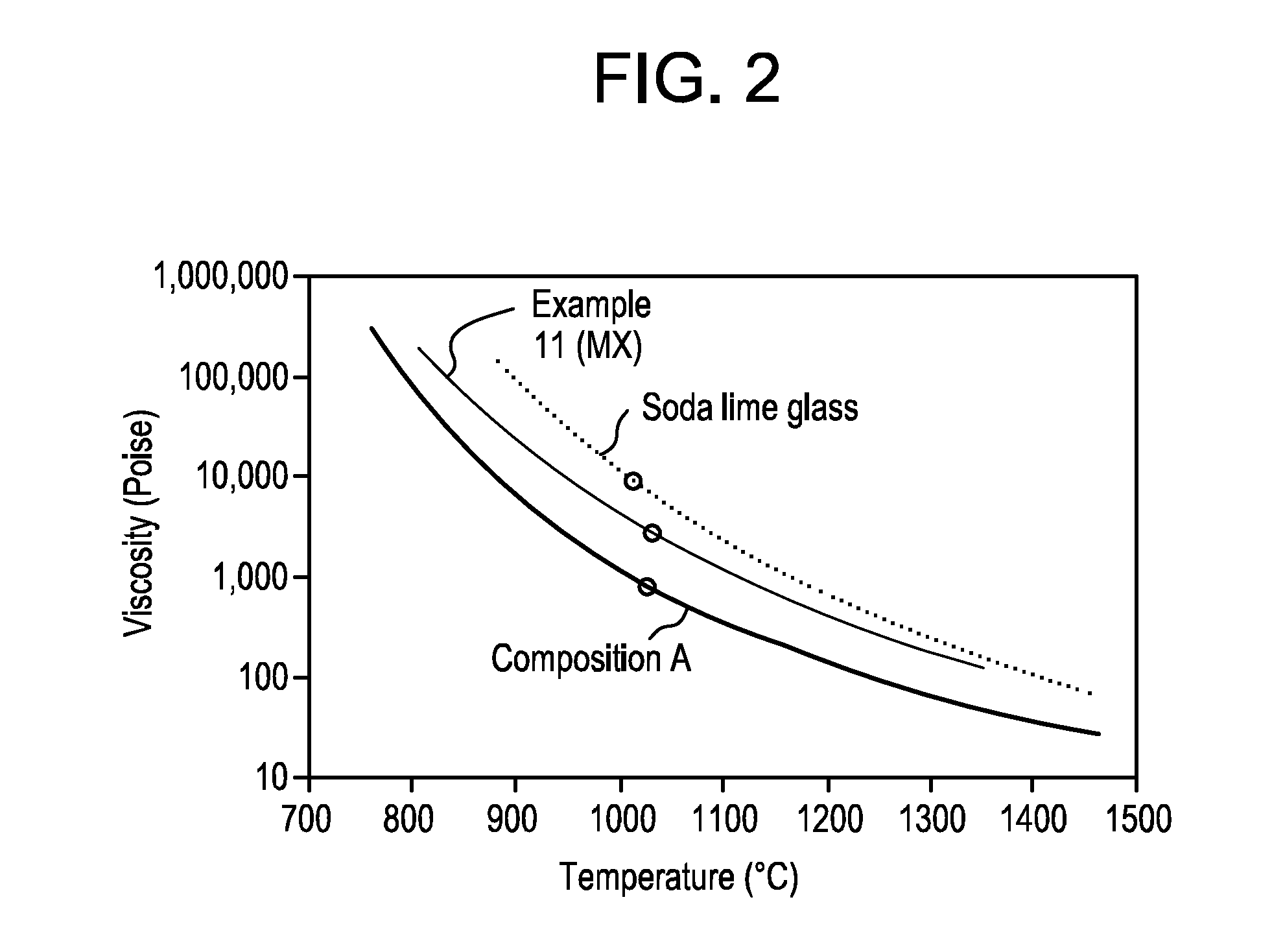

Glass and glass ceramic compositions having a combination of lithium disilicate and -spodumene crystalline phases along with methods of making the glass and glass ceramic compositions are described. The compositions are compatible with conventional rolling and float processes and have high mechanical strength and fracture resistance. Further, the compositions are able to be chemically tempered to even higher strength glass ceramics that are useful as large substrates in multiple applications.

Owner:CORNING INC

Crystallized glass

InactiveUS20090118113A1Improve productivityReduce manufacturing costMagnetic materials for record carriersRecord information storageIn planeMaterials science

In all of an in-plane magnetic recording system and a perpendicular magnetic recording system, there is provided a crystallized glass for a disk substrate for information recording medium, etc., which has satisfactory surface properties capable of sufficiently adapting with a lamp loading system for high-density recording, has high strength such that it is able to withstand high-speed rotation and impact, has heat expansion properties and heat resistance in agreement with respective drive members, has a low melting temperature, has excellent productivity and is reduced in the elution amount of an alkali from the raw material, namely excellent in chemical durability. The crystallized glass of the invention is a crystallized glass containing an SiO2 component and an Li2O component; further containing at least one member selected from an SrO component and a BaO component in a total content of more than 3.5% and not more than 15% in terms of % by mass; and containing at least one member selected among lithium disilicate, lithium monosilicate, α-quartz, an α-quartz solid solution and a β-quartz solid solution as a main crystal phase on the oxide basis.

Owner:OHARA

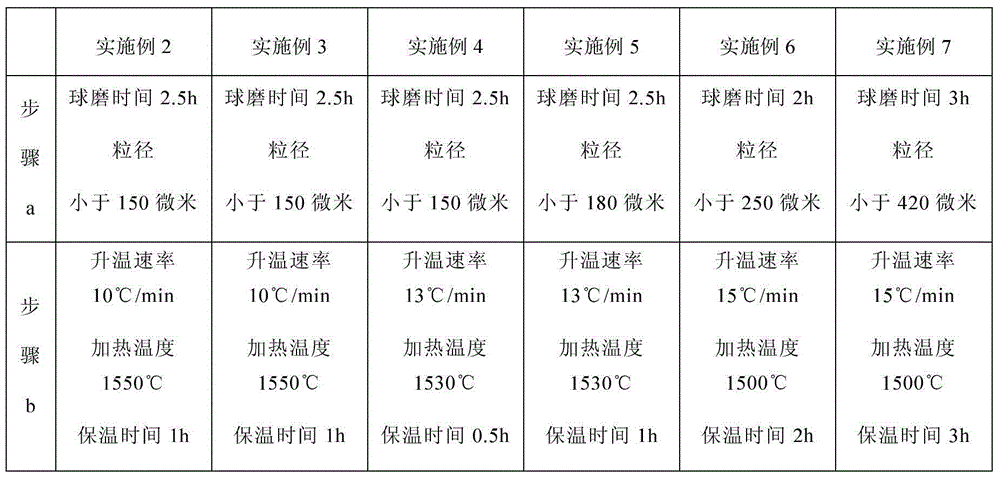

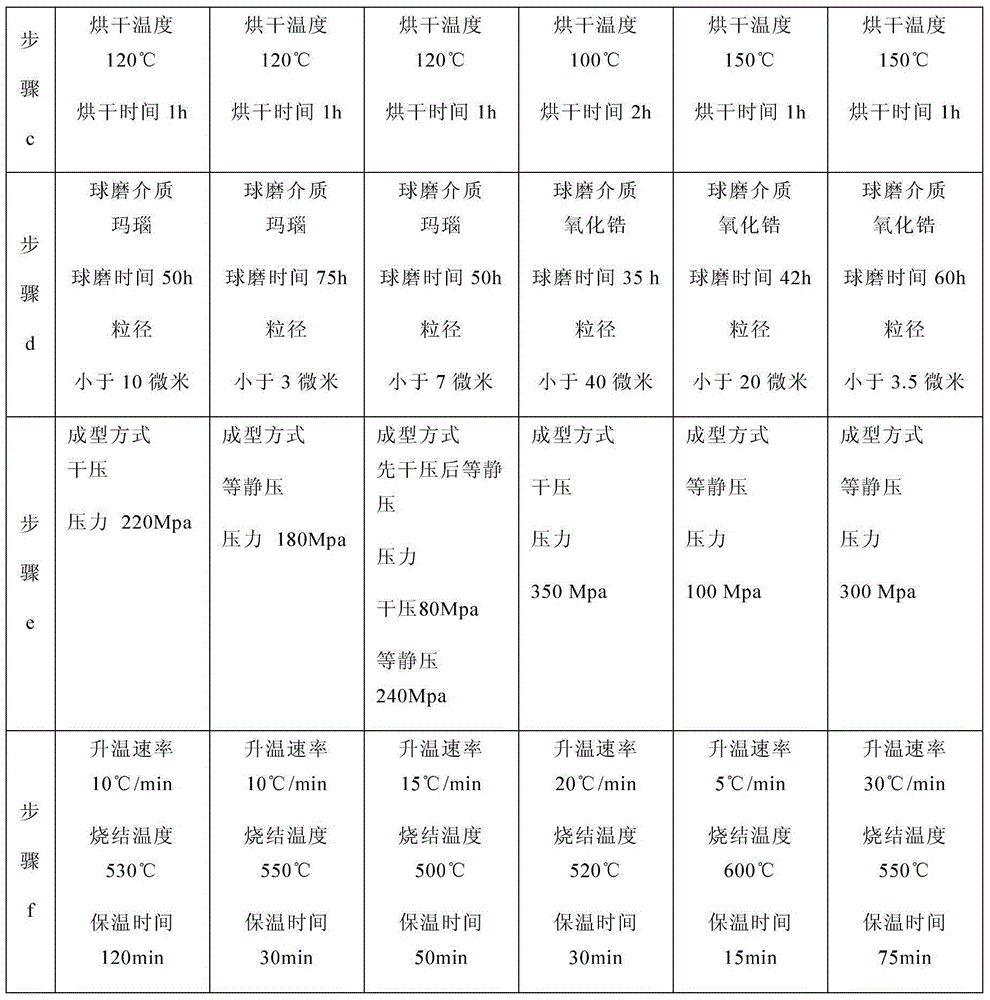

Preparation method for lithium-based glass ceramic for dental prosthesis

The embodiment of the invention discloses a preparation method for lithium-based glass ceramic for dental prosthesis. The preparation method comprises: filling glass powder which is prepared in advance into a die, wherein the grain size of the glass powder is less than 50 microns; and pressing and moulding the powder under 50-500 Mpa to obtain a lithium-based glass ceramic blank; putting the lithium-based glass ceramic blank into a heating device to raise the temperature to 500-600 DEG C for first-time sintering at a temperature raising rate of 1-30 DEG C / min, wherein the insulating time of the first-time sintering is 10-120 minutes; and carrying out furnace cooling to prepare the lithium-based glass ceramic. Compared with lithium disilicate glass ceramic prepared in the prior art, the lithium-based glass ceramic prepared by the technical scheme is relatively low in strength, low in hardness, better in processability, more easy to mould and suitable for a processing room and a chair-side repairing system.

Owner:SHENZHEN UPCERA DENTAL TECH

Preparation method for dental lithium silicate microcrystalline glass

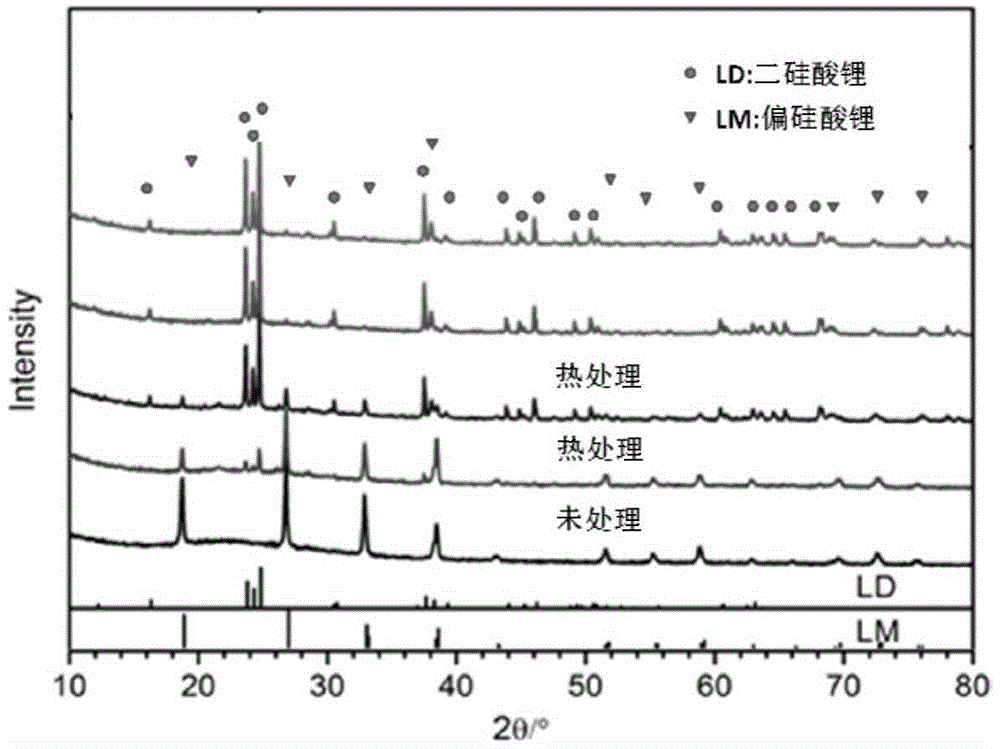

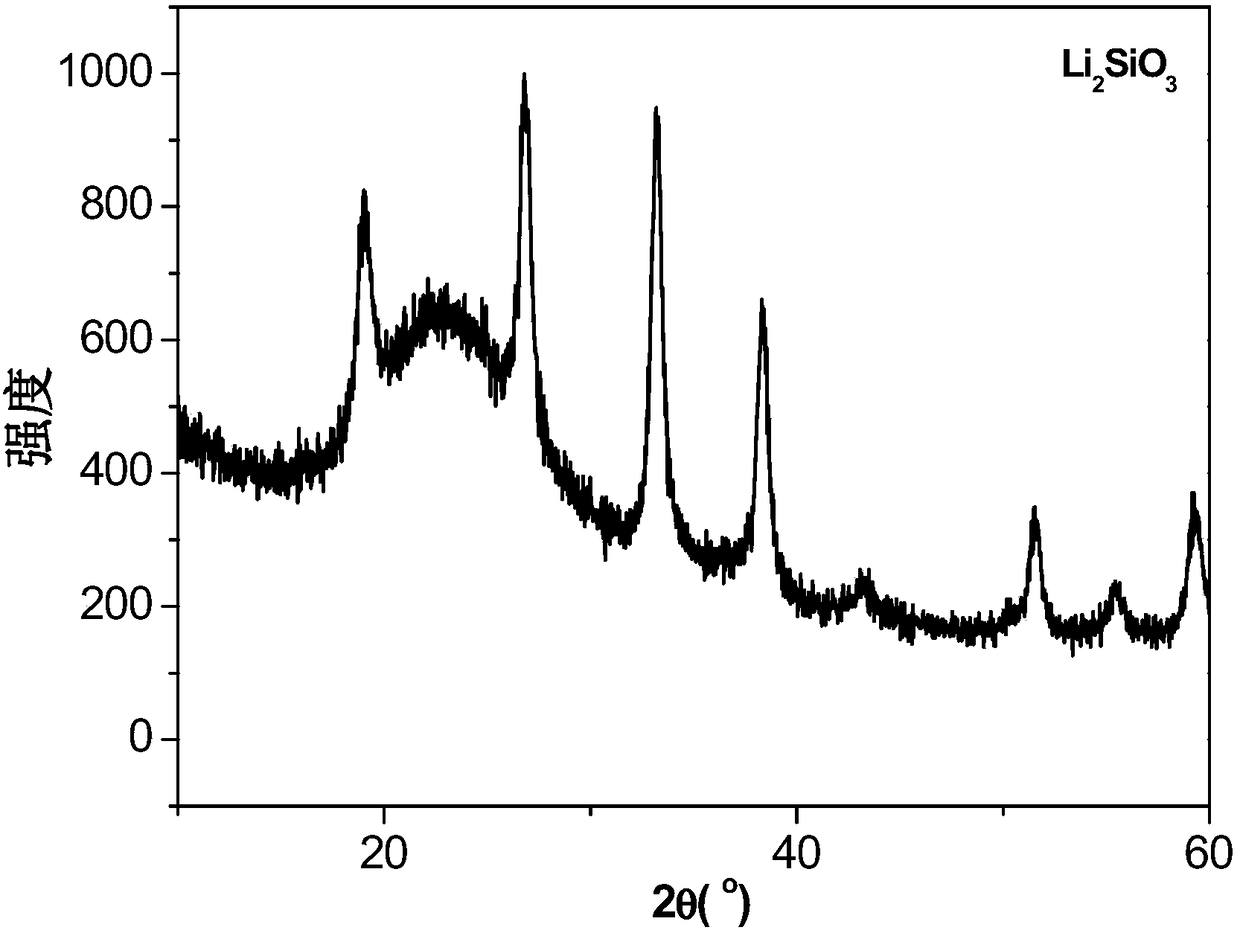

ActiveCN104909571AReduce intensityHigh strengthImpression capsDentistry preparationsLithium metasilicateStructure function

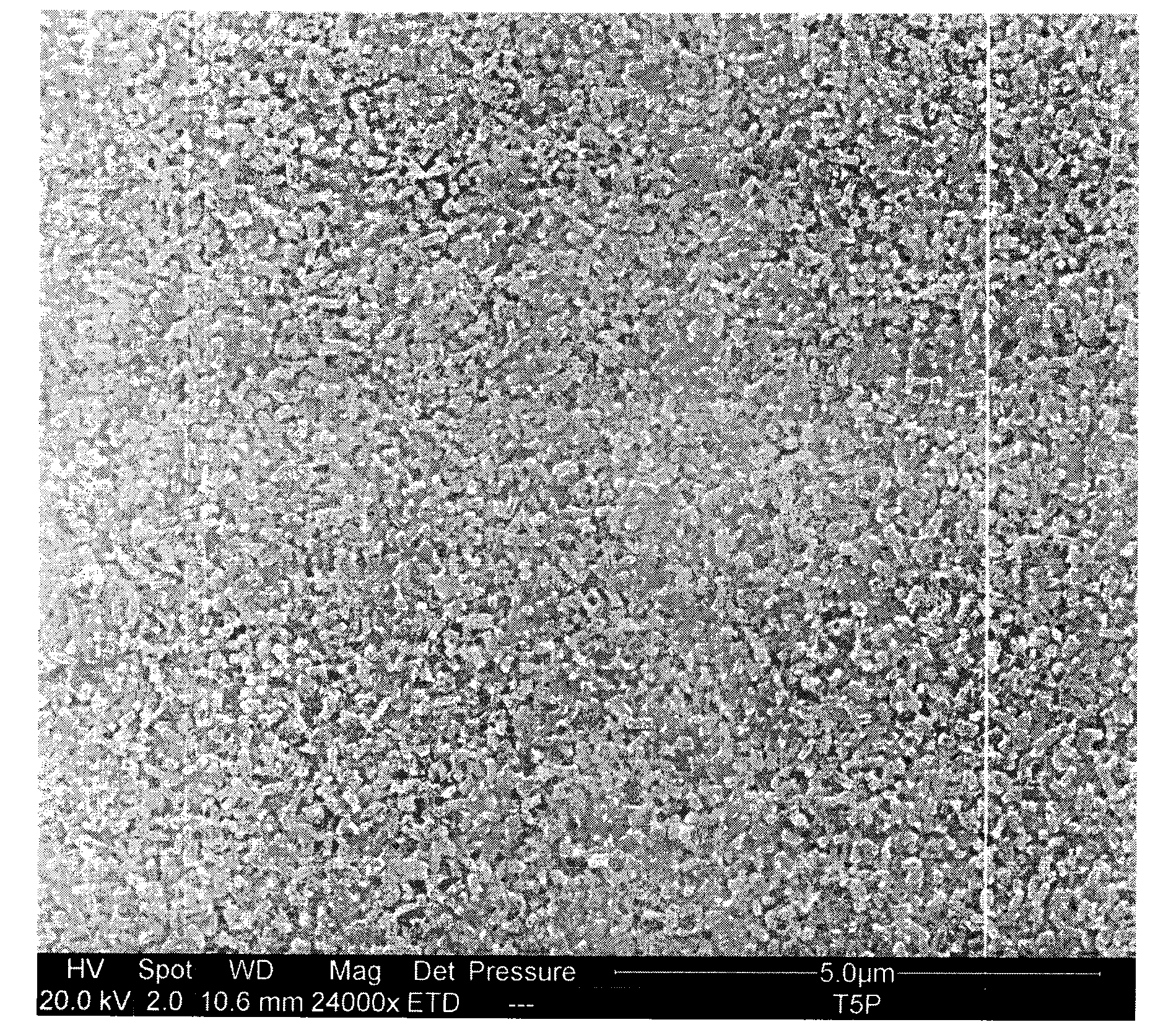

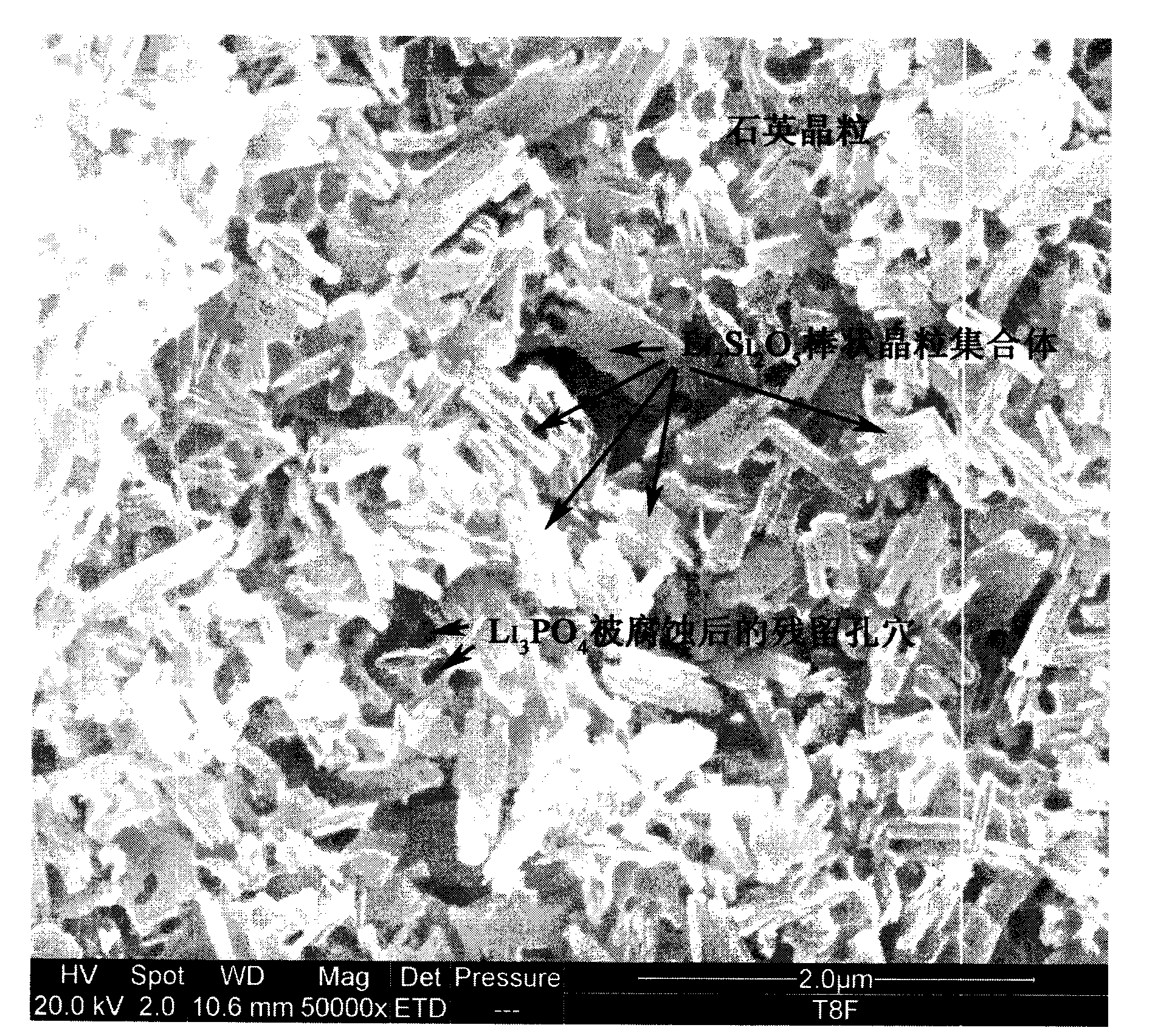

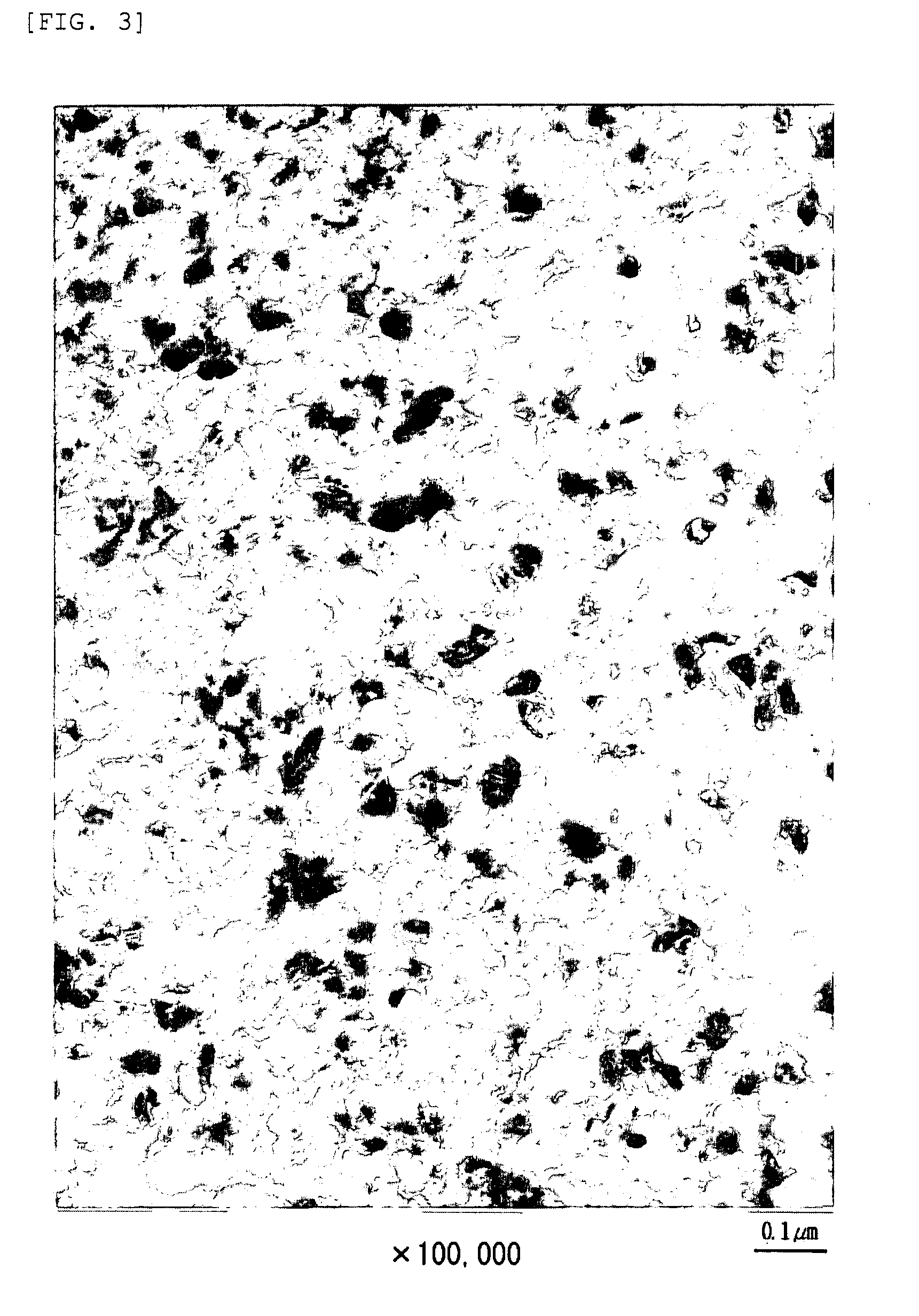

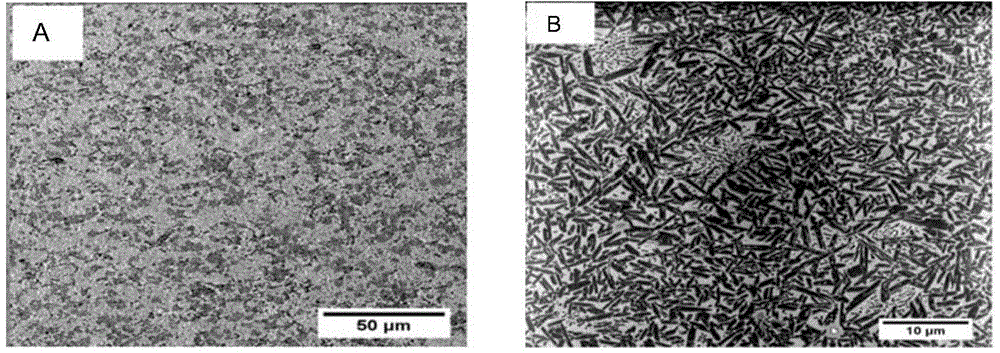

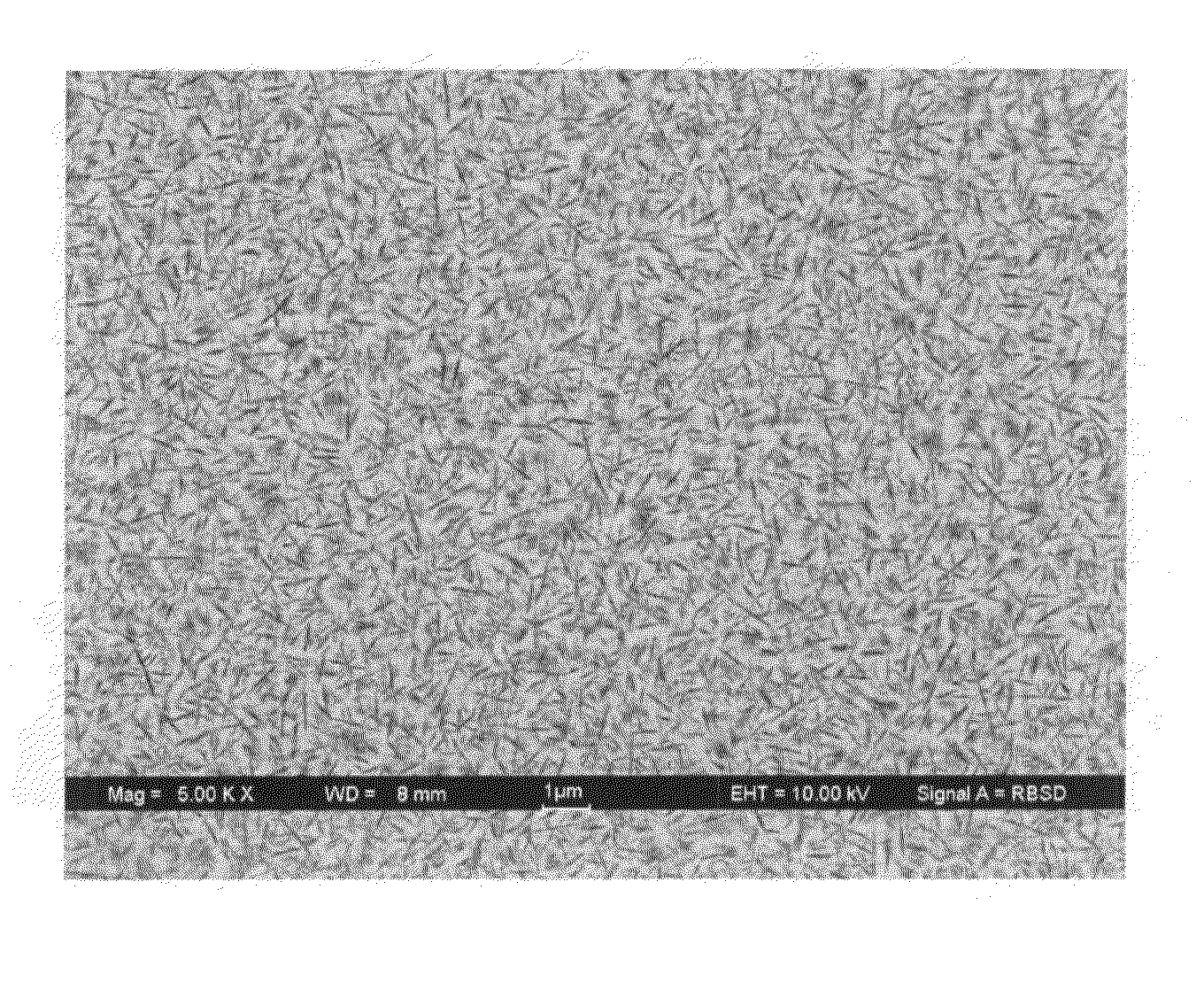

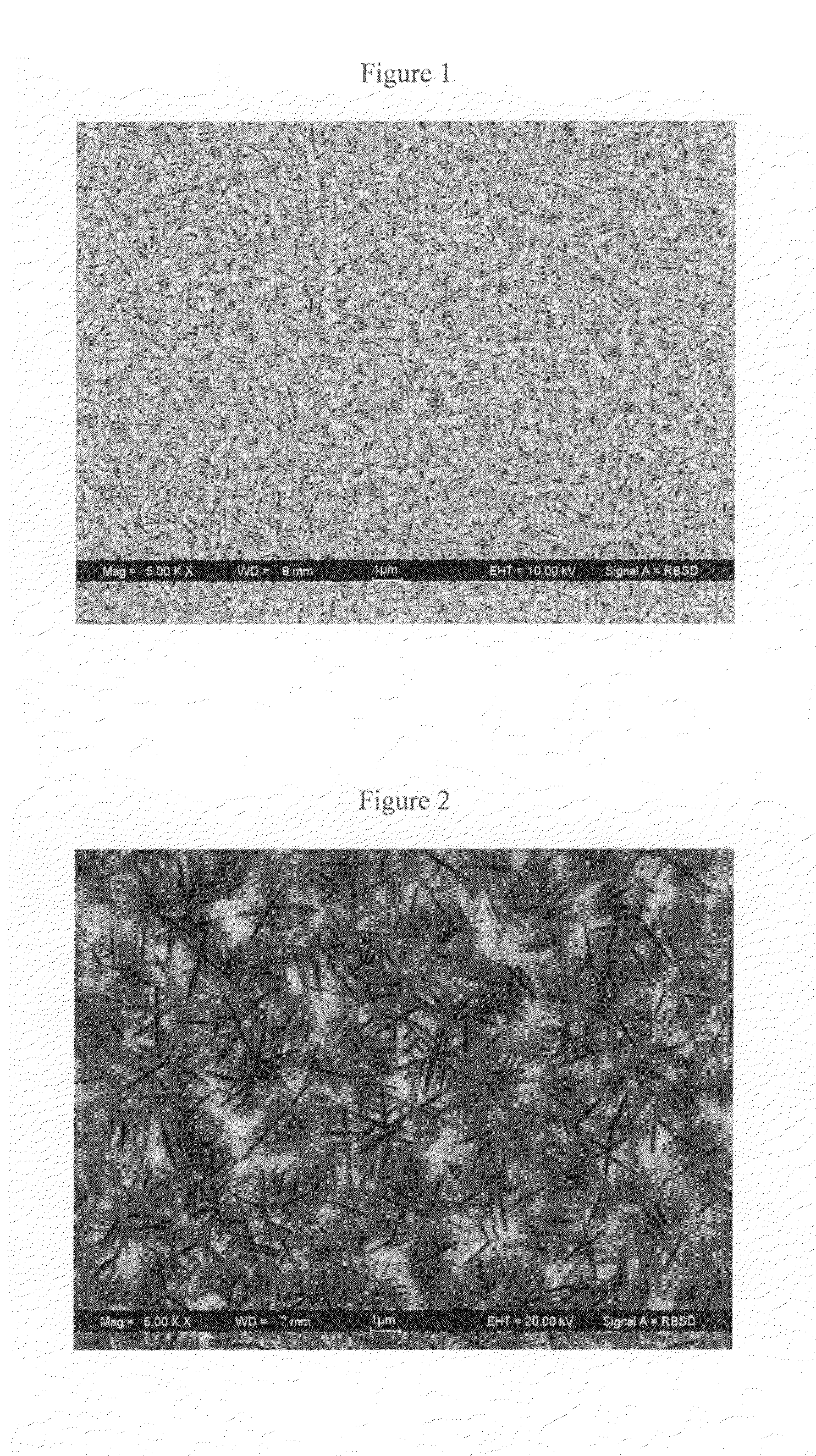

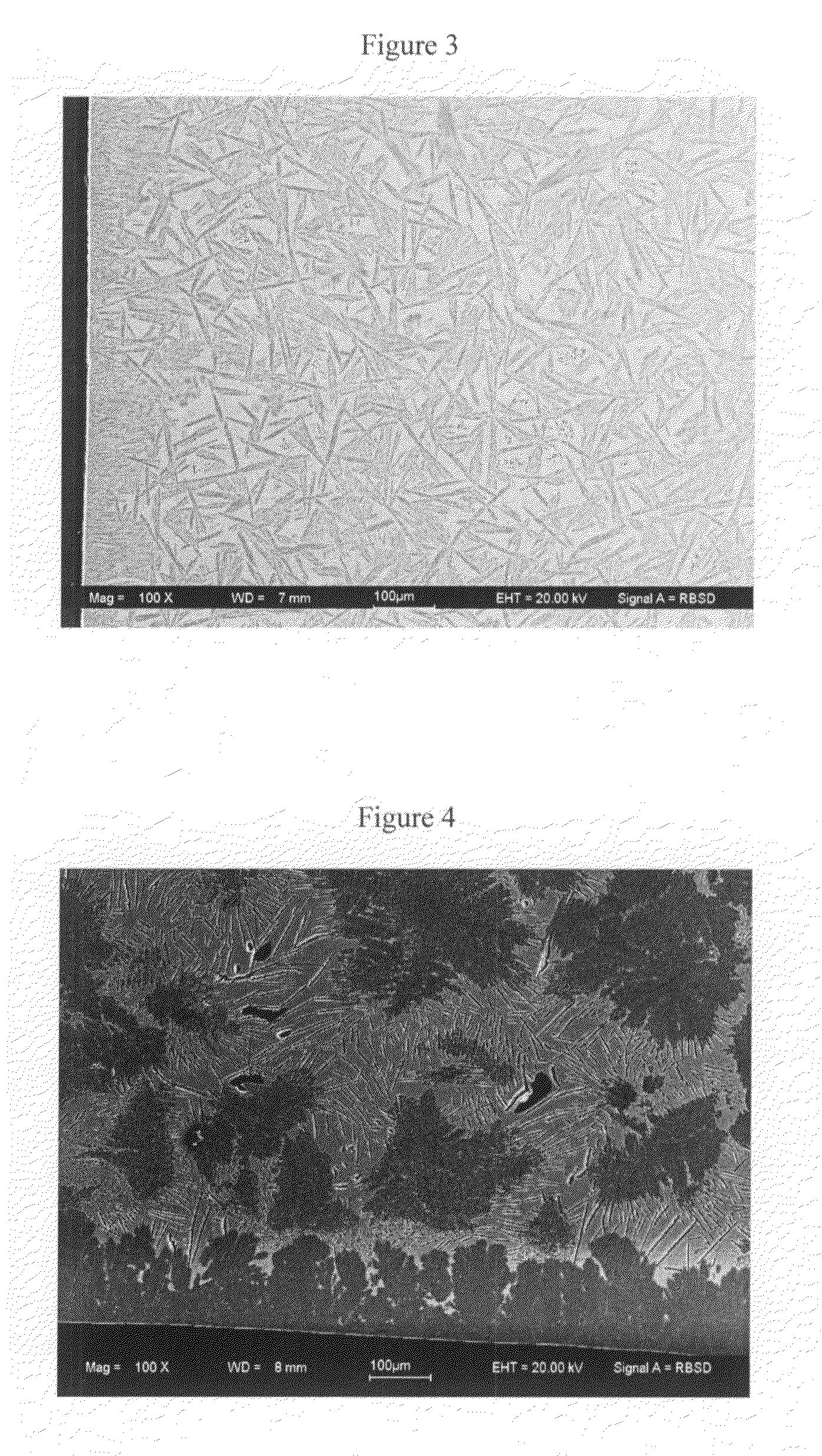

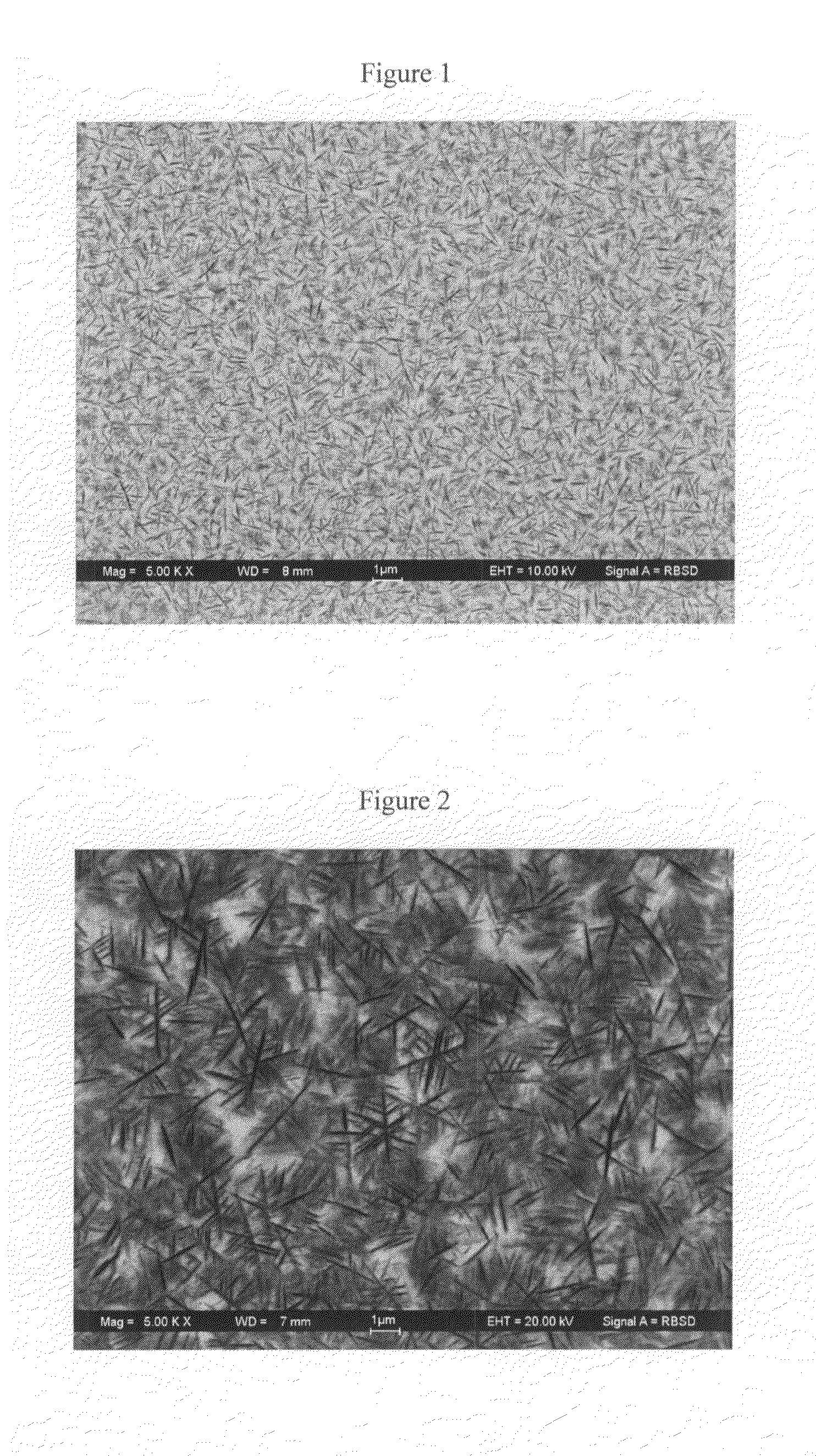

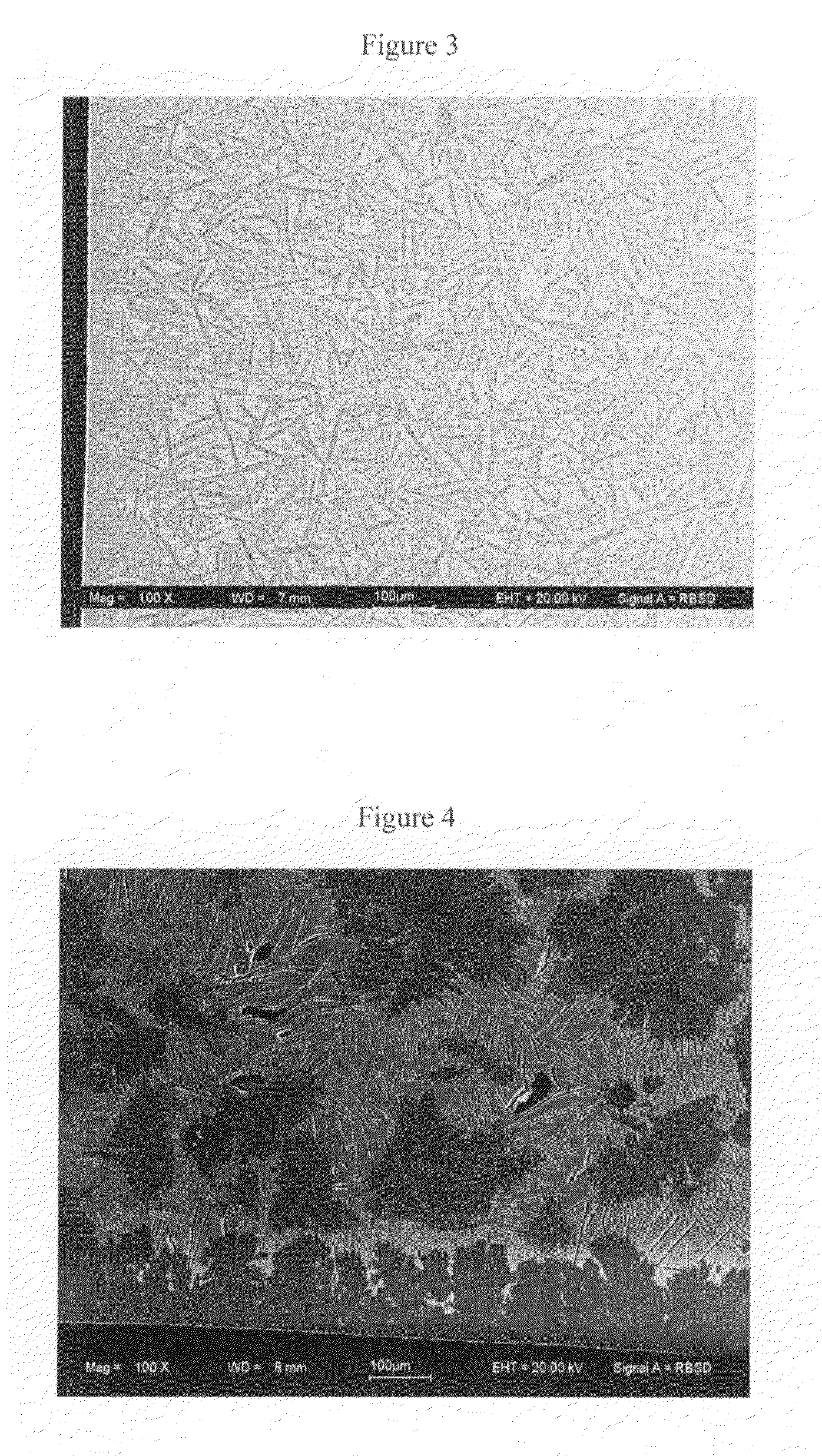

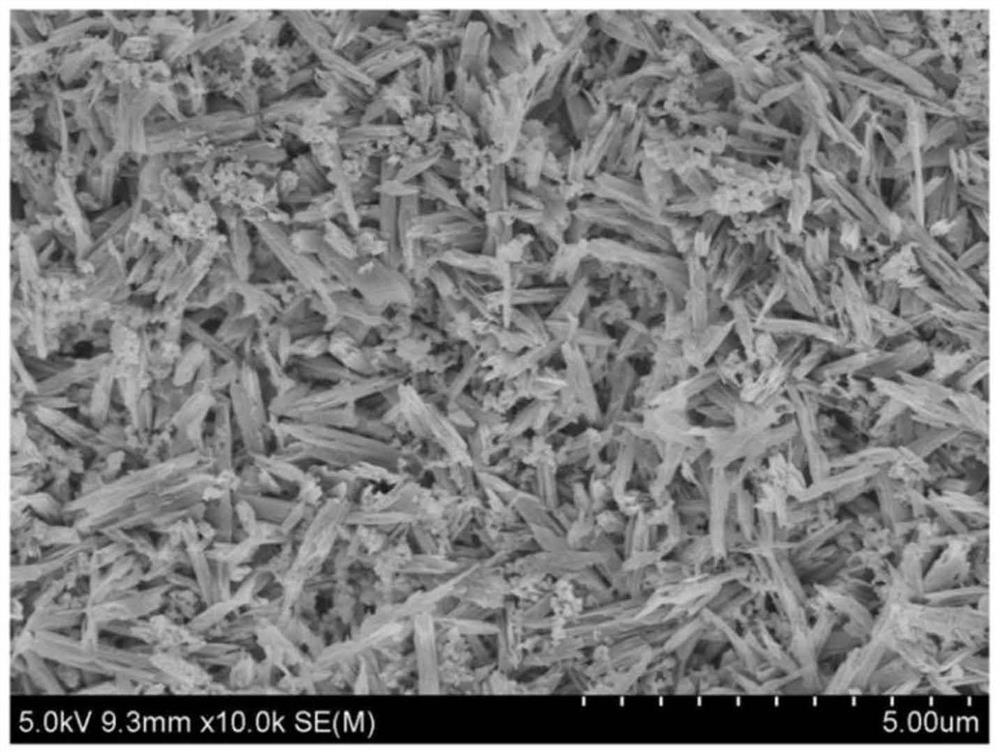

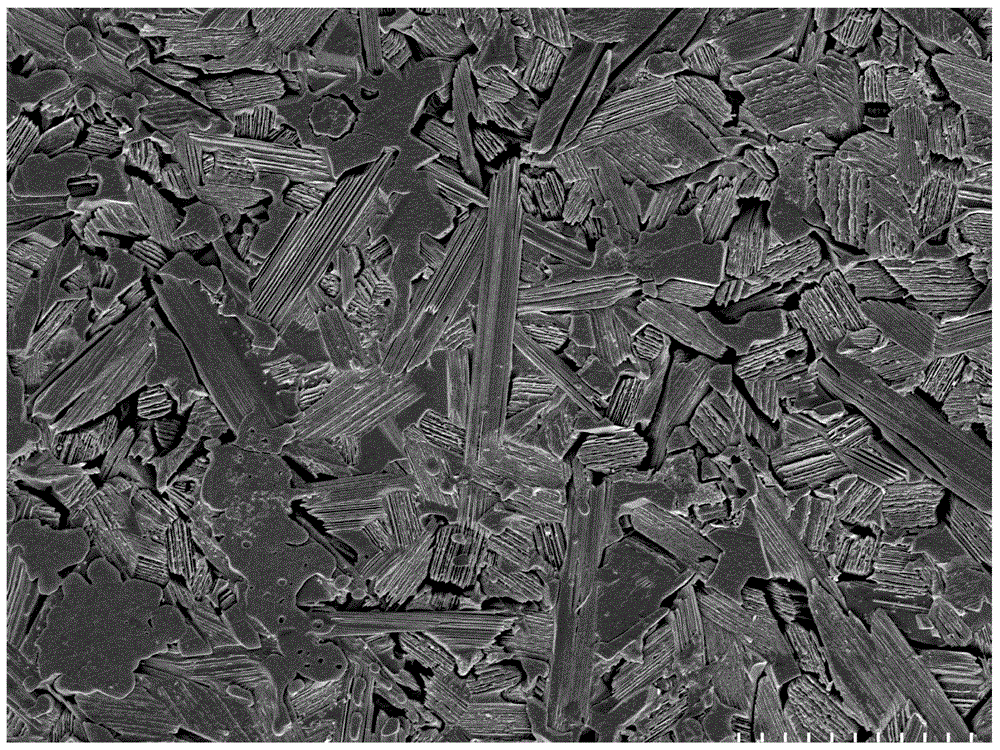

The invention discloses a preparation method for dental lithium silicate microcrystalline glass. Glass powder is subjected to hot-pressing sintering, and after a compact lithium metasilicate microcrystalline glass body is formed, lithium metasilicate (Li2SiO3) crystals are converted into lithium disilicate (Li2Si2O5) crystals through heat treatment. The interior of the microcrystalline glass is uniform rod-shaped lithium disilicate (Li2Si2O5) crystals and has a rod-shaped interlock structure. Color matching agents can be intruduced in the hot-pressing sintering phase of the microcrystalline glass material, the obtained lithium metasilicate microcrystalline glass material has good processability, and unification of the manufacturability, mechanical properties and aesthetic functions of the obtained material is achieved. The technology is simple, the processability is strong, performances are stable, and the microcrystalline glass is suitable structure function integrated material.

Owner:XI AN JIAOTONG UNIV

Lithium disilicate glass-ceramics composite material using ZrO2 as reinforcing phase and method for making same

InactiveCN101139170AGuaranteed densificationGood mechanical propertiesGlass particleMechanical property

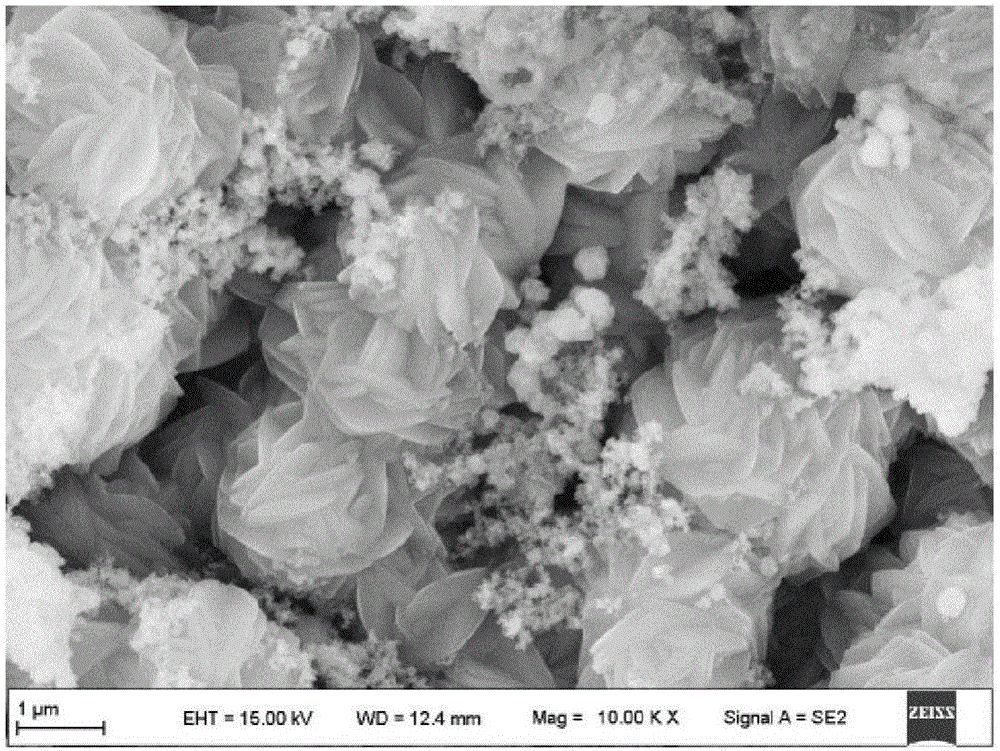

The present invention relates to a lithium disilicate glass-ceramic composite material with ZrO2 as the reinforcing phase and thepreparation method, which solve the problems that the production cycle is long, the cost is high, the products can be easily formed and the mechanical properties of the lithium disilicate glass-ceramic is lower. The present invention is composed of the lithium disilicate base glass and zirconia powders. The preparation method goes in that the ball milling is carried out according to the components of the original glass; the desiccated raw materials are placed in a corundum crucible so as to be melted under high temperature; the glass solution is poured into the distilled water to go into water quenching so as to be changed into 1 to 2mm glass particles; the ball milling is applied to the glass particles after going into the water quenching so as to obtain the glass powders; the lithium disilicate glass powder is taken to be mixed with the zirconia powders and the ball milling is applied to the lithium disilicate glass powder and the zirconia powders with the alcohol as the medium; the vacuum heating-press sintering is implemented and then the lithium disilicate glass-ceramic composite material with ZrO2 as the reinforcing phase is prepared. The present invention is uneasily deformed, has short production cycle and low cost and has excellent bending strength and fracture toughness indexes.

Owner:HARBIN INST OF TECH

Glass-ceramics and method for manufacturing the same

InactiveUS20110136651A1Suitability for press formingLower melting temperatureMagnetic materials for record carriersRecord information storageGlass-ceramicAntimony

For providing glass-ceramics having properties suitable for use as a substrate of an information storage medium of next generation such as one for the perpendicular magnetic recording system without employing arsenic and antimony components which adversely affect human beings and the environment, there are provided glass-ceramics comprising SiO2, Li2O and Al2O3 on oxide basis, comprising lithium disilicate as a crystal phase, and comprising one or more elements selected from the group consisting of Sn, Ce, Mn, W, Ta, Bi, Nb, S, Cl and F.

Owner:OHARA

Rare earth-mixing high strength lithium bisilicate sitall material and preparation method thereof

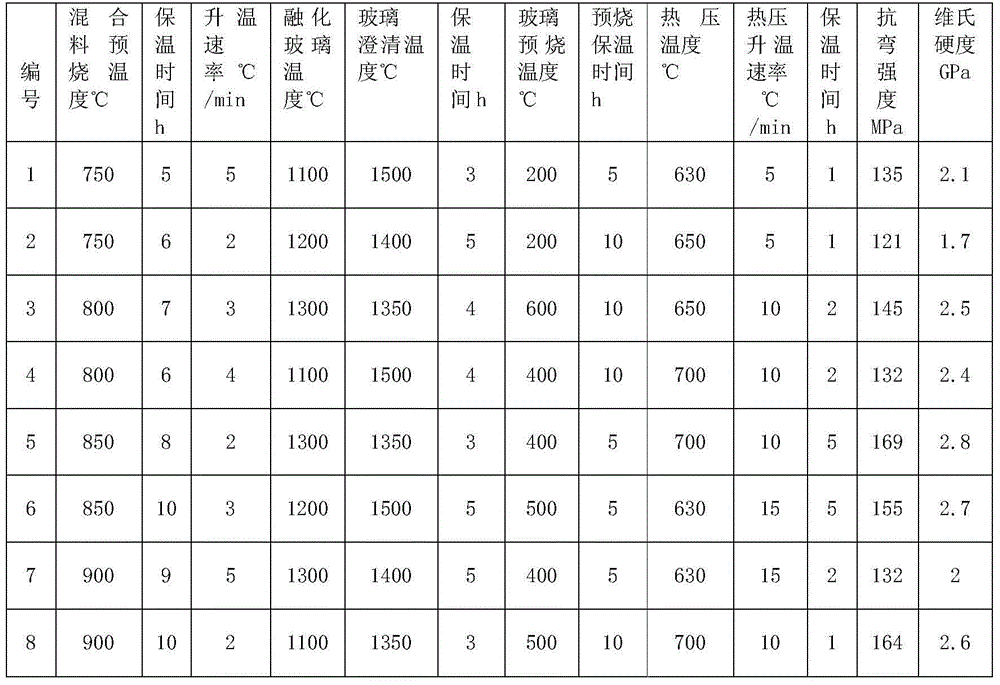

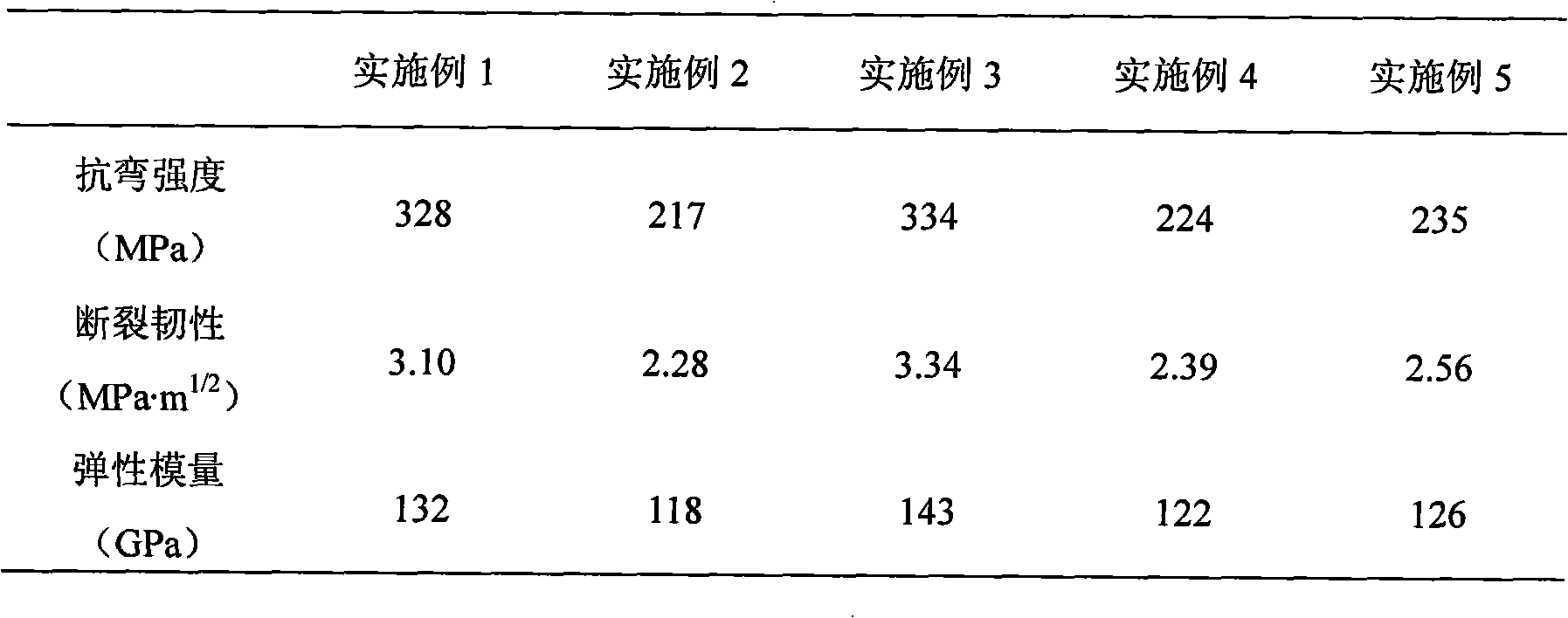

The invention relates to a rare earth-mixing high strength lithium bisilicate sitall material and a preparation method thereof. Parent glass of the invention includes the following components according to molar percentage: 61.2 to 66.0 percent of SiO2, 0 to 2.5 percent of B2O3, 0 to 1.6 percent of Al2O3, 1.0 to 3.7 percent of P2O5, 0 to 2.3 percent of ZrO2, 1.0 to 1.8 percent of K2O, 24.2 to 31.8 percent of Li2O, 0 to 2.0 percent of MgO, 0 to 2.0 percent of CaO, and 0.5 to 4.2 percent of La2O3+Y2O3. A corresponding raw material prepared from the oxidates is processed by the steps of ball milling, 80 mesh sieve sieving and uniform mixing to obtain a batch; the batch is led into a copple to be melted after the temperature from 1480 to 1520 DEG C is maintained for 2 to 3 hours, and the melted batch is cast into a stainless steel mould to be molded and then is annealed at 500 DEG C for 0.5 hour; and the step of coring is carried out in a resistance furnace at the temperature from 500 to 550 DEG C for 1 hour, and the step of crystallization is carried out at the temperature from 600 to 850 DEG C for 2 hours. The crystallization degree of the sitall is as high as 60 to 70 percent, the flexural strength is 100 MPa or more higher than the sitall to which the rare earth oxides are not added, the highest flexural strength reaches 334 MPa, the maximum elastic modulus reaches 143 GPa, and the highest fracture toughness reaches 3.34 MPa-m. The sitall of the invention has favorable stability, and the heat treatment temperature is lower and is easy to control.

Owner:CENT SOUTH UNIV

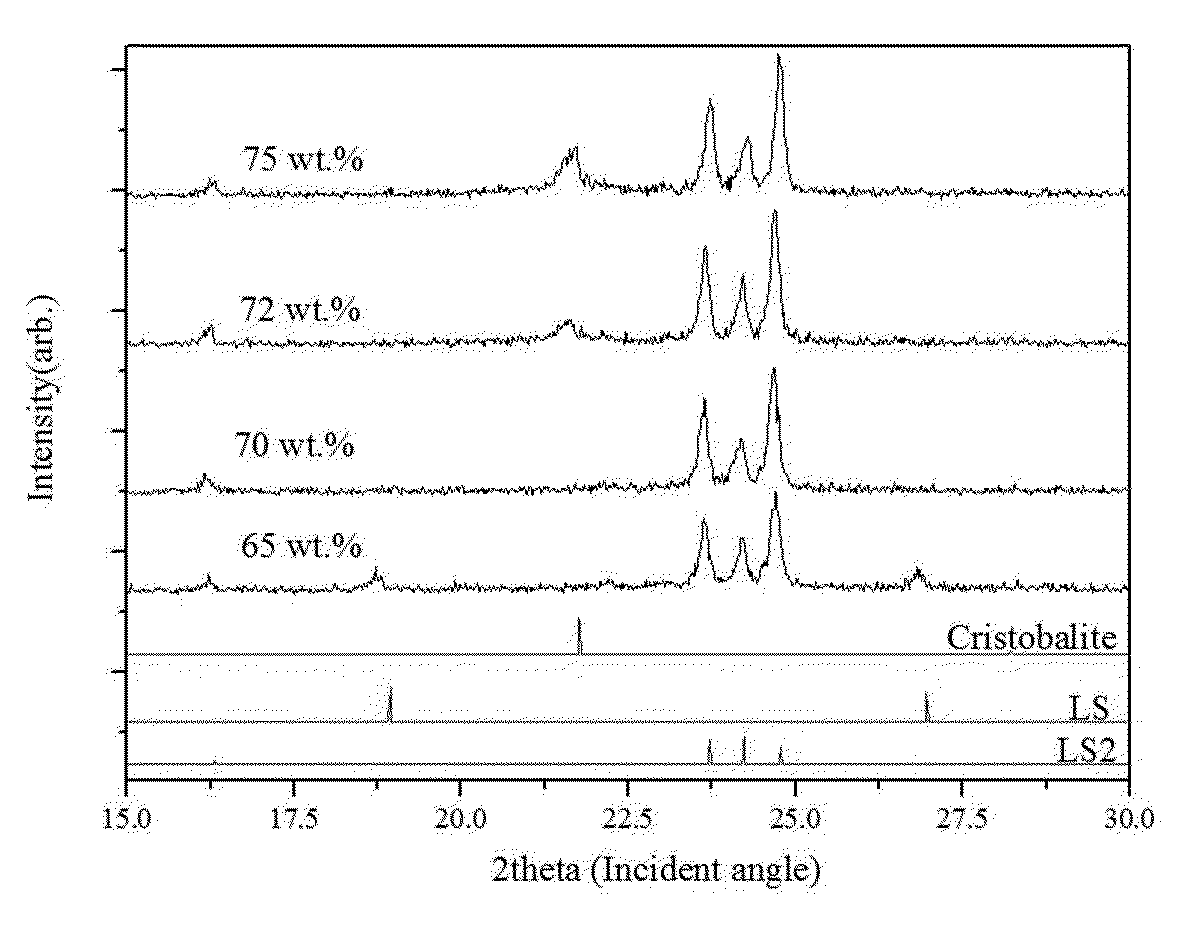

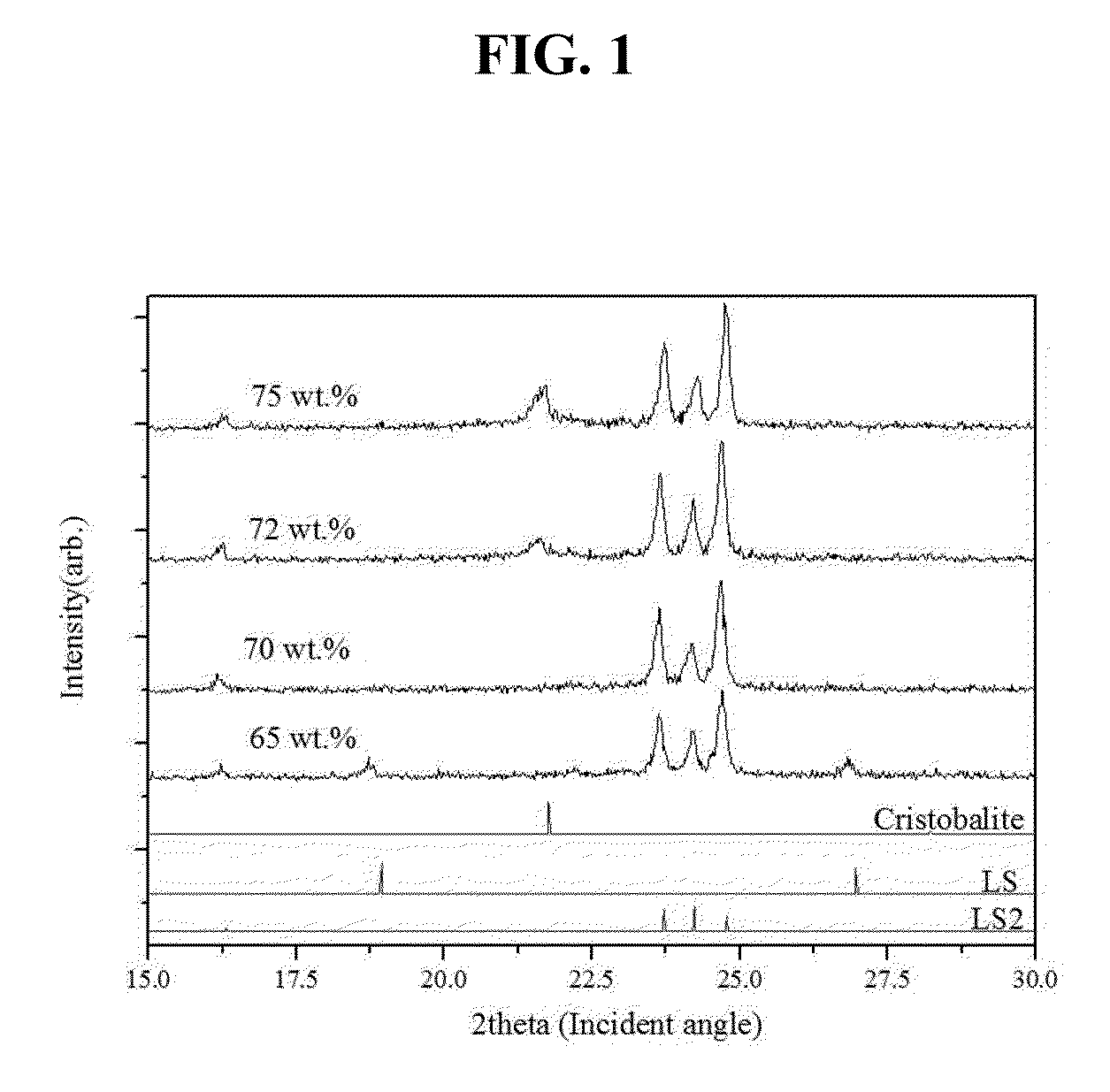

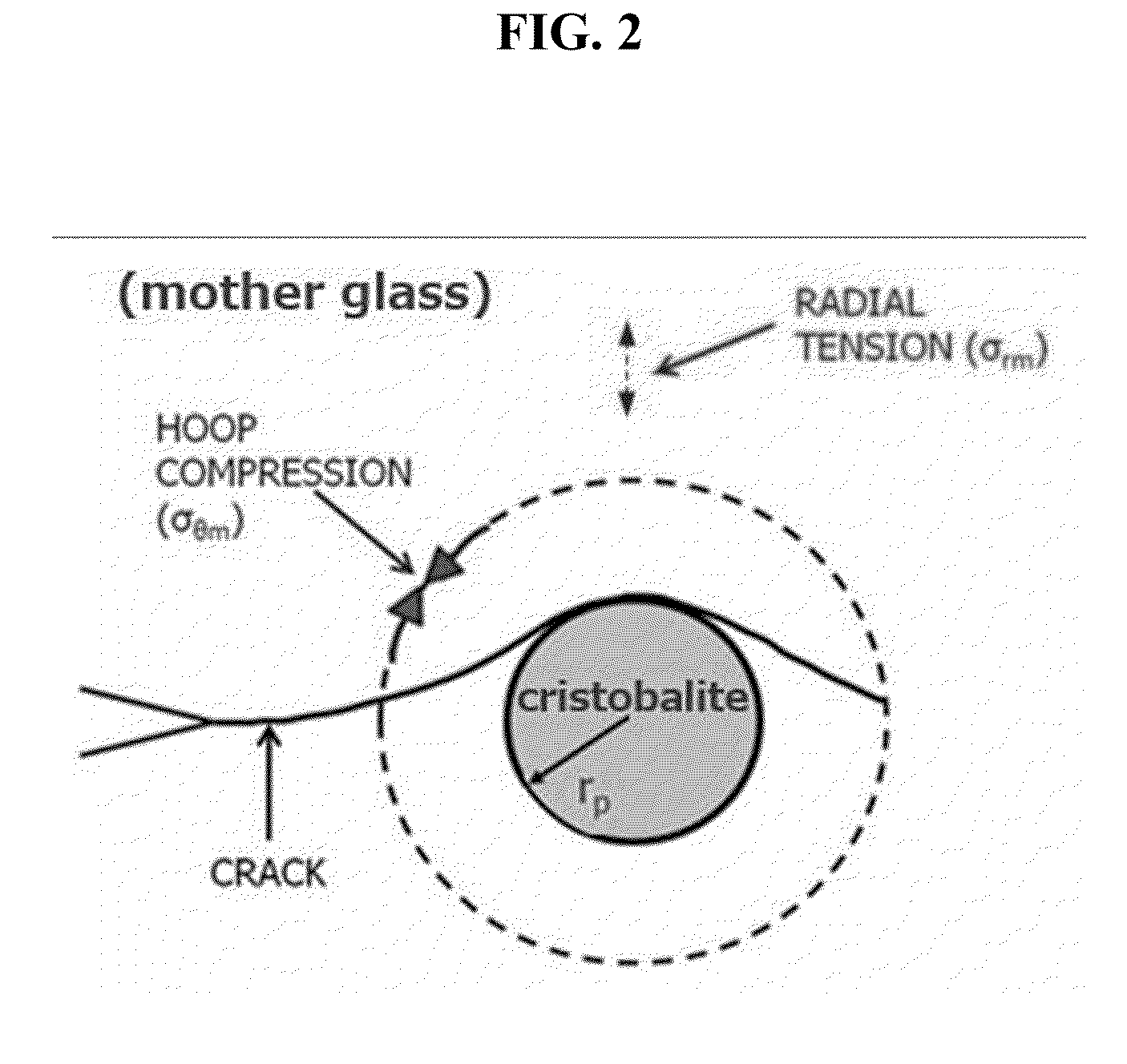

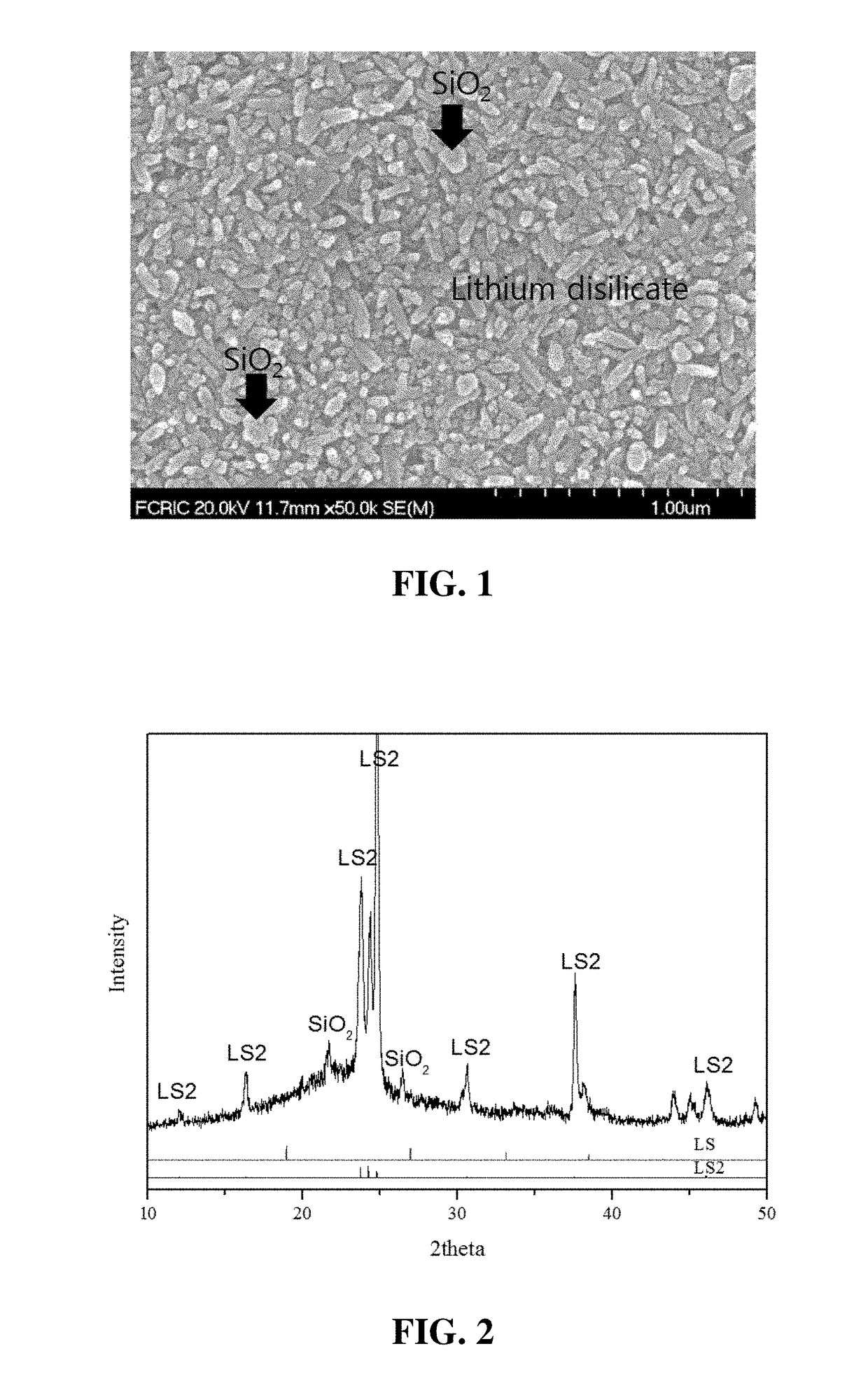

High strength and aesthetic lithium disilicate crystalline glass-ceramics containing cristobalite crystal and preparation method thereof

ActiveUS20160060159A1High strengthEnhances strength and aesthetic light transmittanceImpression capsTooth crownsGlass-ceramicDental restoration

Provided is lithium disilicate crystalline glass containing cristobalite crystal phase for high strength and aesthetic traits and its manufacturing process thereof. Exemplary embodiments of the present invention provide the high strength and aesthetic lithium disilicate crystalline glass, one kind of dental restoration materials, and its manufacturing method which induces the growth of the different crystal phase, cristobalite, from glass with lithium disilicate crystal.

Owner:HAAS & CO GMBH

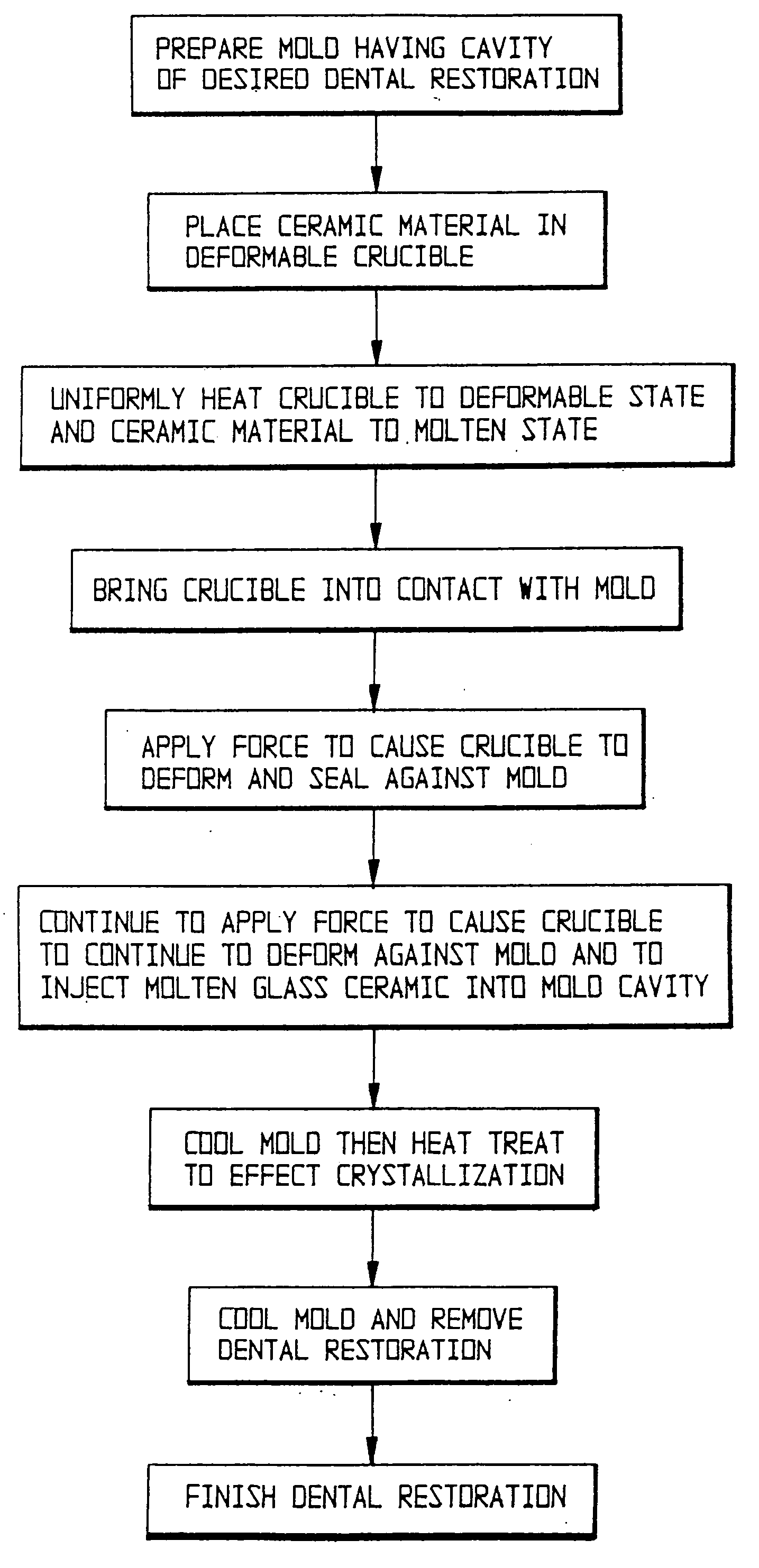

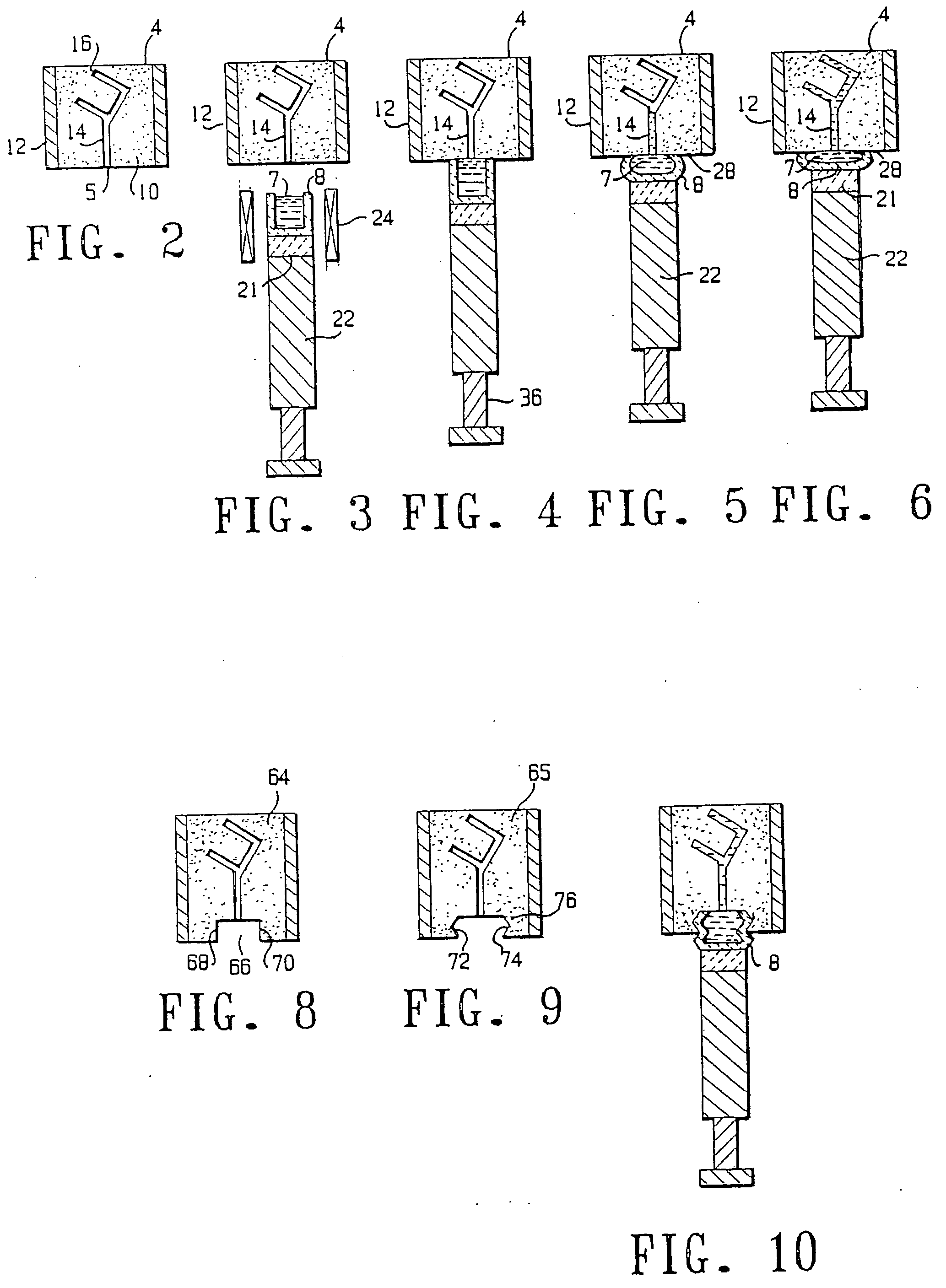

Method for molding dental restorations and related apparatus

InactiveUS20050115460A1Readily molded into dental restorationEasy to useImpression capsOther chemical processesWorking temperatureDental restoration

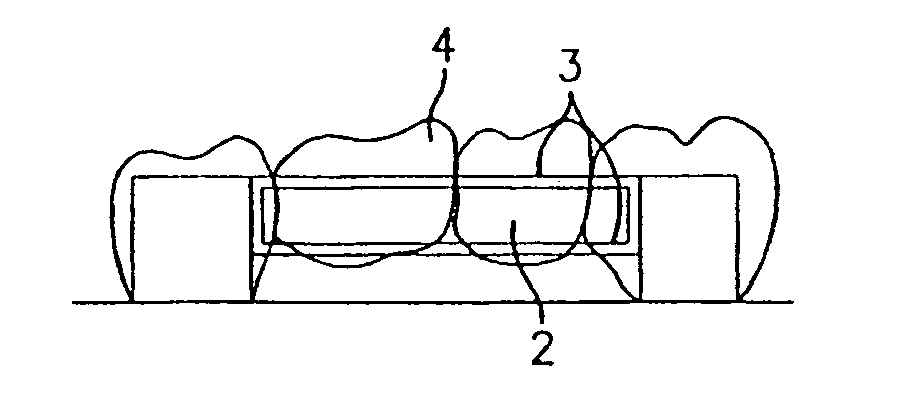

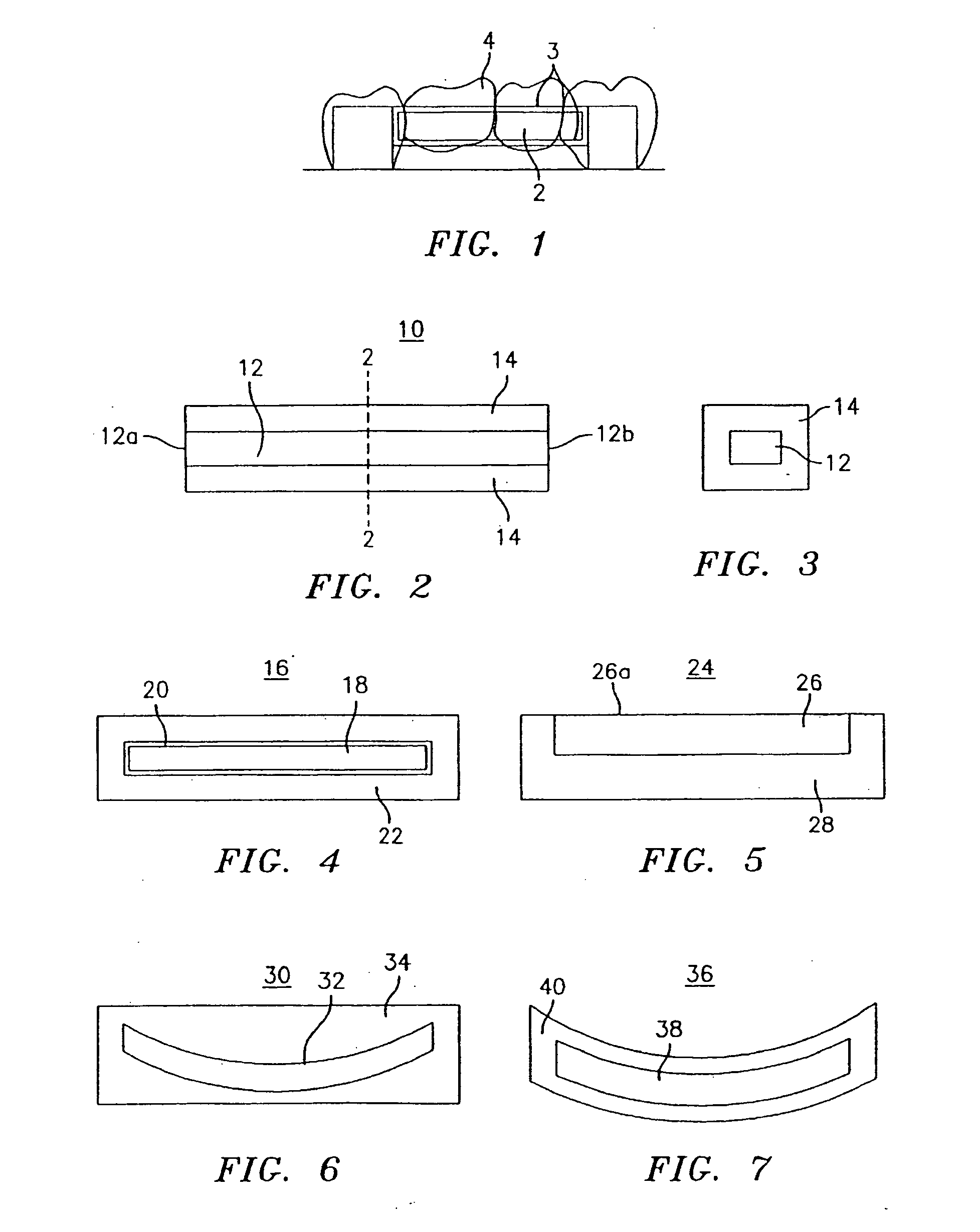

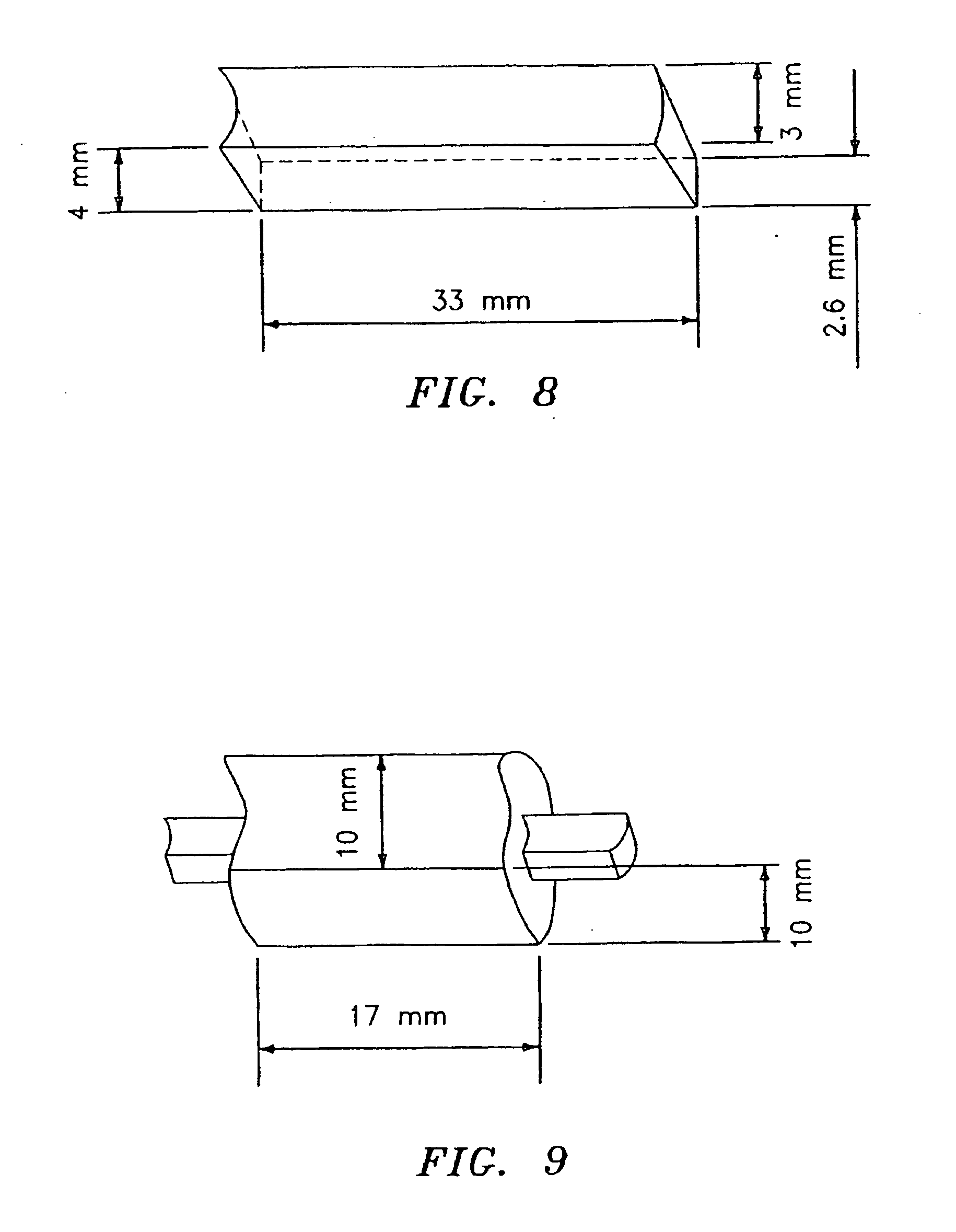

The present invention is concerned with a process for the formation of dental restorations from glass-ceramic materials, and the resulting dental restorations. In this invention, a dental restoration is prepared by placing a glass-ceramic material in a heat-pressure deformable crucible. Heat is then applied to the crucible in order to bring the glass-ceramic material to working range at temperatures above its liquidus temperature. The crucible in which the glass-ceramic material is placed has heat-pressure deformation properties which are matched to the working temperature of the glass-ceramic material being heated. The heat deformation properties of the crucible must be such that when the glass-ceramic material in the crucible is in the working range, the crucible is heat-pressure deformable without rupturing. Once the glass-ceramic material is heated to its working temperature, the crucible is brought into contact with a mold having a preformed cavity therein, the cavity being in the shape of the desired dental restoration. As the distance between the heated glass-ceramic material and the mold is decreased, the crucible is deformed to form a seal with the mold, thereby facilitating the injection of the molten glass-ceramic material into the mold cavity. An interactive seal between the crucible and the mold may be provided for. The composite process may be carried out in a vacuum. The resulting dental restoration has superior optical esthetic and strength properties. The invention further includes the heat-pressure deformable crucible. The invention includes dental restorations which are formed from particular lithium-disilicate glass-ceramics. In addition to forming dental restorations by the process of this invention, the dental restorations may be milled.

Owner:PETTICREW RICHARD W

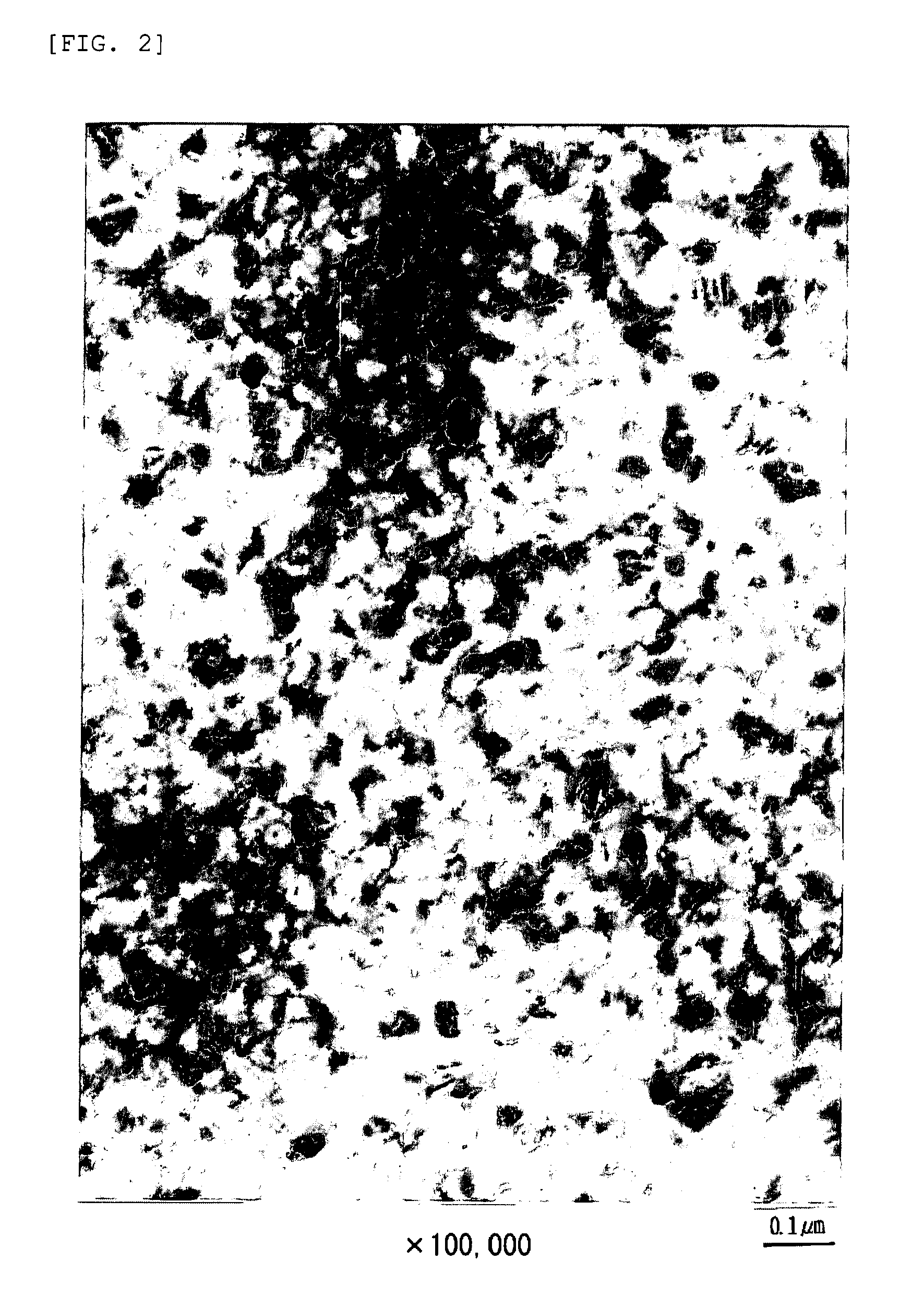

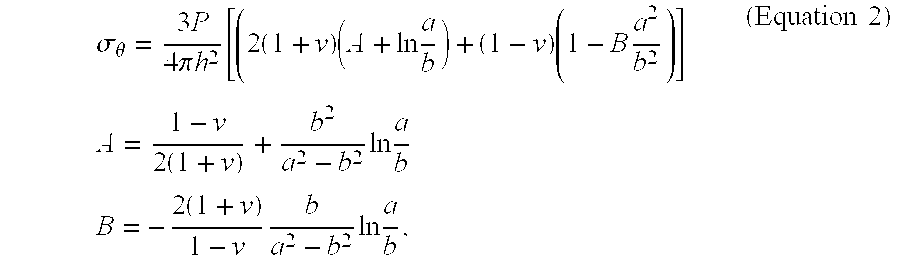

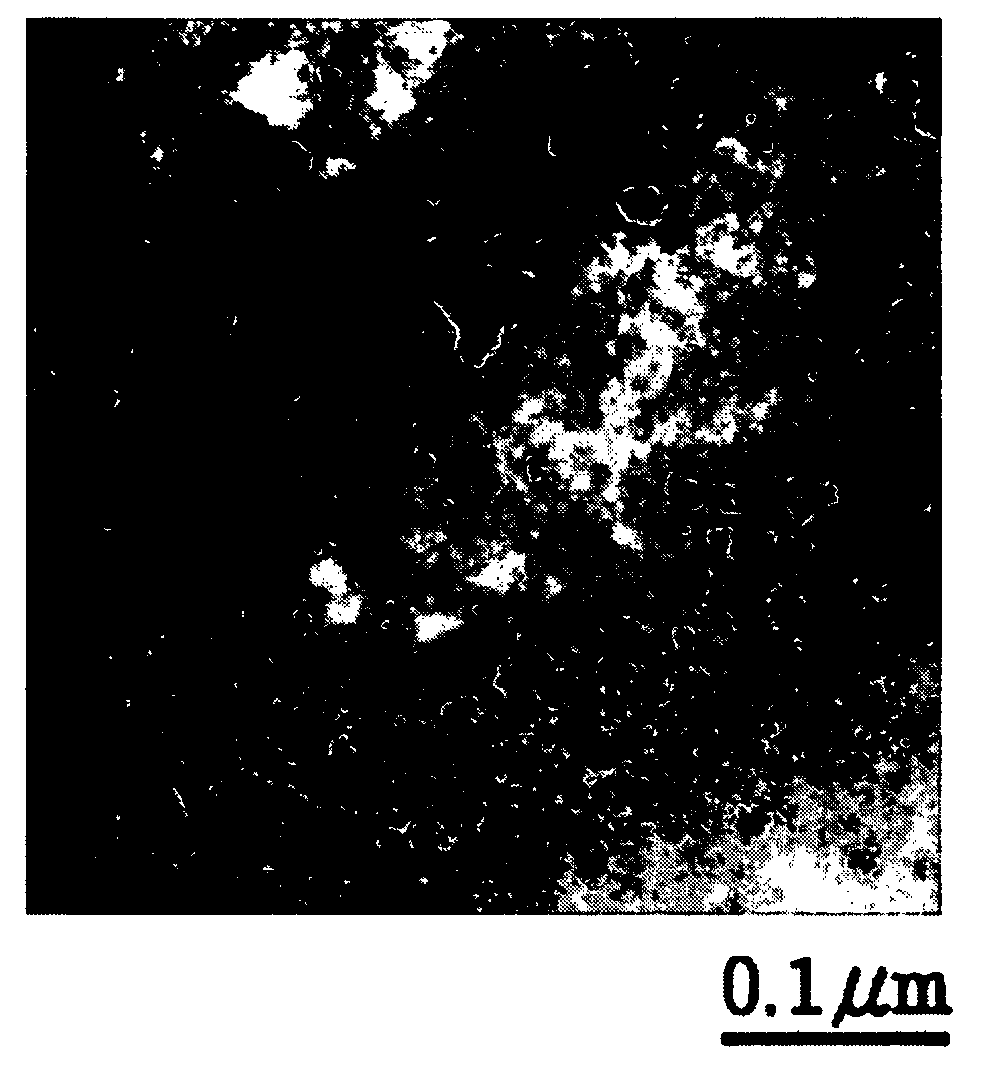

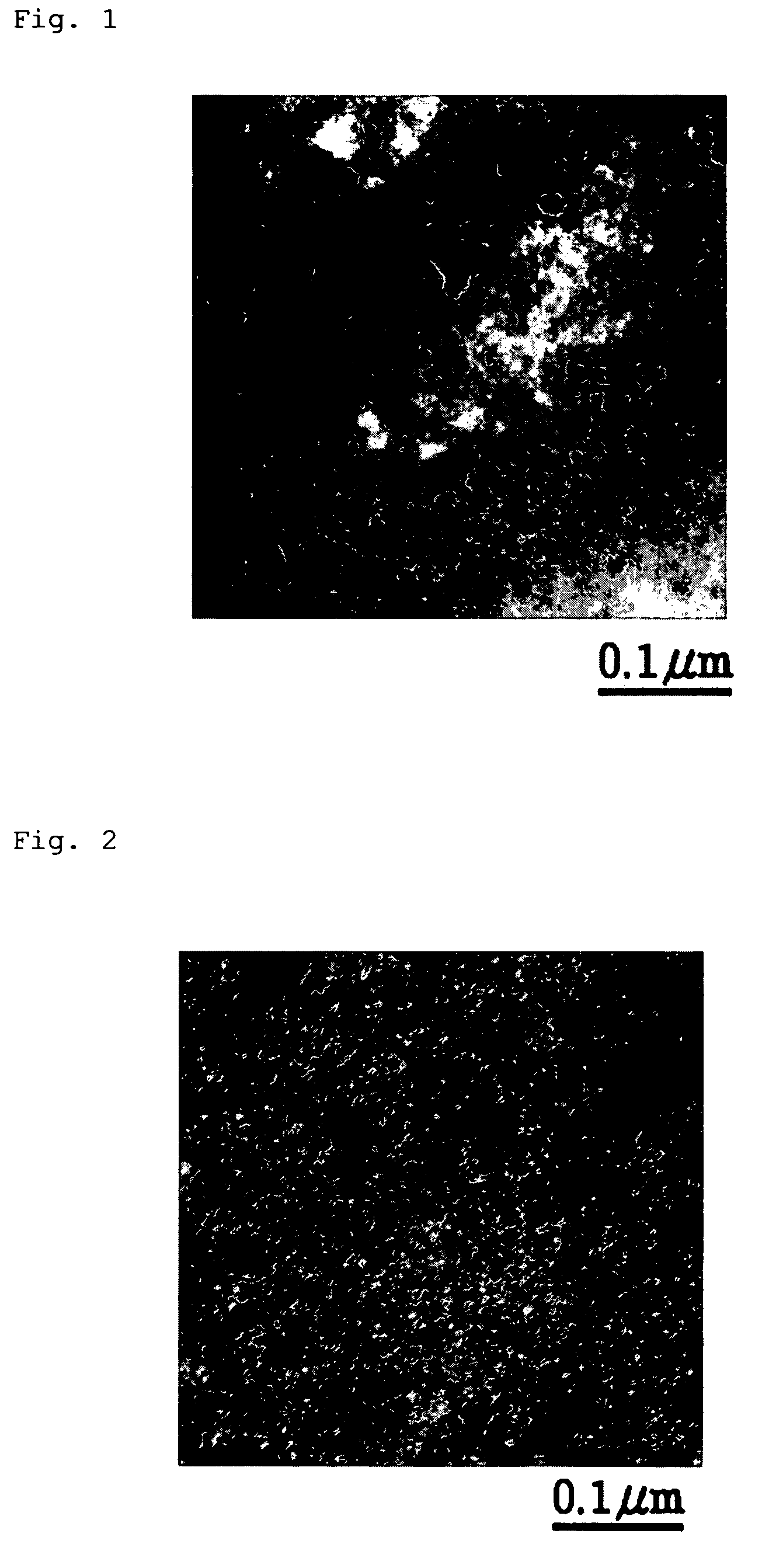

Inorganic composition

InactiveUS20070082294A1High mechanical strengthInhibit deteriorationMagnetic materials for record carriersPhotomechanical apparatusFlexural strengthMaterials science

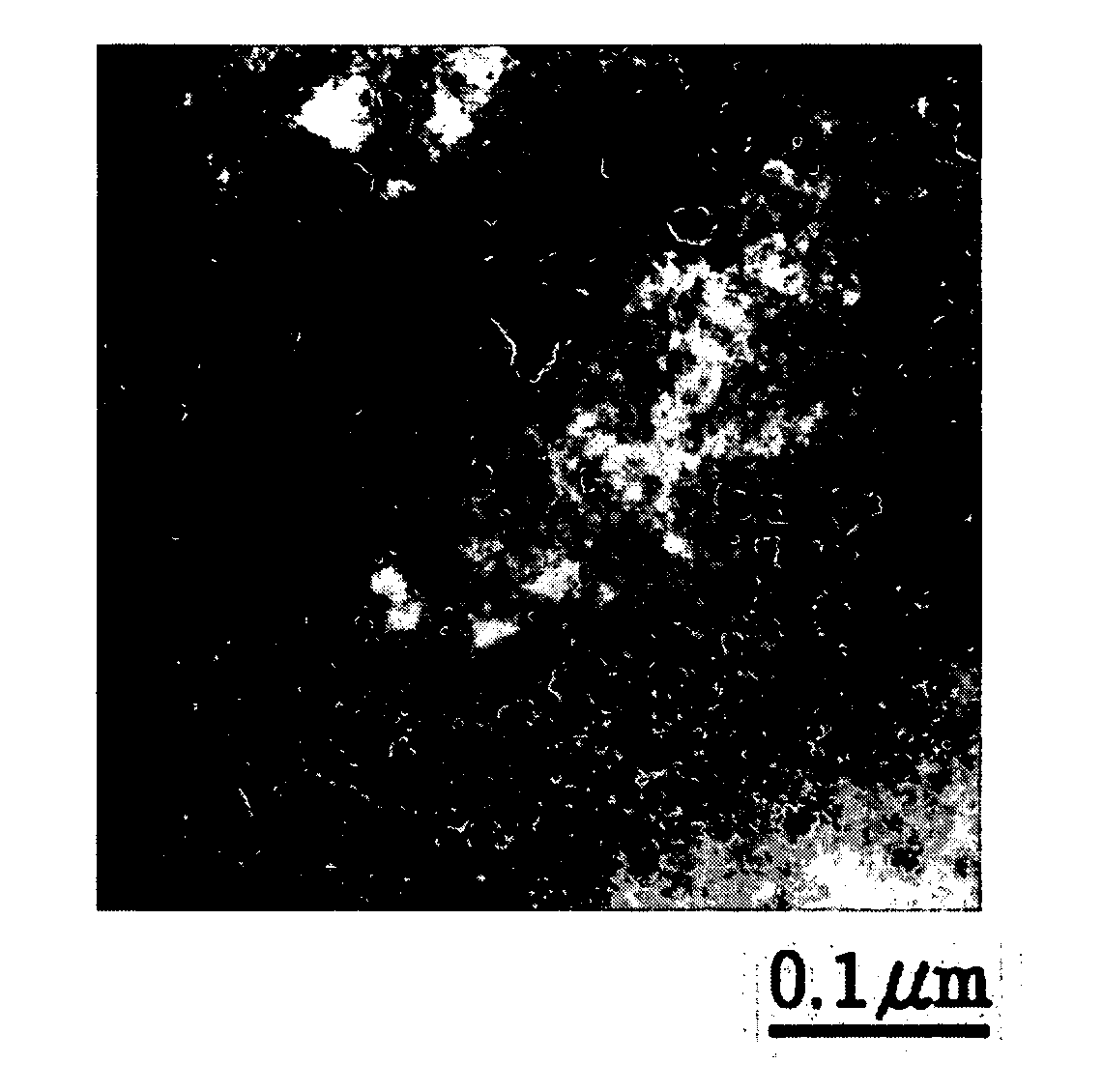

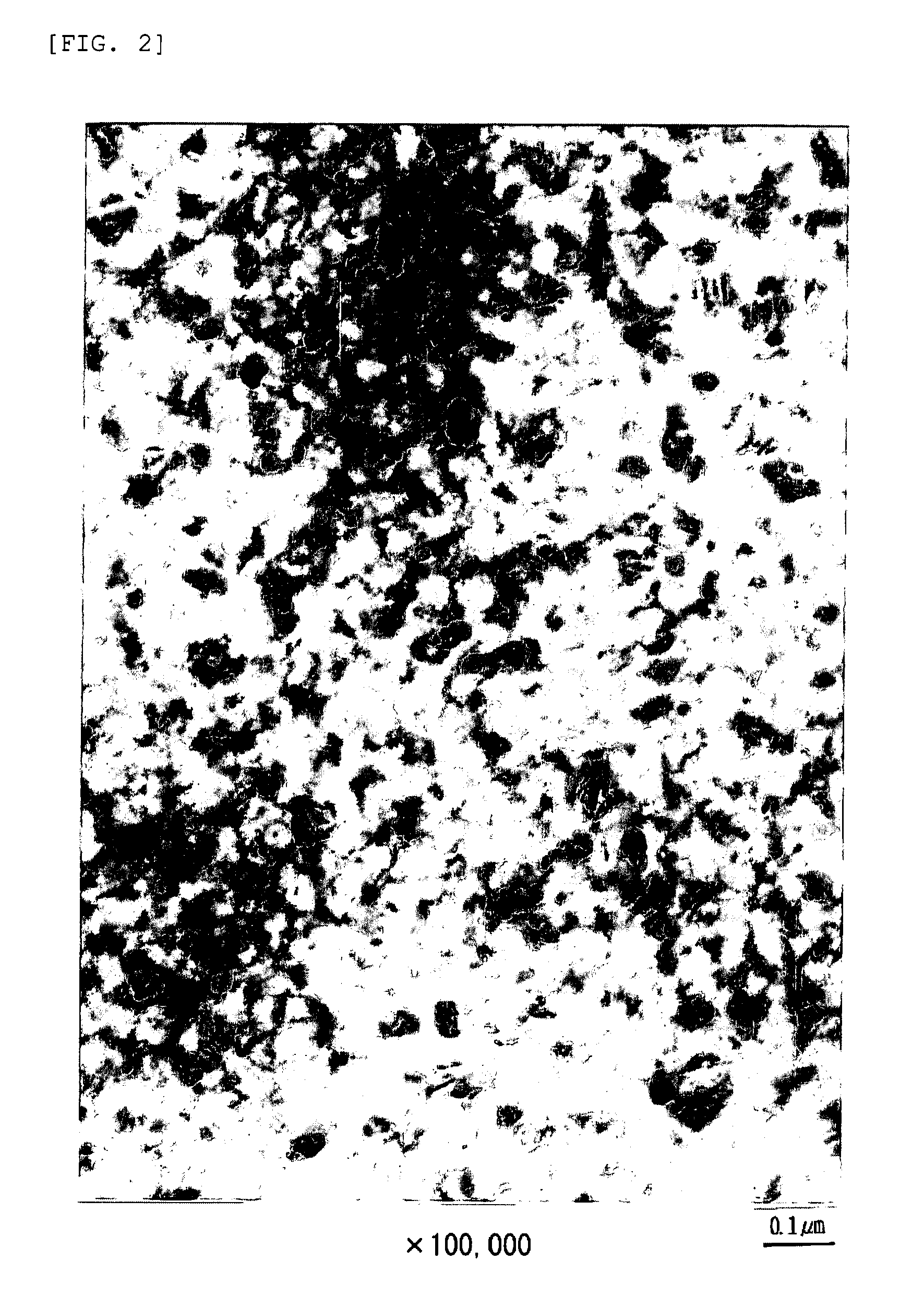

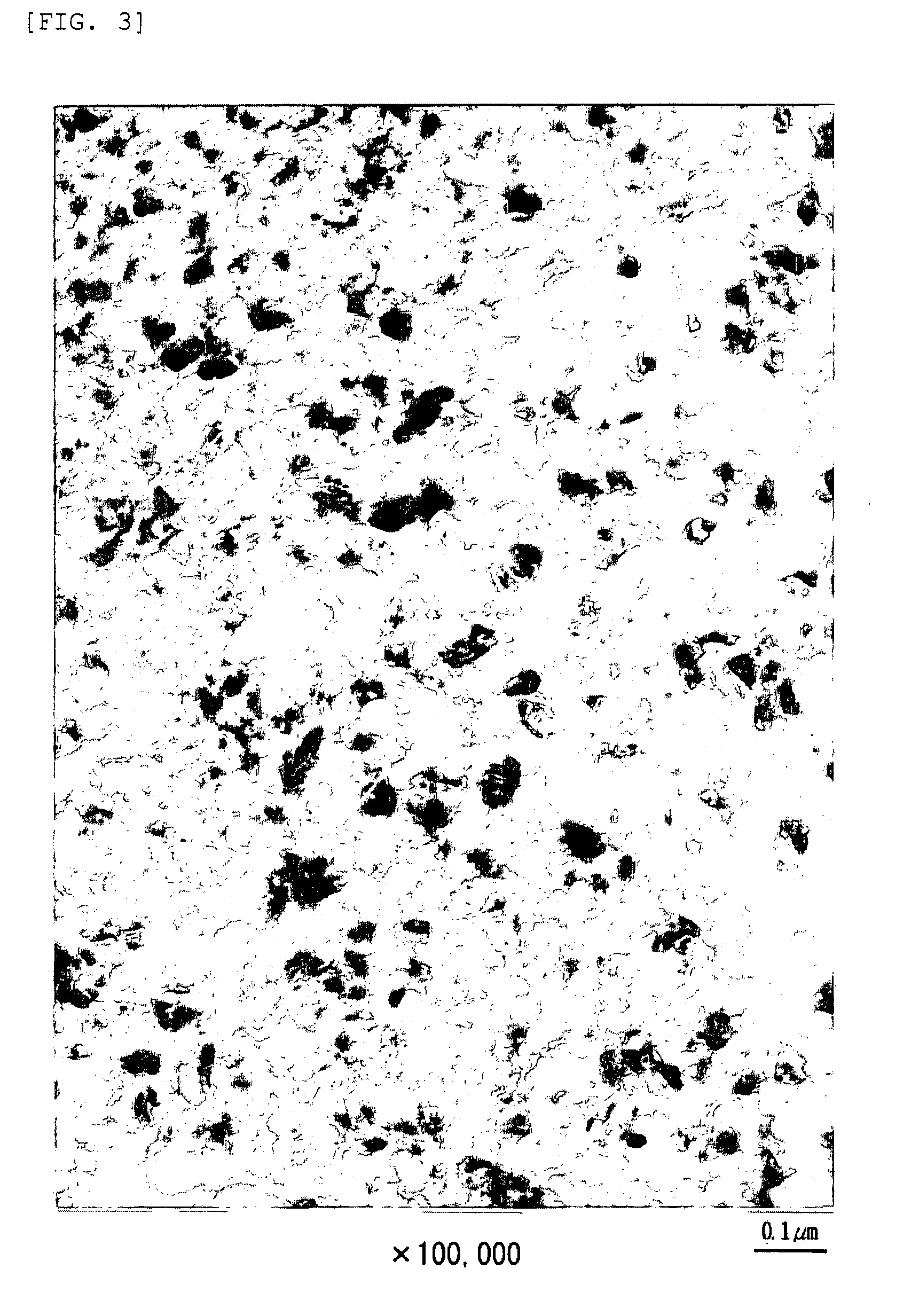

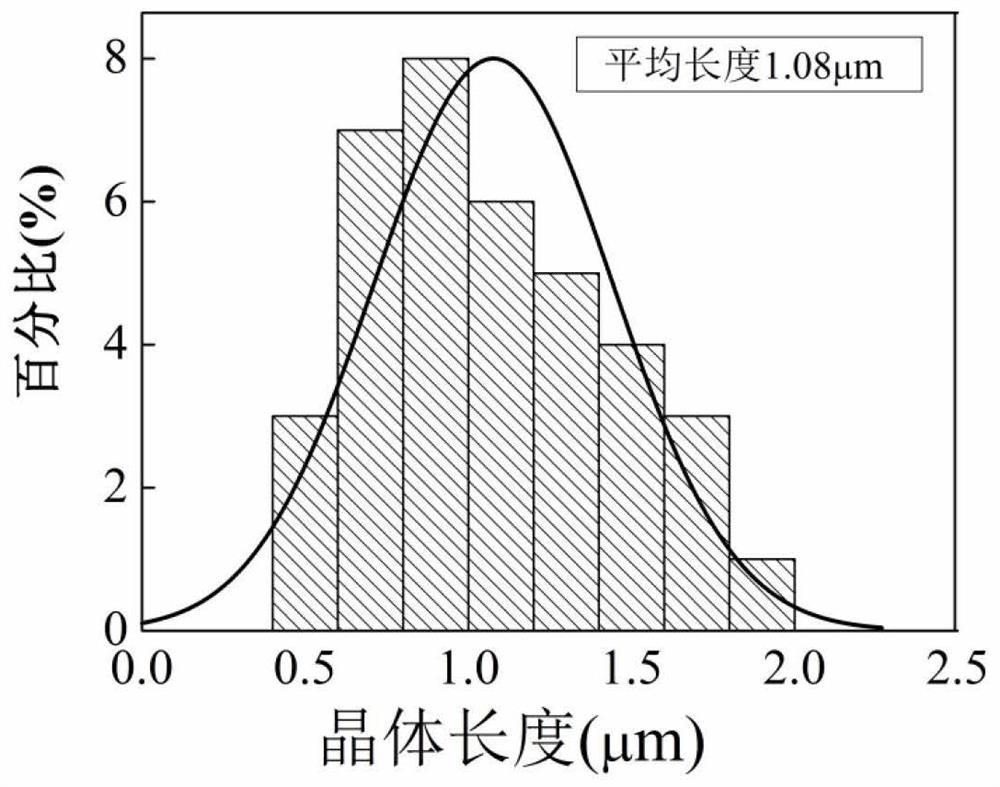

The present invention provides an inorganic composition for use in information recording medium disc substrate and such, having an excellent surface property capable of sufficiently corresponding with a ramp load system for high density recording, a high degree of tolerability to high speed rotation, and high productivity at a low melting point. Specifically, this invention provides an inorganic composition containing one crystalline phase selected from the group consisting of α-quartz (α-SiO2), lithium disilicate (Li2Si2O5) and lithium monosilicate (Li2SiO3), or that contain at least a crystalline phase of lithium monosilicate (Li2SiO3), in which a mean particle diameter of a particle showing a crystalline phase contained in the inorganic composition is 1 μm or less, a ring flexural strength is 300 MPa or more, and a surface roughness (an arithmetic mean roughness) thereof after a polishing process is 10 Å or less.

Owner:OHARA

High strength glass-ceramics having lithium disilicate and beta-spodumene structures

Glass and glass ceramic compositions having a combination of lithium disilicate and β-spodumene crystalline phases along with methods of making the glass and glass ceramic compositions are described. The compositions are compatible with conventional rolling and float processes and have high mechanical strength and fracture resistance. Further, the compositions are able to be chemically tempered to even higher strength glass ceramics that are useful as large substrates in multiple applications.

Owner:CORNING INC

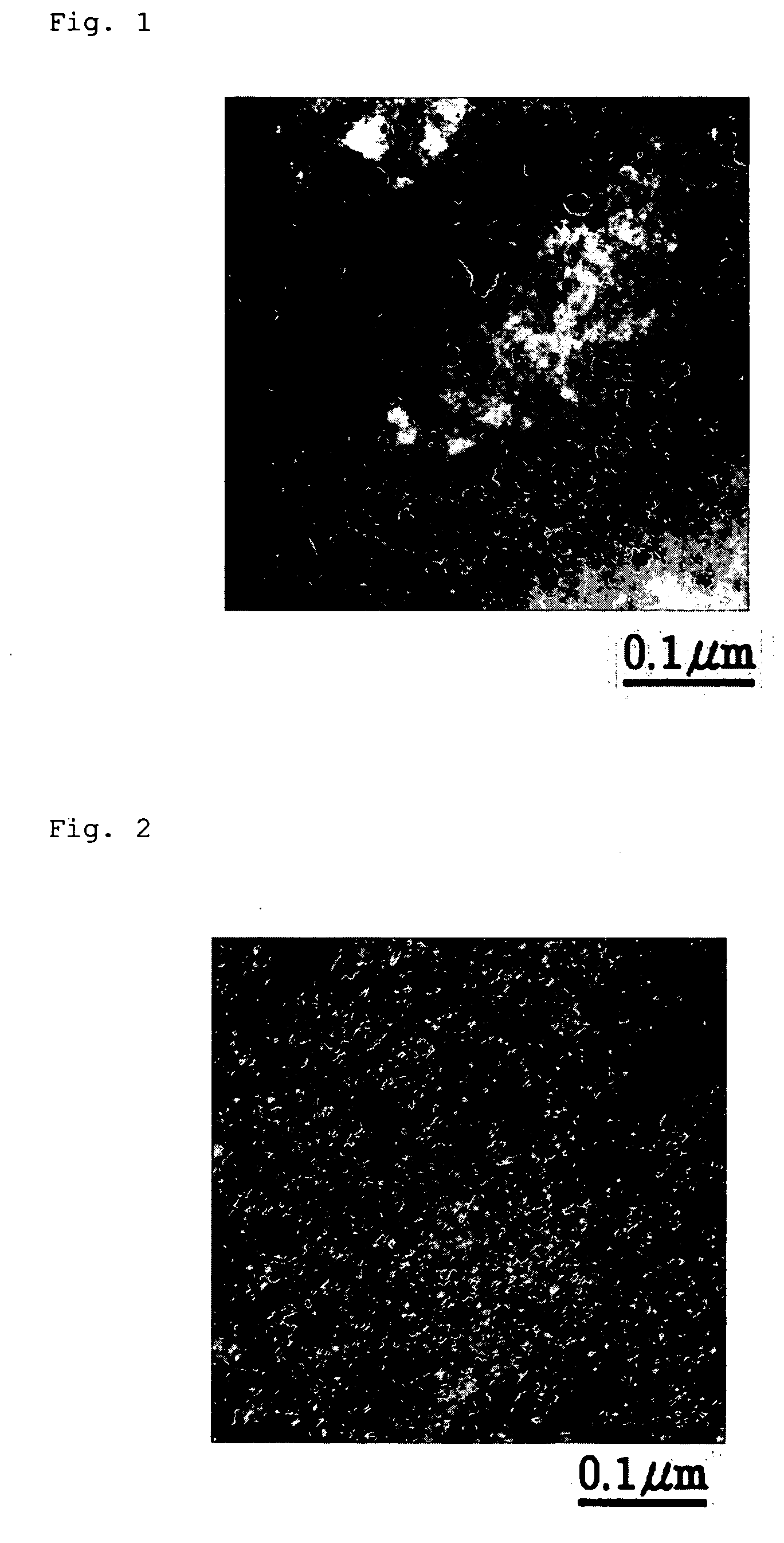

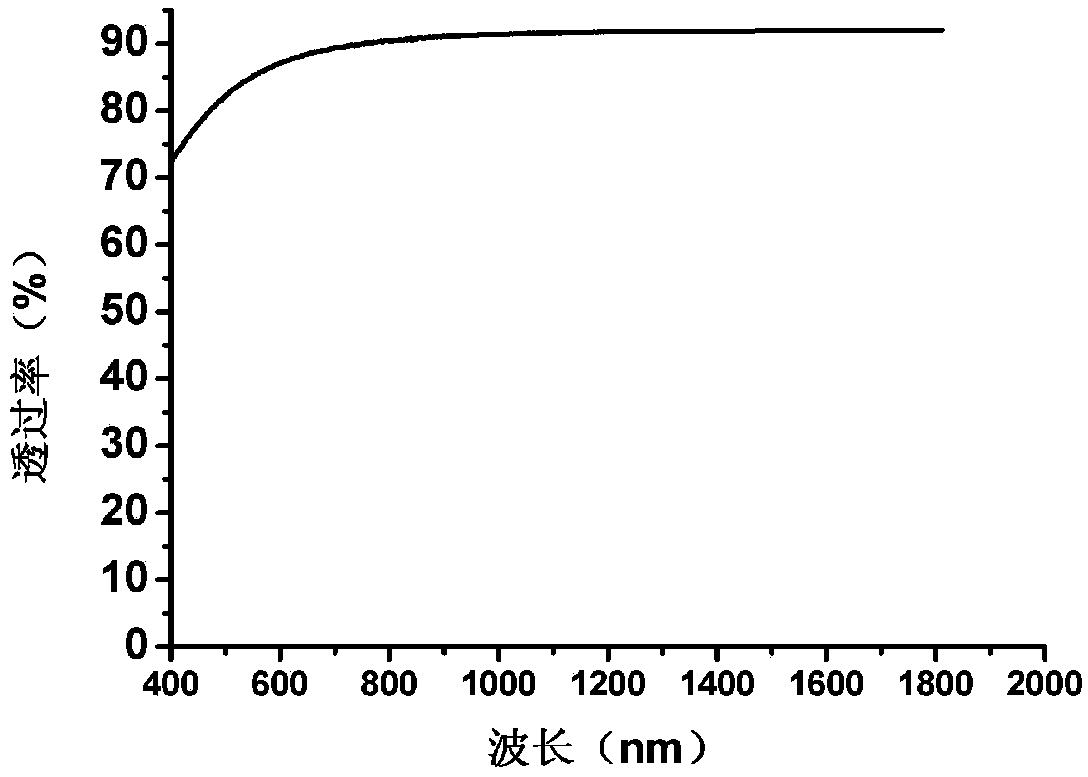

Lithium silicate microcrystalline glass and lithium disilicate microcrystalline glass with high permeability, and preparation method and application thereof

ActiveCN108069611AHigh light transmittanceHigh mechanical strengthImpression capsDentistry preparationsLithiumLength wave

The invention relates to a lithium silicate microcrystalline glass and a lithium disilicate microcrystalline glass with high permeability, and a preparation method and application thereof. The size oflithium silicate crystal in the lithium silicate microcrystalline glass is smaller than 50nm; the size of lithium disilicate crystal in the lithium disilicate microcrystalline glass is smaller than 200nm. The lithium silicate microcrystalline glass and the lithium disilicate microcrystalline glass have the advantages that the basic glass is prepared by the particular combination, a cooperation relationship among SiO2 (silicon dioxide), Li2O (lithium dioxide) and other components is controlled, and a ratio relationship between SiO2 and Li2O is especially controlled; after primary heat treatment, the lithium silicate microcrystalline glass with size smaller than 50nm is obtained; after the lithium silicate microcrystalline glass is subject to heat treatment again, the lithium disilicate microcrystalline glass is prepared, the crystal size of the lithium disilicate microcrystalline glass is controlled to be 200nm or less, the light permeability is 20% to 95% at the wavelength of 550nm, the strength is 360MPa to 450MPa, and the clinical requirement of the high permeability and excellent strength of the lithium disilicate microcrystalline glass can be met.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Inorganic composition

InactiveUS7589038B2High degreeIncrease speedMagnetic materials for record carriersPhotomechanical apparatusFlexural strengthSilicon dioxide

The present invention provides an inorganic composition for use in information recording medium disc substrate and such, having an excellent surface property capable of sufficiently corresponding with a ramp load system for high density recording, a high degree of tolerability to high speed rotation, and high productivity at a low melting point. Specifically, this invention provides an inorganic composition containing one crystalline phase selected from the group consisting of α-quartz (α-SiO2), lithium disilicate (Li2Si2O5) and lithium monosilicate (Li2SiO3), or that contain at least a crystalline phase of lithium monosilicate (Li2SiO3), in which a mean particle diameter of a particle showing a crystalline phase contained in the inorganic composition is 1 μm or less, a ring flexural strength is 300 MPa or more, and a surface roughness (an arithmetic mean roughness) thereof after a polishing process is 10 Å or less.

Owner:OHARA

Process for producing a sintered lithium disilicate glass ceramic dental restoration and kit of parts

InactiveUS20170128174A1Easily be individualizedLow strengthAdditive manufacturing apparatusImpression capsMetallurgyAtmospheric pressure

The present invention is directed to a process for producing a sintered lithium disilicate glass ceramic dental restoration out of a porous 3-dim article, the process comprising the step of sintering the porous 3-dim article having the shape of a dental restoration with an outer and inner surface to obtain a sintered lithium disilicate ceramic dental restoration, the sintered lithium disilicate glass ceramic dental restoration comprising—Si oxide calculated as SiO2 from 55 to 80 wt.-%, —Li oxide calculated as Li2O from 7 to 16 wt.-%, —Al oxide calculated as Al2O3 from 1 to 5 wt.-%, and—P oxide calculated as P2O5 from 1 to 5 wt.-%, wt.-% with respect to the weight of the dental restoration, the sintering being done under reduced atmospheric pressure conditions, the reduced atmospheric pressure conditions being applied at a temperature above 600° C. The present invention is also directed to a kit of parts comprising a porous 3-dim article having the shape of a dental milling block and a respective instruction of use.

Owner:3M INNOVATIVE PROPERTIES CO

Low CTE photomachinable glass

InactiveUS7829489B2Low thermal expansionPhotomechanical apparatusOriginals for photomechanical treatmentThermal expansionMaterials science

The present invention describes a composition, method and article for a photomachinable glass having a coefficient of thermal expansion from less than 6×10−6 / ° C. in the temperature range of 0° C. to 300° C. The photomachinable glass composition is a low expansion glass having an amorphous glass phase and crystalline phases selected from the group consisting of spudomene and lithium disilicate.

Owner:CORNING INC

Glass ceramics

The invention discloses glass ceramics. The glass ceramics is prepared from the following components, in percentage by weight: 65-80% of SiO2, 0-3.5% of Al2O3, 7-12.5% of Li2O, 0.5-3% of K2O, greaterthan or equal to 3% and less than or equal to 10% of Y2O3, 1.5-4% of P2O5, 1-5% of ZrO2, 0.5-2% of MgO and 0.5-2% of ZnO. The glass ceramics solve problem of molding and opalescence presenting of theglass ceramics which take a quartz solid solution and lithium disilicate as main crystal phases by adjusting the components of the glass ceramics, the internal quality of the glass ceramics is uniform, the glass ceramics can be efficiently and stably produced, and the glass ceramics have the high hardness, the high Young modulus and the higher transmittance, and can be widely applied.

Owner:CDGM GLASS LLC

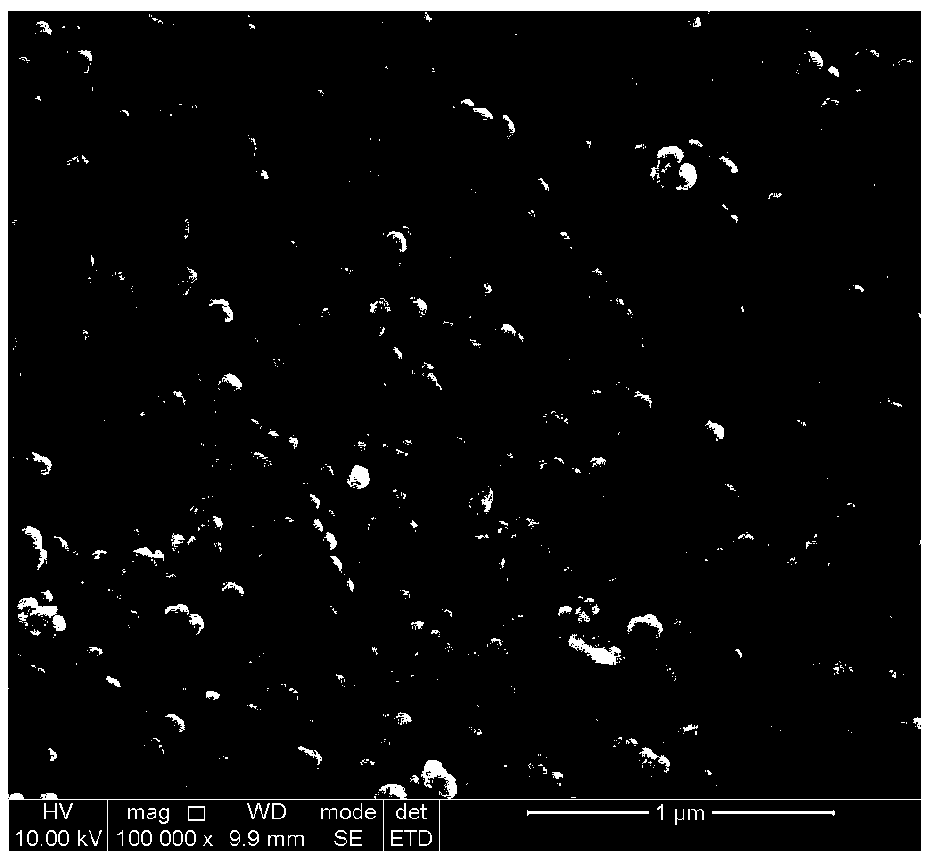

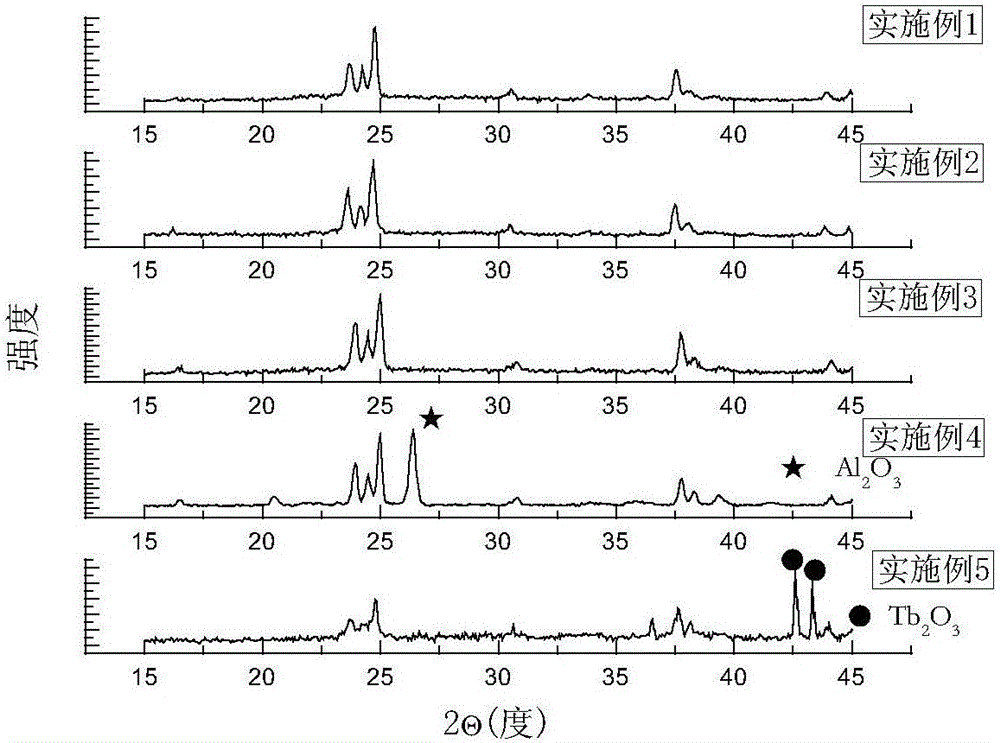

Lithium disilicate glass ceramic, preparation method thereof and application in dental material

ActiveCN106365456AImprove performanceHigh hardnessImpression capsDentistry preparationsRare-earth elementLithium metasilicate

The invention belongs to the field of medical materials and relates to a lithium disilicate glass ceramic, a preparation method thereof and application. The lithium disilicate glass ceramic is prepared from, by mass, SiO2 55%-65%, Li2O 16%-24%, P2O52 2%-5%, Al2O3 8%-12%, K2O 2%-5% and TbO2 1%-10%. According to the method, raw materials are subjected to pre-sintering, calcination, molding by casting and then are subjected to annealing, coring and crystallization to prepare a lithium metasilicate glass ceramic block, the lithium metasilicate glass ceramic block has very good machinability, and heat treatment is performed again after machining to obtain the lithium disilicate glass ceramic. The lithium disilicate glass ceramic prepared by the preparation method is doped with a specific content of rare earth element Tb, a glass grid structure can be destroyed, the viscosity can be reduced, crystallization is promoted, the hardness and bending strength of the glass ceramic are improved, and a novel method is provided for preparation of the lithium disilicate glass ceramic.

Owner:东北大学秦皇岛分校

Microcrystal glass with Li20-SiO2-P205 as main raw materials and production thereof

A glass ceramics with Li2O-SiO2-P2O5 as main materials and its production are disclosed. The glass ceramics consists of SiO2:60í½75wt%, Li2O:15í½18wt%, P2O5:2í½11wt%, ZnO:2.5í½3.5wt%, K2O:4í½6.5wt% and CaO:1í½1.5wt%. The process is carried out by ball grinding, drying, melting the powders in crucible, water quenching the obtained glass solution into blocked glass, ball grinding the glass into powder, placing the powder in hot-pressure sintering furnace, pressurizing by single axle, sintering, mould releasing and cooling to obtain glass ceramics with lithium disilicate. The crystal has better devitrification and mechanical performances.

Owner:HARBIN INST OF TECH

Low CTE photomachinable glass

InactiveUS20080299501A1Reduction factorLow thermal expansionX-ray/infra-red processesPhotomechanical apparatusThermal expansionMaterials science

The present invention describes a composition, method and article for a photomachinable glass having a coefficient of thermal expansion from less than 6×10−6 / ° C. in the temperature range of 0° C. to 300 ° C. The photomachinable glass composition is a low expansion glass having an amorphous glass phase and crystalline phases selected from the group consisting of spudomene and lithium disilicate.

Owner:CORNING INC

Lithium disilicate glass ceramic used for dental zirconia veneering porcelain and preparation method and application thereof

InactiveCN108751721AImprove flexural strengthImprove processing stabilityCrack resistanceFlexural strength

The invention discloses a lithium disilicate glass ceramic used for dental zirconia veneering porcelain and a preparation method and application thereof, the lithium disilicate glass ceramic comprises56%-58% of SiO2, 27%-29% of Li2CO3, 3.7%-3.8% of K2CO3, 2.7%-2.8% of Al2O3, 2.3%-2.4% of ZrO2, 2.5%-2.6% of P2O5, 2.2%-3.8% of B2O3, 0.5% of Ti2O and 0.5% of CeO2. The preparation method comprises the steps that after raw material ball-milling and mixing, melting is performed, a melt is obtained, the melt is poured into a mold, then annealing is performed, and a glass blank is obtained; the glassblank is subjected to crystallization heat treatment, and the lithium disilicate glass ceramic is obtained. The obtained lithium disilicate glass ceramic is high in flexural strength, and the damageprobability of a restoration body due to veneering porcelain cracking can be remarkably reduced. The invention provides a method applying the lithium disilicate glass ceramic as zirconia veneering porcelain, in the restoration body obtained with the method, the bonding strength of the lithium disilicate glass ceramic veneering porcelain with a zirconia substrate is far higher than that of traditional zirconia decoration ceramic porcelain with the zirconia substrate, and the cracking resistance of a zirconia all-ceramic restoration body can be improved remarkably and the service life can be prolonged.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Glass ceramic with high elasticity modulus, and reinforced glass ceramic and preparation method thereof

The invention provides a glass ceramic with high elasticity modulus. The principal crystalline phase of the glass ceramic is composed of at least two selected from the group consisting of lithium silicate, lithium disilicate, petalite and ZrO2. The glass ceramic comprises 18%-30% of Li2O in molar percentage, and the crystal size of the glass ceramic is 10-80 nm; the elastic modulus of the glass ceramic is at least 90 Gpa. The glass ceramic comprises the following components in percentage by mol: 55-70% of SiO2, 3-10% of Al2O3, 1-6% of P2O5, 0.5-5% of ZrO2, 0.5-5% of Na2O, 18-30% of Li2O and 0-3% of Ta2O5. The glass ceramic further comprises at least one of the following oxides: 0 to 0.5% of CeO2, 0 to 0.5% of SnO2, 0 to 5% of B2O3, 0 to 5% of ZnO and 0 to 5% of MgO. The invention relates to the glass ceramic with high Li content; the network structure of the glass ceramic is compact; the obtained principal crystalline phase is composed of lithium disilicate and a beta quartz solid solution; due to the high crystallization ratio and crystal type of the glass ceramic, a material with elasticity modulus higher than 90 Gpa can be obtained; and a glass ceramic material with visible light transmittance higher than 90% can be obtained by controlling the crystal size, and the glass ceramic material can be used for window materials of aviation airplanes, high-speed rails, subways, carsand the like.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

Crystallized glass

InactiveUS8071493B2Low alkali contentSatisfactory surface propertyMagnetic materials for record carriersRecord information storageIn planeRaw material

In all of an in-plane magnetic recording system and a perpendicular magnetic recording system, there is provided a crystallized glass for a disk substrate for information recording medium, etc., which has satisfactory surface properties capable of sufficiently adapting with a lamp loading system for high-density recording, has high strength such that it is able to withstand high-speed rotation and impact, has heat expansion properties and heat resistance in agreement with respective drive members, has a low melting temperature, has excellent productivity and is reduced in the elution amount of an alkali from the raw material, namely excellent in chemical durability. The crystallized glass of the invention is a crystallized glass containing an SiO2 component and an Li2O component; further containing at least one member selected from an SrO component and a BaO component in a total content of more than 3.5% and not more than 15% in terms of % by mass; and containing at least one member selected among lithium disilicate, lithium monosilicate, α-quartz, an α-quartz solid solution and a β-quartz solid solution as a main crystal phase on the oxide basis.

Owner:OHARA

Method for preparing glass-ceramics, capable of adjusting machinability or translucency through change in temperature of heat treatment

ActiveUS20180257973A1Improve machinabilityExcellent chemical durabilityArtificial teethSilicon dioxideGlass-ceramic

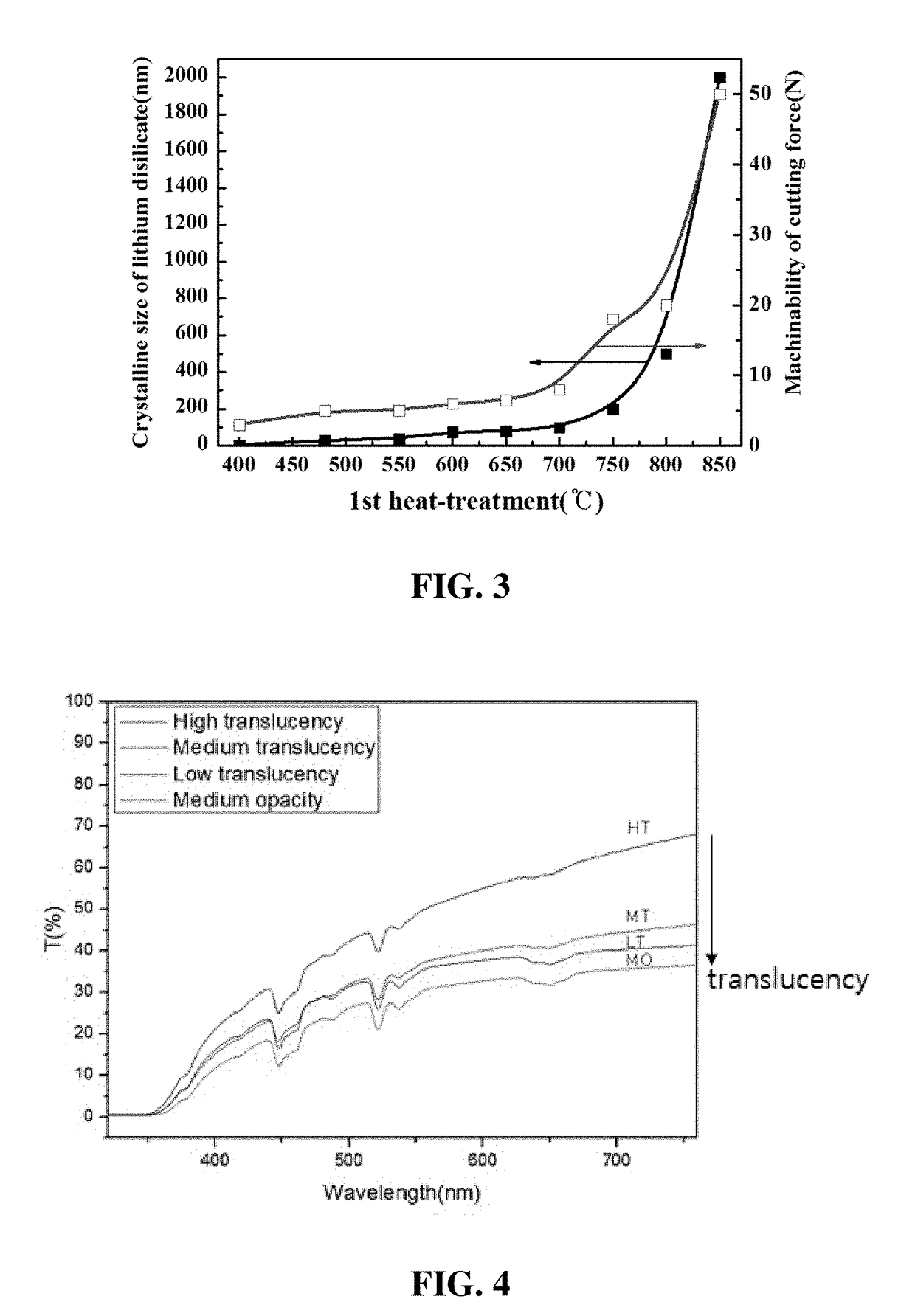

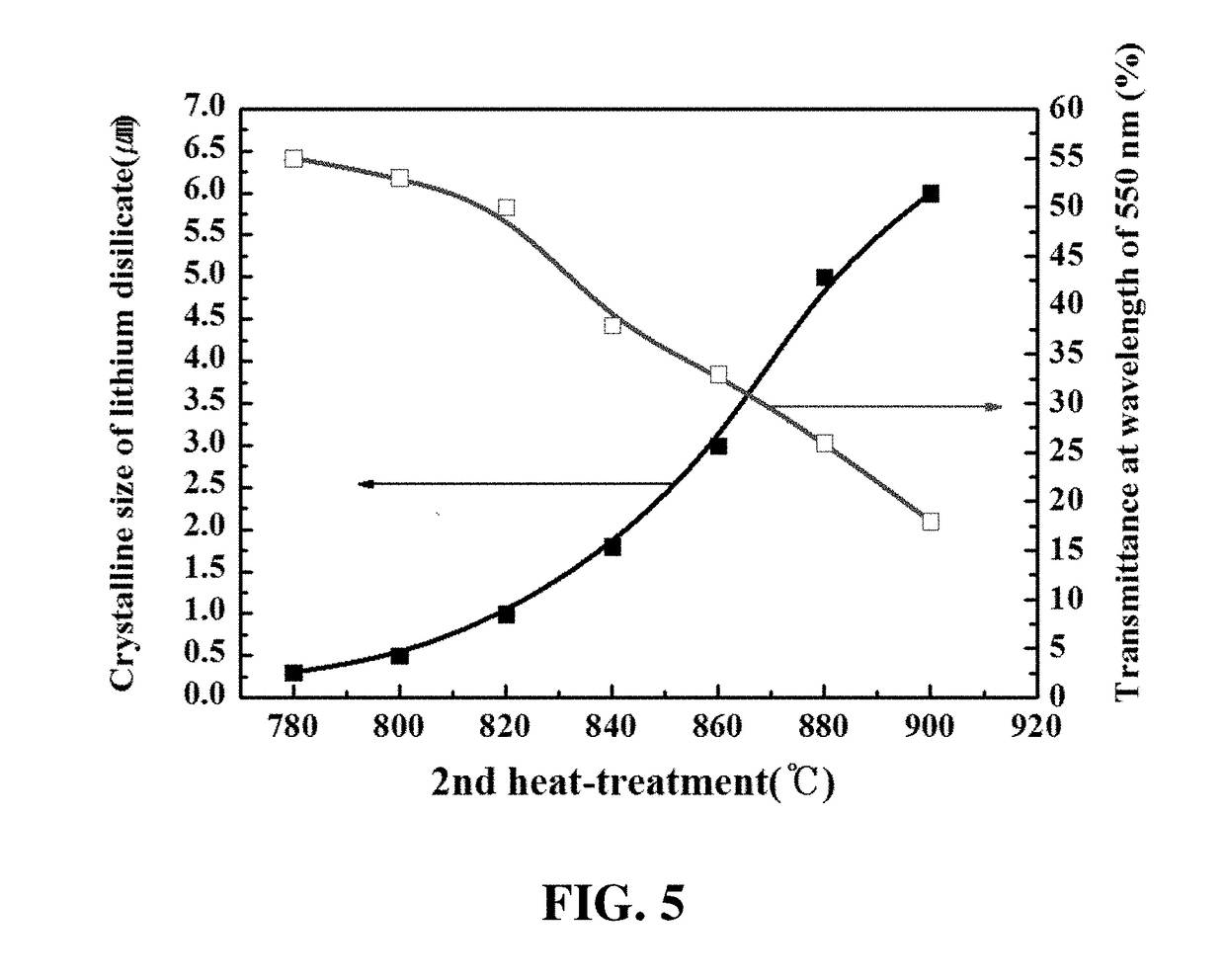

The present invention relates to a method for preparing a lithium disilicate glass-ceramics containing silicate as a main component, and more particularly, to a method for preparing a glass-ceramics, which is capable of adjusting machinability or translucency according to a crystalline size by using a first heat treatment or a second heat treatment. To this end, a method for preparing a glass-ceramics containing a silica crystalline phase includes: performing a first heat treatment on a glass composition at a temperature of 400 to 850° C., so that a lithium disilicate crystalline phase and a silica crystalline phase each having a size of 5 to 2,000 nm are formed through the first heat treatment. After the first heat treatment, the method further includes performing a second heat treatment at a temperature of 780 to 880° C., so that translucency is adjusted by a temperature of the second heat treatment.

Owner:HAAS & CO GMBH

High-strength bacteriostatic antibacterial lithium disilicate glass ceramic and preparation method thereof

ActiveCN106746675AHigh strengthMaintain aestheticsImpression capsDentistry preparationsRestorative materialHigh intensity

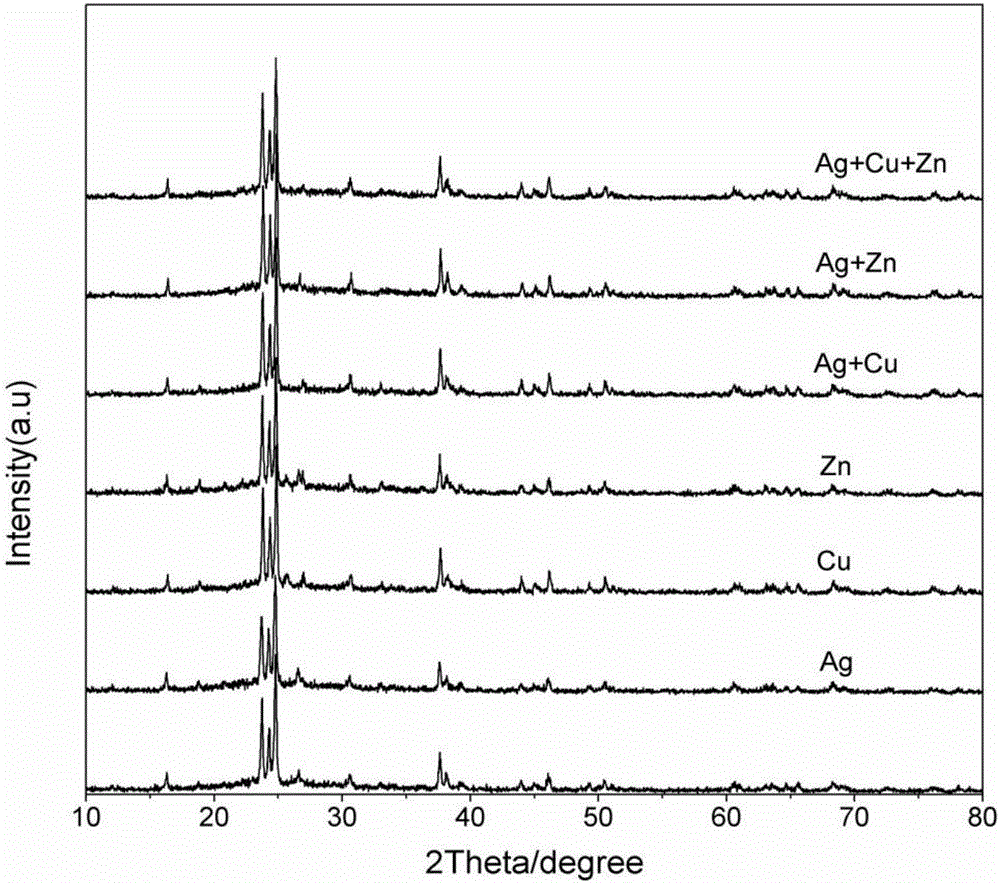

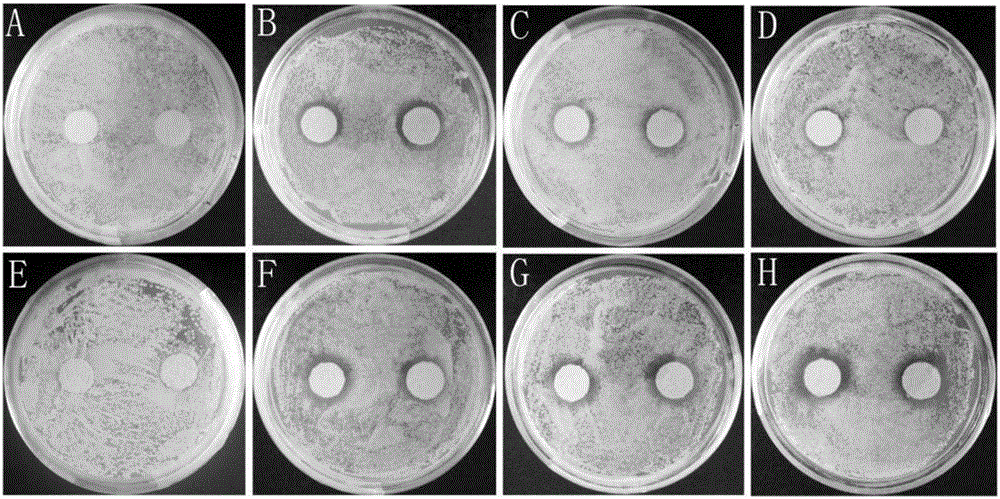

High-strength bacteriostatic antibacterial lithium disilicate glass ceramic and a preparation method thereof belong to the technical field of biological materials. In the prior art, a dental department all-ceramic restorative material obtained by doping Ag<+>, Zn<2+> and Cu<2+> in lithium disilicate glass ceramic does not exist. The high-strength bacteriostatic antibacterial lithium disilicate glass ceramic is characterized by preparing materials for matrix glass according to the weight percentage of the matrix glass, additionally determining the total weight of Ag2O, ZnO and CuO in the high-strength bacteriostatic antibacterial lithium disilicate glass ceramic according to the ratio of 0.1 to 8 percent of the weight of the matrix glass, and preparing the matrix glass by adopting a high temperature melting method, wherein the content of the Ag2O is larger than or equal to 0 percent but less than or equal to 2 percent, ZnO is larger than or equal to 0 percent but less than or equal to 5 percent and CuO is larger than or equal to 0 percent but less than or equal to 1 percent, wherein only the content of AgO2, ZnO and CuO is allowed to be equal to 0 at the same time; coring the prepared matrix glass at the temperature of 450 to 550 DEG C for 1.5 to 2.5 hours; performing three-step crystallization: crystallizing at the temperature of 650 to 680 DEG C for 1 to 3 hours, crystallizing at the temperature of 710 to 740 DEG C for 20 to 60 minutes, crystallizing at the temperature of 800 to 830 DEG C for 10 to 20 minutes, so as to obtain the high-strength bacteriostatic antibacterial lithium disilicate glass ceramic.

Owner:CHANGCHUN UNIV OF SCI & TECH

High-strength and high-permeability lithium disilicate glass ceramic as well as preparation method and application thereof

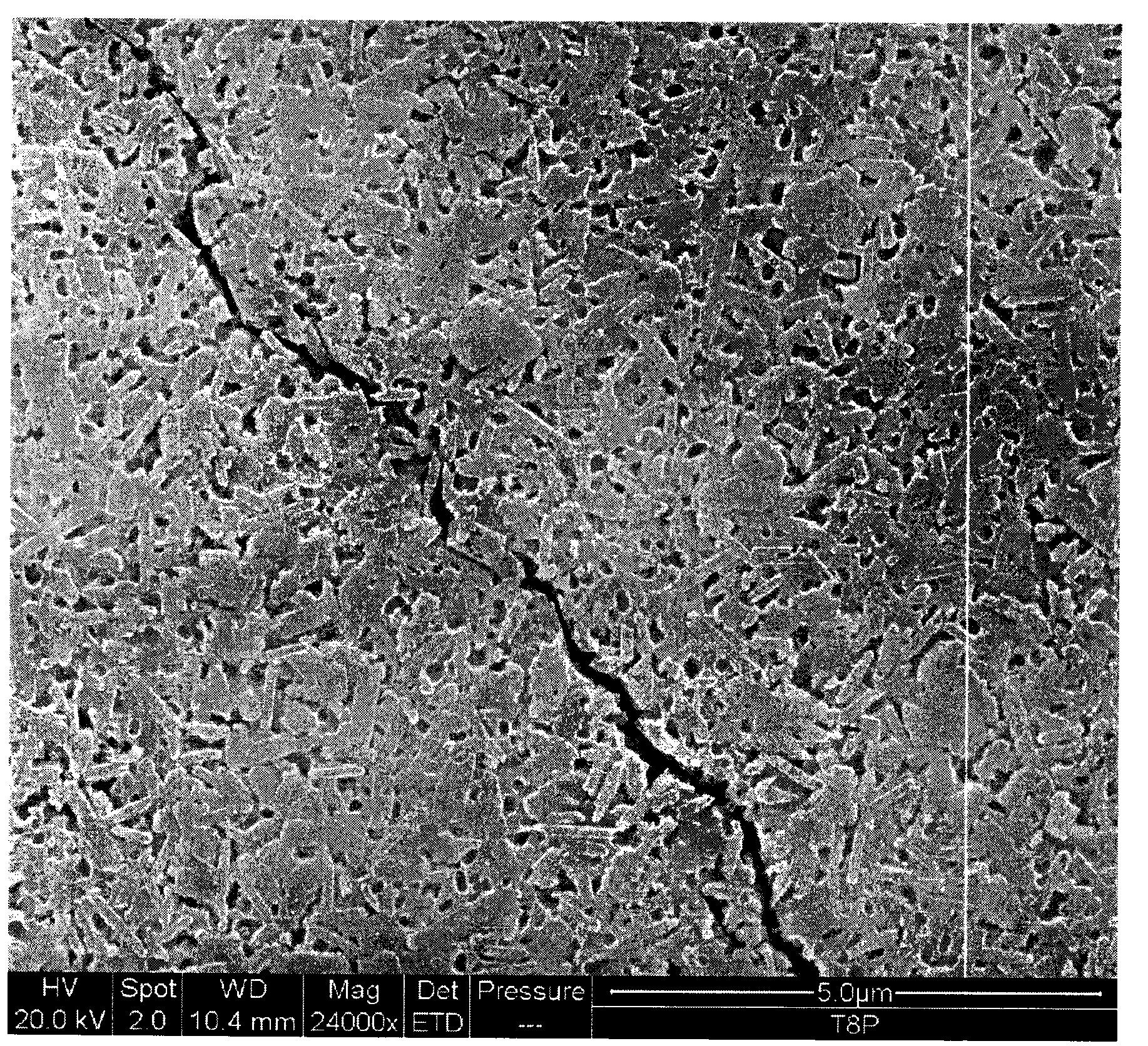

ActiveCN113501668AReduce scatterImprove fracture toughnessImpression capsGlass furnace apparatusOptical transmittanceLithium metasilicate

The invention provides a high-strength and high-permeability lithium disilicate glass ceramic and a preparation method and application thereof. The lithium disilicate glass ceramic with lithium disilicate as a main crystalline phase and lithium metasilicate, lithium phosphate or quartz as an impure phase is prepared by optimizing the raw material ratio and regulating and controlling heat treatment conditions, wherein the size of lithium disilicate crystals is larger than 700 nm, and the length-diameter ratio is not less than 3. The three-point bending strength of the lithium disilicate glass ceramic is 450-750 MPa, the fracture toughness of the lithium disilicate glass ceramic is higher than 3.5 MPa.m<1 / 2>, and the optical transmittance of a sample with the thickness of 1 mm at 550 nm is adjustable within 10%-80%. The lithium disilicate glass ceramic has excellent properties of high strength and high permeability, effectively reduces the risk of restoration collapse, better simulates the toughness and light transmittance of natural teeth, and has a better application prospect.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

Lithium disilicate microcrystalline glass material prepared by using hybrid reaction sintering method and method

The invention provides a lithium disilicate microcrystalline glass material prepared by using a hybrid reaction sintering method and the method. Raw materials for the material comprise lithium metasilicate crystal powder M, quartz sand glass powder S and lithium disilicate basic glass powder D, wherein a mol ratio of M to S to D is 1: 1-2: 0-8. The method comprises the following steps: subjecting lithium metasilicate glass and lithium disilicate basic glass to melting, water quenching and ball milling so as to prepare glass powder; subjecting lithium metasilicate glass powder to crystallization to obtain a crystal; adding the quartz sand glass powder and the lithium disilicate basic glass powder D; and uniformly mixing the above-mentioned three powders and carrying out sintering in a vacuum hot-pressing furnace so as to prepare lithium disilicate microcrystalline glass. The lithium disilicate microcrystalline glass produced by using the method has bending strength of 255 to 420 MPa and fracture toughness of 2.6 MPa.m1 / 2 to 3.5 MPa.m1 / 2. Compared with the prior art, the invention has the following advantages: production cost is reduced; desired pigments can be added into the mixed powder before sintering, which enables the problem of difficult color matching in a melting method to be overcome; a long rod-like crystal grain with length 5 times the size of a single glass powder sintered body is prepared; and a novel approach is opened up for toughening the lithium disilicate microcrystalline glass.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com