Lithium silicate microcrystalline glass and lithium disilicate microcrystalline glass with high permeability, and preparation method and application thereof

A technology of glass-ceramics and lithium disilicate, which is applied in the field of dental restoration materials and biological materials, can solve the problems of low light transmittance and undisclosed light transmittance of lithium disilicate glass-ceramics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0069] Preparation of the basic glass block:

[0070] According to the percentage by weight of each component of the glass described in each embodiment listed in Table 1, take by weighing analytically pure SiO 2 , Li 2 CO 3 、K 2 CO 3 、Al 2 o 3 、TiO 2 and CeO 2 , after fully mixing and grinding with a planetary ball mill, take it out and dry it; put the powder obtained after drying in a platinum alloy crucible, put it in a box-type resistance furnace, and raise the temperature to 1200 ° C ~ 1600 ° C in an air atmosphere, and keep the temperature constant 1h to 5h, and then take it out at 1400°C and cast it into a basic glass block. The base glass block obtained by casting is about 30 grams.

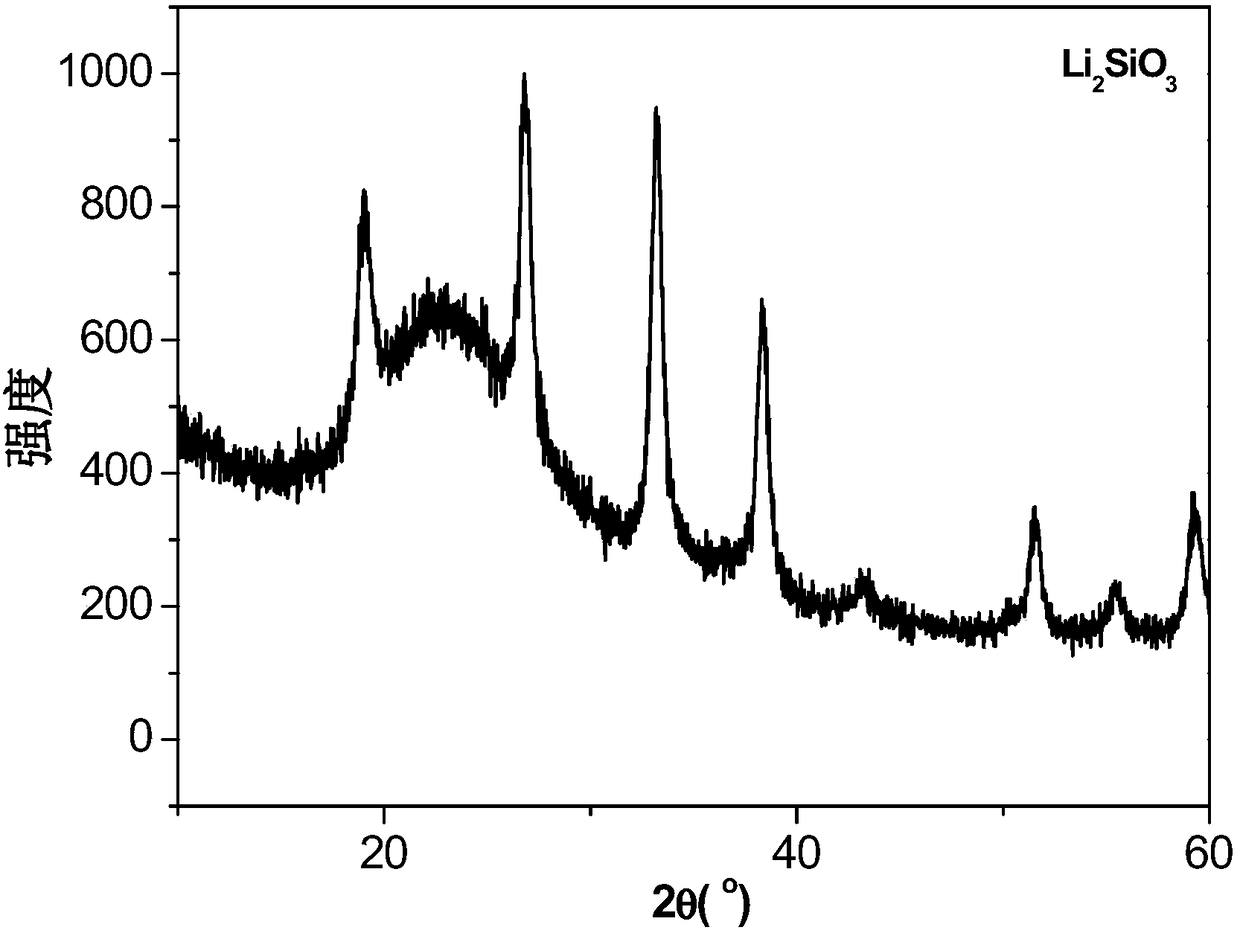

[0071] Preparation of lithium silicate glass-ceramics containing nano-lithium silicate crystals:

[0072] After heat-treating the glass blocks obtained in each example at 500°C to 750°C for 5min to 60min, a single crystal phase of lithium silicate is precipitated to obtain lithiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com