Patents

Literature

73 results about "Lithium metasilicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium metasilicate is an ionic compound with the formula Li₂SiO₃

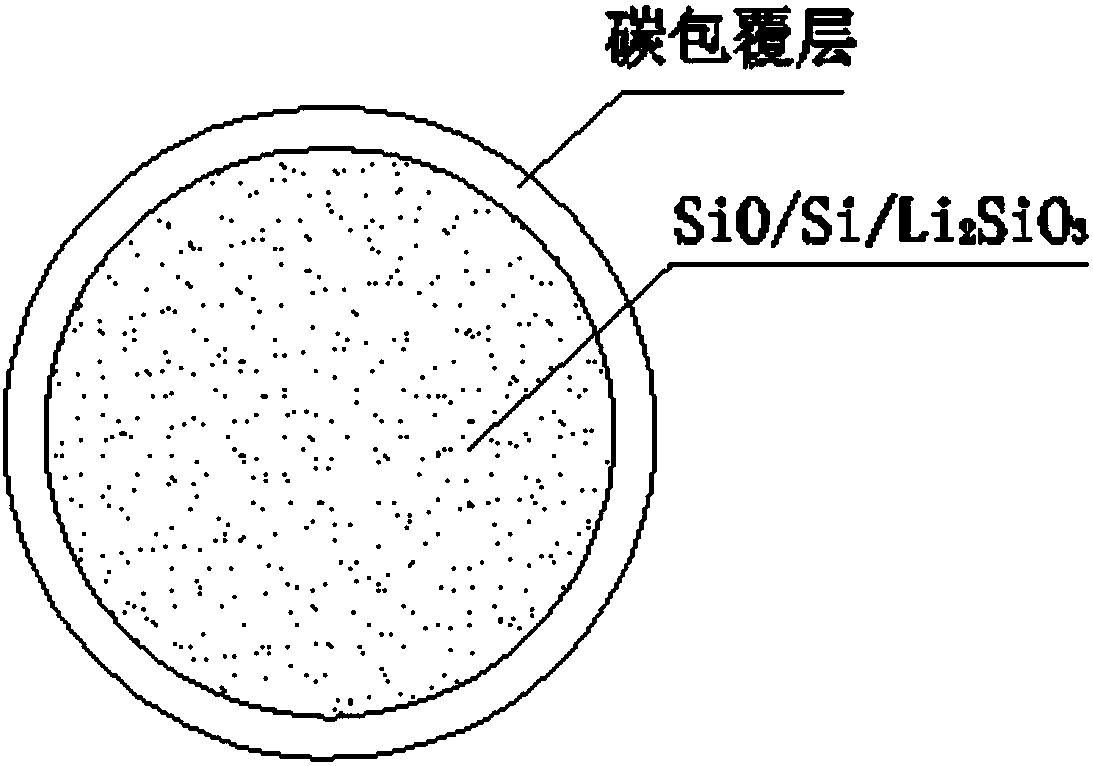

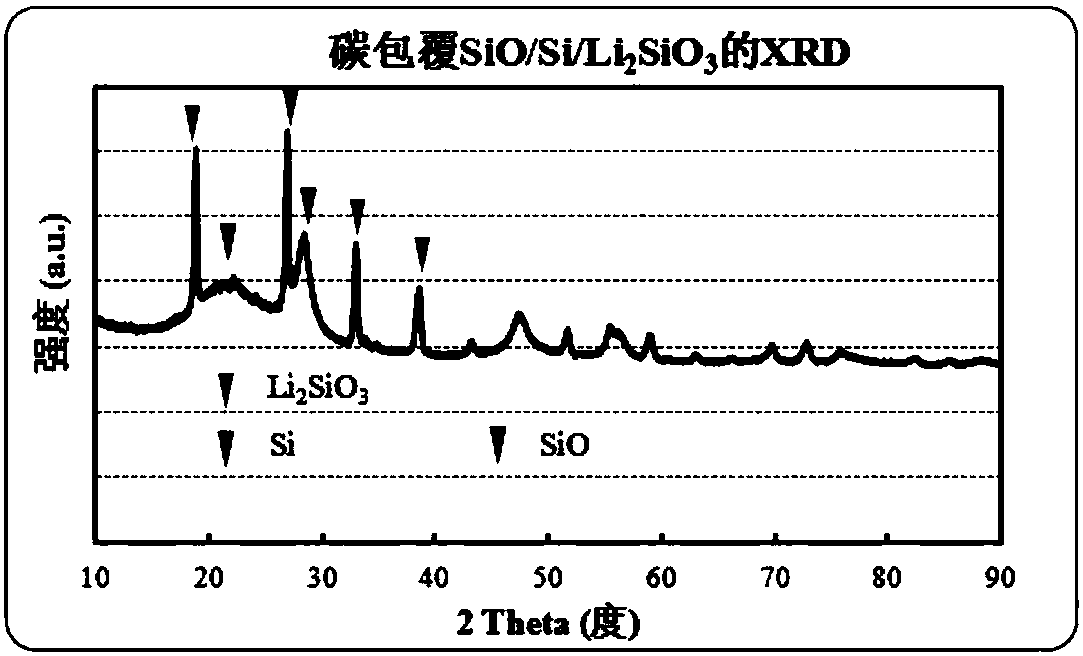

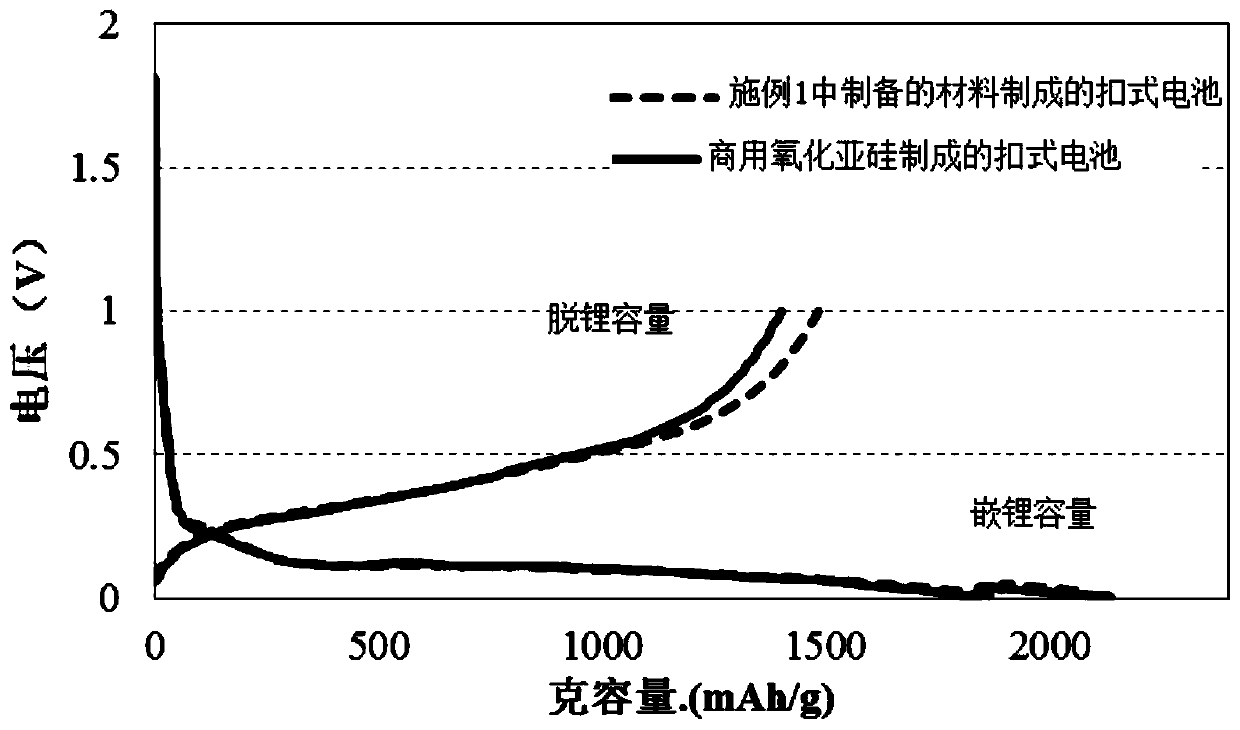

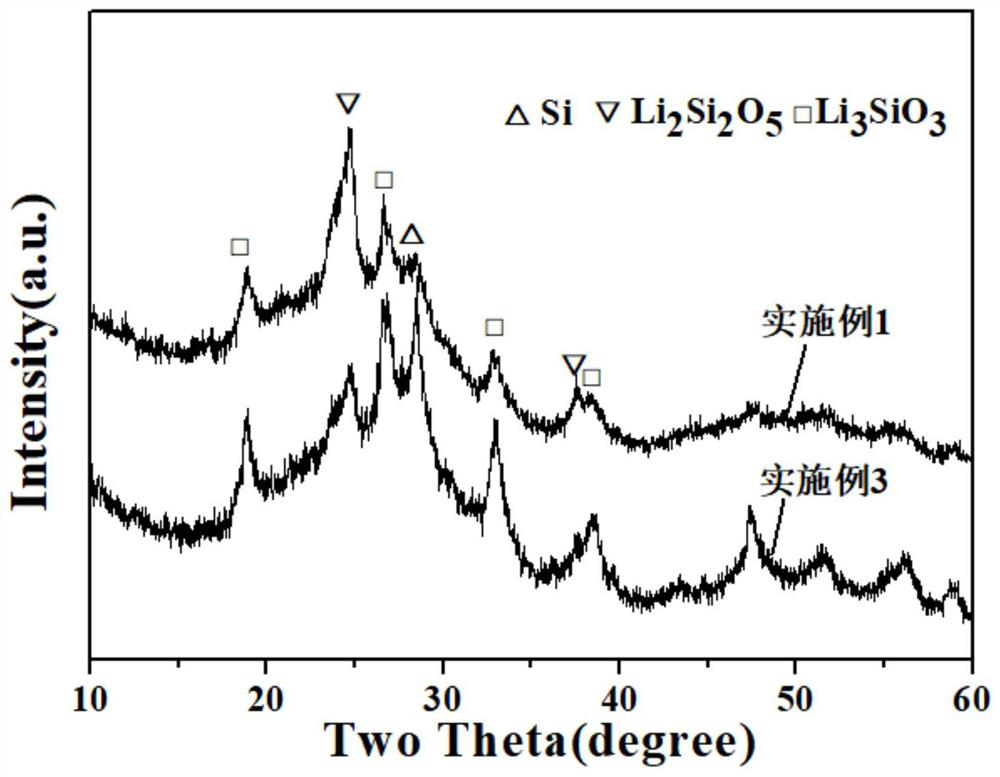

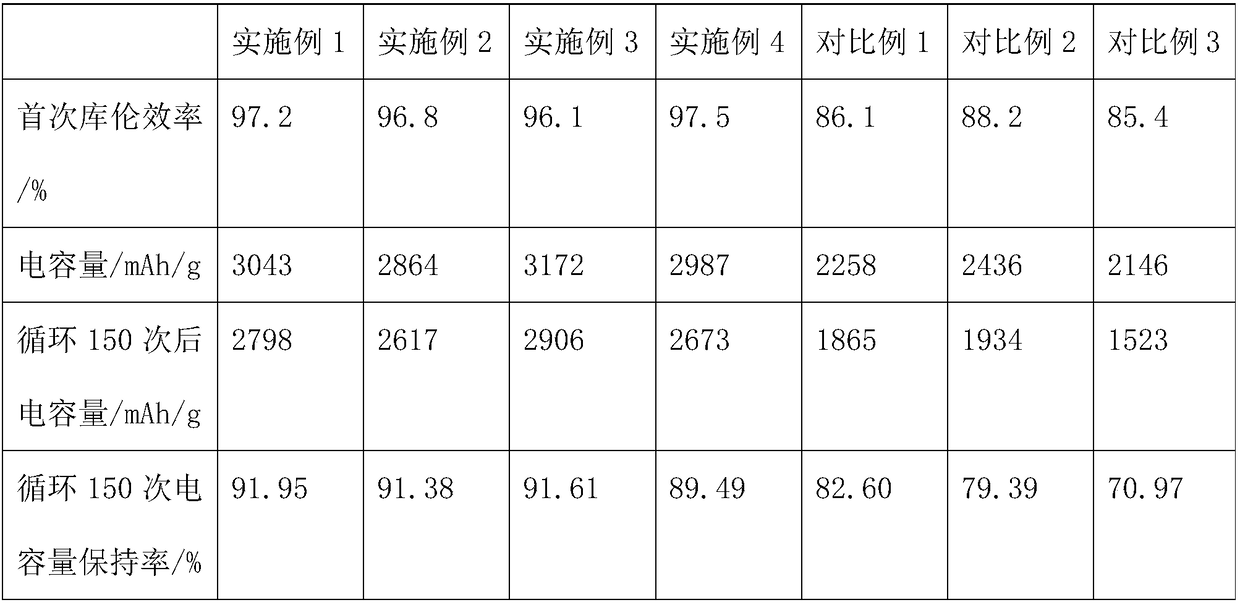

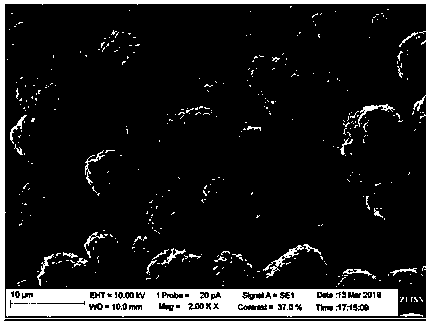

Silicon monoxide/silicon/lithium metasilicate composite negative electrode material and preparation method thereof

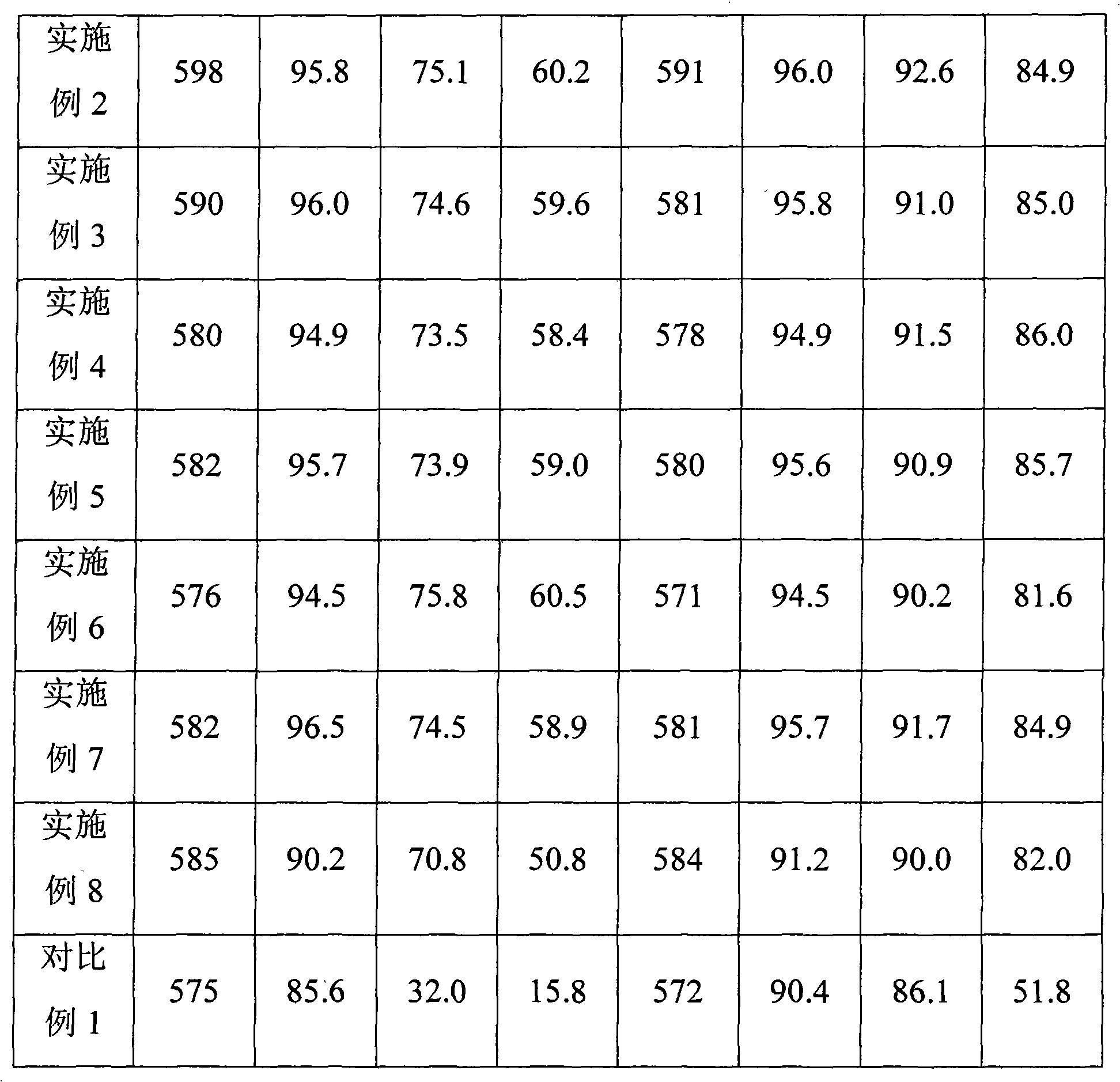

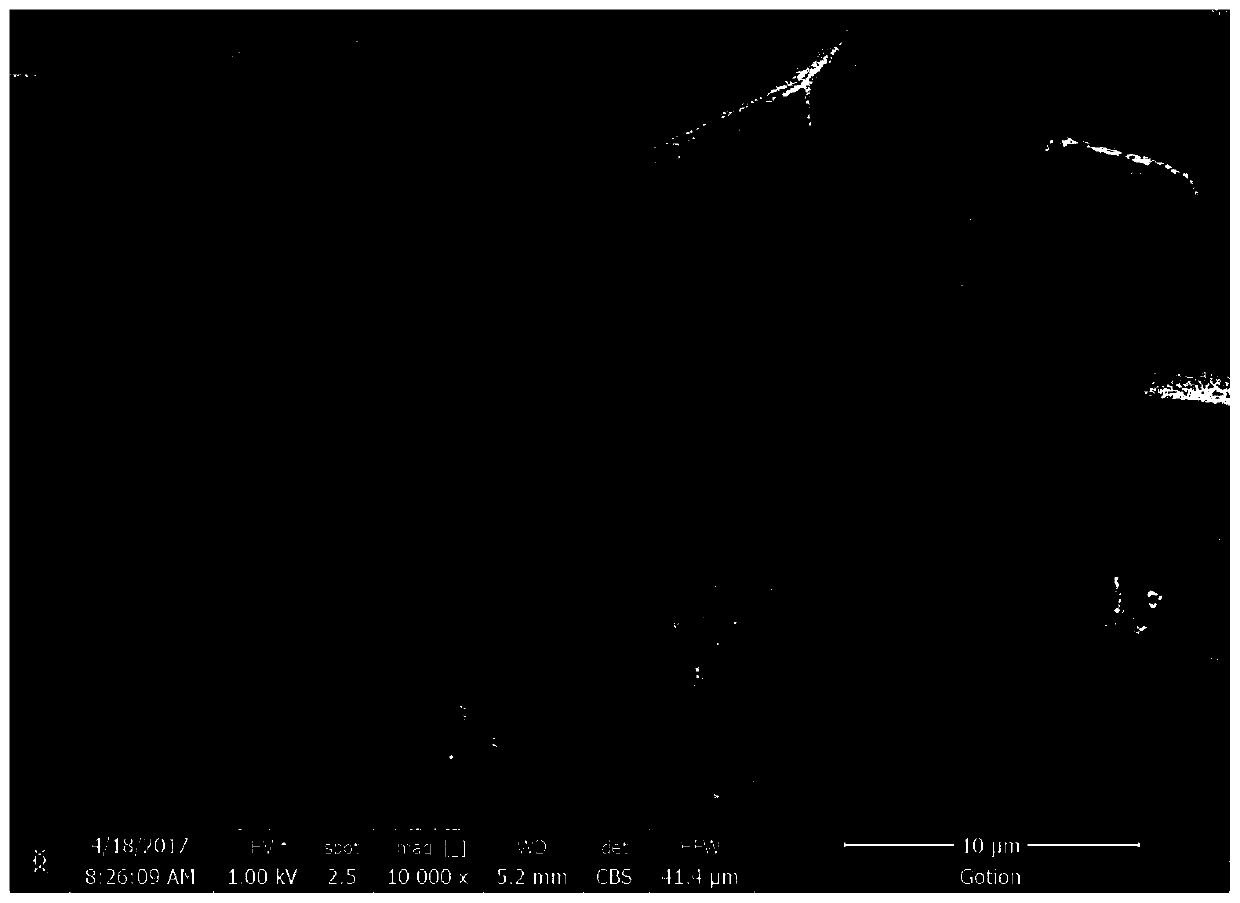

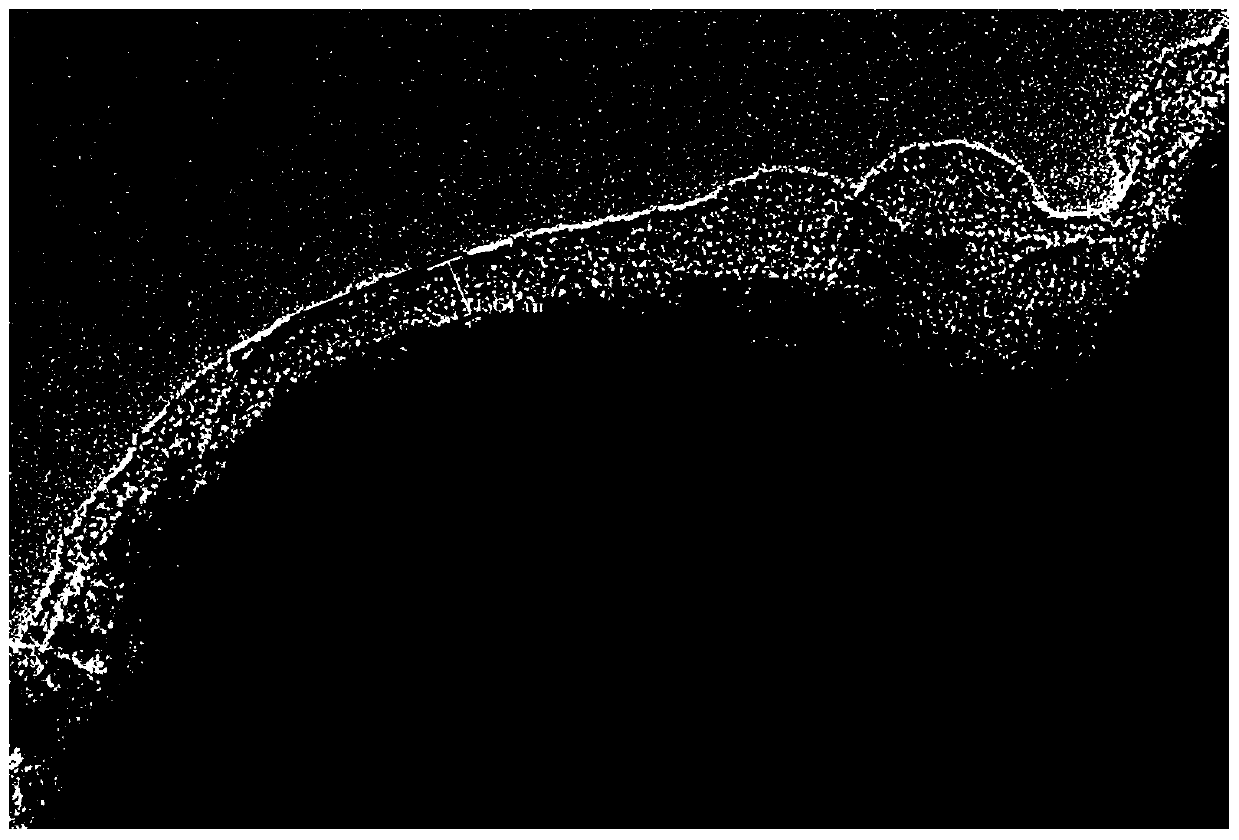

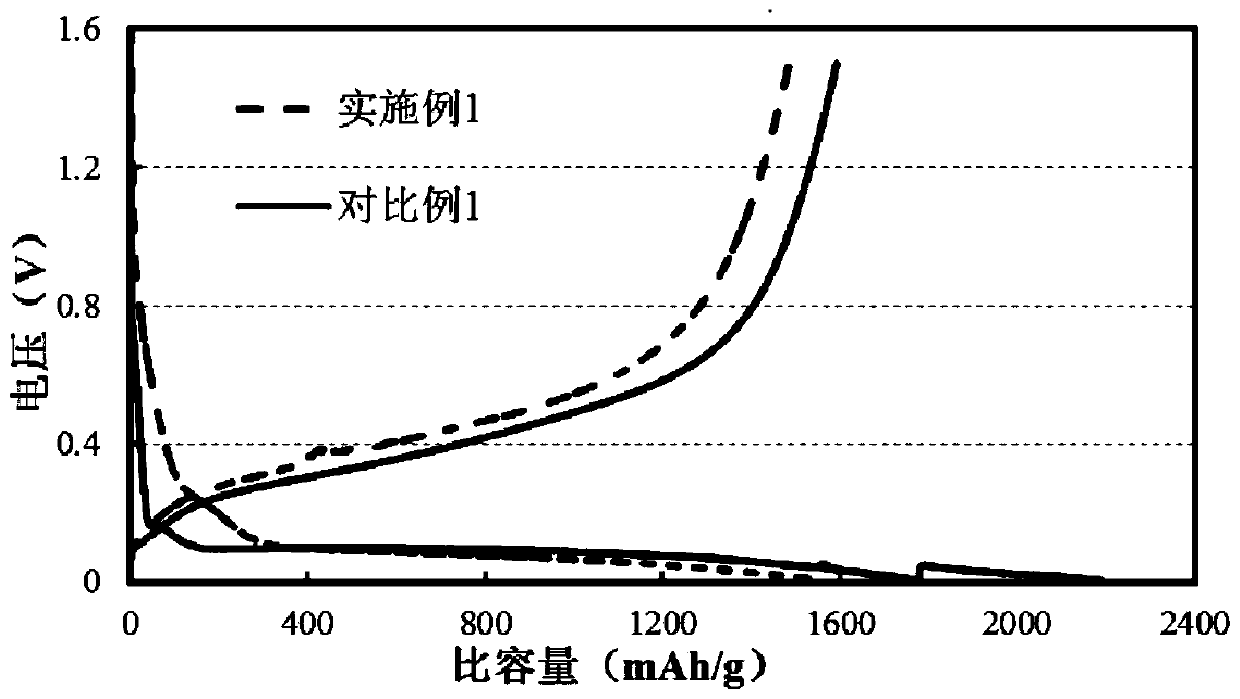

InactiveCN108269979AIncrease capacityImprove the first Coulombic efficiencyCell electrodesSilicon monoxideShielding gas

The invention discloses a silicon monoxide / silicon / lithium metasilicate composite negative electrode material. The silicon monoxide / silicon / lithium metasilicate composite negative electrode material comprises a silicon monoxide / silicon / lithium metasilicate composite material and an inorganic matter coating layer. The invention also provides a preparation method of the silicon monoxide / silicon / lithium metasilicate composite negative electrode material. The preparation method comprises the following steps: taking silicon monoxide and an inorganic compound of lithium element, mixing and ball-milling the silicon monoxide and the inorganic compound of the lithium element, sintering the obtained mixture in a protection gas environment, and naturally cooling the sintered mixture to obtain the silicon monoxide / silicon / lithium metasilicate composite material; and mixing and ball-milling the silicon monoxide / silicon / lithium metasilicate composite material and sintering the obtained mixture undera protection gas condition. The preparation method of the silicon monoxide / silicon / lithium metasilicate composite negative electrode material has the advantages of simplicity, safety, low cost, and easiness in operation and industrial production, and the obtained composite negative electrode material has the advantages of high reversible capacity, excellent cycle performances and high initial Coulomb efficiency.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

High-temperature antioxidizing paint for lowering oxidation burning of steel in heating furnace

InactiveCN101462859AReduce high temperature oxidation burning lossReduce oxidation burning loss per unit areaLithium metasilicateHigh pressure water

The invention relates to a high temperature anti-oxidation coating capable of reducing the oxidation burning loss of stainless steel in a heating furnace. The high temperature anti-oxidation coating is characterized in that the coating comprises solid materials consisting of 46 to 92 percent of basic filler and 8 to 54 percent of composite binder, and water which is 0.5 to 20 folds of the weight of the solid materials. The basic filler comprises several chemical components selected from silicon dioxide, alumina, magnesia, calcium oxide and boric oxide. The composite binder consists of several components selected from sodium silicate, lithium metasilicate and aluminum phosphate. The coating can be painted at the normal temperature or sprayed onto the surface of a stainless steel billet from the room temperature to 1,000 DEG C. The coating can form a protective coat at the high temperature, thereby greatly reducing the high temperature oxidation burning loss of stainless steel at 1,400 DEG C, and reducing the unit area oxidation burning loss by more than 90 percent. After stainless steel is drawn out of the furnace, the iron oxide scale can be fully stripped off under the actions of temperature reduction or high pressure water; the amount of the produced iron oxide scale is also obviously reduced; and the stainless steel surface quality is remarkably improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

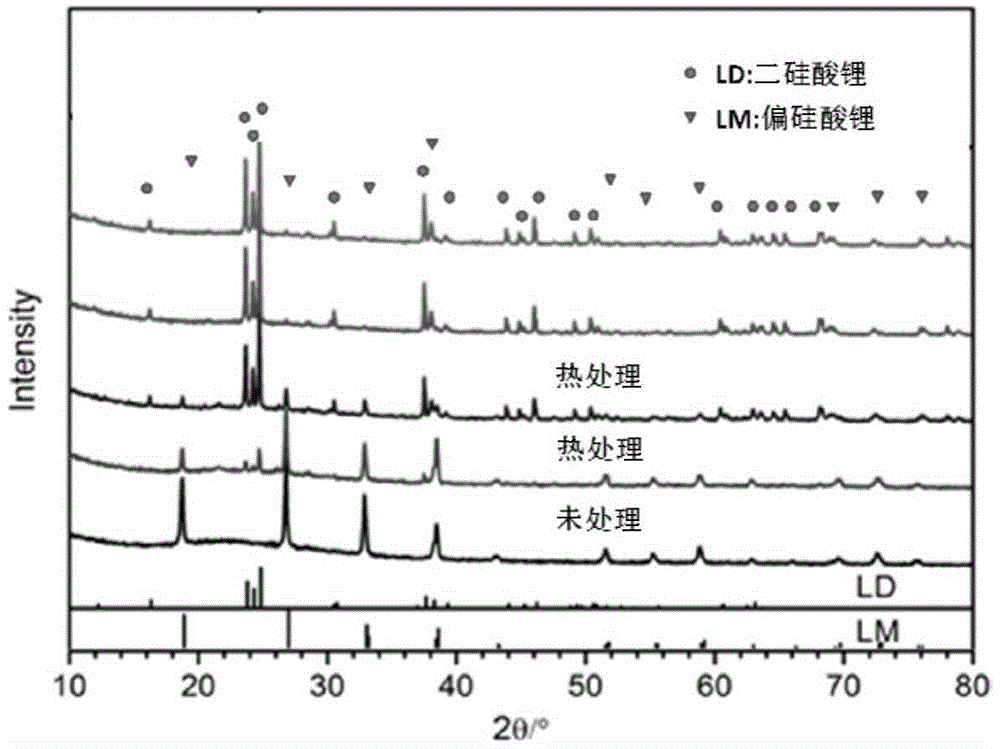

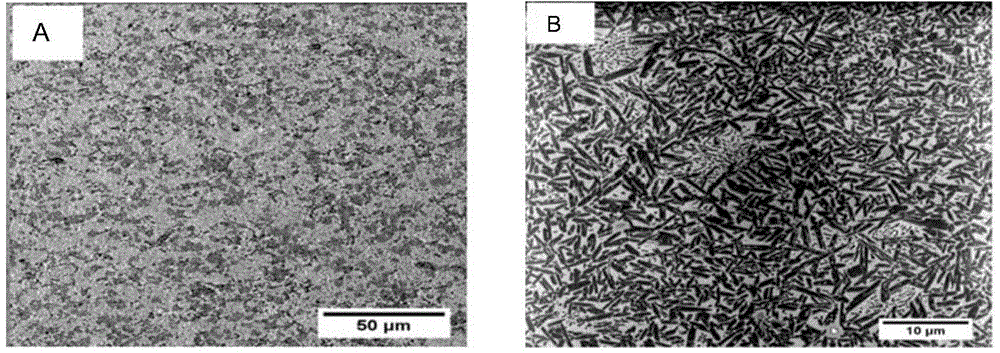

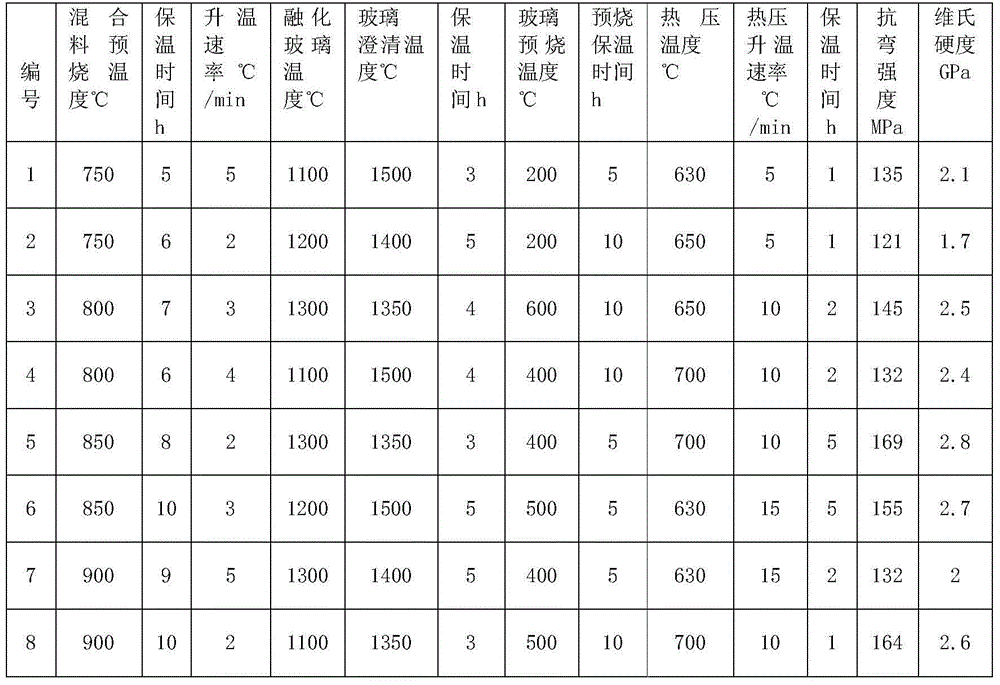

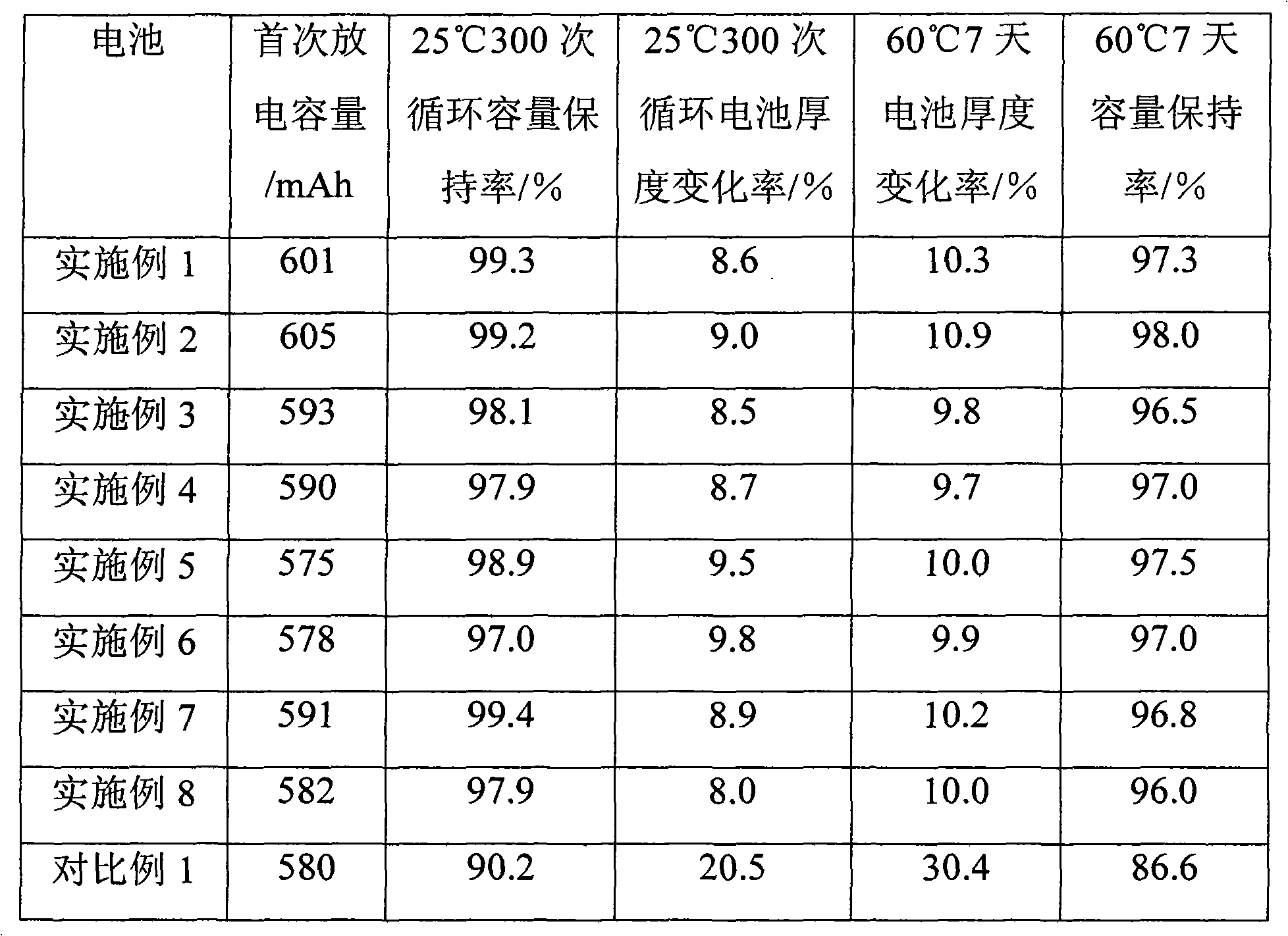

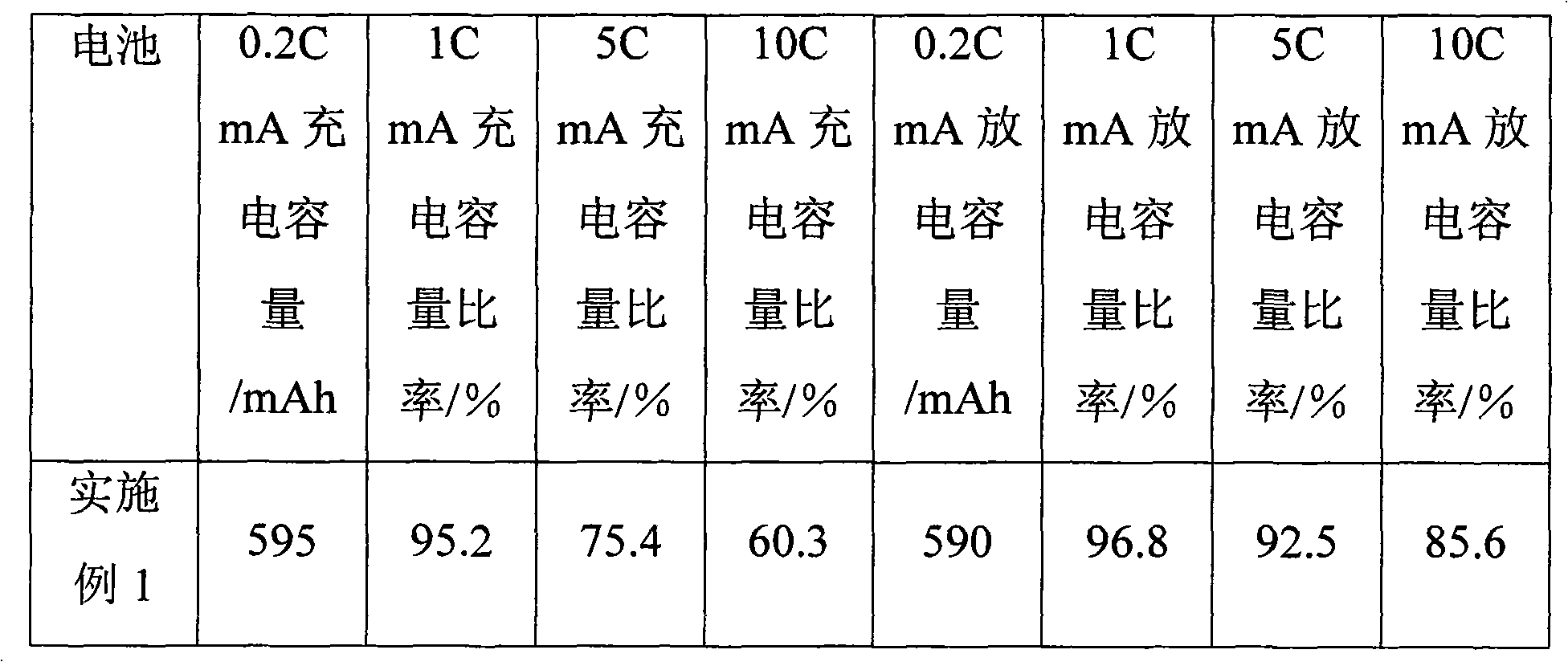

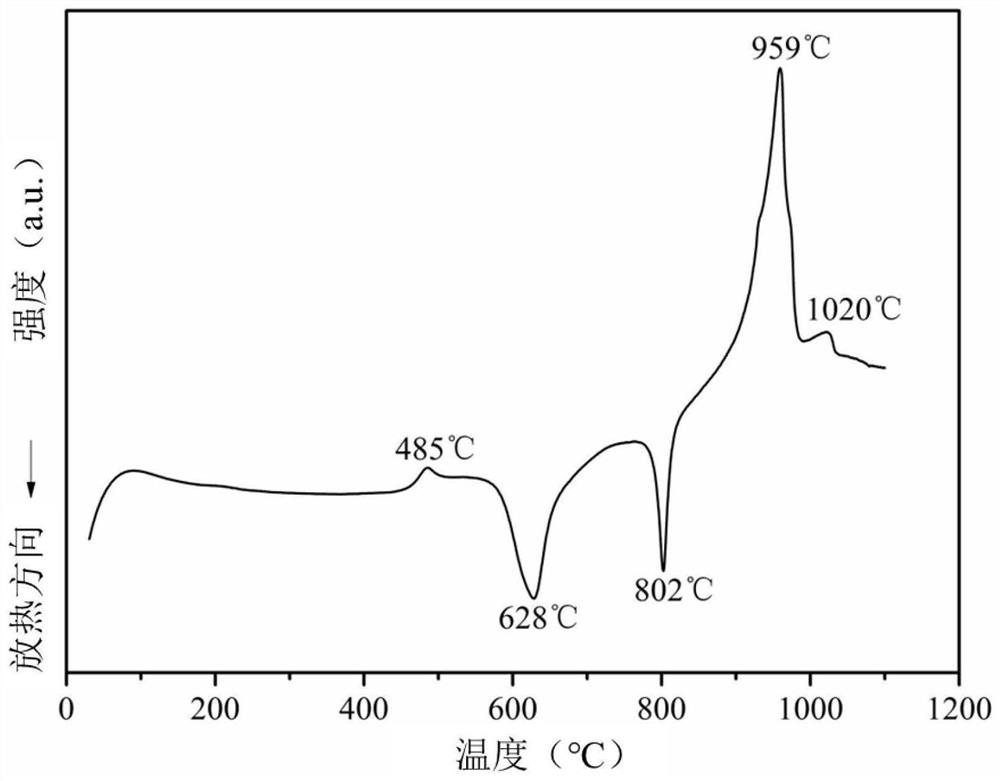

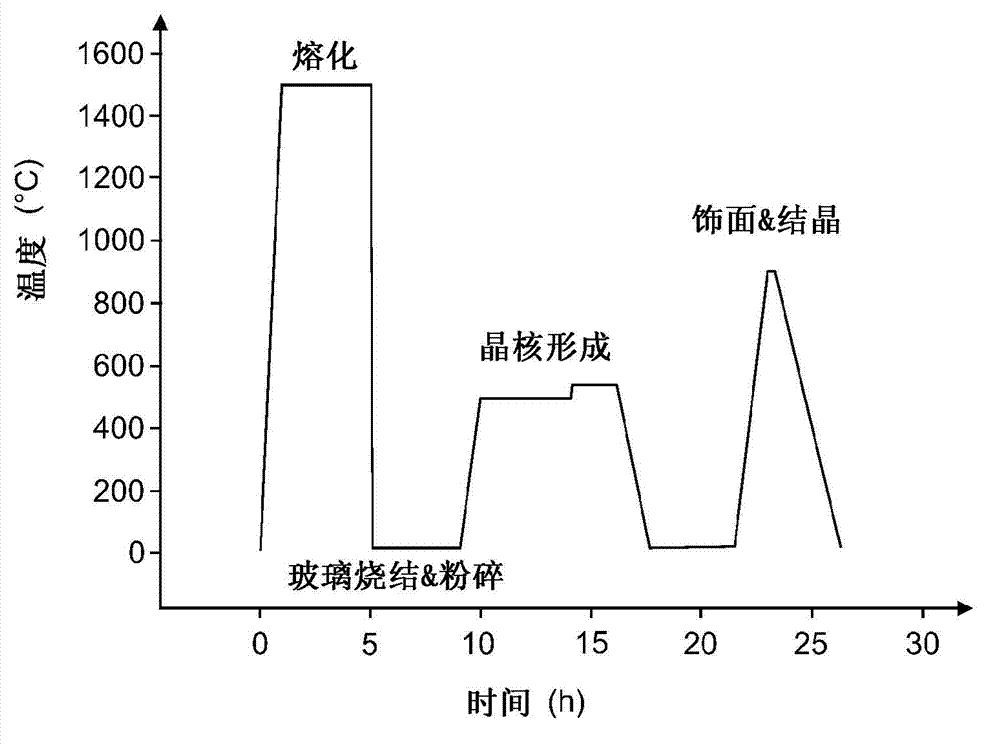

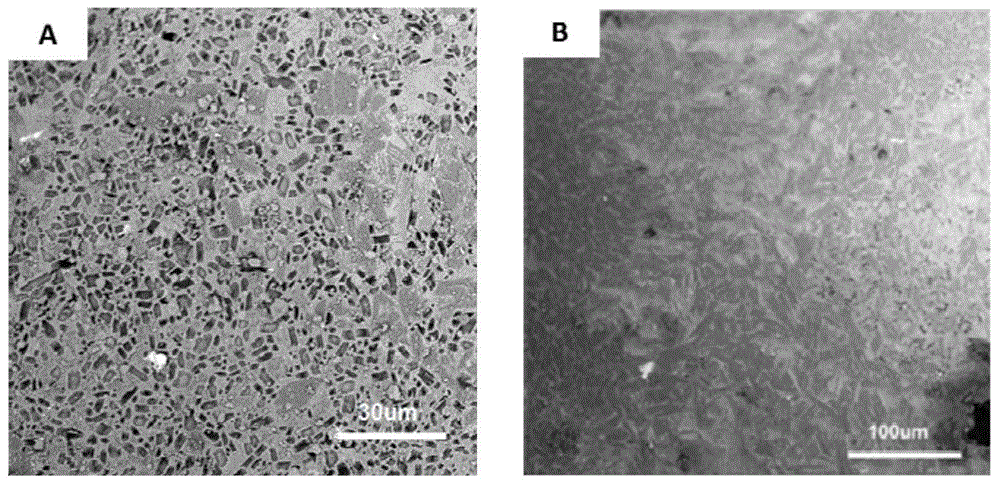

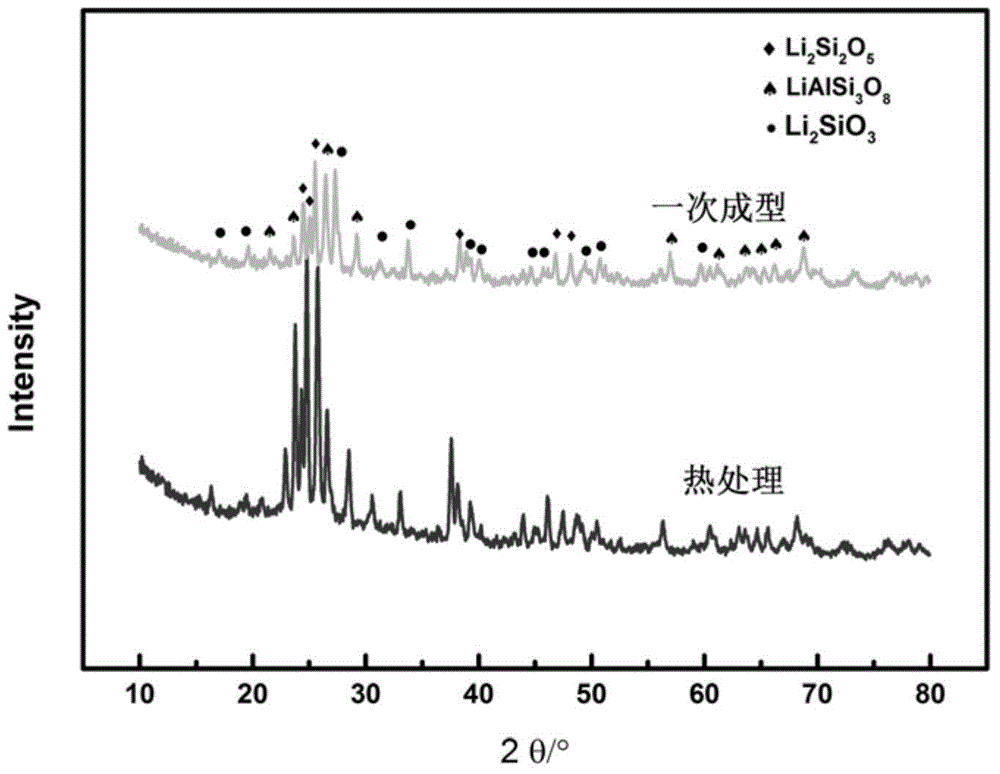

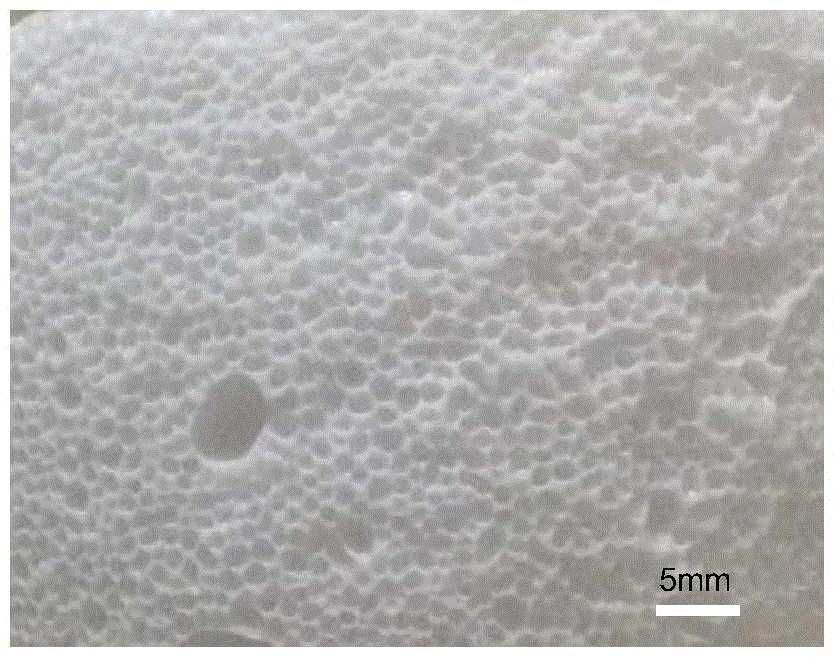

Preparation method for dental lithium silicate microcrystalline glass

ActiveCN104909571AReduce intensityHigh strengthImpression capsDentistry preparationsLithium metasilicateStructure function

The invention discloses a preparation method for dental lithium silicate microcrystalline glass. Glass powder is subjected to hot-pressing sintering, and after a compact lithium metasilicate microcrystalline glass body is formed, lithium metasilicate (Li2SiO3) crystals are converted into lithium disilicate (Li2Si2O5) crystals through heat treatment. The interior of the microcrystalline glass is uniform rod-shaped lithium disilicate (Li2Si2O5) crystals and has a rod-shaped interlock structure. Color matching agents can be intruduced in the hot-pressing sintering phase of the microcrystalline glass material, the obtained lithium metasilicate microcrystalline glass material has good processability, and unification of the manufacturability, mechanical properties and aesthetic functions of the obtained material is achieved. The technology is simple, the processability is strong, performances are stable, and the microcrystalline glass is suitable structure function integrated material.

Owner:XI AN JIAOTONG UNIV

Titanium composite, preparation method thereof and application thereof

ActiveCN101901905AImprove performanceEasy to preparePigmenting treatmentAlkali titanatesLithium chlorideHigh rate

Owner:BYD CO LTD

Powder pre-lithiated silicon-based negative electrode material, preparation method and application thereof

ActiveCN110212183AMake up for loose and porous defectsImprove cycle stabilityNegative electrodesSecondary cellsCarbon layerLithium oxide

The invention discloses a powder pre-lithiated silicon-based negative electrode material, a preparation method and application thereof. A lithium-containing carborane cluster compound coated silicon monoxide material is firstly prepared and obtained, then through segmented heating sintering, boron element in a lithium-containing carborane cluster compound is diffused into a silicon-based materialcontinuously, a part of silicon atoms are replaced to form displaced doping, and the vacancy current-carrying concentration is improved, so that the intrinsic electronic conductivity of the silicon material is improved. Moreover, in the high temperature sintering process, incompletely reacted lithium ions inside the lithium-containing carborane cluster compound react with silicon monoxide, and thebyproducts such as lithium metasilicate, lithium silicate and lithium oxide are further formed to realize pre-lithiation, so that the initial coulomb efficiency of the battery prepared from the material is improved. And then, a uniformly compact carbon layer is formed on the surface of the material through chemical vapor deposition, and the defect that the carbon layer formed by the carbonizationof the carborane cluster compound is relatively loosened and porous can be solved, so that the cycling stability of the material is further improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

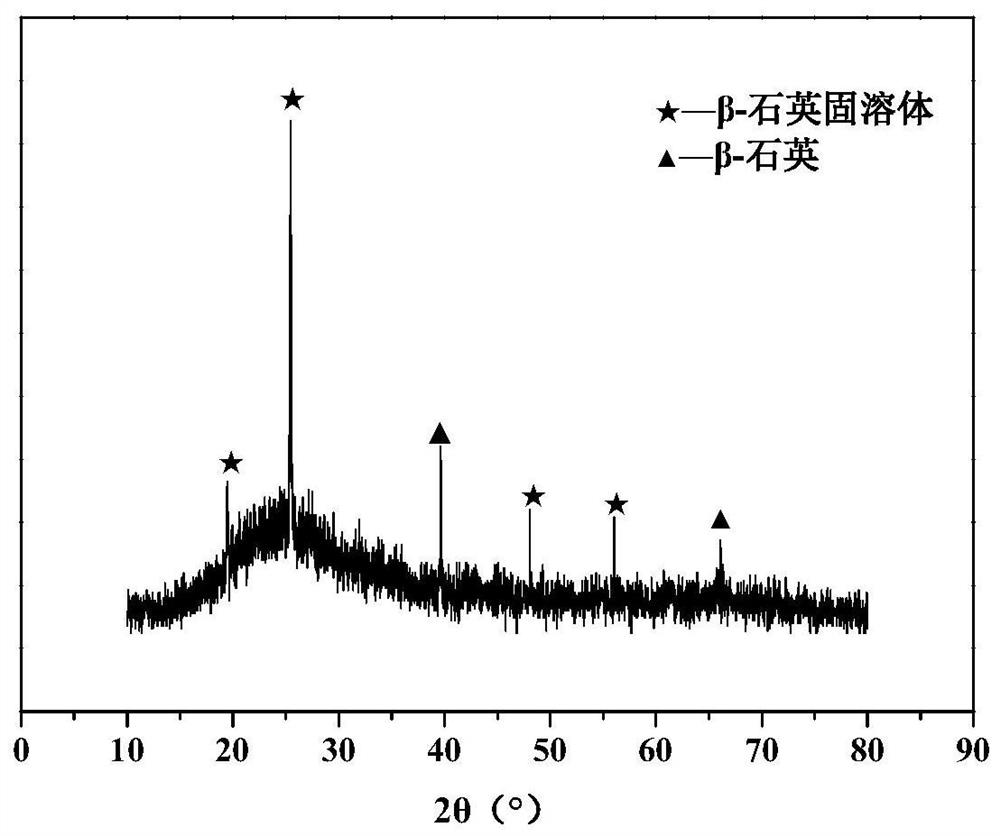

Lithium metasilicate glass ceramic and preparation method thereof

ActiveCN106277798ASimple production processLow requirements for production equipmentCrystal morphologyThermal insulation

Owner:SHENZHEN UPCERA DENTAL TECH

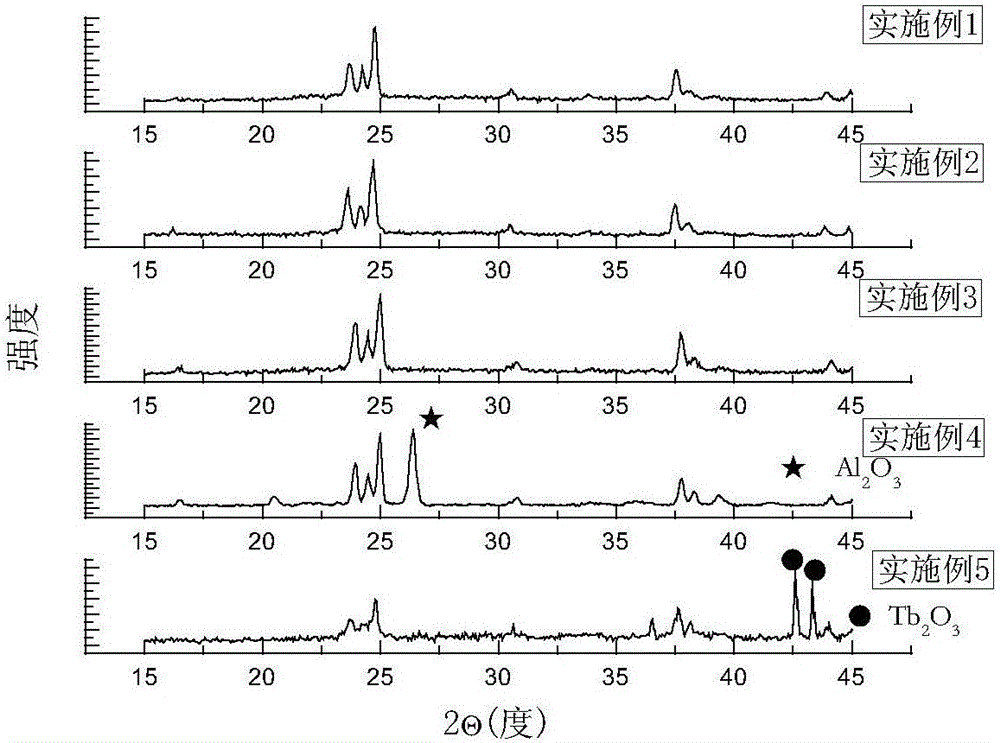

Lithium disilicate glass ceramic, preparation method thereof and application in dental material

ActiveCN106365456AImprove performanceHigh hardnessImpression capsDentistry preparationsRare-earth elementLithium metasilicate

The invention belongs to the field of medical materials and relates to a lithium disilicate glass ceramic, a preparation method thereof and application. The lithium disilicate glass ceramic is prepared from, by mass, SiO2 55%-65%, Li2O 16%-24%, P2O52 2%-5%, Al2O3 8%-12%, K2O 2%-5% and TbO2 1%-10%. According to the method, raw materials are subjected to pre-sintering, calcination, molding by casting and then are subjected to annealing, coring and crystallization to prepare a lithium metasilicate glass ceramic block, the lithium metasilicate glass ceramic block has very good machinability, and heat treatment is performed again after machining to obtain the lithium disilicate glass ceramic. The lithium disilicate glass ceramic prepared by the preparation method is doped with a specific content of rare earth element Tb, a glass grid structure can be destroyed, the viscosity can be reduced, crystallization is promoted, the hardness and bending strength of the glass ceramic are improved, and a novel method is provided for preparation of the lithium disilicate glass ceramic.

Owner:东北大学秦皇岛分校

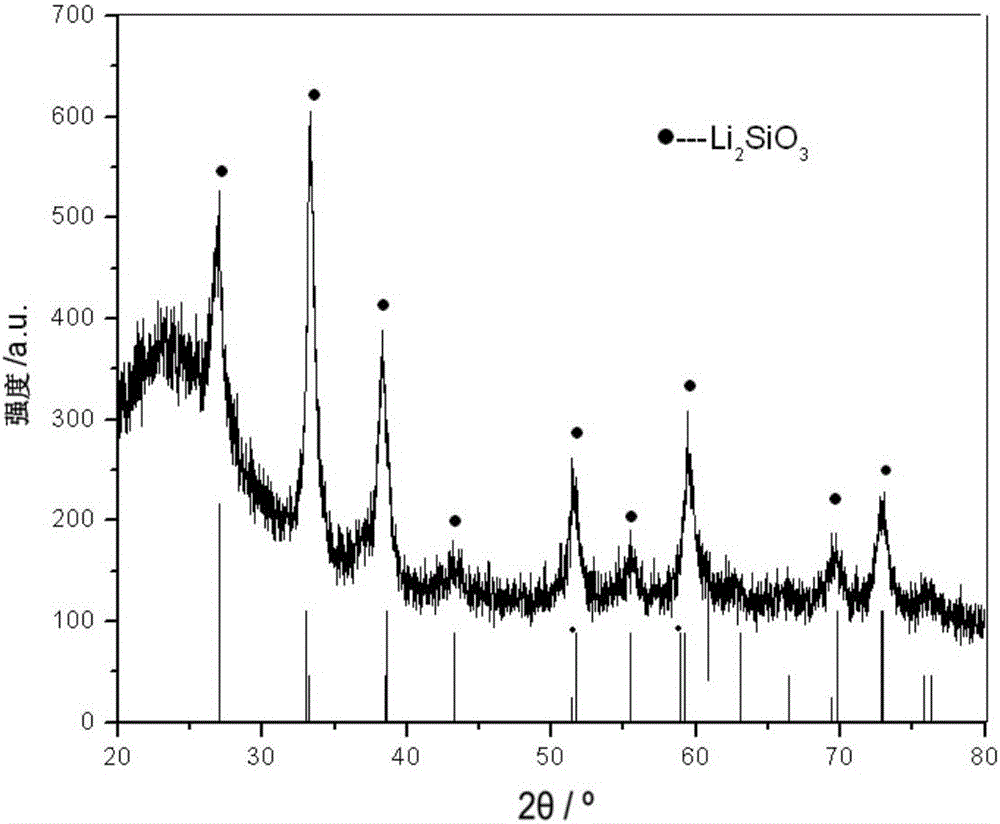

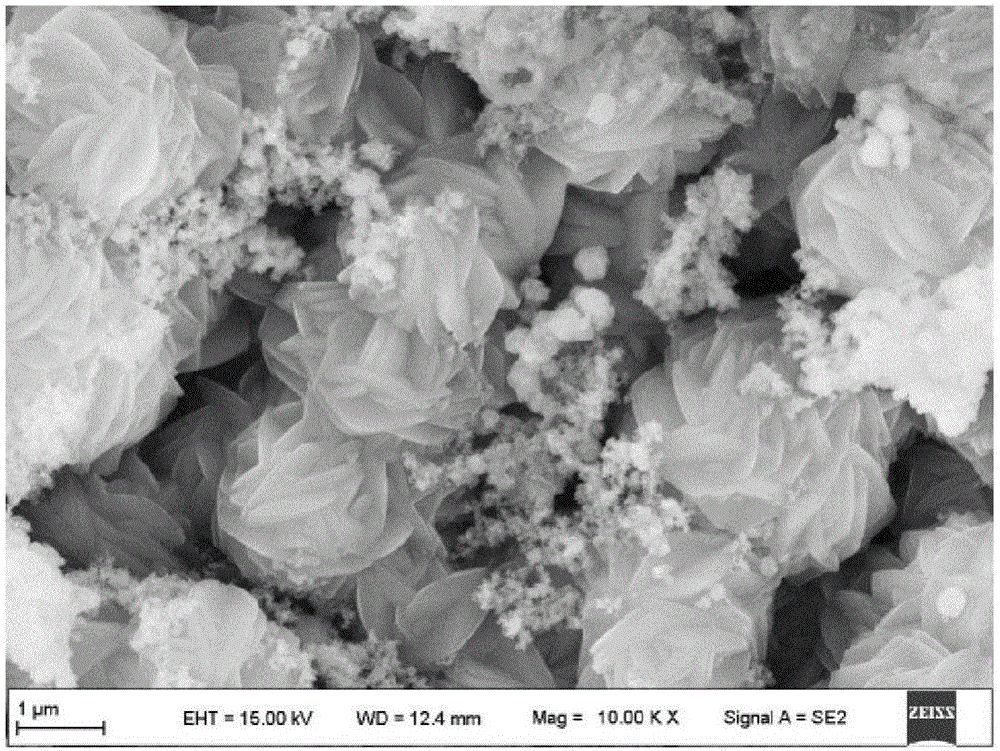

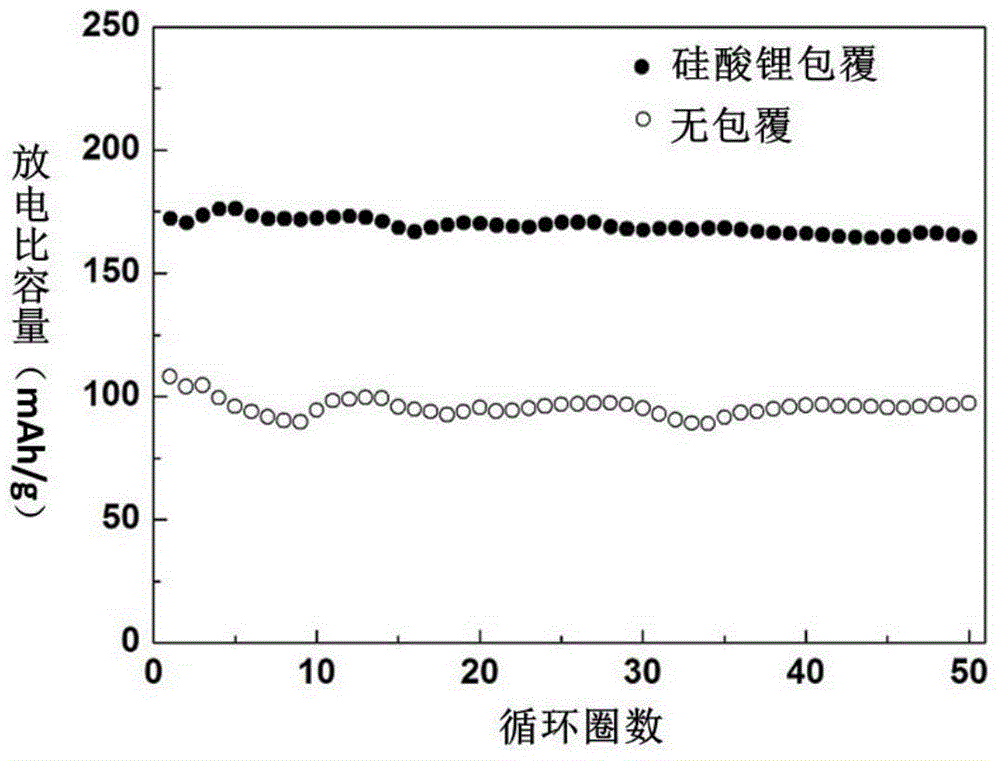

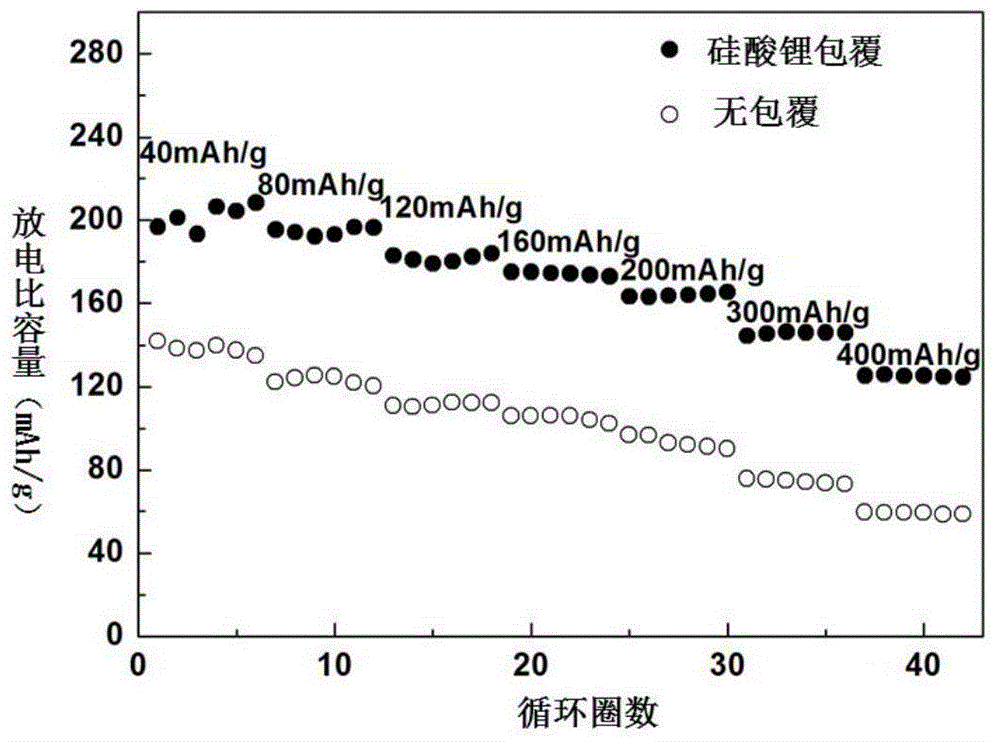

Preparation method of lithium metasilicate coated lithium-enriched laminar positive electrode material of lithium ion battery

ActiveCN104362334AIncrease productionThe results are reproducibleCell electrodesLithium metasilicateLithium-ion battery

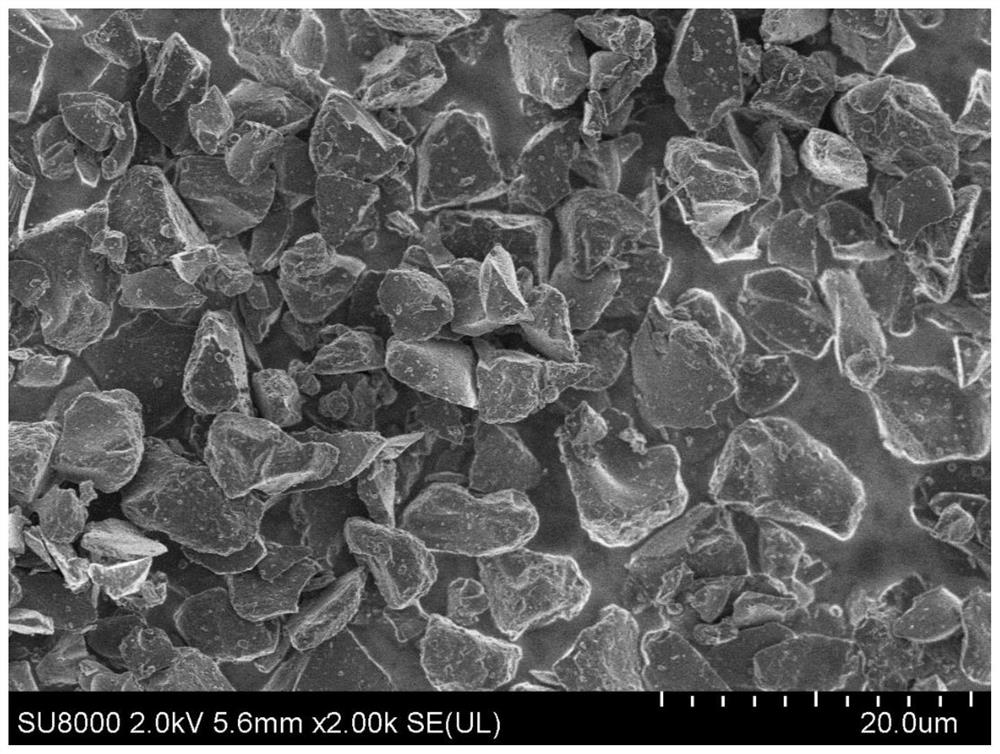

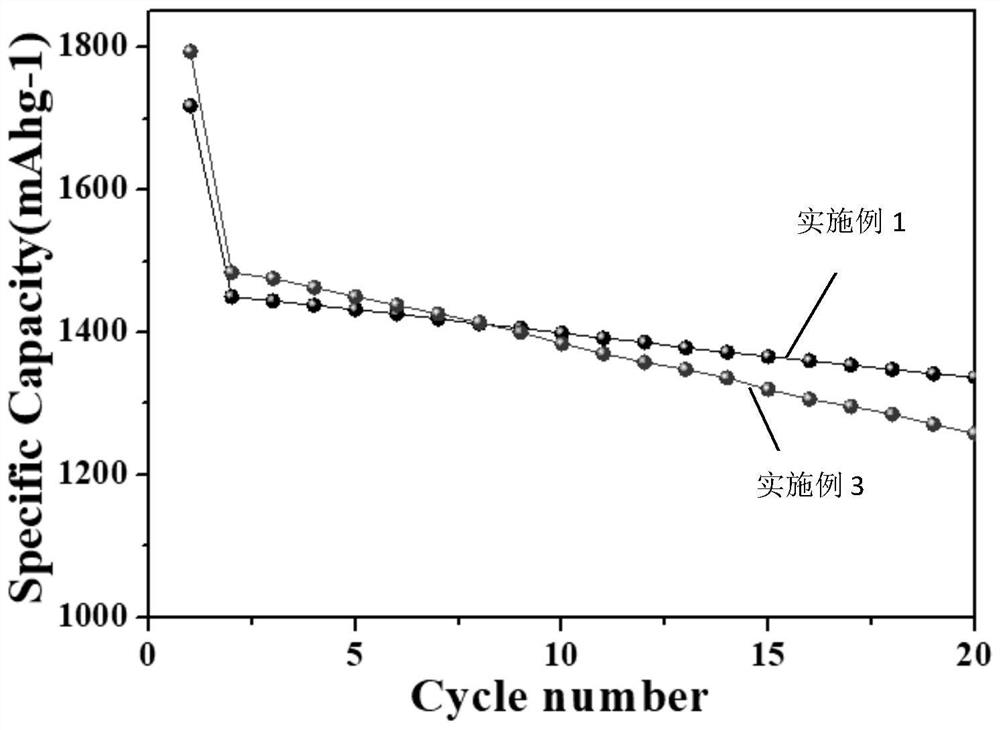

The invention relates to a preparation method of a lithium metasilicate coated lithium-enriched laminar positive electrode material of a lithium ion battery, belonging to the technical field of inorganic materials. According to the method, the lithium metasilicate coated lithium-enriched laminar positive electrode material is prepared by simple co-precipitation, and hydrothermal and high-temperature solid-phase sintering reaction. According to the method, the synthesis process is simple, the production efficiency is high and large-scale production is facilitated. According to the method, raw materials for reactants are easily available, have no toxin and are low in cost; a production process does not need special protection and reaction conditions are easy to control; and the obtained product has the advantages of large output, good result repeatability and the like. Compared with an uncoated material, the lithium metasilicate coated lithium-enriched laminar positive electrode material prepared by the method has the great improvement in the aspects of electrochemical performances including battery specific capacity, cycling stability, multiplying power and the like.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

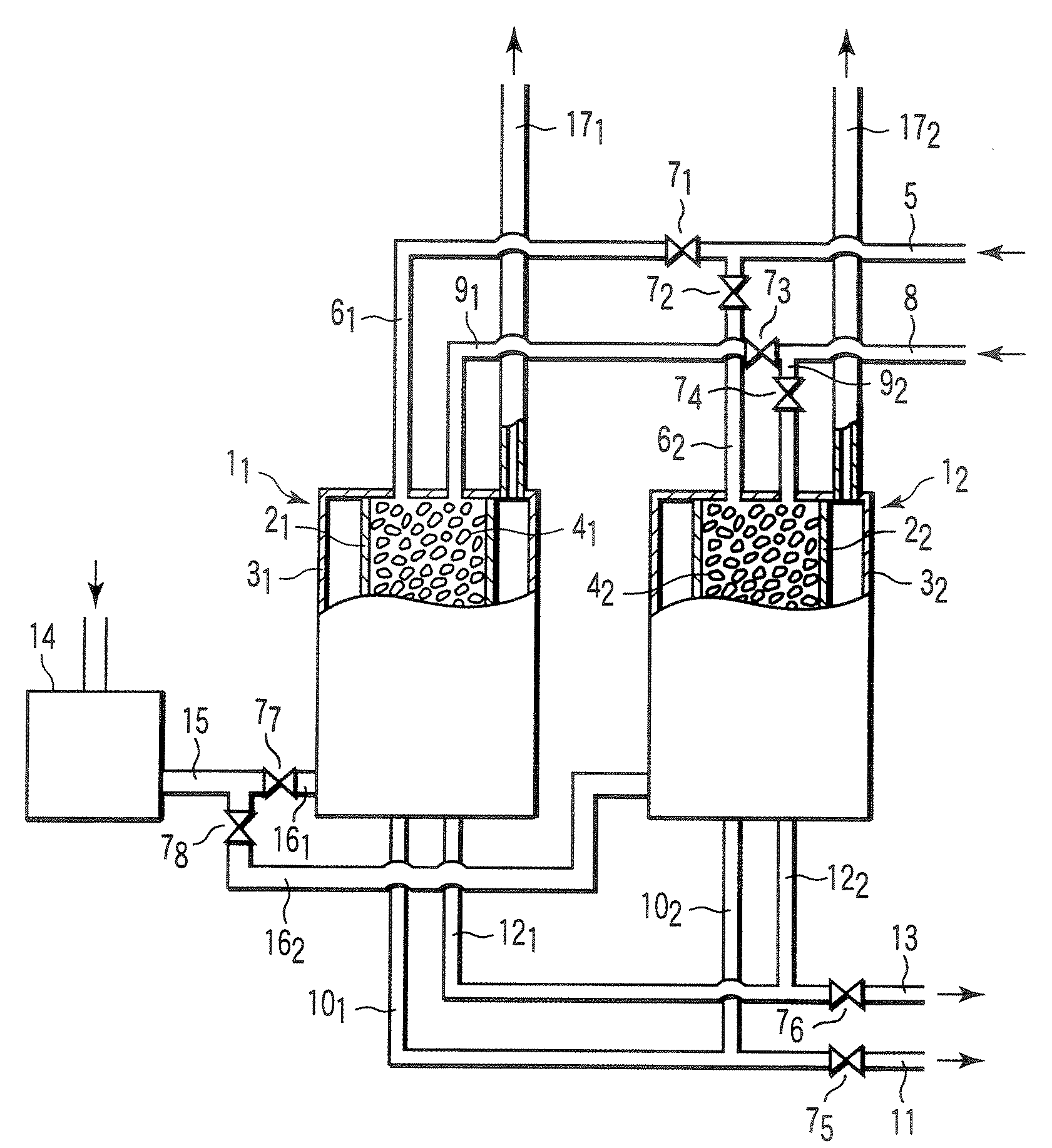

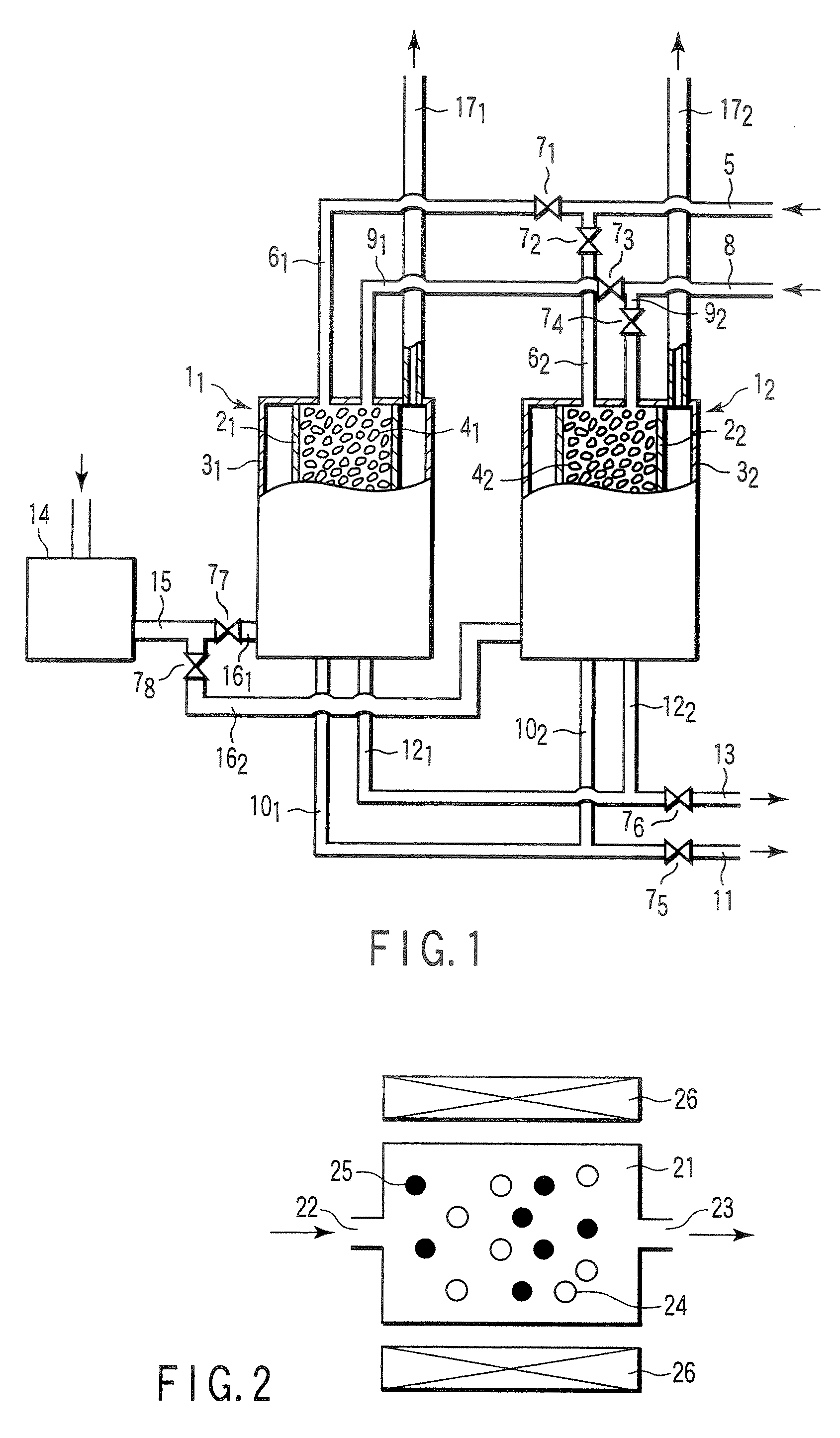

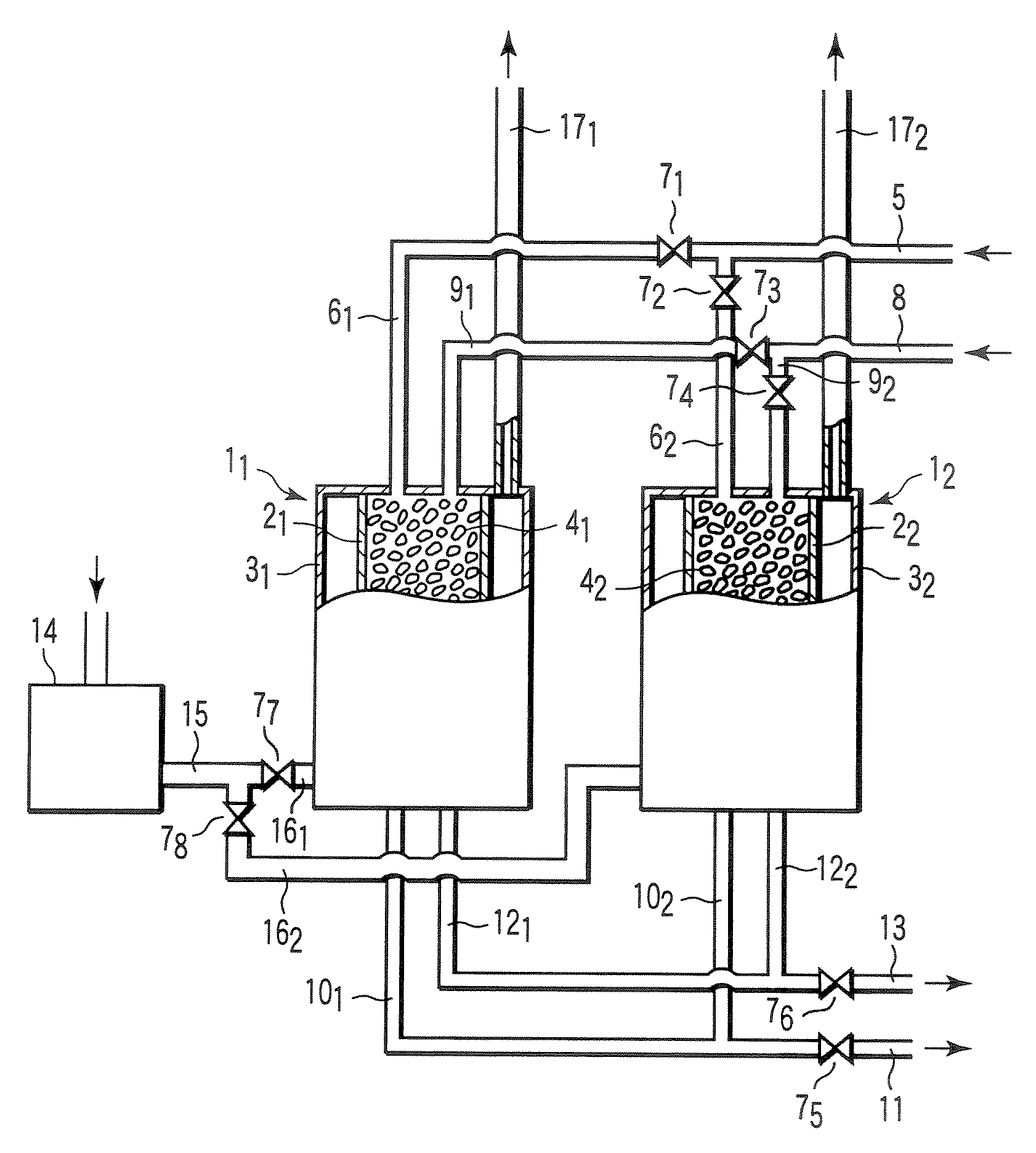

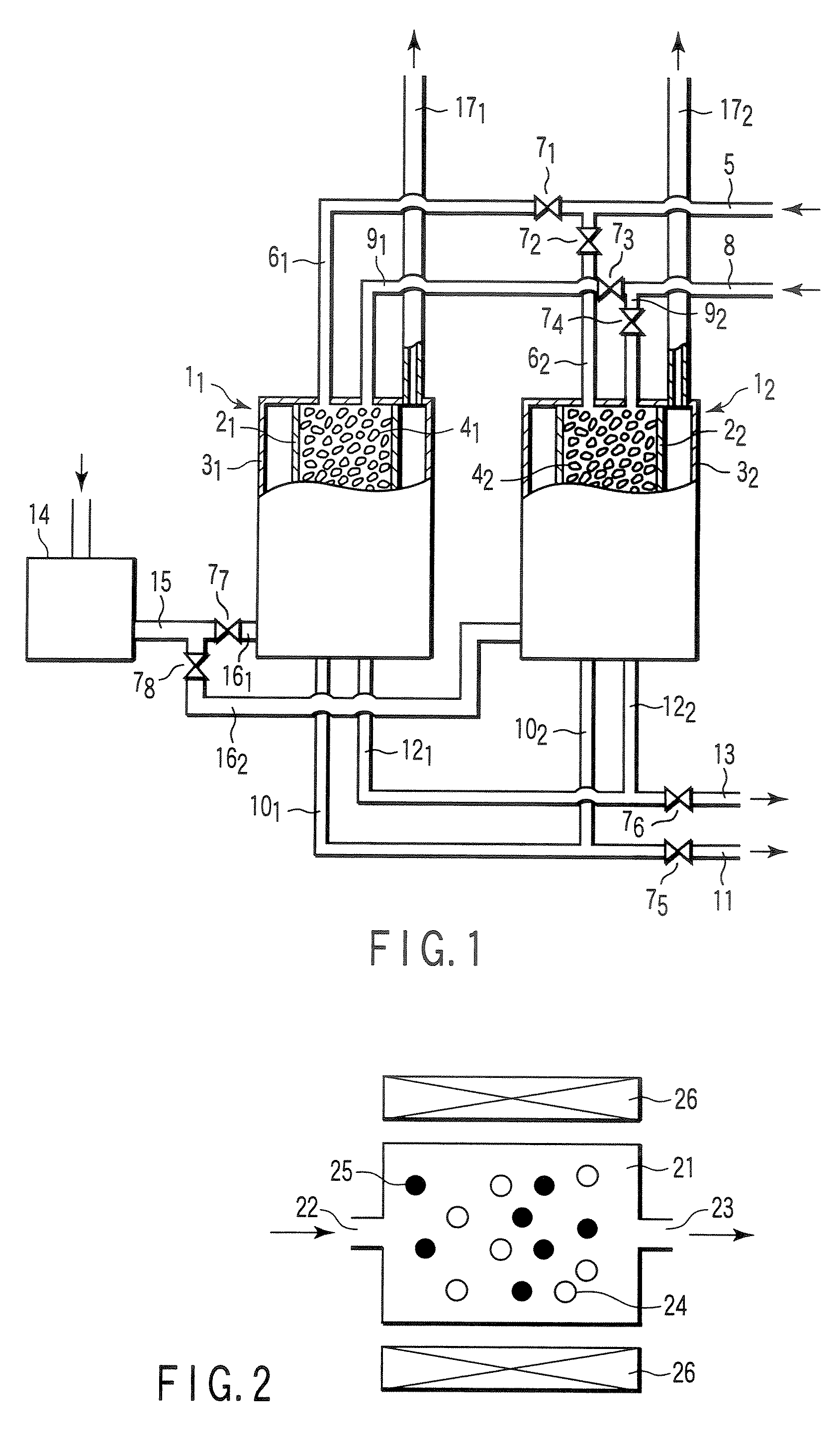

Carbon dioxide absorbent, carbon dioxide separating apparatus, and reformer

A carbon dioxide absorbent includes lithium silicate containing lithium orthosilicate and lithium metasilicate, the lithium metasilicate being contained in an amount of 5% by weight or more to 40% by weight or less with respect to the total amount of lithium orthosilicate and lithium metasilicate, where the lithium metasilicate produced by reaction of the lithium orthosilicate and carbon dioxide is excluded.

Owner:KK TOSHIBA

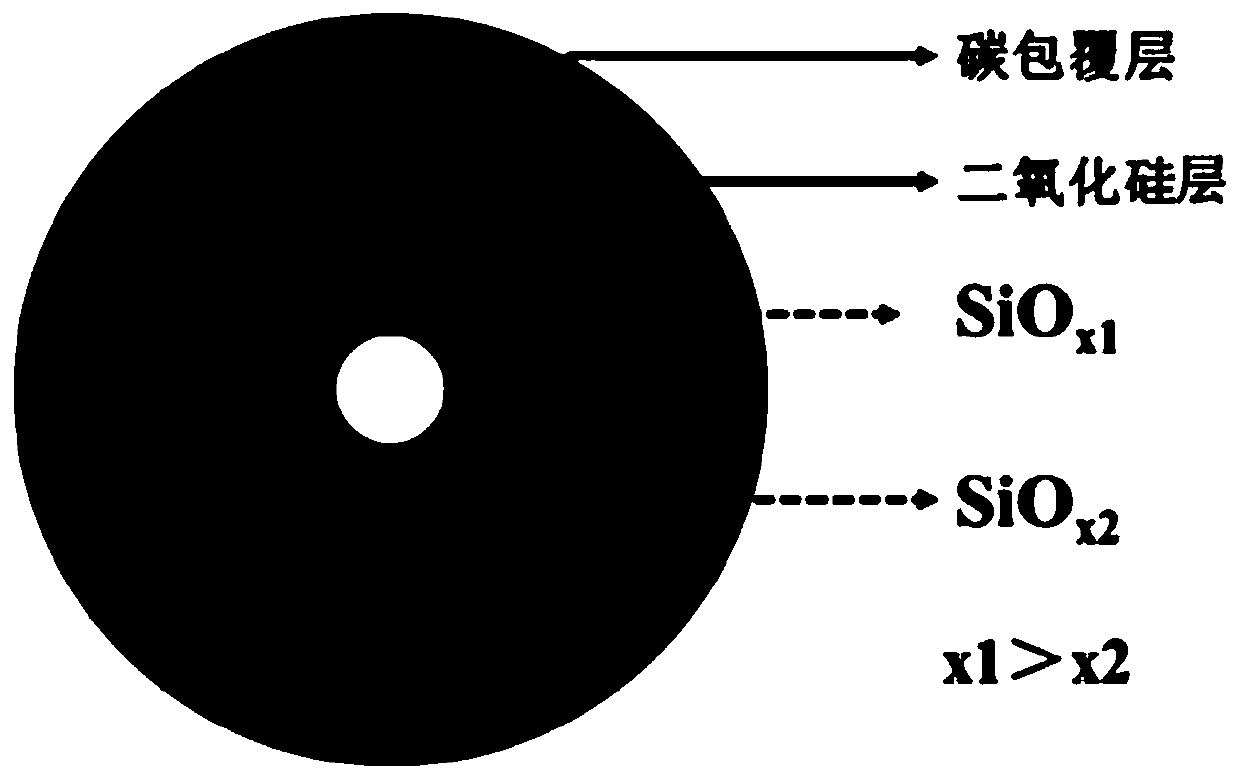

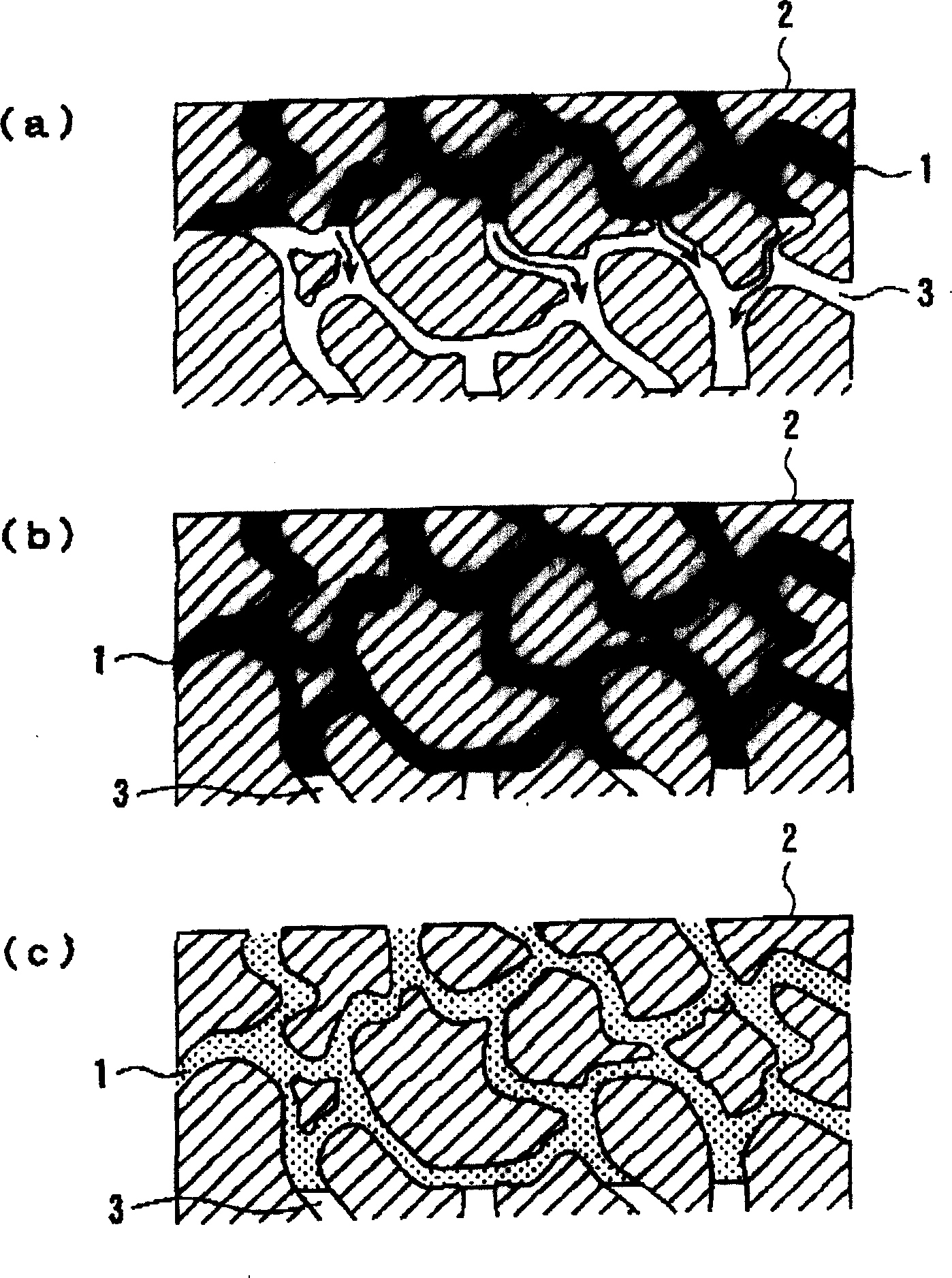

Silicon oxide composite cathode material with gradient structure and preparation method and application thereof

ActiveCN109888246AEasy to prepareEasy to controlCell electrodesSecondary cellsCarbon coatingLithium oxide

The invention discloses a silicon oxide composite cathode material with a gradient structure and a preparation method and application thereof. The silicon oxide composite cathode material with the gradient structure comprises a core-shell structure which is formed by a silicon dioxide layer, a silicon oxide material layer (SiOx) and a carbon coating layer, which are distributed in sequence from inside out, wherein the silicon oxide material layer is a layered structure comprising at least two layers; and a mole ratio of Si to O in the layered structure is gradually increased from inside out. Due to the gradient structure, the stress of silicon oxide is more uniform during volume expansion in the charging process, so that the surface pulverization of particles can be effectively decreased;and meanwhile, the oxygen content in the internal silicon oxide is relatively high, and more byproducts such as lithium oxide, lithium silicate, lithium metasilicate and the like can be generated, sothat the volume expansion generated in the charging process can be further buffered. Moreover, more silicon is concentrated on the outer surface during lithium embedding, so that material polarizationcan be greatly decreased and the performance in lithium ion batteries can be improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

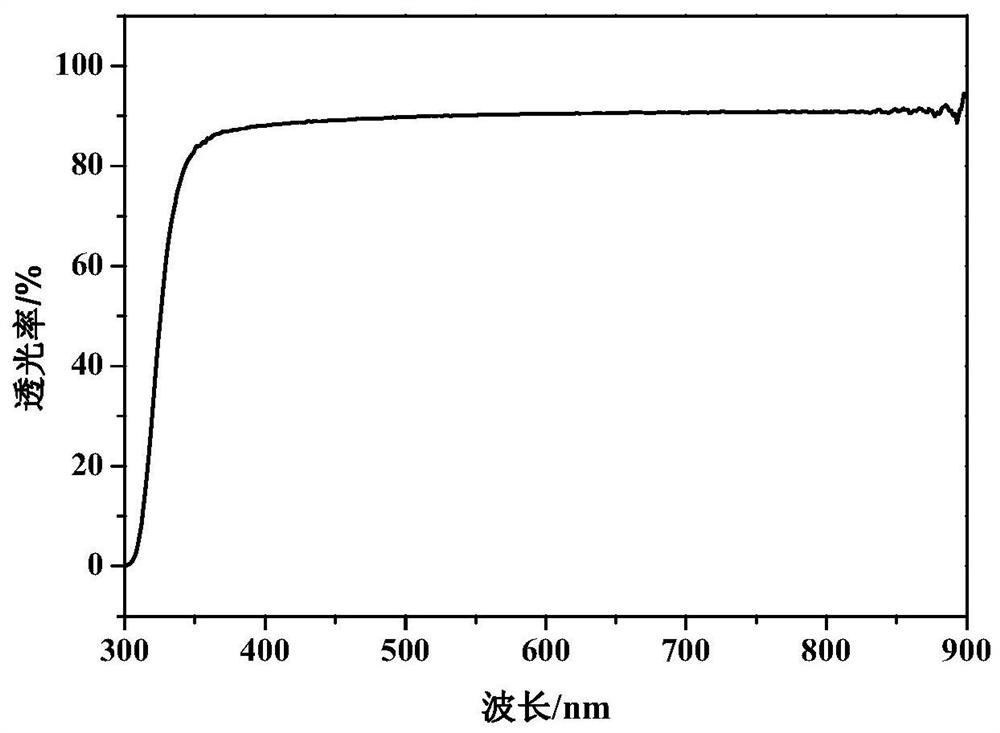

High-strength and high-permeability lithium disilicate glass ceramic as well as preparation method and application thereof

ActiveCN113501668AReduce scatterImprove fracture toughnessImpression capsGlass furnace apparatusOptical transmittanceLithium metasilicate

The invention provides a high-strength and high-permeability lithium disilicate glass ceramic and a preparation method and application thereof. The lithium disilicate glass ceramic with lithium disilicate as a main crystalline phase and lithium metasilicate, lithium phosphate or quartz as an impure phase is prepared by optimizing the raw material ratio and regulating and controlling heat treatment conditions, wherein the size of lithium disilicate crystals is larger than 700 nm, and the length-diameter ratio is not less than 3. The three-point bending strength of the lithium disilicate glass ceramic is 450-750 MPa, the fracture toughness of the lithium disilicate glass ceramic is higher than 3.5 MPa.m<1 / 2>, and the optical transmittance of a sample with the thickness of 1 mm at 550 nm is adjustable within 10%-80%. The lithium disilicate glass ceramic has excellent properties of high strength and high permeability, effectively reduces the risk of restoration collapse, better simulates the toughness and light transmittance of natural teeth, and has a better application prospect.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

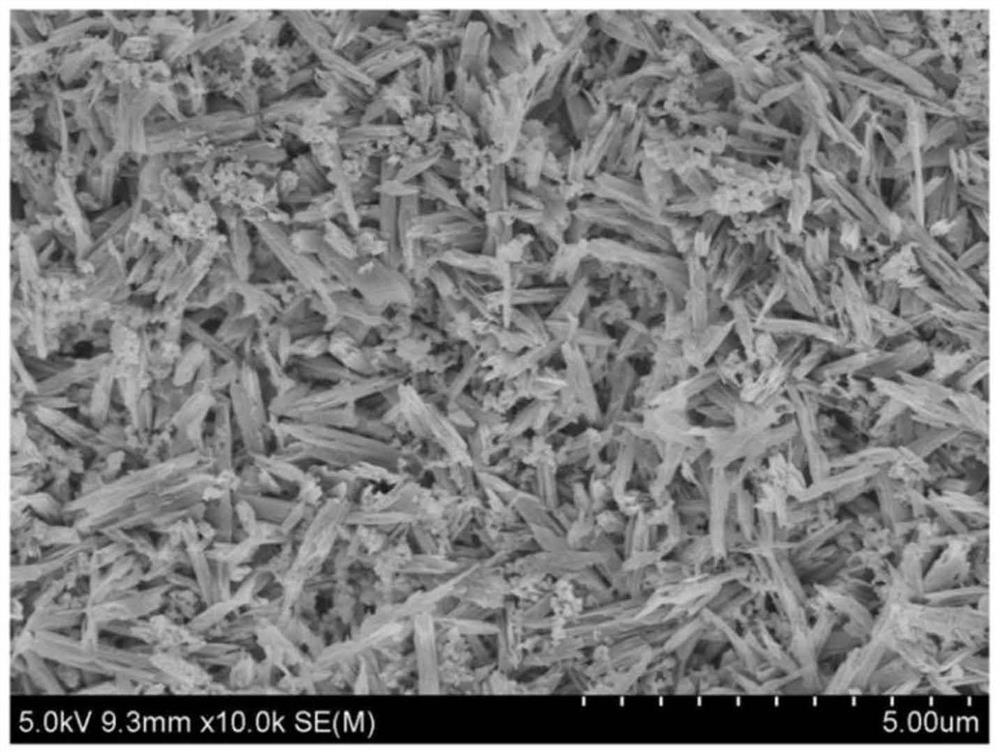

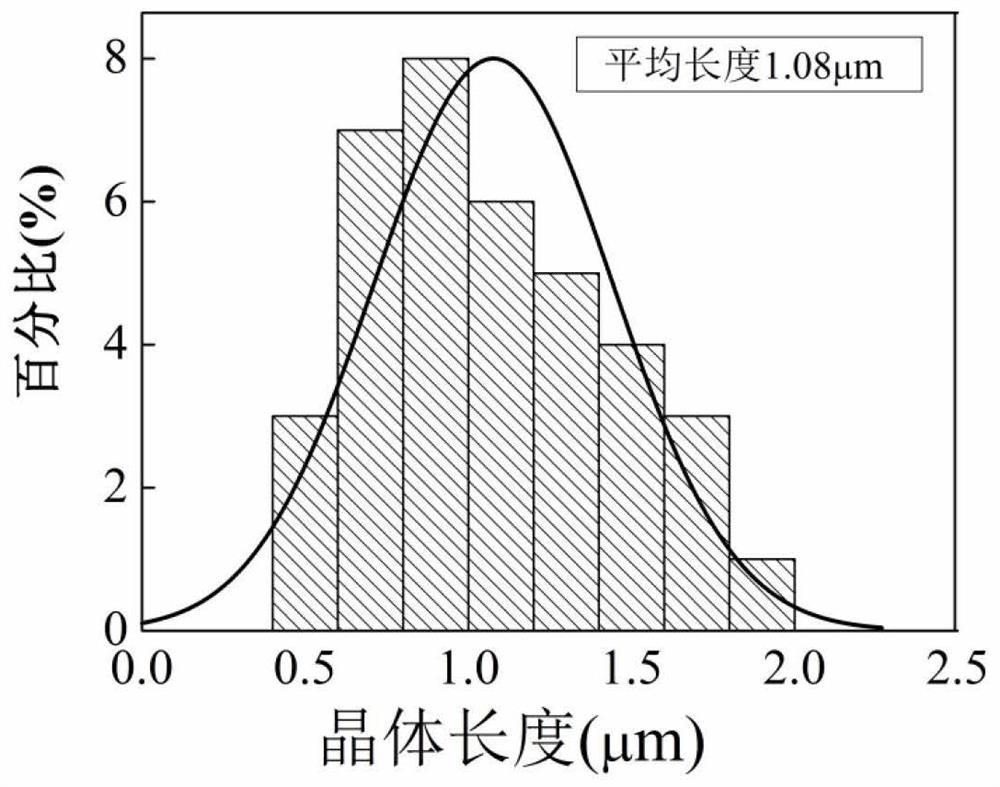

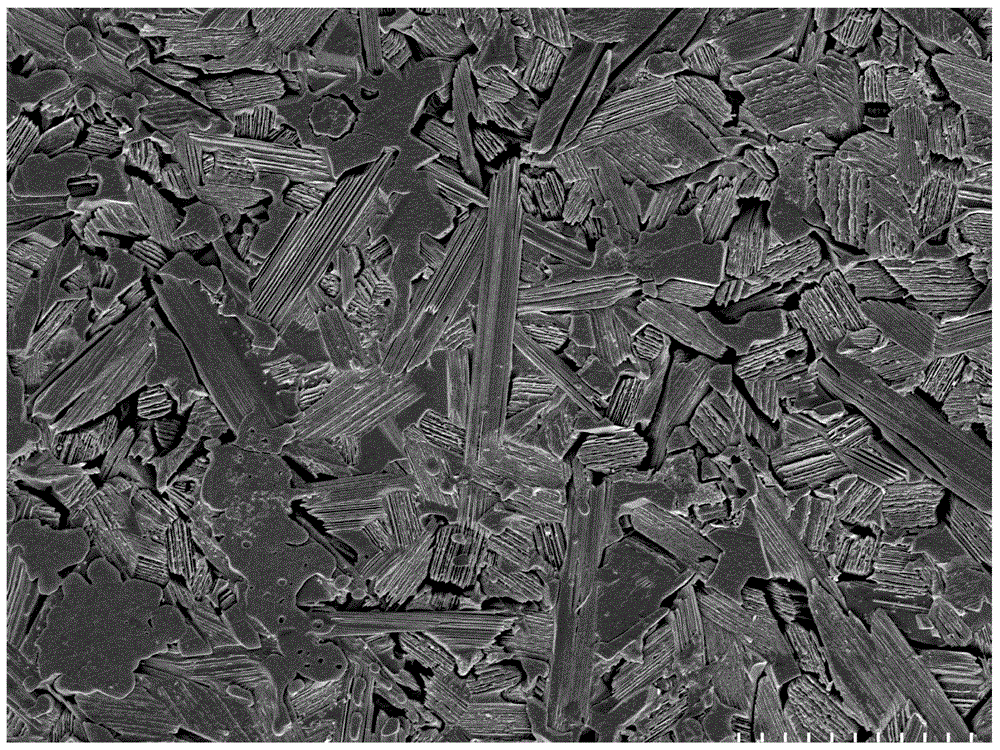

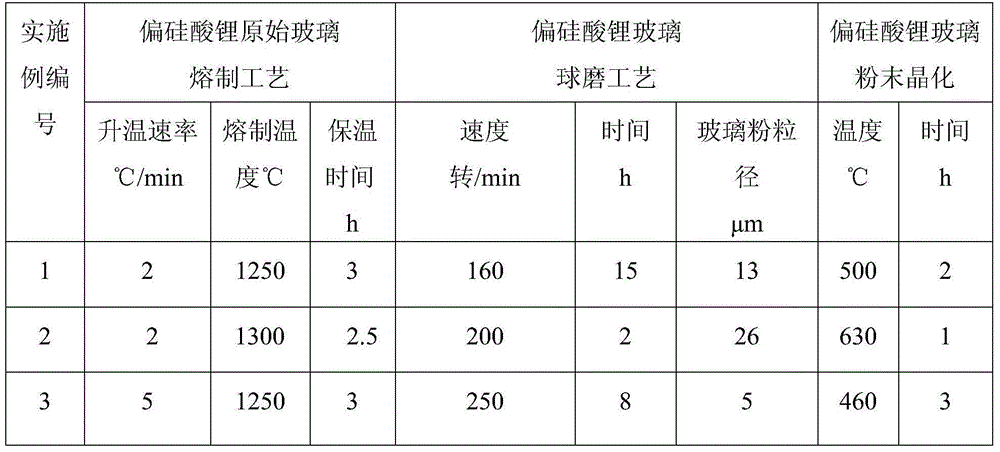

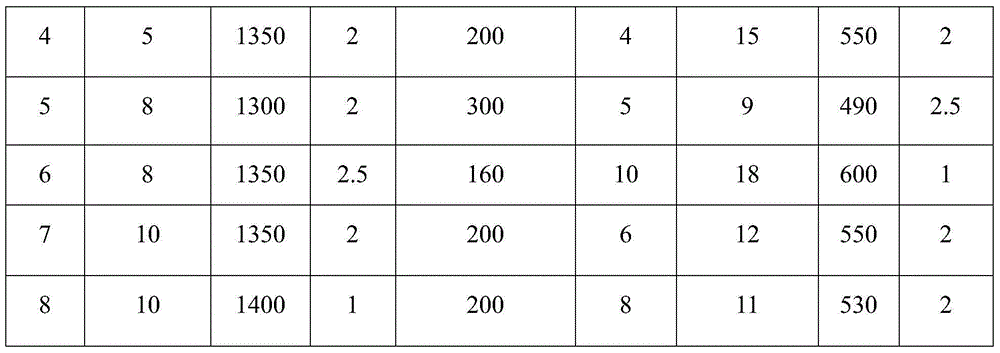

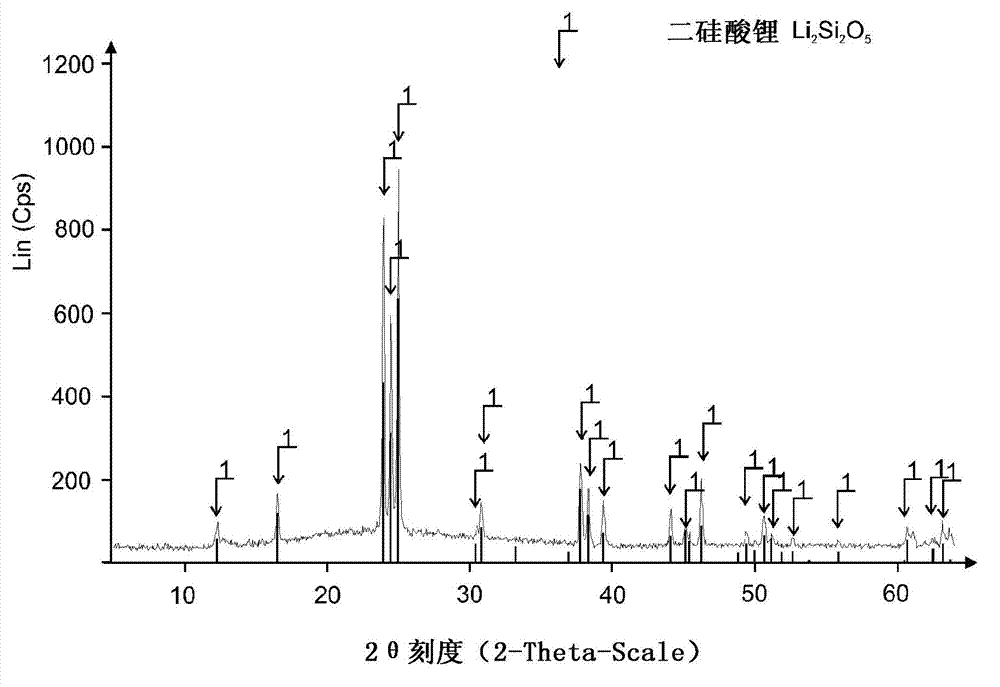

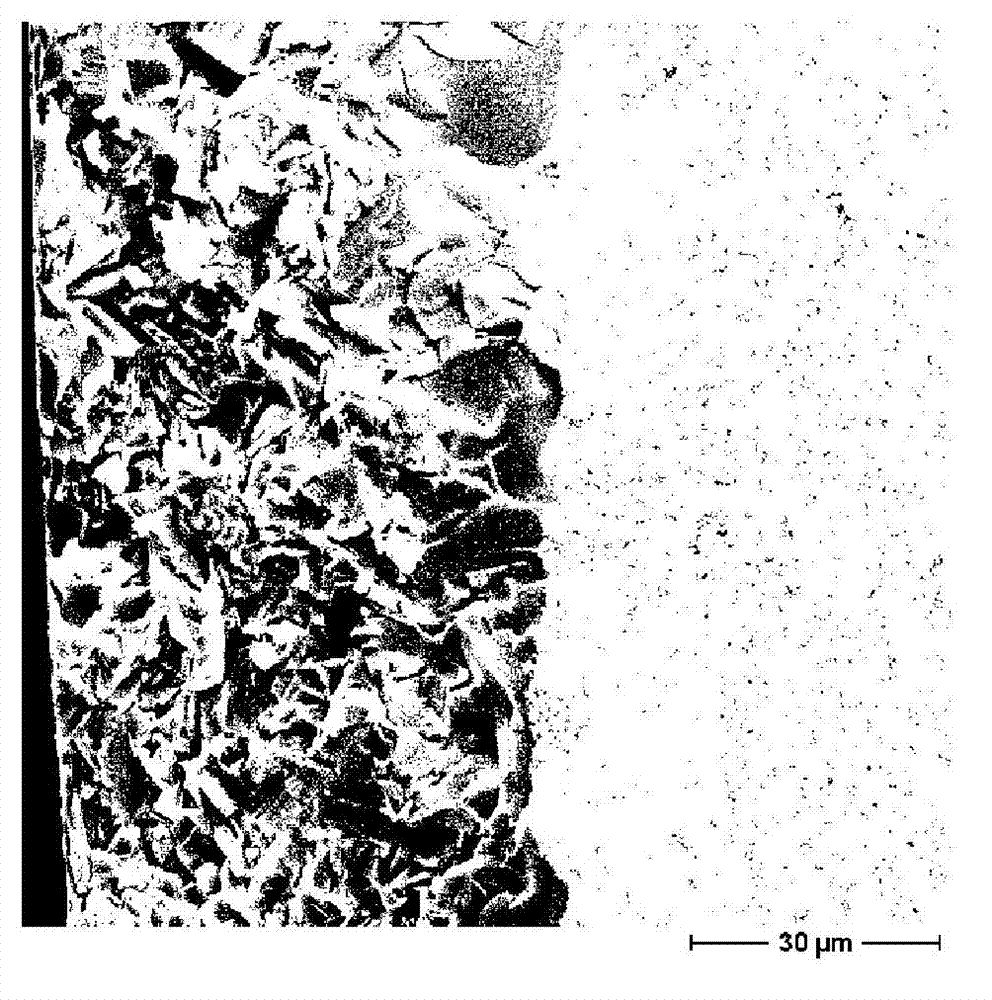

Lithium disilicate microcrystalline glass material prepared by using hybrid reaction sintering method and method

The invention provides a lithium disilicate microcrystalline glass material prepared by using a hybrid reaction sintering method and the method. Raw materials for the material comprise lithium metasilicate crystal powder M, quartz sand glass powder S and lithium disilicate basic glass powder D, wherein a mol ratio of M to S to D is 1: 1-2: 0-8. The method comprises the following steps: subjecting lithium metasilicate glass and lithium disilicate basic glass to melting, water quenching and ball milling so as to prepare glass powder; subjecting lithium metasilicate glass powder to crystallization to obtain a crystal; adding the quartz sand glass powder and the lithium disilicate basic glass powder D; and uniformly mixing the above-mentioned three powders and carrying out sintering in a vacuum hot-pressing furnace so as to prepare lithium disilicate microcrystalline glass. The lithium disilicate microcrystalline glass produced by using the method has bending strength of 255 to 420 MPa and fracture toughness of 2.6 MPa.m1 / 2 to 3.5 MPa.m1 / 2. Compared with the prior art, the invention has the following advantages: production cost is reduced; desired pigments can be added into the mixed powder before sintering, which enables the problem of difficult color matching in a melting method to be overcome; a long rod-like crystal grain with length 5 times the size of a single glass powder sintered body is prepared; and a novel approach is opened up for toughening the lithium disilicate microcrystalline glass.

Owner:XI AN JIAOTONG UNIV

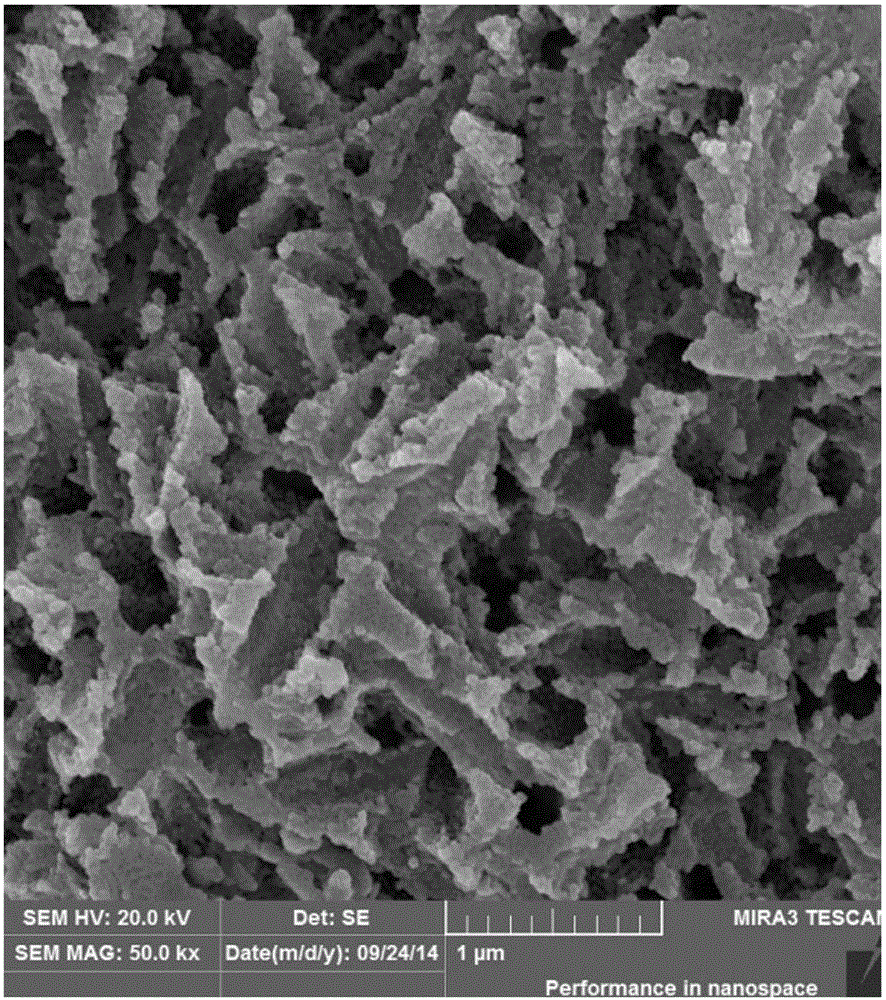

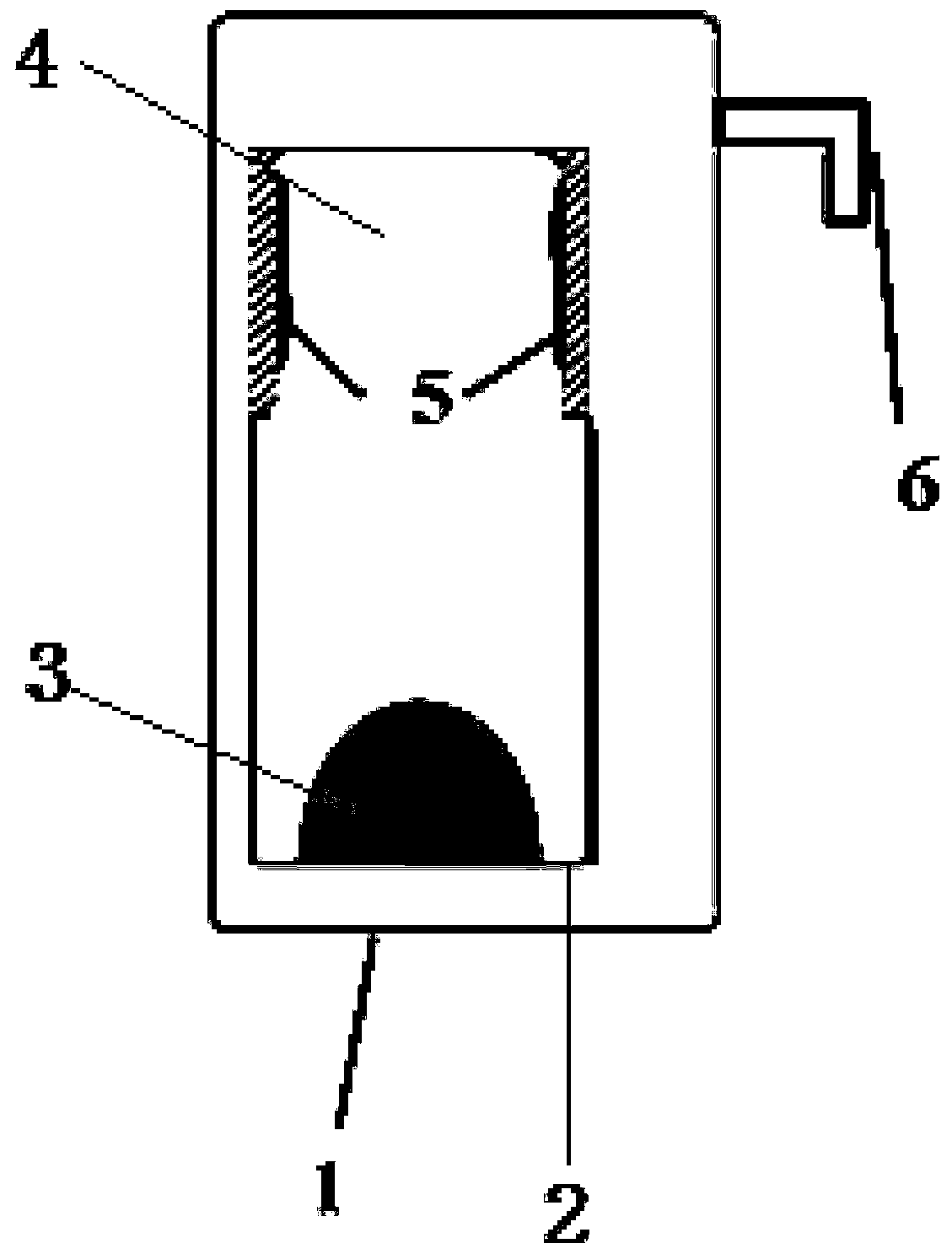

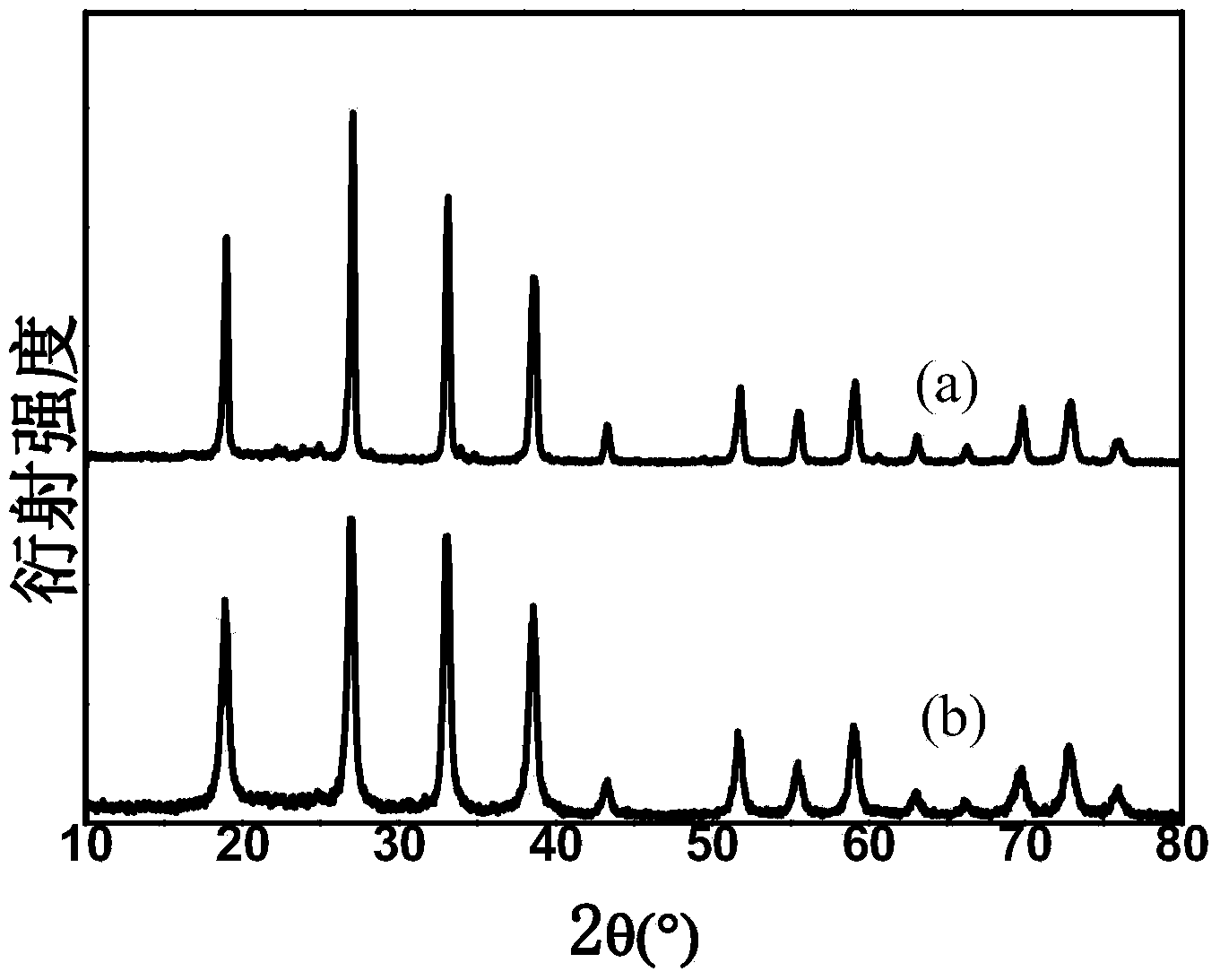

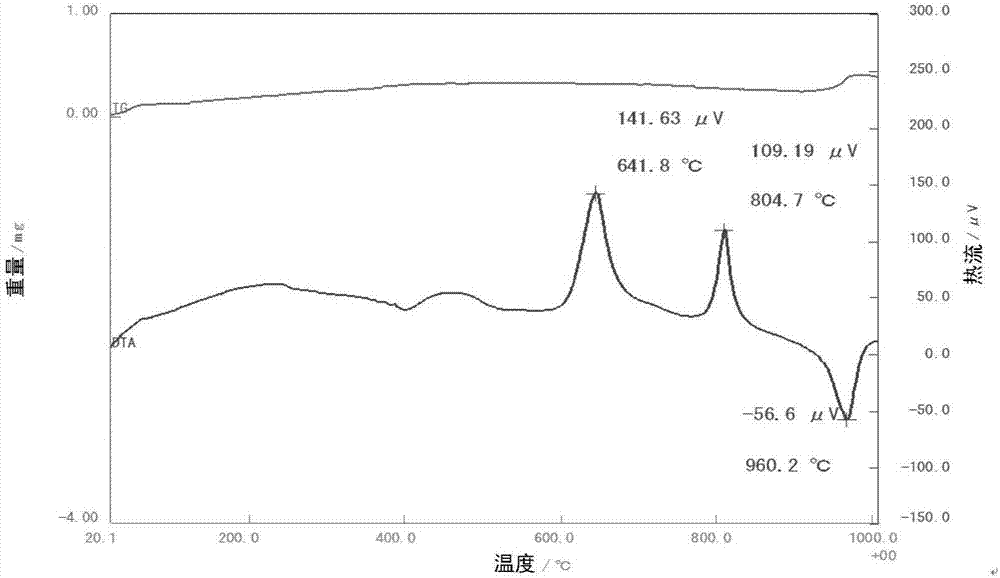

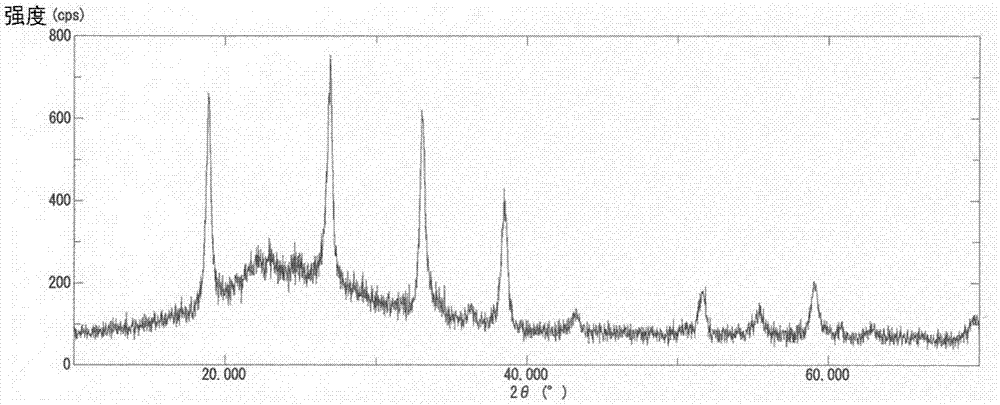

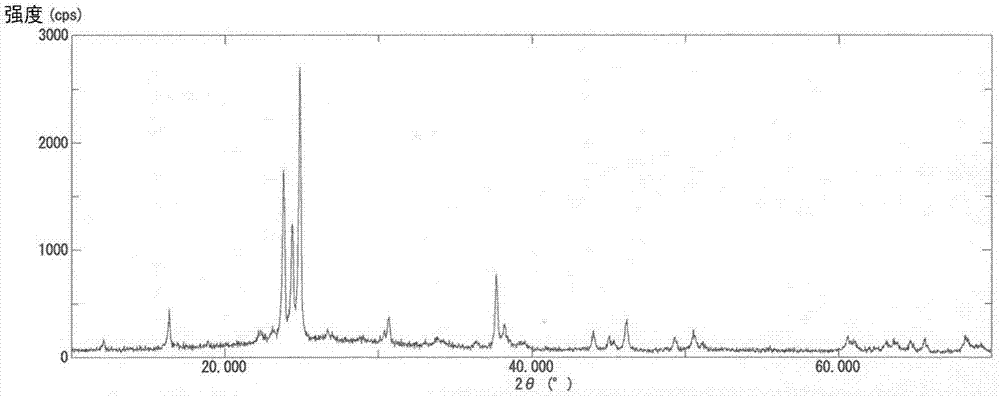

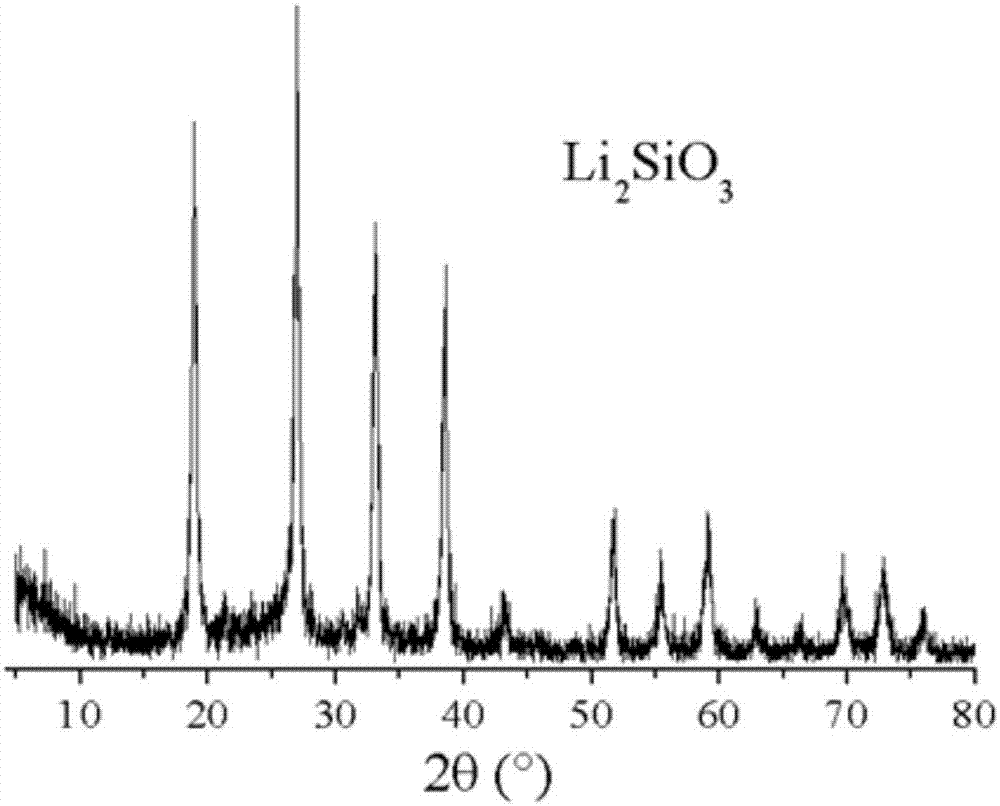

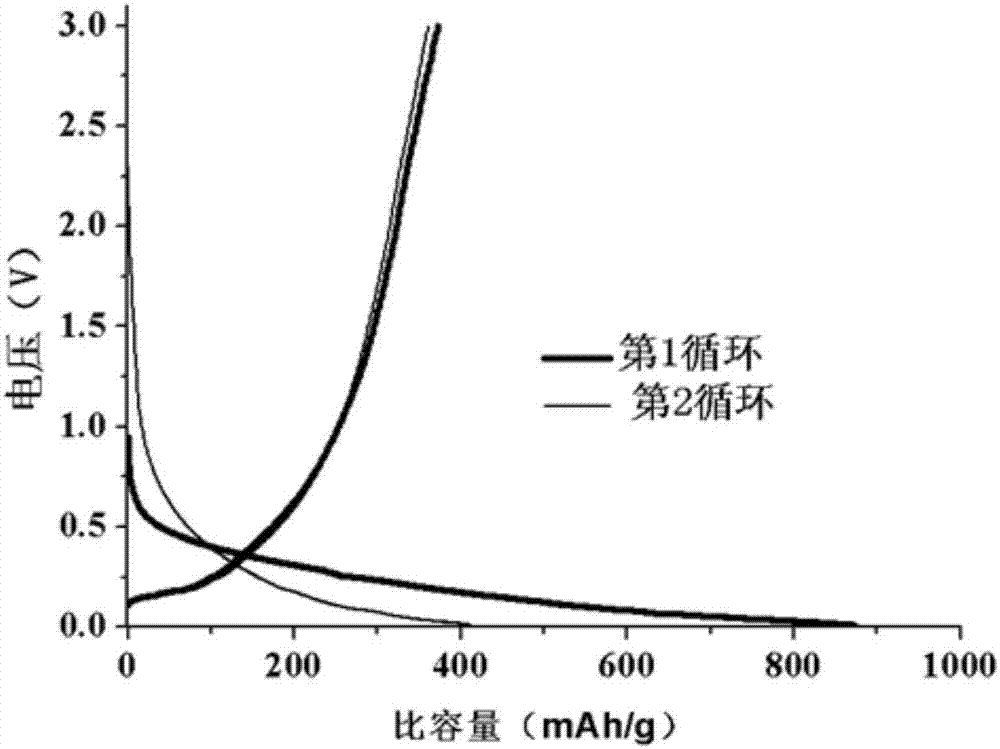

High temperature solid state preparation method of lithium ion battery cathode material lithium metasilicate

InactiveCN104022282ASimple processPromote crystallizationCell electrodesSecondary cellsTube furnaceLithium metasilicate

The invention discloses a high temperature solid state preparation method of a lithium ion battery cathode material lithium metasilicate. The method is as below: uniformly mixing a lithium source and a silicon source according to the molar ratio of 2: 1, and milling for 6-24 h to obtain a precursor; sintering the uniformly mixed precursor respectively in air, inert gas and a reducing atmosphere at 200-450 DEG C for 2-12 h, naturally cooling, and grinding to obtain a powdered material; and milling the powdered material for 6-24 h again, placing the powdered material into a tube furnace, sintering respectively in the air, inert gas and a reducing atmosphere at 550-1000 DEG for 4-24 h, and naturally cooling to obtain the lithium metasilicate cathode material. The invention also relates to addition of a carbon material in the preparation process to obtain a carbon coated lithium metasilicate cathode material. The invention has the advantages of simple process and easy operation. The lithium metasilicate material synthesized by the method has low intercalation potential (0.1-1 V), stable structure and excellent cycling performance.

Owner:SOUTH CHINA UNIV OF TECH

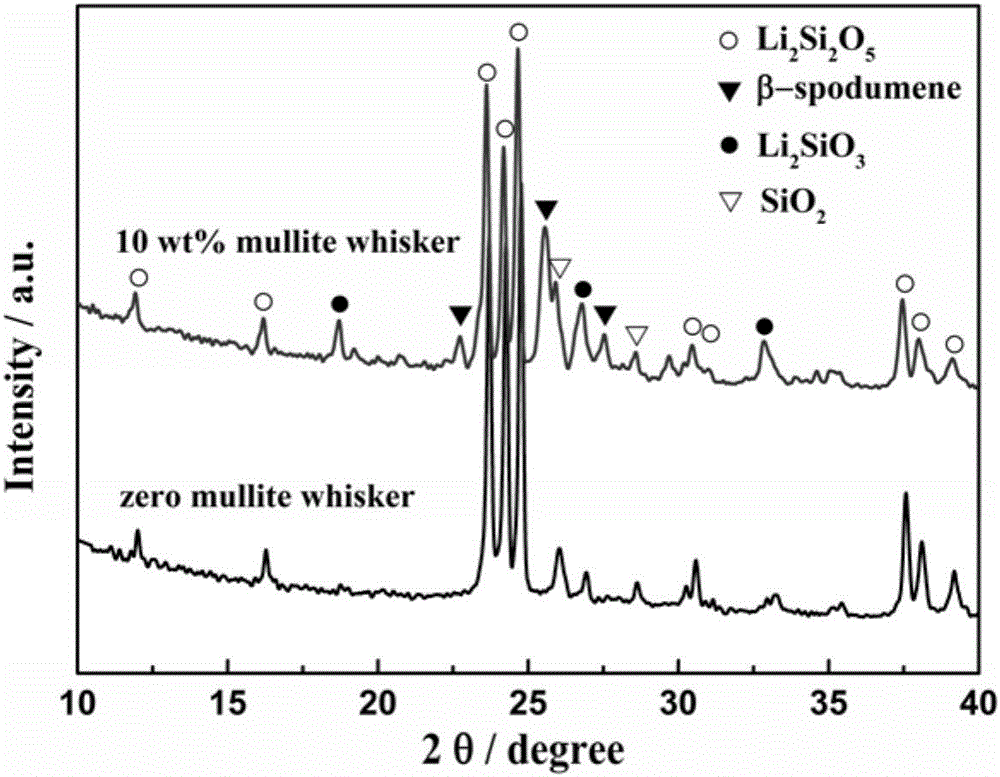

Lithium, aluminum and silicon series microcrystalline glass for dentistry and preparation method thereof

ActiveCN107522404AHigh strengthImprove fracture toughnessImpression capsDentistry preparationsDispersityLithium metasilicate

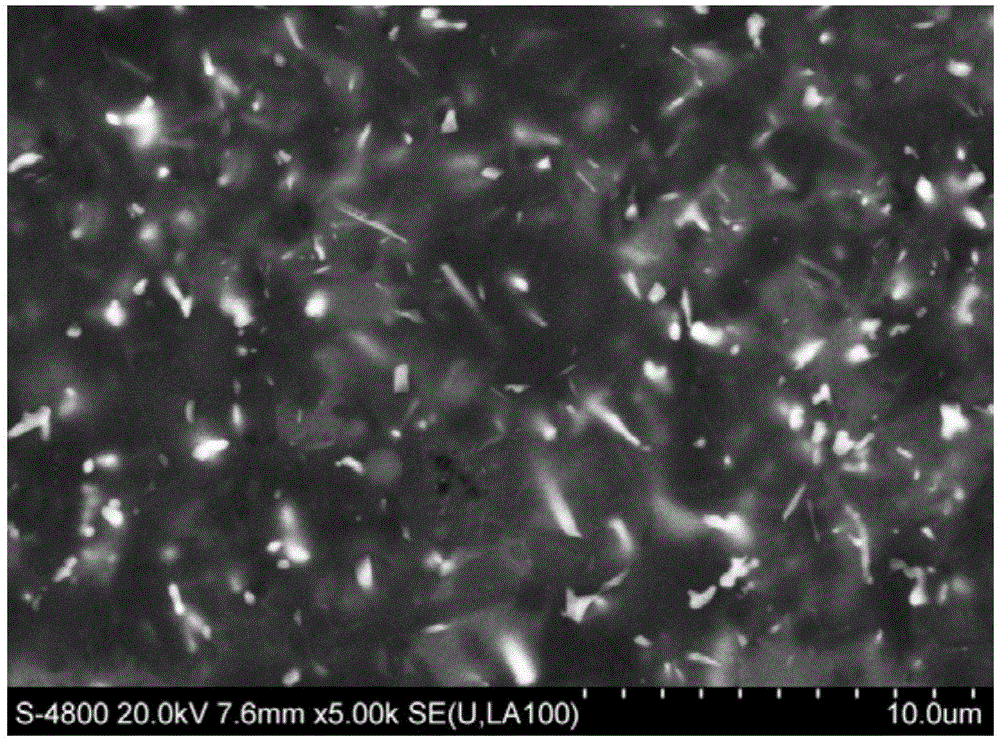

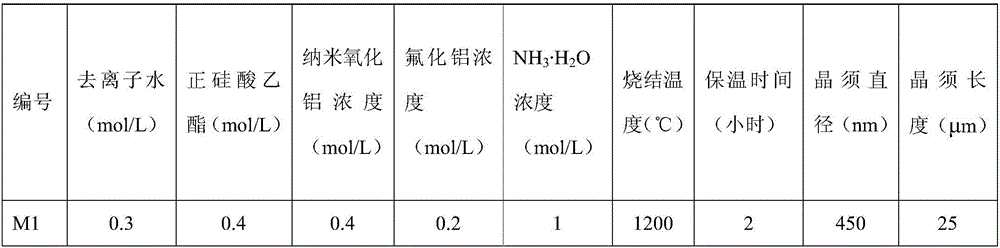

The invention discloses lithium, aluminum and silicon series microcrystalline glass for dentistry and a preparation method thereof. The preparation method includes: using Li2CO3, SiO2, K2CO3 and La2O3 as raw materials, and adopting a method of melt cooling combined with water quenching to prepare lithium-silicon binary glass powder; using A12O3, AlF3 and tetraethyl orthosilicate as raw materials, and adopting a sol gel-sintering method to prepare mullite crystal whisker with high dispersity; subjecting the glass powder and the mullite crystal whisker to mixing and hot-pressing sintering, wherein in the process of sintering, the mullite crystal whisker is in in-situ reaction with the glass powder to be converted into beta-spodumene crystal whisker; finally to obtain the lithium, aluminum and silicon series microcrystalline glass taking the beta-spodumene crystal whisker, lithium disilicate and lithium metasilicate as main crystal phase. The lithium, aluminum and silicon series microcrystalline glass has the advantages of high strength, high toughness, low thermal expansion coefficient and translucence and has wide application prospect in the field of restorative dentistry.

Owner:XI AN JIAOTONG UNIV

Pre-lithiated silicon monoxide/carbon composite material and preparation method and application thereof

InactiveCN111900369AImprove the first effectImprove conductivityNegative electrodesSecondary cellsCarbon compositesCarbon coating

The invention discloses a pre-lithiated silicon monoxide / carbon composite material and a preparation method and application thereof. The preparation method comprises: mixing silicon monoxide, a lithium source and a heat absorbing agent to be uniform, then conducting heat treatment, washing and filtering under the protective atmosphere, and obtaining a pre-lithiated product; and putting the pre-lithiated product into a rotary kiln, heating, introducing pyrolysis gas, and carrying out carbon coating by vapor deposition to obtain the pre-lithiated silicon monoxide / carbon composite material. The method is simple to operate, low in cost, free of difficult-to-control steps and suitable for amplification. The obtained composite material has a core-shell structure, the core material contains at least one of lithium silicate and lithium metasilicate sources, irreversible components in silicon monoxide can be effectively consumed, and the first effect is improved. The pyrolytic carbon on the outer layer can relieve volume expansion of silicon monoxide and improve the conductivity of the material. The material is used in the lithium ion battery, and the theoretical capacity and the first effect are improved to a certain extent.

Owner:SHAANXI COAL & CHEM TECH INST

Veneering ceramic for dental restorations made of yttrium-stabilized zirconium dioxide and method for applying said veneering ceramic

The invention relates to veneering ceramics for dental restorations, wherein the framework ceramic is made of yttrium-stabilized zirconium dioxide. The aim of the invention is to develop a translucent veneering ceramic based on lithium disilicate and a method for applying the veneering ceramic for dental restorations made of yttrium-stabilized zirconium dioxide. Said veneering ceramic should not contain any leucite, lithium metasilicate, or ss-spodumene and should have very good chemical resistance, high adhesive strength with respect to zirconium dioxide, and good surface quality. According to the invention, said aim is achieved for a veneering ceramic on yttrium-stabilized zirconium dioxide in that the veneering ceramic is produced from the following components: a) SiO2 55.0 - 72.5 mass percent; b) Nb2O5 6.0 - 19.8 mass percent; c) B2O3 1.0 - 9.0 mass percent; d) Al2O3 1.2 - 6.0 mass percent; e) Li2O 5.0 - 16.5 mass percent; f) Na2O 1.4 - 11.0 mass percent; and g) ZrO2 0.5 - 4.0 mass percent, and is provided with a thin glass layer formed during the crystallization on the surface of the veneering ceramic.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Preparation method of lithium-silicate-based gradient ceramic microspheres

The invention relates to a preparation method of lithium-silicate-based gradient ceramic microspheres, belonging to the field of nuclear materials. Lithium carbonate is used as a lithium source, and lithium metasilicate or silicon dioxide is used as a silicon source. The preparation method comprises the following steps: on the basis of preparing Li2CO3+Li2SiO3 or Li2CO3+SiO2 gel spheres by a colloid forming technique, flushing and dissolving lithium carbonate with a certain thickness by using deionized water to leave the lithium metasilicate or silicon dioxide outer layer, impregnating in an organic solvent to exchange out water in the gel spheres, and finally, carrying out high-temperature calcining and sintering in an air atmosphere to obtain the lithium silicate ceramic microspheres with gradient structure. The lithium metasilicate or silicon dioxide protective layer with stable chemical properties, which coats the lithium silicate gradient ceramic microsphere surface, can improve the compatibility between the lithium silicate ceramic microspheres and structural material, isolate the interior lithium silicate from contact with air and perform the moistureproof function, thereby being beneficial to storage and transportation of the lithium silicate ceramic microspheres. The method is simple in technical process, does not need complex or expensive equipment, and can easily implement industrial production.

Owner:UNIV OF SCI & TECH BEIJING

Al2O3-free lithium silicate glass composition

PendingCN107265846AEfficient precipitationImpression capsGlass shaping apparatusSilicate glassLithium metasilicate

To provide a dental lithium silicate glass composition capable of providing a dental lithium silicate glass ceramic capable of efficiently precipitating the main crystals (lithium disilicate and / or lithium metasilicate) even after heat treatment. To provide a Al2O3-free dental lithium silicate glass composition including the following components: SiO2: 60.0 to 80.0% by weight, Li2O: 10.0 to 17.0% by weight, K2O: 0.5 to 10.0% by weight, ZrO2: 0.0 to 5.0% by weight, a nucleating agent: 1.0 to 6.0% by weight, a glass stabilizer: 0.0 to 8.0% by weight and a colorant: 0.0 to 10.0% by weight.

Owner:SHOFU INC

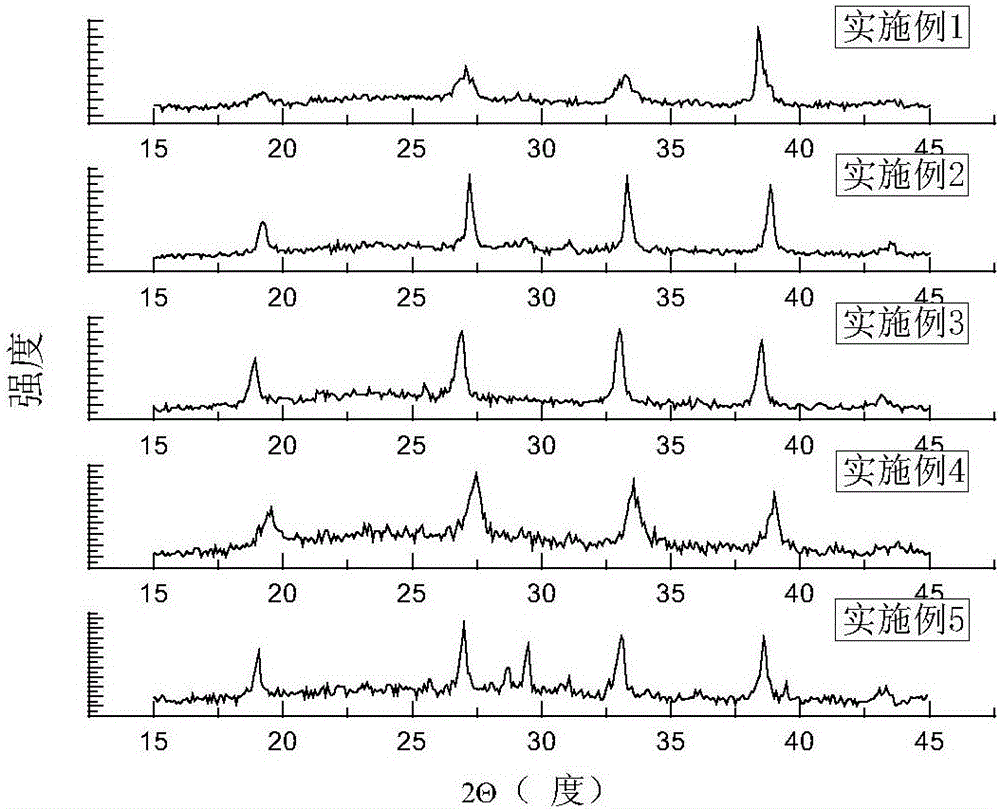

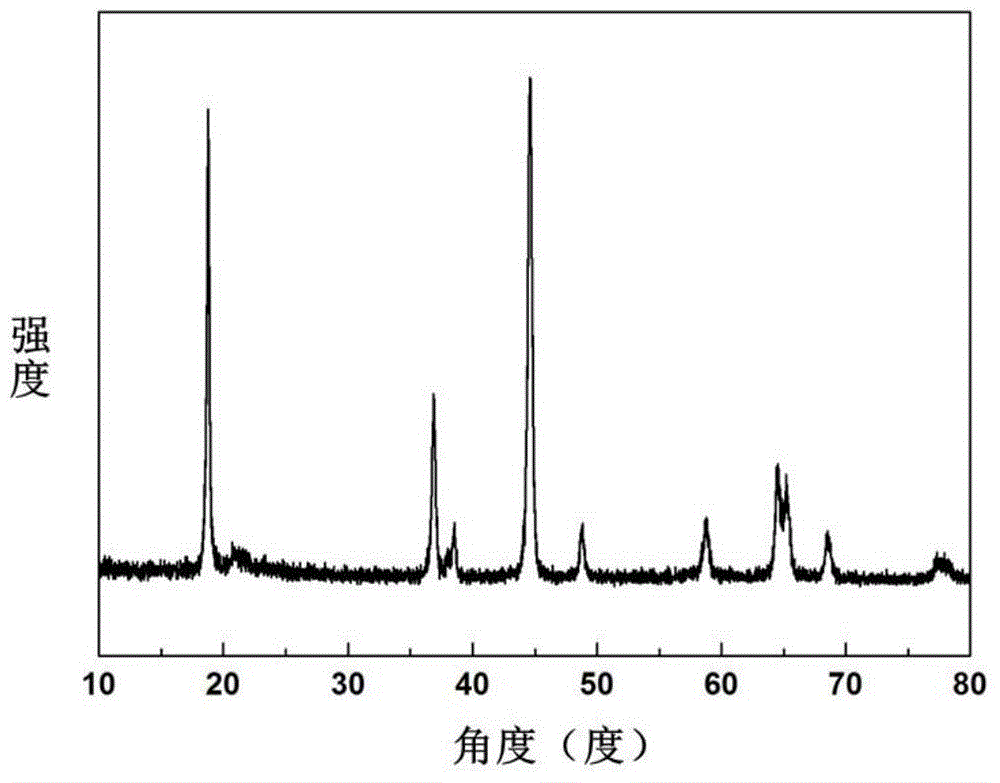

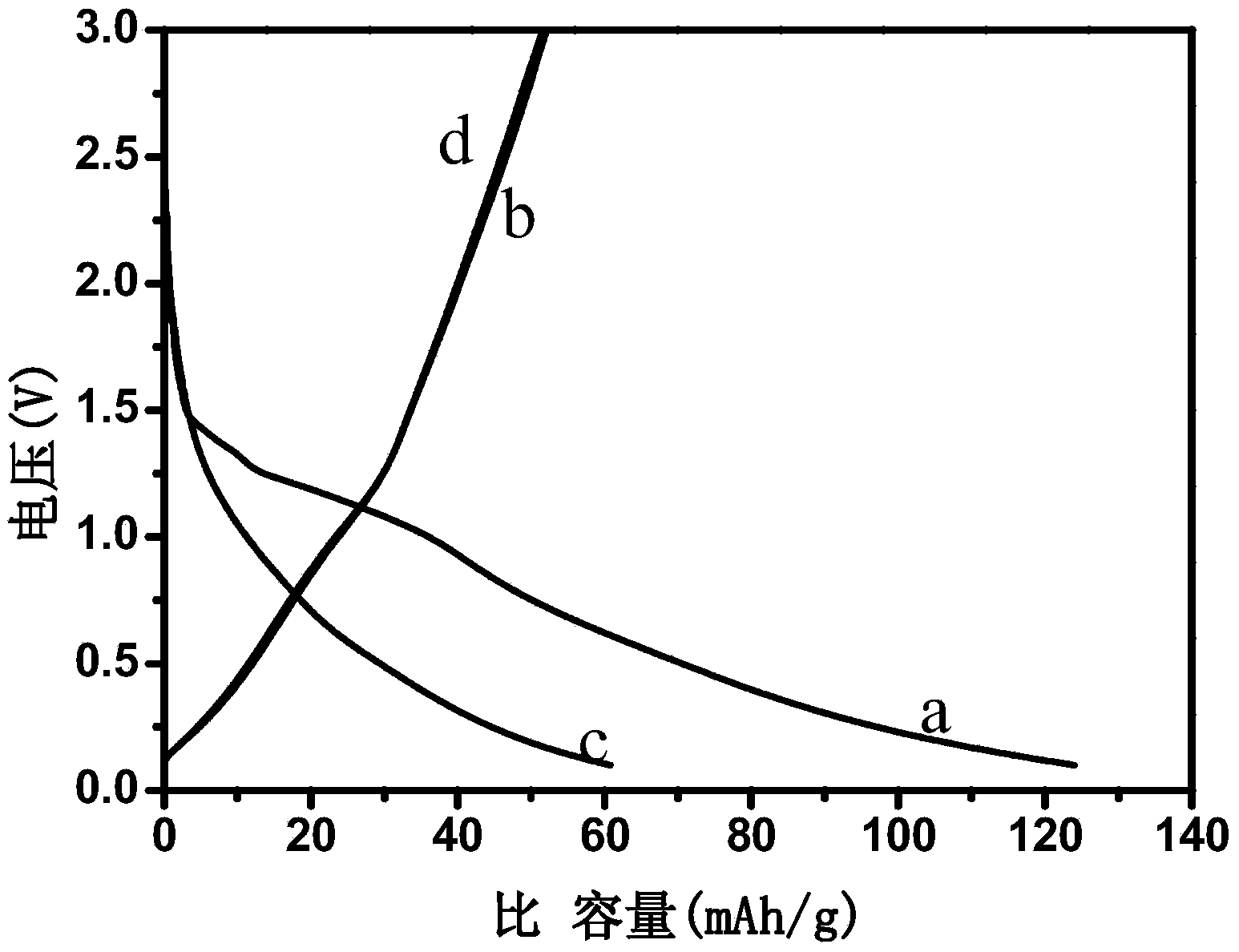

Lithium-metasilicate-modified lithium titanate cathode material and preparing method and application thereof

ActiveCN105514391AEasy to makeEasy to operateNegative electrodesSecondary cellsLithium metasilicateElectron

The invention discloses a lithium-metasilicate-modified lithium titanate cathode material and a preparing method and application thereof. The expression of the lithium titanate cathode material is LTO / LSO. The preparing method comprises the steps of weighing lithium titanate emulsion and lithium metasilicate emulsion in proportion, conducting even mixing, conducting drying at 100-200 DEG C, conducting sintering for 3-10 h at 650-900 DEG C, then naturally decreasing temperature to room temperature, and conducting grinding. The prepared lithium-metasilicate-modified lithium titanate cathode material has excellent ion and electron conduction performance, has high coulombic efficiency and excellent electrochemical performance without surface carbon covering as a lithium ion battery cathode material, and has high coulombic efficiency, high reversible capacity and excellent cycling stability even during rapid charging / discharging under the current density of 500 mA / g. The preparing method is simple, operation is convenient, and practicality is high.

Owner:SHANDONG UNIV

Preparation method of Li-Al-Si porous microcrystalline glass

Owner:XI AN JIAOTONG UNIV

Aluminum alloy anode oxide film nickel-free hole sealing agent and preparing method thereof

InactiveCN105200486AImprove permeabilityImprove adhesionSurface reaction electrolytic coatingCelluloseLithium metasilicate

The invention discloses an aluminum alloy anode oxide film nickel-free hole sealing agent. The hole sealing agent is prepared from, by weight, 8-8.5 parts of magnesium acetate, 19-20 parts of triethanolamine, 3-3.2 parts of ammonium acetate, a proper amount of deionized water, 0.1-0.2 part of borax, 0.2-0.3 part of nanometer crystalline cellulose, 0.6-0.7 part of nanometer aluminum oxide, 0.4-0.5 part of lithium metasilicate, 2.6-2.8 parts of dodecafluoroheptylpropyltrimethoxysilane, 1-1.2 parts of tetrabutyl titanate, 45-48 parts of ethyl alcohol, 8.6-9 parts of ammonium hydroxide and 0.3-0.4 part of fluorine-containing surfactant. Tetrabutyl titanate is used for forming nanometer titanium dioxide, lithium metasilicate, dodecafluoroheptylpropyltrimethoxysilane and fluorine-containing surfactant are used at the same time, and by means of reaction, permeability, cohesiveness and hydrophobicity of the hole sealing agent can be improved; by using borax, nanometer crystalline cellulose and nanometer aluminum oxide, lubricity and wear resistance of an oxidation film are improved.

Owner:MAANSHAN JIECHUANG PLASTIC TECH CO LTD

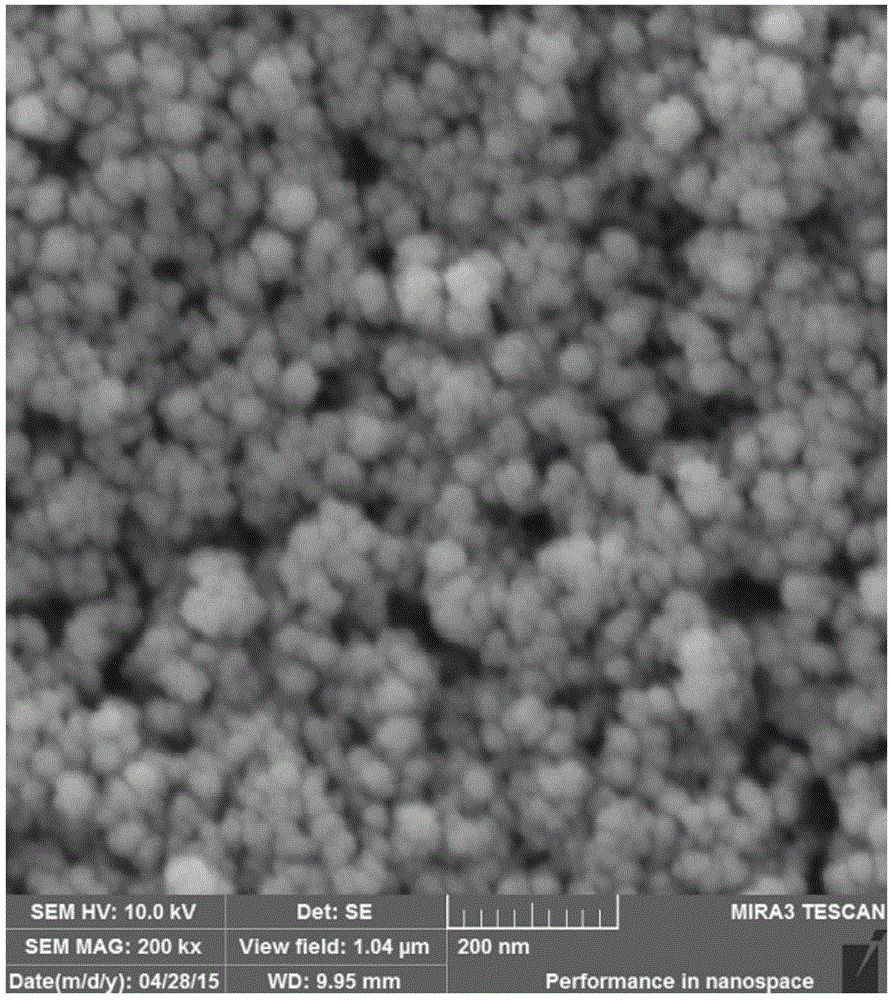

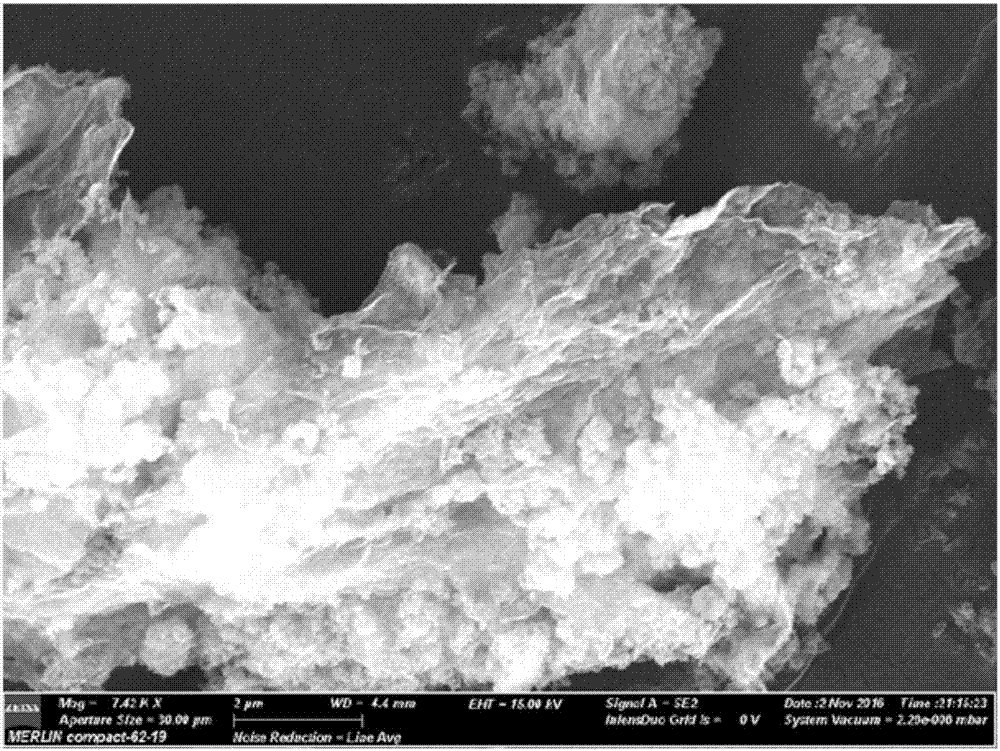

Lithium metasilicate doped graphene lithium ion battery anode material and preparation method thereof

InactiveCN107195884AGuaranteed exchange channelEasy transferCell electrodesSecondary cellsCalcium hydroxideDoped graphene

The invention belongs to the technical field of a lithium ion battery, and particularly relates to a lithium ion battery anode material. The invention particularly discloses a lithium metasilicate doped graphene lithium ion battery anode material, which is prepared by the following steps of: adding a mixture of silicon powder and graphite oxide into aqueous solution of ethanol, which contains lithium hydroxide, and synthesizing a Li2SiO3 / GE precursor by adopting a hydrothermal method; and sintering the Li2SiO3 / GE precursor under the protection of argon to obtain the lithium metasilicate doped graphene lithium ion battery anode material. The lithium metasilicate doped graphene lithium ion battery anode material provided by the invention, by experimental proofs, can improve specific capacity and cycle performance of a battery.

Owner:HENAN POLYTECHNIC UNIV

Scrape-resistant expandable graphite water-based ultra-thin fire-resistant coating for steel structures and preparation method thereof

InactiveCN106752598AImprove heat resistanceImprove antioxidant capacityFireproof paintsAnti-corrosive paintsWater basedHexamethylenetetramine

The invention discloses a scrape-resistant expandable graphite water-based ultra-thin fire-resistant coating for steel structures, prepared from the following raw materials in parts by weight: 20-22 parts of ammonium polyphosphate, 7-8 parts of pentaerythritol, 7-8 parts of melamine, 4-5 parts of expandable graphite, 3-3.5 parts of chlorinated paraffin, 23-25 parts of a 0.1Mol / L zinc nitrate water solution, 23-25 parts of a 0.1Mol / L hexamethylenetetramine water solution, 0.8-1 part of ethyl orthosilicate, 1.6-1.8 parts of lithium metasilicate, a proper amount of water, 42-43 parts of methyl methacrylate, 3-3.5 parts of graphene, 1.2-1.5 parts of molybdenum disulfide nanosheets, 3-4 parts of gelatin and 0.6-0.8 part of barium fluoride. The gelatin is used for modifying the graphene, molybdenum disulfide nanosheets and barium fluoride, so the graphene, molybdenum disulfide nanosheets and barium fluoride are uniformly dispersed in the coating, and the compactness, waterproofness, rotproofness and especially scrape resistance of a coating layer are greatly improved.

Owner:TIANCHANG YINHU PAINT

Nickel-free hole sealing agent for easy-to-film antibacterial aluminum alloy anodic oxide film and preparation method thereof

InactiveCN105200494AImprove permeabilityImprove adhesionSurface reaction electrolytic coatingIsolation effectLithium metasilicate

The invention discloses a nickel-free hole sealing agent for an easy-to-film antibacterial aluminum alloy anodic oxide film. The nickel-free hole sealing agent is prepared from, by weight, 8-8.5 parts of magnesium acetate, 19-20 parts of triethanolamine, 3-3.2 parts of ammonium acetate, an appropriate amount of deionized water, 0.6-0.7 part of triethanolamine dilaurate, 0.3-0.4 part of cobalt lactate, 0.3-0.4 part of sodium tripolyphosphate, 0.8-1 part of silica sol, 0.4-0.5 part of lithium metasilicate, 2.6-2.8 parts of dodecafluoroheptyl-propyl-trimethoxysilane, 1-1.2 parts of tetrabutyl titanate, 45-48 parts of ethyl alcohol, 8.6-9 parts of ammonia water and 0.3-0.4 part of fluorine-containing surfactant. According to the nickel-free hole sealing agent, the triethanolamine dilaurate, the cobalt lactate, the sodium tripolyphosphate and the silica sol are used, so that the film-forming property of the sealing agent is improved, films can be formed quickly, and the sealing agent can be permeated in the films; the hole sealing speed is high, and the air isolation effect is good; besides, the antibacterial effect is achieved, and the corrosion resistance is improved.

Owner:MAANSHAN JIECHUANG PLASTIC TECH CO LTD

Modified mixed zinc-rich paint and process thereof

InactiveCN106752158AStirring speed is fastAlkali metal silicate coatingsAnti-corrosive paintsAdhesion forceMetasilicate

The invention relates to modified mixed zinc-rich paint and a process thereof. According to a method, lithium metasilicate and potassium metasilicate are used as composite base materials; a surfactant of dodecyl glycol amide is added; the wettability of metal zinc powder is improved; the adhesion force of the paint is enhanced; the prepared zinc-rich paint has good comprehensive performance.

Owner:李玉秀

Graphene battery positive material with high specific capacity and preparation method thereof

InactiveCN108550853AWide variety of sourcesImprove the first Coulombic efficiencyCell electrodesBenzoic acidLithium metasilicate

The invention discloses a graphene battery positive material with high specific capacity and a preparation method thereof. The graphene battery positive material comprises the following raw materialsin parts by weight: 6 to 10 parts of graphene, 3 to 4 parts of vanadium pentoxide, 2.4 to 4 parts of sodium dodecyl benzene sulfonate, 4 to 6 parts of benzoic acid, 5 to 8 parts of nanosilicon dioxide, 4 to 8 parts of silicon carbide particles, 3 to 10 parts of lithium metasilicate, 6 to 10 parts of passion fruit and 0.8 to 1.5 parts of zinc oxide. The graphene battery positive material is wide inraw material source, different raw materials are prepared by adopting different technologies, the raw materials are of a synergistic effect, the prepared finished product has the advantages of good initial coulombic efficiency, high capacity and high cycling stability, and the using requirement of people can be met.

Owner:姜雪

Microcrystalline glass, and preparation method and application thereof

ActiveCN112939472ASolve the problem of low performance improvementLithium metasilicateProtective glasses

The invention relates to the field of glass, and particularly discloses a microcrystalline glass, and a preparation method and application thereof. Based on the total weight of the microcrystalline glass, the microcrystalline glass comprises, by weight, 52-65% of SiO2, 12-27% of Al2O3, 5-19% of Na2O, 0-3.5% of K2O, 2-7% of MgO, 3-10% of Li2O, 0.5-5% of ZrO2 and 0-4.5% of TiO2. The microcrystalline glass includes a microcrystalline portion having a spherical crystalline phase, and a glass phase portion, the degree of crystallization is 10-25 wt%, and the spherical crystalline phase includes at least one of lithium disilicate, beta-quartz, a beta-quartz solid solution, Mg2TiO4, and lithium metasilicate. The microcrystalline glass has the advantages of high light transmittance, high strength, excellent impact resistance and excellent falling resistance, and is especially suitable for being used as display device protective glass.

Owner:SICHUAN XUHONG OPTOELECTRONICS TECH +1

Concrete modified material and its mfg. method

The present invention relates to a concrete texture modifying material and the preparing method thereof, at least two materials are selected from sodium silicate, potassium silicate, lithium metasilicate are selected for mixing, and the sodium hydroxide are added into the mixed liquid. The method for making the concrete texture modifying material is respectively choosing at least two materials from sodium silicate, potassium silicate, lithium metasilicate for mixing with a molar ratio 1:1, then adding sodium hydroxide into the mixed liquid, and then is prepared by filtering after stirring for a certain time. The advantage of the invention is that the velocity of gelatinization can be adjusted by adjusting the adding amount of sodium hydroxide in the mixed liquid, the deterioration of concrete caused by the entering of the air is prevented by permeating the mixed liquid into the slit of the concrete for gelatinization according to the condition of the concrete deterioration, the acid can be neutralized and the concrete deterioration can be prevented. Meanwhile the function of mixed alkali is used for preventing alkaline framing member reaction, salt damage, freezing dissolving and the like.

Owner:富田 豊 +2

Porous lithium salt aerogel coated graphite composite material and preparation method thereof

InactiveCN109904434AImprove liquid absorption and retention capacityImprove first-time efficiencyCell electrodesMaterials preparationPore distribution

The invention relates to the technical field of lithium ion battery material preparation, and discloses a porous lithium salt aerogel coated graphite composite material. The composite material is of acore-shell structure, wherein the inner core is graphite, and the shell is a porous lithium metaaluminate / lithium metasilicate / lithium titanate ternary compound. By use of the porous lithium salt aerogel coated graphite composite material and the preparation method thereof, the surface of the graphite is coated with the porous lithium salt compound, the characteristic of large own specific surface area of the porous lithium salt is used for improving the liquid adsorption and liquid retaining capability of the material, sufficient lithium ions are provided for subsequent charging and discharging, and the rate performance of the material is improved. Meanwhile, the sufficient lithium ions provide lithium ions for forming an SEI (Solid Electrolyte Interphase) membrane in an initial charging and discharging process, and the initial efficiency of the material is improved. The porous lithium salt compound prepared with an aerogel method has the characteristics of reasonable pore distribution and stable structure, can contain sufficient lithium ions, and supplements lithium ions consumed in the subsequent long-circulation process of materials so as to improve the circulation performance of the material.

Owner:江苏贝肯盛创新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com