Al2O3-free lithium silicate glass composition

A technology of glass composition and lithium silicate, which is applied in the field of dental crown restorations, can solve problems such as impact, high material strength, and poor material strength

Pending Publication Date: 2017-10-20

SHOFU INC

View PDF9 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

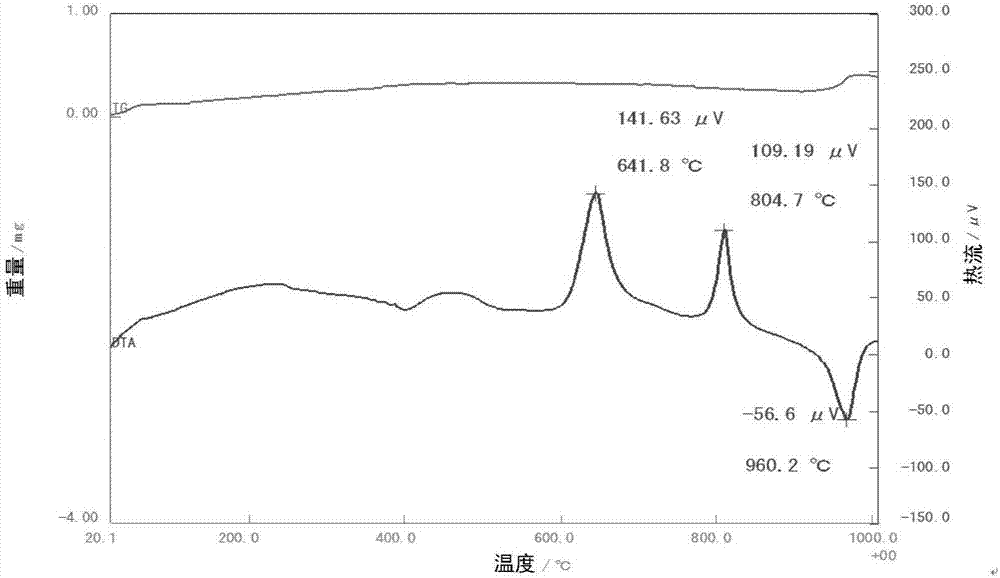

[0010] Therefore, based on the Al contained in the composition of the conventional lithium silicate glass composition 2 o 3 Influenced by the influence, the main crystals aimed at high strength cannot be efficiently precipitated, due to the Li in the composition 2 O or P 2 o 5 Various crystals are also precipitated, so the high material strength pursued by dental glass ceramics cannot be exhibited.

Furthermore, the precipitation of various crystals not only has a bad influence on the strength of the material, but also has a bad influence on the transparency.

[0011] Therefore, for dental crown restorations used in cosmetic restoration treatments in the dental field, although high mechanical strength capable of withstanding severe occlusal pressure and aesthetics similar to natural teeth are pursued, the current situation is still There is no lithium silicate glass composition satisfying these characteristic requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0136] The present invention will be described in detail based on the following examples. However, the present invention is not limited to the scope of these examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

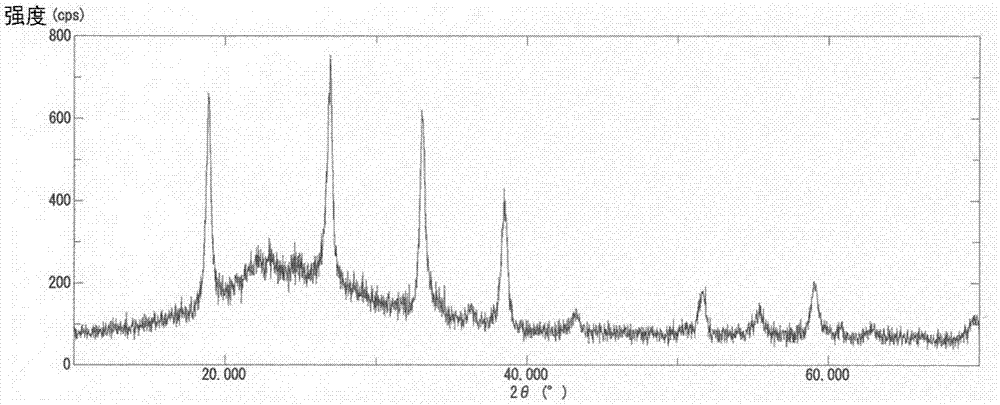

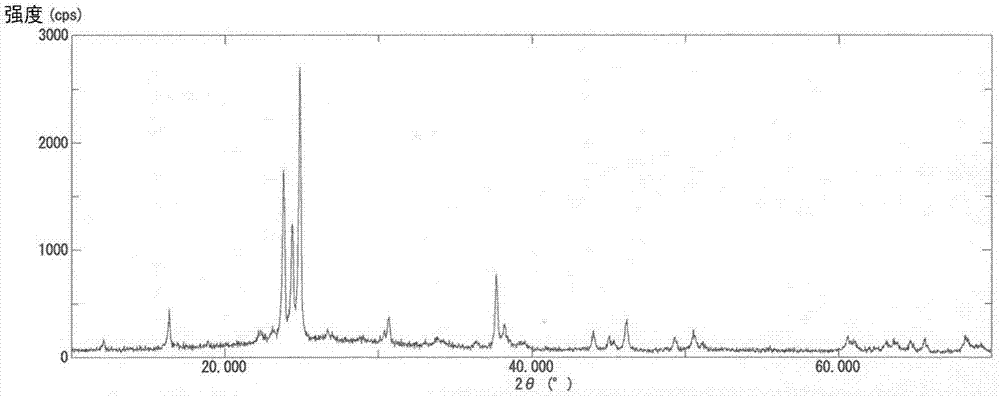

To provide a dental lithium silicate glass composition capable of providing a dental lithium silicate glass ceramic capable of efficiently precipitating the main crystals (lithium disilicate and / or lithium metasilicate) even after heat treatment. To provide a Al2O3-free dental lithium silicate glass composition including the following components: SiO2: 60.0 to 80.0% by weight, Li2O: 10.0 to 17.0% by weight, K2O: 0.5 to 10.0% by weight, ZrO2: 0.0 to 5.0% by weight, a nucleating agent: 1.0 to 6.0% by weight, a glass stabilizer: 0.0 to 8.0% by weight and a colorant: 0.0 to 10.0% by weight.

Description

technical field [0001] The present invention relates to an Al-free toothbrush for the production of dental crown restorations made of ceramics for cosmetic restorative treatment in the field of dentistry 2 o 3 Lithium silicate glass composition, glass ceramics obtained by heat treatment, and crown restorations made using it. Background technique [0002] In the past, in the cosmetic restoration treatment in the field of dentistry, ceramic crown restorations have been used clinically, and almost all of these restorations contain leucite crystals (KAlSi 2 o 6 ) of glass ceramics. Since the refractive index of the leucite crystal is similar to that of the surrounding glass substrate, the glass ceramics containing the leucite crystal has transparency, and as a result, a dental crown restoration with excellent aesthetics can be produced. However, since leucite crystals are dendritic, the propagation of cracks generated inside the glass ceramic cannot be suppressed, and high m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C3/097C03C3/078C03C10/00C03B19/02C03B32/02A61K6/027A61K6/838

CPCC03B19/02C03B32/02C03C3/078C03C3/097C03C10/00A61K6/836A61K6/833A61K6/74A61K6/16A61K6/802A61K6/818A61C5/77C03C4/0021

Inventor 竹内大辅寺前充司

Owner SHOFU INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com