Mechanical method and apparatus for removing polycarprolactam dimers

A polycaprolactam dimer, mechanical method technology, applied in separation methods, chemical instruments and methods, filtration separation and other directions, can solve the problem of affecting nylon 6 post-processing procedures, inability to reopen ring-opening polymerization, particularly serious component blockage, etc. problem, to achieve the effect of convenient cleaning, low cost and small material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

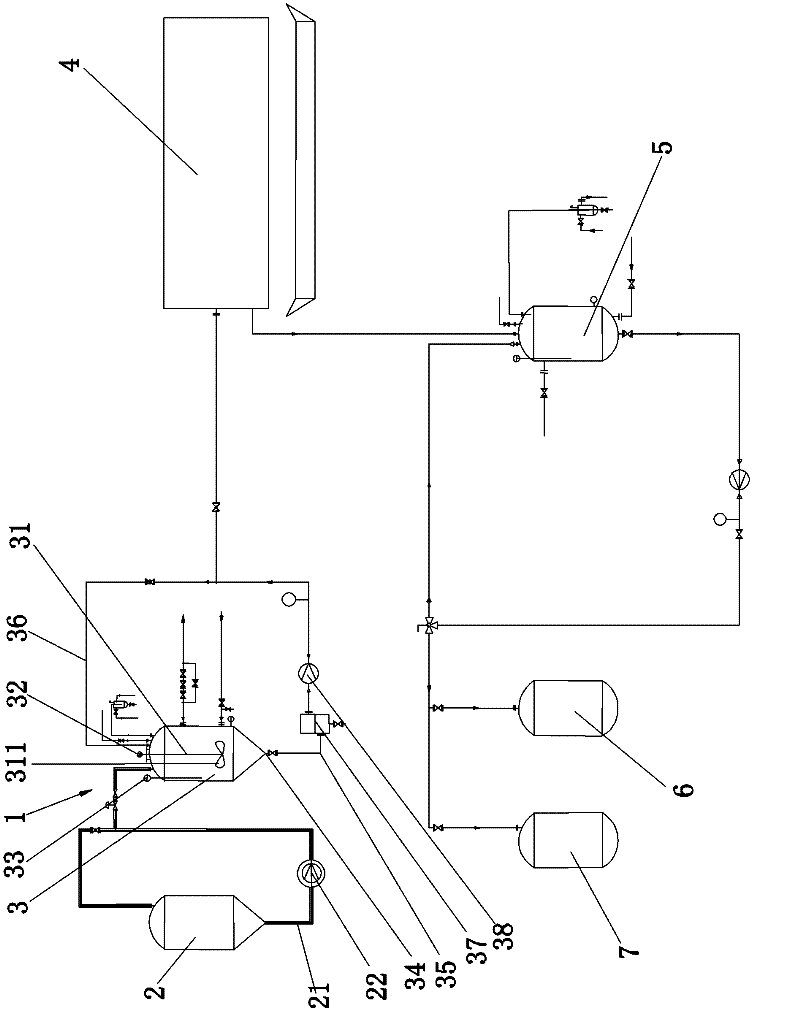

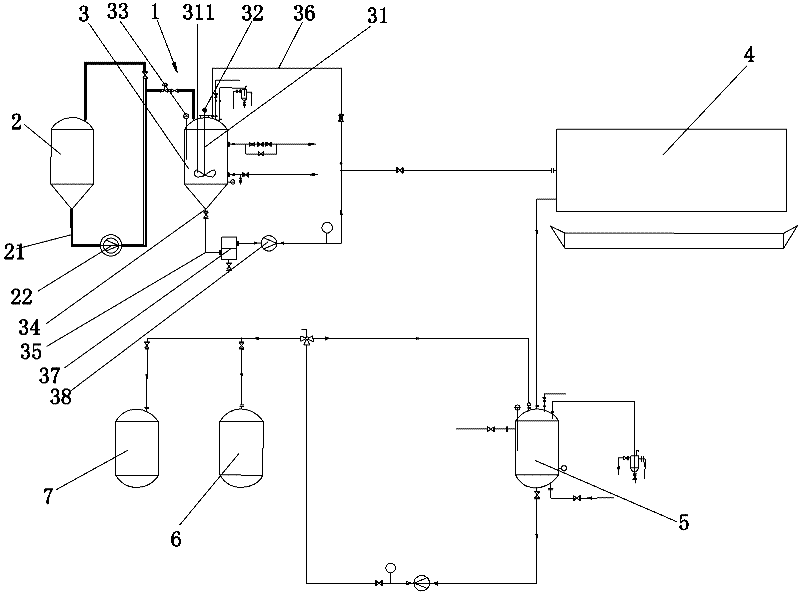

[0030] A mechanical method for removing polycaprolactam dimers comprises the following steps:

[0031](1) The caprolactam concentrated solution concentrated by three-effect evaporation with a temperature of 120°C is sent to the cooling tank 3 of the concentrated solution through the concentrated solution pump 22. The concentration of the concentrated solution is 80%. There is a circulating cooling water coil in the cooling tank 3. An agitator 31 is installed on the top of the cooling tank 3, and the agitator impeller 311 is fan-shaped. The concentrated solution is cooled to 85°C by circulating water to crystallize the cyclic oligomers in the caprolactam concentrated solution. Stir with a stirrer 31 to disperse the crystals evenly in the cooled caprolactam concentrated solution to prevent the crystals from settling and blocking equipment and pipelines .

[0032] (2) Pre-filter the caprolactam concentrated solution cooled to 85°C with the coarse filter 37, and then pressurize i...

Embodiment 2

[0036] A mechanical method for removing polycaprolactam dimers comprises the following steps:

[0037] (1) The caprolactam concentrated solution with a temperature of 110°C that has been concentrated by three-effect evaporation is sent to the concentrated solution cooling tank 3 through the concentrated solution: 37, the concentration of the concentrated solution is 75%, and there is a circulating cooling water coil in the concentrated solution cooling tank 3 A stirrer 31 is installed on the top of the cooling tank 3, and the impeller 311 of the stirrer 31 is fan-shaped. The concentrated solution is cooled to 80°C by circulating water to crystallize the cyclic oligomers in the caprolactam concentrated solution. Stir with a stirrer 31 to evenly disperse the crystals in the cooled caprolactam concentrated solution to prevent the crystals from settling and blocking equipment and pipelines .

[0038] (2) Pre-filter the caprolactam concentrate cooled to 80°C with the coarse filter...

Embodiment 3

[0042] A mechanical method for removing polycaprolactam dimers comprises the following steps:

[0043] (1) The caprolactam concentrated solution concentrated by three-effect evaporation with a temperature of 130°C is sent to the concentrated solution cooling tank 31 through the concentrated solution: 37, the concentration of the concentrated solution is 85%, and there is a circulating cooling water coil in the concentrated solution cooling tank 31 A stirrer 31 is installed on the top of the cooling tank 31, and the impeller 311 of the stirrer 31 is fan-shaped. The concentrated solution is cooled to 93°C by circulating water to crystallize the cyclic oligomers in the caprolactam concentrated solution. Stir with a stirrer 31 to evenly disperse the crystals in the cooled caprolactam concentrated solution to prevent the crystals from settling and blocking equipment and pipelines .

[0044] (2) Pre-filter the caprolactam concentrate cooled to 93°C with the coarse filter 31, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com