High-strength and high-permeability lithium disilicate glass ceramic as well as preparation method and application thereof

A lithium disilicate, glass ceramic technology, applied in glass manufacturing equipment, glass furnace equipment, dental preparations, etc., can solve problems such as strength maintenance, achieve high permeability fracture toughness, reduce the risk of chipping, and the process is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This embodiment provides a preparation method of high-strength and high-permeability lithium disilicate glass ceramics, the preparation method comprising the following steps:

[0072] (1) Put the raw materials of lithium disilicate glass ceramics into the mixer according to the proportion, mix the ingredients for 40 minutes, put them in a platinum crucible after mixing, and melt them at 1450°C for 5 hours, and wait until the components are evenly distributed and there are no air bubbles After escaping completely, the basic glass liquid is obtained;

[0073] (2) Pour the basic molten glass obtained in step (1) into a mold at 420°C for annealing for 10 hours, and then naturally cool to room temperature to obtain a matrix glass;

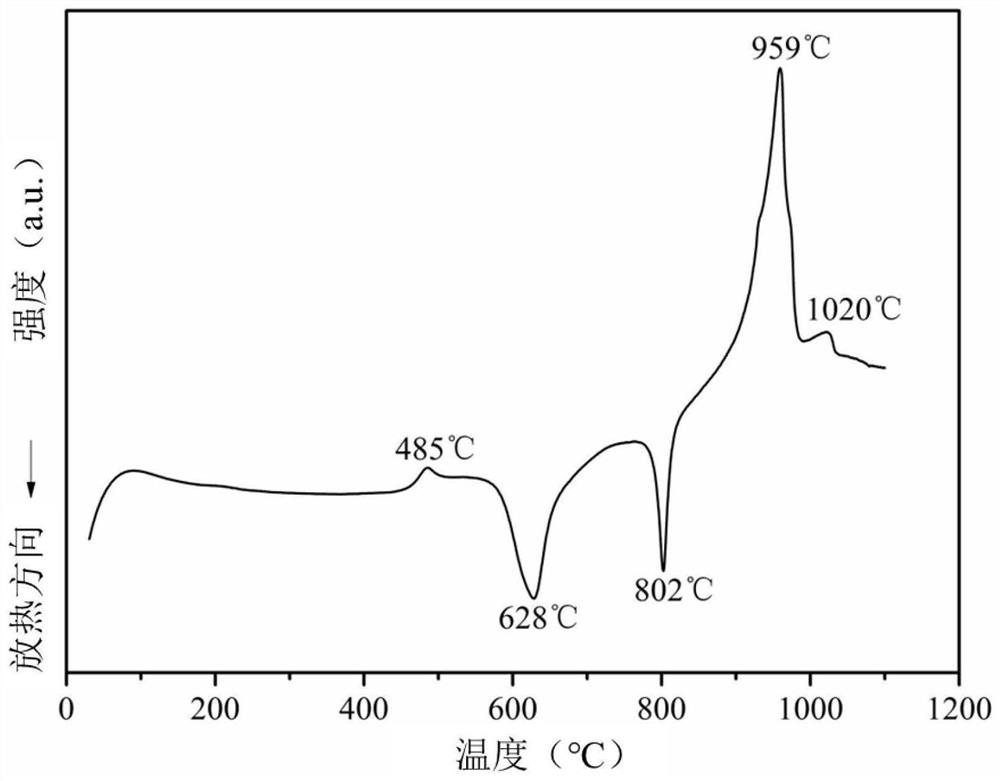

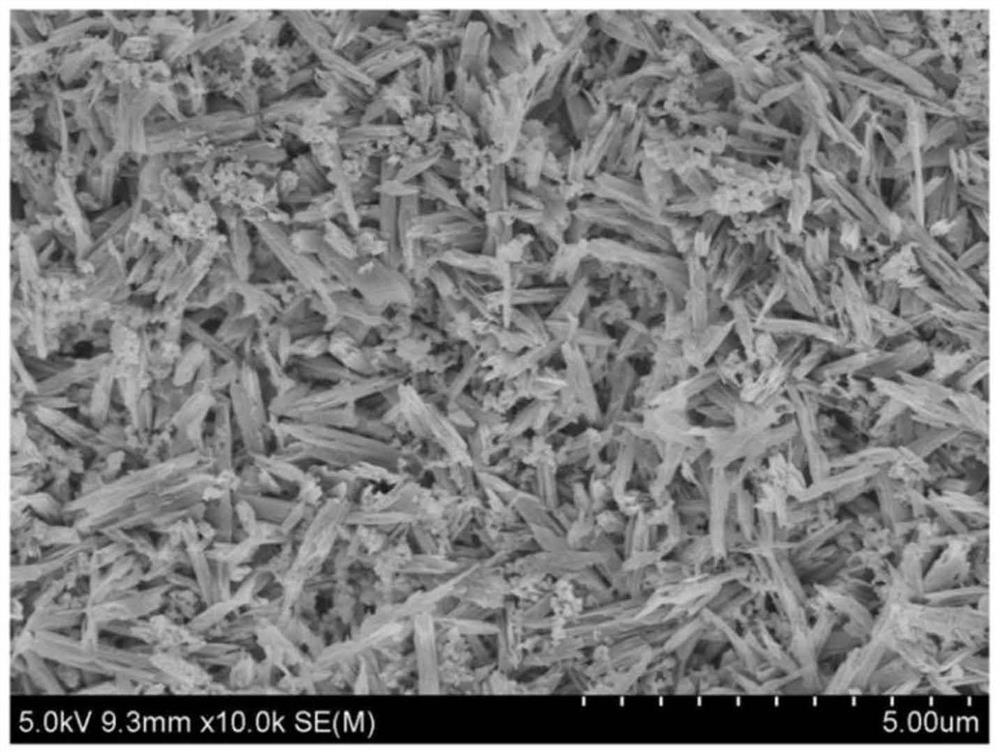

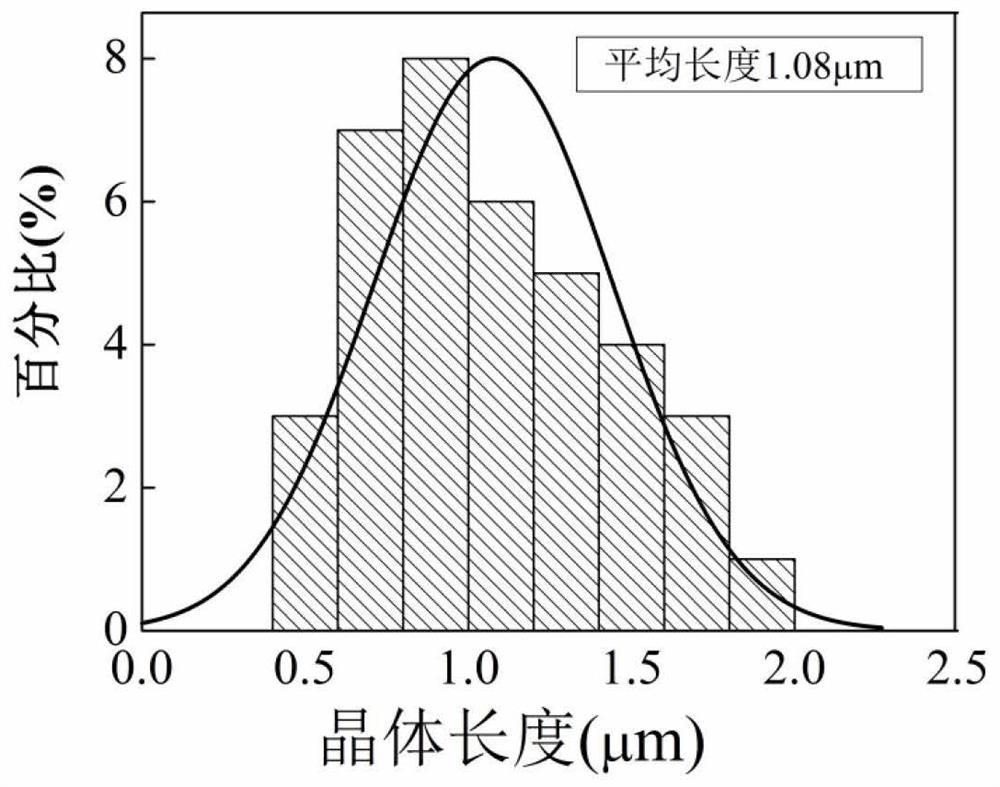

[0074] Heat the base glass to 520°C, keep it warm for 130 minutes, and then cool it down to room temperature naturally; then raise the temperature to 660°C, keep it warm for 150 minutes, then cool it down to room temperature naturally; then use C...

Embodiment 2

[0082] This embodiment provides a preparation method of high-strength and high-permeability lithium disilicate glass ceramics, the preparation method comprising the following steps:

[0083] (1) Put the raw materials of lithium disilicate glass ceramics into the mixer according to the proportion, mix the ingredients for 30 minutes, put them in a platinum crucible after mixing, and melt them at 1450°C for 3 hours, until the components are evenly distributed and there are no air bubbles After escaping completely, the basic glass liquid is obtained;

[0084] (2) Pour the basic molten glass obtained in step (1) into a mold at 400°C for annealing for 3 hours, and then naturally cool to room temperature to obtain a matrix glass;

[0085] Heat the base glass to 550°C, keep it warm for 100 minutes, and then cool it down to room temperature naturally; then raise the temperature to 660°C, keep it warm for 180 minutes, then cool it down to room temperature naturally; then use CAD / CAM mac...

Embodiment 3

[0087] This embodiment provides a preparation method of high-strength and high-permeability lithium disilicate glass ceramics, the preparation method comprising the following steps:

[0088] (1) Put the raw materials of lithium disilicate glass ceramics into the mixer according to the proportion, mix the ingredients for 60 minutes, put them in a platinum crucible after mixing, and melt them at 1450°C for 5 hours, and wait until the components are evenly distributed and there are no air bubbles After escaping completely, the basic glass liquid is obtained;

[0089] (2) Pour the basic molten glass obtained in step (1) into a mold at 450°C for annealing for 2 hours, and then naturally cool to room temperature to obtain a matrix glass;

[0090] Heat the base glass to 570°C, keep it warm for 140 minutes, and then cool it down to room temperature naturally; then raise the temperature to 670°C, keep it warm for 210 minutes, and then cool it down to room temperature naturally; then us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com