Preparation method of Li-Al-Si porous microcrystalline glass

A porous glass-ceramic and fast technology, applied in the field of preparation of Li-Al-Si series porous glass-ceramic, can solve the problems of single crystal structure and complicated preparation process, and achieve good thermal stability, simple process, ultra-low temperature Effect of Thermal Expansion Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with specific embodiments.

[0019] (1) According to the formula ingredients in Table 1, LiO 2 , K 2 O, CaO 2 , Na 2 O is introduced in the form of Na 2 CO 3 ,K 2 CO 3 , Ca 2 CO 3 , Na 2 CO 3 , The grade of raw materials is experimental grade analytical grade, mixed evenly by ball milling, the ball milling medium is absolute ethanol, and the ratio of balls, materials, and medium is 2:1:1.

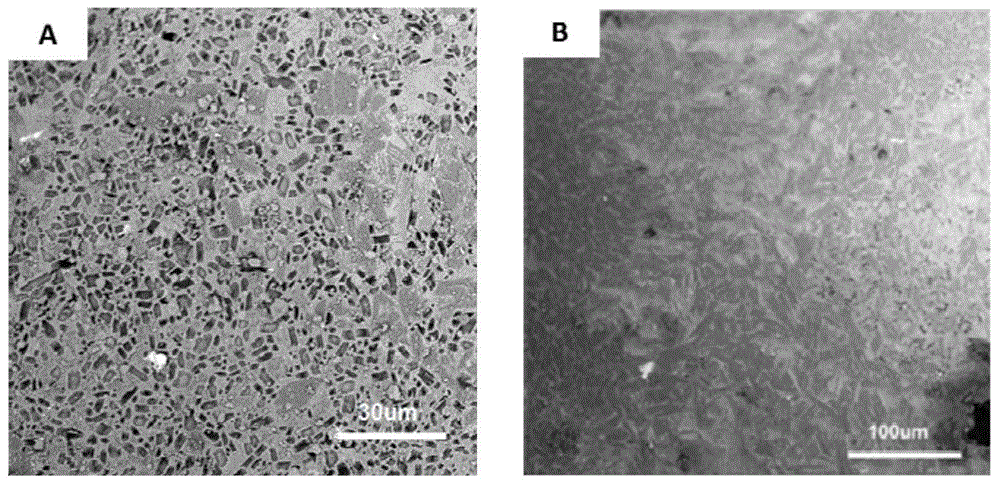

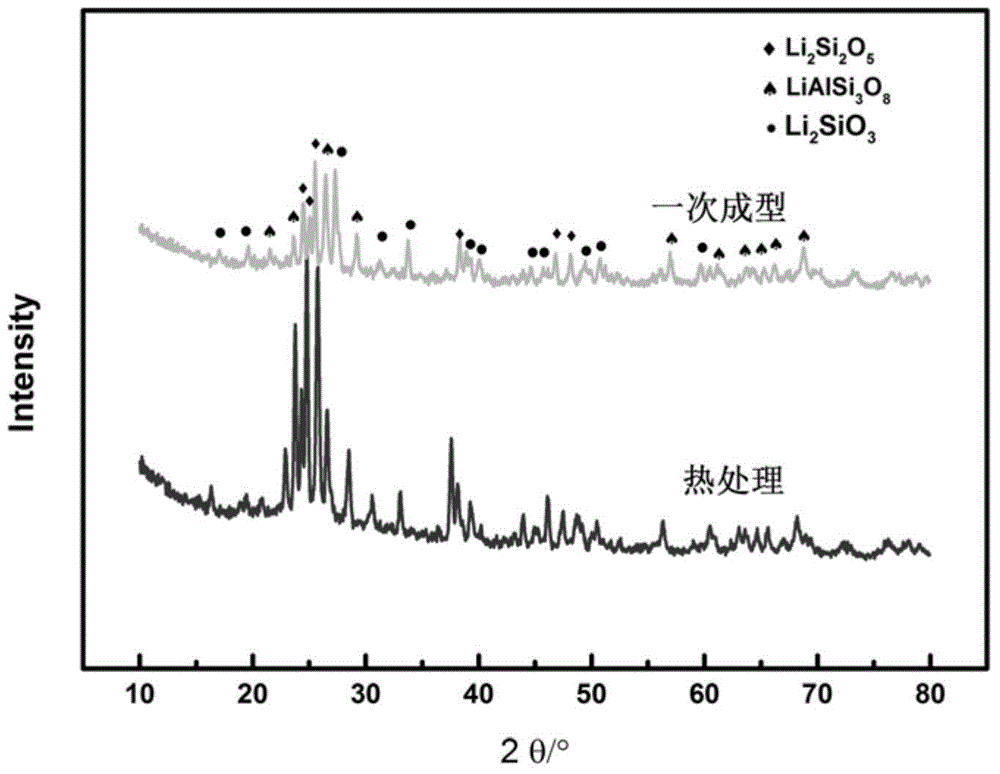

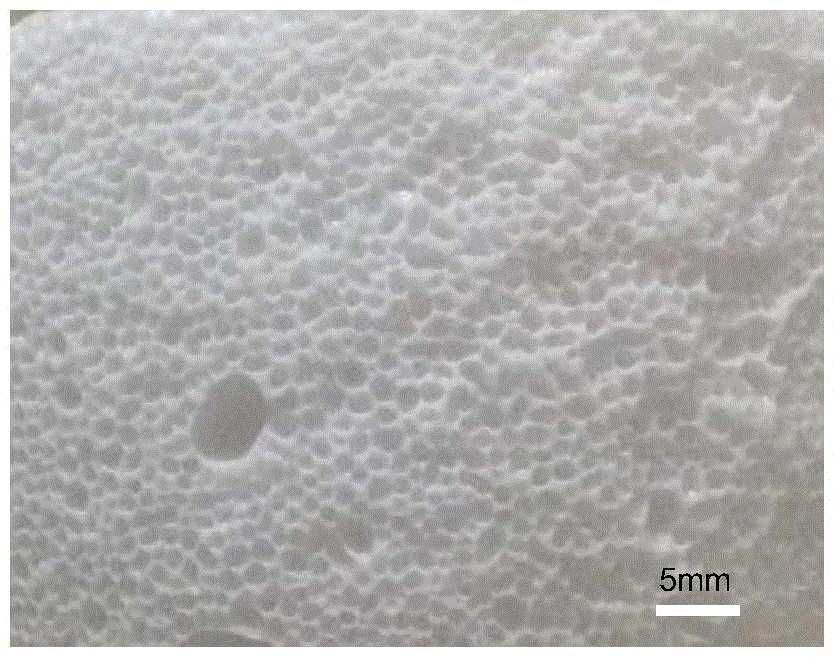

[0020] (2) The mixture is loosely packed into the crucible, and sintered with the process parameters in Table 2 in an air furnace to induce SiO 2 with Li 2 CO 3 The reaction between releases CO 2 The molten glass body is formed, and the mixture of glass liquid and gas forms a porous structure. The porous structure is retained during the cooling process, and a small amount of crystals are produced in the glass through phase separation. The porous glass-ceramic obtained at this stage has a pore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com