Coal slime tailings, sintered brick prepared from coal slime tailings and preparation method thereof

A technology for sintering bricks and tailings, which is applied in the direction of manufacturing tools, clay products, ceramic products, etc. It can solve the problems of high deformation of green body stacking, difficult use of coal slime, energy waste, etc., and achieve fast sintering speed and low production cost , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0082] Example 1: Preparation of standard bricks

[0083] The raw material of the present invention is the tailings separated by a specific separation column, and the percentage of each component in the tailings is: SiO 2 40%, Al 2 o 3 16%, Fe 2 o 3 is 1%, CaO is 1%, and the rest are other elements; the plasticity index is 11; the moisture content is 22-25%, the calorific value is 1.25MJ / Kg, and the particle size is less than 0.045mm, which accounts for 95%. For example:

[0084] Standard bricks are prepared as follows:

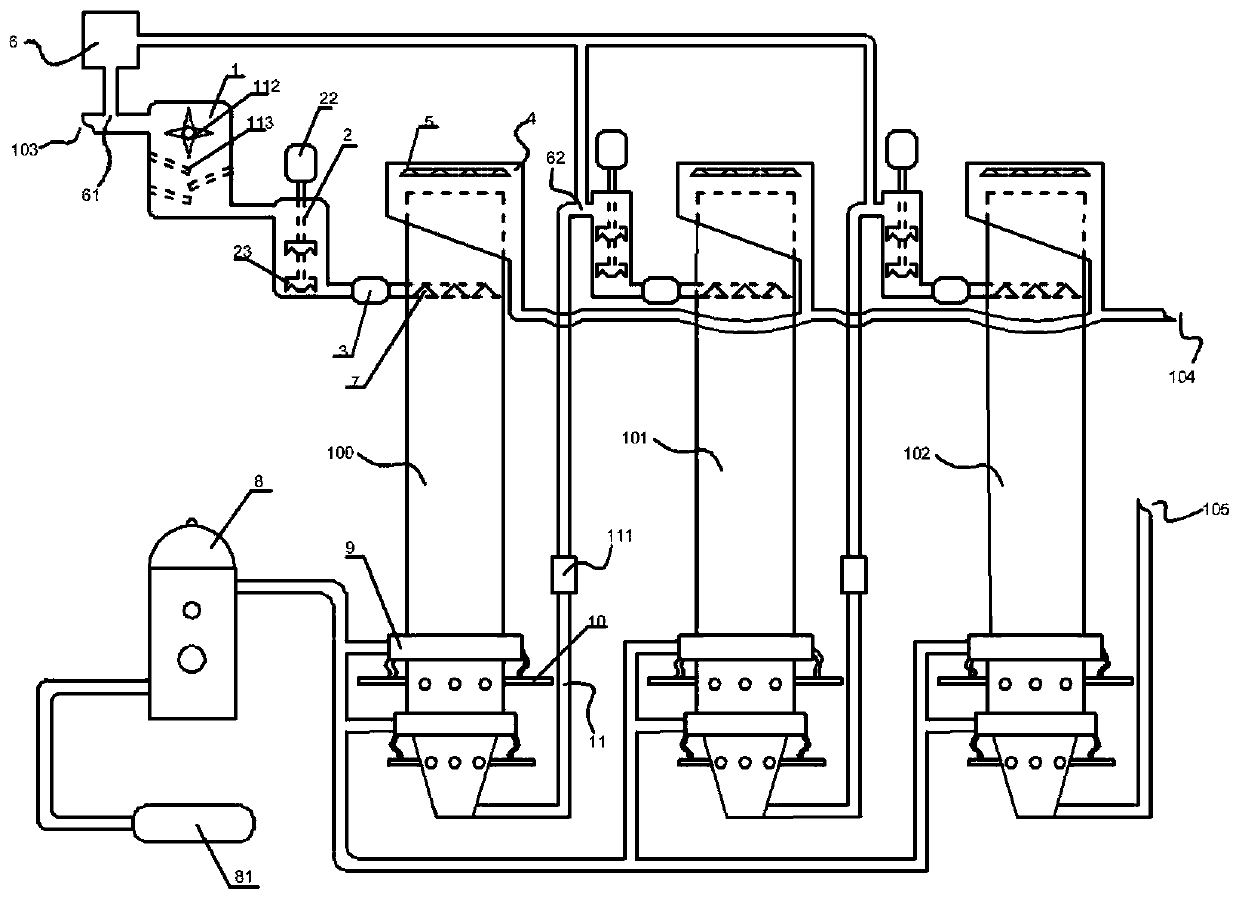

[0085] Step 1: Transport the raw material tailings to a coal slime drying equipment for drying to a water content of 12-15%. The coal slime drying equipment is a coal slime drum drying system.

[0086] Step 2: Transport the tailings obtained in step 1 to two continuous first and second stirring systems of SJJ280×36 for stirring and rolling; the stirring speed of the first stirring system is 100-3000r / min, preferably 200 ~220r / min; the stirring speed of ...

example 2

[0091] Example 2: Preparation of porous bricks

[0092] The tailings whose raw materials are separated by a specific separation column, the percentage of each component in the tailings is: SiO 2 45%, Al 2 o 3 20%, Fe 2 o 3 CaO is 2%, CaO is 2%, and the rest are other elements; plasticity is 12; calorific value is 1.6MJ / Kg, the moisture content of the tailings is 22-25%, and the particle size is <0.045mm, accounting for 95% as an example.

[0093] The preparation method of the porous brick is as follows:

[0094] Step 1: Transport the raw material tailings to a coal slime drying equipment for drying to a water content of 12-15%. The coal slime drying equipment is a coal slime drum drying system.

[0095] Step 2: Transport the tailings obtained in step 1 to two continuous first and second stirring systems of SJJ280×36 for stirring and rolling; the stirring speed of the first stirring system is 100-3000r / min, preferably 200 ~220r / min; the stirring speed of the second stirri...

example 3

[0100] Example 3: Preparation method of hollow brick

[0101] The raw material is the tailings separated by a specific sorting column, and the percentage of each component in the tailings is: SiO 2 50%, Al 2 o 3 25%, Fe 2 o 3 is 3%, CaO is 3%, and the rest are other elements; the plasticity is 13; the calorific value is 2.0MJ / Kg, the moisture content of the tailings is 22-25%, and the particle size is <0.045mm, accounting for 95% as an example.

[0102] The preparation method of the hollow brick is as follows:

[0103] Step 1: Transport the raw material tailings to a coal slime drying equipment for drying to a water content of 12-15%. The coal slime drying equipment is a coal slime drum drying system.

[0104] Step 2: Transport the tailings obtained in step 1 to two continuous first and second stirring systems of SJJ280×36 for stirring and rolling; the stirring speed of the first stirring system is 100-3000r / min, preferably 200 ~220r / min; the stirring speed of the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com