Patents

Literature

298results about How to "Improve peeling resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dedicated pouring material for cement kiln outlet and jetting coal pipe and preparation method thereof

InactiveCN101445379AImprove thermal shock performanceGood alkali resistanceCarbide siliconCement factory

The invention discloses a dedicated pouring material for a cement kiln outlet and a jetting coal pipe, which comprises the following components by the weight percentage: 20 to 30 percent of sintered plate-shaped corundum, 20 to 30 percent of sintered and synthesized mullite, 10 to 15 percent of chrome corundum, 5 to 10 percent of silicon carbide, 3 to 5 percent of silicon carbide superfine powder, 3 to 5 percent of magnesia alumina spinel, 5 to 8 percent of zircon sand, 2 to 5 percent of activated Al2O3 micro powder, 2 to 5 percent of silicon micro powder, 3 to 5 percent of pure calcium aluminate cement, 1 to 2 percent of stainless steel fiber, 5 to 10 percent of synthesized zirconium mullite grinding powder, 0.1 to 0.15 percent of composite additives and 0.01 to 0.1 percent of explosion proof fiber. The invention further discloses a method for preparing the pouring material. The pouring material is applicable to the dry-process cement kiln outlets and the jetting coal pipes in large-scale cement plants and has the advantages of high wear resistance, good anti-stripping resistance and long service life.

Owner:JIANGSU GUOHAO REFRACTORY TECH

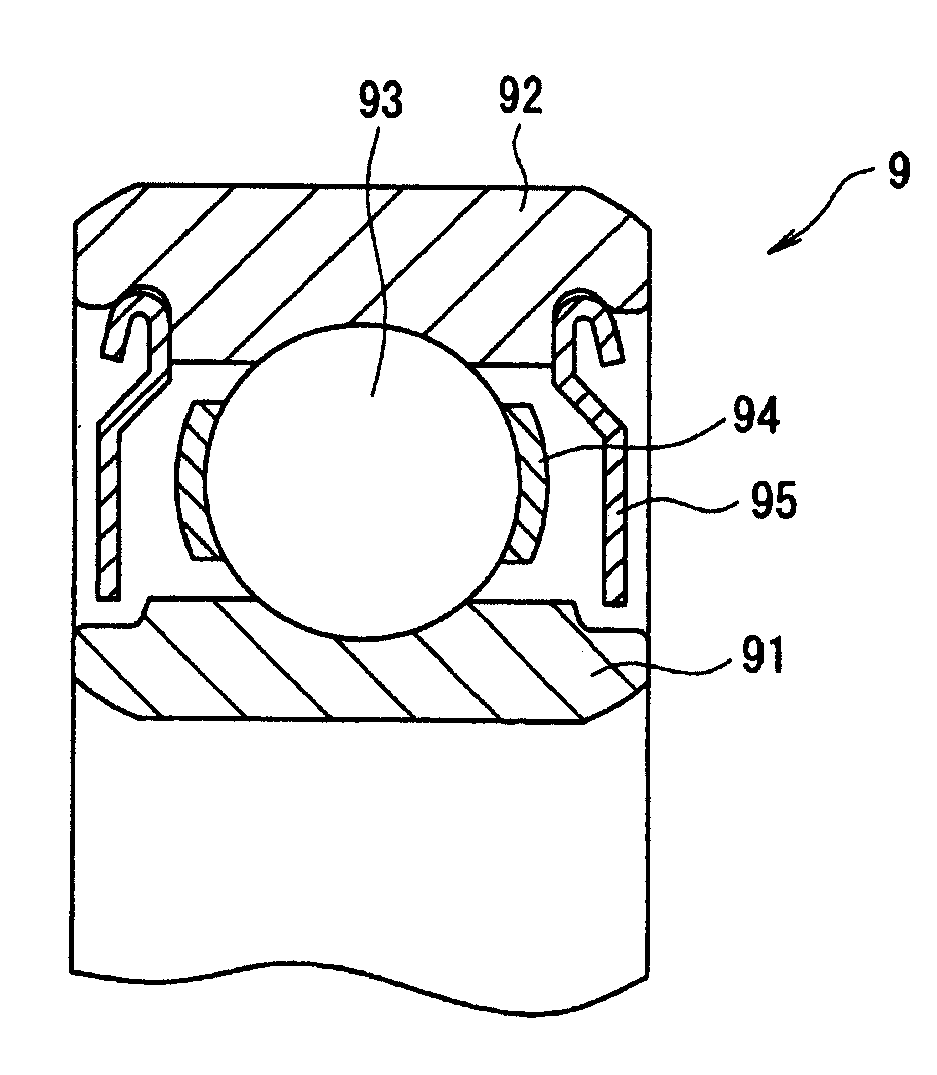

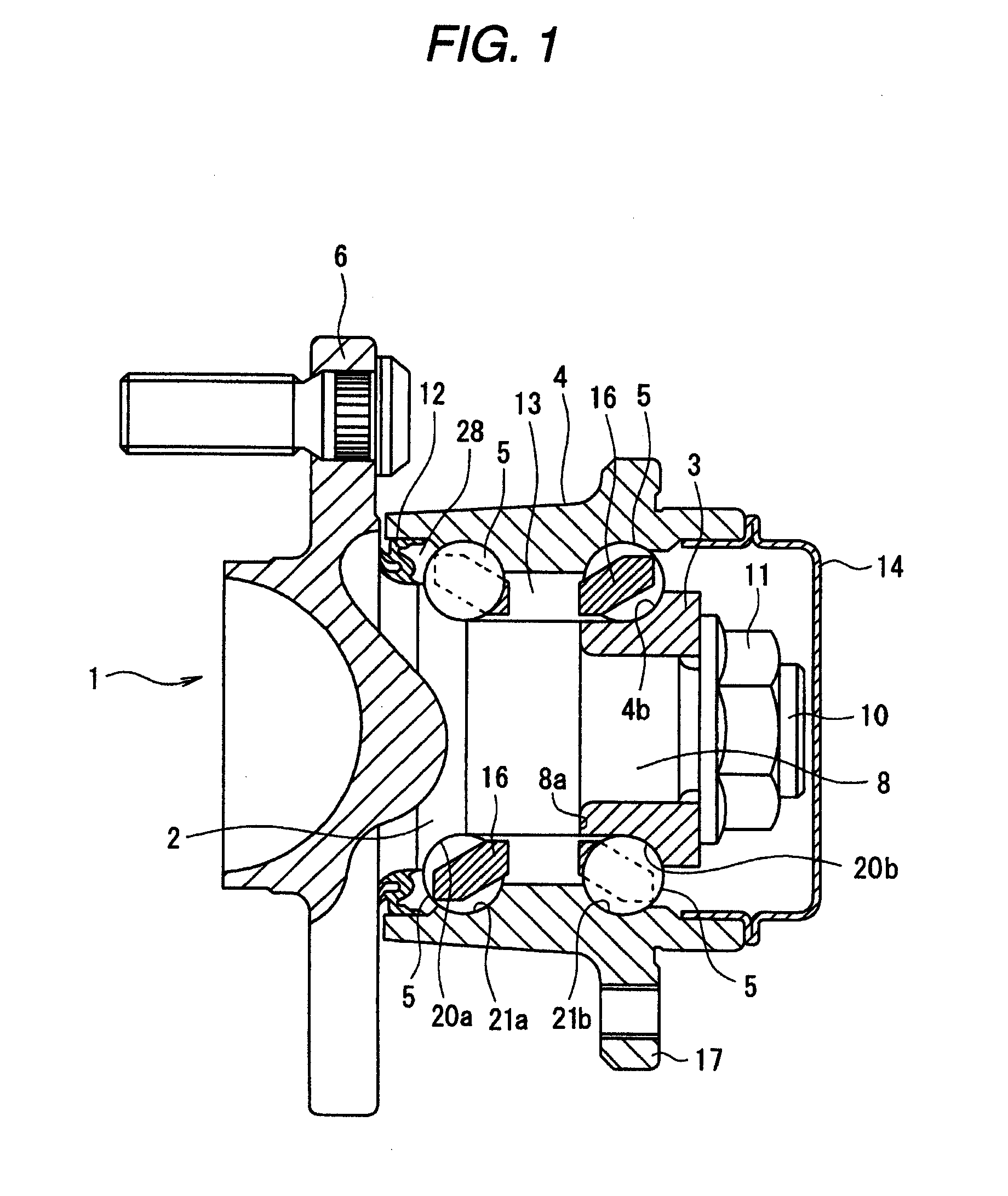

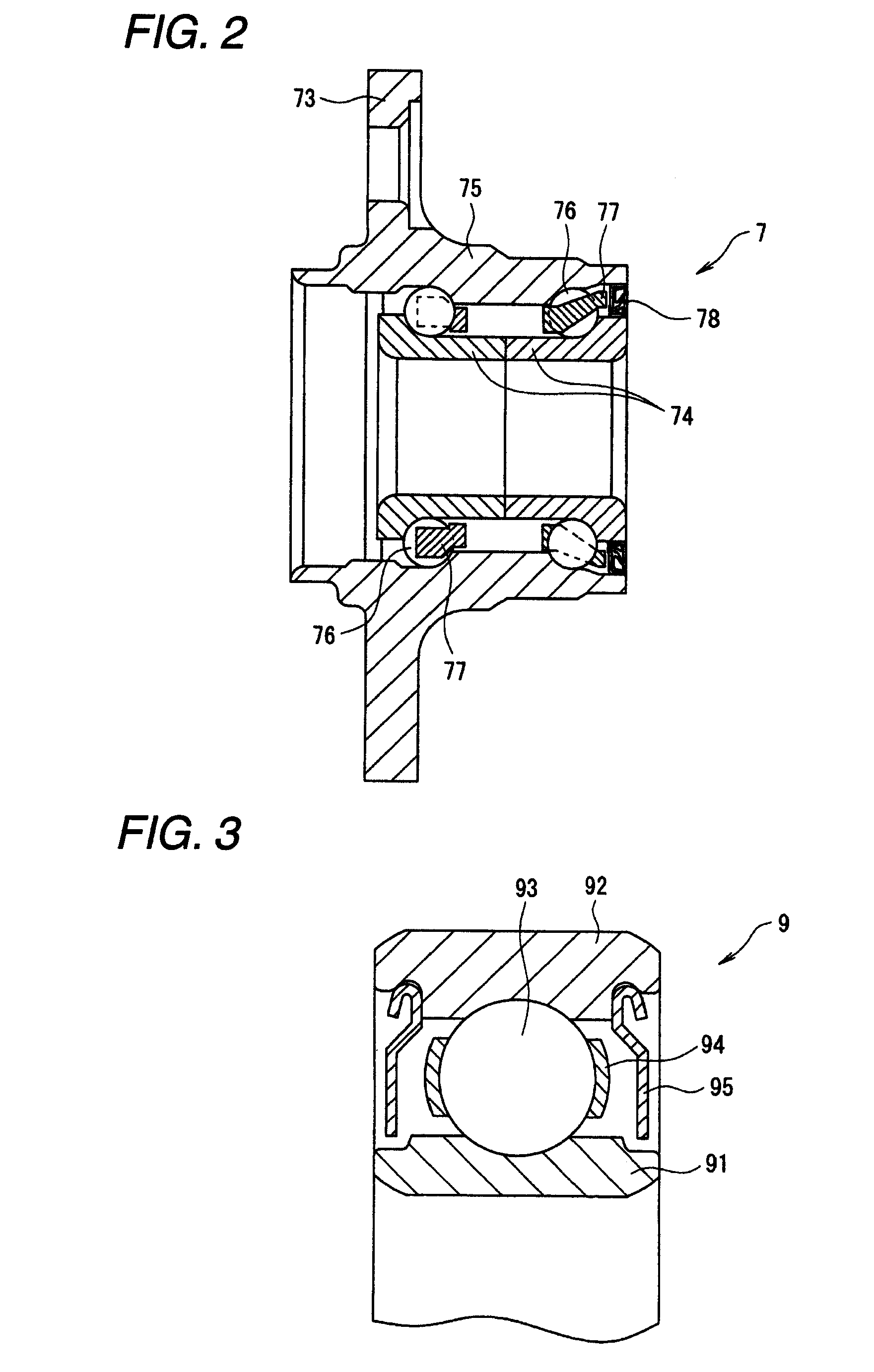

Grease Composition For Hub Unit Bearing, And Hub Unit Bearing For Vehicle

InactiveUS20090003742A1Improve peeling resistanceImprove the lubrication effectOrganic chemistryHubsRolling-element bearingAdditive ingredient

An object of the invention is to provide a grease composition capable of keeping a good lubrication condition for a long period of time even when water has mixed therein, thereby inhibiting white structure flaking and corrosion. Another object is to provide a vehicular hub unit bearing which hardly suffers from white structure flaking and corrosion even when used in an environment where water may penetrate into it and which therefore has a long life.The invention provides a rolling bearing with, sealed up therein, a grease composition containing a waterproof film-forming additive added thereto; a grease composition for hub unit bearings, containing a base oil that comprises at least one of mineral oil and synthetic oil as the main ingredient thereof, and a thickener and a flaking inhibitor; and a vehicular hub unit bearing with the grease composition sealed up therein.

Owner:NSK LTD +1

Corundum-spinel pouring material containing nano-magnesium carbonate

The invention relates to a corundum-spinelle lithical concreting material containing nano magnesium carbonate and a preparation method. In the method, the corundum-spinelle lithical concreting material containing nano magnesium carbonate is prepared by taking the currently and commonly used corundum-spinelle lithical concreting material as the base, adding nano magnesium carbonate powder, and adopting high efficient dispersant and proper mixing technique. With the method adopted, not only the adverse impact of magnesium oxide hydration on the concreting material workability caused by adding magnesia to generate spinelle in situ is avoided, but also the dreg resistance and thermal shock resistance of the existing corundum-spinelle lithical concreting material are improved. The corundum-spinelle lithical concreting material containing nano magnesium carbonate prepared by the invention can be widely used in high temperature industries such as steel, nonferrous metal, ceramic, petrochemical and the like, and can also be used for refractory material products such as air bricks which are baked after concreting moulding.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Zirconium oxide sandwich composite calcining-endure plate and preparation process thereof

The invention discloses a zirconium oxide sandwich composite calcining-endure plate. The zirconium oxide sandwich composite calcining-endure plate comprises a matrix mullite calcining-endure plate and zirconium oxide paint. The matrix mullite calcining-endure plate comprises the following raw materials in percentage by mass: 20 to 25 percent of andalusite with thickness degree between 1 and 1.5 mm, 5 to 10 percent of andalusite with thickness degree between 0.5 and 1 mm, 5 to 8 percent of andalusite with thickness degree less than 0.5 mm, 10 to 15 percent of plate-shaped corundum with thickness degree between 0.5 and 1 mm, 5 to 10 percent of plate-shaped corundum with thickness degree less than 0.5 mm, 5 to 10 percent of electrical melting mullite with thickness degree between 0.5 and 1 mm, 8 to 12 percent of sillimanite powder, 15 to 20 percent of alpha-aluminium oxide (Al2O3) powder, 2 to 3 percent of silica micropowder, 3 to 4 percent of clay and 3 to 4 percent of binding agent. The zirconium oxide paint comprises the following raw materials in percentage by mass: 75 to 80 percent of zirconium oxide with granularity less than or equal to 600 meshes and 20 to 25 percent of silicasol. In addition, the invention also provides a process for preparing the zirconium oxide sandwich composite calcining-endure plate. The zirconium oxide sandwich composite calcining-endure plate has the advantages of high-temperature resistance, high mechanical strength, stable chemical properties, high stability of thermal shock resistance, long service life and high anti-stripping property.

Owner:夏卫平

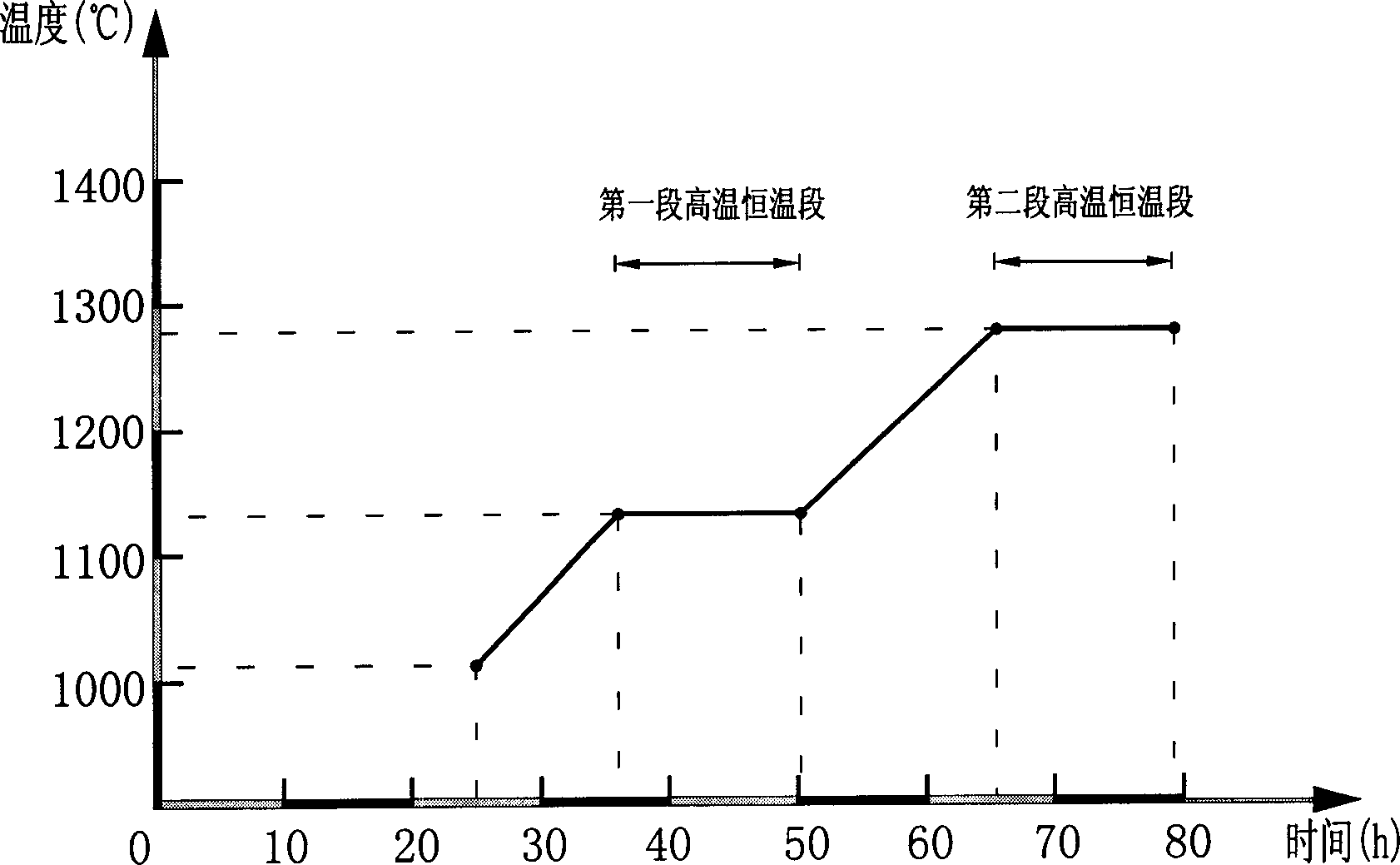

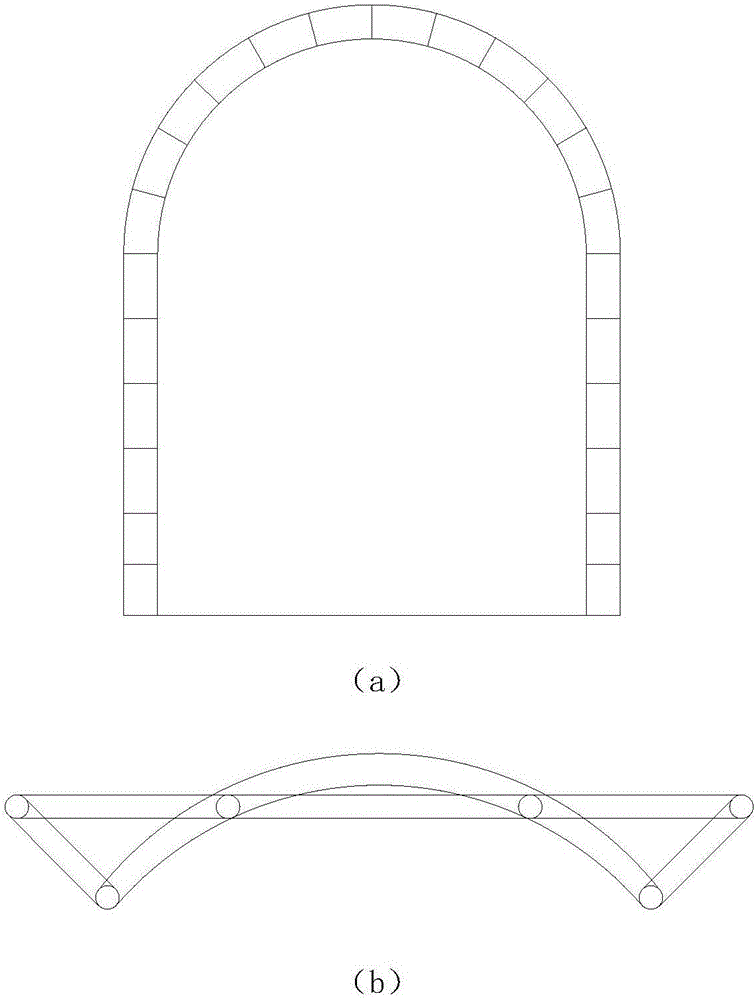

Ltigh crystalline structure iolite mullite kiln, kiln refractory product and calcining technology

The present invention relates to a kind of high crystal structure cordierite-mullite kiln furniture, kiln furnace refractory product and roasting process. Its raw material includes (by weight portion) 50-80 portions of main crystal phase material and 20-50 portions of combined compound matrix material, in the above-mentioned raw material a proper quantity of crystal nucleus formation agent can be added. Its roasting process includes two stages of high-temperature constant-temperature microcrystallization nucleation intensification treatment. Said invention also provides the concrete steps of every stage.

Owner:揭东县热金宝新材料科技有限公司 +2

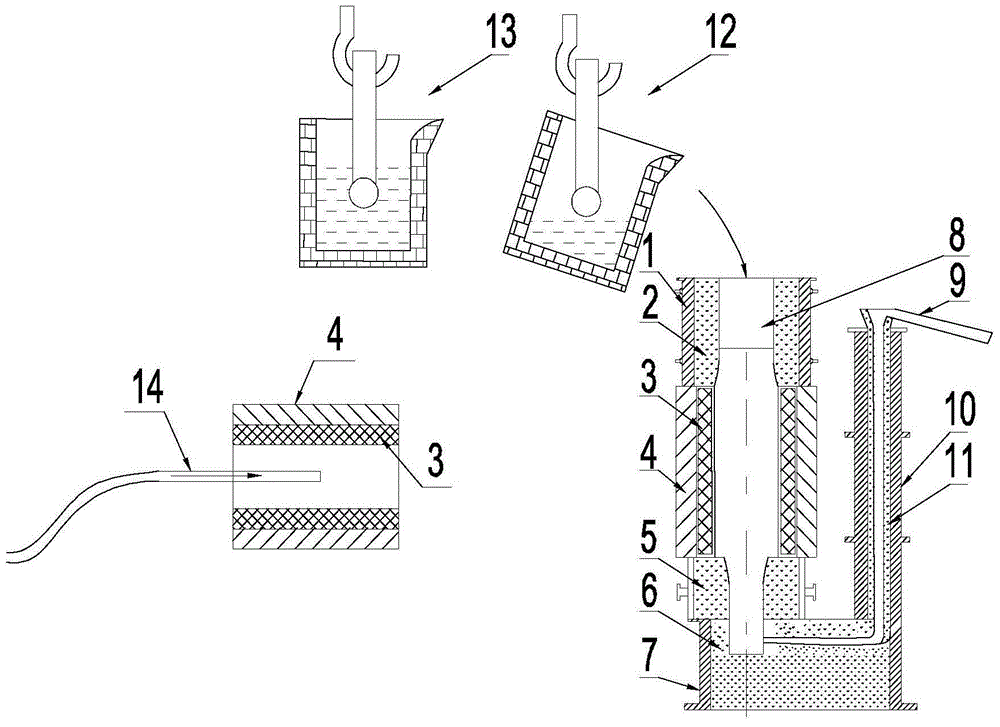

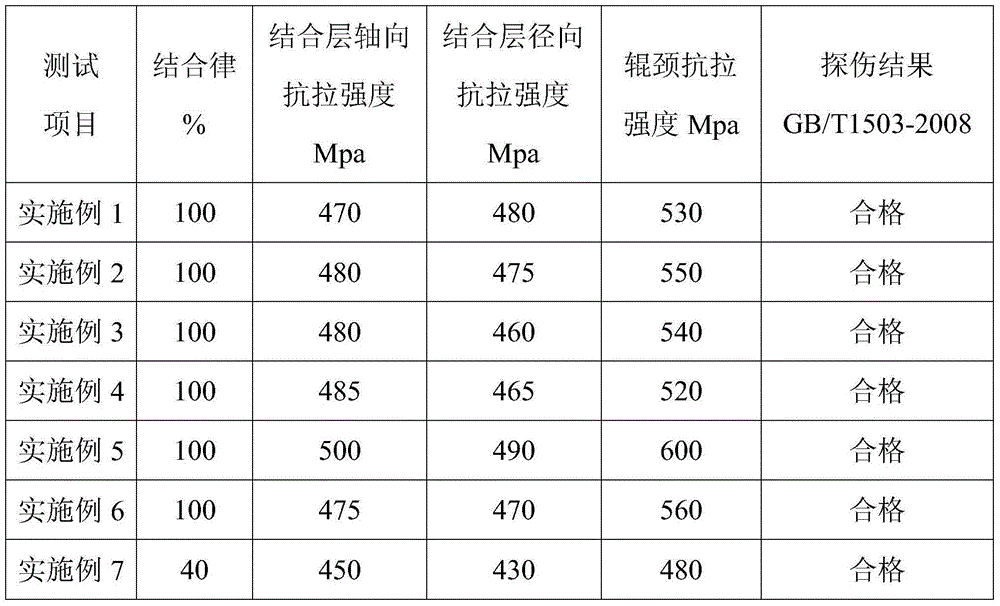

Manufacturing method for high-vanadium high-speed steel composite roll

The invention discloses a manufacturing method for a high-vanadium high-speed steel composite roll suitable for a narrow strip rolling mill. The manufacturing method comprises the steps that an outer layer of a roll body is poured by adopting a centrifugal pouring method, and after the outer layer of the roll body is poured with high-vanadium high-speed liquid steel, inert gas is continuously pumped into a cavity of the outer layer of the roll body; a centrifuge stops rotating when the outer layer temperature of high-vanadium high-speed steel reaches 1220-1280 DEG C, the inert gas is stopped being blown in, and then liquid iron in the core of the roll body is poured through mould closing. According to the manufacturing method for the high-vanadium high-speed steel composite roll, the bonding rate of the high-vanadium high-speed steel of the outer layer and the liquid iron in the core is significantly improved, the binding rate is improved from 40 percent to 100 percent, the bonding strength is improved from about 350 Mpa in the past to about 450 Mpa, and therefore the anti-stripping performance of a roll body bonding layer of the high-vanadium high-speed steel roll is greatly improved; meanwhile, the element amount formed by carbide on the corrosion outer layer of the liquid iron of the core is removed, therefore, roll neck tissues are improved, the tensile strength of the roll neck is improved, and the roll breakage phenomenon in use is effectively and completely eradicated.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Zirconium-containing high-strength wear-resistant castable

The invention discloses a zirconium-containing high-strength wear-resistant castable, which comprises, by weight: 23-32% of brown fused alumina, 42-52% of sintered mullite, 4-8% of corundum powder, 6-10% of mullite fine powder, 3-5% of a-AI2O3, 2-5% of fused alumina zirconia fine powder, 3-5% of silica powder, 6-10% of pure calcium aluminate cement and 0.1-0.15% of a water reducing agent. The zirconium-containing high-strength wear-resistant castable is prepared by: firstly grinding and mixing the corundum powder, the mullite fine powder, the a-AI2O3 and the fused alumina zirconia powder, then adding the remaining various raw materials, and performing mixing stirring. The castable product disclosed in the invention has the characteristics of high bonding strength, strong anti-scouring performance, high compressive strength, good wear resistance, and good thermal shock resistance and stripping resistance, etc.

Owner:巩义市科恒耐火材料有限公司

Gunning mix for converter

InactiveCN101602612AGood adhesionImprove peeling resistanceManufacturing convertersGranularityMolten steel

The invention discloses a gunning mix for a converter, which comprises the following components in percentage by weight: 40 to 60 percent of forsterite of which the particle size is between 0.1 and 5 millimeters, 10 to 30 percent of dolomite of which the particle size is between 0.1 and 3 millimeters, 10 to 20 percent of sintered mid-range magnesia of which the particle size is between 0.01 and 0.088 millimeter, 0.5 to 5 percent of burning and coagulation accelerator, and 1 to 5 percent of bonding agent. When applied to the converter, the forsterite gunning mix prepared by adopting the formulation has the advantages of high adhesive rate, good spalling resistance, quick sintering, erosion resistance, scouring resistance and small high temperature expansion, and simultaneously is insusceptible to gun blockage during the construction. Besides, gunning mix has abundant available mineral products with low price so as to play a role of saving important energy resources, has no influence on the quality of molten steel in use, and is free from causing pollution to the environment.

Owner:陈红良

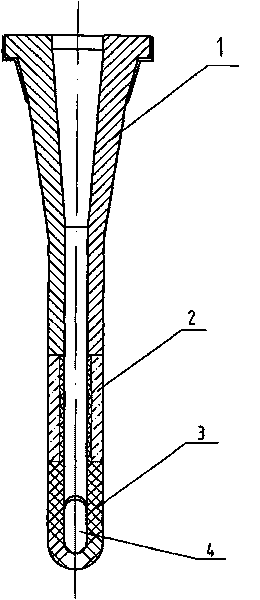

Tundish quick-replaceable sewage outlet used for metal continuous casting plate blank

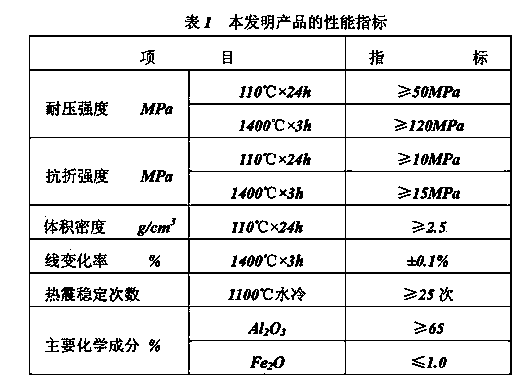

ActiveCN101704099AHigh mechanical strengthHigh temperature resistance and thermal shock resistanceMelt-holding vesselsSlagCorundum

The invention relates to a tundish quick-replaceable sewage outlet used for the metal continuous casting plate blank. The main technical characteristic of the sewage outlet is that a sewage outlet body, an inner slag line and an outer slag line are separately made from refractory materials with different components and proportions and the sewage outlet is prepared from the following raw materials in parts by weight: a. body materials: 18-25 parts of graphite, 10-15 parts of bauxite 24#, 10-15 parts of bauxite 36#, 20-25 parts of bauxite 150#, 10-20 parts of quartz, 3-5 parts of metallic silicon, 2-4 parts of silicon carbide and 1-3 parts of boron glass powder; b. inner slag line materials: 18-33 parts of graphite, 55-70 parts of white alundum, 2-4 parts of metallic silicon powder, 2-4 parts of silicon carbide powder and 3-5 parts of aluminum oxide powder; and c. outer slag line materials: 6-20 parts of graphite, 75-90 parts of electric-melting stable zirconia, 1-3 parts of metallic silicon and 1-3 parts of silicon carbide. The tundish quick-replaceable sewage outlet of the invention can be used to solve the problem that the sewage outlet product of the prior art has short service life, lower mechanical strength and high production cost.

Owner:山东东耐高温材料股份有限公司

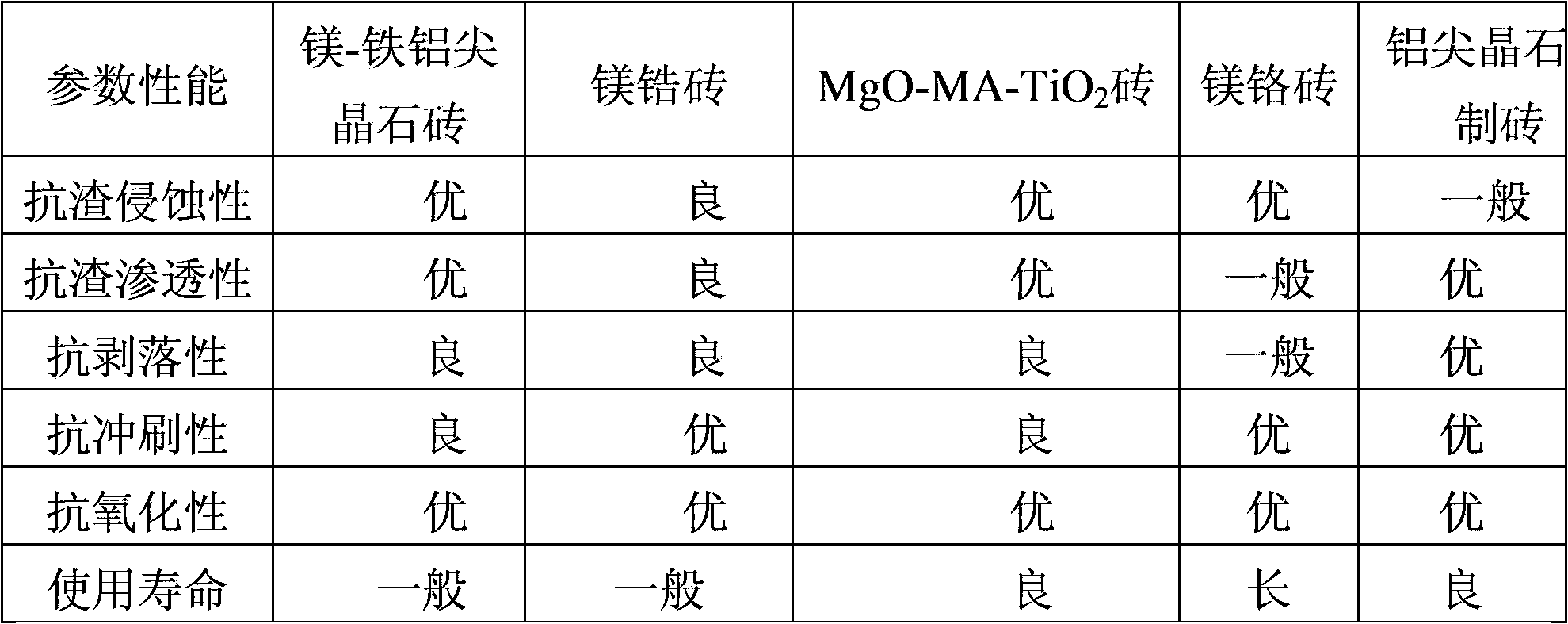

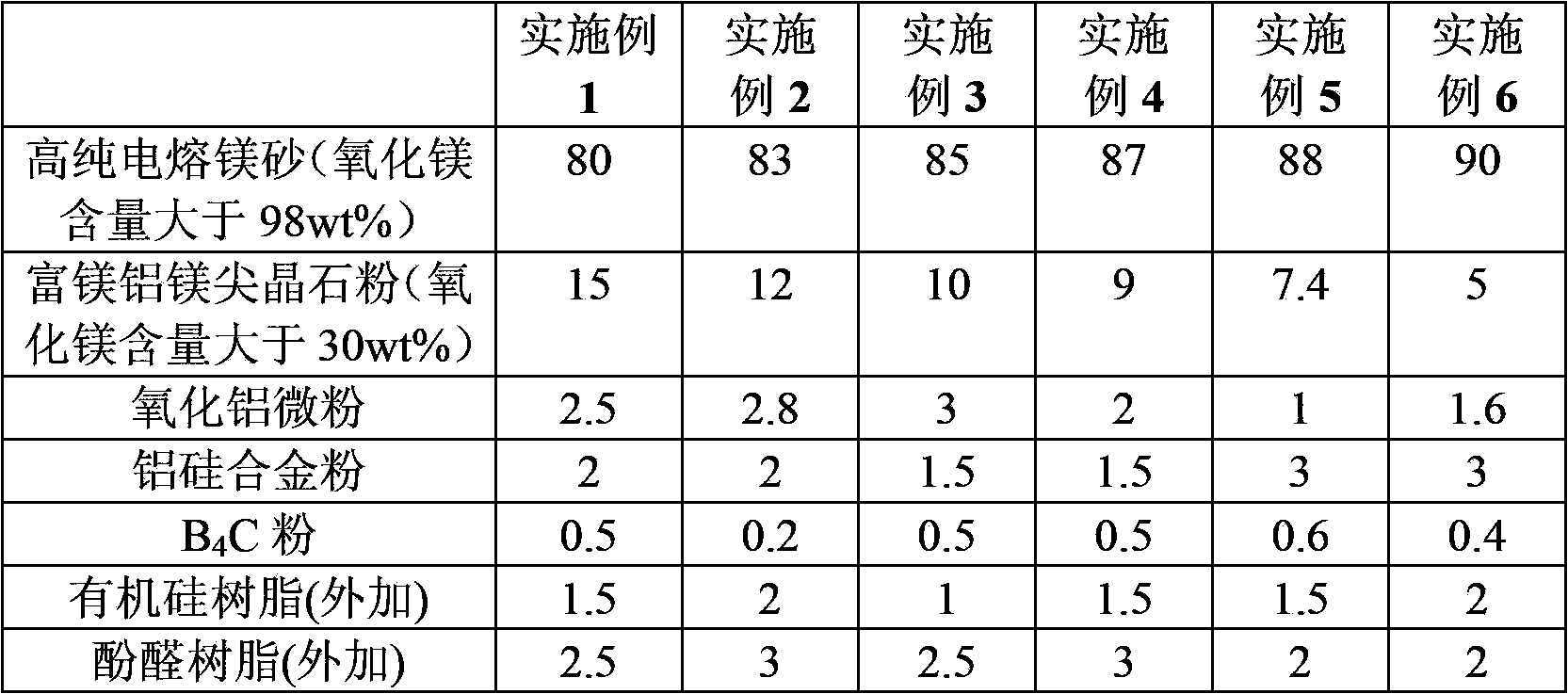

Unfired magnesia-alumina spinel brick

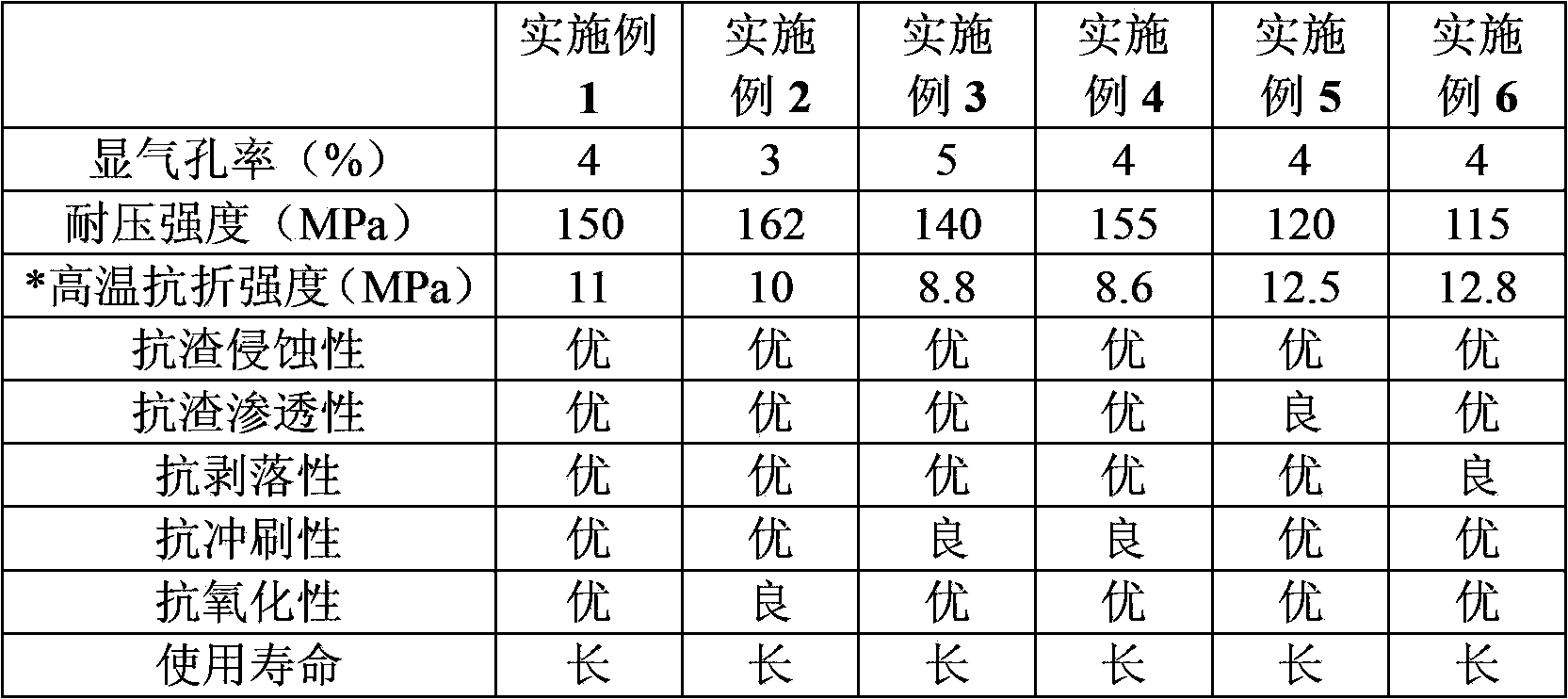

The invention discloses an unfired magnesia-alumina spinel brick. The unfired magnesia-alumina spinel brick comprises the following chemical components by mass: 80 to 90% of fused magnesia, 5 to 15% of magnesium-rich magnesia-alumina spinel, 1 to 3% of micro alumina powder, 1 to 3% of aluminum-silicon alloy powder and 0.2 to 0.6% of B4C. The chemical components are bonded together by using 3.5 to 5 wt% of an added binder. The content of magnesium oxide in the fused magnesia is greater than 98 wt%, and the content of magnesium oxide in the magnesium-rich magnesia-alumina spinel is greater than 30 wt%. The unfired magnesia-alumina spinel brick provided by the invention has excellent slag reaction resistance, slag penetration resistance, anti-stripping performance, anti-scouring performance, resistance to oxidation and a long service life, does not include the harmful element--chromium, avoids pollution and harm to human beings and the environment, needs low production cost and has a wide application scope.

Owner:BAOSHAN IRON & STEEL CO LTD

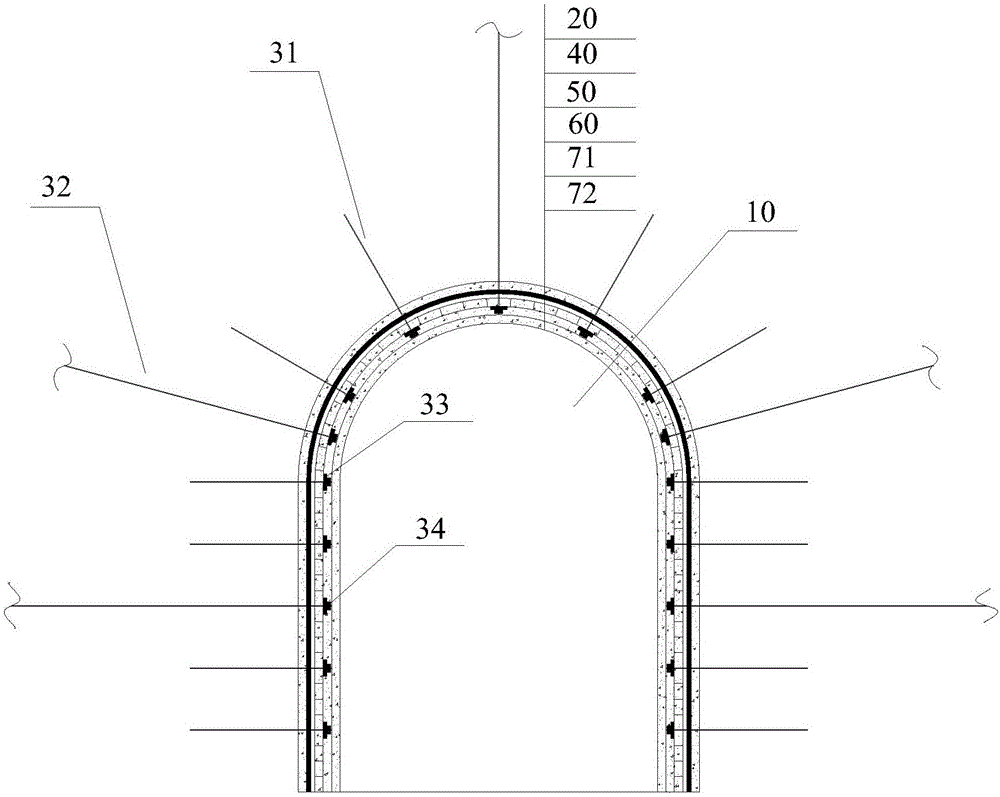

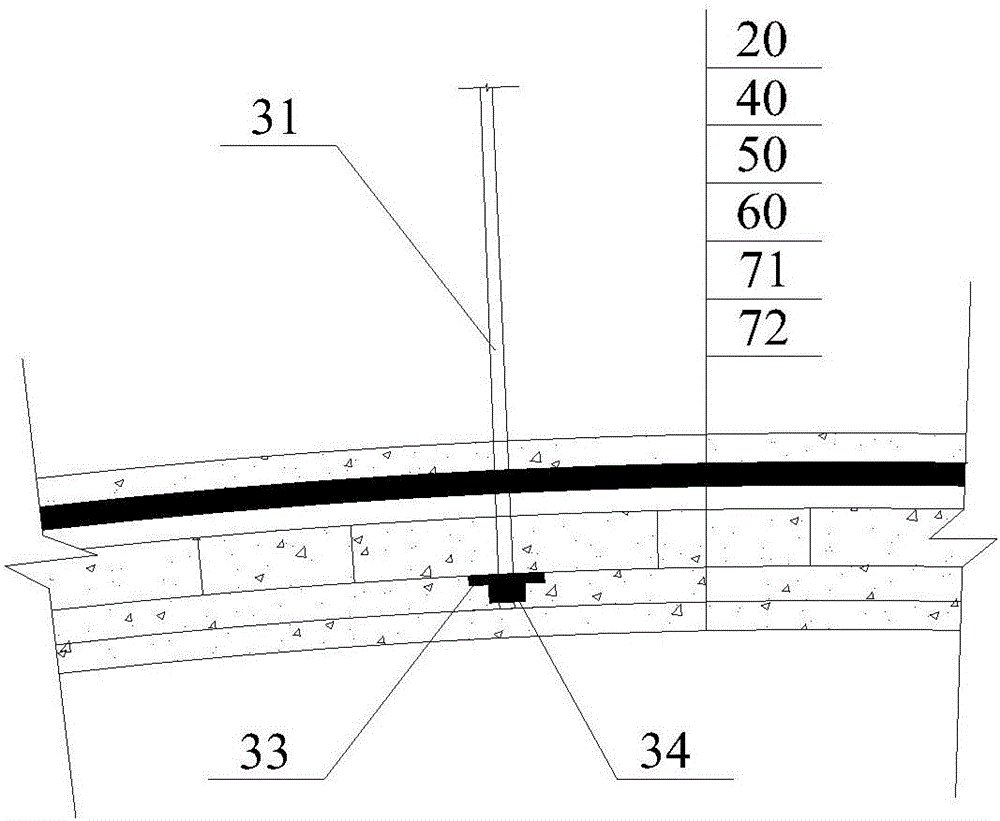

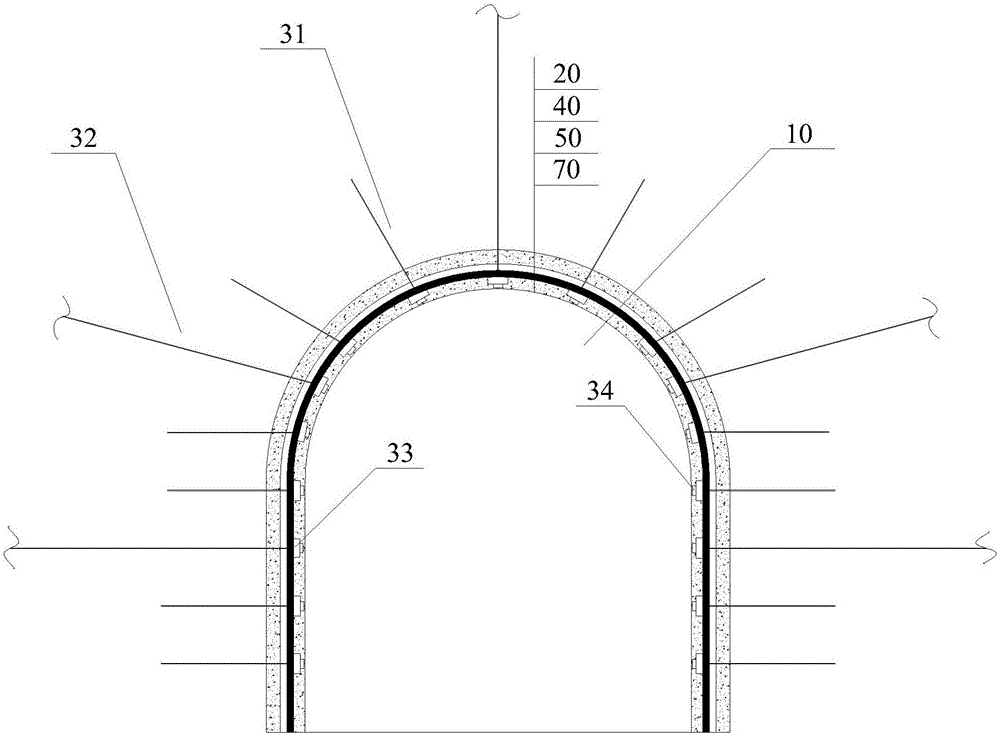

Supporting structure for composite anchor mesh steel bar support of deep well high-stress soft rock roadway and construction method thereof

InactiveCN106761811AImprove stabilityAvoid loose damageUnderground chambersTunnel liningSupporting systemShotcrete

The invention provides a supporting structure for a composite anchor mesh steel bar support of a deep well high-stress soft rock roadway and a construction method thereof. Firstly, anchor rods and anchor ropes are stroke into the interior of surrounding rock, and the set length is exposed; then, steel bar meshes and polyester fiber meshes are laid and hung through the outward-exposing portion of the anchor rods and the anchor ropes, the steel bar meshes are closely attached to the surrounding rock to be laid, and the polyester fiber meshes are closely attached to the steel bar meshes to be laid; a steel bar mesh shell support is erected; the anchor rods and the anchor ropes pass through the steel bar meshes, the polyester fiber meshes and the steel bar mesh shell support in sequence and are fixed on the steel bar mesh shell support through trays and nuts; a first concrete shotcrete layer is poured to close the whole supporting structure, and initial supporting is finished; and finally, a second concrete shotcrete layer is poured, and second supporting is finished. Through initial supporting, the whole structure and the surrounding rock deforms jointly, the yielding effect is given play, and surrounding rock pressure is released, and then second supporting is conducted. Meanwhile, the flexibility and pressure releasing effects of the polyester fiber meshes are utilized, so that the surrounding rock pressure is evenly distributed in the whole supporting system.

Owner:ANHUI UNIV OF SCI & TECH

A strip steel hot-dip galvanizing process

ActiveCN102268623AGood corrosion resistanceGood peeling resistanceHot-dipping/immersion processesCorrosionOxide

The invention discloses a strip steel hot-dip galvanizing technology. The technology comprises the following steps: 1) pickling, adding surfactant in the pickling solution to remove oxide on the surface of the strip steel and lay a foundation for the increase of the corrosion resistance of the coating; and 2) adopting a coating solution formula to further increase the corrosion resistance of the coating. The coating solution comprises the following components by weight percent: 1.5-2.0% of Al, 1.3-1.8% of Mg, 0.2-0.6% of Cu, 0.02-0.05% of Sn, 0.05-0.15% of Ce and the balance of Zn.

Owner:WUXI GUANGRUN METAL PROD CO LTD

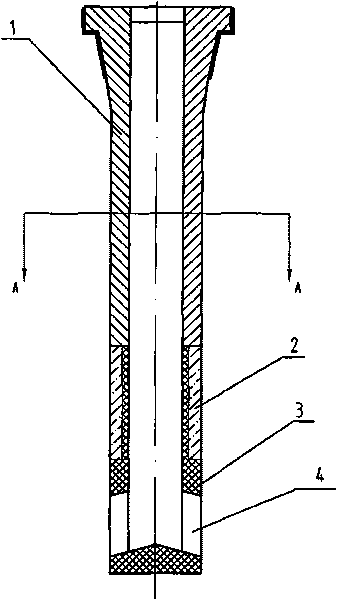

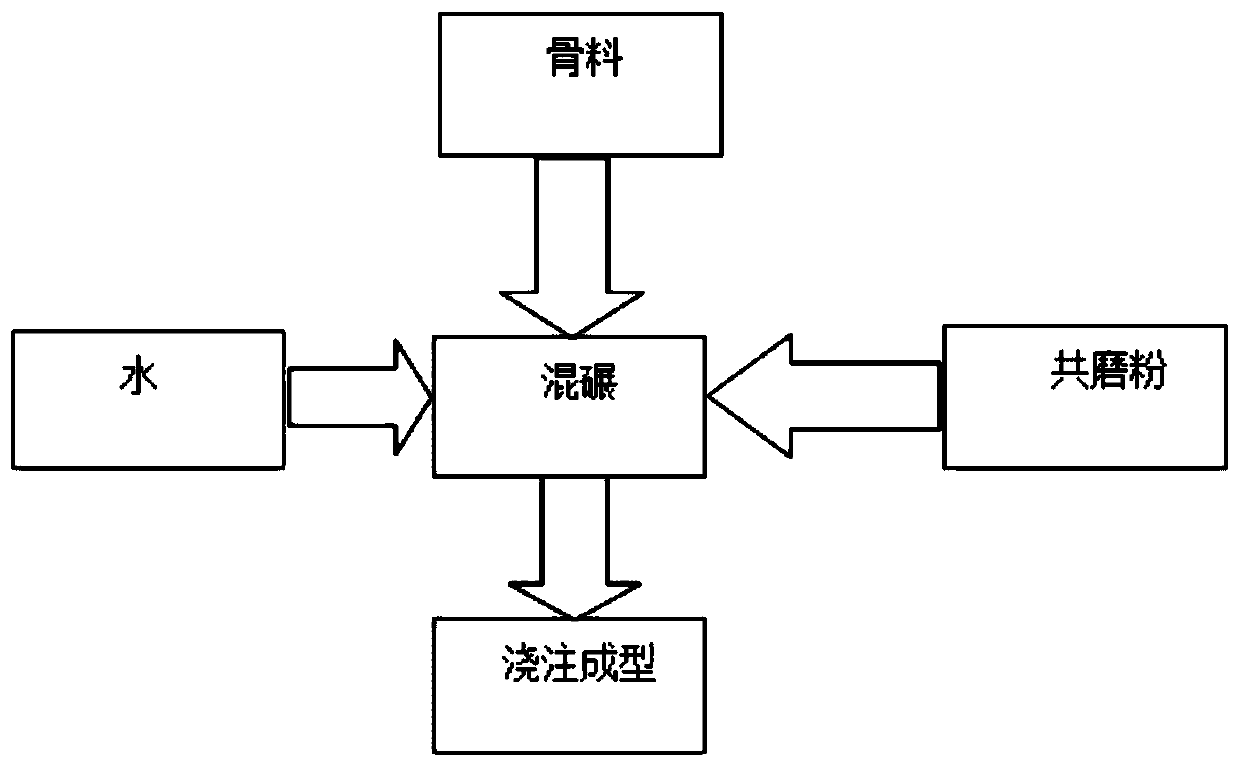

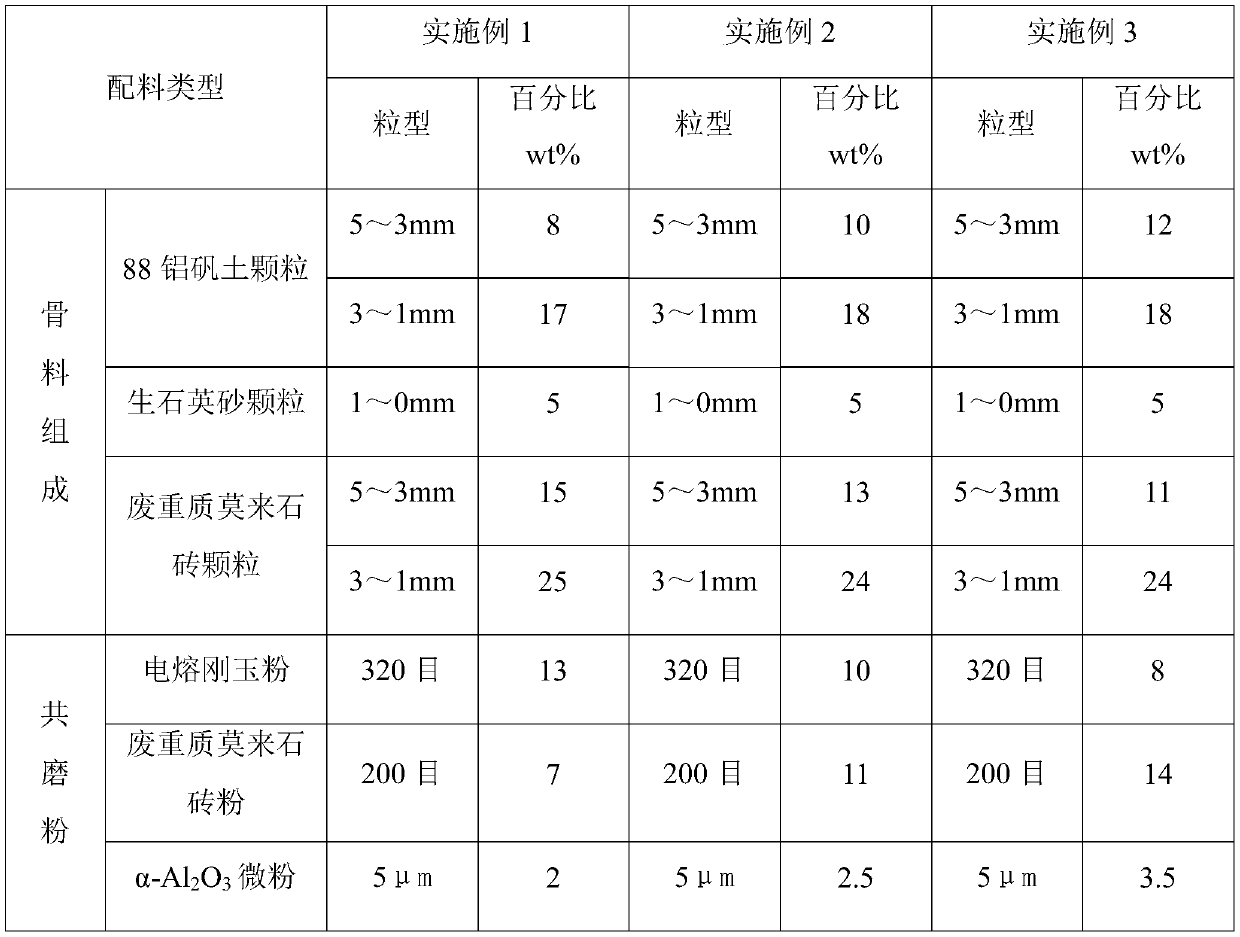

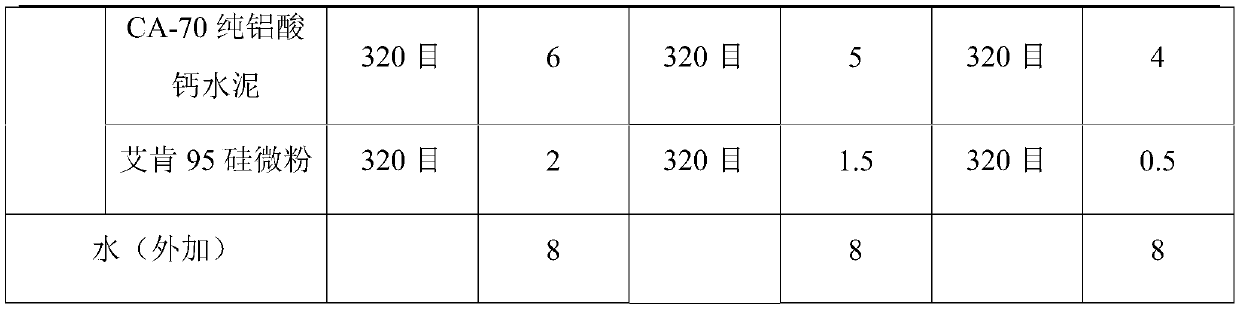

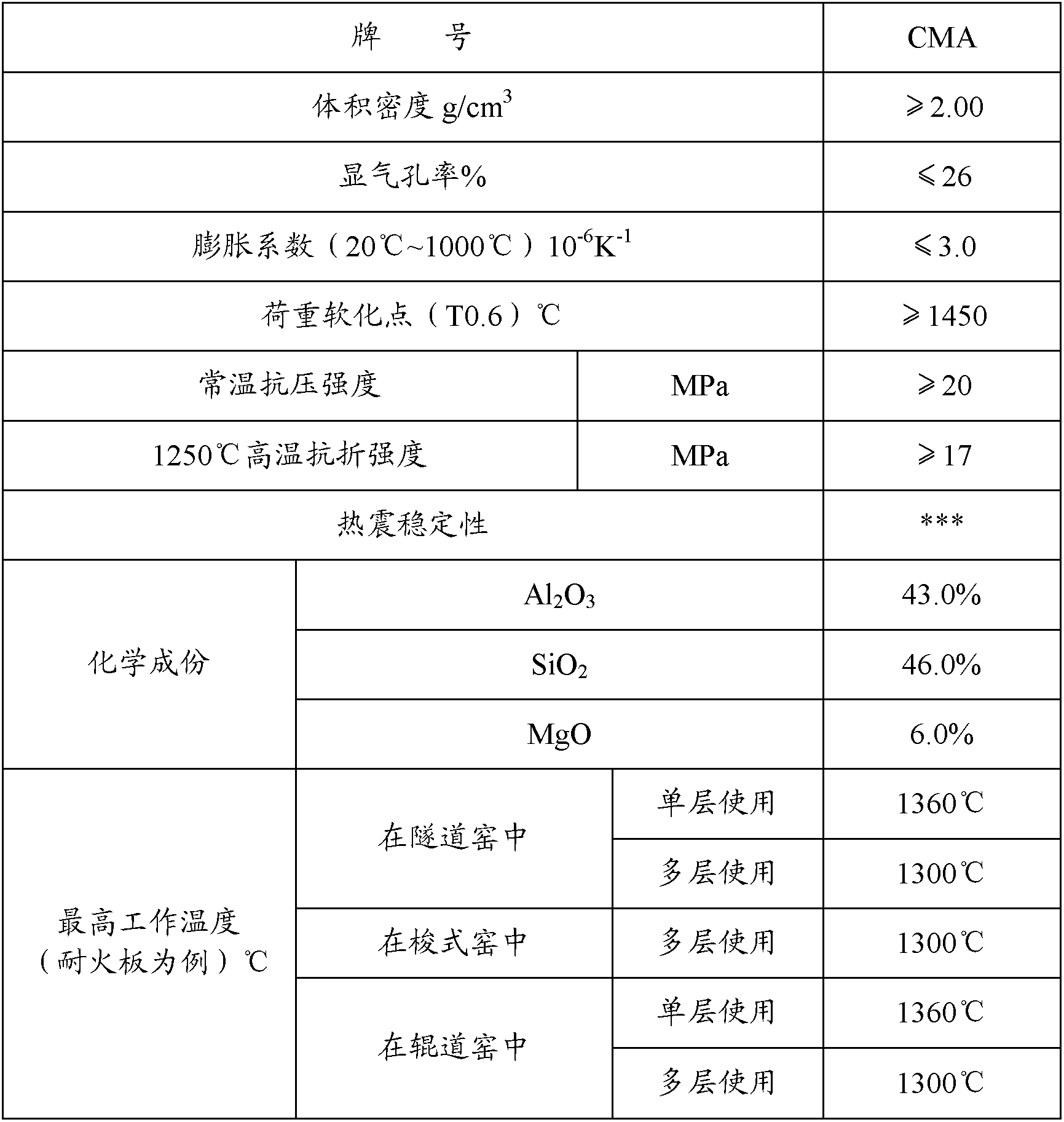

Pouring forming high life corundum mullite ladle lower nozzle brick and preparation method thereof

InactiveCN110526722AImproved thermal shock stabilityImproved thermal shock stability and improved spalling resistancePrillBrick

The invention discloses a pouring forming high life corundum mullite ladle lower nozzle brick and a preparation method thereof, and belongs to the technical field of lower nozzle bricks. The raw materials of aggregate for the lower nozzle brick of a ladle are prepared from 30-40wt% of recycled particles of a waste heavy mullite brick, 20-30wt% of bauxite particles, and 1-10wt% of raw quartz sand particles; the raw materials for co-grinding power are prepared from 2-18wt% of recycled fine powder of the waste heavy mullite brick, 10-20wt% of electrofused corundum fine powder, 1-10wt% of alpha-Al2O3micro powder, 0.5-3.0wt% of silica micro powder, and 3-8wt% of pure calcium aluminate cement; total weight percentage of each raw material is 100%; and in addition, water accounts for 8wt% of totalweight of the raw materials. According to the corundum mullite, thermal shock stability of the ladle lower nozzle brick is improved, and spalling resistance and erosion resistance of slag and moltensteel of the ladle lower nozzle brick are improved.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

High-crystal mullite-iolite high-temperature industrial ceramic and production method for same

The invention relates to a high-crystal mullite-iolite high-temperature industrial ceramic and a production method for the same. Raw materials comprise, by weight, 40-80 parts of main crystal phase materials, 20-60 parts of combined composite substrate materials and an appropriate amount of composite microcrystal nucleating agent. A roasting process of the production method includes a two-stage constant-temperature roasting method and a two-stage composite crystallization synthetic reaction characteristic enhancing process, wherein the two-stage constant-temperature roasting method includes the steps of performing constant-temperature heat preservation for 10-15 hours at the temperature of 200 DEG C, and performing constant-temperature heat preservation for 10-15 hours at the temperature of 500 DEG C; and the two-stage composite crystallization synthetic reaction characteristic enhancing process includes the steps of sintering for 10-15 hours under the ordinary pressure and at the temperature ranging from 1100 DEG C to 1150 DEG C, and sintering for 20-25 hours under the ordinary pressure and at the temperature ranging from 1420 DEG C to 1430 DEG C. A refractory product produced bythe method has the advantages of excellent oxidation resistance, high refractoriness, high usage temperature, low thermal expansion coefficient, high compression strength, hypobarism, excellent heat stability, anti-strip performance and high high-temperature bending strength. The process of the method has the advantages of simple process, low cost and suitability for mass production, and is applicable to preparing kiln furniture, industrial ceramics and structural materials.

Owner:GUANGDONG REJINBAO NEW MATERIAL TECH +2

Carbon-free ladle brick and preparation method thereof

ActiveCN102515794ASolve the problem of non-scouring resistance and aggregate powder separationGood structural flexibilityThermal expansionConstruction aggregate

The invention discloses a carbon-free ladle brick and a preparation method thereof. The carbon-free ladle brick is prepared by using bauxite chamotte, a corundum raw material, magnesium oxide and alumina micro powder as main raw materials, adding iron oxide, a magnesium chloride solution, sodium hexametaphosphate and canary dextrin, mixing the above-mentioned materials by using special procedures, storing an obtained mixed for 30 min, carrying out compression molding and drying the mixture at a temperature of 200 DEG C for 24 h. According to the invention, iron oxide and alumina micro powder are enabled to exist in gaps between aggregate and powder and form hercynite with a low thermal expansion coefficient at a medium-high temperature, and no excess iron oxide enters into a matrix, which enables the ladle brick to have good high temperature stability and anti-stripping performance; therefore, the problem that molten steel carburetting caused by high temperature melting loss of a refractory brick influences smelting quality is overcome, and the prepared carbon-free ladle brick has excellent performances of high strength, washing resistance, a long service life, etc.

Owner:山西高科耐火材料股份有限公司

Method for preparing tabular corundum brick for working lining of carbon-free steel ladle

ActiveCN103992126AImproved thermal shock stabilityReduce the content of CaOSteelmakingCompression molding

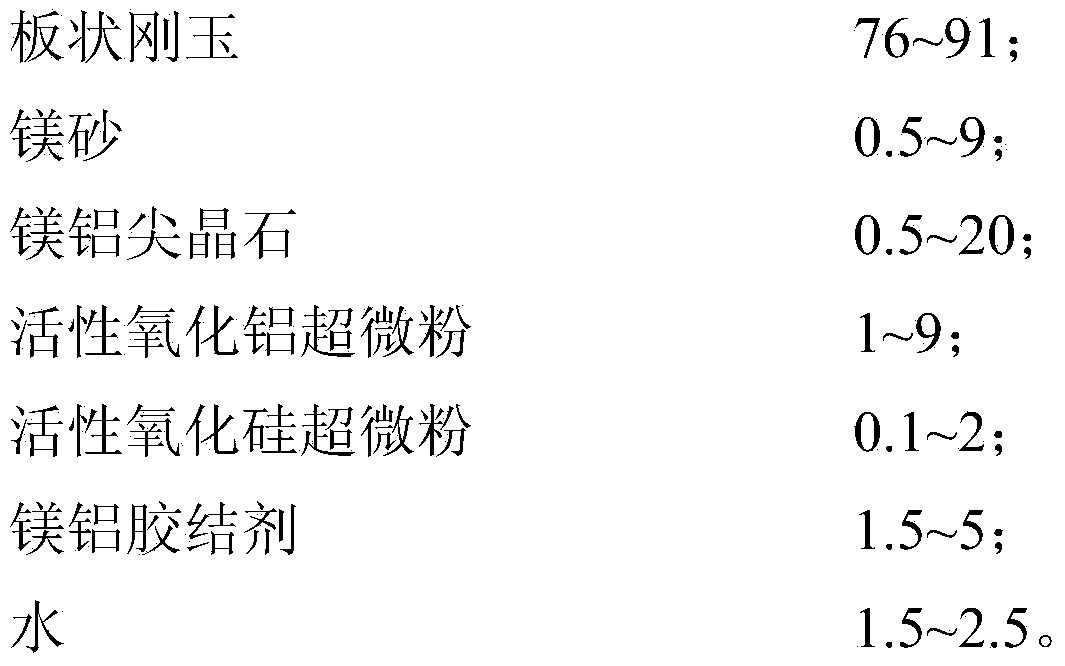

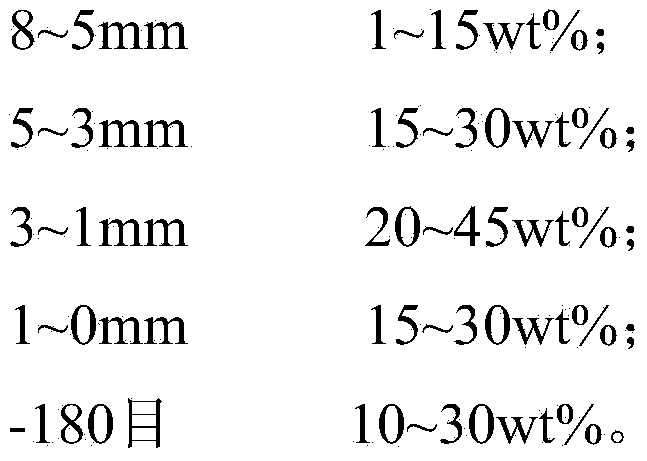

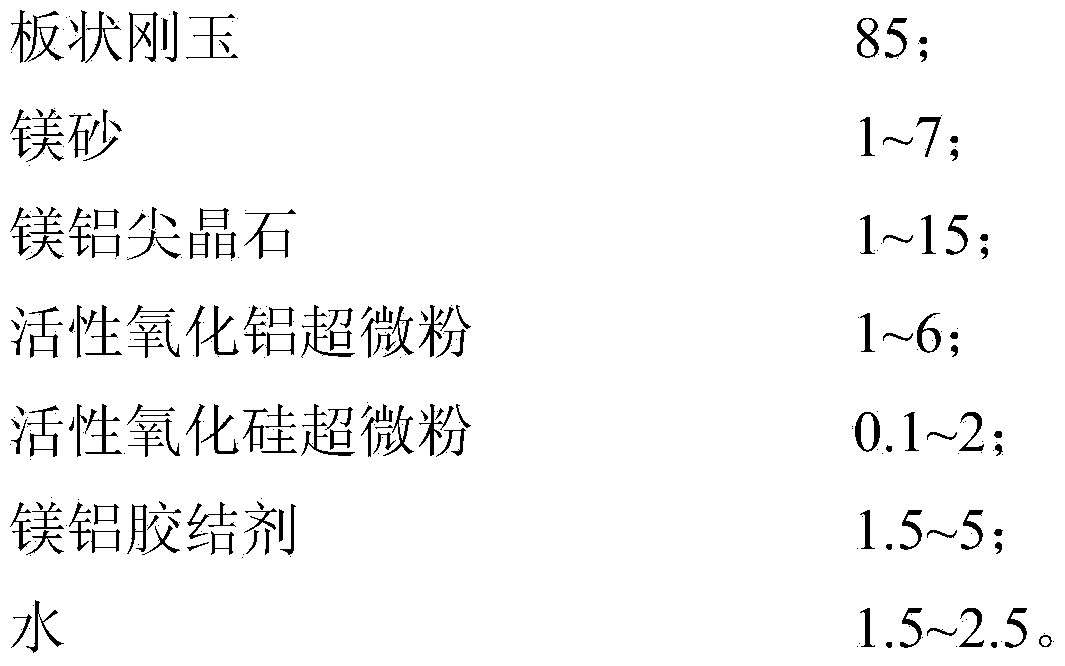

The invention discloses a method for preparing a tabular corundum brick for a working lining of a carbon-free steel ladle. The method comprises the steps of uniformly mixing the raw materials of the tabular corundum brick, and sequentially carrying out compression molding pressing and low-temperature baking to obtain the tabular corundum brick, wherein the tabular corundum brick comprise the following raw materials in parts by weight: 76-91 parts of tabular corundum, 0.5-9 parts of magnesia, 0.5-20 parts of magnesium-aluminum spinel, 1-9 parts of activated aluminum oxide ultrafine powder, 0.1-2 parts of activated silicon oxide ultrafine powder, 1.5-5 parts of a magnesium-aluminum cementing agent and 1.5-2.5 parts of water. The method for preparing the tabular corundum brick for the working lining of the carbon-free steel ladle is simple, the service life of the tabular corundum brick is long and free of carbon, and the tubular corundum brick can satisfy the demands on clean steelmaking.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

Modified cement mortar pavement patching material and pavement patching construction method

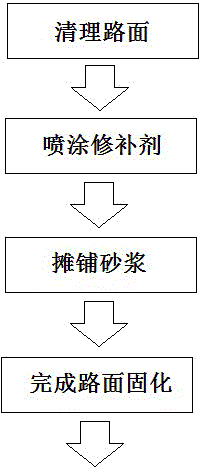

The invention discloses a modified cement mortar pavement patching material and a pavement patching construction method. The modified cement mortar pavement patching material is prepared by uniformly mixing the following components: silicate cement, sand, macadam, a component A, a component B and water, wherein the macadam is an optional component material or a default component material; the component A is epoxy resin; the component B is an epoxy resin curing agent. The modified cement mortar pavement patching material is applied to the patching construction of microcracks, pitted surfaces and pits in a cement concrete pavement; the early compression strength, the breaking strength and the bonding strength of the modified cement mortar pavement patching material are higher than the early compression strength, the breaking strength and the bonding strength of normal cement mortar; the modified cement mortar pavement patching material is beneficial for the rapid patching of damaged concrete pavements, good in patching quality and low in cost.

Owner:SHANGHAI UNIV

Preparation method of specific high-performance wear-resistant castable for coal burner

InactiveCN101805195AImprove thermal shock resistanceStrong thermal shock resistanceWear resistantTemperature resistance

The invention discloses a preparation method of specific high-performance wear-resistant castable for a coal burner, which comprises the following steps that: (1) raw material which comprises corundum, carborundum, corundum powder, alumina powder, silica micro powder, pure calcium aluminate cement, stainless steel fiber, anti-explosion fiber and water reducing agent is homogenized; (2) the homogenized raw material is poured into a forced mixer to be mixed, dry material is put in at one step according to the capacity of the mixer to be dry mixed for 2 to 6min and added with water to be wet mixed for 4 to 8min, the input of the water is strictly controlled, so that the water is stably 4 to 5 percent of the total weight of the raw material; and (3) the product is naturally cured for more than 50h at 25DEG C of ambient temperature and stripped after being fully hardened. The product prepared by the preparation method is characterized by high temperature resistance, anti-erosion, wear resistance and other performance, and has long service life.

Owner:蒋美芳

Slurry for preparing polycrystalline silicon crucible coat and preparation method thereof

InactiveCN101892517AImprove peeling resistanceHigh strengthPolycrystalline material growthSingle crystal growth detailsCrucibleSlurry

The invention relates to slurry for preparing a polycrystalline silicon crucible coat in the field of semiconductors or photovoltaics, and also to a preparation method thereof. The slurry for preparing the polycrystalline silicon crucible coat comprises silicon nitride powder and a solvent, and is characterized in that: the silicon nitride powder is treated by an oxidant to form the silicon nitride powder of which the surface is coated with encapsulated silicon oxide. After the slurry for preparing the polycrystalline silicon crucible coat is coated on a crucible and baked, the silicon oxide and the silicon nitride form a combined layer with a higher strength, so that the crucible coat with a high antistrip performance is obtained; and meanwhile, the oxide in the slurry for preparing the polycrystalline silicon crucible coat avoids aggregation, can be uniformly coated on the surface of silicon nitride particles, has low oxygen content, and avoids the influences on the quality of a silicon ingot.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

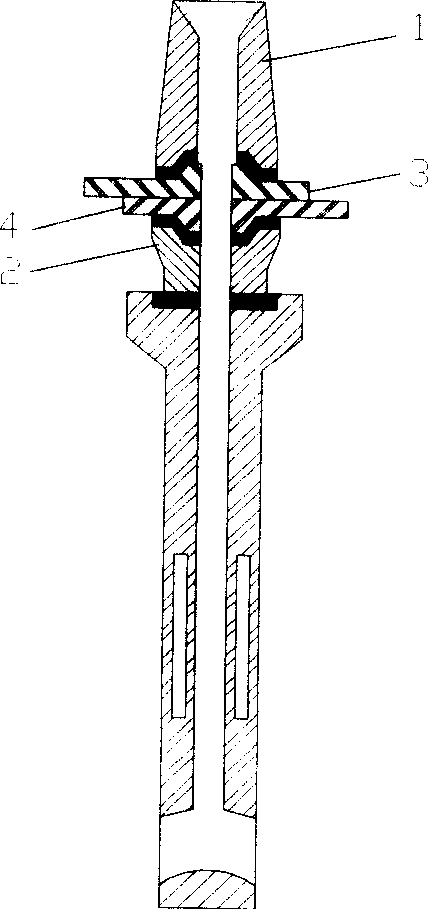

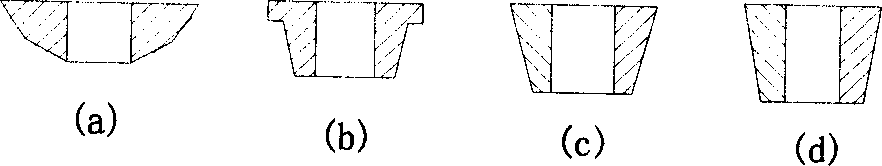

Dispersive air brick

InactiveCN101607832AGood resistance to molten steel erosionStable erosion performanceCeramicwareInorganic saltsBrick

The invention relates to an air brick, in particular to a dispersive air brick manufactured by a cast molding technology. The materials comprise main raw materials, micro-powder, an expanding agent, a bonding agent, a dispersing agent, a microvesicle air entraining agent and a foam stabilizing agent, wherein the microvesicle air entraining agent adopts rosin ester air entraining agent, the foam stabilizing agent adopts nonionic type acid amide foam stabilizing agent, and the dispersing agent adopts organic nonionic type water reducing agent. Inorganic salt ionic type water reducing agent and acidic and weak acidic retarder are not recommended to use in the materials. A blank molded by the materials needs to be immediately maintained at high temperature so as to accelerate blank hardening. The dispersive air brick adopts the cast molding technology and has simple technology process, less equipment investment and high production efficiency, and not only the dispersive air brick with a regular shape can be manufactured, but also a large special-shape dispersive air brick can be manufactured; and the manufactured product has even air hole distribution, stable venting performance, molten steel scouring resistance, high erosion ability and good stripping resistance.

Owner:LUOYANG LIER REFRACTORY MATERIAL +2

Novel aluminum-zirconium-carbon slide brick for flow control in metallurgy industry

InactiveCN1884203AImprove normal and high temperature strengthImproved thermal shock stabilityBrickMullite

The invention discloses a new typed sliding brick in the iron smelting course, which comprises the following parts: 60-125 percent sintered or electric melting corundum, 10-20 percent sintered Al2O3 powder under 50 mum, 5-15 percent sintered or electric melting zirconium mullite, 5-20 percent sintered or electric melting zirconium corundum, 1-5 percent metal Si, 1-8 percent carbon material and 0.5-4.0 anti-oxidization agent.

Owner:ANSHAN CHOSUN REFRACTORIES

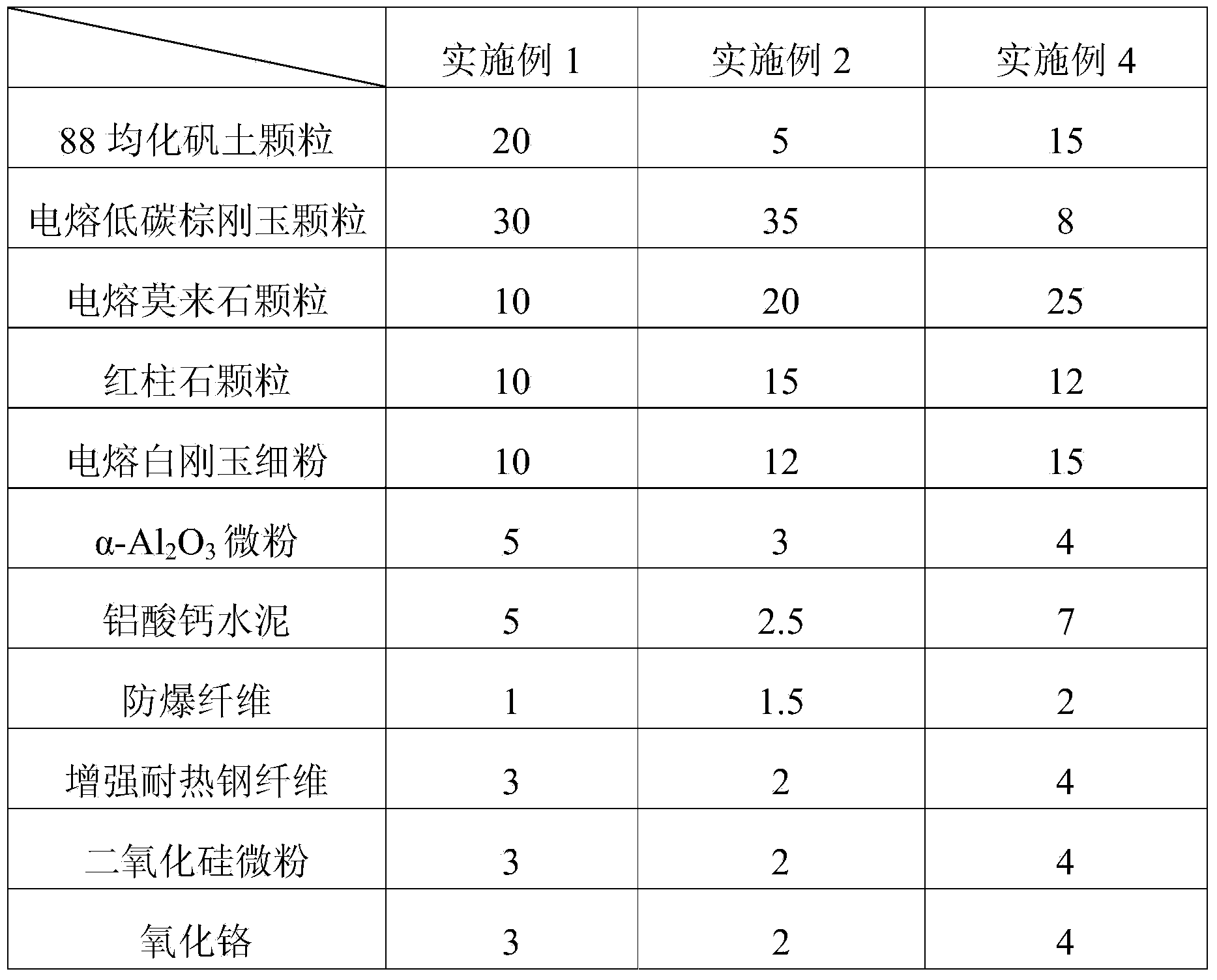

Alumina electric furnace cover and preparation method thereof

The invention aims to provide an alumina electric furnace cover, which is high in thermal shock resistance, density and iron slag erosion resistance and long in service life. The alumina electric furnace cover comprises the following components in percentage by weight: 5 to 20 percent of 88 homogenized alumina particles, 8 to 35 percent of electrofused low-carbon brown aluminum oxide particles, 10 to 25 percent of electrofused mullite particles, 10 to 15 percent of andalusite particles, 10 to 15 percent of electrofused white corundum fine powder, 3 to 5 percent of alpha-Al2O3 micro powder, 2.5 to 7 percent of calcium aluminate cement, 1 to 2 percent of explosion-proof fibers, 2 to 4 percent of reinforced heat-resistant steel fibers, 2 to 4 percent of silicon dioxide micro powder and 2 to 5 percent of chromium oxide. A preparation method comprises the following steps of uniformly mixing the electrofused white corundum fine powder, the alpha-Al2O3 micro powder, the silicon dioxide micro powder and the explosion-proof fibers; adding the electrofused mullite particles and the andalusite particles, stirring the mixture for at least 3min, adding the other raw materials, and stirring the mixture for at least 8min; adding water and a water reducing agent, performing stirring and casting molding, and performing natural curing, de-molding and drying.

Owner:北京利尔高温材料股份有限公司

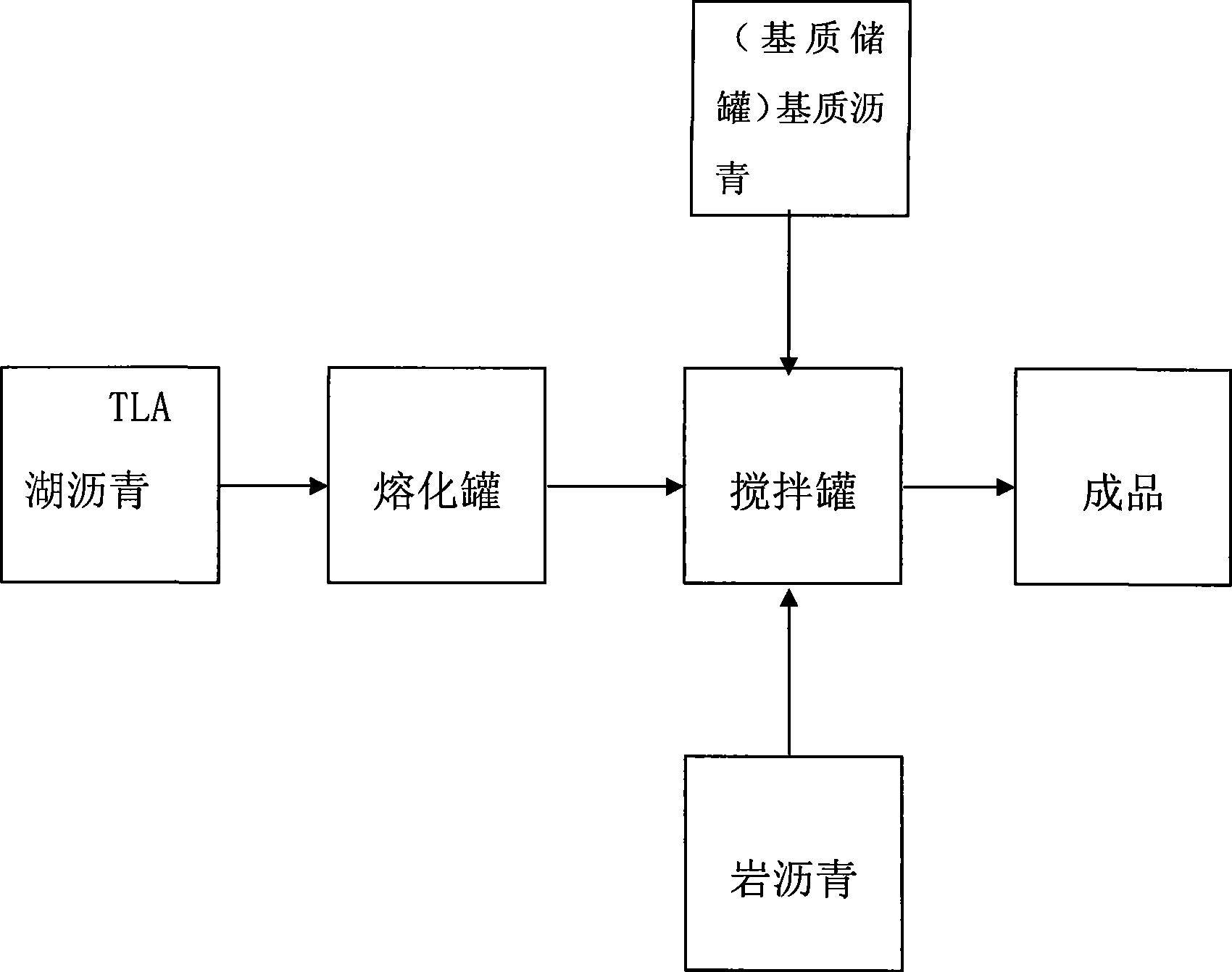

Natural compound modified asphalt and preparation method thereof

ActiveCN101445658AImproved stability and resistance to deformationIncreased durabilityBuilding insulationsNatural compoundPolymer modified

The invention discloses natural compound modified asphalt and a preparation method thereof. The modified asphalt is prepared by utilizing the following materials according to the following weight parts: 30 parts to 95 parts of basic asphalt, 5 parts to 70 parts of Trinidad lake asphalt (TLA) and 1 part to 40 parts of rock asphalt. The method comprises the technical processes of: melting the basic asphalt at a temperature of 120 DEG C to 140 DEG C; melting the TLA at a temperature of 165 DEG C to 195 DEG C; and mixing the melted basic asphalt and the melted TLA and stirring the mixture of the basic asphalt and the Trinidad lake asphalt for 10 min to 50 min at ta temperature of 165 DEG C to 195 DEG C, and adding rock asphalt powder in the stirring process so as to obtain the finished product. The modified asphalt can improve temperature sensibility, increase the stability, deformation resistance, toughness, cracking resistance performance, anti-fatigue and cracking-resistant strength and durability, prolong the service life of the road and reduce the time for maintenance and overhaul and the maintenance cost; simultaneously the modified asphalt has excellent environment-friendly performance and can reduce pollution generated in the production process of a polymer modifier.

Owner:石家庄都市明珠科技有限公司

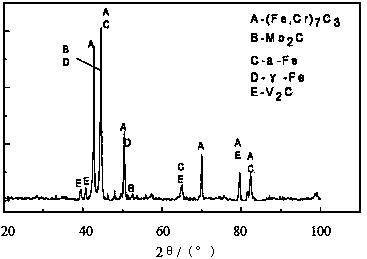

Surface wear-resistant strengthening treatment method for high-carbon cold work die steel

InactiveCN103225055AExtended service lifeDense tissueSolid state diffusion coatingHigh carbonWear resistant

The invention relates to a surface wear-resistant processing technology for a high-carbon cold work die steel, and particularly relates to a preparation method for vanadium-carbon-boron wear-resistant layer of the high-carbon cold work die steel. According to the method, a salt bath formed by mixing borax and BCl2+NaCl+KCl according to a certain proportion is used as a carrier; V2O5, Al and the metal yttrium are added in the salt bath; and the above materials are permeated for 6 hours at a temperature of 1,040-1,060 DEG C. The thickness of the vanadium-carbon-boron wear-resistant layer prepared by the method is 12-15 [mu]m; the hardness is HV2,900-3,3300; the vanadium-carbon-boron wear-resistant layer is compact in microstructure, and has good bonding strength with a matrix, excellent wear resistance, seizure resistance and anti-stripping capacity; and the wear-resistant layer is stable in quality. The high-carbon cold work die steel is directly subjected to quenching (or normalizing) and tempering for 8-10 hours at a temperature of 200-250 DEG C after the vanadium-carbon-boron penetrating treatment, so that toughness of the matrix is not reduced; and service life of the die is increased by a plurality times to ten times. Besides, the method is pollution-free in treatment process and good in energy conservation, and overcomes the disadvantages of unstable quality of vanadizing layer in mixed salt bath.

Owner:WUXI SHENGYUAN METAL PRODS

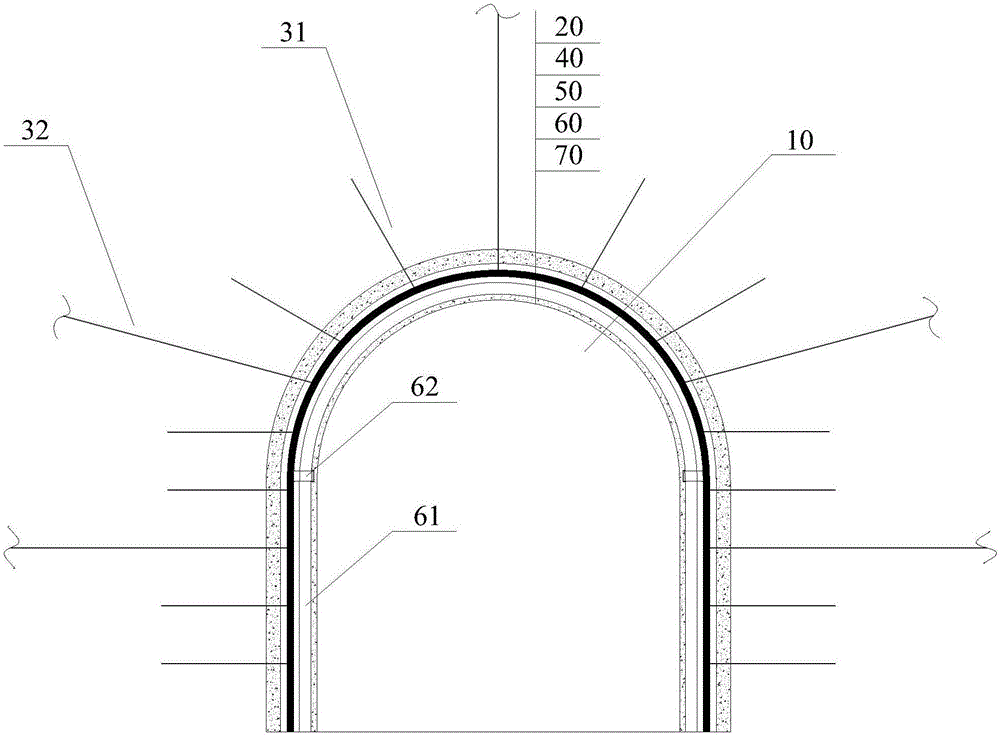

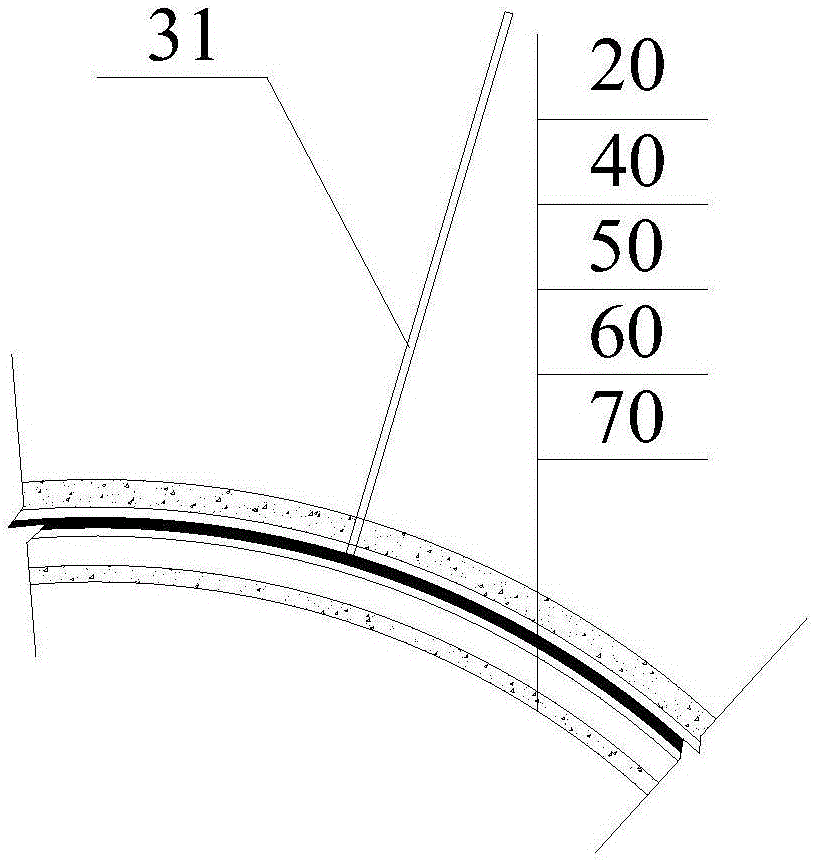

U-shaped steel reinforced composite anchor net support structure for high-stress soft rock tunnel of deep well and construction method thereof

ActiveCN106401605AStrong and stable supportStrong engineering practicabilityUnderground chambersTunnel liningPolyesterFiber

The invention provides an U-shaped steel reinforced composite anchor net support structure for a high-stress soft rock tunnel of a deep well and a construction method thereof. The construction method comprises the following steps of firstly, punching an anchor bolt and an anchor cable into a surrounding rock, supporting the surrounding rock, and exposing with setting lengths; then, sequentially paving and hanging a polyester fiber net and a reinforcement net on the exposing parts of the anchor bolt and the anchor cable, tightly paving the polyester fiber net onto the surrounding rock, tightly paving the reinforcement net onto the polyester fiber net, building an U-shaped steel bracket, enabling the anchor bolt and the anchor cable to sequentially penetrate through the polyester fiber net and the reinforcement net, and fixing on the reinforcement net by trays and screw caps; casting a concrete spray layer to seal the whole support structure. The construction method has the advantages that by using the U-shaped steel bracket, the reinforcement net and the polyester fiber net as skeletons, and forming a reinforced concrete sealing structure with the concrete spraying layer, the flexibility and pressure relief functions of the polyester fiber net are utilized, the pressure of the surrounding rock is uniformly distributed into the whole support system, and the active support property of the anchor bolt and anchor cable, and the passive support property of the reinforcement net and the U-shaped steel bracket are fully utilized.

Owner:ANHUI UNIV OF SCI & TECH

Corundum dry type ramming material for medium-frequency induction furnace and preparation method of corundum dry type ramming material

InactiveCN109320217AHigh refractorinessPromote densificationMedium frequencyUltimate tensile strength

The invention particularly relates to a corundum dry type ramming material for a medium-frequency induction furnace and a preparation method of the corundum dry type ramming material. According to thetechnical scheme, 48-68wt% of fused alumina particles, 20-40wt% of tabular corundum and 6-16wt% of fused magnesia are used as raw materials, 0.5-1.5wt% of the raw materials of yttrium oxide micro powder, 0.5-1.0wt% of titanium dioxide fine powder, 0.5-2.0wt% of ZrOCl<2>.8H<2>O fine powder and 0.5-1.0wt% of nickel oxide fine powder are additionally added, uniform mixing is performed, and the corundum dry type ramming material for the medium-frequency induction furnace is obtained. The prepared corundum dry type ramming material for the medium-frequency induction furnace has the characteristicsof high refractoriness, good volume stability, high high-temperature strength, good anti-strip performance, excellent anti-scour performance and good anti-erosion performance.

Owner:湖南立达高新材料有限公司

Hot repair mat for molten iron desulphurization

InactiveCN103183514AGood adhesion at high temperatureHigh bonding strengthThermal shockBonding strength

The invention aims to disclose a hot repair mat for molten iron desulphurization, which comprises the following components in percentage by weight: 10 to 24 percent of special-grade flint clay, 40 to 54 percent of bauxite chamotte, 5 to 10 percent of silicon carbide fine powder, 4 to 8 percent of alumina submicron powder, 5 to 10 percent of binding clay, 4 to 8 percent of expanding agent, 0.5 to 1.5 percent of additive and 10 to 15 percent of additional bonding agent. Compared with an existing product, the hot repair mat for molten iron desulphurization has the technical characteristics of good high temperature adhesivity, high bonding strength, good thermal shock resistance, antistrip performance, resistance to erosion and wear, good plasticity and the like, can meet the requirement of different molten iron desulphurization equipment on rapid hot repair, adopts easily obtained raw materials, is low in cost, has a long service life and fulfills the aim of the invention.

Owner:SHANGHAI BAOMING REFRACTORIES CO LTD

Dedicated self-shield flux-cored surfacing welding wire for manufacturing and repairing roll surface of squeeze roller of roller press

ActiveCN103464929AImprove applicabilityExtended service lifeWelding/cutting media/materialsSoldering mediaFerrosiliconRare earth

The invention discloses a dedicated self-shield flux-cored surfacing welding wire for manufacturing and repairing a squeeze roller of a roller press. The dedicated self-shield flux-cored surfacing welding wire comprises a steel belt layer and a flux-cored layer; the dedicated self-shield flux-cored surfacing welding wire is characterized in that alloy elements of metal powders added in the flux-cored layer in mass percentage are respectively 70%-80% of ferrochrome, 1%-5% of ferromanganese, 1%-5% of ferrosilicon, 1%-3% of ferrovanadium, 1%-3% of ferromolybdenum, 0.5%-2% of rare earth and 8%-12% of graphite. The dedicated self-shield flux-cored surfacing welding wire disclosed by the invention has excellent wear-resisting performance and anti-strip performance, is convenient to weld and does not need any medium protection, the applicability of a welding wire is greatly increased, conditions are provided for realizing automatic welding of a large workpiece, the production efficiency is increased, and the service life of a roll surface of the squeeze roller of the roller press is prolonged.

Owner:柳州市三龙耐磨焊接科技有限公司

Coal-injection duct precast brick pouring material

The invention discloses a coal-injection duct precast brick pouring material. The coal-injection duct precast brick pouring material comprises, by weight, 50-60% of white corundum, 10-15% of mullite, 10-15% of fine corundum powder, 4-6% of fused spinel, 4-6% of silicon carbide and 8-10% of an additive. The coal-injection duct precast brick pouring material has the advantages of high strength, high temperature resistance, wear resistance, stable product performances and long life.

Owner:CHANGXING SANZHONG KILN TECH

A synthesis process of a monododecyl phosphate asphalt anti-stripping agent

InactiveCN104693234AHigh activityImprove adaptabilityGroup 5/15 element organic compoundsBuilding insulationsPhosphateReaction temperature

The invention synthesizes a dodecylphosphate mixture from phosphorus pentoxide and lauryl alcohol by an esterification reaction. By adopting monododecyl phosphate as a target product, influences of each reaction parameter on the reaction yield are researched, and the optimum synthesis conditions are determined as follows: the reaction time is 4 h, the mole ratio of the lauryl alcohol to the phosphorus pentoxide is 2.1, the reaction temperature is 85 DEG C, and the mole ratio of water to the phosphorus pentoxide is 0.8. The yield of the monododecyl phosphate can be 80% under the optimum reaction conditions. Anti-stripping performance of the monododecyl phosphate is tested by utilization of a water boiling method, and results show that: when an anti-stripping agent is not added, adhesion of asphalt and granite building stone is of the second grade; when an anti-stripping agent is added, adhesion of asphalt and granite building stone is of the fourth grade; and the monododecyl phosphate synthesized has good anti-stripping performance.

Owner:QINGDAO HUICHENG PETROCHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com