Dedicated self-shield flux-cored surfacing welding wire for manufacturing and repairing roll surface of squeeze roller of roller press

A technology for surfacing welding wire and squeezing roller, which is applied in the direction of manufacturing tools, welding medium, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

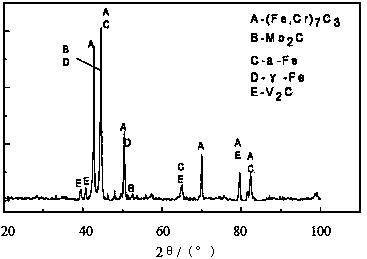

[0028] The flux cored welding wire of the present invention is made up of steel strip layer and flux core layer, and steel strip layer adopts H08A low-carbon steel strip, and the metal drug powder that adds in the flux core layer, the mass percentage content of each alloy element is: ferrochromium 70~ 80%, ferromanganese 1~5%, ferrosilicon 1~5%, ferrovanadium 1~3%, ferromolybdenum 1~3%, rare earth 0.5~2, graphite 8~12%.

[0029] The production process of the flux cored wire is as follows:

[0030] (1) Passivate the alloy powder of ferrosilicon, ferrochrome and ferromanganese, and then mix the powder;

[0031] (2) The steel strip is rolled into a U shape;

[0032] (3) Fill the powder into the steel belt layer;

[0033] (4) tightly packed;

[0034] (5) drawing forming;

[0035] (5) Drawing into the final product.

[0036] Among them, the passivation treatment process of ferrosilicon, ferrochrome and ferromanganese in step (1) is heat treatment to prevent excessive loss of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com