Method for preparing tabular corundum brick for working lining of carbon-free steel ladle

A carbon-free ladle and corundum brick technology, applied in the field of refractory materials, can solve the problems of hindering life and shortening the service life of corundum spinel prefabricated bricks, etc., to achieve improved stability and strength, good anti-stripping performance, and good volume stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Mix plate-like corundum and magnesia evenly, then add magnesium-aluminum cement and water in sequence, and finally add mixed powder composed of magnesium-aluminum spinel, activated alumina ultrafine powder and activated silica ultrafine powder, and mix well , to obtain mud; the weight loss of the magnesium-aluminum cement under the condition of 1050 ° C is less than 30%.

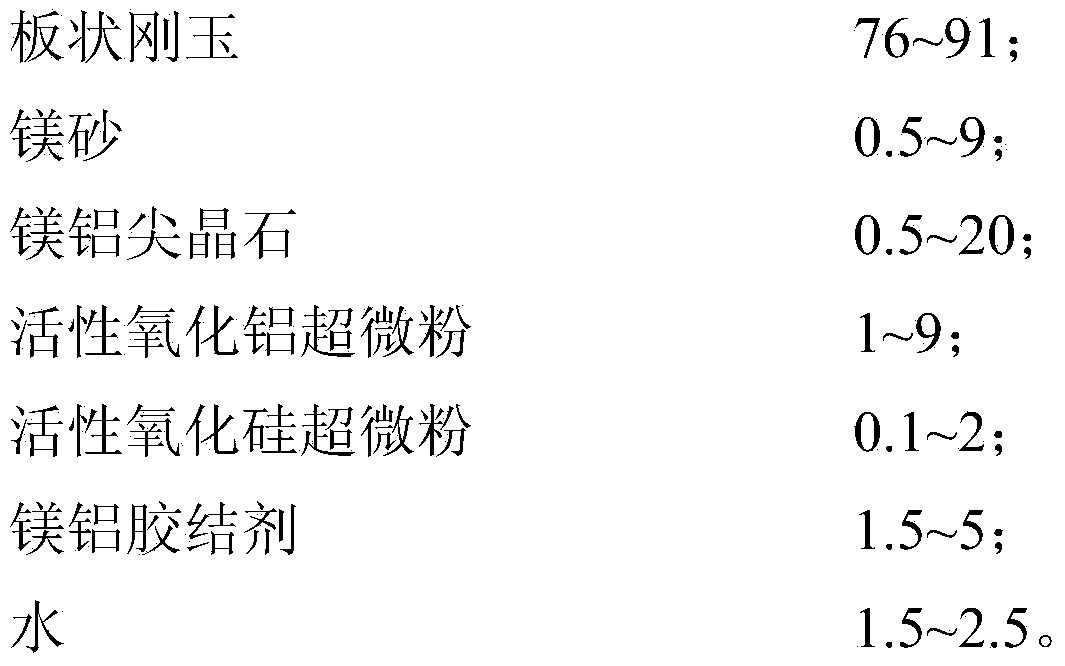

[0042] See Table 1 for the proportions by weight of platy corundum, magnesia, magnesia-alumina spinel, activated alumina superfine powder, activated silica superfine powder, magnesia-alumina spinel and water;

[0043] (2) The mud material is pressed into shape, and baked at 180-200° C. for 8 hours to obtain a plate-shaped corundum brick.

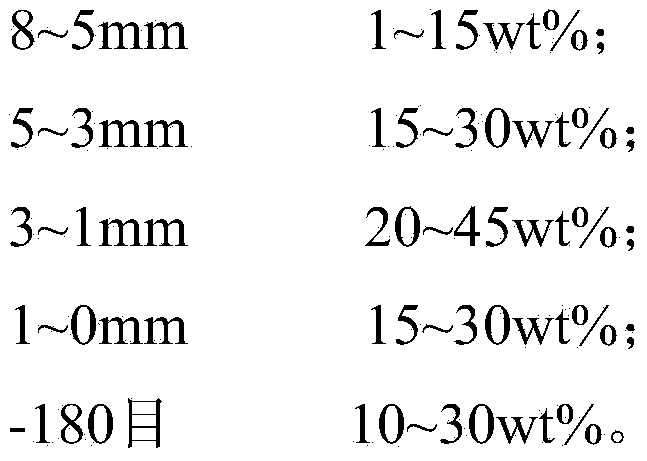

[0044] The particle size distribution of tabular alumina in this embodiment is: 8-5mm6wt%; 5-3mm25wt%; 3-1mm38wt%; 1-0mm16wt%; -180 mesh (ie, particle size≤0.088mm) 15wt%;

[0045] The particle size distribution of fused magnesia is: 1~0mm60wt%; -180 mesh 40wt%...

Embodiment 2

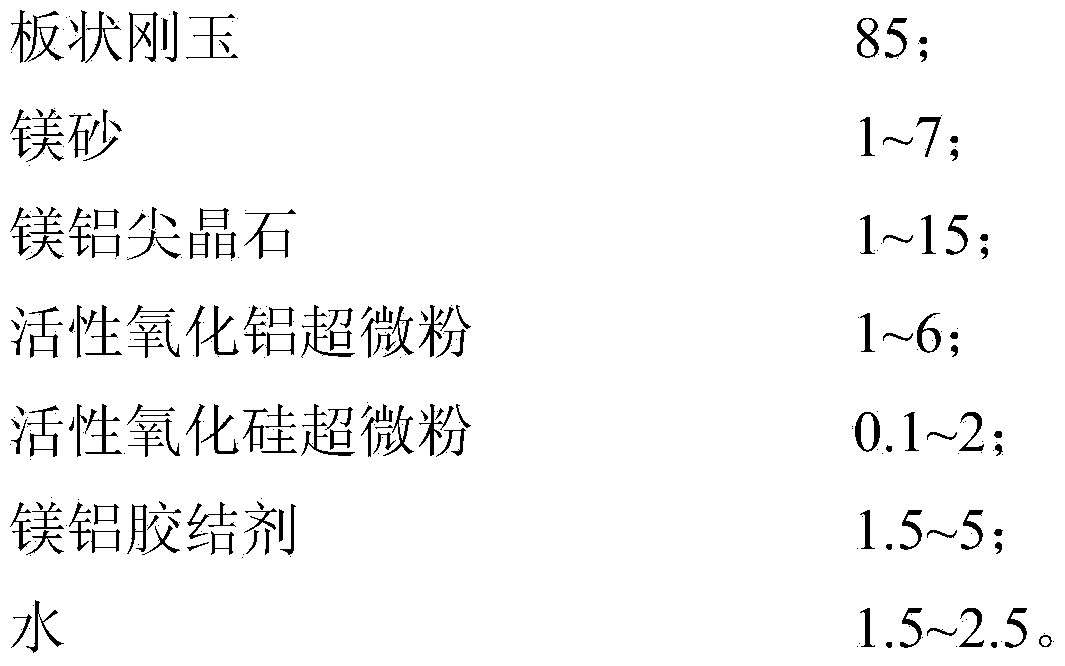

[0051] Using the same preparation method as in Example 1, the proportions by weight of tabular corundum, magnesia, magnesia-alumina spinel, activated alumina superfine powder, activated silica superfine powder, magnesia-alumina spinel and water are shown in Table 2 .

[0052] Table 2

[0053]

Embodiment 3

[0055] Using the same preparation method as in Example 1, the proportions by weight of tabular corundum, magnesia, magnesia-alumina spinel, activated alumina superfine powder, activated silica superfine powder, magnesia-alumina spinel and water are shown in Table 3 .

[0056] table 3

[0057]

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com