Inner lining structure for torpedo pot and aluminium carbonize silicon carbide brick and high aluminium brick used for torpedo pot

A torpedo tank and lining technology, applied in the field of refractory materials, can solve the problems of poor corrosion resistance of molten iron and slag, fast erosion of slag lines and scoured parts, and low service life of medium and low-grade bricks, achieving low production costs, significant economic benefits, Reduce the effect of brick sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

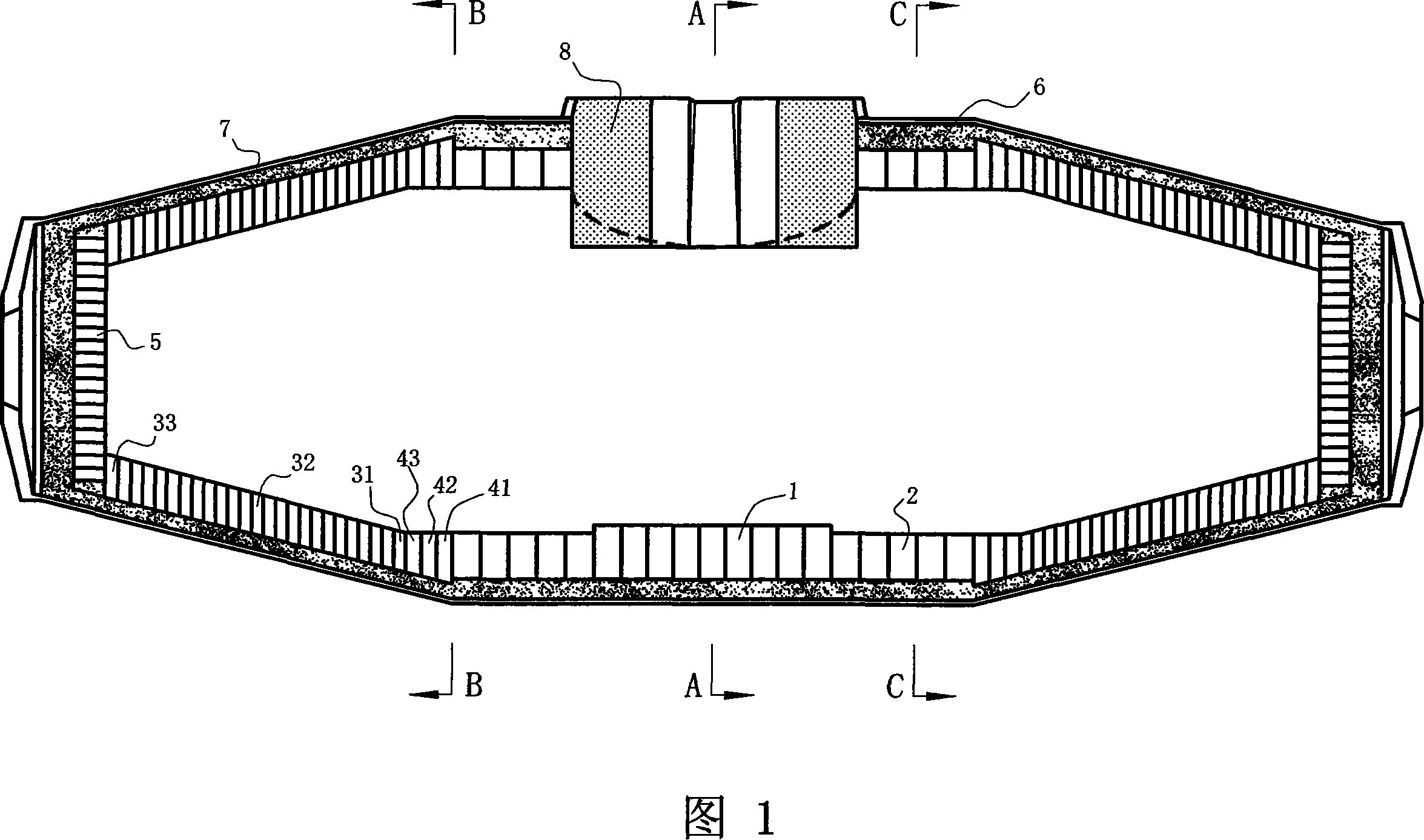

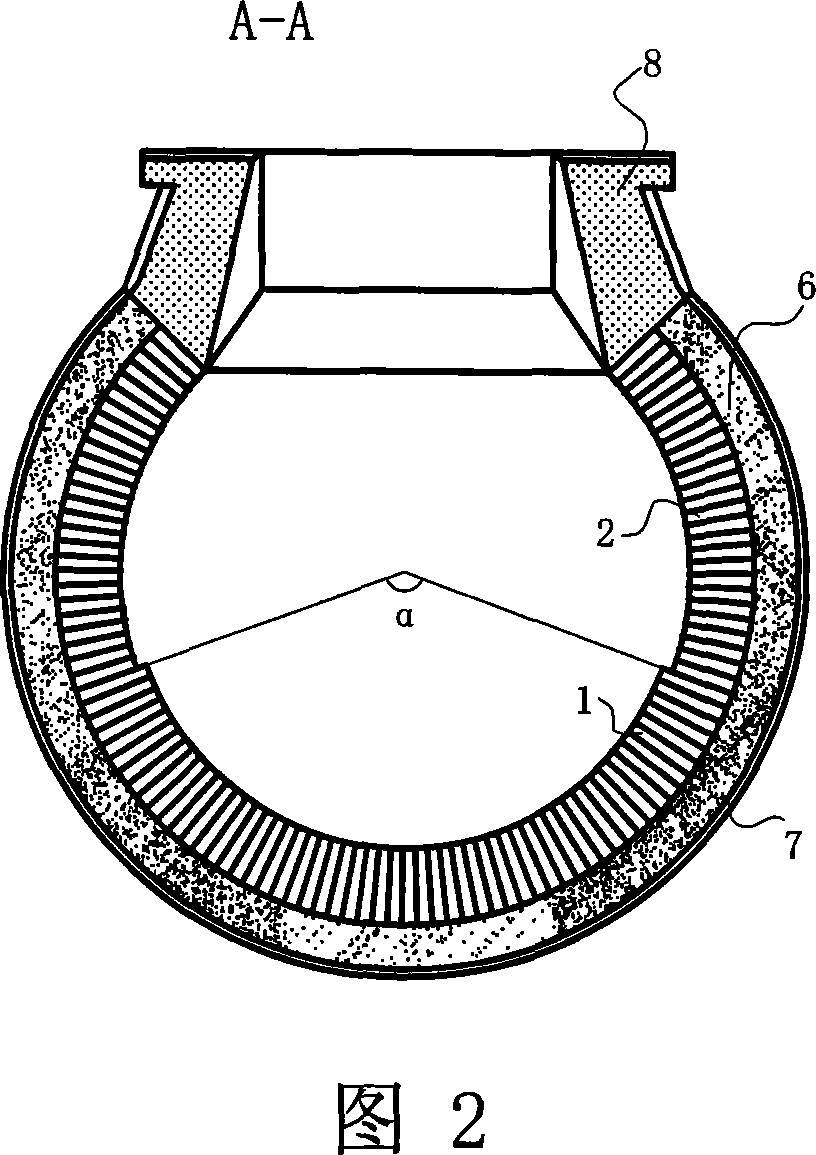

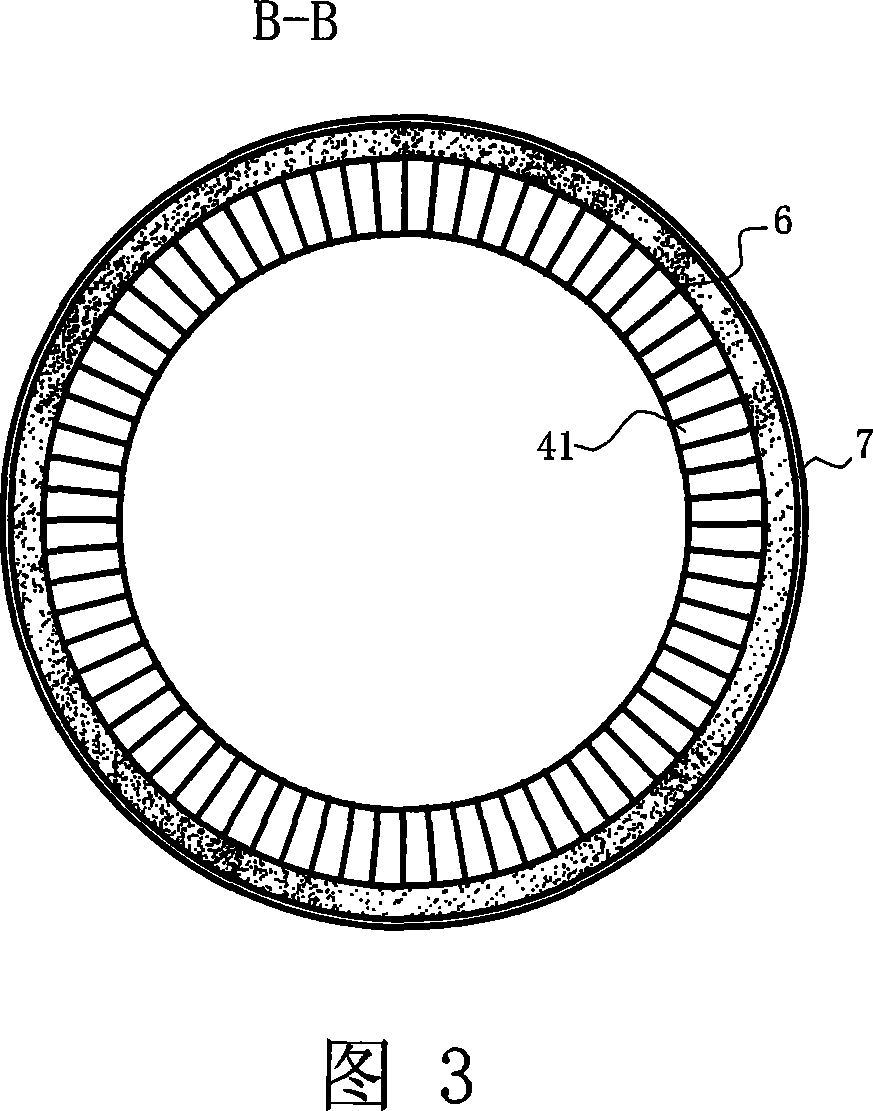

[0049] Embodiment 1: Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7, Fig. 8, Fig. 9, the torpedo tank lining structure of this embodiment contains a tank body shell 7, and the tank The body shell 7 is composed of a cylindrical shell section in the middle, a truncated cone shell section connected symmetrically at both ends, and a closed arc surface section at the end of each truncated cone shell section; a tank mouth 8 is provided in the middle of the side of the cylindrical shell section; the combination The inner wall of the shell 7 is built with a refractory brick working layer, and between the inner wall of the combined shell 7 and the refractory brick working layer is a castable permanent layer 6 sprayed with light refractory materials; the refractory brick working layer contains a cylindrical shell inner lining construction section, truncated cone shell lining masonry section and end wall lining masonry section.

[0050] The part of the inner lining s...

Embodiment 2

[0093] Embodiment two: basically the same as embodiment one, the similarity is no longer described, and the difference is:

[0094] Raw material formula: bauxite 30%, fused corundum 20%, silicon carbide 30%, graphite 7%, sintered corundum 7%, metal aluminum 1%, metal silicon 1%, phenolic resin 3%.

Embodiment 3

[0095] Embodiment three: basically the same as embodiment one, the similarity is no longer described, and the difference is:

[0096] Raw material formula: bauxite 12%, fused corundum 65%, silicon carbide 6%, graphite 6%, sintered corundum 7%, metal aluminum 0.5%, metal silicon 0.5%, phenolic resin 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com