Repairing method of rotary kiln liner fireproof material

A refractory and rotary kiln technology, applied in the direction of lining repair, etc., can solve the problems of loss of repairing kiln lining, shortening of the service life of local refractories, falling off, etc., so as to avoid the impact of the red kiln accident and increase the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

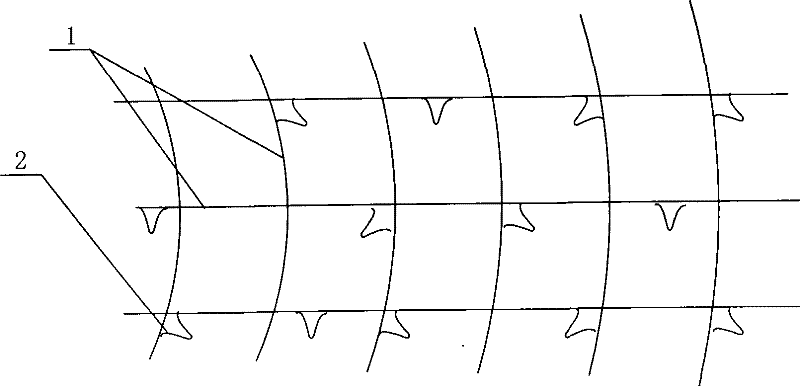

[0025] Such as figure 1 As shown, the rotary kiln kiln lining refractory repair method of the present invention is characterized in that comprising the following steps:

[0026] 1) Remove the ring layer on the surface of the rotary kiln lining refractory material, avoid excessive mechanical vibration force to loosen the unloose part,

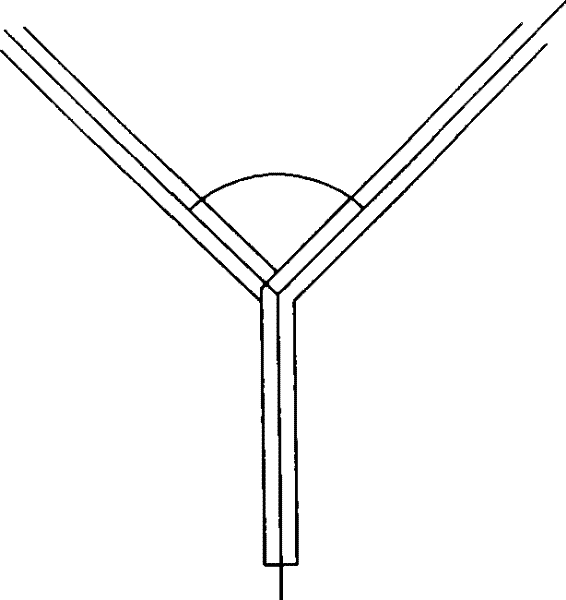

[0027] 2) The welded metal network frame structure is fixed on the kiln bricks or the anchors of the pouring belt through U-shaped nails and Y-shaped nails.

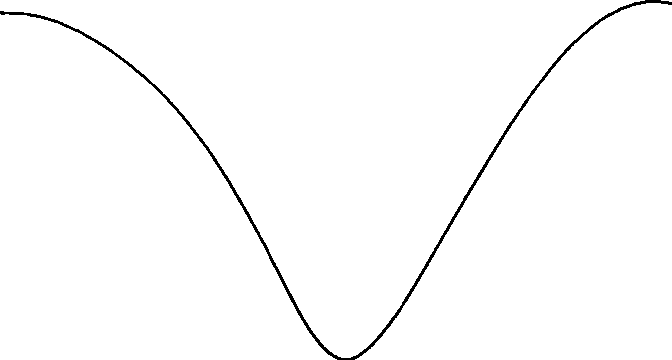

[0028] 3) Brush the bonding agent on the working surface, pour the refractory material on the brushed bonding agent to form a refractory casting belt, and set the furnace body shrinkage joint plate between the casting belt and the casting belt,

[0029] Such as Figure 4 As shown, 4) After the pouring is completed, there must be a 65-80 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com