Coolant compressor

A technology for compressors and refrigerants, applied in mechanical equipment, machines/engines, liquid variable capacity machines, etc., can solve the problems of piston processing cost, high processing cost, uneconomical, etc., and achieve high torque and small structural size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

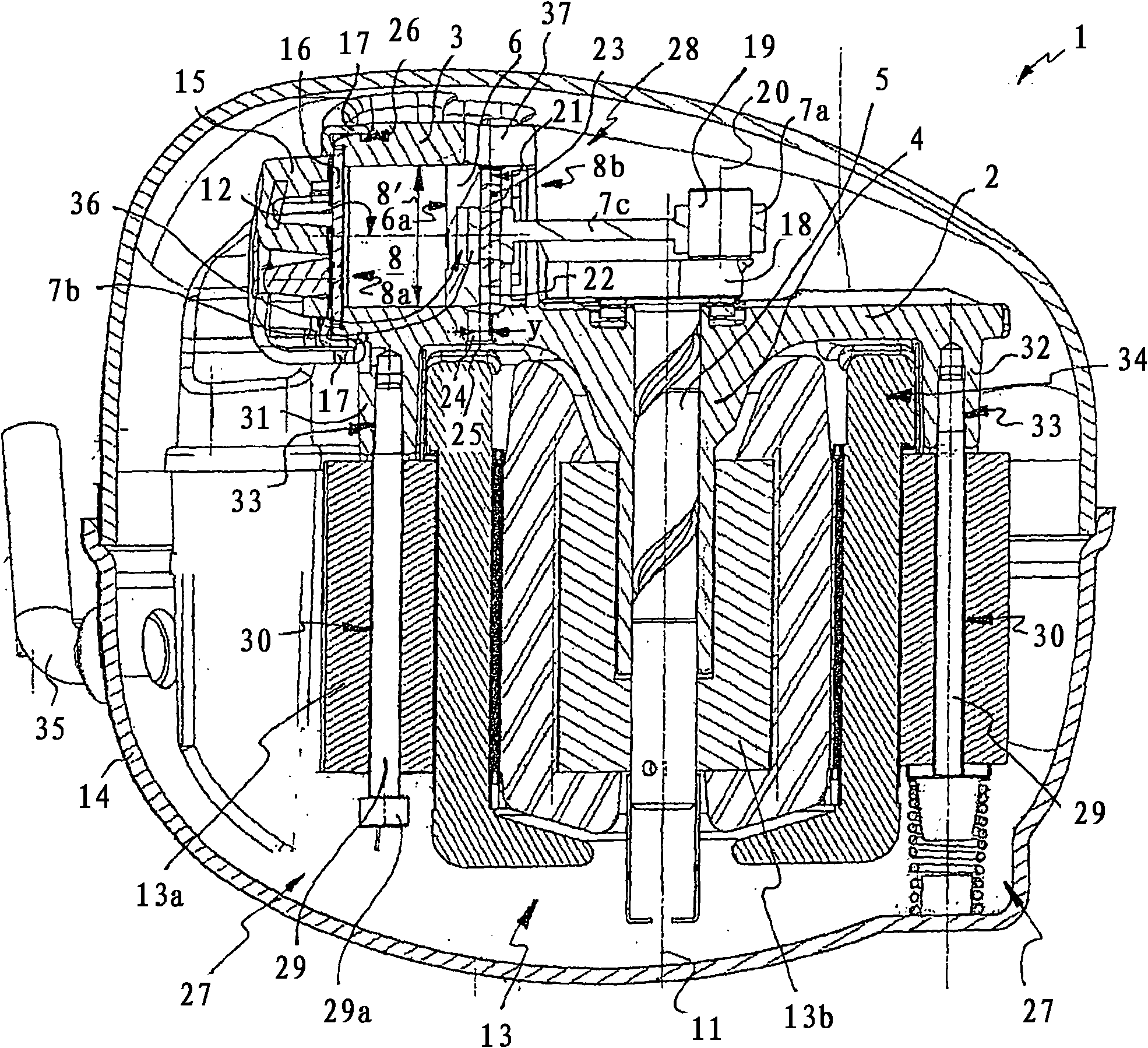

[0041] figure 1 A refrigerant compressor according to the invention is shown comprising a hermetically sealed compressor housing 14 . Arranged in the compressor housing 14 is an electric motor 13 , which is supported in the bottom region of the compressor housing 14 by means of an elastic bearing.

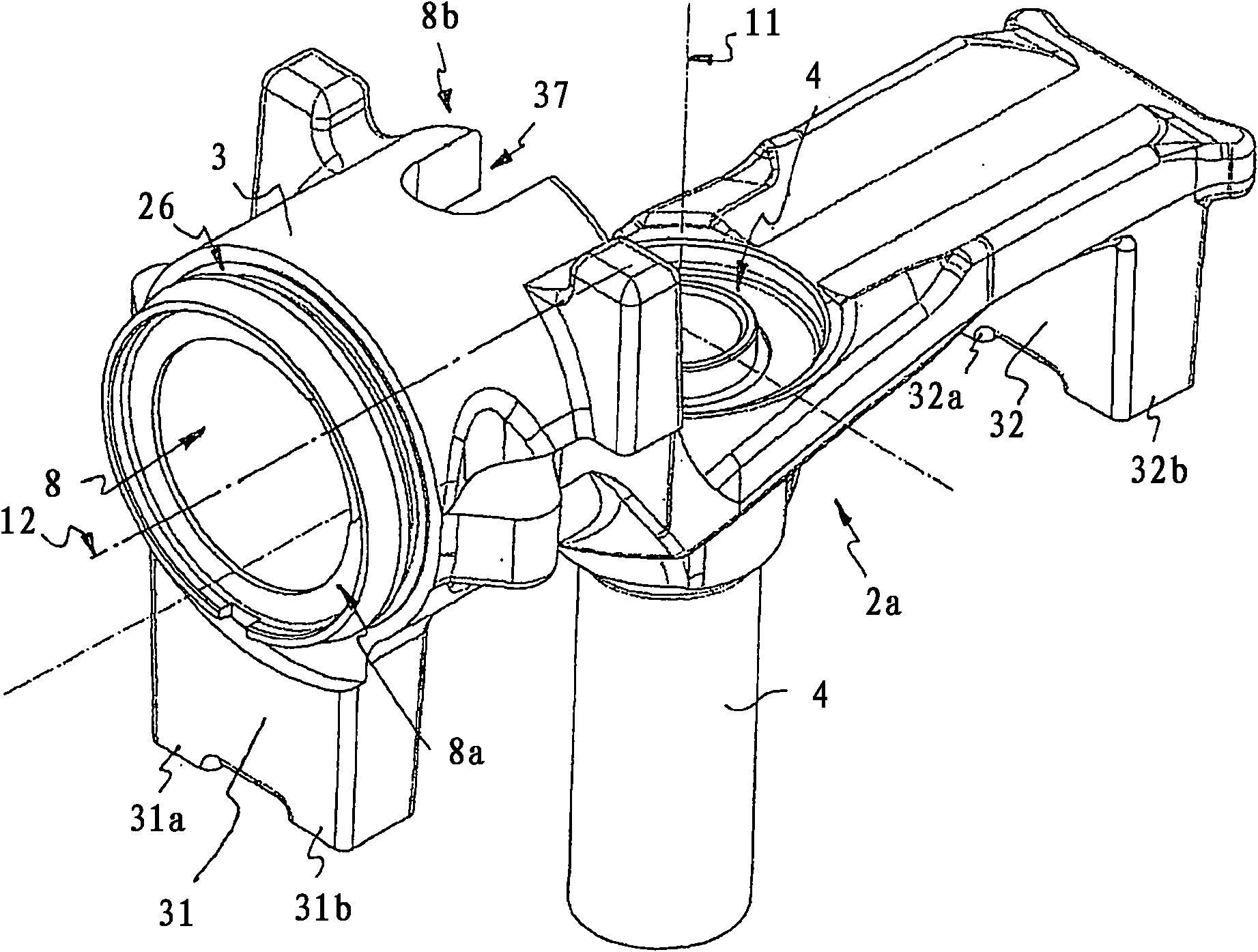

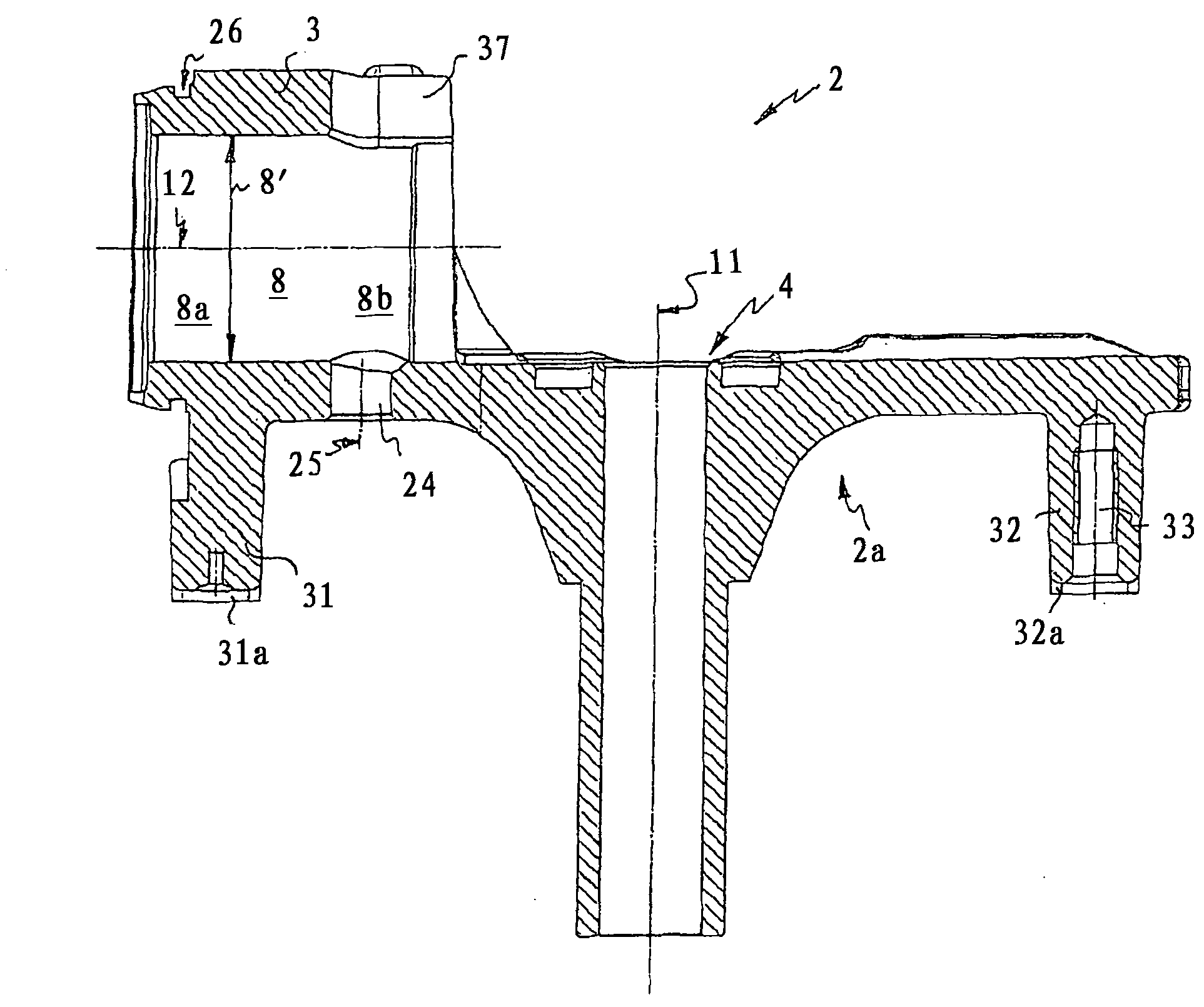

[0042] Mounted on the electric motor 13 is a bridge-shaped support body 2 , which is fastened to the stator 13 a of the electric motor 13 by means of screw elements 29 . exist figure 2 The supporting body 2 shown in a partial view spans the upper part of the motor winding 34 of the electric motor 13 (also referred to as "upper winding end") and has two mutually opposite foot elements 31 and 32, which are supported on the stator 13a . Each foot element 31, 32 has two abutments 31a, 31b or 32a, 32b on the end faces, so that the support body 2, which is formed narrowly, is therefore stably supported on the stator 13a on a total of four support surfaces (see press Figure 5 Bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com