Patents

Literature

75 results about "Impact tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tooth impaction. An impacted tooth is one that fails to erupt into the dental arch within the expected developmental window. Because impacted teeth do not erupt, they are retained throughout the individual's lifetime unless extracted or exposed surgically.

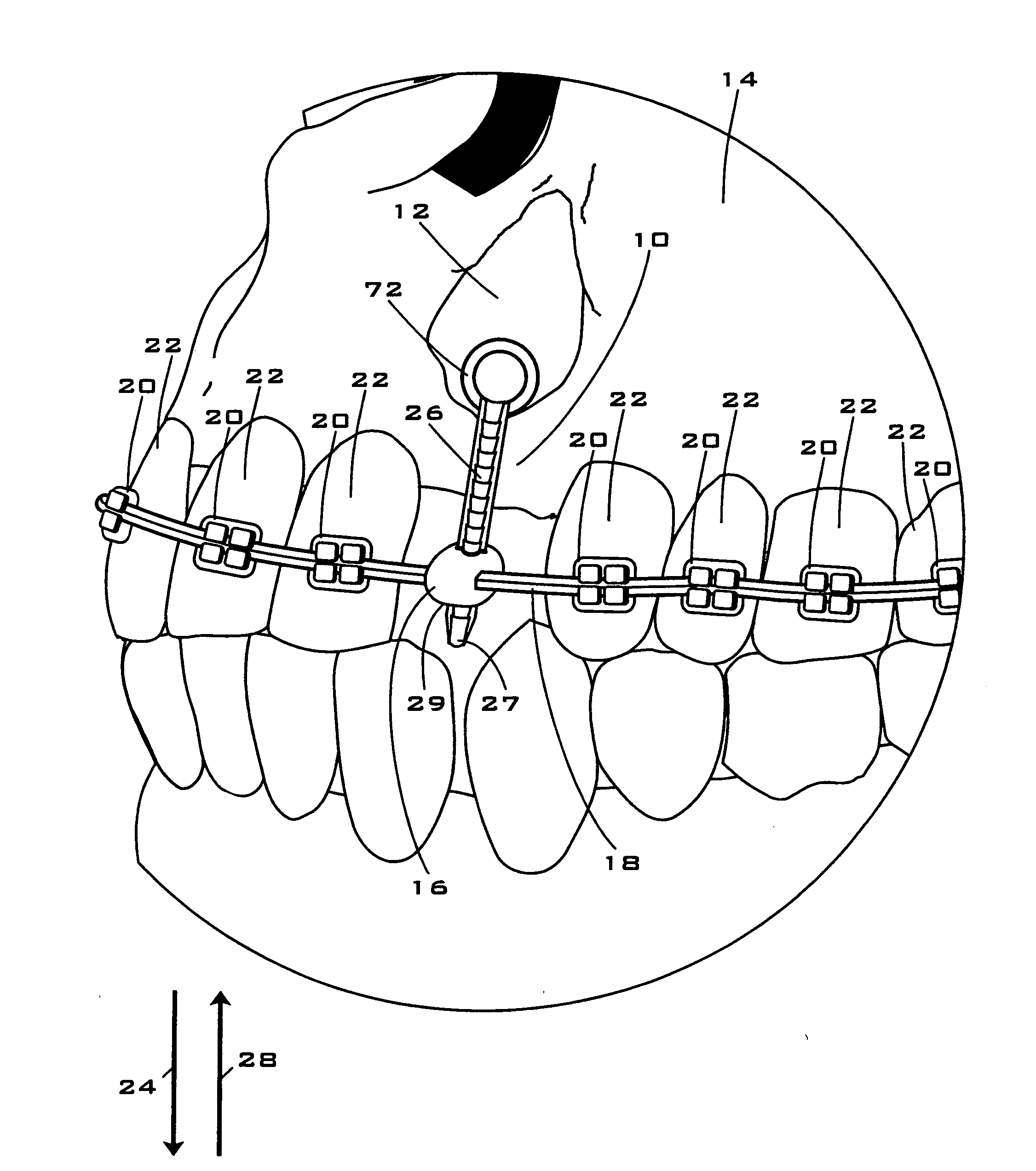

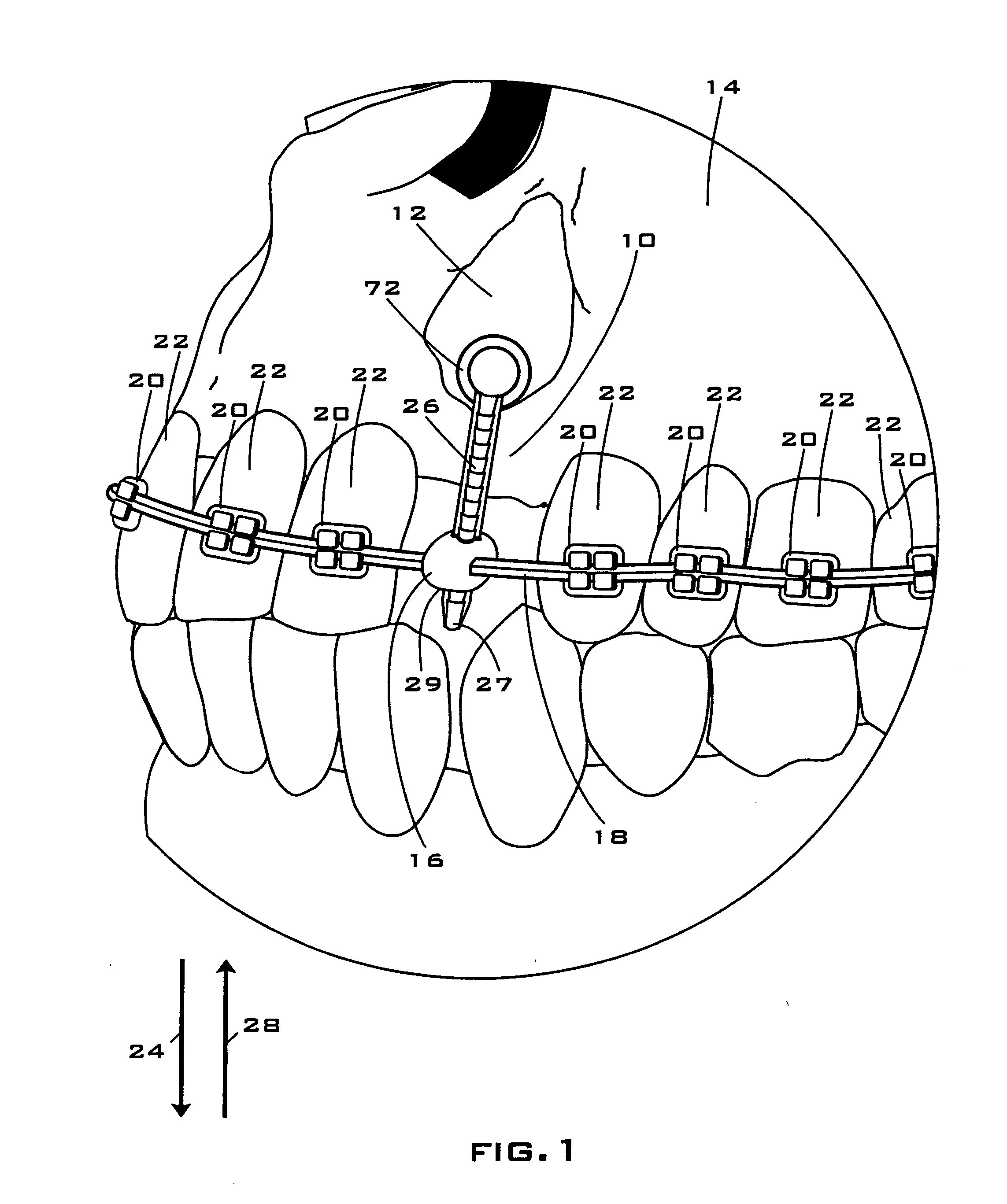

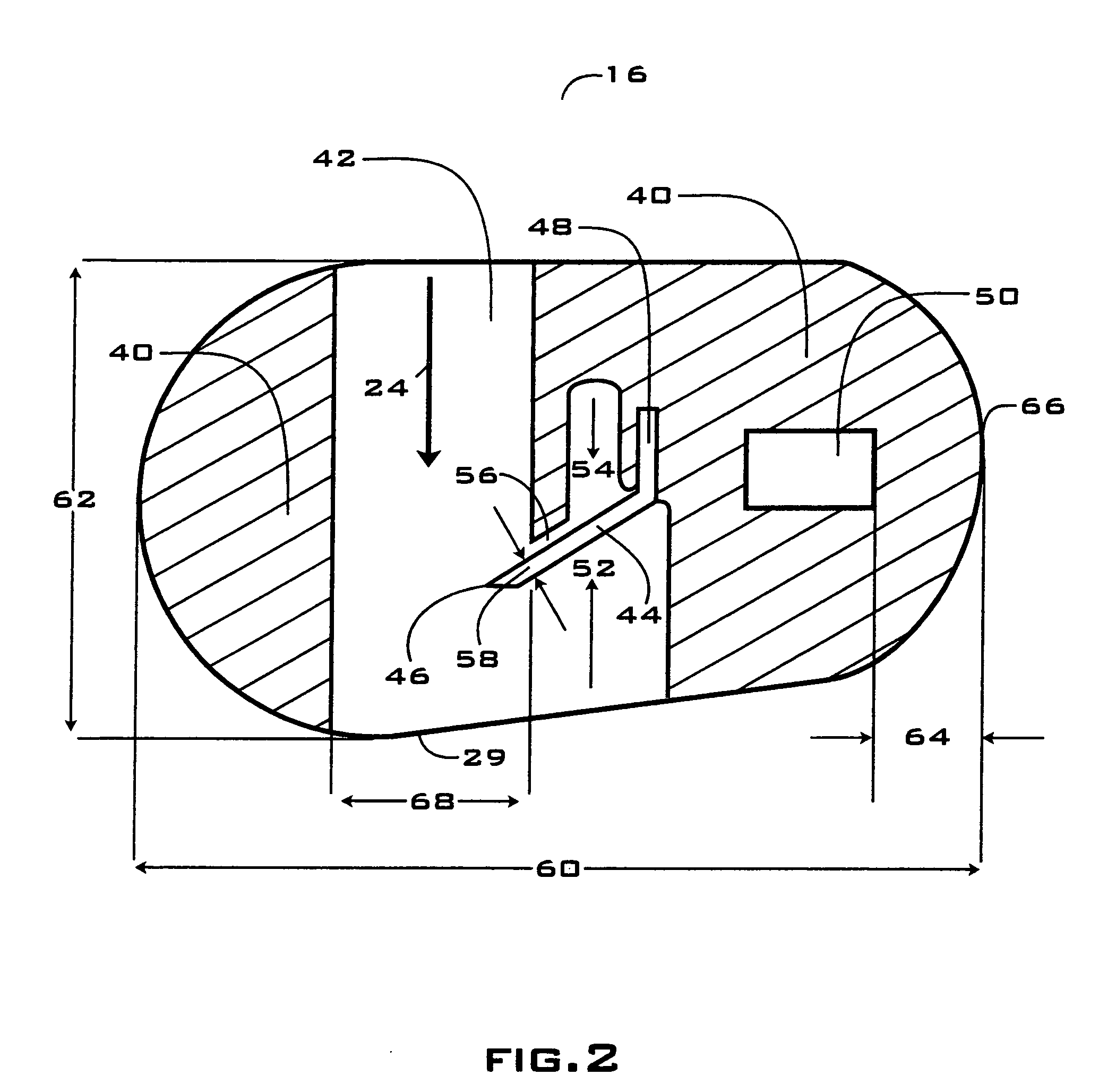

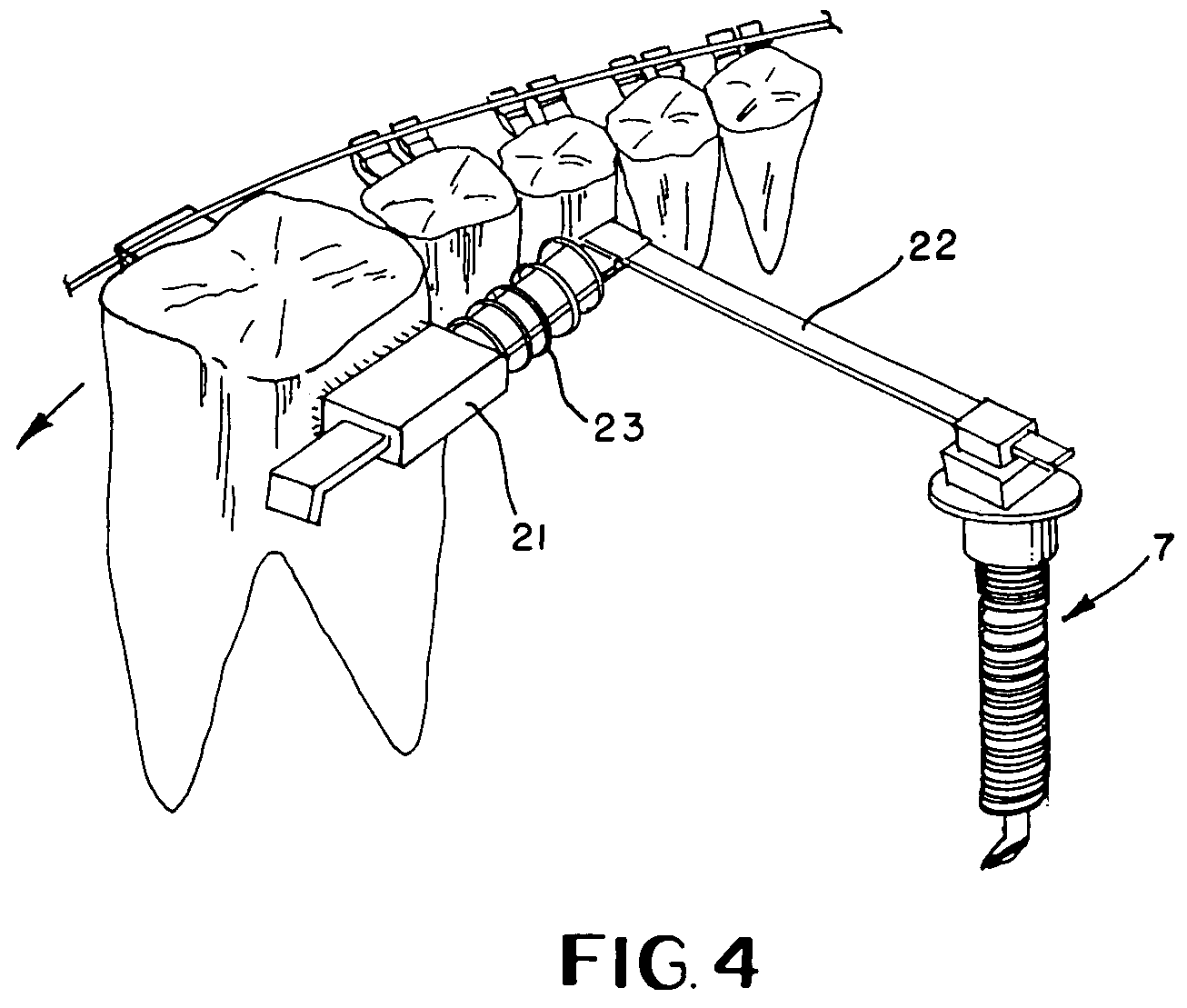

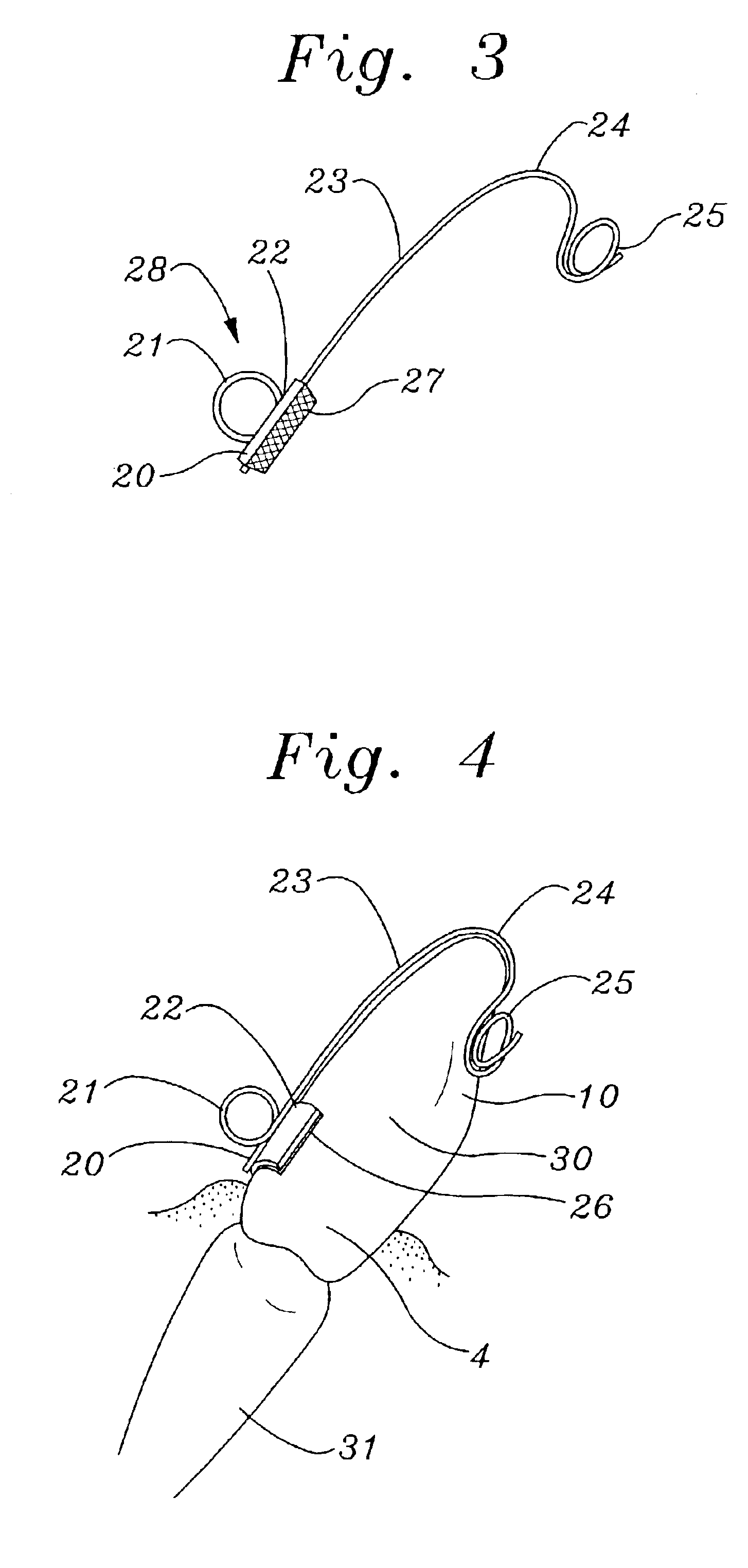

Apparatus for moving a misplaced or impacted tooth

A self-adjusting apparatus for moving an impacted tooth, wherein said apparatus is comprised a locking mechanism, an archwire disposed within said locking mechanism, and a ligature movably connected to said locking mechanism.

Owner:SPALTY CORY J

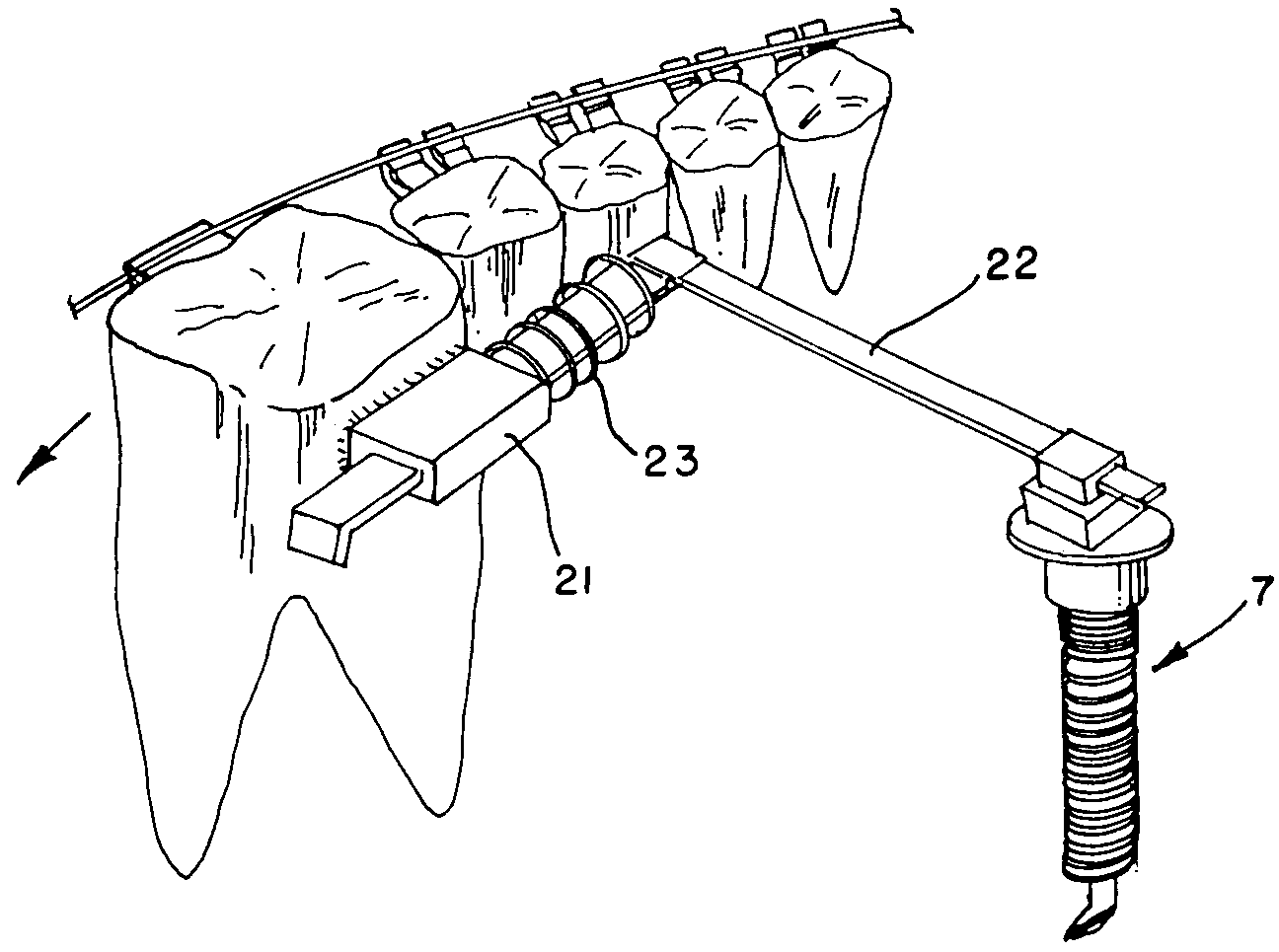

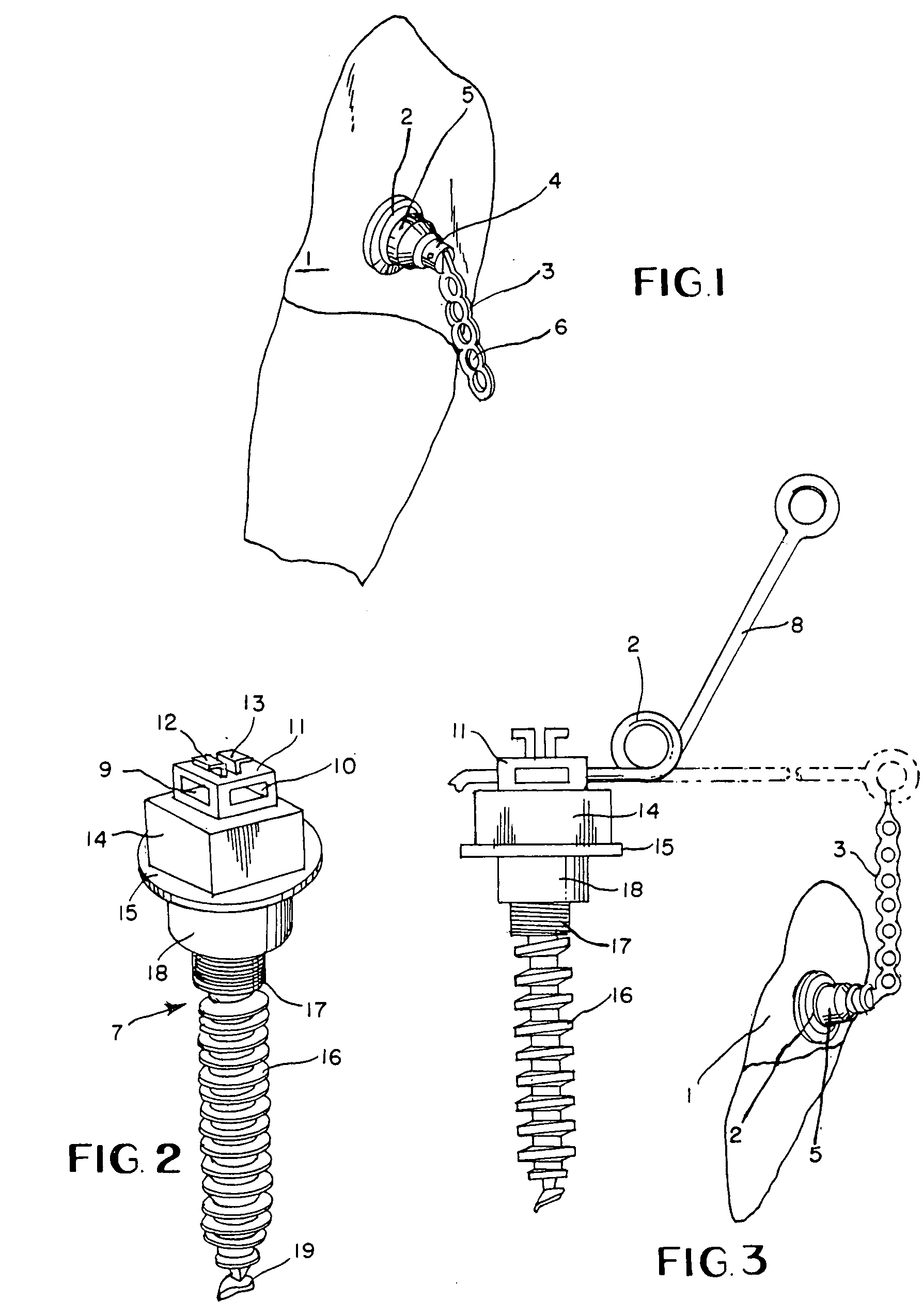

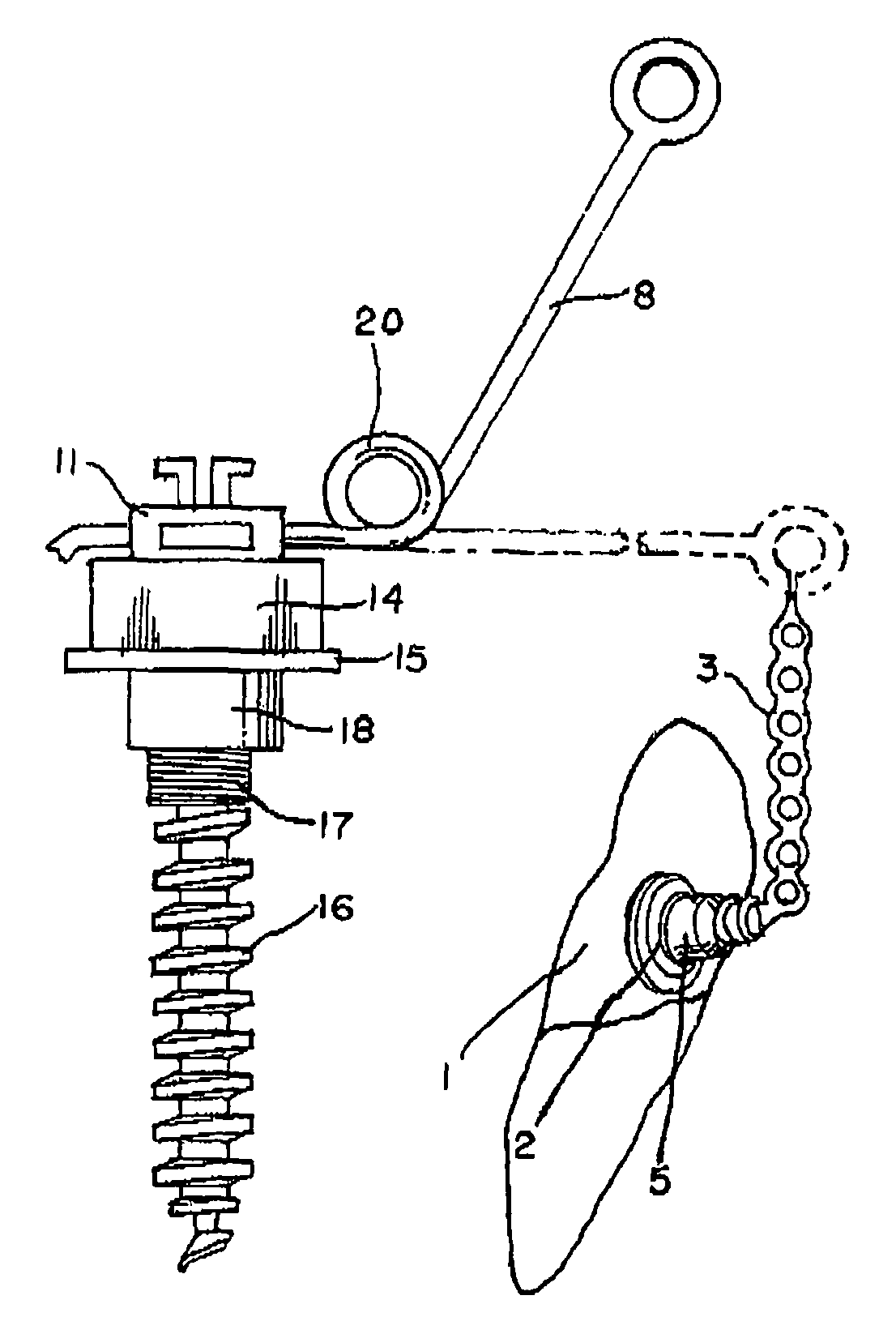

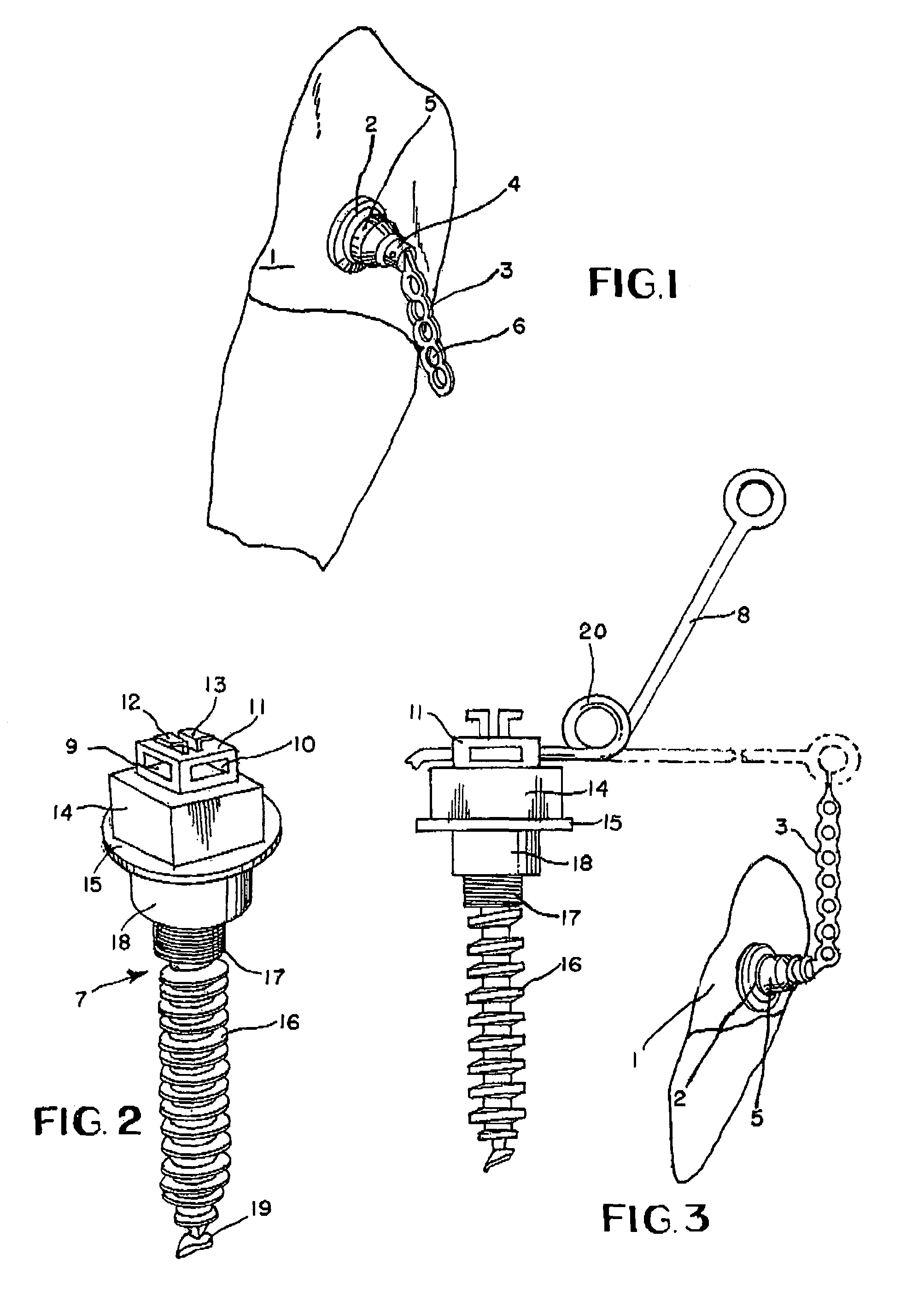

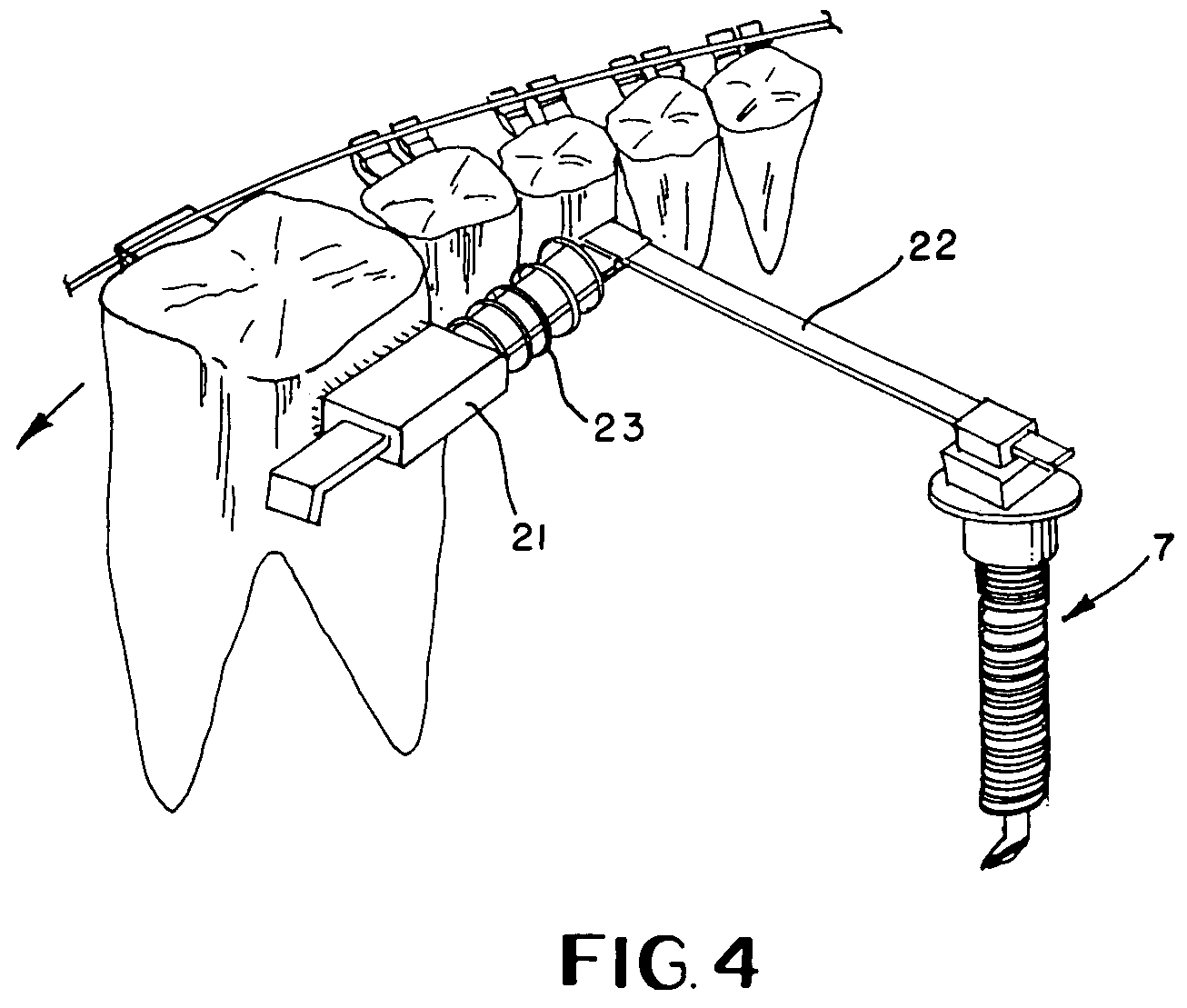

Impacted tooth appliance

An impacted tooth appliance including a micropin bone anchor with a quadrilateral aperture formed therein, a rigid apertured ribbon secured to the impacted tooth by means of a rotatable bracket secured to the tooth, the ribbon pivoted on the bracket, and the ribbon and the micropin interconnected by means of spring-biased quadrilateral wire.

Owner:YAZDI MOHAMADREZA

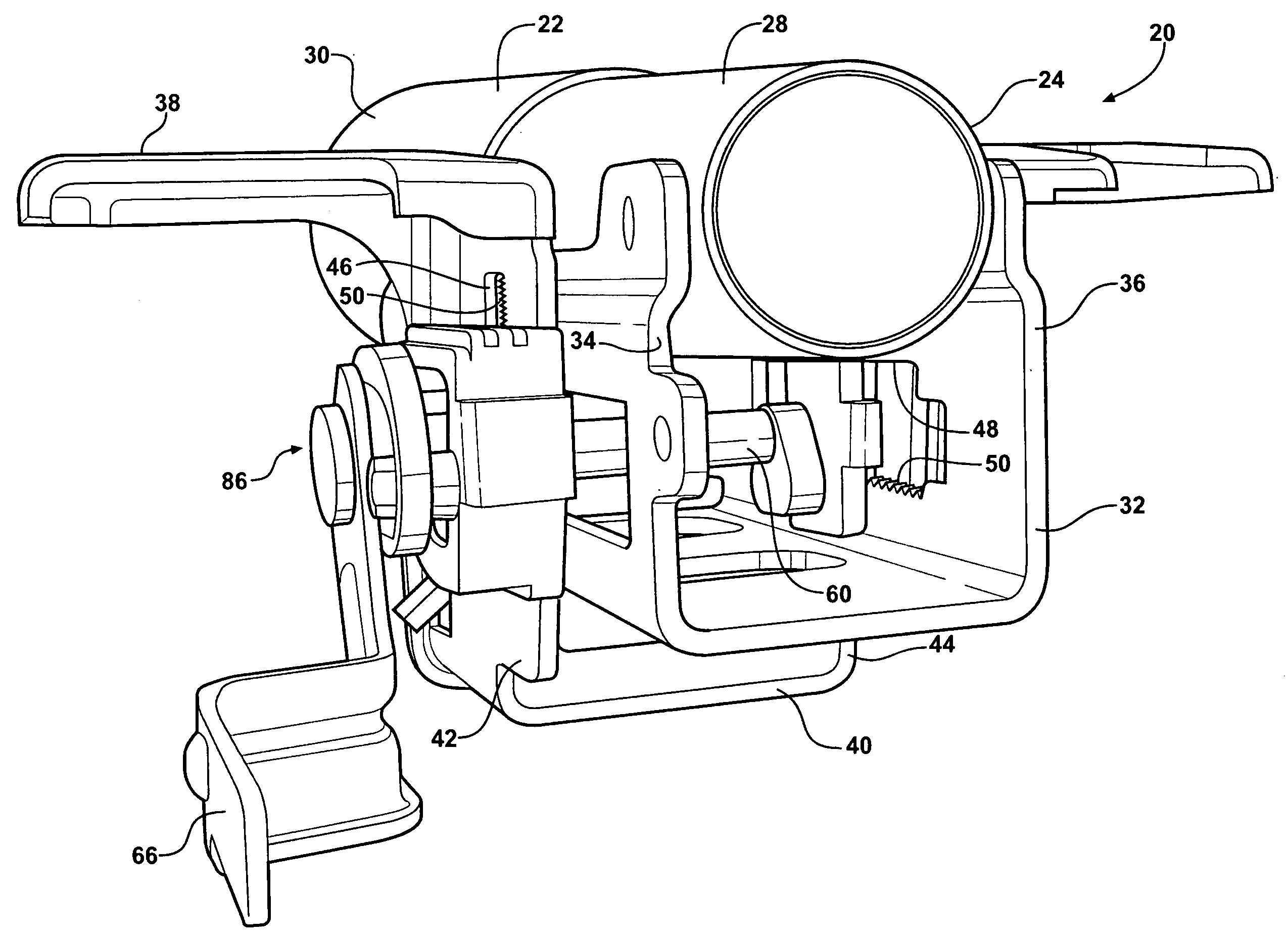

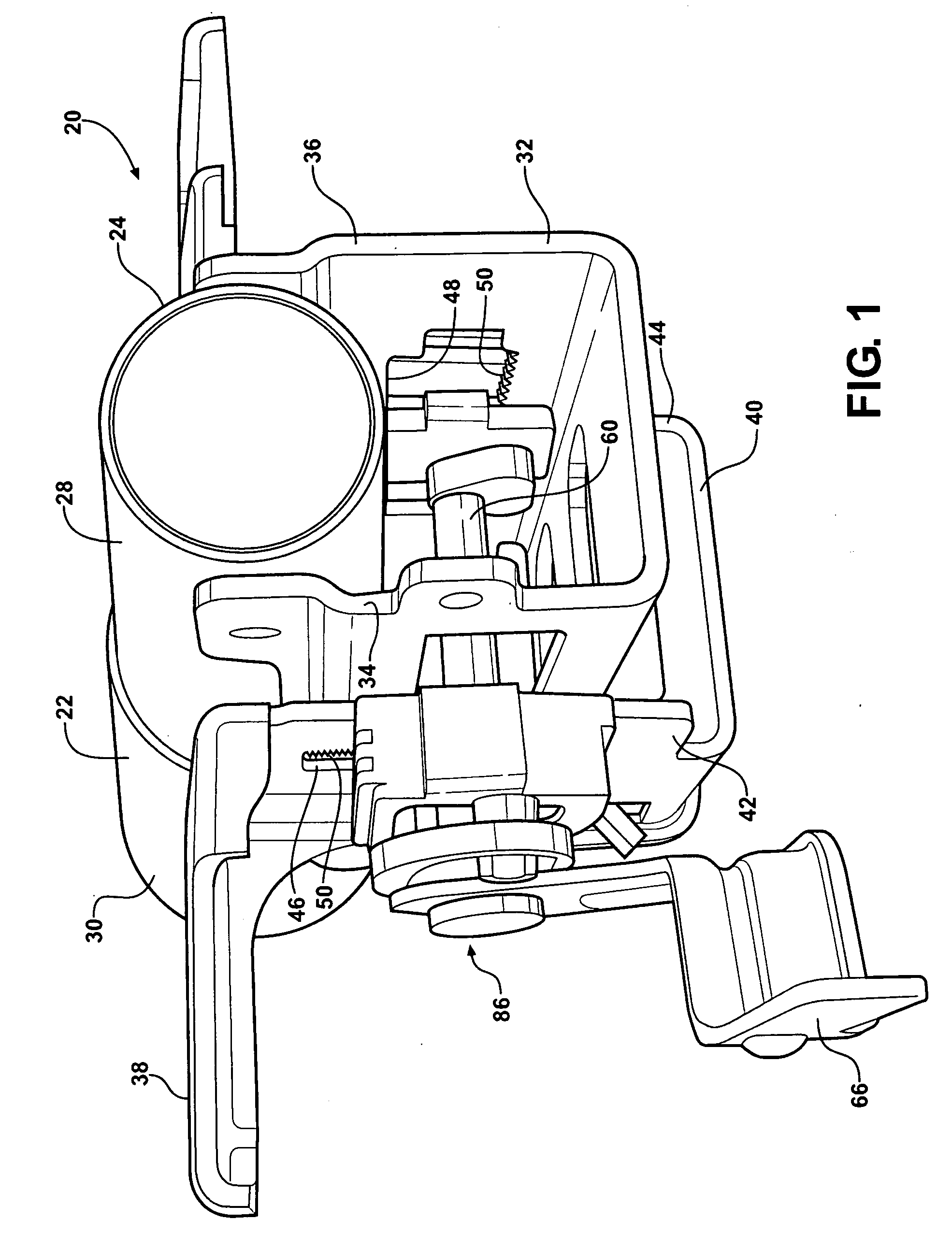

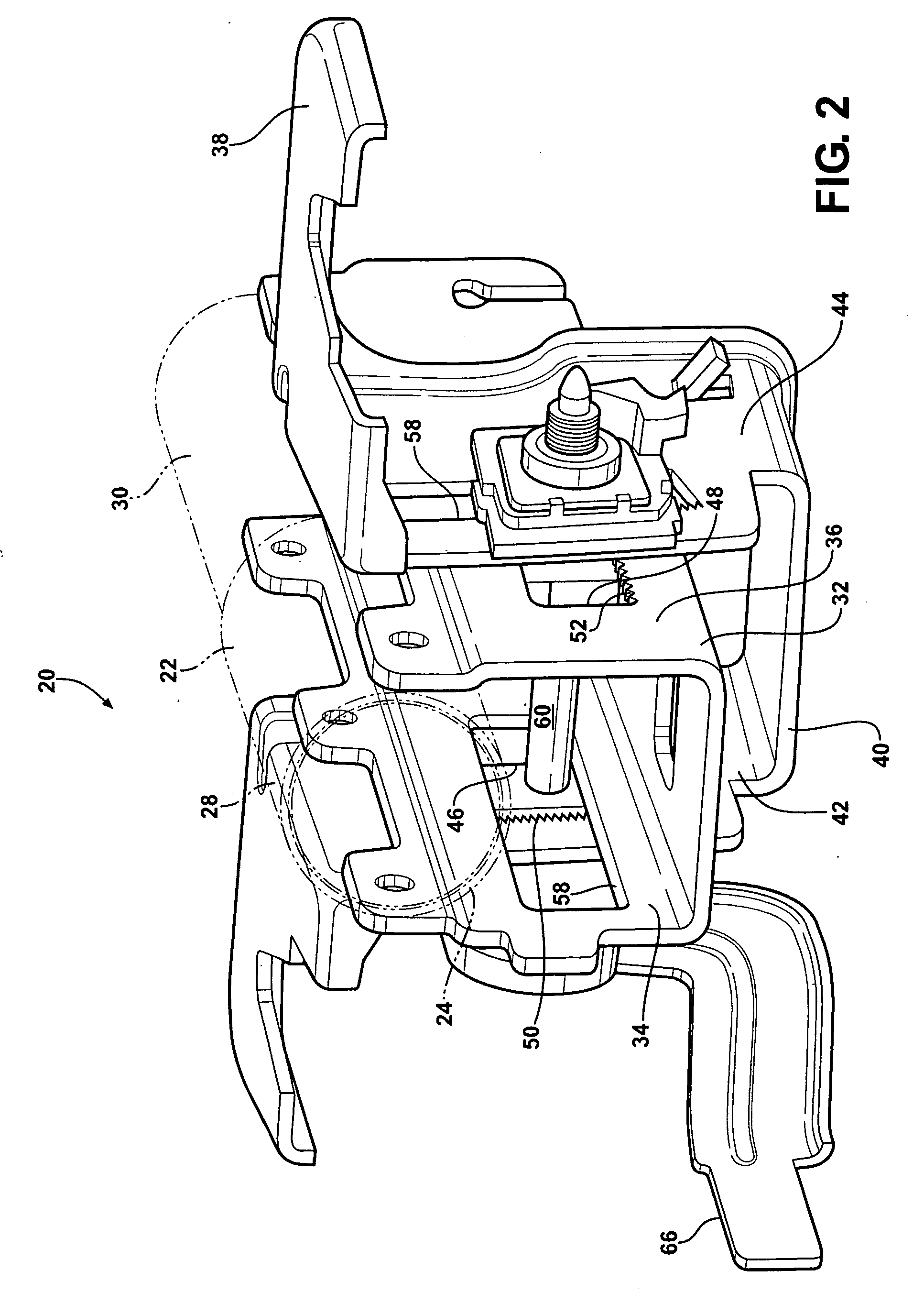

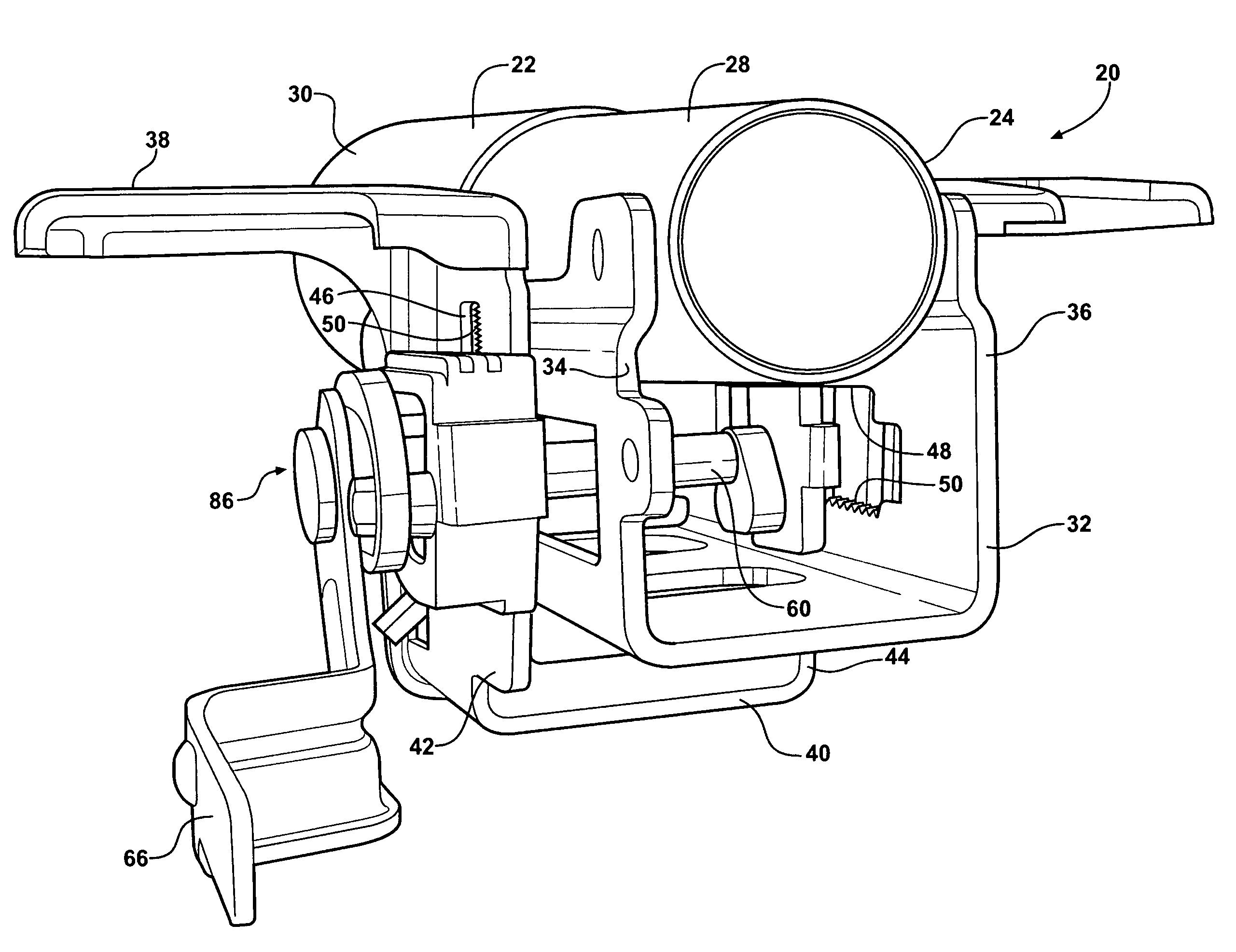

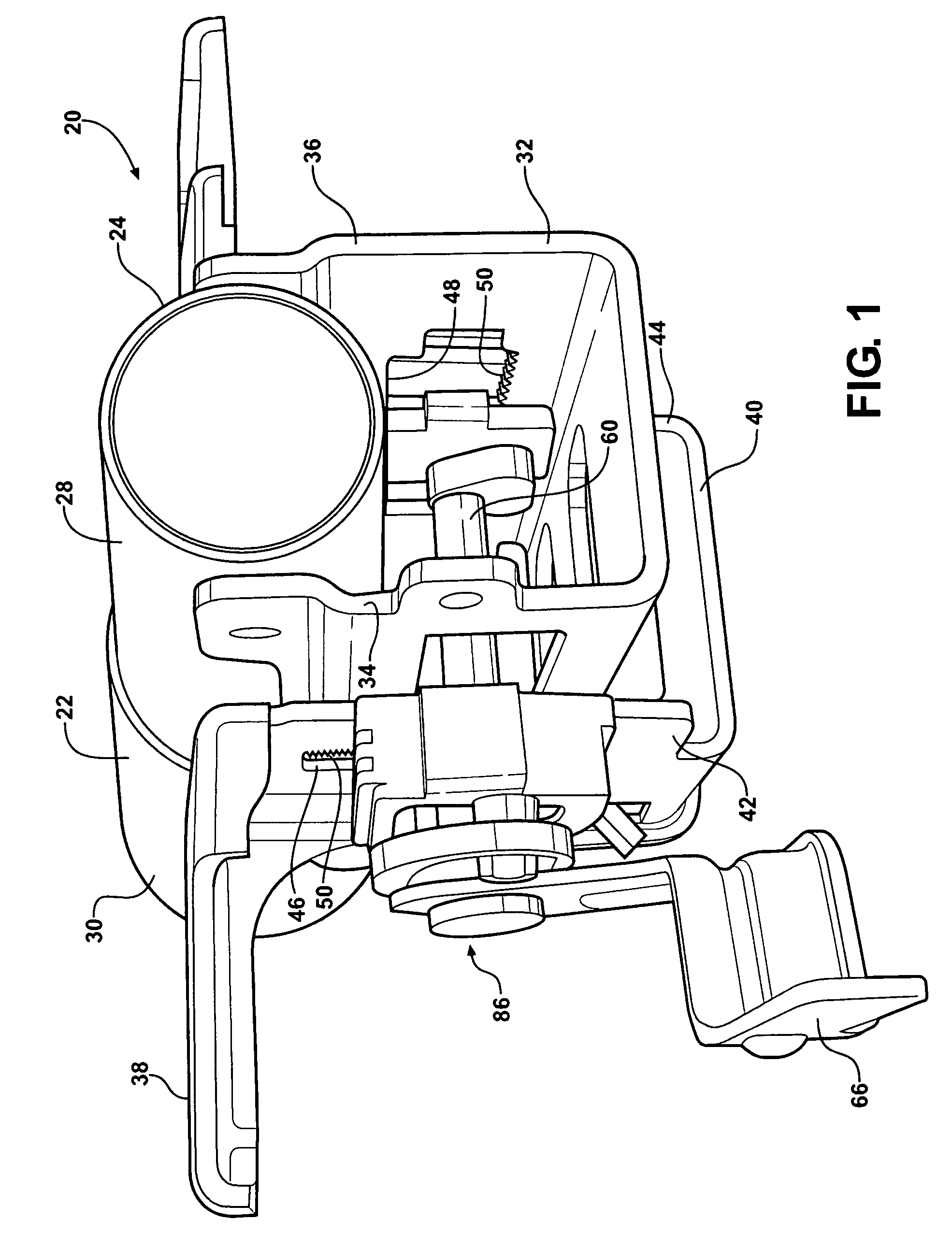

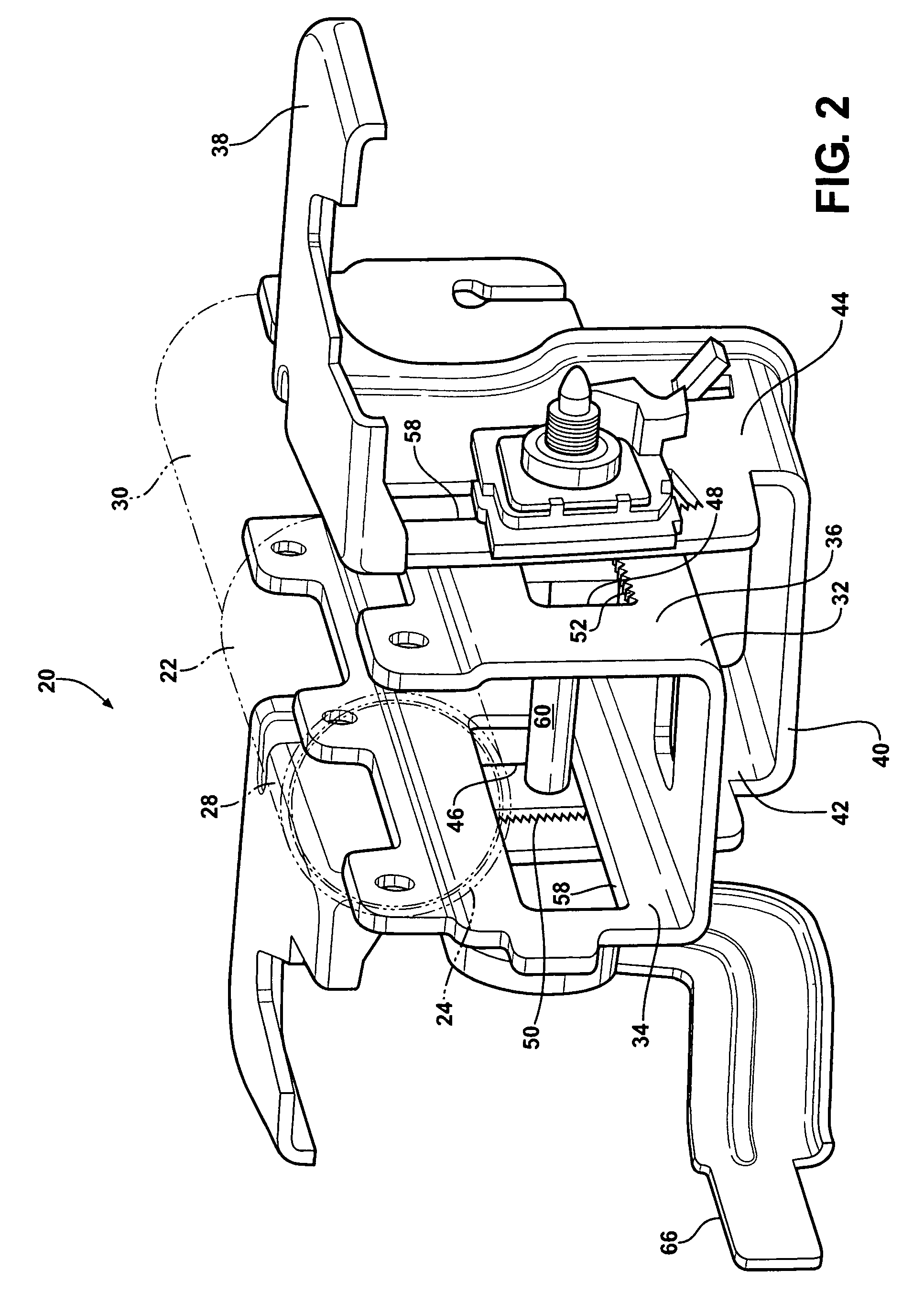

Locking mechanism for an adjustable steering column having impact teeth

A steering column assembly includes a mounting bracket and a column jacket moveable relative to the mounting bracket. The mounting bracket defines a rake slot having rake slot teeth and a telescope slot having telescope slot teeth. A shaft extends through the rake slot and the telescope slot transverse to a longitudinal axis of the column jacket. A rake lock having rake lock teeth is disposed within the rake slot and a telescope lock having telescope lock teeth is disposed within the telescope slot. The shaft extends through and rotatably supports the rake lock and the telescope lock. The rake lock and the telescope lock rotate as the rake lock and the telescope lock move into interlocking toothed engagement with the slot teeth to avoid peak-to-peak contact between the lock teeth and the slot teeth, thereby permitting full meshing engagement between the lock teeth and the slot teeth.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Locking mechanism for an adjustable steering column having impact teeth

A steering column assembly includes a mounting bracket and a column jacket moveable relative to the mounting bracket. The mounting bracket defines a rake slot having rake slot teeth and a telescope slot having telescope slot teeth. A shaft extends through the rake slot and the telescope slot transverse to a longitudinal axis of the column jacket. A rake lock having rake lock teeth is disposed within the rake slot and a telescope lock having telescope lock teeth is disposed within the telescope slot. The shaft extends through and rotatably supports the rake lock and the telescope lock. The rake lock and the telescope lock rotate as the rake lock and the telescope lock move into interlocking toothed engagement with the slot teeth to avoid peak-to-peak contact between the lock teeth and the slot teeth, thereby permitting full meshing engagement between the lock teeth and the slot teeth.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Impacted tooth appliance

An impacted tooth appliance including a micropin bone anchor with a quadrilateral aperture formed therein, a rigid apertured ribbon secured to the impacted tooth by means of a rotatable bracket secured to the tooth, the ribbon pivoted on the bracket, and the ribbon and the micropin interconnected by means of spring-biased quadrilateral wire.

Owner:YAZDI MOHAMADREZA

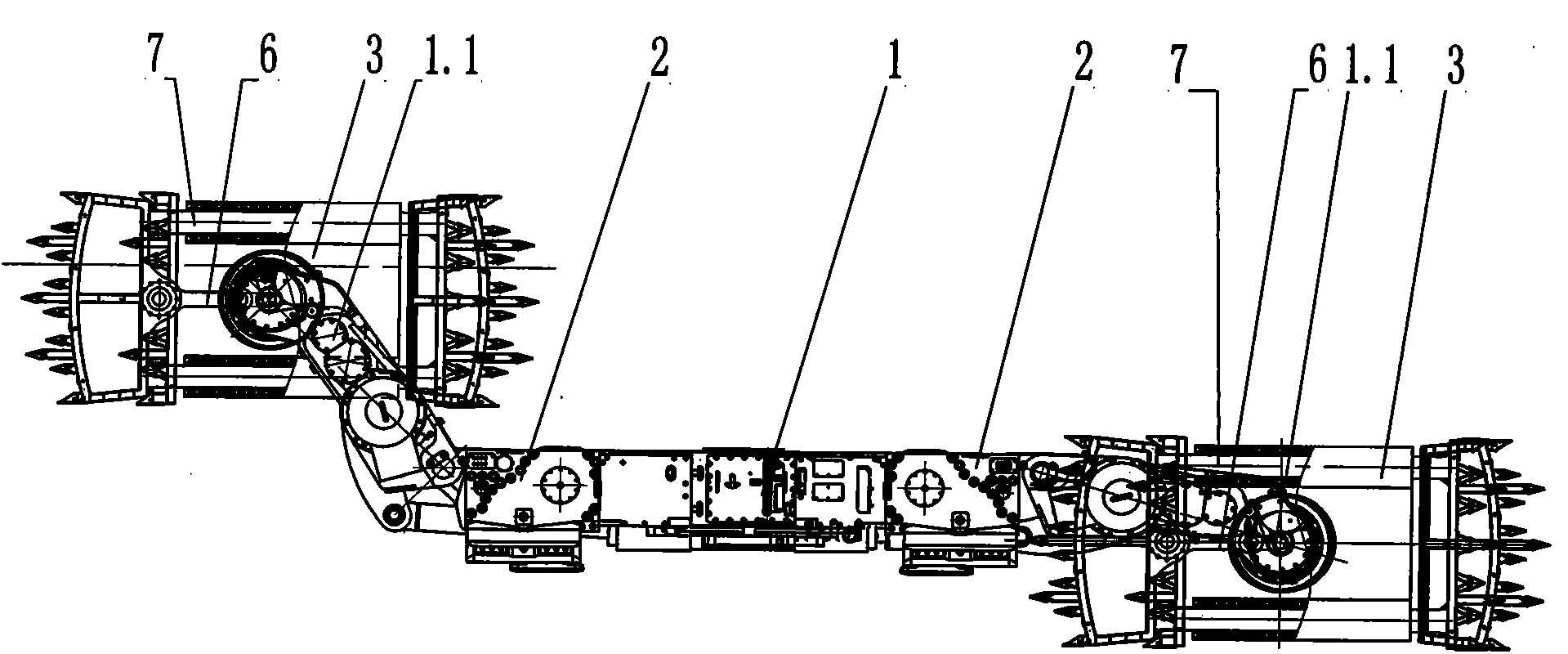

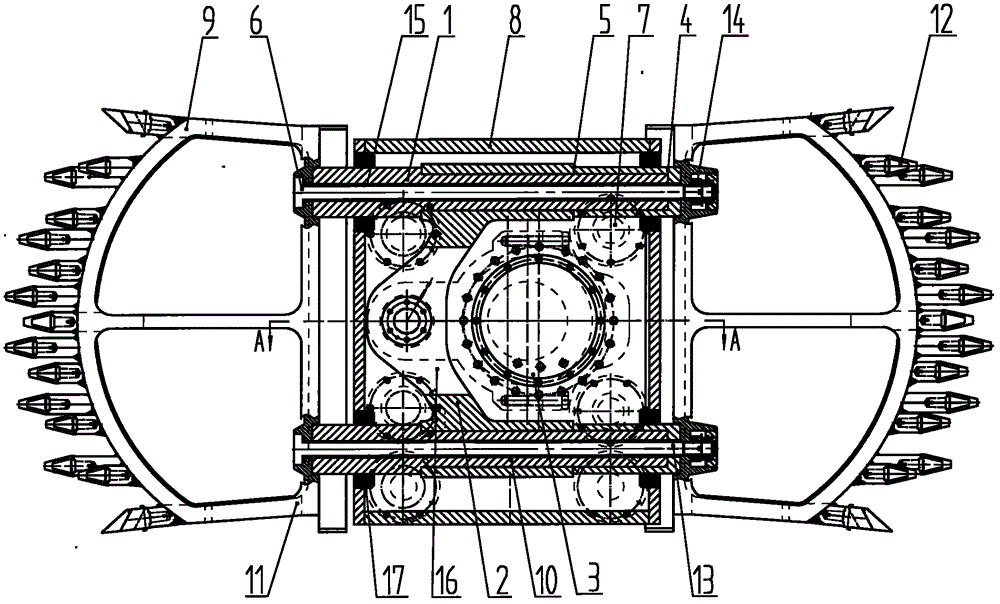

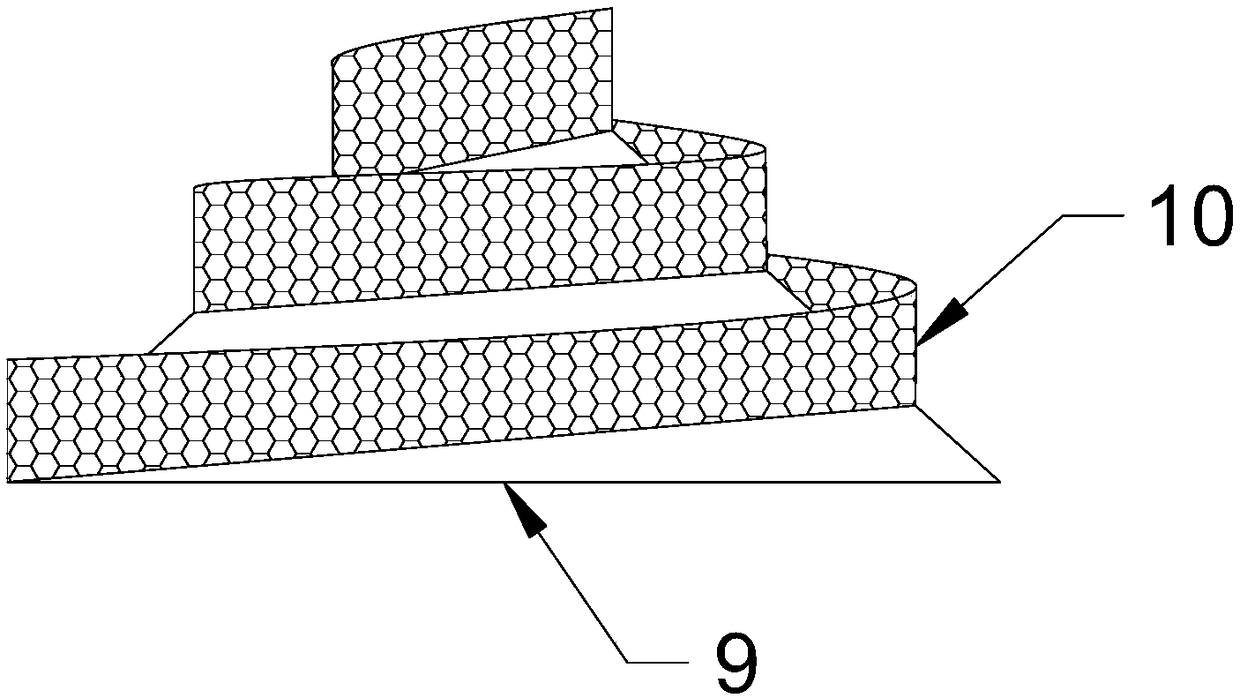

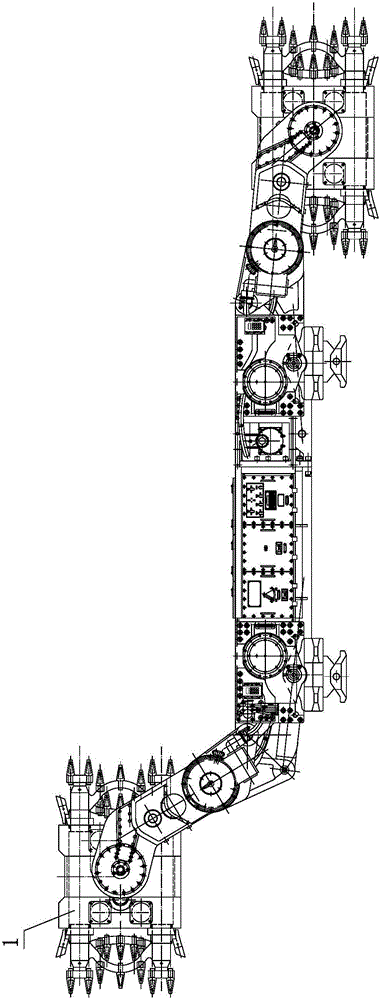

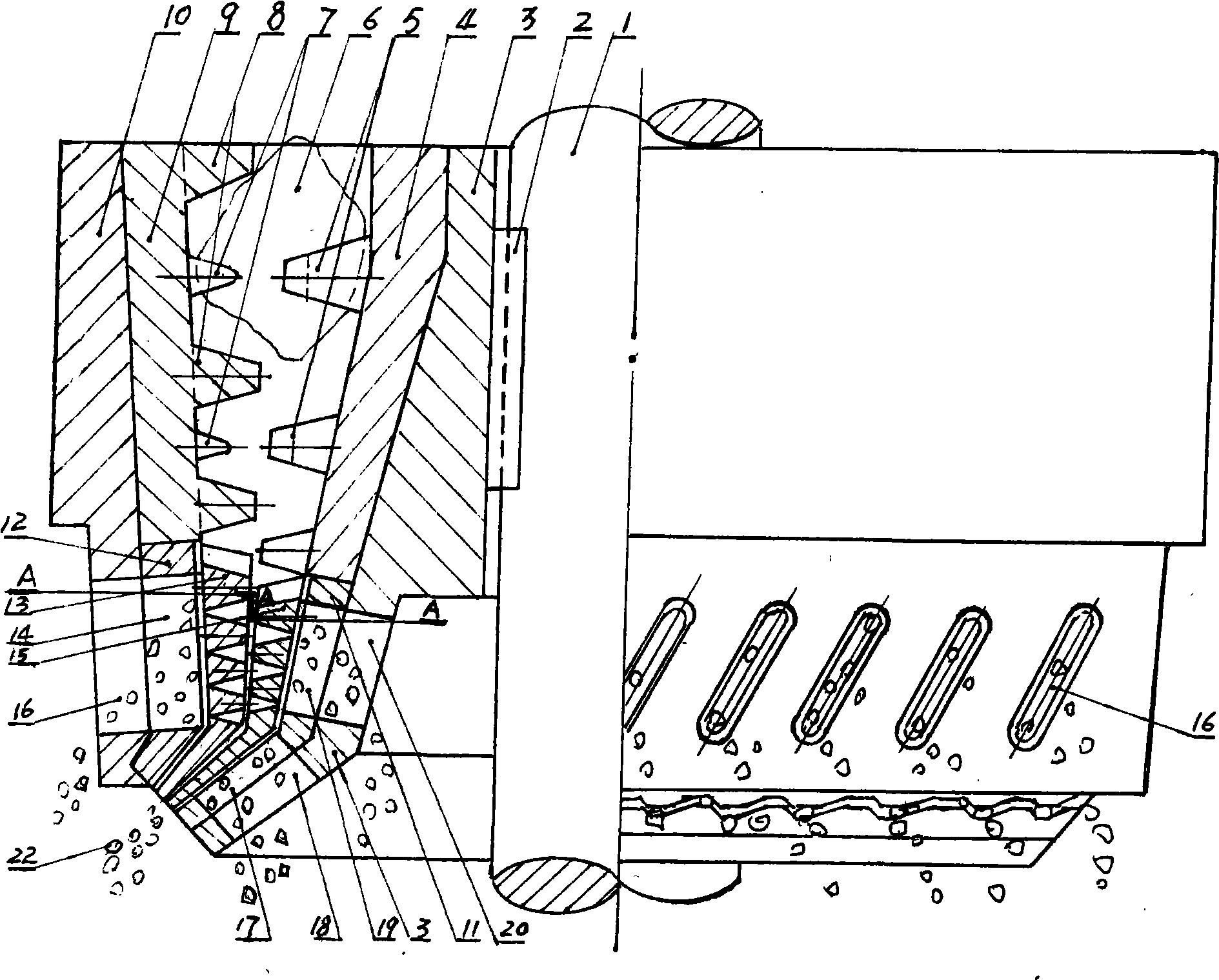

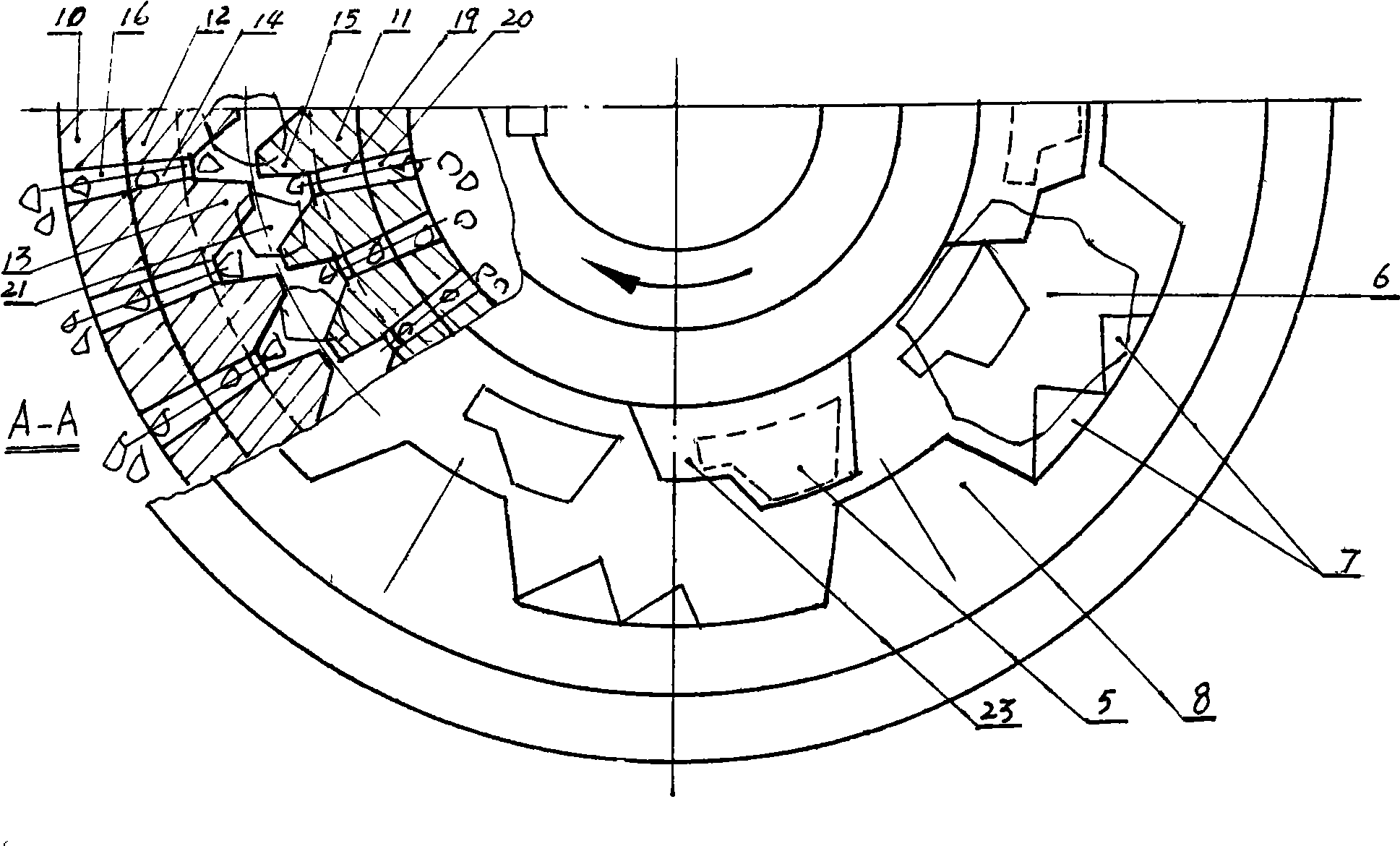

Step-tooth excavating method of reciprocating impact excavators, and step-tooth reciprocating impact excavator used for realizing step-tooth excavating method

ActiveCN103510953AReduce compressive stressReduce intensitySlitting machinesCutting machinesImpact toothEngineering

The invention belongs to the field of machinery, is especially suitable for the field of excavating, and specifically relates to a step-tooth excavating method of reciprocating impact excavators, and a step-tooth reciprocating impact excavator used for realizing the step-tooth excavating method. The step-tooth reciprocating impact excavator comprises a machine body, a travelling mechanism, an impact blanking mechanism and the like; the impact blanking mechanism is arranged on the machine body; and the travelling mechanism is arranged on the lower part of the machine body. The impact blanking mechanism comprises a step-tooth impact-cutting device, an impact power box, a power impact part, an impact guiding element and the like; step teeth are formed by adjacent impact teeth arranged on the step-tooth impact-cutting device. The step-tooth impact-cutting device is driven by the power impact part, material to be excavated is impacted to be step shaped so as to obtain two or more opposite free faces, and pressure stress and / or structural strength relative to original material is reduced greatly. When the impact teeth is used for excavating for another time, the two or the more opposite free faces are used for reducing impact resistance greatly; generation of oversized material blocks, which fall because of excavating, is avoided; impaction efficiency is increased, and equipment depreciation is reduced.

Owner:刘素华

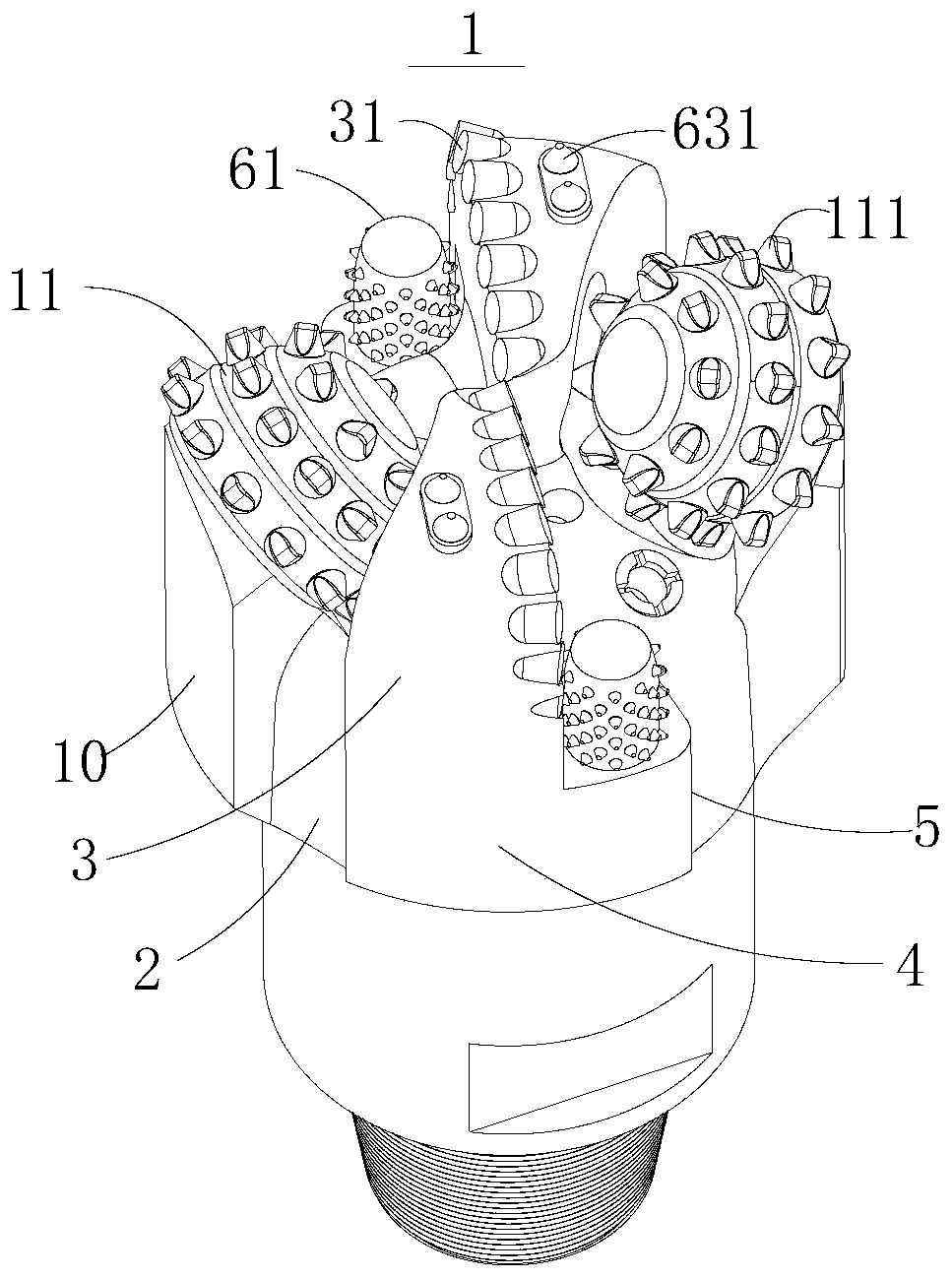

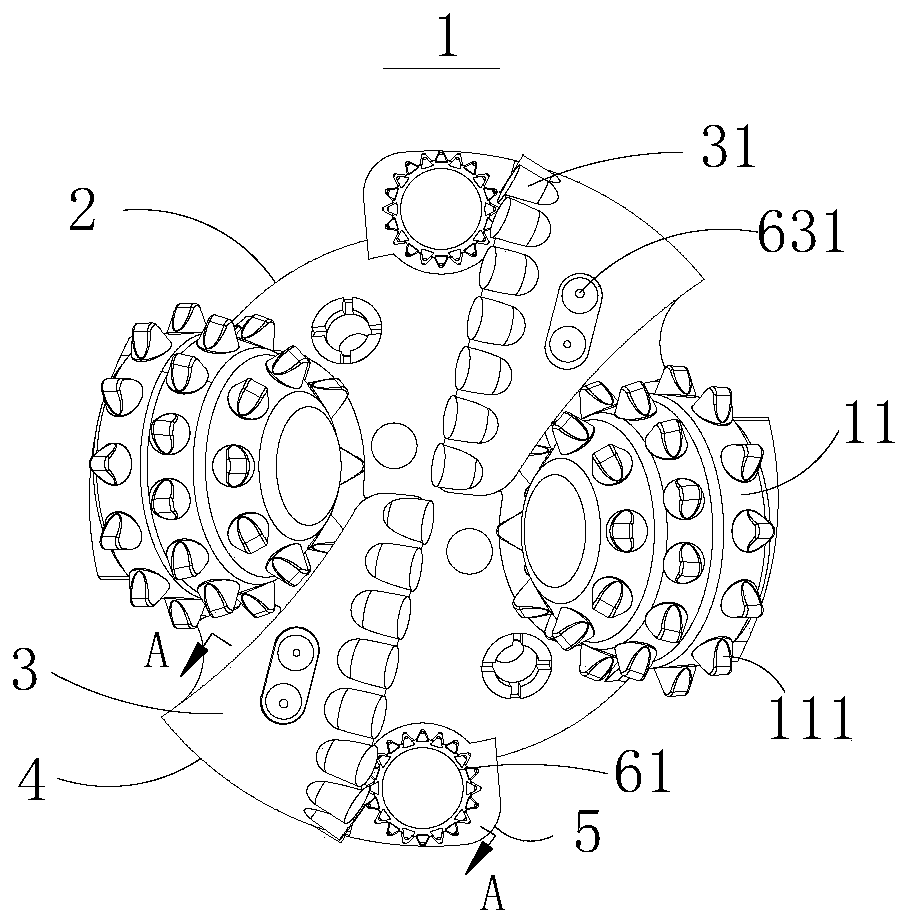

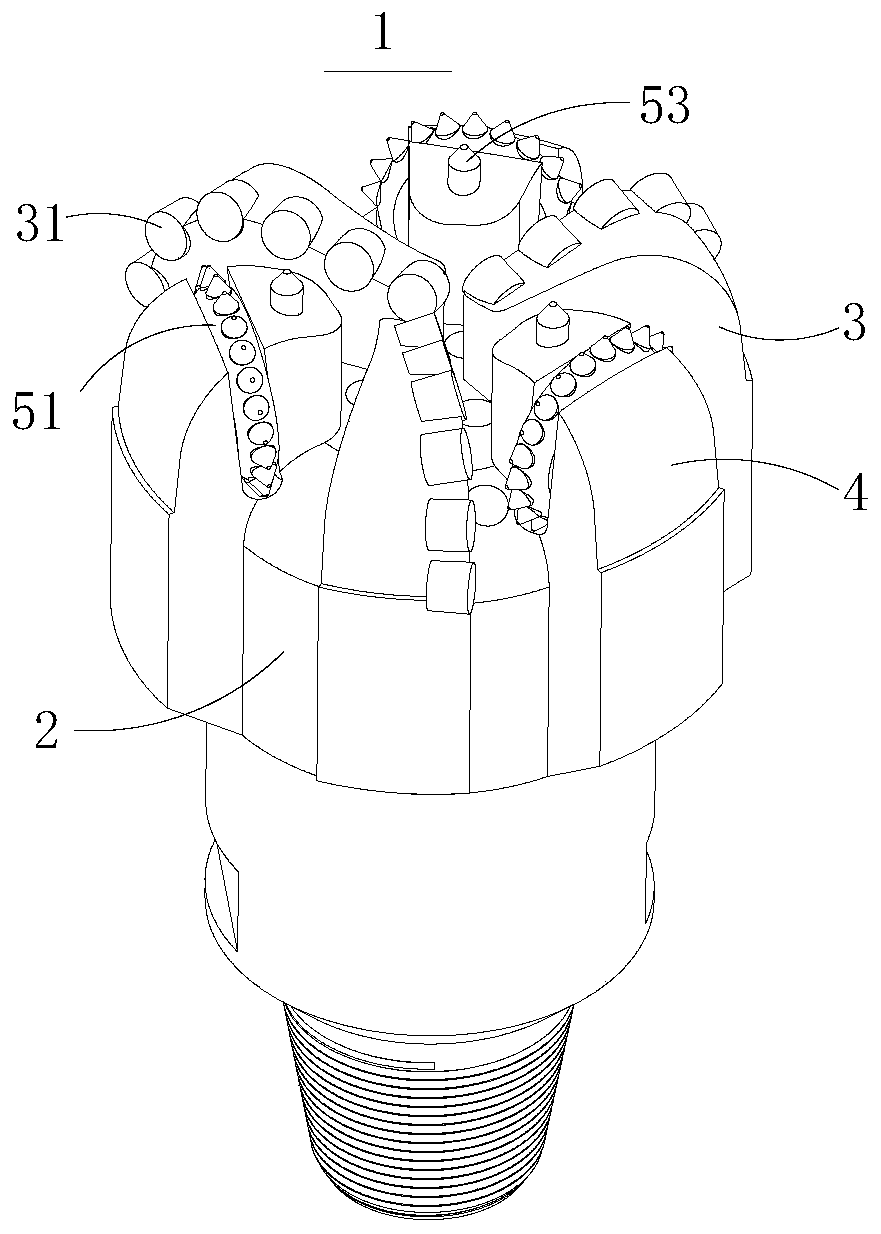

Composite drill bit

The invention discloses a composite drill bit. The composite drill bit comprises a drill bit body, a cutter wing, a tooth palm and a tooth wheel, the cutter wing and the drill bit are fixedly connected or integrally formed, cutting teeth are arranged on the cutter wing, the tooth wheel is rotatably connected with the tooth palm through a shaft, teeth are arranged on the tooth wheel, the compositedrill bit is characterized in that an impact unit is arranged on the composite drill bit, and the impact unit is composed of a rolling body, a transmission device and an impact device; the rolling body can rotate along self axis; and the impact device is composed of an impact rod and at least one impact tooth. According to the composite drill bit, the rock breaking efficiency is improved, meanwhile the drilling cost is saved, and the circumferential vibration of the composite drill bit can further be reduced.

Owner:SOUTHWEST PETROLEUM UNIV +1

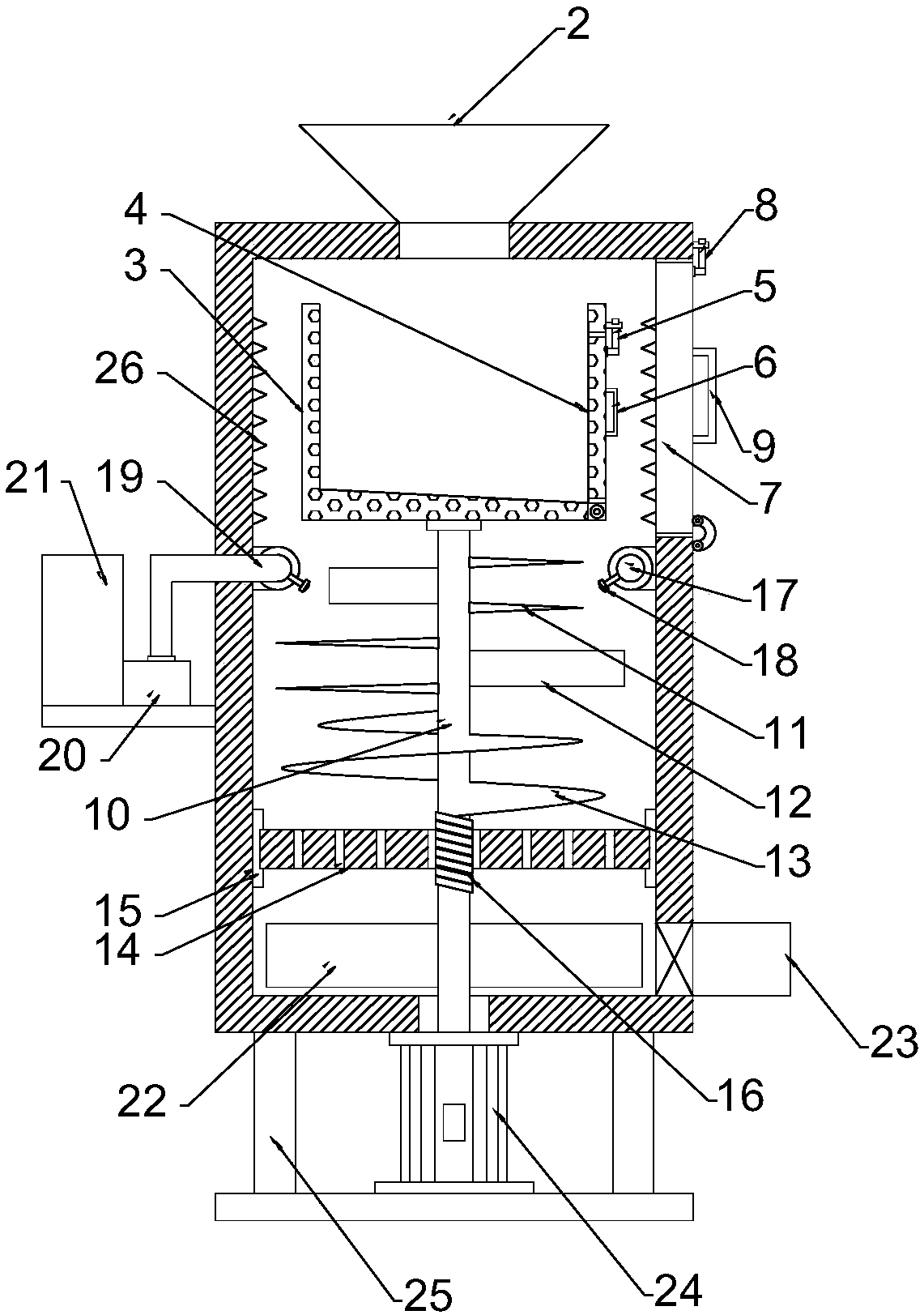

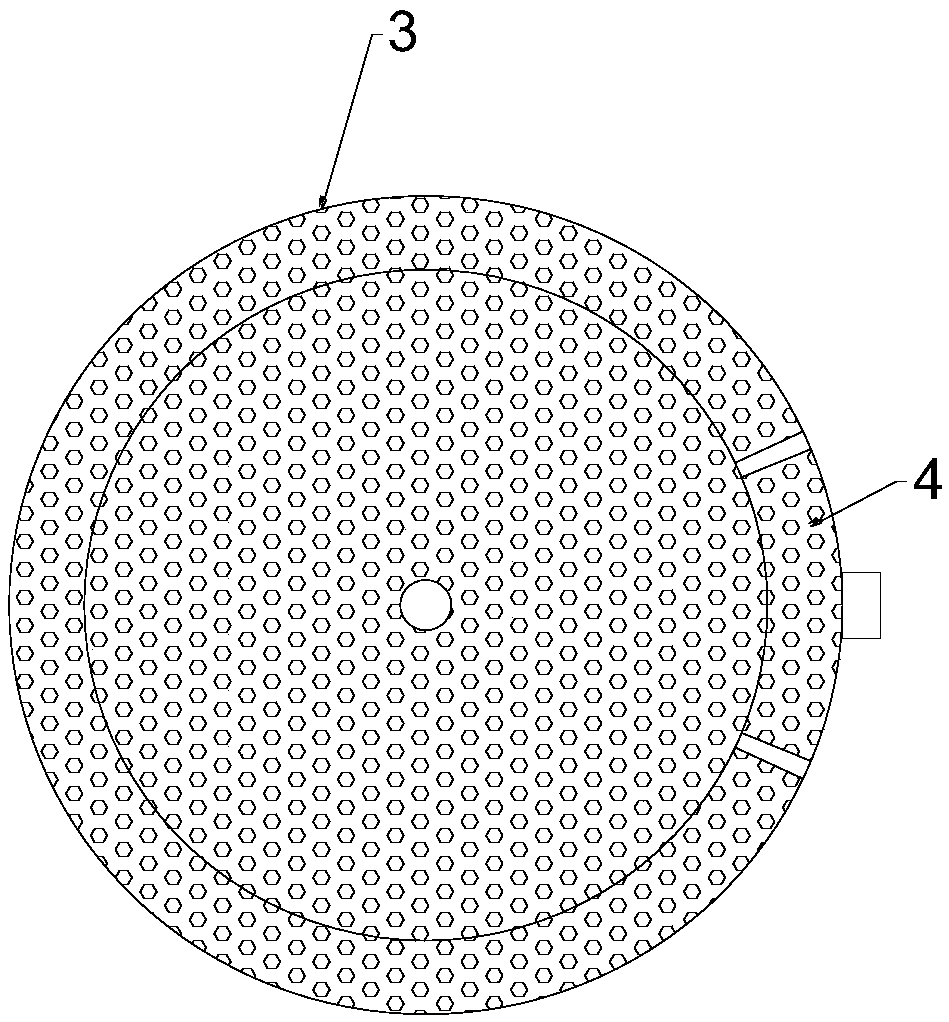

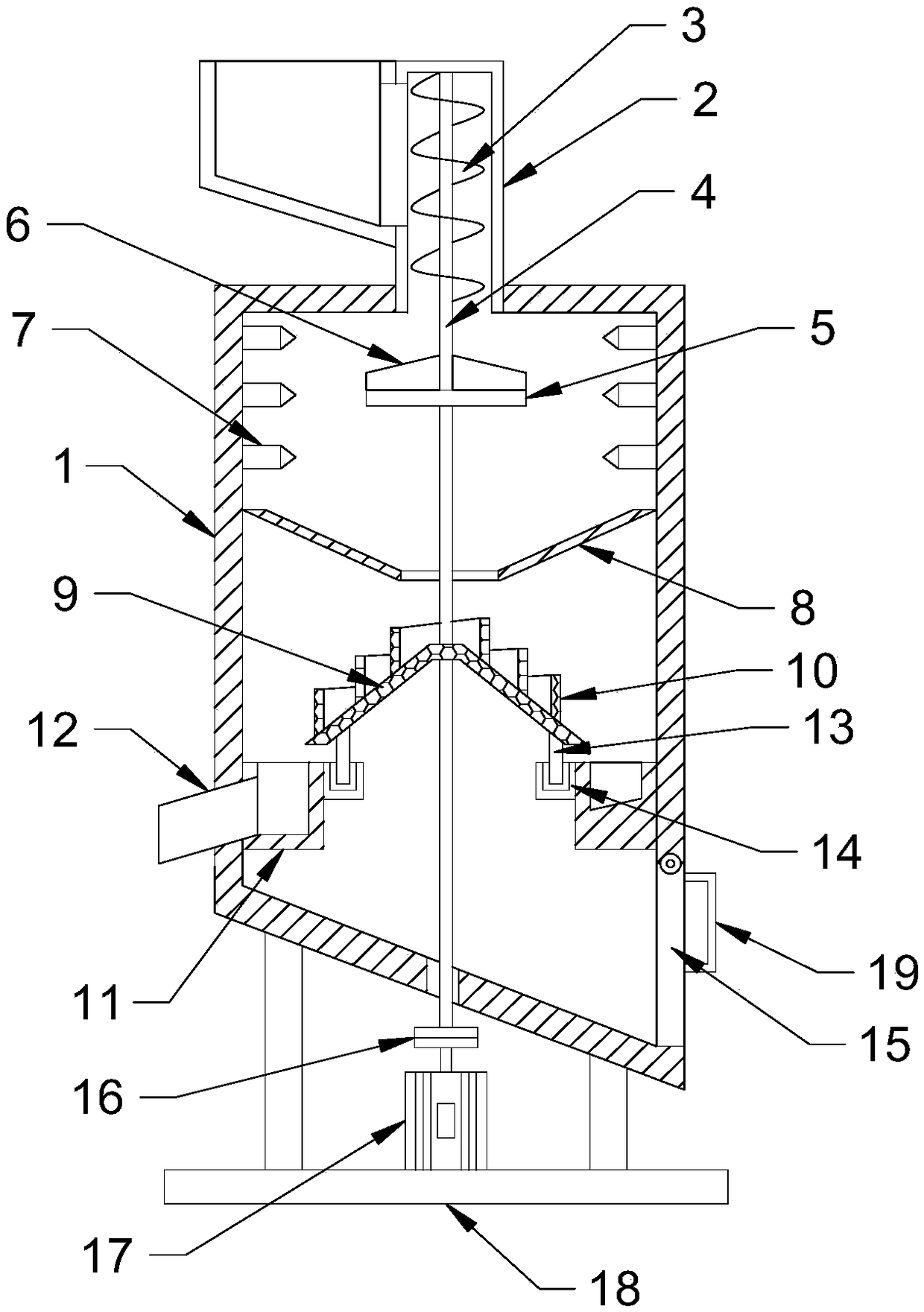

Liquid medicine mixing apparatus for treating soil

InactiveCN108452697AImprove governance effectEasy to take outRotary stirring mixersTransportation and packagingImpact toothSoil treatment

The invention discloses a liquid medicine mixing apparatus for treating soil. The liquid medicine mixing apparatus comprises a shell, a crushing cutter, a stirring plate and a driving motor; the top of the shell is communicated with a feeding hopper, and a centrifugal cylinder is arranged below the feeding hopper in the shell; and the inner wall, disposed outside the centrifugal cylinder, of the shell is uniformly provided with impact teeth. The centrifugal cylinder is used for screening large-particle impurities in the soil; meanwhile, by arranging hinged door panels, the large-particle impurities are convenient to take out; by arranging the centrifugal cylinder and the impact teeth, the hardened soil particles are easier to scatter under the effect of a centrifugal force, the subsequentcrushing is facilitated, and sufficient mixing of crushed soil and the liquid medicine is more facilitated; and the crushing cutter, the stirring plate, an atomizing spray head and a spiral blade areused for crushing and mixing the soil, the atomizing spray head enables the liquid medicine to sufficiently contact the falling soil, and the soil treatment effect is improved.

Owner:刘志坚

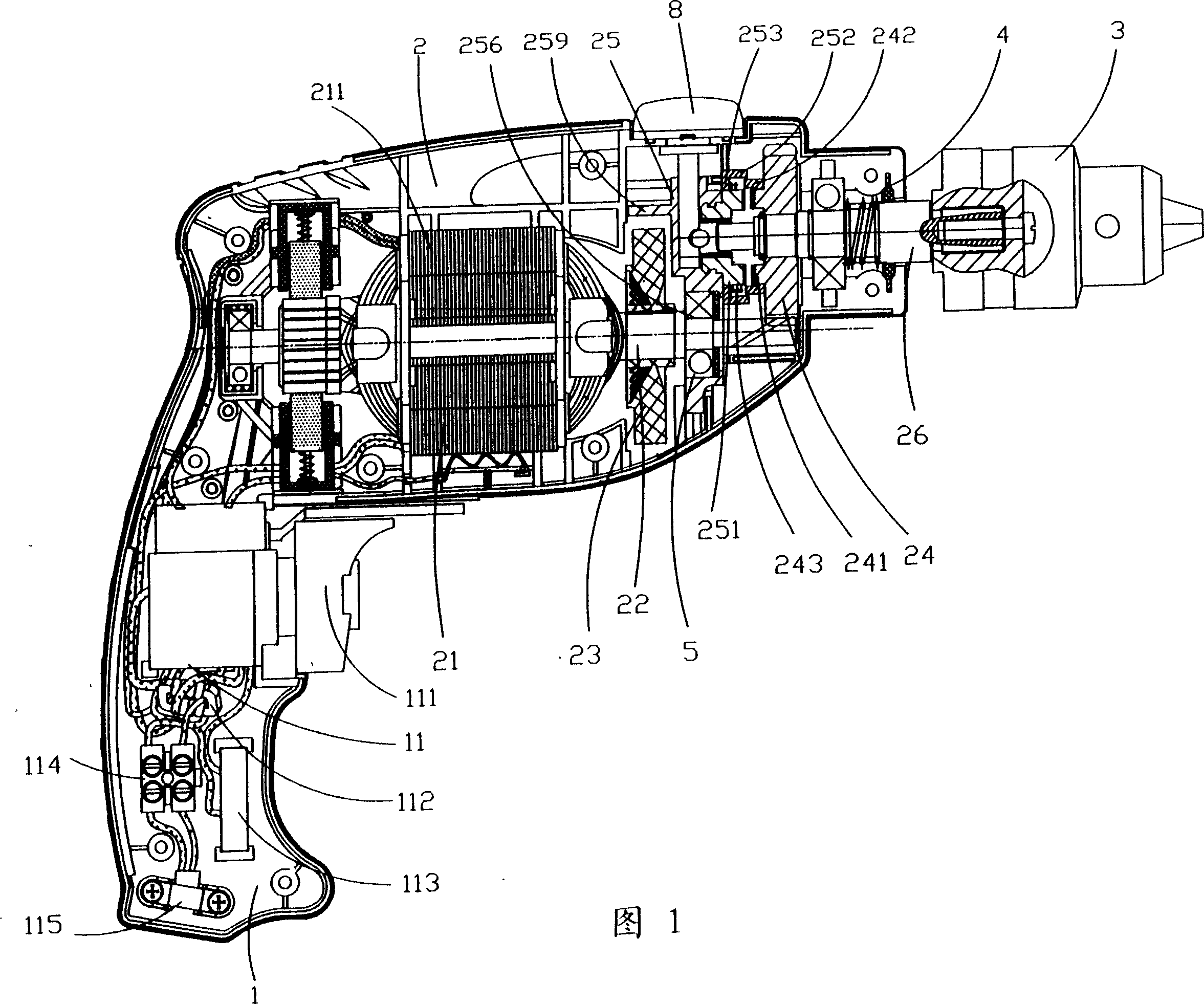

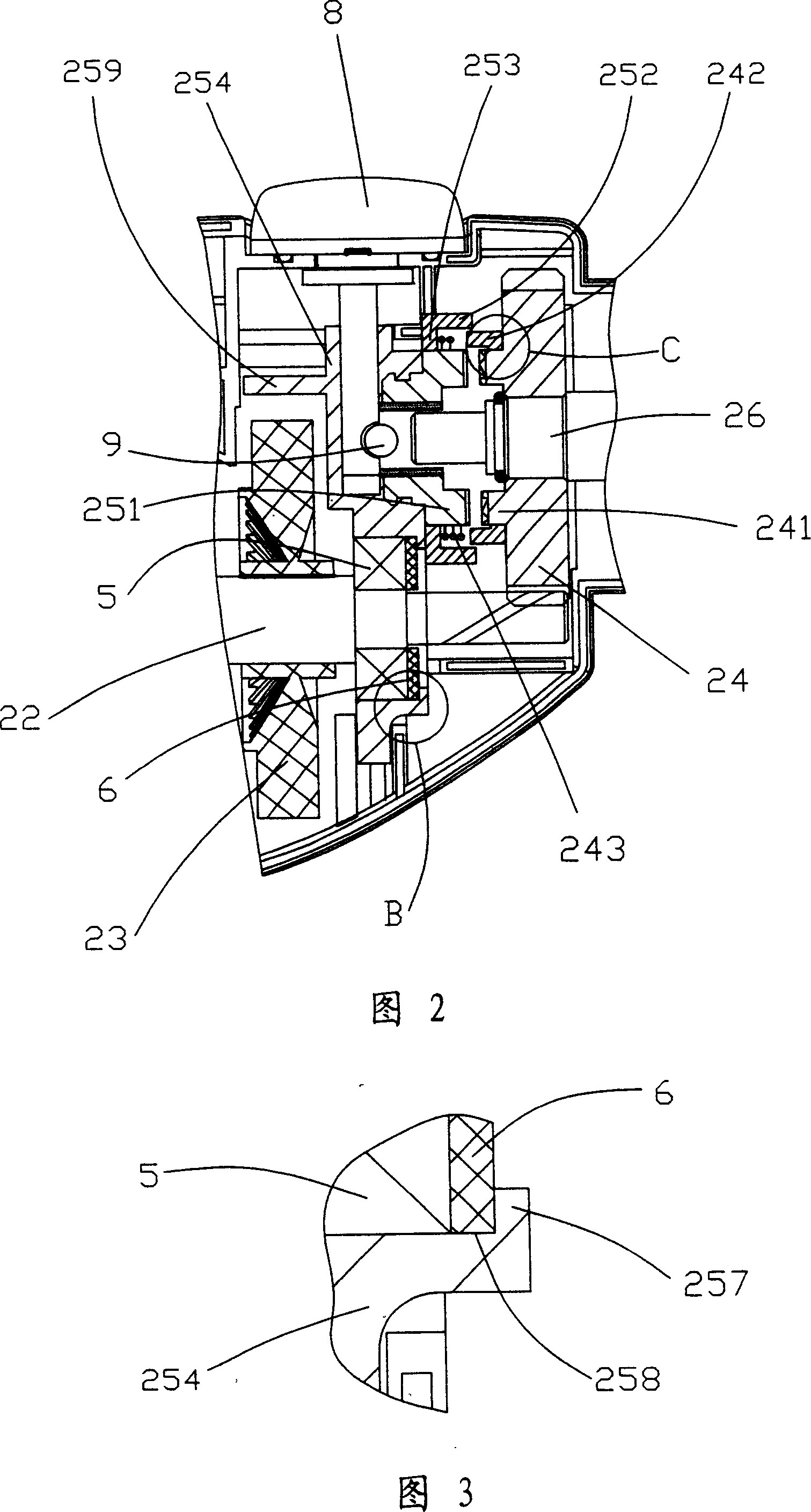

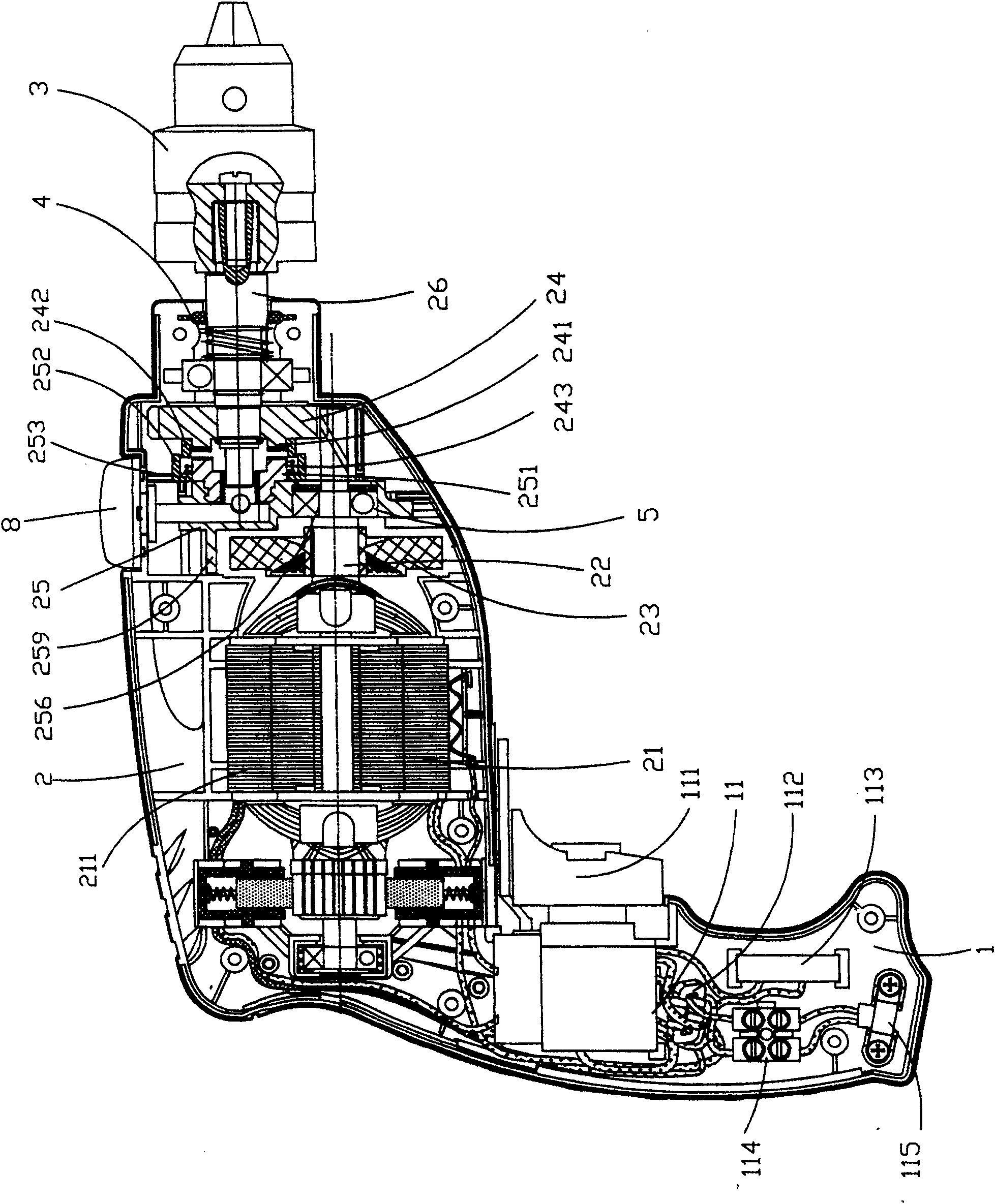

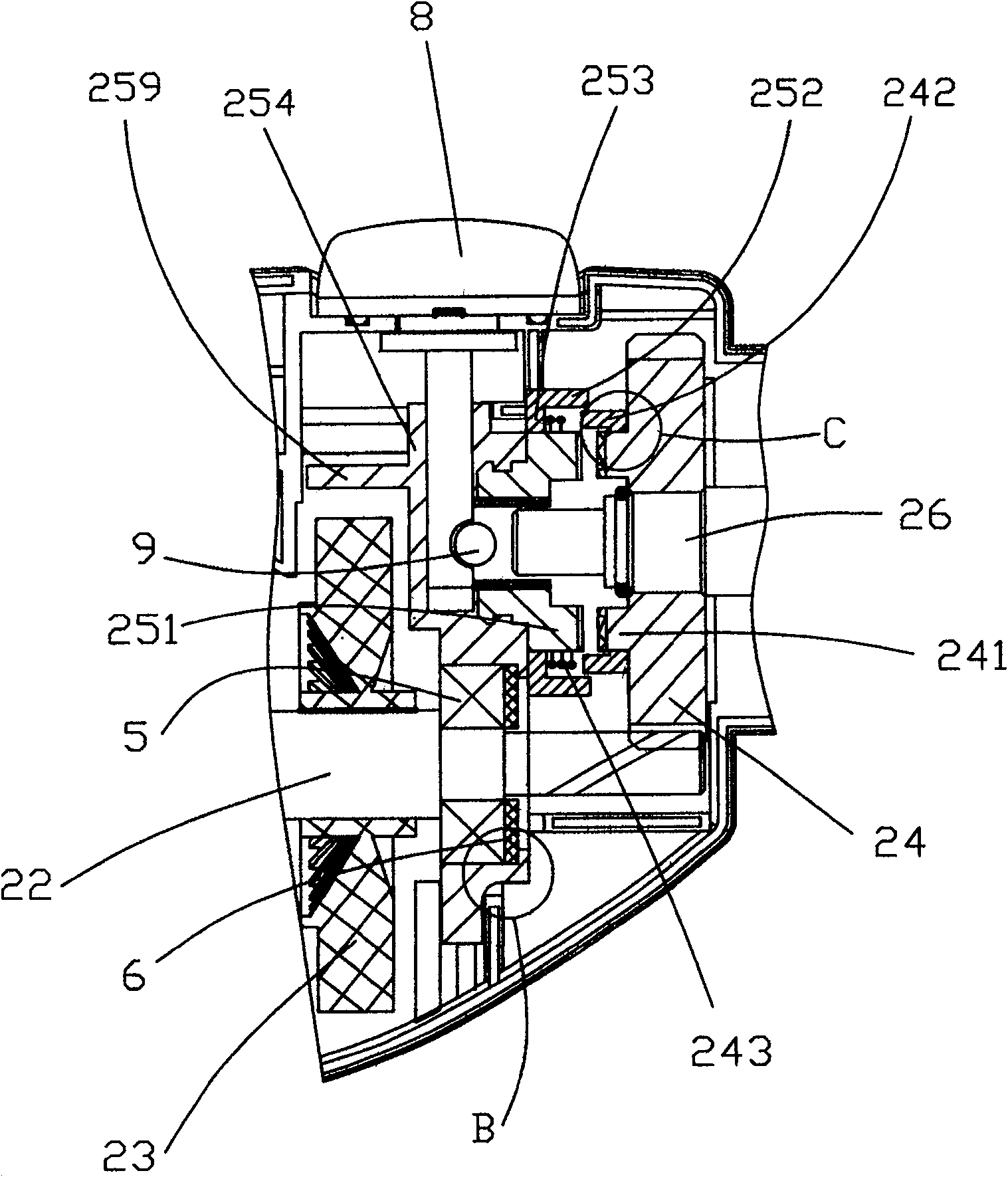

New type electric impact drill

InactiveCN101091997AReduce damage rateGuaranteed normal operationPortable percussive toolsPortable drilling machinesImpact toothGear wheel

The invention relates to a novel impact electric drill that includes handle, frame and drill chuck. Switch component is installed on handle. Motor, motor shaft, heat sink, driving gear, impact device and output shaft are installed in the frame. The drill chuck is installed on one end extending out of the frame. A first impact tooth is set on the inner side surface of driving gear. The corresponding section of impact device has the second impact tooth. A first circle wall is set outside the first impact tooth. And the outside of the second impact tooth has the second circle wall matching with the first circle wall. The first circle wall and the second circle wall form sealed structure to make the impact teeth gain good lubrication all the time.

Owner:吴世雄

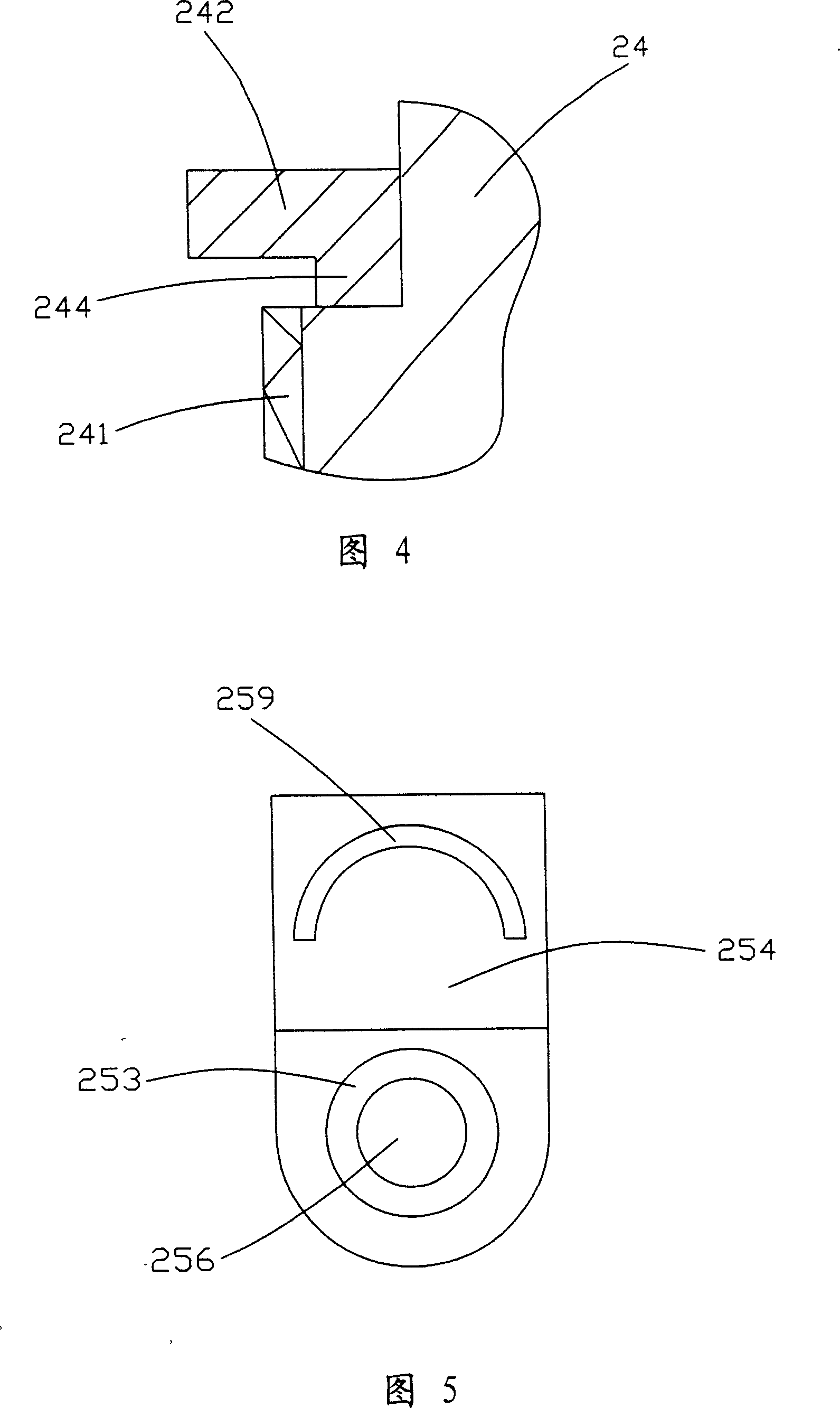

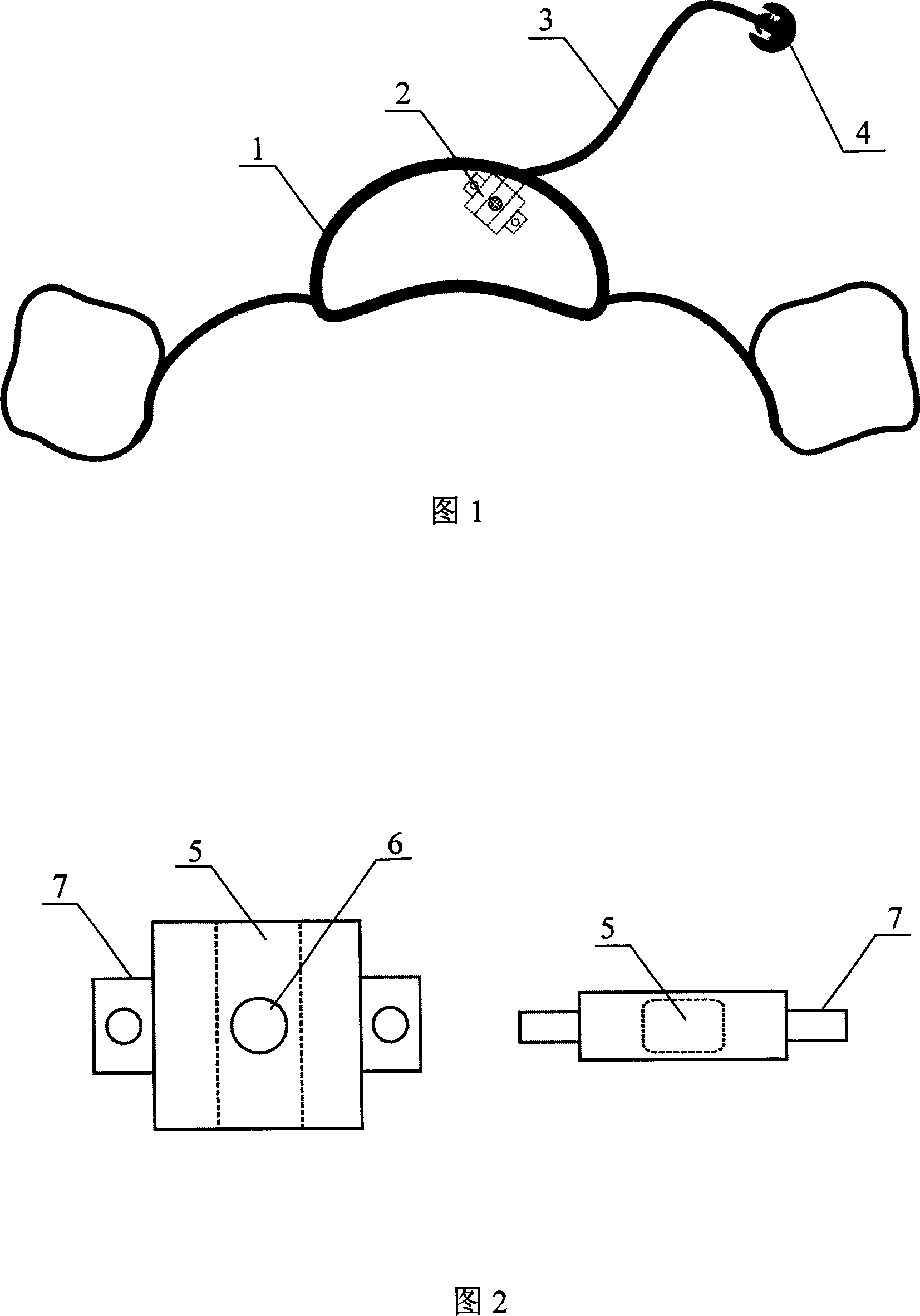

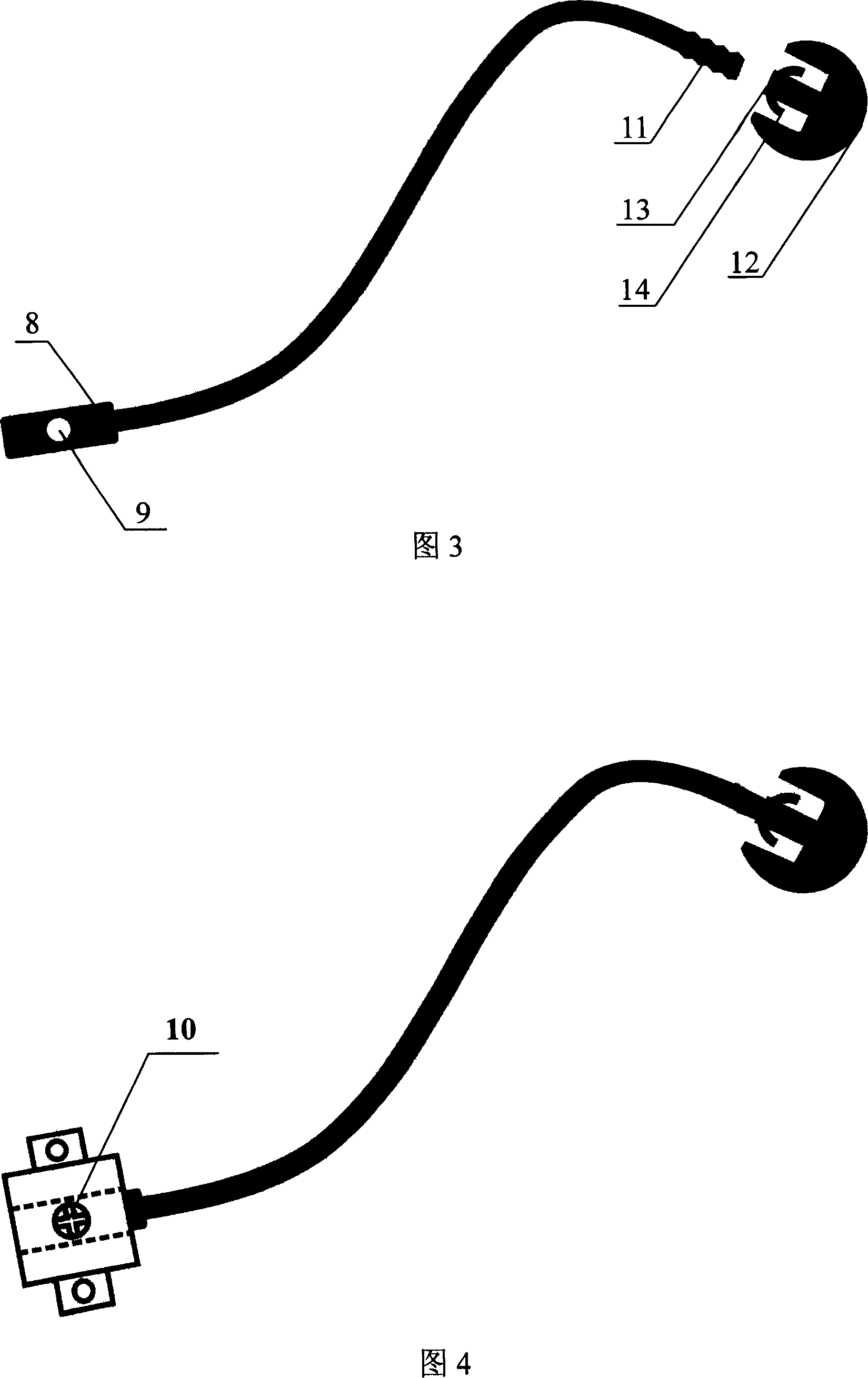

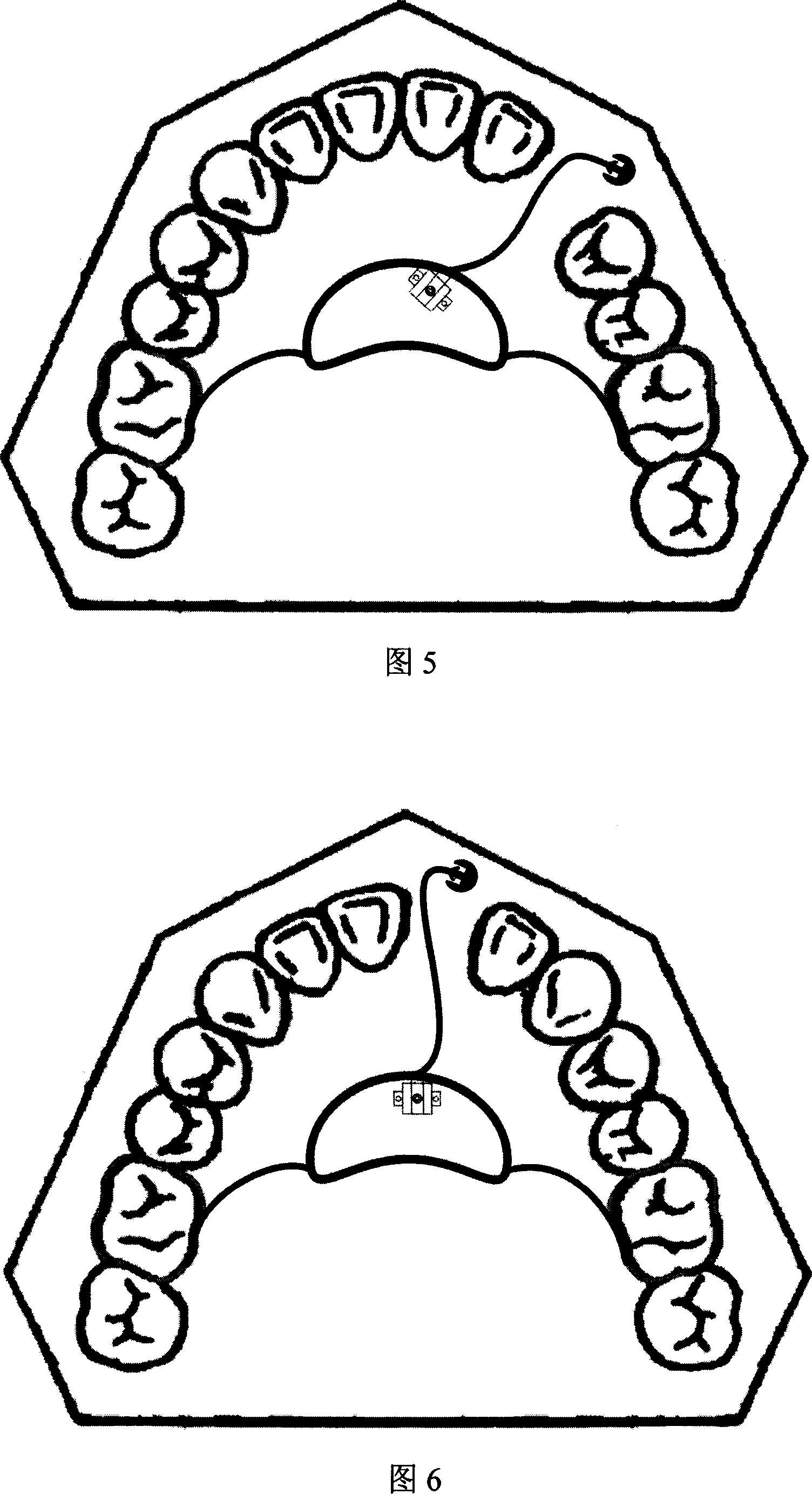

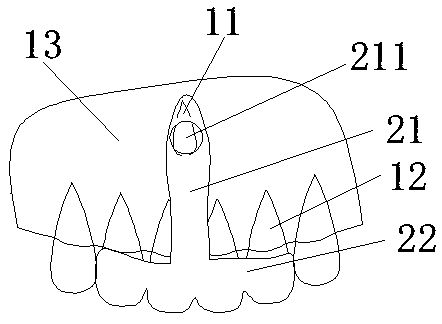

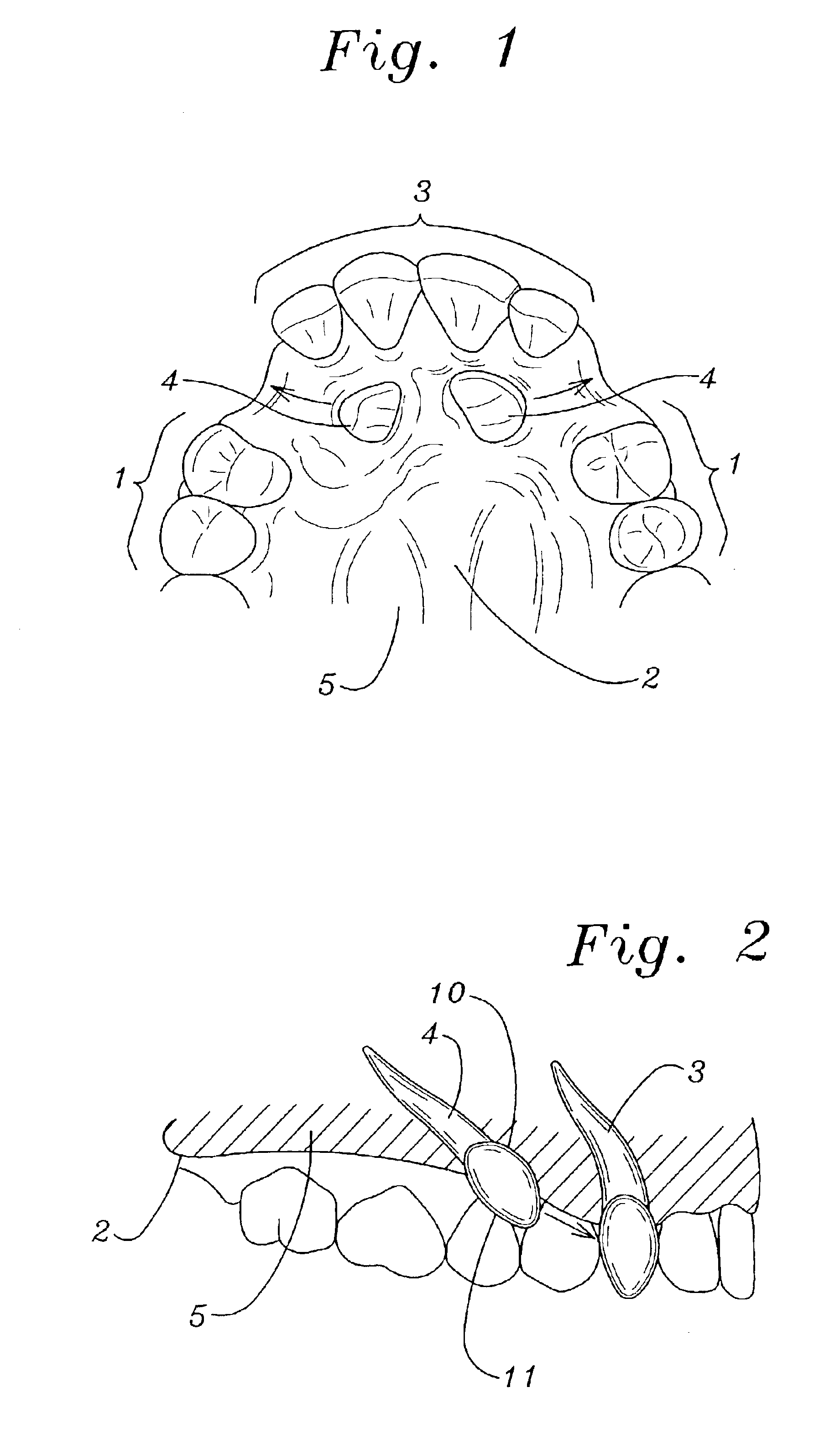

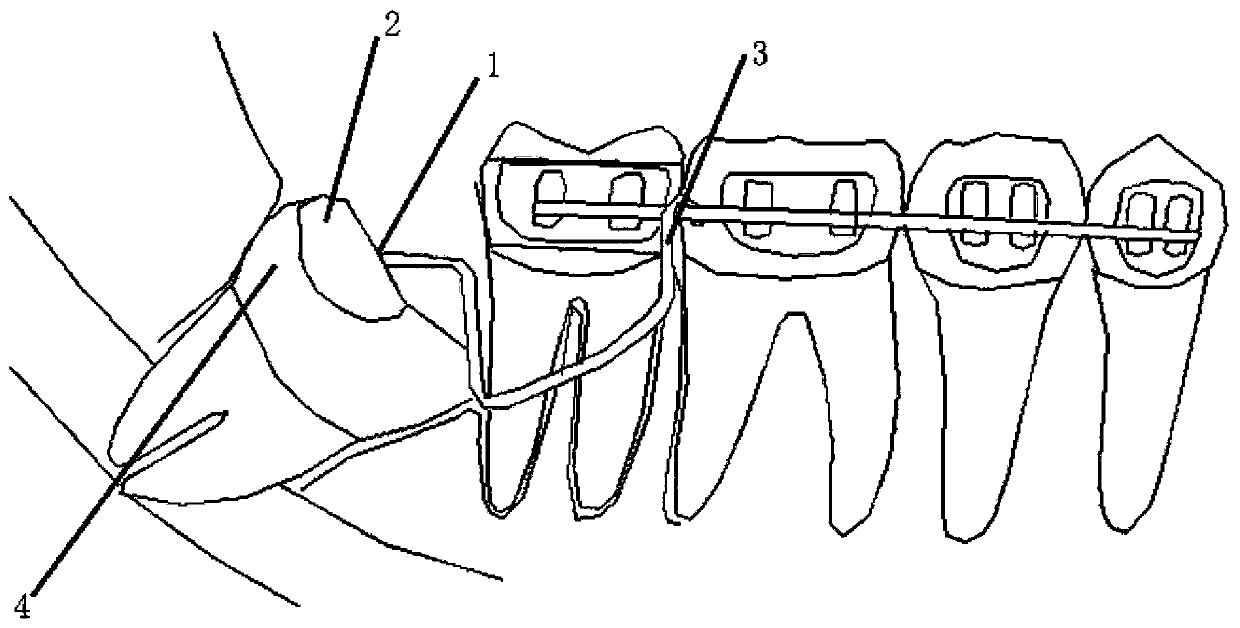

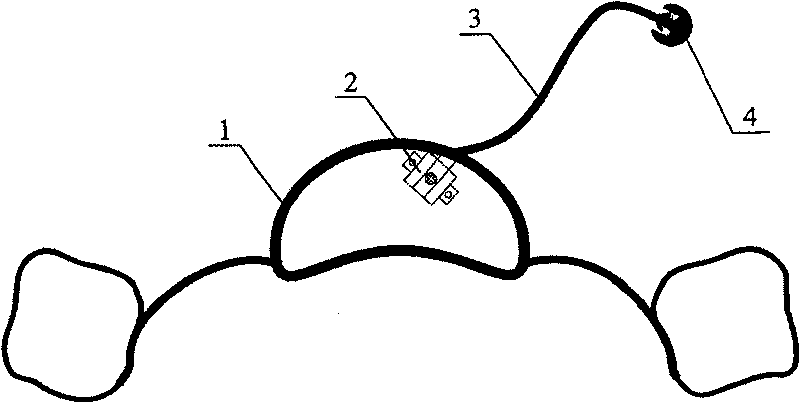

Upper jaw embedded impacted tooth quide rod type correcting appliance

The present invention relates to oral orthodontic technology, and is especially one kind of guide rod type orthodontic appliance for upper jaw embedded canine teeth. The orthodontic appliance includes a plastic palatal arch support, a fixing block, a guide rod, and an extraction device. The present invention aims at providing one kind of guide rod type orthodontic appliance for upper jaw embedded canine teeth with 3D adjustable orthodontic force, no use of dentition as anchorage and less irritation on upper lip mucous membrane. The present invention has the advantages of small orthodontic force, less blocking interference of adjacent teeth, reduced teeth moving resistance, less irritation on mucous membrane, etc.

Owner:温州医科大学附属口腔医院

Application of allograft acellular dermal matrix in oral diseases

The invention relates to application of an allograft acellular dermal matrix in oral diseases, in particular to application of the allograft acellular dermal matrix in the repairing of cleft lip and / or alveolar cleft, cleft palate and oral mucous membrane defect, the repairing of periodontal defect and gingival recession, the repairing of nasal mucosa, tooth implantation, the repairing of furcation involvement and the prevention of complications such as dry socket after impacted tooth extraction, and belongs to the technical field of biological medical material tissue engineering. The allograft acellular dermal matrix is a product improved by a process, the mechanical performance of the product is suitable for surgery, and the sewing strength of the product is 16-18N; the allograft acellular dermal matrix is free of immunological rejection, capable of fast inducing tissue regeneration, soft in texture after implantation, free of contour feeling and good in in-vivo compatibility and hasa stable stent and template effect.

Owner:BEIJING JAYYALIFE BIOTECH CO LTD

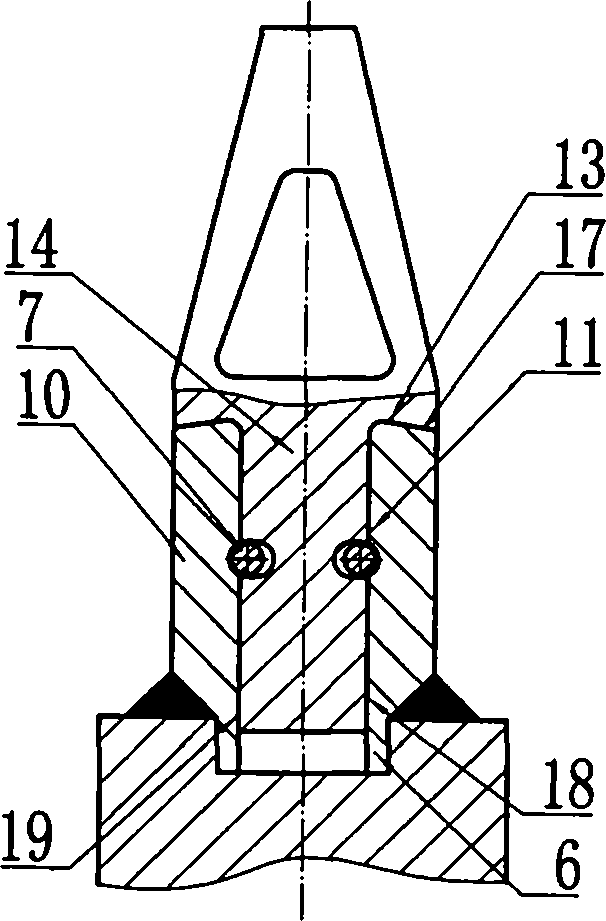

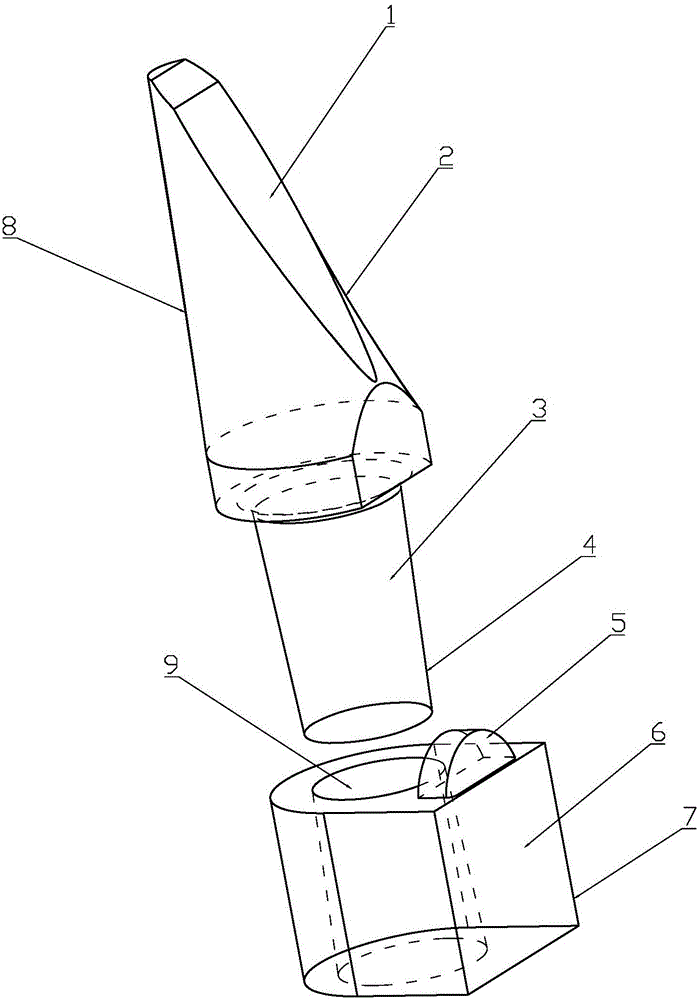

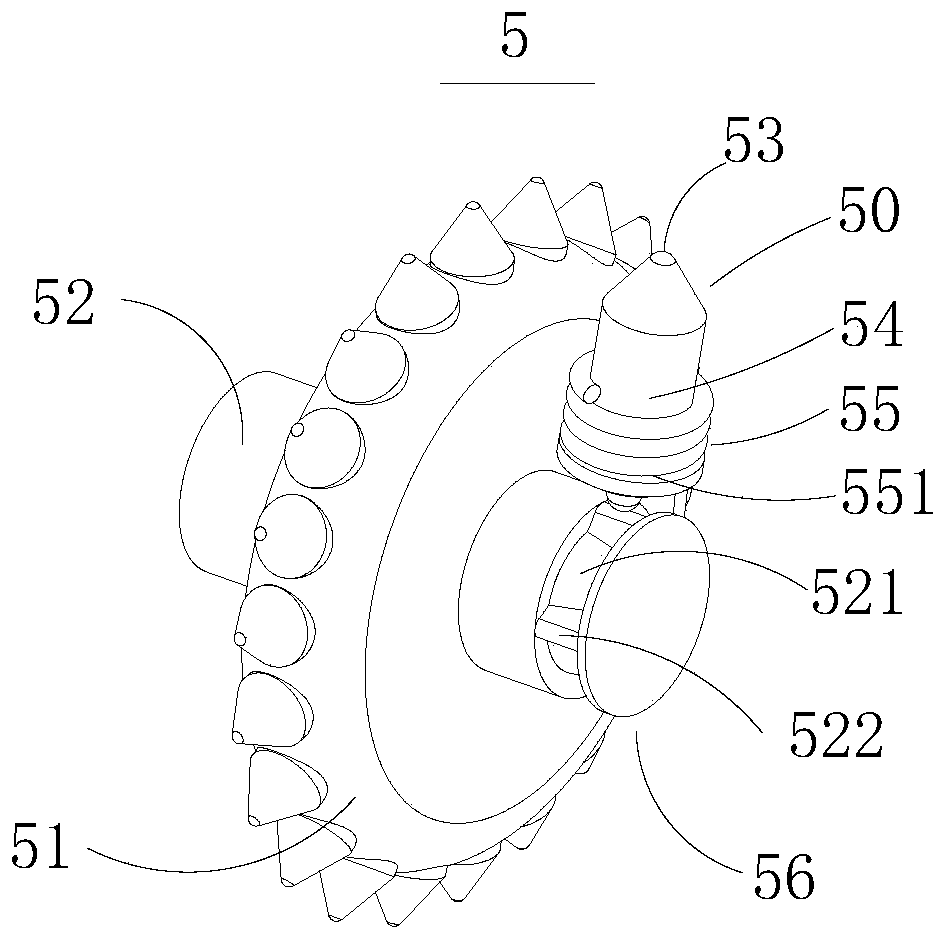

Jack anti-rotating easily-detachable reciprocating impact head of digger

ActiveCN103912273AIncrease intensityImprove efficiencySlitting machinesCutting machinesImpact toothPull force

The invention relates to the field of diggers and especially relates to a jack anti-rotating easily-detachable reciprocating impact head specifically for a reciprocating impact digger. The jack anti-rotating easily-detachable reciprocating impact head comprises a reciprocating impact head device. The reciprocating impact head device comprises a reciprocating impact head. The reciprocating impact head comprises a reciprocating impact tooth, a permanent seat and a clamp spring or an elastic pin or a lock pin. The reciprocating impact tooth comprises an impact tooth and an impact tooth shoulder. The impact tooth is arranged on an impact tooth insertion column or an impact tooth jack member. The impact tooth shoulder is arranged at a lower part of the impact tooth or is arranged at the end of the impact tooth jack member. The reciprocating impact tooth and the permanent seat comprise hole-slots for arrangement of the clamp spring or the elastic pin or the lock pin. The clamp spring or the elastic pin or the lock pin is arranged in the hole-slots and goes through and connects the reciprocating impact tooth and the permanent seat. The clamp spring or the elastic pin or the lock pin bears a backward pull force produced by reciprocating impact motion. The impact tooth insertion column is inserted into a tooth base jack member or a tooth base insertion column is inserted into the impact tooth jack member. The impact tooth shoulder is tightly fastened to a tooth base shoulder so that a reciprocating impact counter-acting force can be born. A jack anti-rotating structure is fastened to a column anti-rotating structure so that reciprocating impact tooth rotation is prevented.

Owner:刘素华

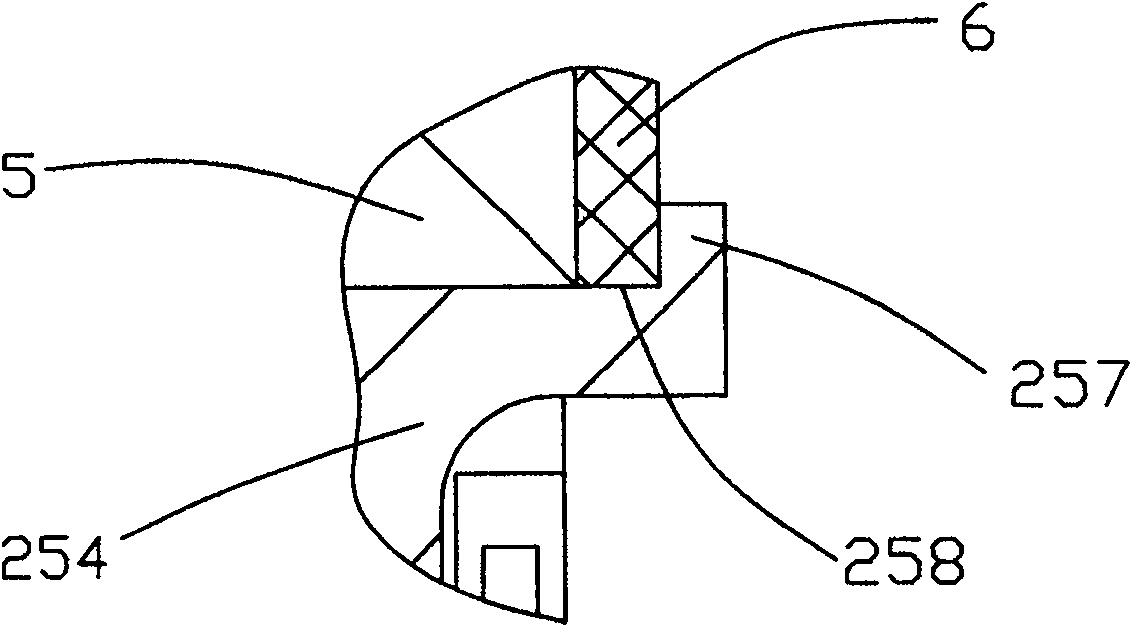

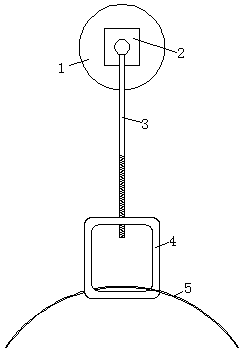

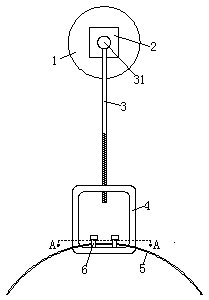

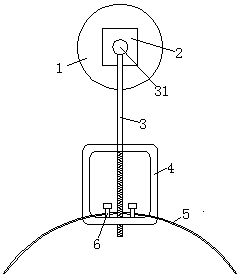

Traction device bonded to impacted teeth

The invention provides a traction device bonded to impacted teeth. A ceramic bottom plate can be bonded onto the impacted teeth, a stainless steel plate is arranged on the ceramic bottom plate, a stainless steel ball is sunken in a concave ball groove of the stainless steel plate and can make rotary motion in the concave ball groove, a stainless steel rod is arranged at the top of the stainless steel ball, and an external thread is arranged on the upper half part of the stainless steel rod. A length adjusting unit comprises a stainless steel adjusting rod, the top of the stainless steel adjusting rod is inwards provided with an internal thread, the internal thread of the stainless steel adjusting rod is in matched connection with the external thread of the stainless steel rod, and a stainless steel ring is arranged at the bottom end of the stainless steel adjusting rod and connected with a fixed orthodontic appliance through an elastic chain or an auxiliary arch. The stainless steel adjusting rod can play a role in fixing and adjusting the length of the traction device so as to meet the requirement for traction of the impacted teeth at different depths. The traction device is smallin size, stimulation to surrounding tissue is little, and the comfort of a patient is good. Manufacturing is simple and standardized, and batch production is easy.

Owner:李佳岭

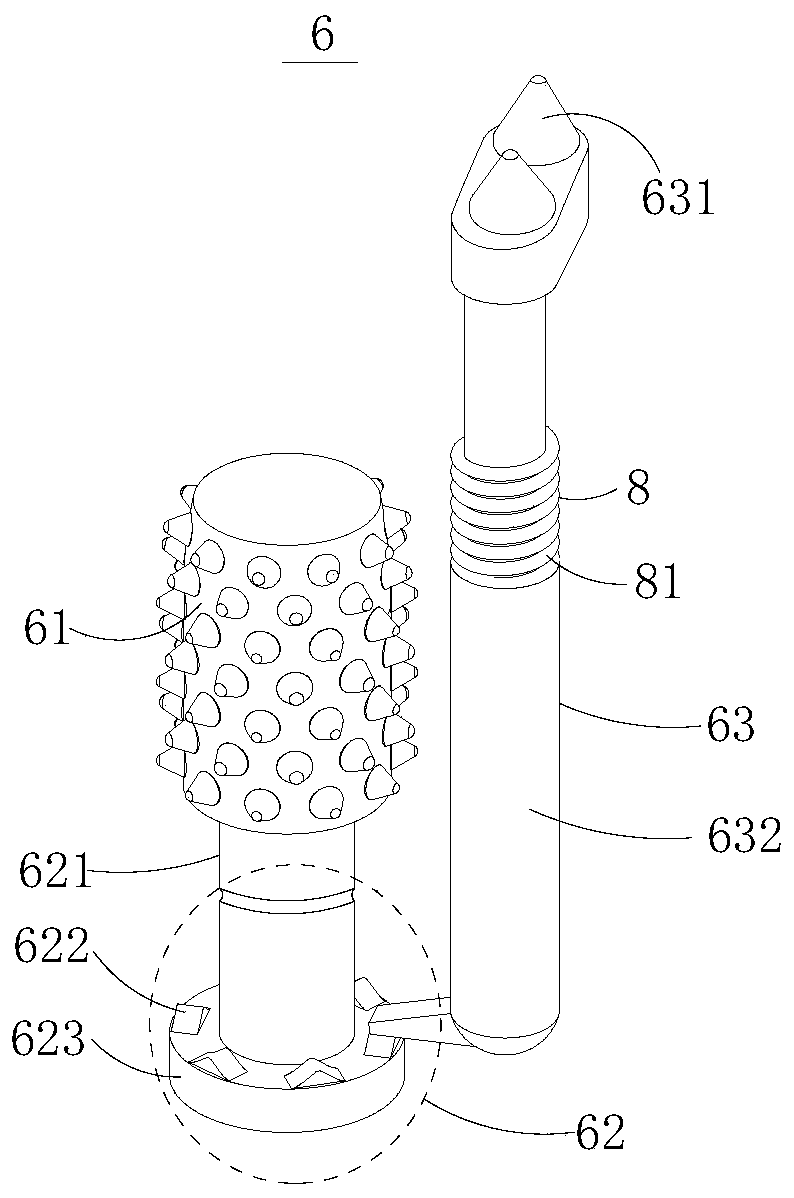

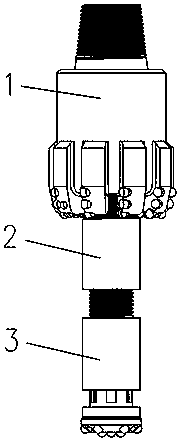

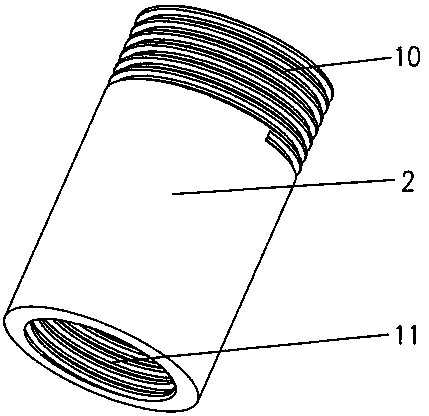

High-efficiency rock-breaking combination tool with punching-and-rotating scraping-and-cutting stepping function

The invention relates to a high-efficiency rock-breaking combination tool with a punching-and-rotating scraping-and-cutting stepping function, and the high-efficiency rock-breaking combination tool iscomposed of a front chopping bit, a nipple, and a PDC drill. The front chopping bit is connected with the nipple, impact teeth are mounted on the chopping bit, and flutes and water spraying nozzles are formed at the outer side of the chopping bit; the upper end of the nipple is connected with the PDC drill through a screw thread; PDC teeth are diagonally distributed on PDC blades; and the flutesare formed between every two adjacent PDC blades, and the water spraying nozzles are arranged on the flutes. The model of the nipple can be replaced, and the length of a stepping structure between thefront chopping bit and the rear PDC drill is adjusted by installing nipples of different series with different lengths. Through a punching-and-rotating scraping-and-cutting stepping structure of thechopping bit and the PDC drill, hierarchical crushing of a rock is realized, and the difficulty of rock breaking is reduced; and the combination of different rock breaking tools can be realized, the vibration during the drilling process is greatly reduced, the adaptability of rock breaking of the drill to deep complicated formation is improved, the rock breaking efficiency is improved, and the service life of the drill is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV

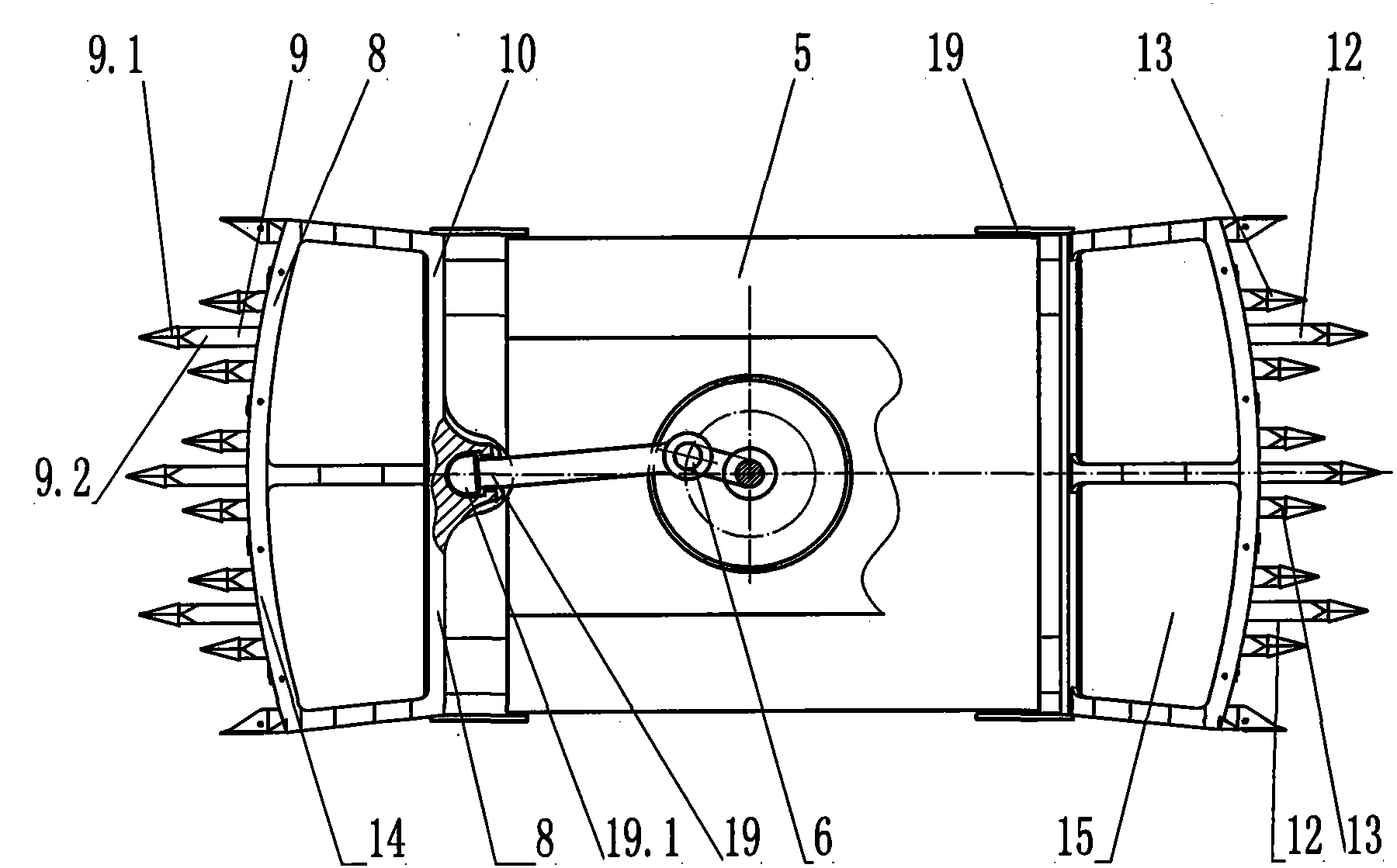

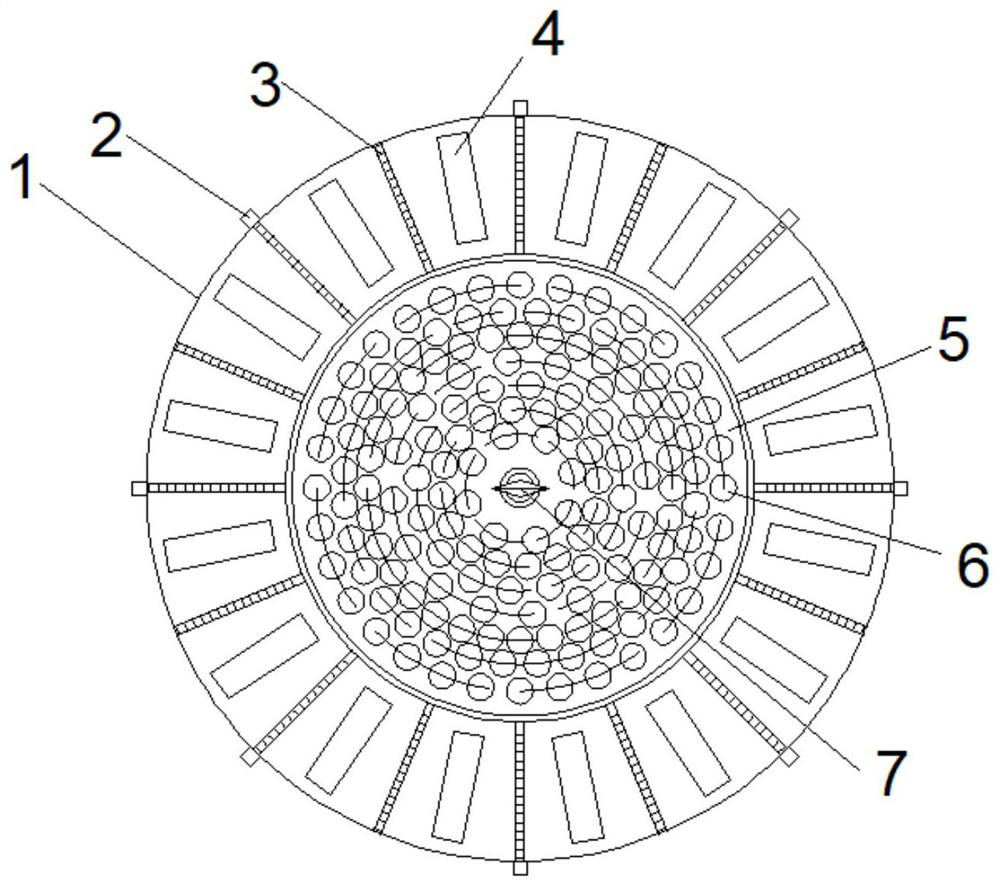

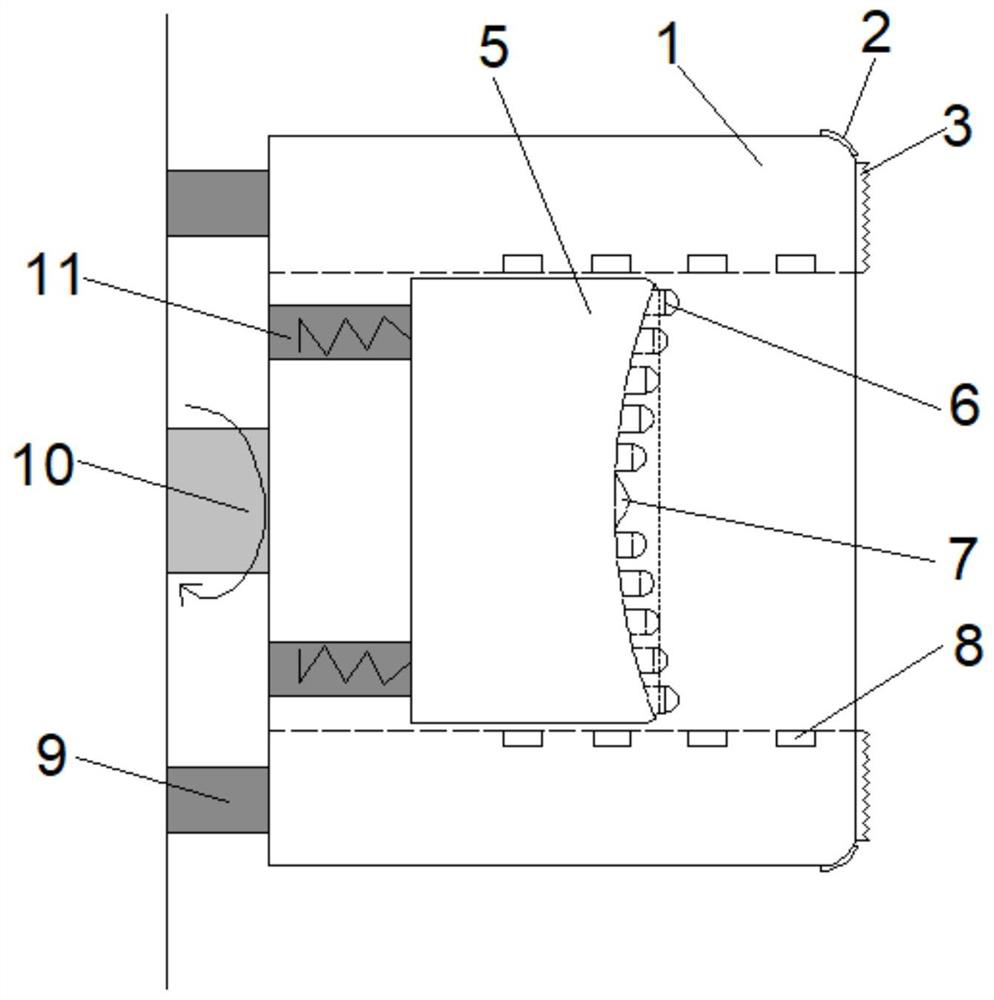

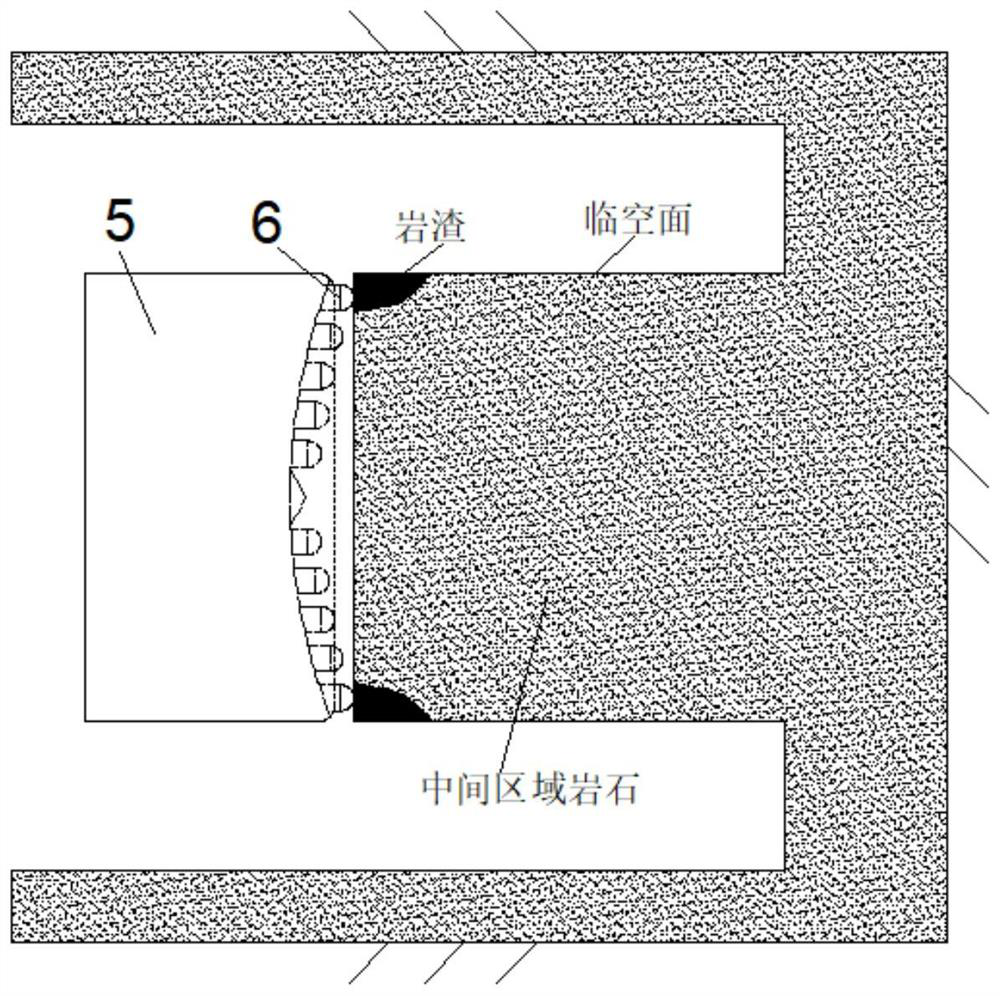

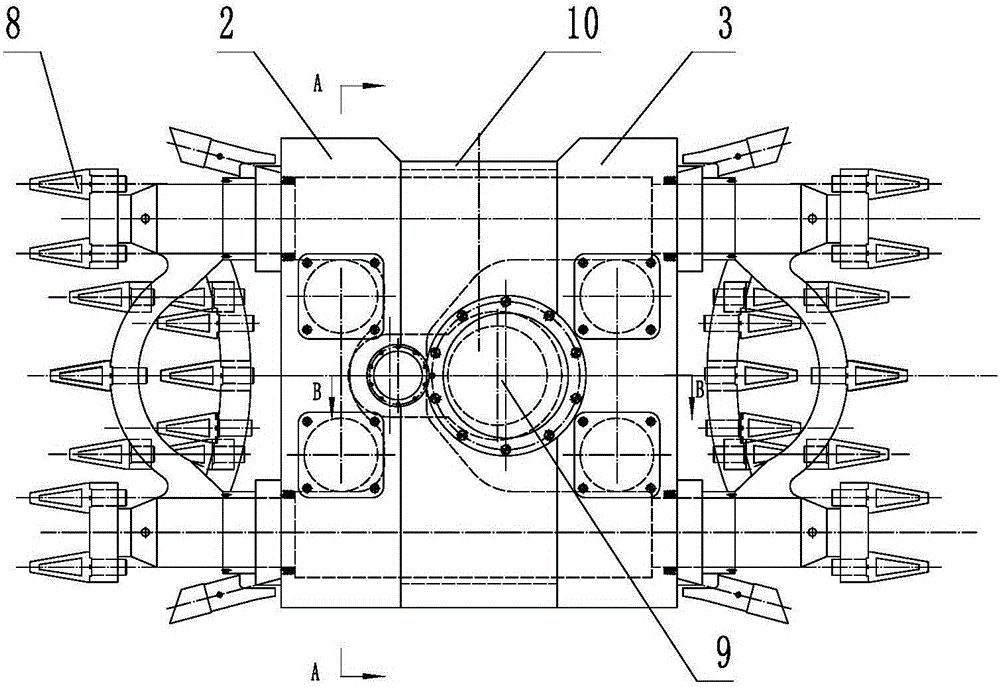

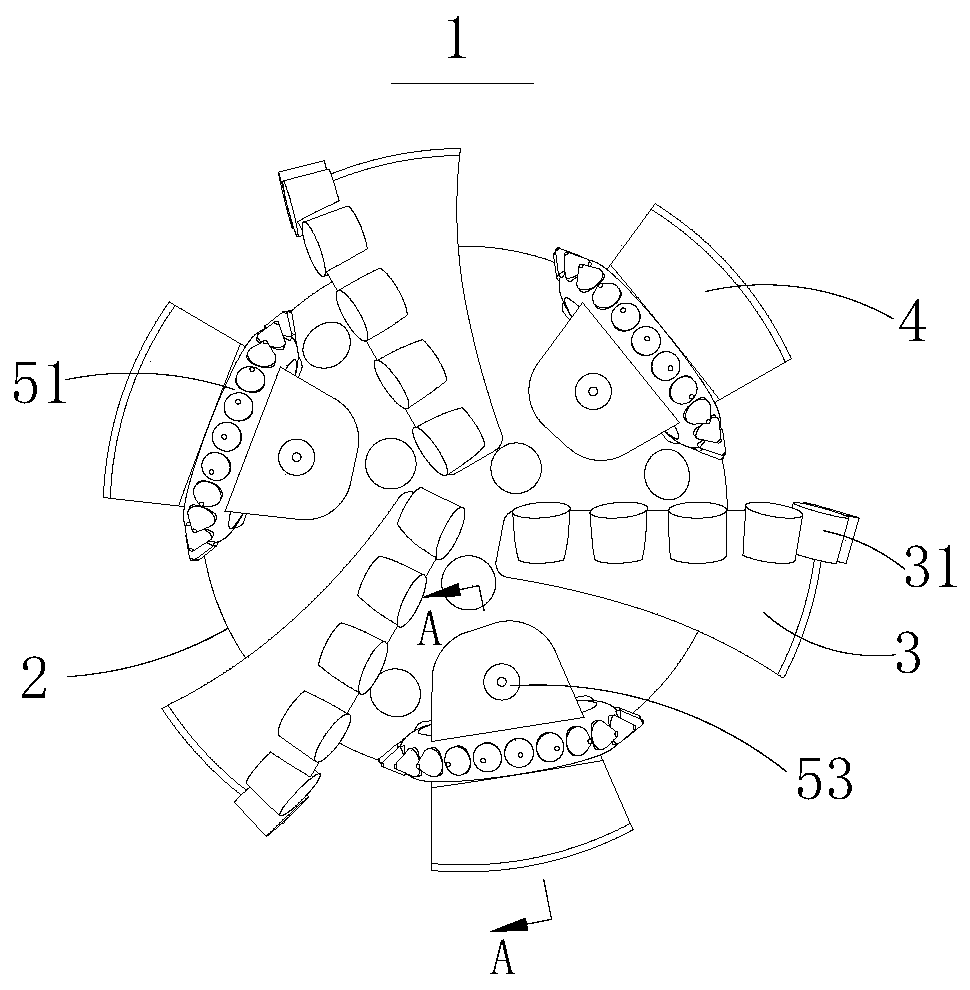

Heading machine cutter head suitable for extremely hard rock stratum

ActiveCN112682057AReduce cutting rock loadImprove cutting stabilityTunnelsImpact toothClassical mechanics

The invention discloses a heading machine cutter head suitable for an extremely hard rock stratum. The heading machine cutter head suitable for the extremely hard rock stratum is composed of an outer ring cutter head, an edge scraper, a sawtooth cutter, an outer opening, an inner ring cutter head, impact teeth, sharp teeth, an inner opening, a thrust cylinder, a rotating motor and an impact cylinder. The outer ring cutter head firstly drives the sawtooth cutter and the edge scraper to excavate an annular tunnel, and then the inner ring cutter head drives the impact teeth and the sharp teeth to impact rock in a middle area by using a free face, so that efficient rock breaking of a heading machine is realized.

Owner:HUNAN NORMAL UNIVERSITY

A method for rapidly assembling and disassembling a reciprocating impact tooth to a through hole tooth base and an impacting device with the through hole tooth base with the reciprocating impact tooth capable of being rapidly assembled and disassembled

The invention belongs to the field of machinery and particularly relates to a method for rapidly assembling and disassembling a reciprocating impact tooth to a through hole tooth base and an impacting device with the through hole tooth base with the reciprocating impact tooth capable of being rapidly assembled and disassembled. The device comprises an insertion through hole reciprocating impact tooth, a reciprocating impact tooth through hole base, an insertion through hole reciprocating impact tooth handle, and the like. The insertion through hole reciprocating impact tooth handle is arranged in the reciprocating impact tooth through hole base, and is retained in a manner that the insertion through hole reciprocating impact tooth handle is retained against the reciprocating impact tooth through hole base via a tapered surface. A rotation-stopping device and the like are also arranged. The method and the device achieve rapid disassembly of the insertion through hole reciprocating impact tooth. The method and the device are practical and efficient, and expand the applications of a reciprocatingly impacting mining machine.

Owner:刘素华

Guide plate for precise tooth extraction, manufacturing method and use method of guide plate

The purpose of the invention is to alleviate the discomfort caused by the large wound when the impacted tooth is extracted, and provided are a guide plate for precise tooth extraction, a manufacturingmethod of the guide plate and a use method of the guide plate. The guide plate is composed of a tooth extraction site positioning part and a guide plate fixing part, The shape of the fixing part of the guide plate is fitted to the non-extracted teeth or oral mucosa or alveolar bone, and the guide plate is fixed in the oral cavity. The fixing part of the guide plate is fixed to the non-extracted teeth or oral mucosa or alveolar bone. The fixed part of guide plate can fix the guide plate in the oral cavity, and the position of impacted tooth to be extracted can be determined by the extraction positioning hole, which can greatly reduce the size of wound, alleviate the discomfort of patients after extraction, and accelerate the wound healing.

Owner:福建医科大学附属口腔医院

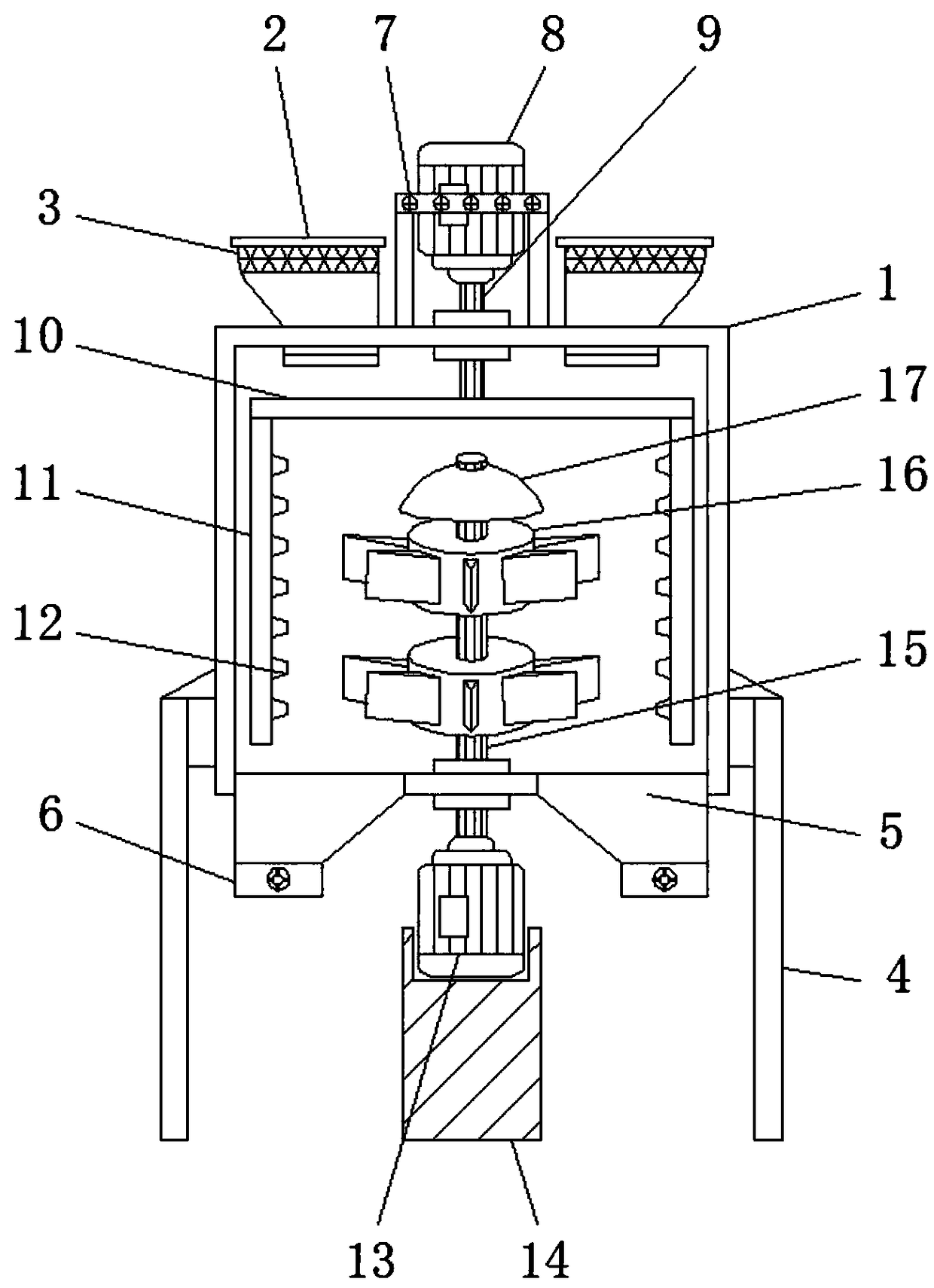

Rotary type impact plate mining sanding machine

The invention discloses a rotary type impact plate mining sanding machine. The rotary type impact plate mining sanding machine comprises a case, a motor frame and a lower motor; ore inlets are formedin the left side and the right side of the upper end face of the case, filter nets are fixed into the ore inlets, a rack is fixed to the lower end of the side face of the case, the motor frame is fixed to the middle of the upper end face of the case, an upper motor is fixed to the middle of the motor frame, impact plates are mounted at the two ends of the lower end face of a connecting frame, impact teeth are fixed to the inner walls of the impact plates, the lower motor is arranged below the case, and an impeller is connected to the outer side of a second-stage rotating shaft. According to the rotary type impact plate mining sanding machine, the case is of a cylindrical structure, a storage chamber is of a conical structure, ore sand can be completely discharged under the gravity of the ore sand, the screen nets of the ore inlets carry out preliminary screening on the ore, the cylindrical impact plates rotating clockwise and the impeller rotating anticlockwise are matched to sand theore, work efficiency is improved, impact force on the ore can be improved, and the sanding effect is ideal.

Owner:SHICHENG COUNTY HENGXING MINERAL PROCESSING EQUIP MFG CO LTD

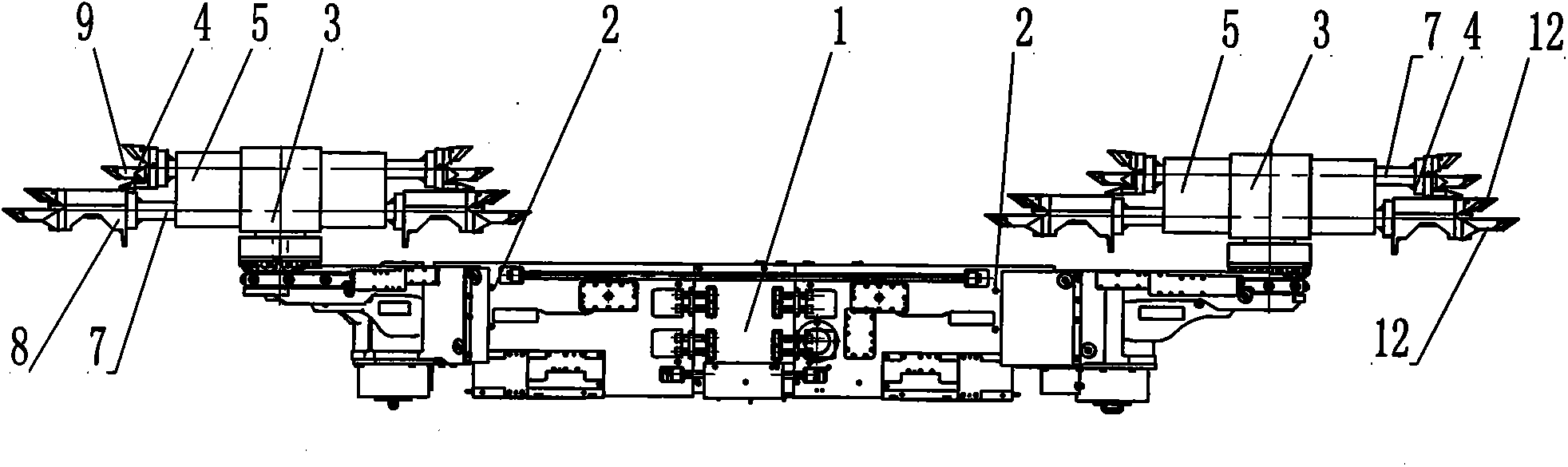

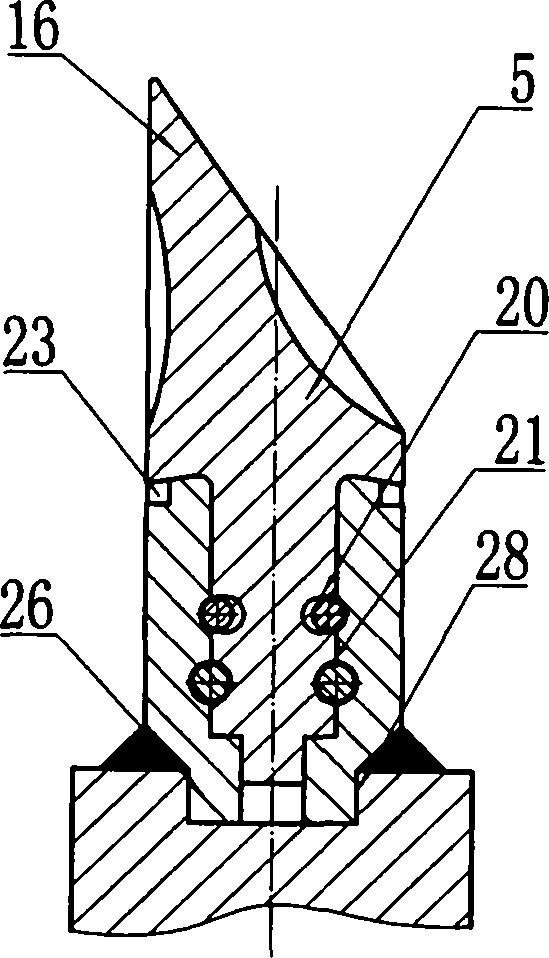

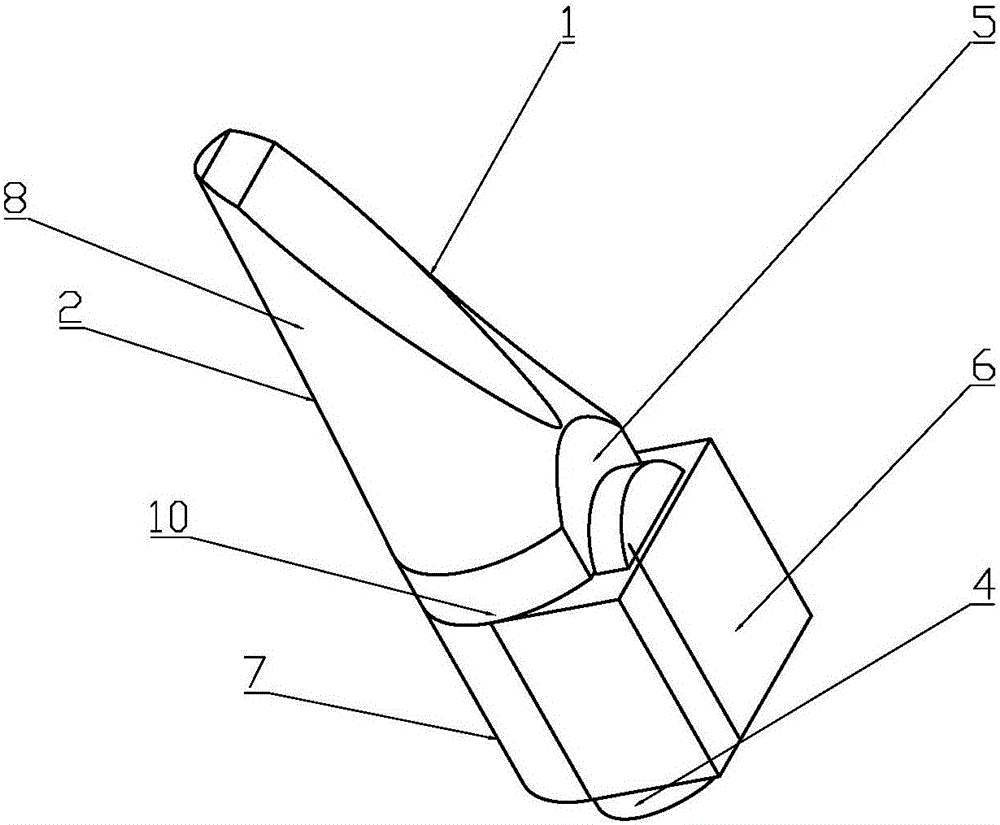

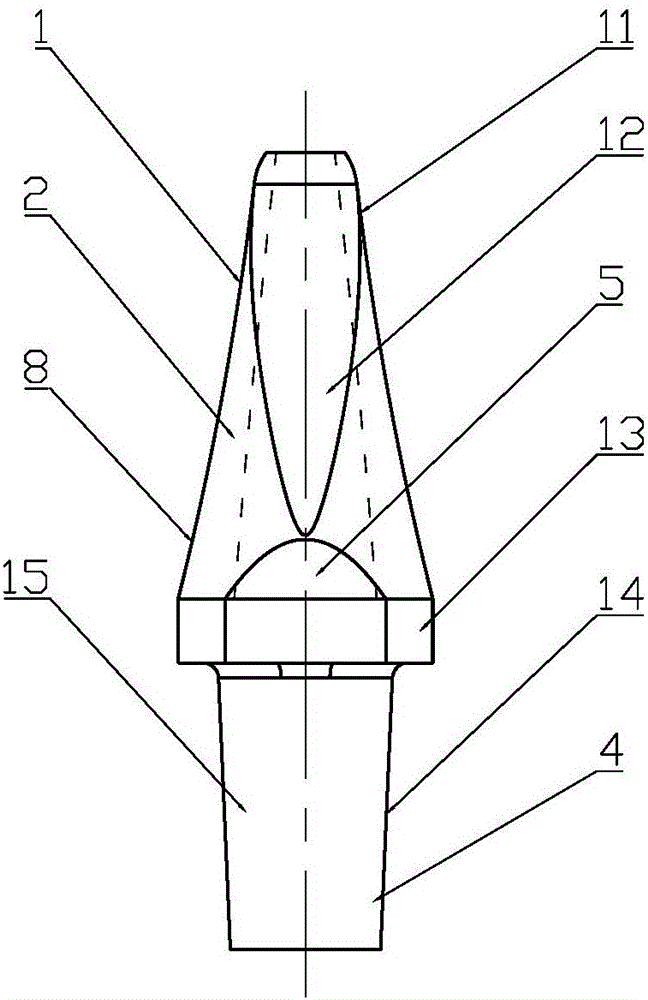

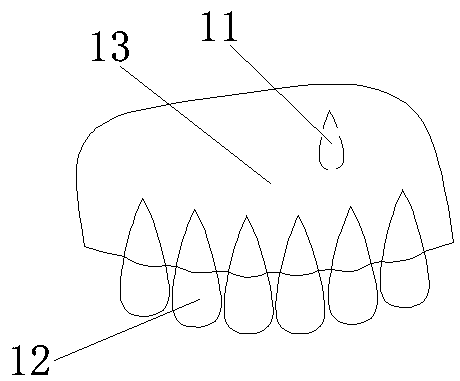

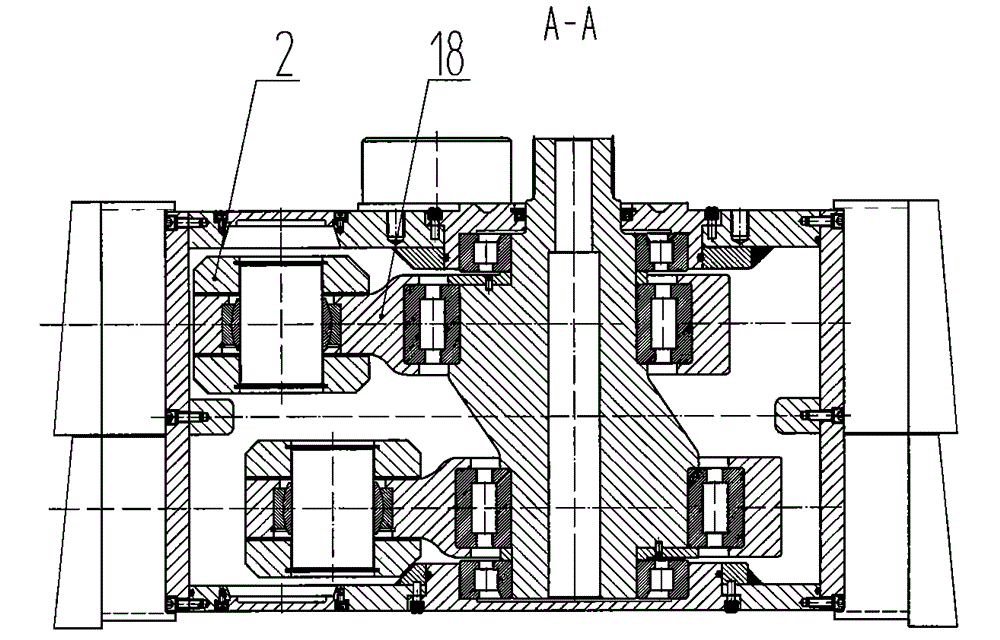

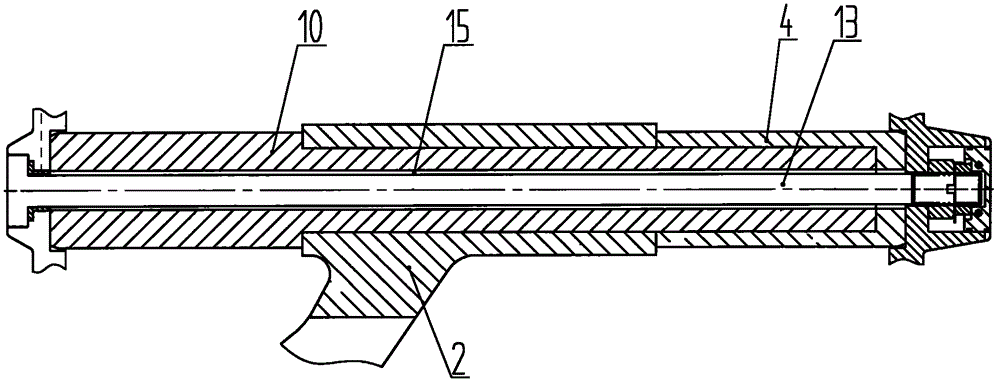

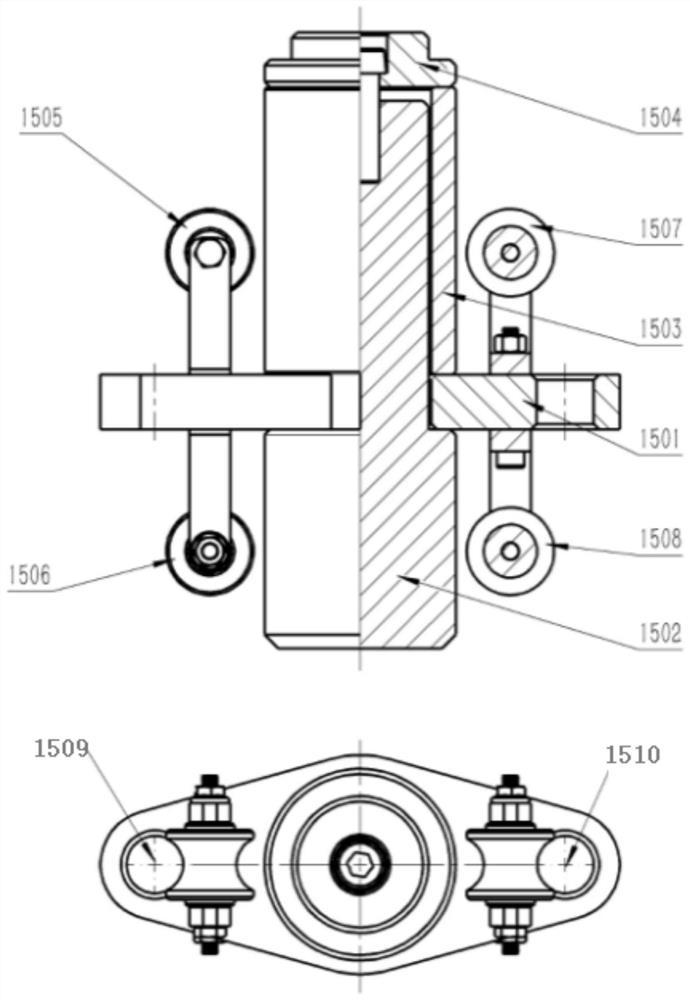

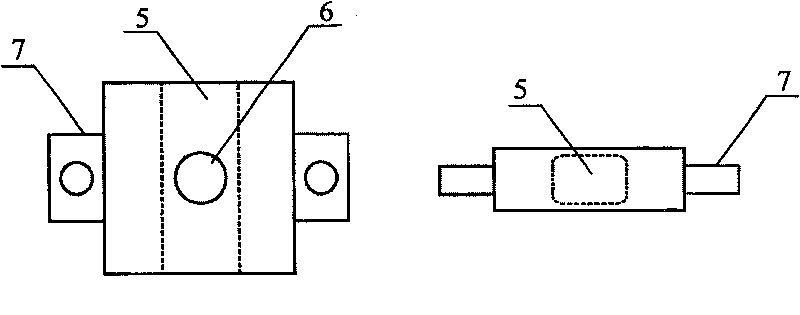

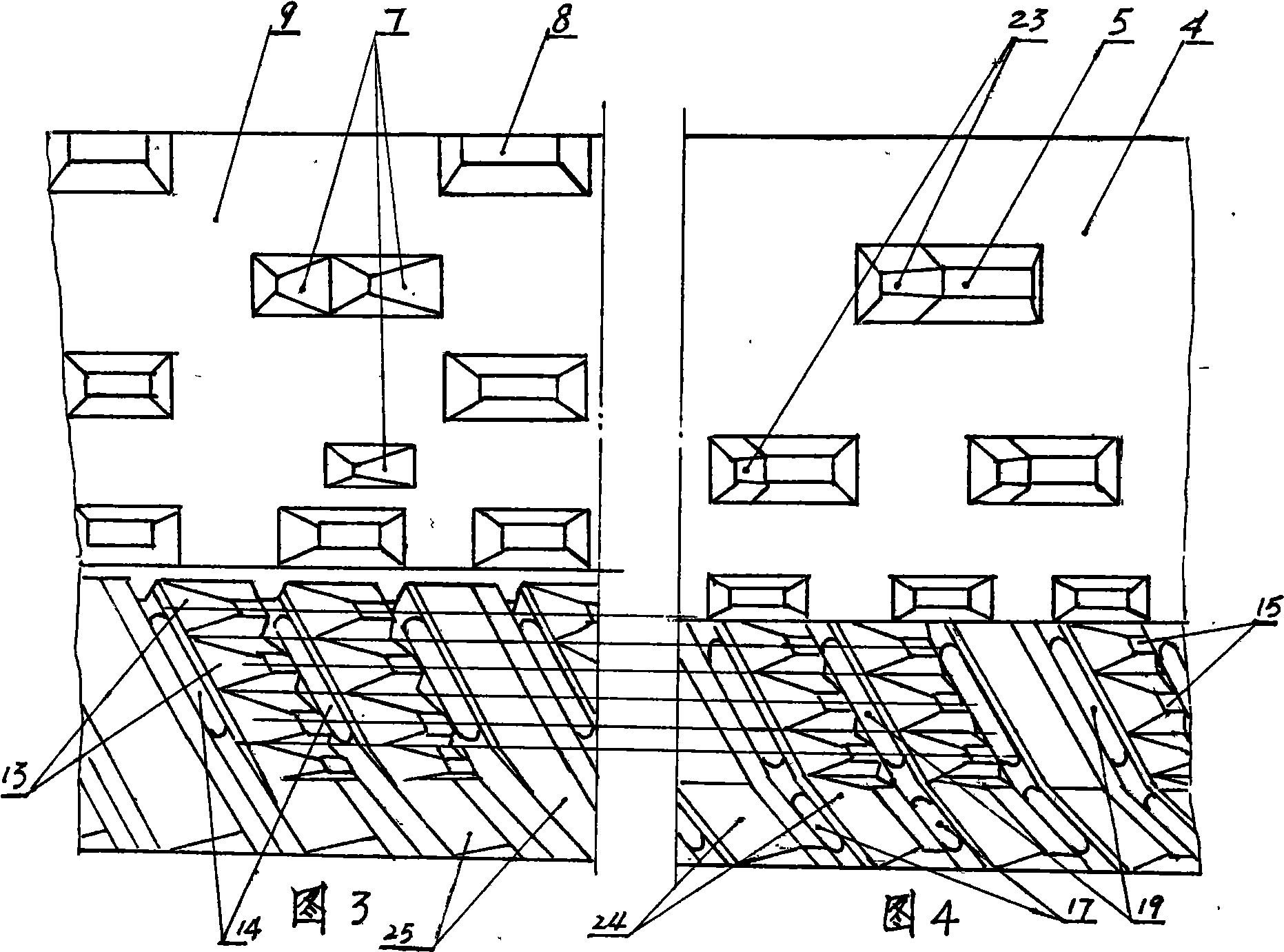

Long screw rod fastening guide wear-resistant sleeve reciprocating impact excavating part easy to machine as well as assemble and disassemble for mining machine

ActiveCN104420870AReduce difficultyHigh precisionEngine sealsSlitting machinesImpact toothRolling resistance

A reciprocating-impact excavating part for use in an excavating machine and having wear-resistant guiding sleeves that are easy to process / assemble / disassemble and are fastened by elongated threaded rods. Wear-resistant guiding sleeves (4) are arranged between impact guiding members (1) and an enclosure (8) and / or arranged between the impact guiding members (1) and rolling friction bodies (7). Impact heads (9) are arranged at one ends or either ends of the impact guiding members (1). Impacting teeth (12) are arranged on impacting teeth bases (11). When guiding threaded rods (13) are separated from the impact guiding members (1), the guiding threaded rods (13) are run through guiding threaded-rod holes (15) to be mated with guiding nuts (14) to fasten the impacting teeth bases (11), the wear-resistant guiding sleeves (4), the impact guiding members (1), and a guiding rod connector (2) into a single-body reciprocating impact frame (16). Alternatively, when the guiding threaded rods (13) and the impact guiding members (1) are a single body, the guiding threaded rod (13) are mated with the guiding nuts (14) to fasten the impacting teeth bases (11), the wear-resistant guiding sleeves (4), and the guiding rod connector (2) into the single-body reciprocating impact frame (16). The wear-resistant guiding sleeves (4) are driven by the guiding rod connector (2) and supported by the rolling friction bodies (7) to make reciprocating movements, thus increasing the practicability and service life of equipment.

Owner:刘素华

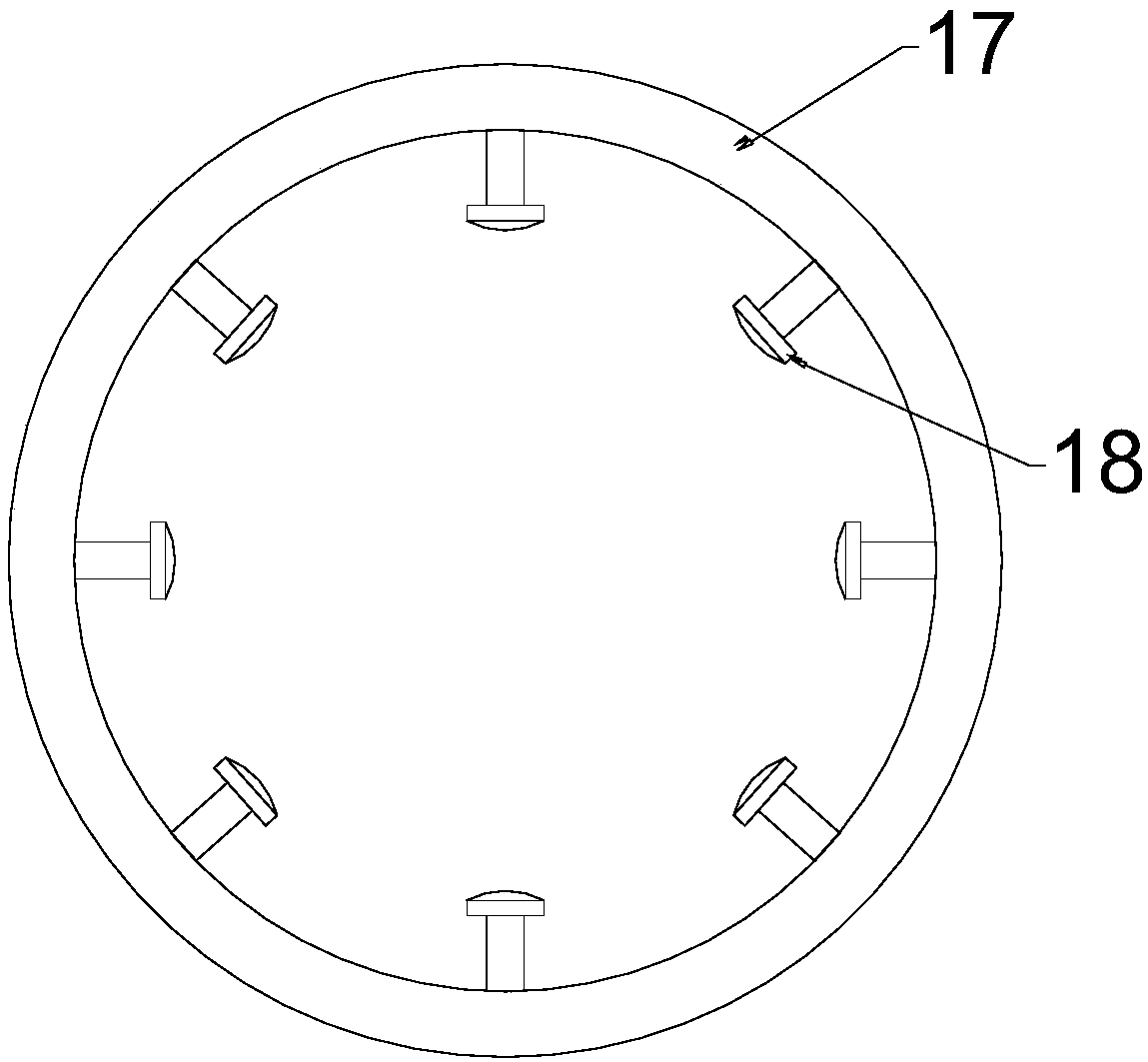

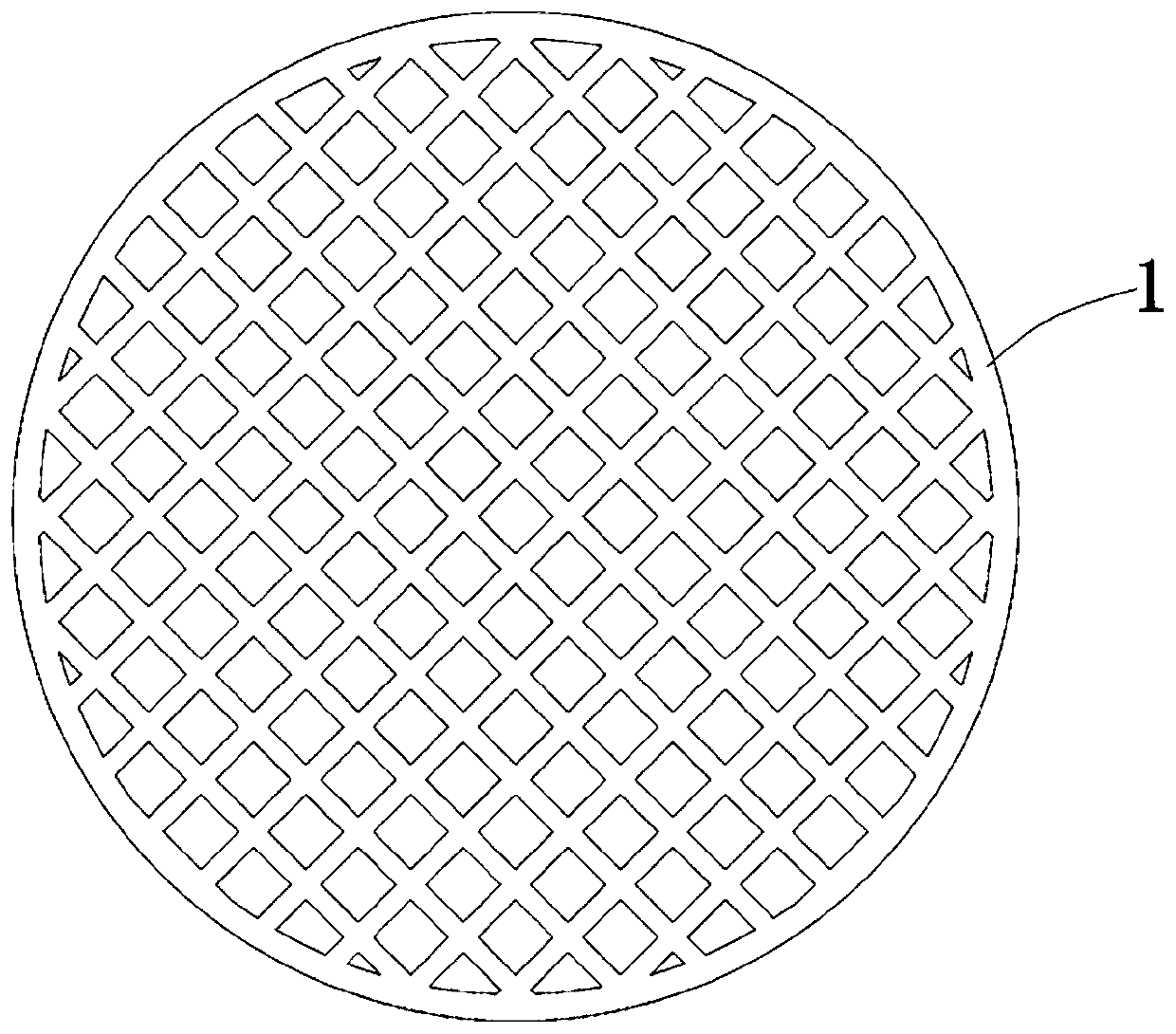

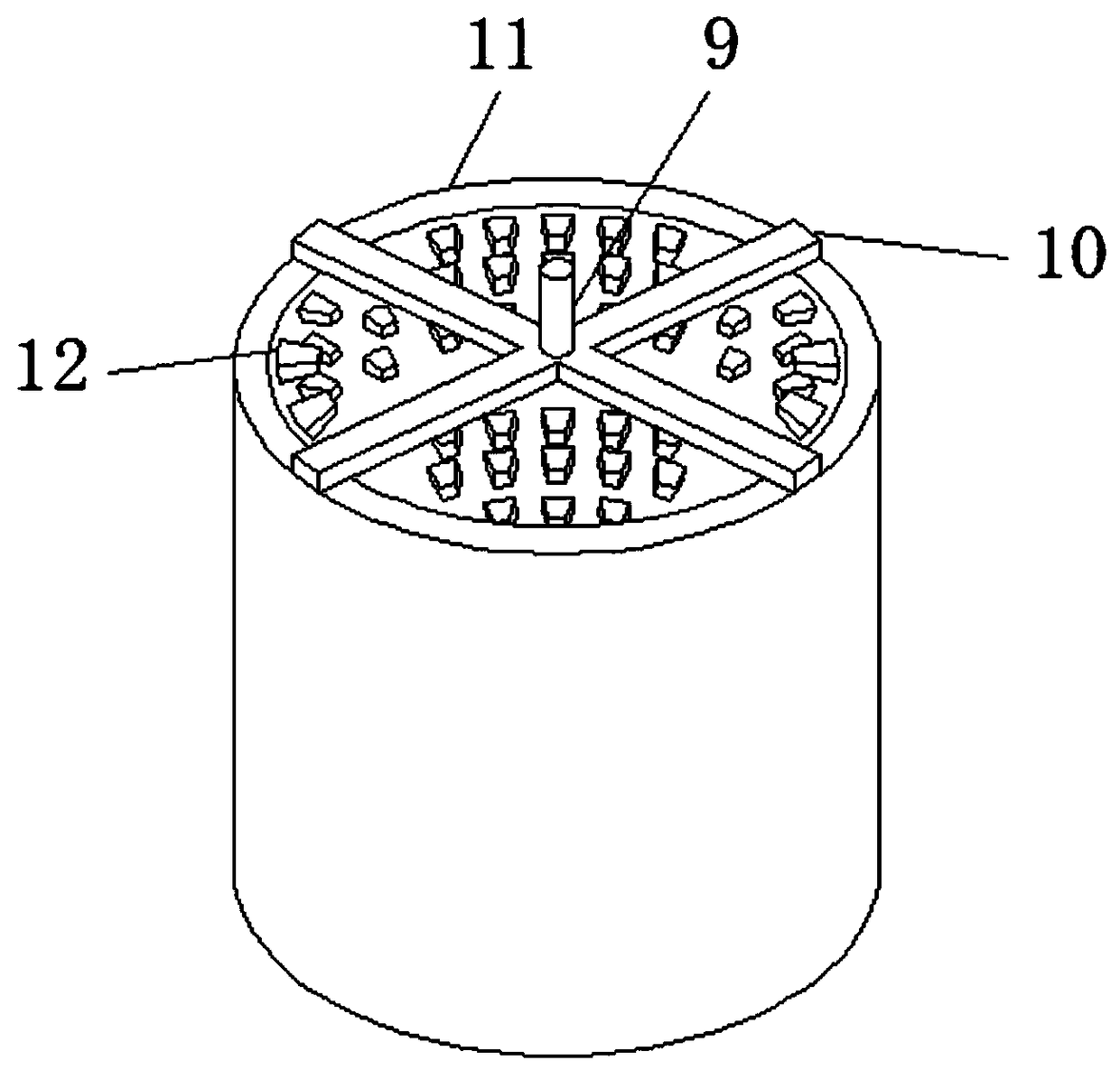

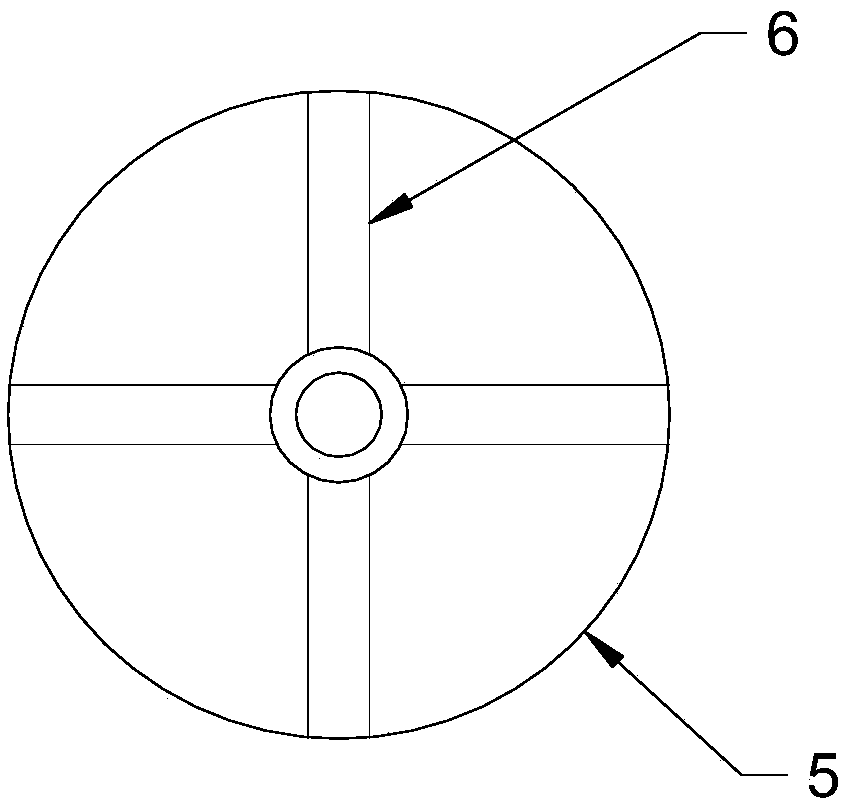

Fine sand screening device

InactiveCN109482309AHigh removal rateImprove screening rateSievingScreeningImpact toothScreening effect

The invention discloses a fine sand screening device. The fine sand screening device comprises a box body, an impacting mechanism and a screening mechanism; the impacting mechanism is arranged in thebox body, and the impacting mechanism comprises a scattering disc and impacting teeth; tooth plates with circumferential distribution are perpendicularly and fixedly connected to the upper end surfaceof the scattering disc, a center shaft is fixed to the scattering disc in a sleeving mode, and the impacting teeth with circumferential distribution are uniformly distributed at the positions, located on the inner wall of the outer side of the scattering disc, of the box body; and the screening mechanism comprises a collection cover and a screening cover, the screening cover is arranged below thecollection cover, the screening cover is fixedly connected with a spiral screen plate in a spiral rising shape, and a slag collecting groove is formed below the screening cover. Sand blocks and the impacting teeth are impacted and crushed by arranging the scattering disc and the impacting teeth, and subsequent screening is facilitated; and the tapered screening cover and the spiral screen plate in a spiral rising shape are arranged to enable sand material comprising waste slag to roll in a spiral waste slag channel, sufficient screening is achieved, the removal rate of the waste slag is improved, the screening out rate of fine sand is improved, and thus, the screening effect is improved.

Owner:王亮

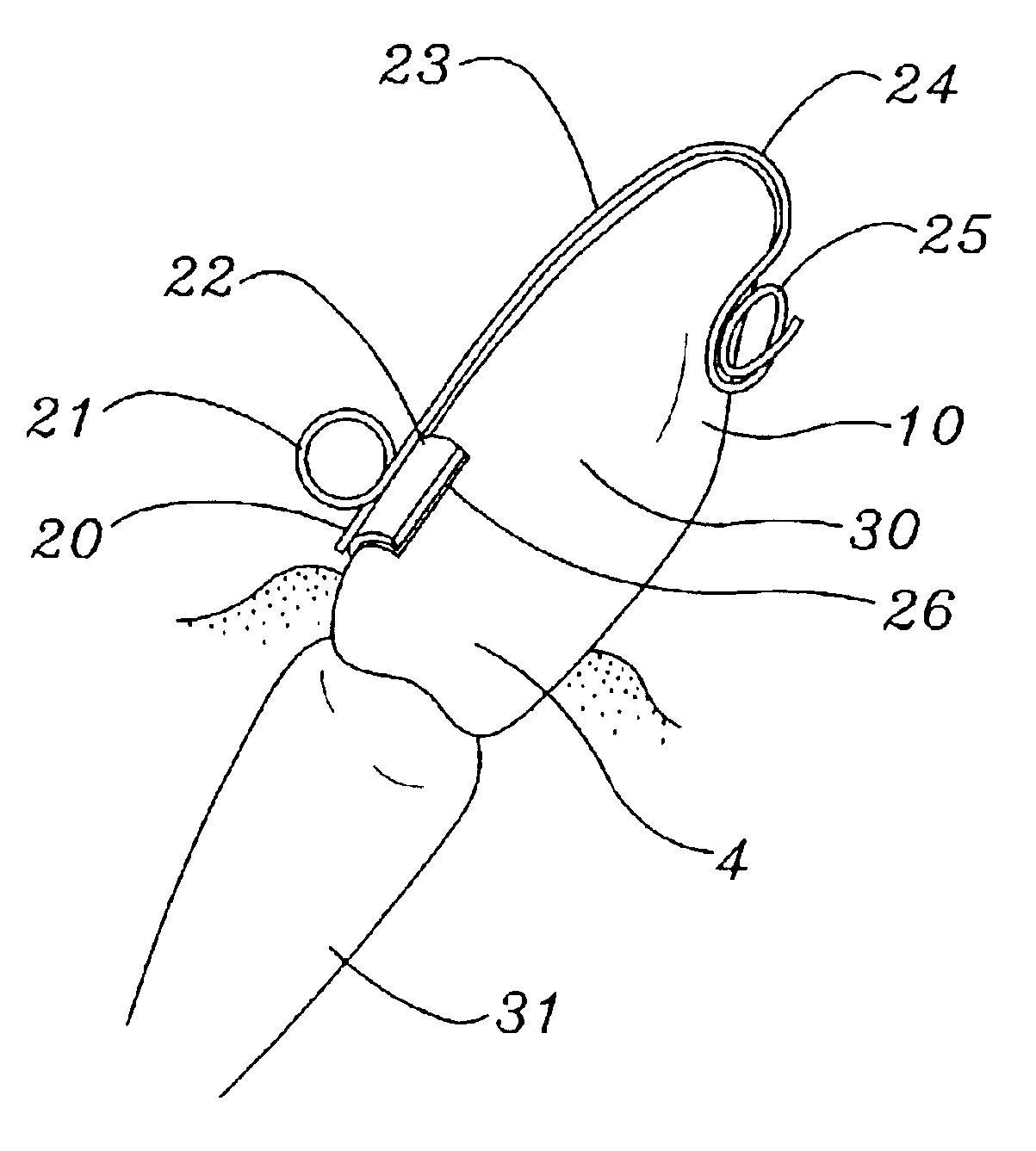

Attachment offset tooth eyelet

The invention is an orthodontic bondable offset tooth eyelet which is attached to the lingual surface of an impacted tooth placing an orthodontic force attaching eyelet on an unattachable labial or buccal surface, the labial placement assures the tooth will arrive in its final position rotationally correct.

Owner:GRAHAM NEIL JOHN

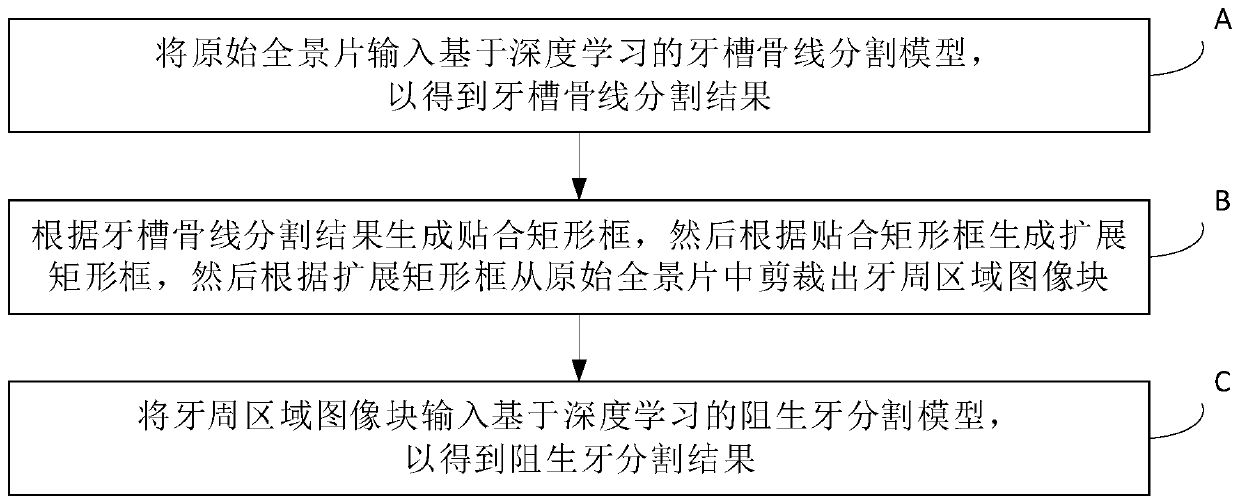

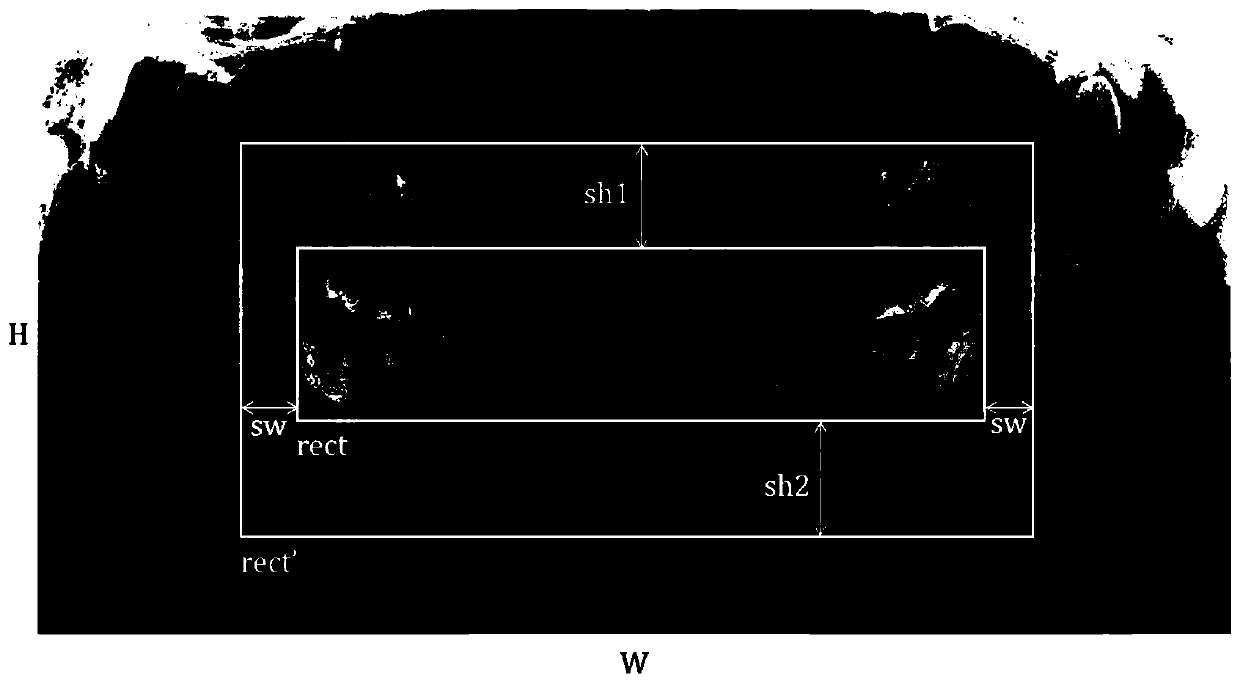

Panoramic film impacted tooth recognition method and device based on deep learning

The invention provides a panoramic film impacted tooth recognition method and device based on deep learning. The method comprises the following steps: inputting an original panoramic film into an alveolar bone line segmentation model based on deep learning to obtain an alveolar bone line segmentation result; generating an attached rectangular frame according to the alveolar bone segmentation result, generating an extended rectangular frame according to the attached rectangular frame, and cutting out periodontal region image blocks from the original panoramic sheet according to the extended rectangular frame; and inputting the periodontal region image block into the deep learning-based obstructive tooth segmentation model to obtain an impacted tooth segmentation result.

Owner:北京羽医甘蓝信息技术有限公司

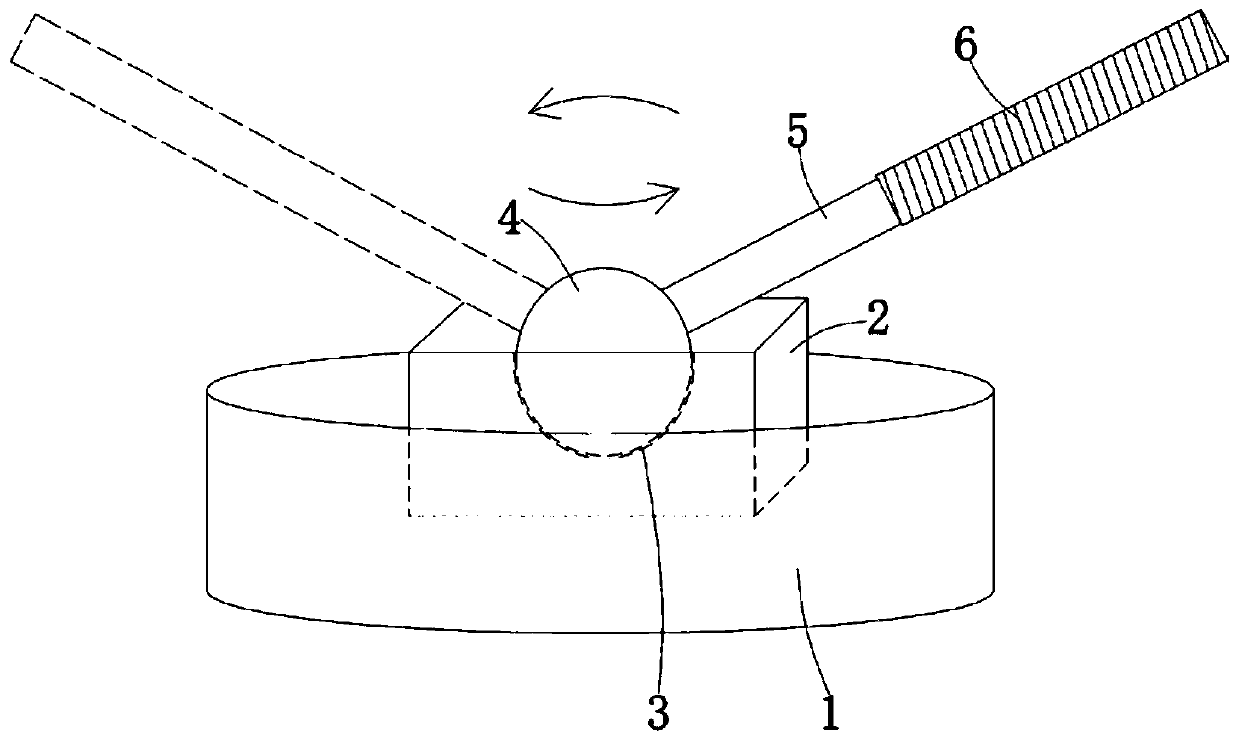

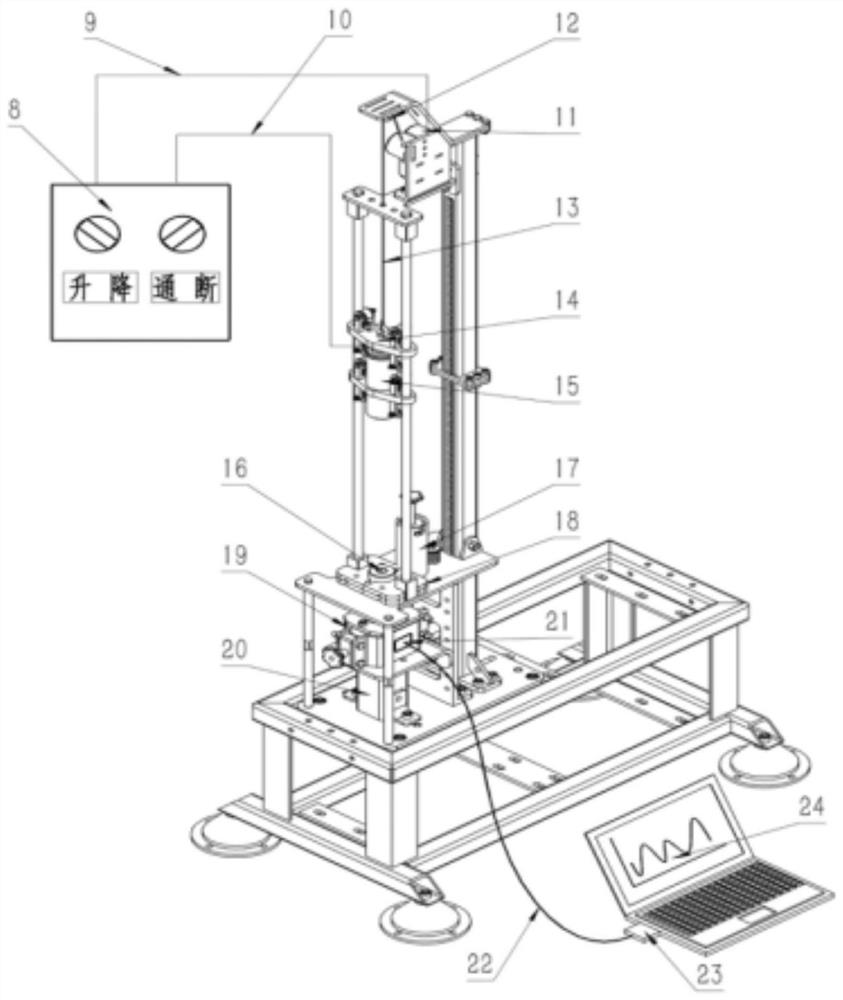

Impact rock breaking mechanism testing device

ActiveCN111929181AFlexible adjustment of impact energyHigh degree of automationClimate change adaptationStrength propertiesImpact toothData acquisition

The invention discloses an impact rock breaking mechanism test device. The device comprises a punching hammer mechanism, a broken rock clamping assembly, a pre-pressure mechanism, a broken rock toothclamping mechanism, a rock sample fixing mechanism, a data acquisition system and the like, the punching hammer mechanism is located above the broken rock clamping assembly and right faces the brokenrock clamping assembly, and the impact work borne by broken rock is adjusted by adjusting the impact height and / or the impact hammer mass of the punching hammer mechanism; the broken rock clamping assembly finally changes the shape and size of broken rock by changing the shape of the first half clamp and the shape of the second half clamp, and therefore the broken rock suitable for drilling of a special stratum is selected. And the pre-pressure mechanism applies pre-pressure to the test rock sample to simulate a real rock breaking working condition. Impact energy can be adjusted by adjusting the mass and the impact height of the impact hammer, impact teeth of different specifications, sizes and shapes can be replaced, circumferential and axial prepressing of a rock sample can be tested, repeatability is good, the stress and crushing process of a rock sample test block can be monitored, and the rock crushing mechanism can be deeply revealed.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

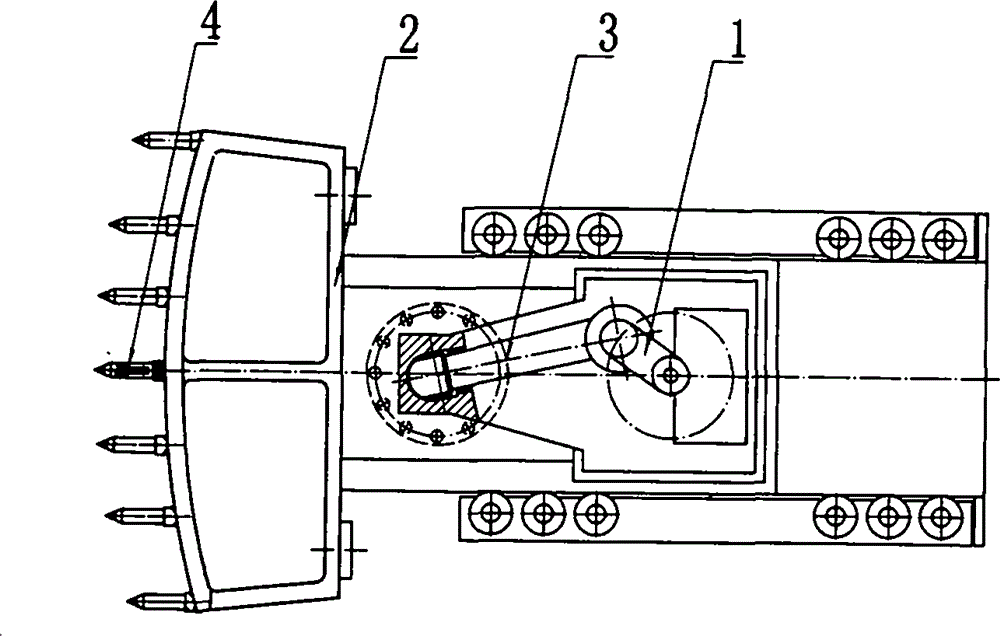

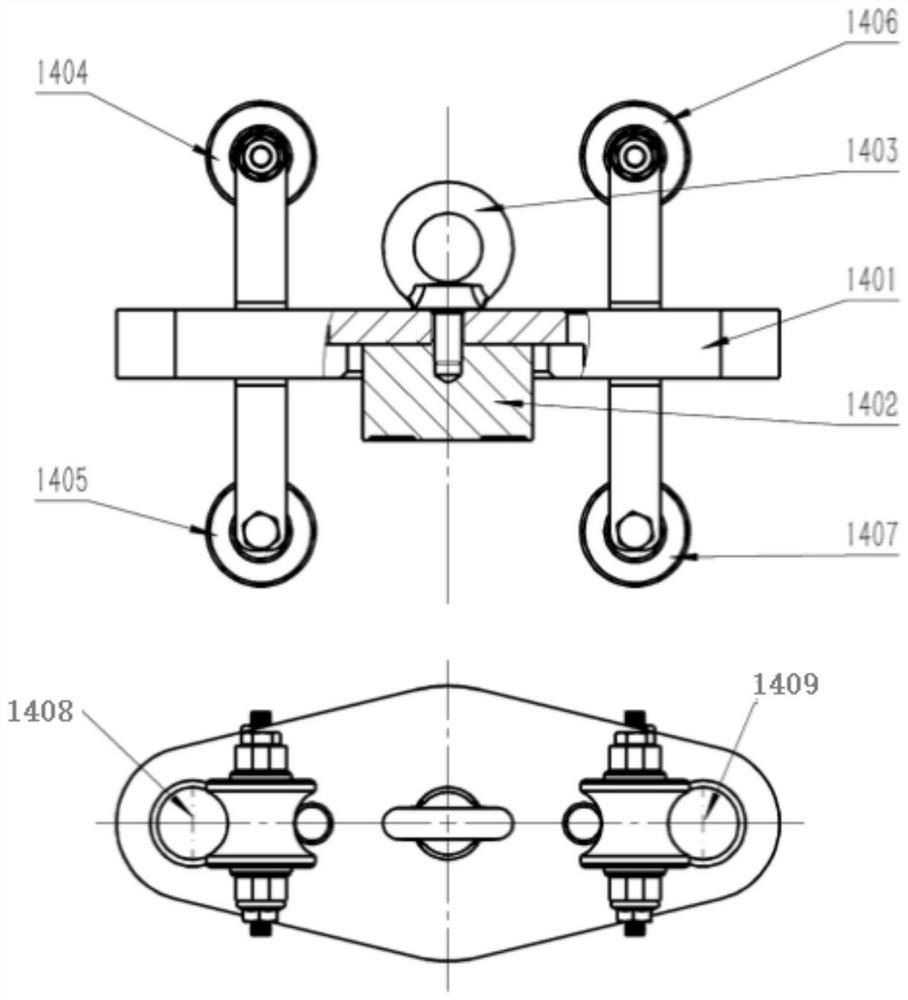

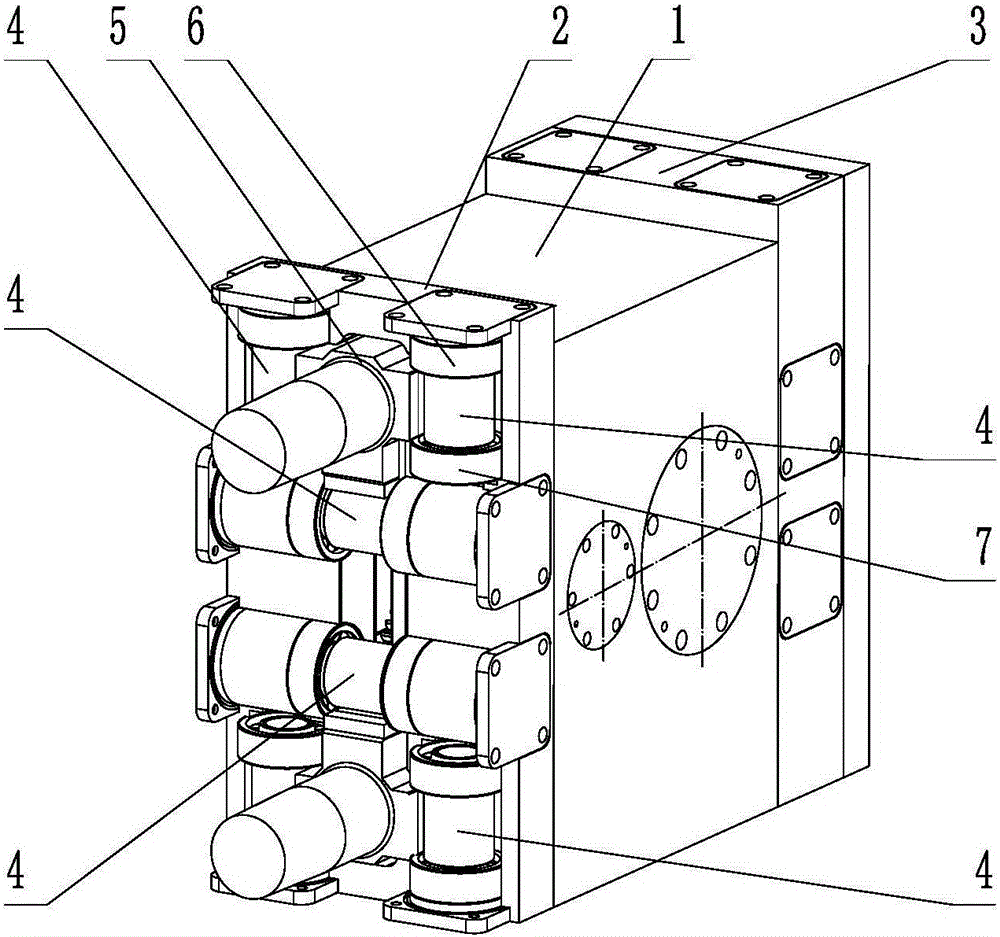

A reciprocating impact mining apparatus mounted with fitted rolling guide rotation-stopping assembly blocks for implementing a guide rotation-stopping method for mounting the fitted rolling guide rotation-stopping assembly blocks

ActiveCN105971596AIncrease guide cohesionIncrease the strength of orientationDriving meansTunnelsImpact toothEngineering

The invention belongs to the field of machinery and particularly relates to a reciprocating impact mining apparatus mounted with fitted rolling guide rotation-stopping assembly blocks for implementing a guide rotation-stopping method for mounting the fitted rolling guide rotation-stopping assembly blocks. The mining apparatus comprises linked guide sealed tooth-inserting bases, a reciprocating power device, rolling guide rotation-stopping devices, fitted rolling guide rotation-stopping assembly blocks, an integrated block connecting piece, a guide rotation-stopping box sealing piece and reciprocating impacting teeth. The reciprocating impacting teeth are disposed at front ends of the linked guide sealed tooth-inserting bases. A connecting rod drives a single tooth-inserting base to form a single-tooth-inserting base reciprocating impact device. The fitted rolling guide rotation-stopping assembly blocks increase guide cohesive force and guide uprighting force. A plurality of supporting ear plates supporting a plurality of the rolling guide rotation-stopping devices are formed as an integrated plate through the fitted rolling guide rotation-stopping assembly blocks. The integrated plate enables intensification and substantialization of a space required by supporting the plurality of the rolling guide rotation-stopping devices and improves the positioning precision of the plurality of rolling guide rotation-stopping devices.

Owner:JINING CITY CUSTOMKEY ELECTROMECHANICAL TECH CO LTD

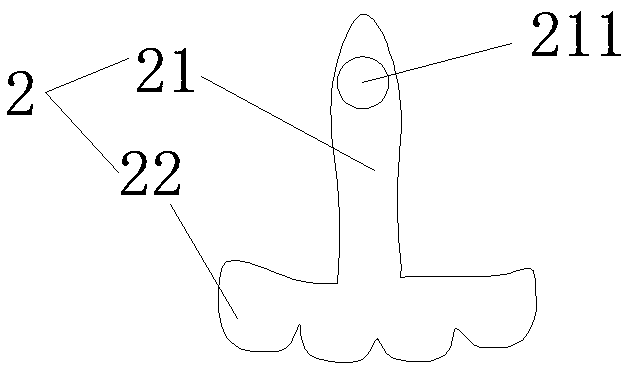

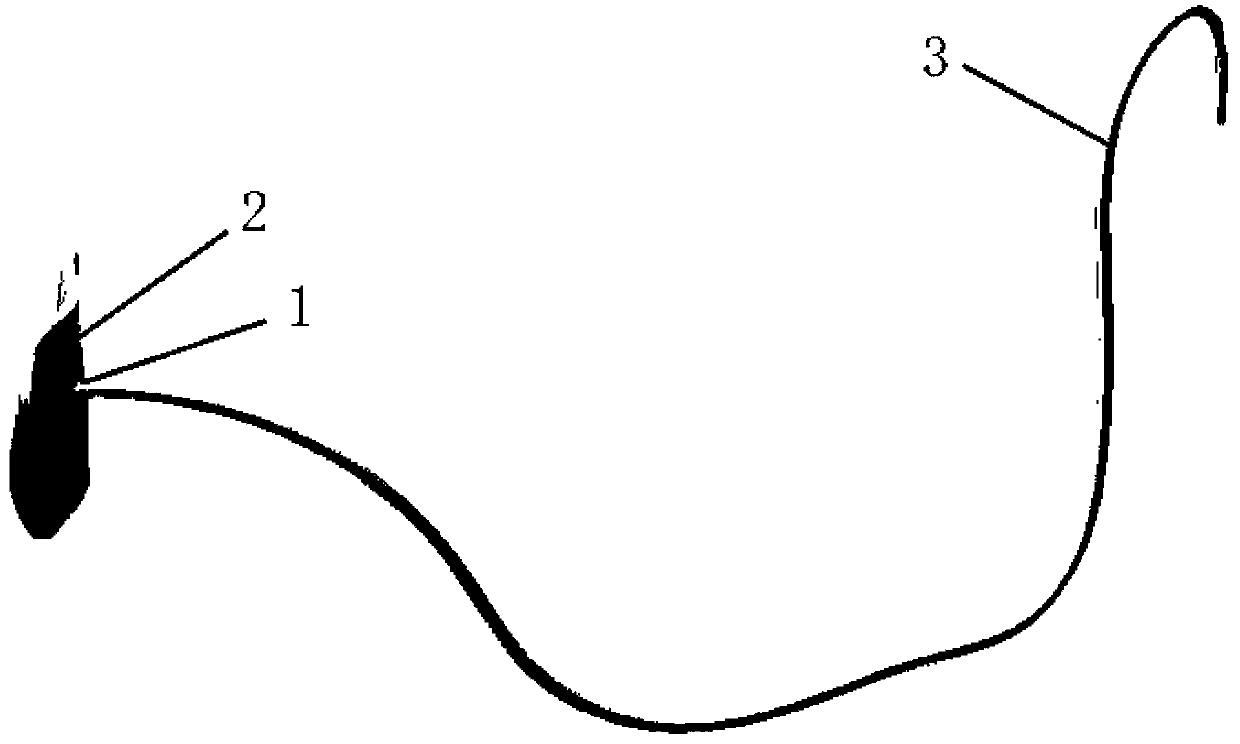

Titanium alloy embedded tooth individual traction accessory printed through three-dimensional technology

PendingCN109662787AGood compatibilityNot easy to fall offAdditive manufacturing apparatusOthrodonticsImpact toothImpacted tooth

The invention relates to the technical field of medical treatment, in particular to a titanium alloy embedded tooth individual traction accessory printed through a three-dimensional technology. According to the titanium alloy embedded tooth individual traction accessory printed through the three-dimensional technology, according to the best traction pulling path for an impacted tooth, an adhesionpart and the traction direction of the traction accessory are designed, and the best specific part of a main traction accessory body and the best position of a traction hook are determined. Based on atitanium alloy material, according to the best design scheme for the traction accessory device, the main traction accessory body and the traction hook which completely fit the corresponding tooth surface are printed, wherein the main traction accessory body and the traction hook are integrally formed. The main traction accessory body and the traction hook can completely fit the tooth surface, andafter adhesion, the main traction accessory body and the traction hook cannot easily fall; compared with traditional stainless steel, the titanium alloy material is significantly excellent, the phenomenon of the soft and sclerous tissue inflammatory reaction cannot easily occur; the integrated structure is firmer, and the phenomenon of fracturing cannot easily occur.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Upper jaw embedded impacted tooth guide rod type correcting appliance

The present invention relates to oral orthodontic technology, and is especially one kind of guide rod type orthodontic appliance for upper jaw embedded canine teeth. The orthodontic appliance includesa plastic palatal arch support, a fixing block, a guide rod, and an extraction device. The present invention aims at providing one kind of guide rod type orthodontic appliance for upper jaw embeddedcanine teeth with 3D adjustable orthodontic force, no use of dentition as anchorage and less irritation on upper lip mucous membrane. The present invention has the advantages of small orthodontic force,less blocking interference of adjacent teeth, reduced teeth moving resistance, less irritation on mucous membrane, etc.

Owner:温州医科大学附属口腔医院

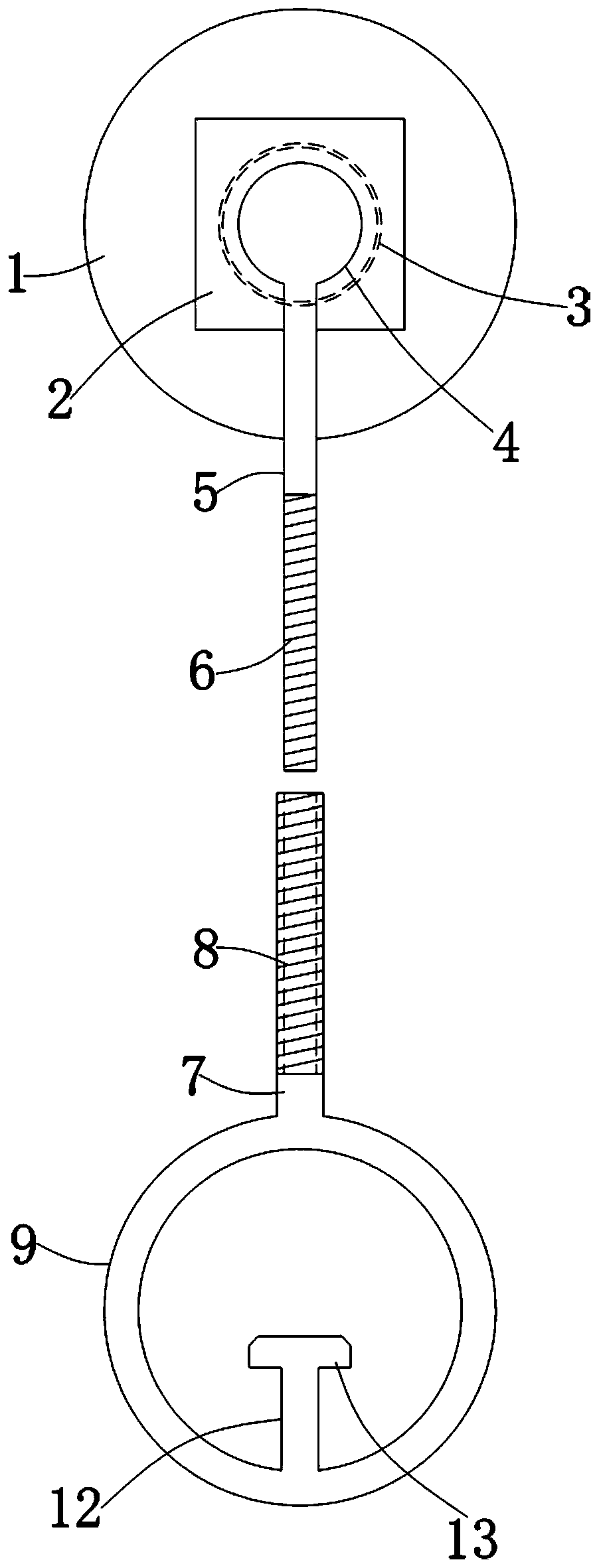

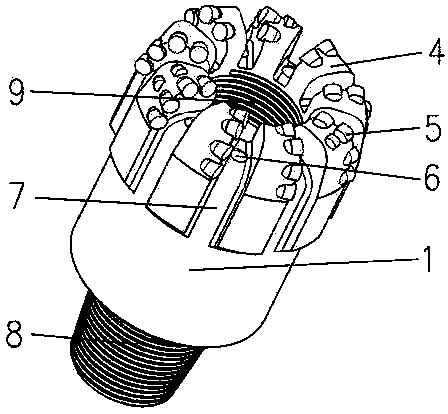

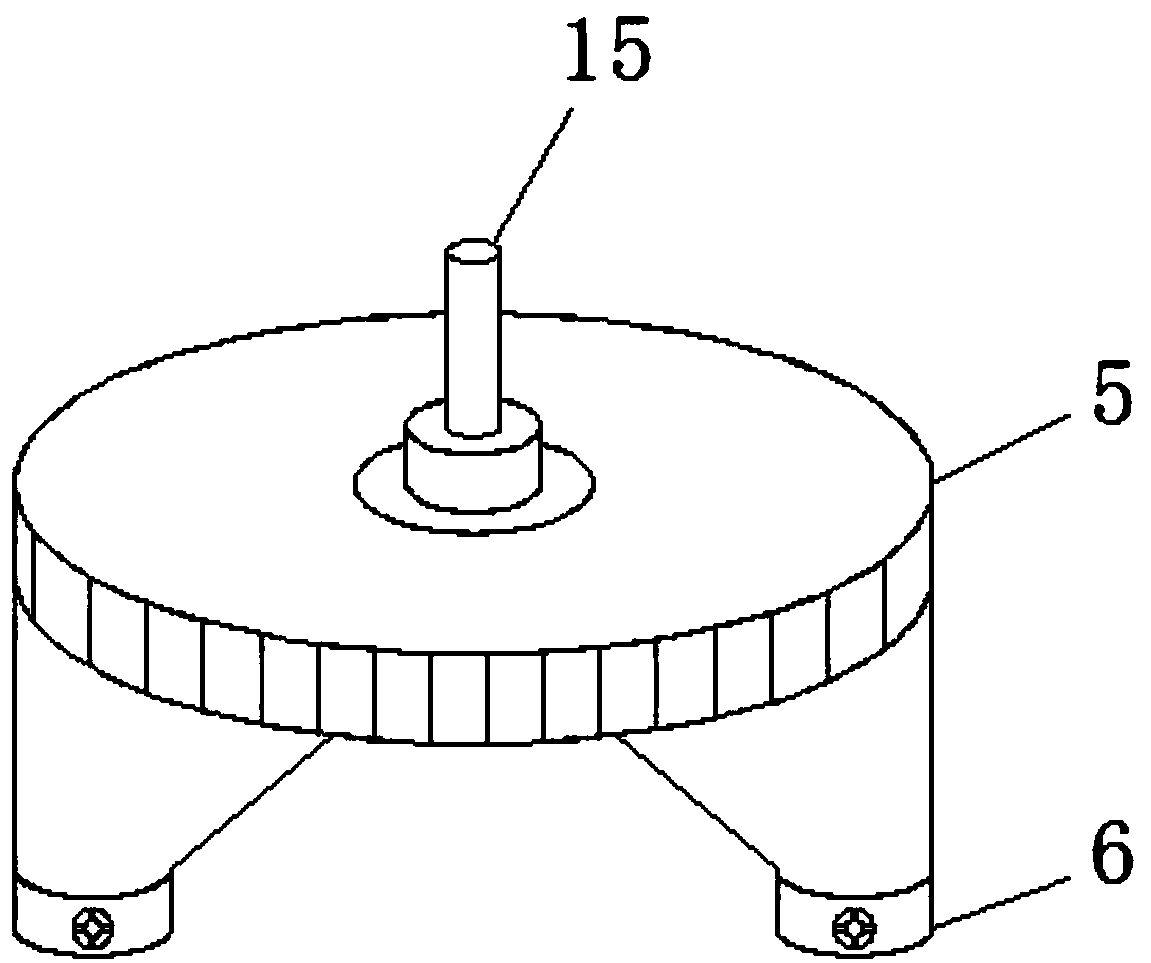

PDC drill bit with self-impact capability

A PDC drill bit with the self-impact capability comprises a drill bit body and cutter wings, wherein the cutter wings are fixedly connected with the drill bit body or integrally formed, cutting teethare arranged on the cutter wings, a supporting body is arranged on the drill bit body, a self-impact unit is arranged on the supporting body, and the self-impact unit consists of a rolling body, a transmission device and an impact device; the rolling body can rotate around the axis of the rolling body; the impact device consists of an impact body and at least one impact tooth; and the rotation ofthe rolling body can realize the impact of the impact device through the transmission device. According to the PDC drill bit with the self-impact capability, an impactor tool does not need to be arranged when rock breaking is achieved, drilling cost is saved, meanwhile, invasion capacity of the cutting teeth is improved, and rock breaking efficiency is improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

New type electric impact drill

InactiveCN100562391CReduce damage rateGuaranteed normal operationPortable percussive toolsPortable drilling machinesImpact toothGear wheel

The invention relates to a novel impact electric drill that includes handle, frame and drill chuck. Switch component is installed on handle. Motor, motor shaft, heat sink, driving gear, impact device and output shaft are installed in the frame. The drill chuck is installed on one end extending out of the frame. A first impact tooth is set on the inner side surface of driving gear. The corresponding section of impact device has the second impact tooth. A first circle wall is set outside the first impact tooth. And the outside of the second impact tooth has the second circle wall matching with the first circle wall. The first circle wall and the second circle wall form sealed structure to make the impact teeth gain good lubrication all the time.

Owner:吴世雄

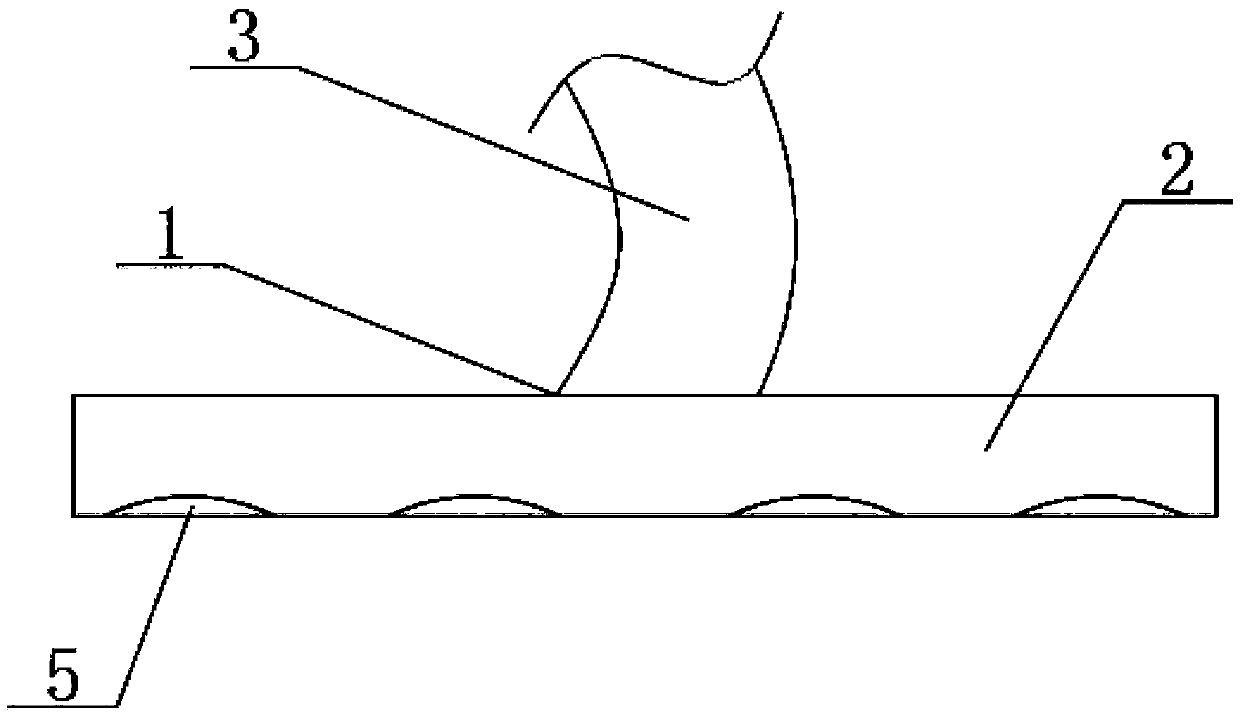

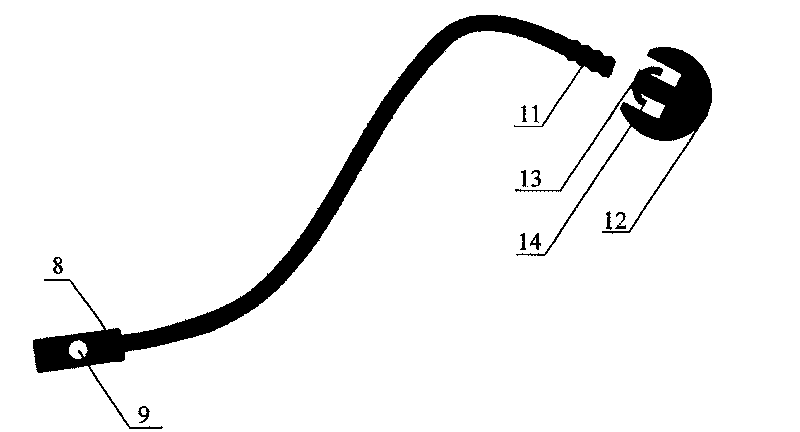

Impacted tooth traction apparatus

The invention relates to an impacted tooth traction apparatus. The traction apparatus comprises a bottom plate, a fixed block, a connecting rod and a traction ring, wherein the bottom plate is used for connecting with an impacted tooth, the fixed block is fixedly arranged on one end of the bottom plate, one end of the connecting rod is connected with the fixed block, the other end of the connecting rod is provided with threads, and is connected with the traction ring through the threads, the traction ring is rotated, and the traction ring moves along the connecting rod toward or away from thebottom plate. The traction apparatus has a simple structure, a high bonding success rate, and is convenient for the strength traction of the impacted tooth in the three dimensional direction by usingan arch-wire or a rubber chain.

Owner:NANJING STOMATOLOGICAL HOSPITAL

Compound tooth-shaped conical broken grinding head with point press teeth and long strip sieve pores

InactiveCN101543796ASmooth dischargeAvoid Repeated FragmentationGrain treatmentsImpact toothCircular cone

A compound tooth-shaped conical broken grinding head with point press teeth and long strip sieve pores consists of an inner cone sleeve connected on a main shaft through keys, an upper inner cone lining board, a lower inner cone lining board, an outer cone sleeve, an upper outer cone lining board and a lower outer cone lining board, wherein a point press lug boss on an impact face of an impact tooth of the upper inner cone lining board and the point press teeth on the upper outer cone lining board efficiently carry out point press, splitting and breaking on big-lump materials; and the long strip sieve pores on the lower inner cone lining board and lower outer cone lining board discharge a material of which the grain size meets the standard, prevent repeated fragmentation and reduce the consumption of a grinding material so as to achieve the aims of energy conservation and consumption reduction. The split type lining boards are easy to mount and repair.

Owner:黄琳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com