Heading machine cutter head suitable for extremely hard rock stratum

A cutterhead and formation technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of large rock-breaking load and limited rock-breaking efficiency of the cutterhead, so as to reduce impact rock-breaking load, improve cutting stability and Cutting efficiency and the effect of improving rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

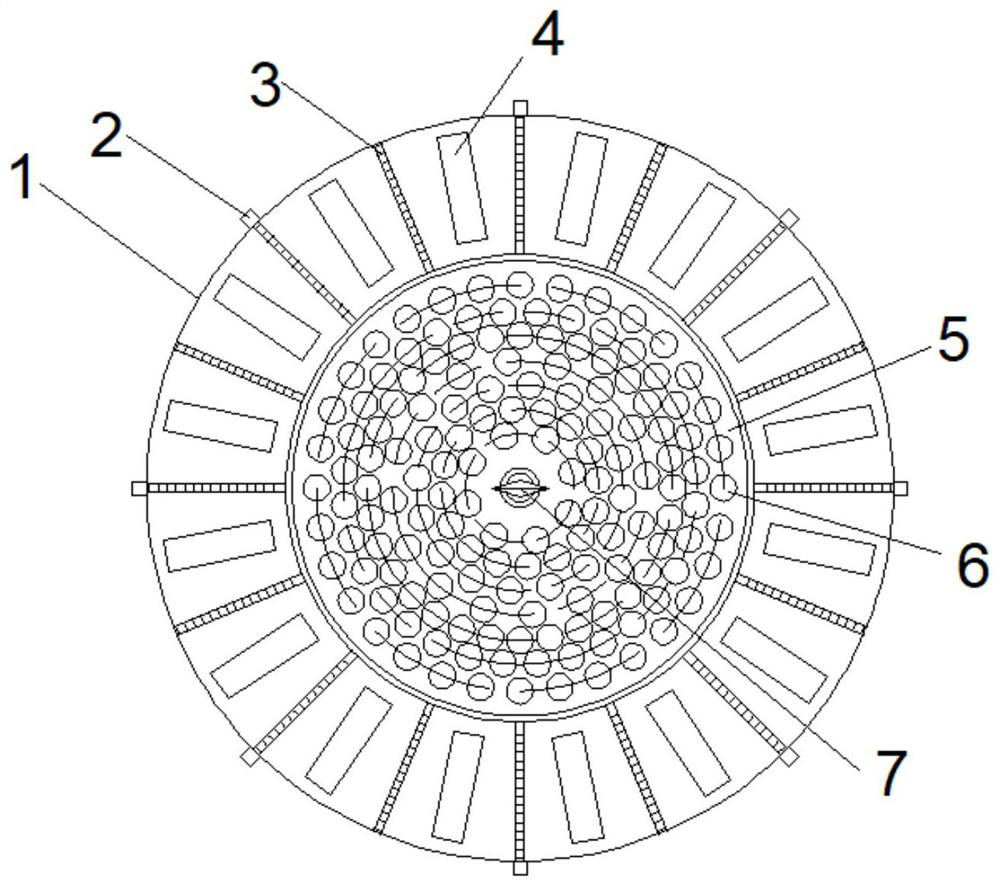

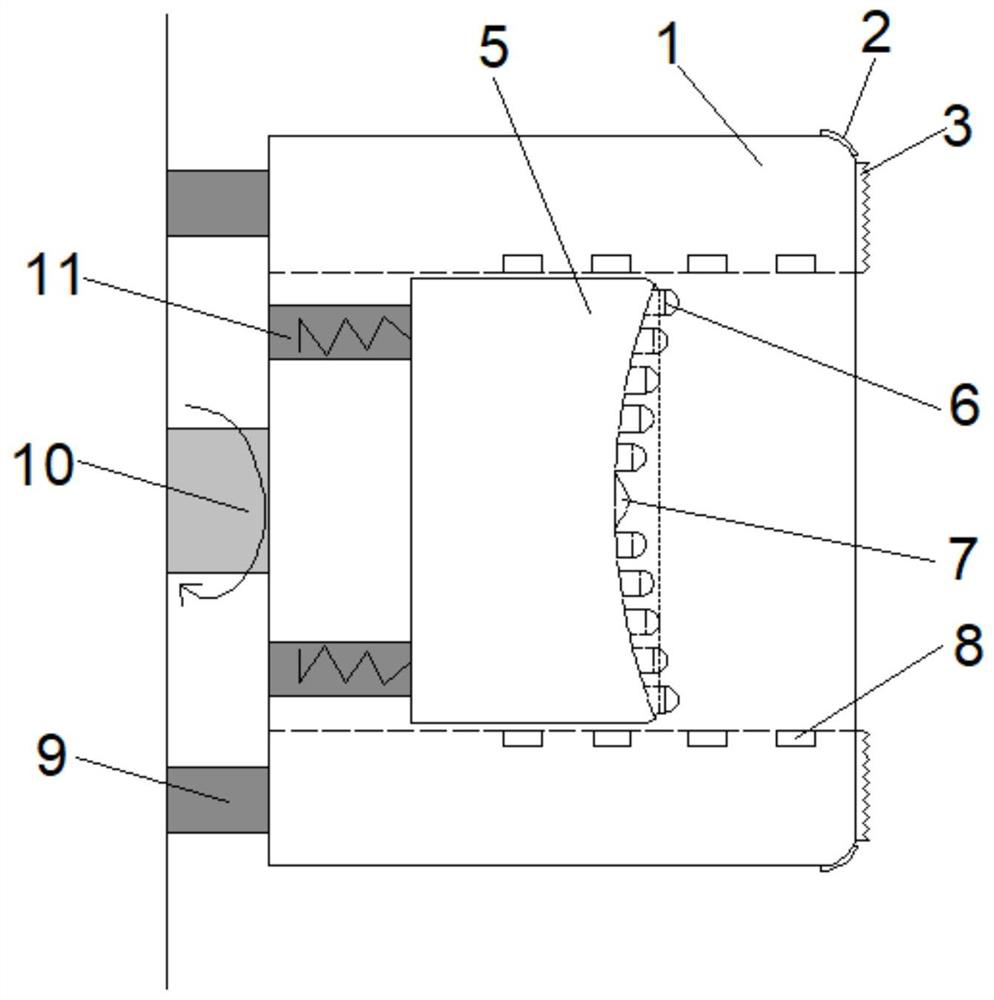

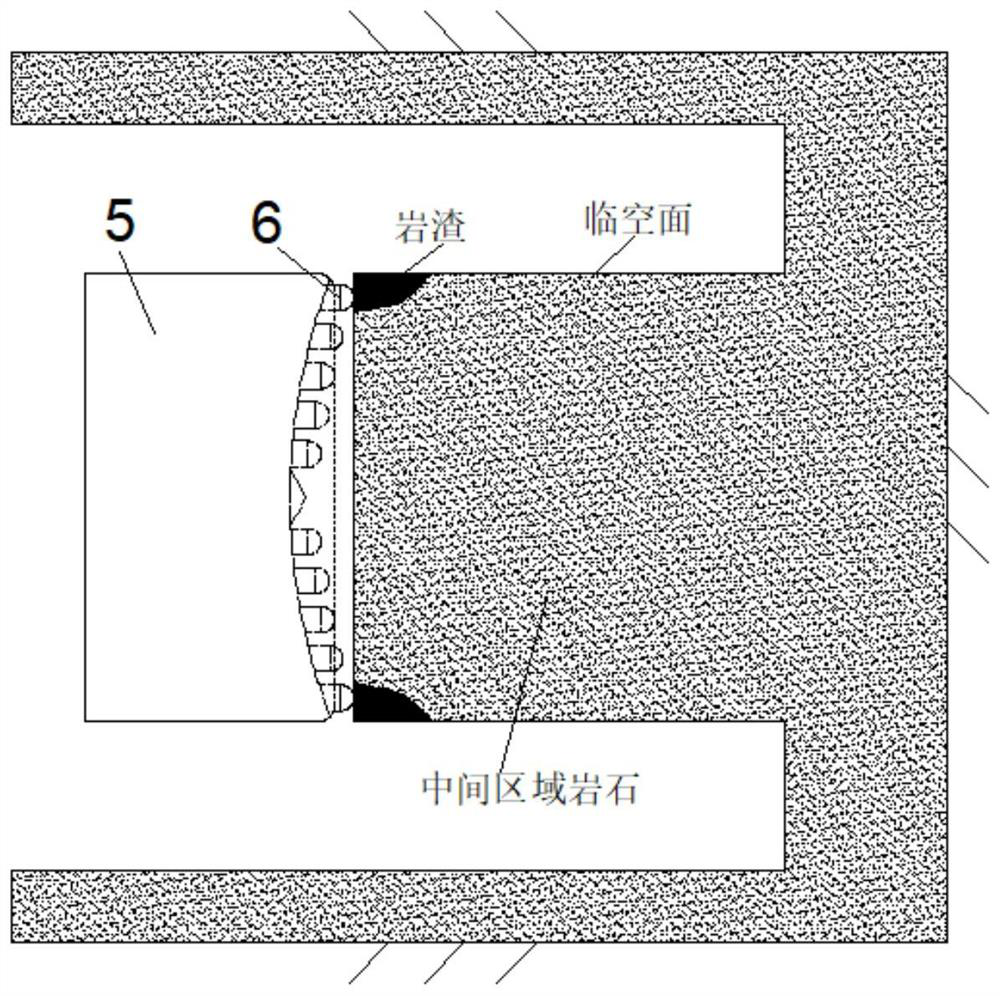

[0023] as attached figure 1 And attached figure 2 As shown, a roadheader cutter head suitable for extremely hard rock formations consists of an outer ring cutter head 1, an edge scraper 2, a serrated knife 3, an outer opening 4, an inner ring cutter head 5, impact teeth 6, and tines 7, The inner opening 8, the propulsion cylinder 9, the rotary motor 10 and the impact cylinder 11 constitute.

[0024] The outer ring cutter head 1 is in the shape of a ring column, and the inner hollow area is equipped with an inner ring cutter head 5, which is cylindrical, and the front end surface of the inner ring cutter head 5 is made concave; the outer ring cutter head 1 and the inner ring cutter head There is a certain gap between the ring cutterheads 5, and the inner ring cutterhead 5 can slide in the inner cavity of the outer ring cutterhead 1; The thru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com