Crystalline silicon single-knife guillotine

A cutting machine, crystal silicon technology, applied in the direction of manufacturing tools, stone processing equipment, work accessories, etc., can solve the problems of silicon rod transfer difficulties, not considering the silicon rod crystal pulling process, overcapacity, etc., to improve cutting stability , compact structure, and the effect of reducing equipment manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

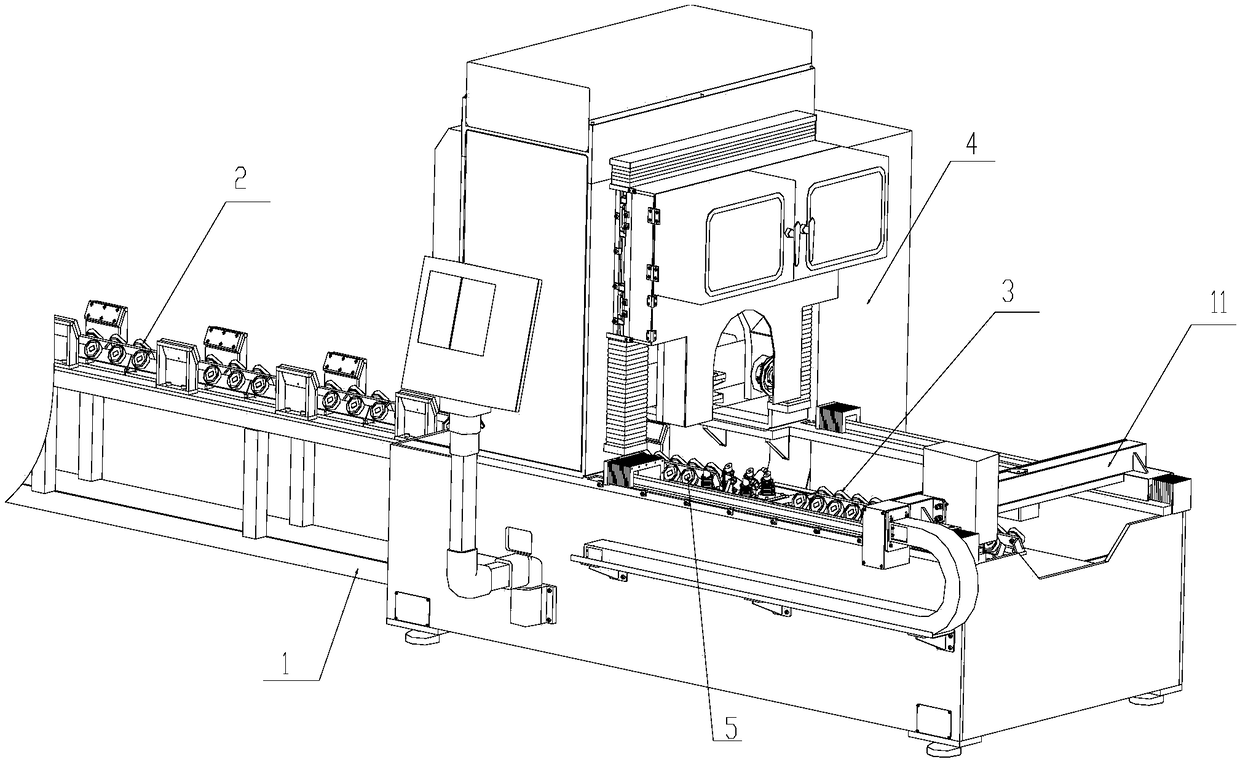

[0029] refer to figure 1 , a crystal silicon single-knife cutting machine, including a base 1, a conveying mechanism and a cutting mechanism 4, the conveying mechanism and the cutting mechanism 4 are located above the base 1. The conveying mechanism is divided into two stages along the axial direction of the crystal silicon, which are respectively the feed conveying assembly 2 and the unloading conveying assembly 3. The crystal silicon is conveyed to the cutting mechanism 4 through the feed conveying assembly 2 for cutting. The crystalline silicon is exported through the feeding and conveying assembly 3.

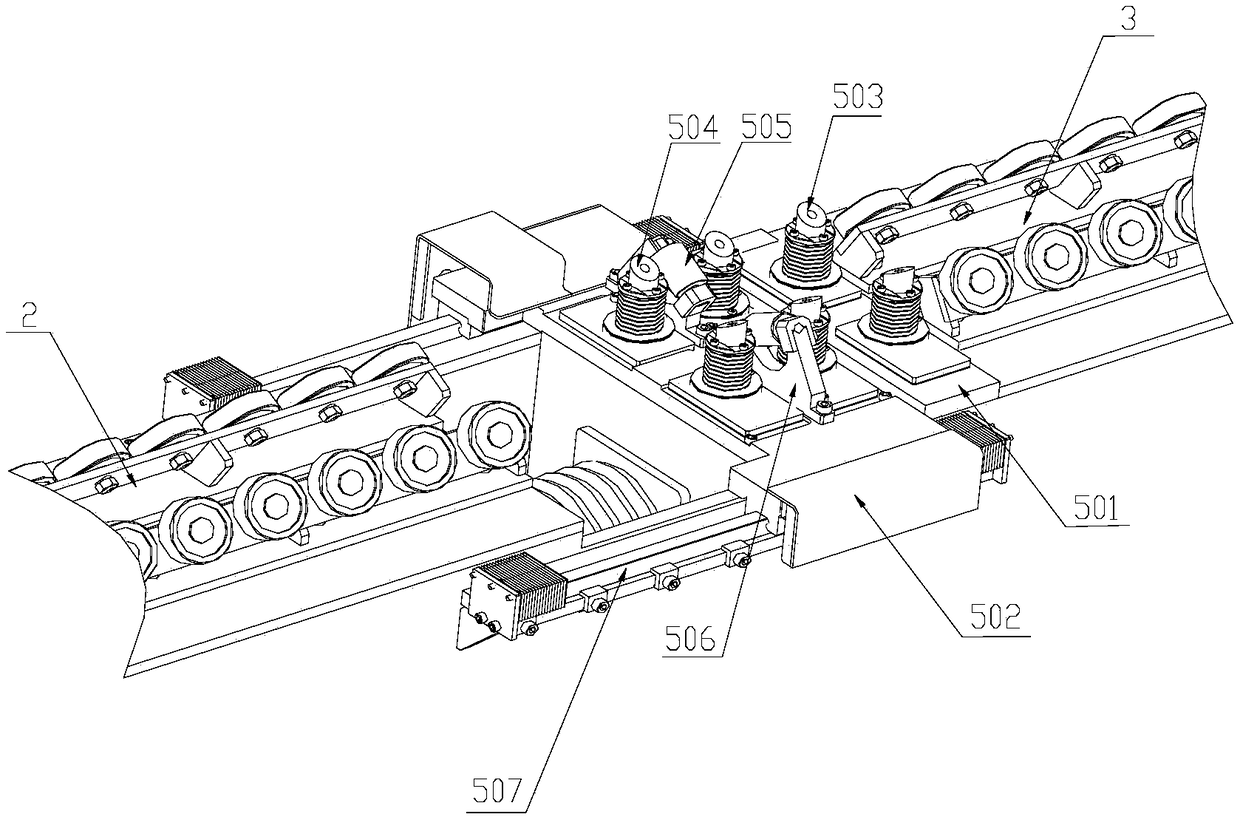

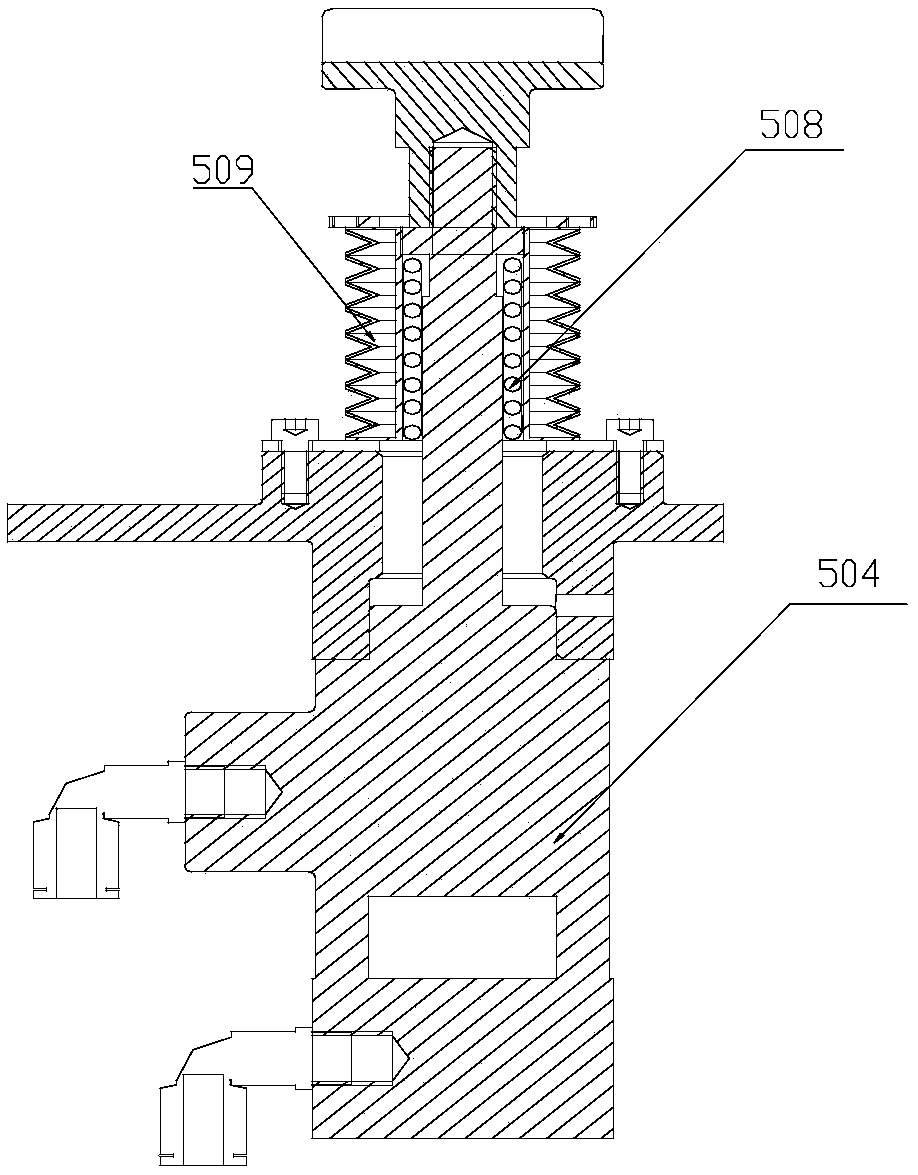

[0030] In order to facilitate the cutting of crystal silicon of different lengths, a movable supporting mechanism 5 is provided between the feeding conveying assembly 2 and the unloading conveying assembly 3 . refer to figure 2 , the movable support mechanism 5 includes a relatively slidable first slide table 501 and a second slide table 502, the base 1 is provided with a...

Embodiment 2

[0034] refer to figure 1 , Figure 4 with Figure 5 , the cutting mechanism 4 straddles above the movable supporting mechanism 5 and is connected to the base 1 through a supporting column 6 . The cutting mechanism 4 includes a support frame 401, a lift assembly 402 and a cutting head, wherein the lift assembly 402 is fixedly connected to the support column 6, the cutting head is located on the support frame 401, and at the same time, the lift assembly 402 passes through the connecting plate 7 It is connected with the support frame 401 to push the support frame 401 to slide along the support column 6 , and the support frame 401 is provided with a through hole 403 through which the crystal silicon passes. When the crystalline silicon is located in the through hole 403 , the lifting assembly 402 drives the cutting head to move down to cut the crystalline silicon.

[0035]The lift assembly 402 includes a lift motor 412, a reducer 413 and a first ball screw 414, the output end o...

Embodiment 3

[0040] refer to figure 1 with Image 6 , the jaw assembly 11 is provided at the blanking and conveying assembly 3, and the jaw assembly 11 includes a beam 1101 and a drive motor 1102. The beam 1101 is perpendicular to the axial direction of the crystal silicon, and it is close to the One side is provided with a positioning block 1103 communicating with the beam 1101 , and the driving motor 1102 is located on the other side of the beam 1101 . The base 1 is provided with a feed slide rail extending along the axial direction of the crystal silicon, and the driving motor 1102 drives the jaw assembly 11 to move along the feed slide rail to drag the crystal silicon to be transported along the conveying mechanism.

[0041] The end of the positioning block 1103 is provided with a vacuum chuck 1104, and the vacuum chuck 1104 is used to suck the crystal silicon or the sample that needs to be cut. At the same time, the positioning block 1103 can effectively prevent the crystal silicon o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com