Electric heavy-duty vehicle wheel rim driving assembly

A technology of wheel drive and motor drive, which is applied in the direction of electric components, vehicle components, and control/drive circuits, etc. It can solve the problems of low integration and high cost of the motor system, and achieve cost saving, layout and high integration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

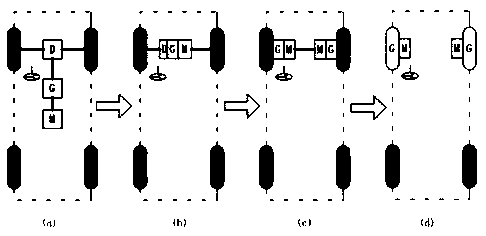

Method used

Image

Examples

specific Embodiment approach 1

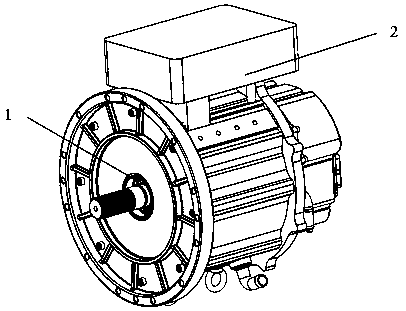

[0023] The wheel drive assembly of the electric heavy-duty vehicle in this embodiment comprises a permanent magnet synchronous motor 1, a motor driver 2, and a cooling pipeline 3. The motor driver 2 is fixed on the upper end of the permanent magnet synchronous motor 1, and the two form an assembly Structure; the cooling pipe 3 includes a flat plate structure arranged in an S-shape and a helically coiled cylindrical structure, and the two parts are connected. The flat plate structure arranged in an S-shape is installed in the motor driver 2 to dissipate heat for it. Corresponding openings provided on the shell of the motor driver 2 are used for running pipes in a planar structure formed in an S-shaped bending arrangement; the helically coiled cylindrical structure is wrapped around the periphery of the permanent magnet synchronous motor 1 to dissipate heat for it.

[0024] The permanent magnet synchronous motor 1 is a sinusoidal built-in permanent magnet synchronous motor, and t...

specific Embodiment approach 2

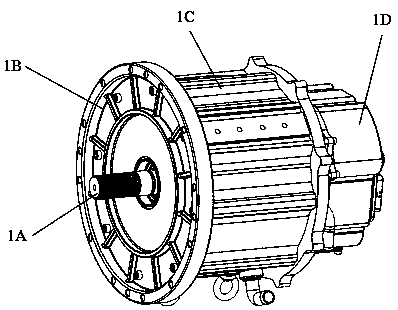

[0026] The difference from Embodiment 1 is that in the wheel drive assembly of electric heavy-duty vehicles in this embodiment, the permanent magnet synchronous motor 1 includes an output shaft 1A, a flange end cover 1B, a motor casing 1C, and a motor rear cover 1D , liquid inlet 1E, liquid outlet 1F, lifting ring 1G, power cable interface 1H, control signal cable interface 1J;

[0027] The motor casing 1C is the bearing and protection structure of the permanent magnet synchronous motor 1. The front end of the motor casing 1C is fixedly packaged with a flange end cover 1B, and the rear end of the motor casing 1C is fixedly packaged with a motor back cover 1D; the output shaft 1A is driven by a permanent magnet synchronous motor. The flange end cover 1B of the front end of the motor 1 passes through the body, and one end of the output shaft 1A is connected with the rotor of the motor, and the other end has a spline structure, which is used to connect with the wheel of the heavy-...

specific Embodiment approach 3

[0031] Different from the second specific embodiment, the wheel drive assembly of the electric heavy-duty vehicle in this embodiment, such as Figure 6-Figure 7 As shown, the motor driver 2 includes a driver outer shell 2A, a fixed frame 2B, and a connecting block 2C. A control system for controlling the permanent magnet synchronous motor 1 is installed inside the driver outer shell 2A, and a connecting block 2B is connected to the lower surface of the driver outer shell 2A. With the fixed frame 2C, the driver housing 2A is fixed with the motor casing 1C of the permanent magnet synchronous motor 1 through the connecting block 2B and the fixed frame 2C;

[0032] A row of copper column mounting holes 2D and a control signal cable passing hole 2E are provided on the mounting surface at the bottom of the connection block 2C. Since the permanent magnet synchronous motor 1 is a three-phase motor, the power cables are divided into A, B, and C. Similar as Figure 8 As shown, there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com