Patents

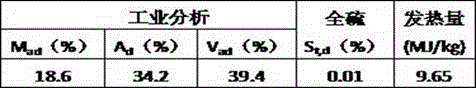

Literature

92results about How to "Achieve cleanliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

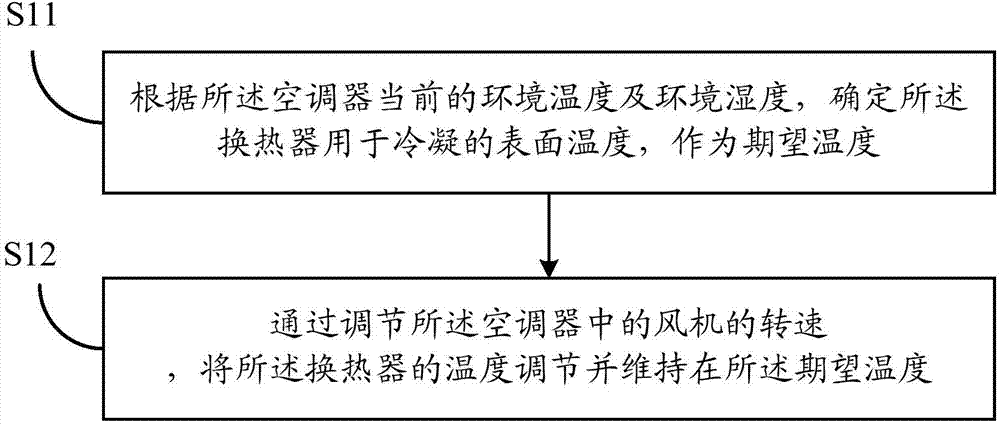

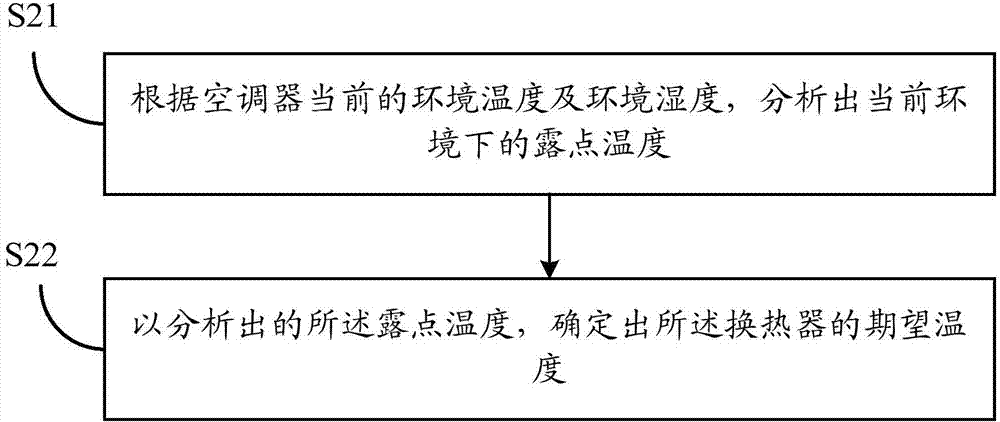

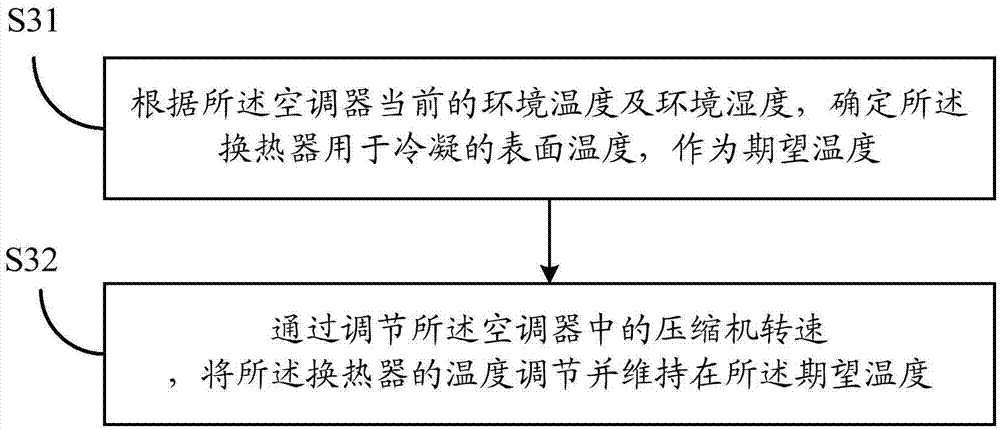

Method and device for collecting condensed water to clean air conditioner based on rotation speed regulation of compressor

ActiveCN104848481ATemperature rise or fallAchieve cleanlinessMechanical apparatusSpace heating and ventilation safety systemsLiquid waterEngineering

A method and a device for collecting a condensed water to clean an air conditioner based on rotation speed regulation of a compressor are disclosed. A heat exchanger in the air conditioner is used for condensing water vapor inside the air conditioner into a liquid water, and thereby cleaning the dirt adhered on the surface of the heat exchanger. The step of condensing the water vapor into the liquid water comprises: determining a surface temperature for condensation of the heat exchanger as an expected temperature, on the basis of a current environment temperature and a current environment humidity of the air conditioner; regulating and maintaining the temperature of the heat exchanger at the expected temperature by regulating the rotation speed of the compressor in the air conditioner. An optimal temperature of the heat exchanger in the current environment is determined by analyzing the influence of the environment temperature and the environment humidity to the dew point, thereby acquiring enough condensed water for cleaning the dirt on the surface of the heat exchanger. When the actual temperature of the heat exchanger is unequal to the expected temperature, the rotation speed of the compressor is regulated to rise up or lower down the temperature of the heat exchanger, accordingly maintaining the temperature of the heat exchanger at the determined optimal temperature, and thereby achieving the automatic cleaning and self-adaptive regulation of the heat exchanger, and ensuring the cleaning effect of the heat exchanger.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

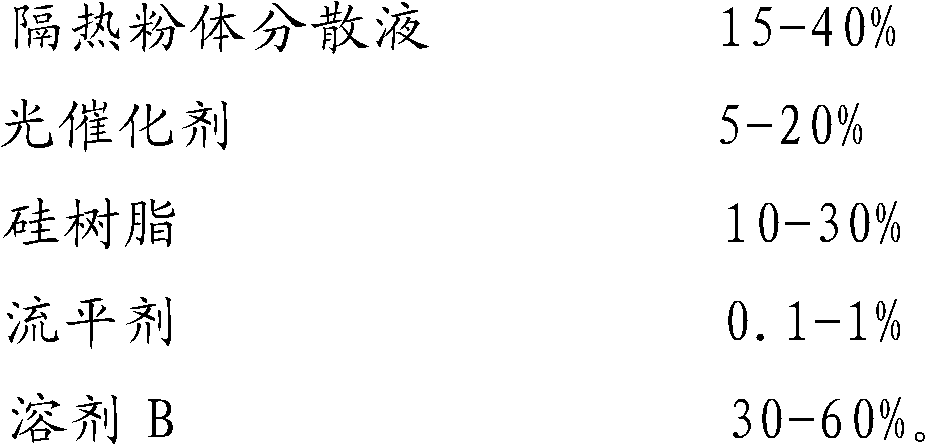

Preparation method of transparent thermal insulation self-cleaning coating

The invention relates to a preparation method of a transparent thermal insulation self-cleaning coating. The method comprises the following steps: (1) preparation of a photocatalyst: evenly mixing tetrabutyl titanate, ethyl orthosilicate and anhydrous ethanol, adding the mixture into a mixed solution containing inorganic acid, water and acetylacetone, stirring at 40-80 DEG C for 5-15 h, and cooling; (2) preparation of a thermal insulation powder dispersion liquid: adding a thermal insulation powder into a solvent A added with a dispersant and a defoamer to form a mixed solution, dispersing the mixed solution by stirring at high speed for 0.5-2 h, and then dispersing the mixed solution with ultrasonic for 15-40 min; and (3) preparation of a transparent thermal insulation self-cleaning coating: evenly mixing the photocatalyst, the thermal insulation powder dispersion liquid, a silicon resin, a leveling agent and a solvent B at room temperature. The preparation method has simple process, and is convenient for construction; the method provided by the invention can prepare a uniform and stable transparent thermal insulation self-cleaning coating, which has good thermal insulation performance, excellent cleaning performance, and good use effect.

Owner:北京圣润东方科技有限公司

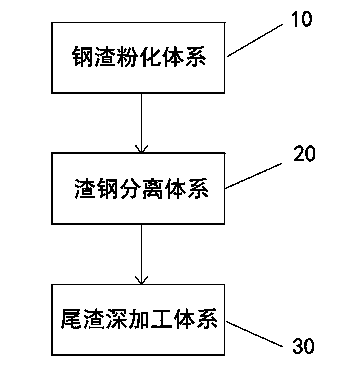

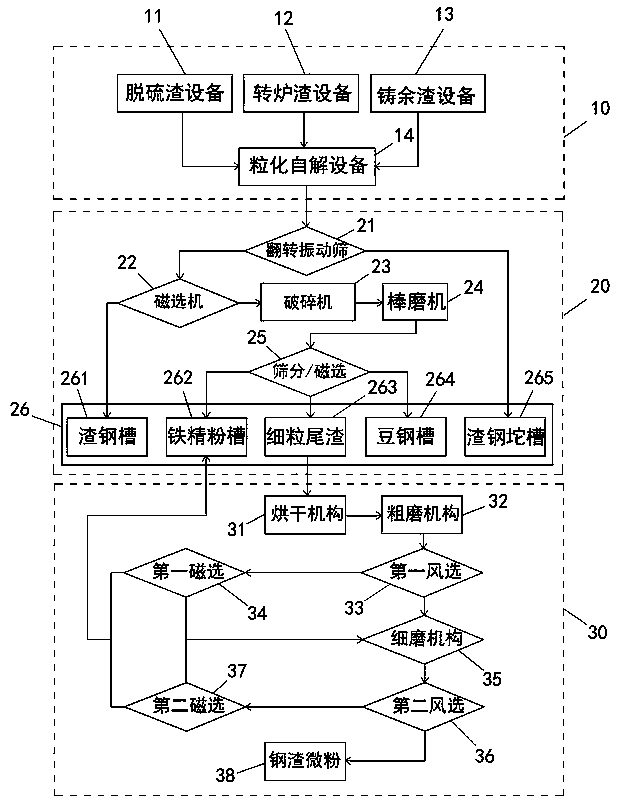

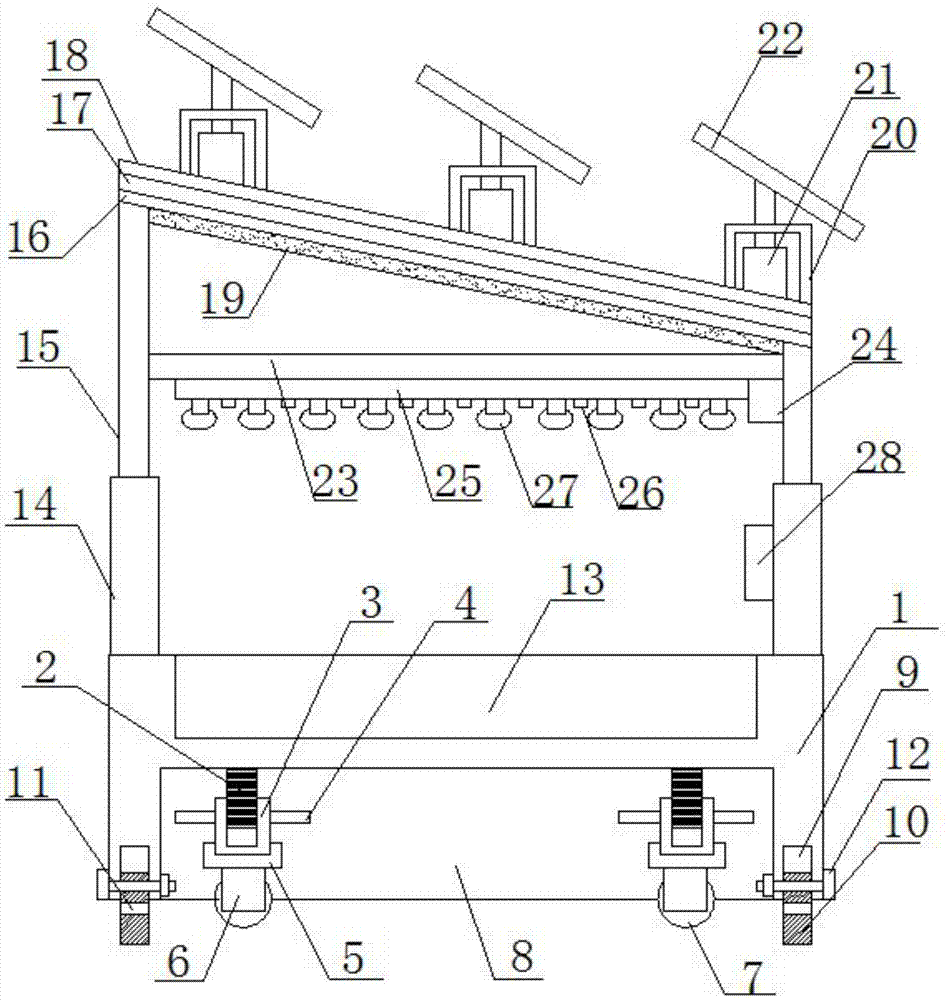

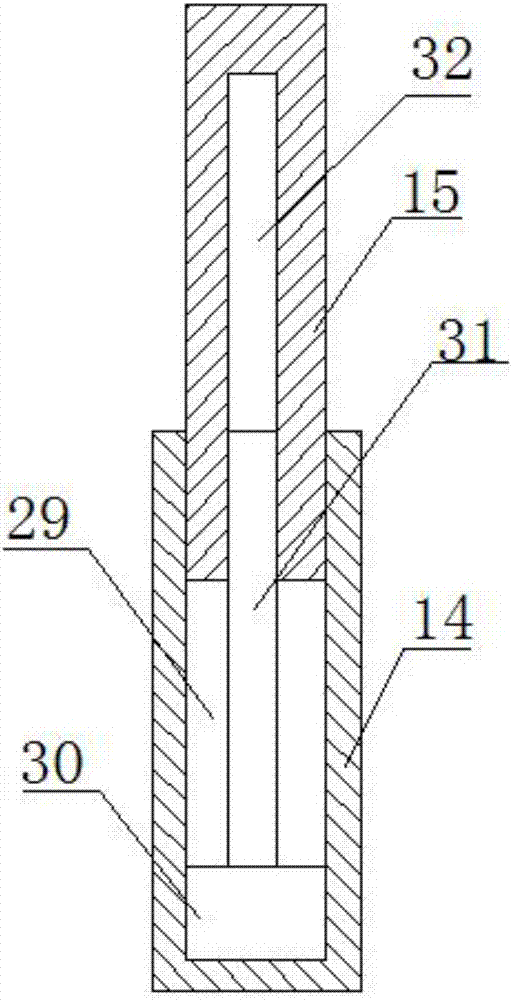

System and method for converting steel slag into renewable resources

ActiveCN103555867AEfficient use ofShort processRecycling and recovery technologiesProcess efficiency improvementSlagMagnetic separator

The invention discloses a system and a method for converting steel slag into renewable resources. The system comprises a steel slag powdering system, a steel slag separating system and a tail slag deep processing system, wherein the steel slag powdering system comprises desulphurization slag equipment, converter slag equipment, casting residue equipment and granulation self-extracting equipment which is communicated with the desulphurization slag equipment, the converter slag equipment and the casting residue equipment respectively; the steel slag separating system is connected with the granulation self-extracting equipment and comprises overturn vibration equipment, a magnetic separator, a crushing machine, a rod mill, screening / magnetic separation equipment and material storage equipment, wherein the overturn vibration equipment, the magnetic separator, the crushing machine, the rod mill, and the screening / magnetic separation equipment are led to the material storage equipment; the tail slag deep processing system is connected with a fine tail slag device and comprises a drying mechanism, a coarse grinding mechanism, a fine grinding mechanism, a first winnowing mechanism, a second winnowing mechanism, a first magnetic separation mechanism, a second magnetic separation mechanism and a steel slag fine powder groove. By the combination of the structures of the system, the design construction of the system for converting the steel slag into the renewable resources, which is clean and environment-friendly and reduces occupation space, is realized.

Owner:WISDRI ENG & RES INC LTD

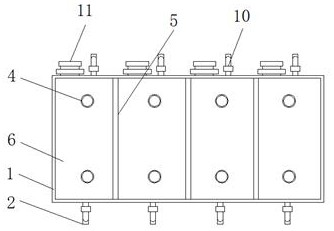

Household greenhouse

InactiveCN107295918AEasy to moveEasy to fixClimate change adaptationGreenhouse cultivationGreenhouseEngineering

The invention discloses a household greenhouse. The household greenhouse comprises a planting bed, a groove is formed in the lower side of the planting bed, first threaded rods are arranged on four corners inside the groove, rotating rods are arranged at the lower ends of the first threaded rods, first threaded cavities with openings formed in the upper ends are formed inside the rotating rods, the lower ends of the first threaded rods are arranged inside the first threaded cavities, rotating handles are arranged on the outer sides of the rotating rods, rotating bases are arranged at the lower ends of the rotating rods, wheel frames are arranged on the lower sides of the rotating bases, universal wheels are installed on the wheel frames, sliding grooves are formed in the left end and the right end of the lower side of the planting bed, supporting plates are arranged inside the sliding grooves, a plurality of fixing holes are formed in the supporting plates, the supporting plates penetrate through the fixing holes through bolts and are connected with the planting bed, a planting groove is formed in the upper side of the planting bed, supporting columns are arranged on four corners of the upper side of the planting bed, and a greenhouse top comprises a first glass plate and a second glass plate. The household greenhouse is simple in structure, convenient to use, suitable for a household, convenient to move, good in planting effect and high in automatic degree.

Owner:宫勋

Soap-free fluorocarbon emulsion prepared from perfluoroalkyl ethylenes through copolymerization and preparation method of soap-free fluorocarbon emulsion

ActiveCN105859949AImprove performanceHigh fluorine content on the surfaceCoatingsEmulsionMechanical stability

The invention discloses soap-free fluorocarbon emulsion prepared from perfluoroalkyl ethylenes through copolymerization and a preparation method of the soap-free fluorocarbon emulsion. The soap-free fluorocarbon emulsion is prepared from the following raw materials in percentages by mass through copolymerization: 4-40% of a fluorine-containing component, 50-70% of a component which does not contain fluorine, 3-8% of a pigment dispersing component, 2-8% of a crosslinking component, and 2-8% of a polymerizable emulsifier component. The soap-free fluorocarbon emulsion prepared by the invention is good in mechanical stability, low-temperature stability and ion stability; the problem that an emulsifier of the conventional emulsion is released into the environment is avoided during film formation; and the soap-free fluorocarbon emulsion is environmentally friendly.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

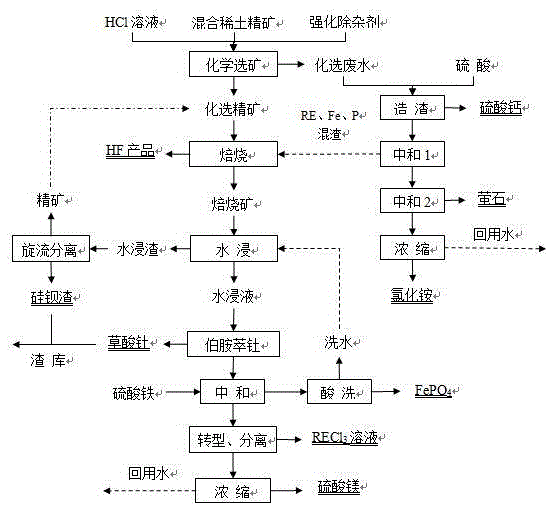

Method for cleaning smelted mixed rare earth concentrate by concentrated sulfuric acid

InactiveCN105568006AImprove dissolution rateIncrease dissolution rateProcess efficiency improvementResource recoveryWastewater

The invention relates to a method for cleaning smelted mixed rare earth concentrate by concentrated sulfuric acid. The method is characterized by comprising the following steps of chemically selecting and gathering mixed rare earth concentrate by use of a hydrochloric acid solution and a reinforced impurity remover, mixing the chemically-selected concrete with the concentrated sulfuric acid to roast at a low temperature, carrying out water leaching on roasted concentrate, carrying out resource recovery on a water leaching fluid, carrying out tail gas absorption, and recycling chemical-selected wastewater resources. The method has the advantages that the source of three wastes of a current concentrated sulfuric acid high-temperature roasting process is solved at the front end of concentrate treatment, so that various problems in a low-temperature acid method are solved, the follow-up three-waste treatment difficulty is greatly reduced, the rare earth direct recovery rate is increased, and the purpose of comprehensively recycling various resources in the concentrate and auxiliary materials is finally realized.

Owner:BAOTOU RES INST OF RARE EARTHS

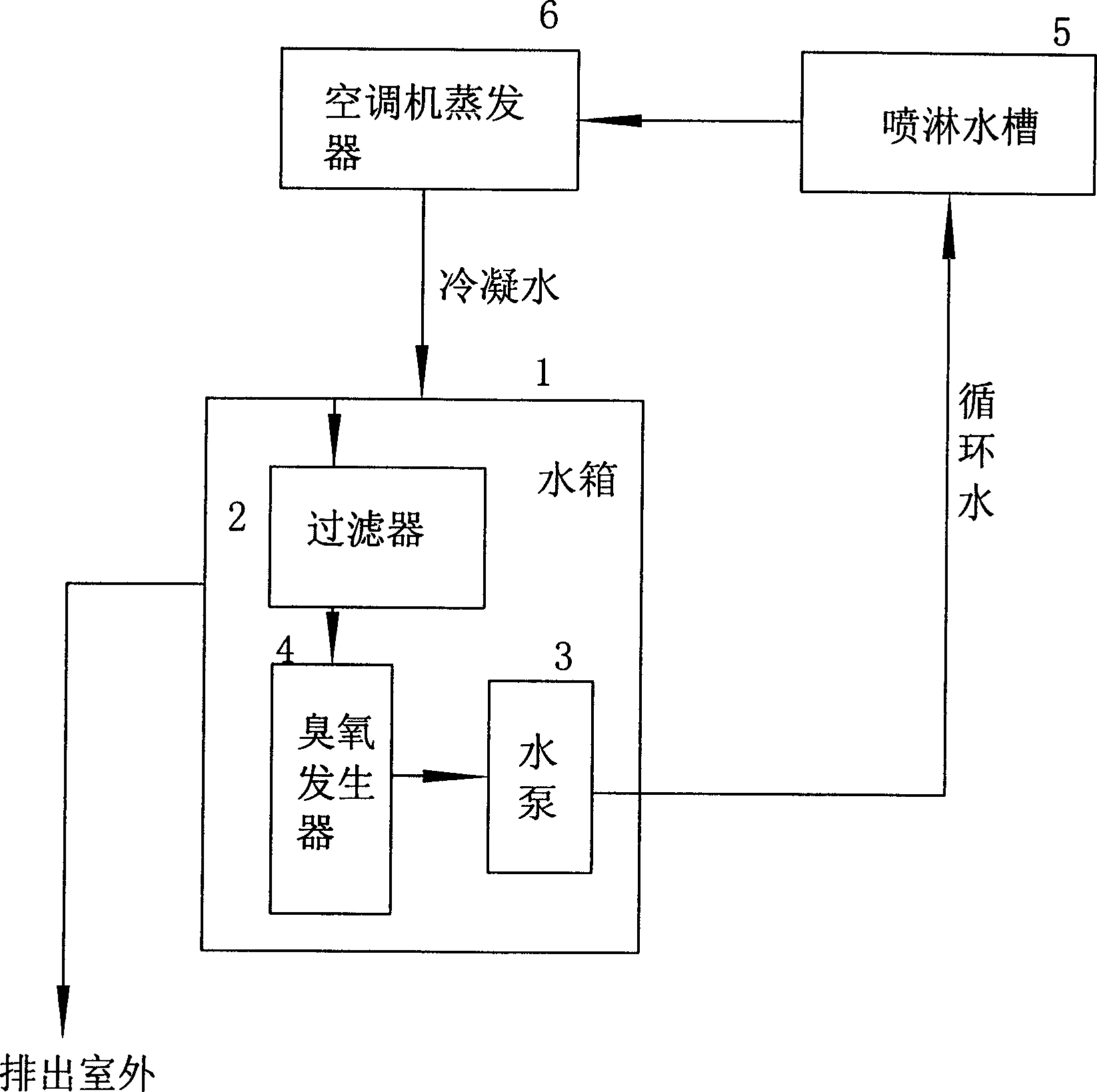

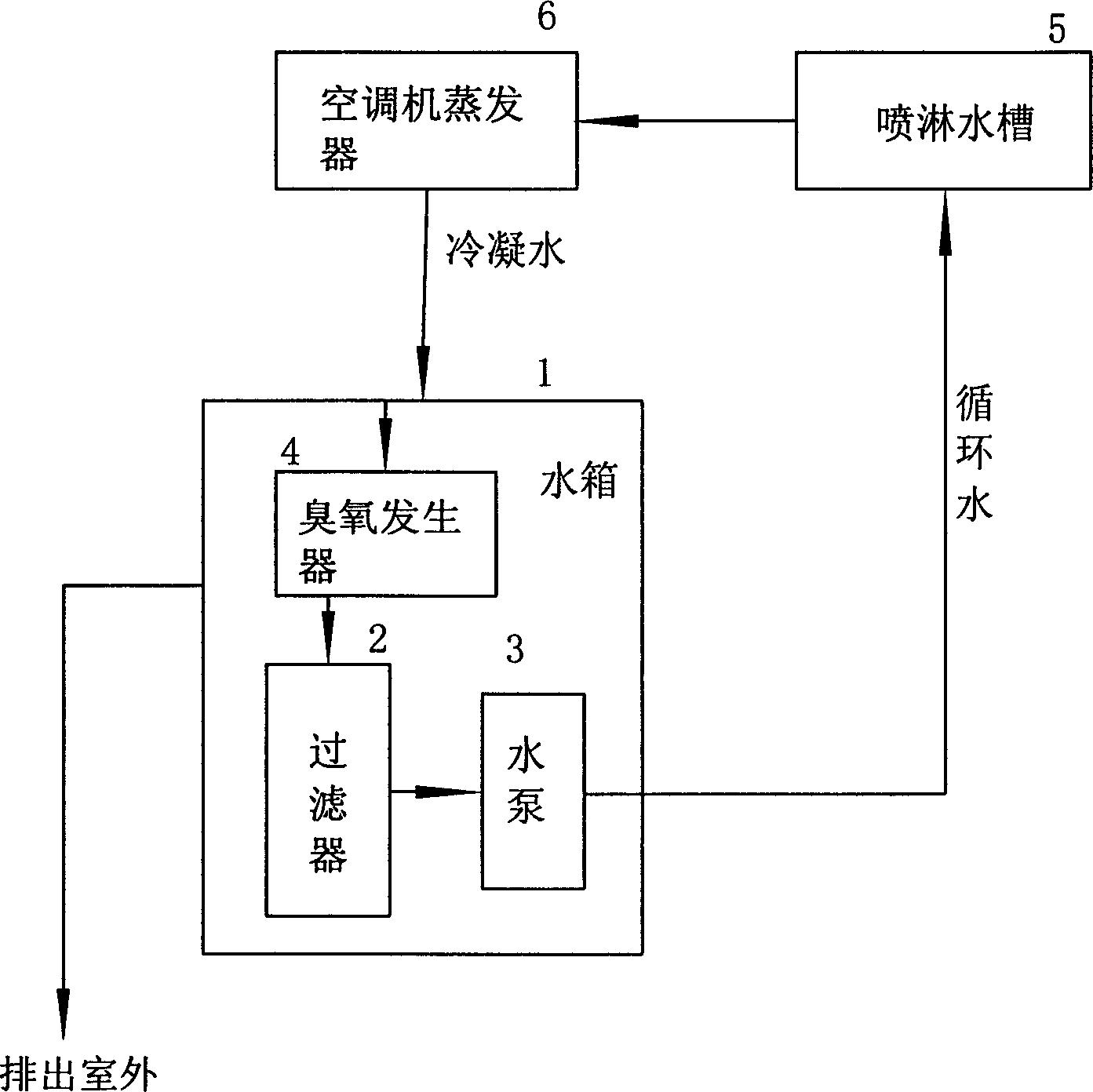

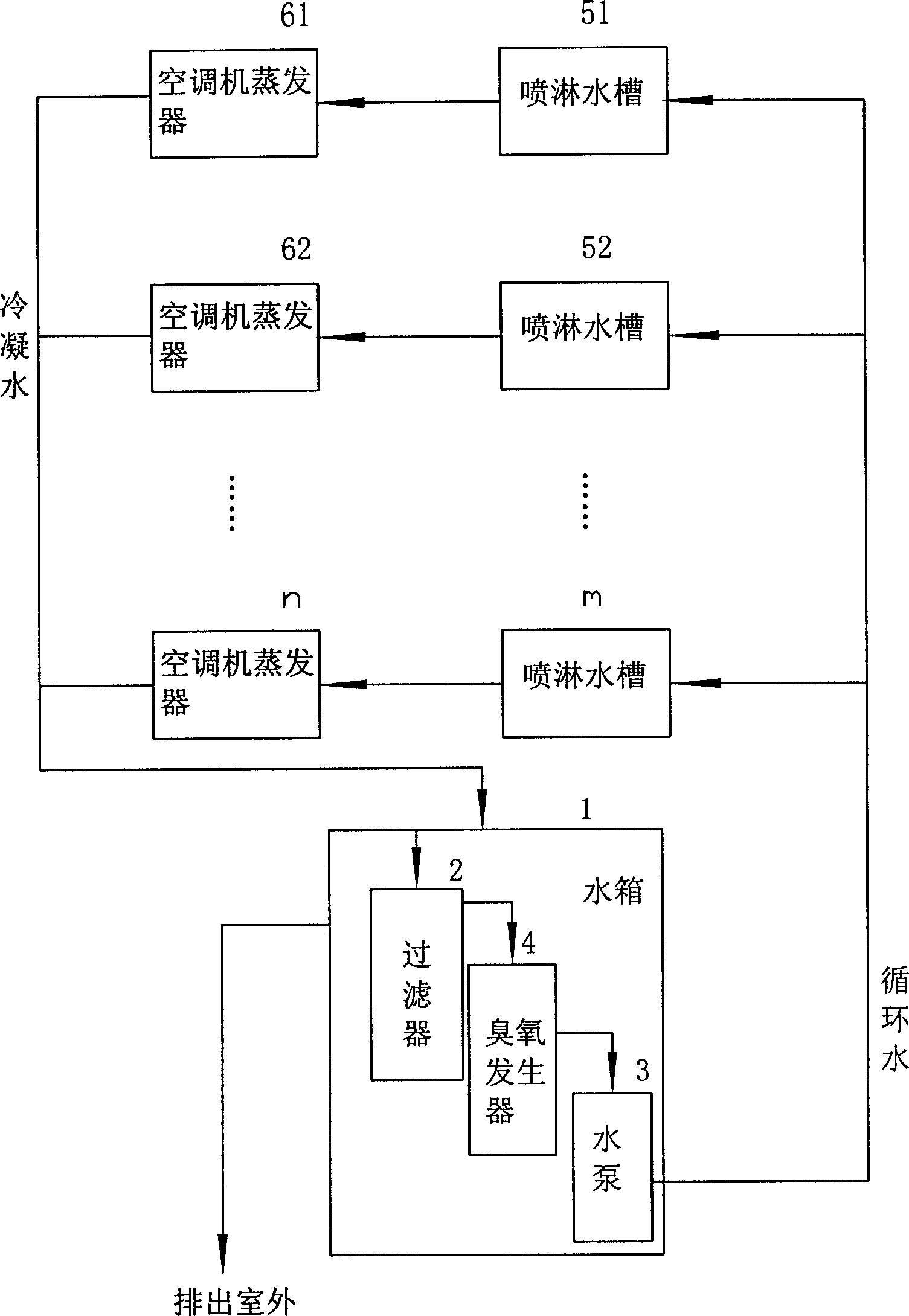

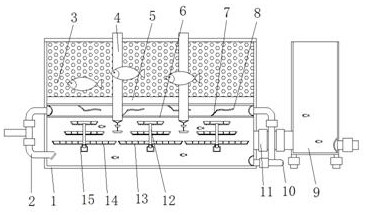

Method and apparatus for air moisture-holding purifying of single/central air conditioner

InactiveCN1752643ATemperature decrease/increaseGood energy saving effectCondensate preventionLighting and heating apparatusEngineeringMoisture

The present invention discloses a single-body / central air-conditioner air moisture-retaining and purifying method and its equipment. It is characterized by that said method includes the following steps: collecting condensate water condensed by evaporator of air conditioner, filtering, sterilizing and agin spraying the sterilized condensate water on the surface of evaporator, and making the circulating water containing condensate water implement heat exchange with air so as to attain the invented goal.

Owner:陈勇

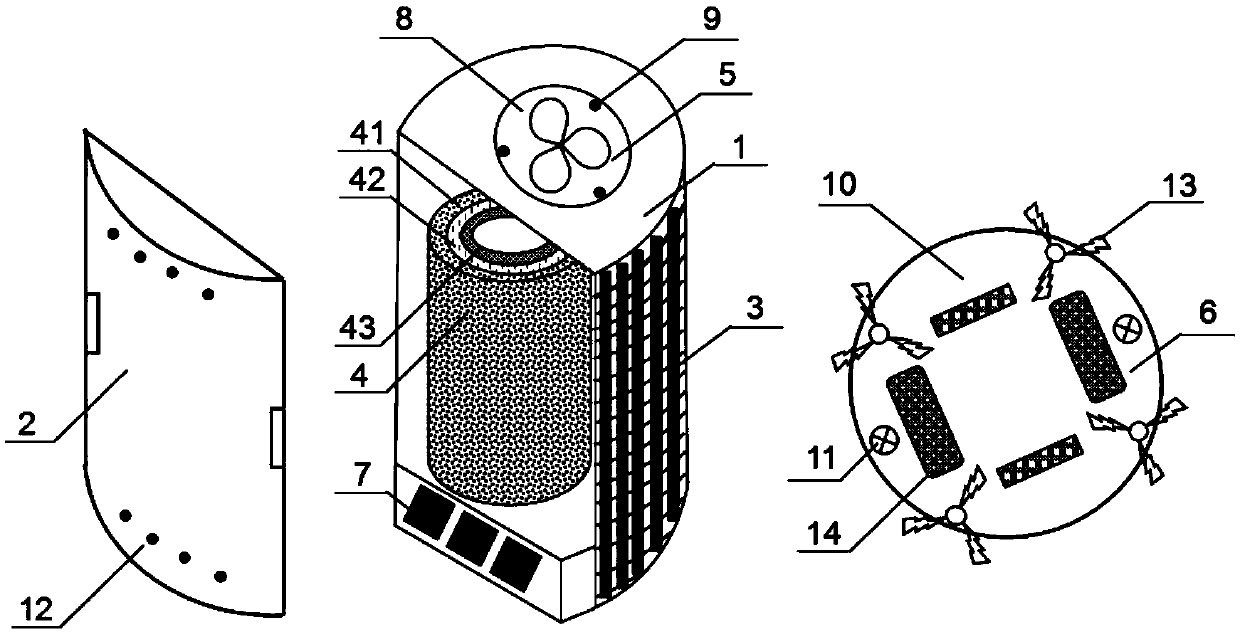

Movable efficient formaldehyde removing and air purification device

InactiveCN111013376AEffective filteringImprove air qualityGas treatmentDispersed particle filtrationActivated carbonFiltration

The invention discloses a movable efficient formaldehyde removal and air purification device, which comprises a case, a case door, an air inlet, a filter cartridge, an air outlet, a base and a controlsystem, wherein the air inlet is formed in the side surface of the case, the air outlet is formed in the upper portion of the case, the control system is arranged at the bottom of the case, a drivingdevice is arranged on the base, and the filter cartridge is arranged in the case, is of a multi-layer structure and comprises a filter layer, an adsorption layer and a decomposition layer. By adopting a purification mode of multi-stage filtration, active carbon adsorption and decomposition of formaldehyde with manganese-based oxide, solid and gas pollutants in air can be efficiently purified at the same time, and formaldehyde is thoroughly decomposed into carbon dioxide and water; the air purifier can automatically move to purify multi-area air through movable and infrared induction so as toachieve the effect of one-machine multi-room and multi-area circulating continuous purification; and the movable efficient formaldehyde removal and air purification device is high in air purificationefficiency, good in formaldehyde removal effect, simple in structure, economical, environmentally friendly and suitable for productization and large-scale application and popularization.

Owner:SHENZHEN CITY THROUGH SCI & TECH OF NEW ENERGY CO LTD

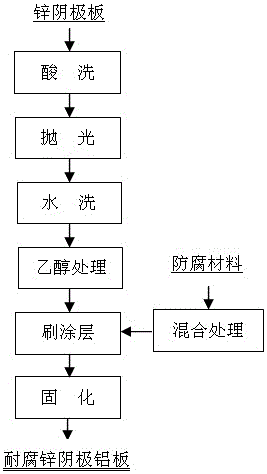

Preparation method for anticorrosive zinc cathode aluminum plate with coating

ActiveCN106757177AExtended service lifeAchieve drynessPhotography auxillary processesAnti-corrosive paintsZincEnergy consumption

The invention relates to a preparation method for an anticorrosive zinc cathode aluminum plate with a coating. Surface treatment is carried out on an ordinary zinc cathode aluminum plate, a deoiled and decontaminated zinc cathode aluminum plate with a clean surface is obtained, then, liquid coating which is mixed to be uniform is sprayed to the corrosive area of the zinc cathode aluminum plate in a spraying manner, and through curing treatment, the anticorrosive zinc cathode aluminum plate with the coating is obtained. According to the preparation method, the process investment is small, the process procedures are simple, no special requirement is made for equipment, the energy consumption is low, no pollution is caused, and the application prospects are wide.

Owner:湖南株冶有色金属有限公司

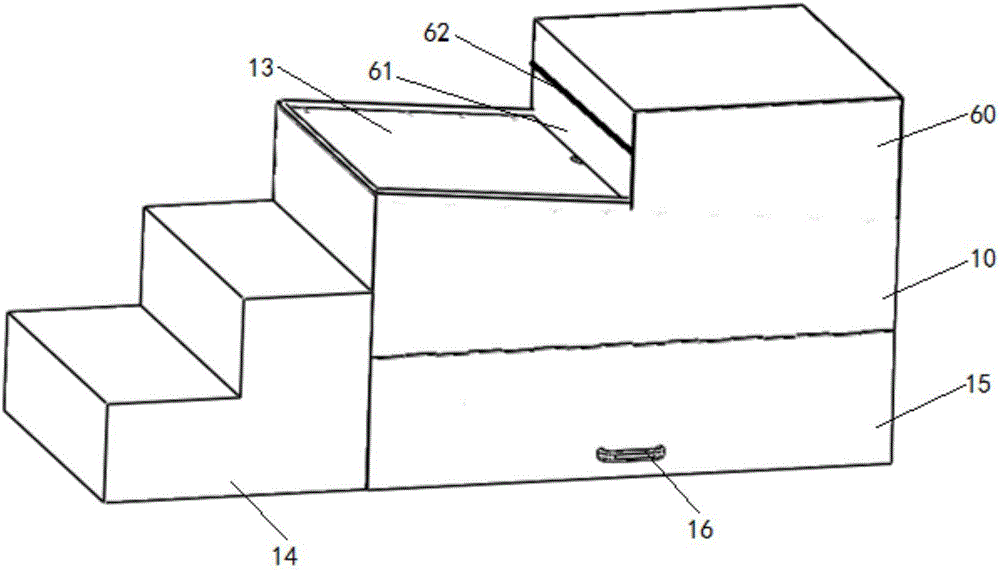

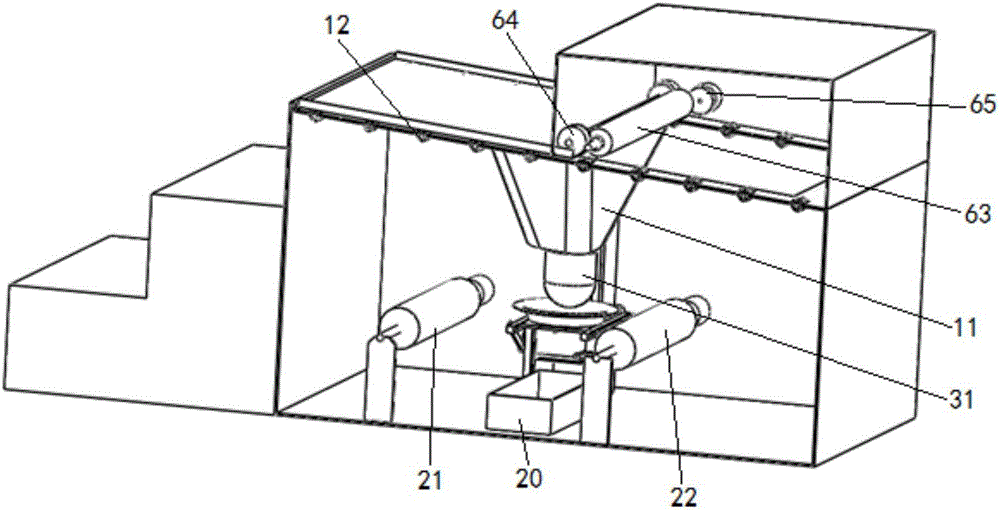

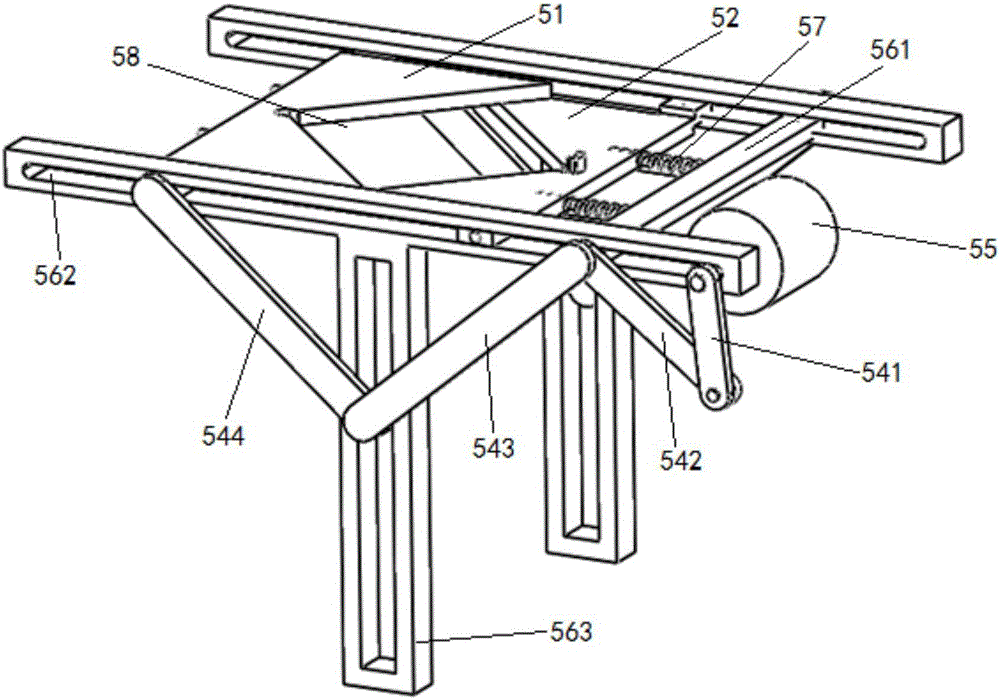

Pet excrement treatment nanny machine and pet excrement treatment method

InactiveCN106305441AGuaranteed continuous feedPrevent leakageAnimal housingEngineeringCompanion animal

The invention discloses a pet excrement treatment nanny machine and a pet excrement treatment method. The pet excrement treatment nanny machine comprises a shell frame, and an automatic excrement treatment device and a main controller which are arranged in the shell frame, wherein the automatic excrement treatment device comprises a feeding mechanism, a molding mechanism, a sealing mechanism and a mouth locking and shearing mechanism; the feeding mechanism comprises a feed roller, a tubular membrane and a material receiving roller; the molding mechanism comprises an upper die and a lower die which are used for pressing a membrane into a containing cavity in a matching way; the sealing mechanism comprises a rotary platform, and the rotary platform can rotate around the axis of the rotary platform; the mouth locking and shearing mechanism comprises a guide rail bracket, and an upper mouth locking plate, a lower mouth locking plate and a shear knife which are arranged on the guide rail bracket; an excrement inlet is formed in the shell frame at the upper end of the feeding mechanism. The pet excrement treatment nanny machine is compact in structure and simple to use, is capable of automatically and continuously collecting and packaging the excrement of a pet, and achieves the effects of cleaning and disinfection treatment, thus guaranteeing the health of the pest and a human body.

Owner:SHANGHAI DIANJI UNIV

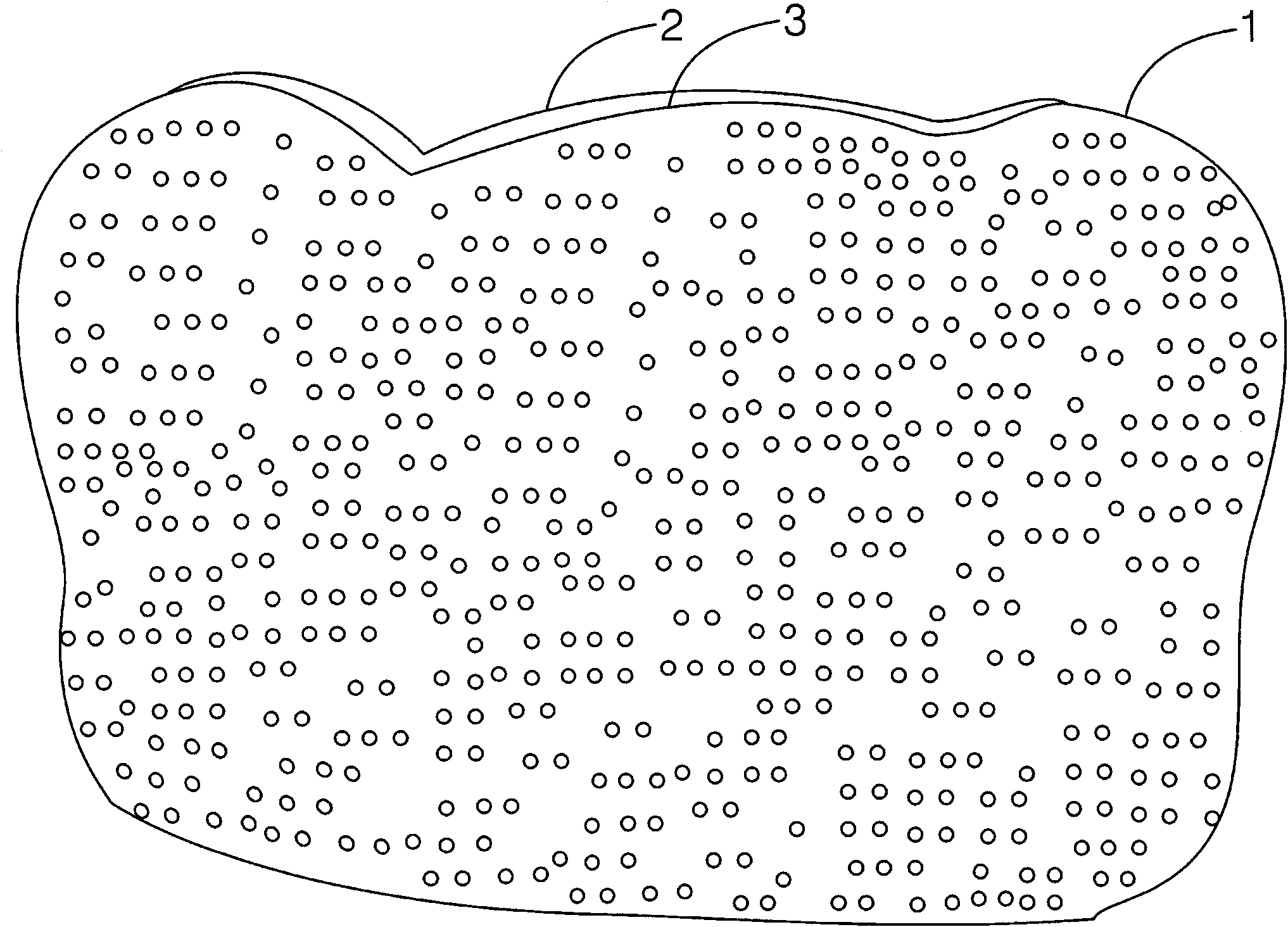

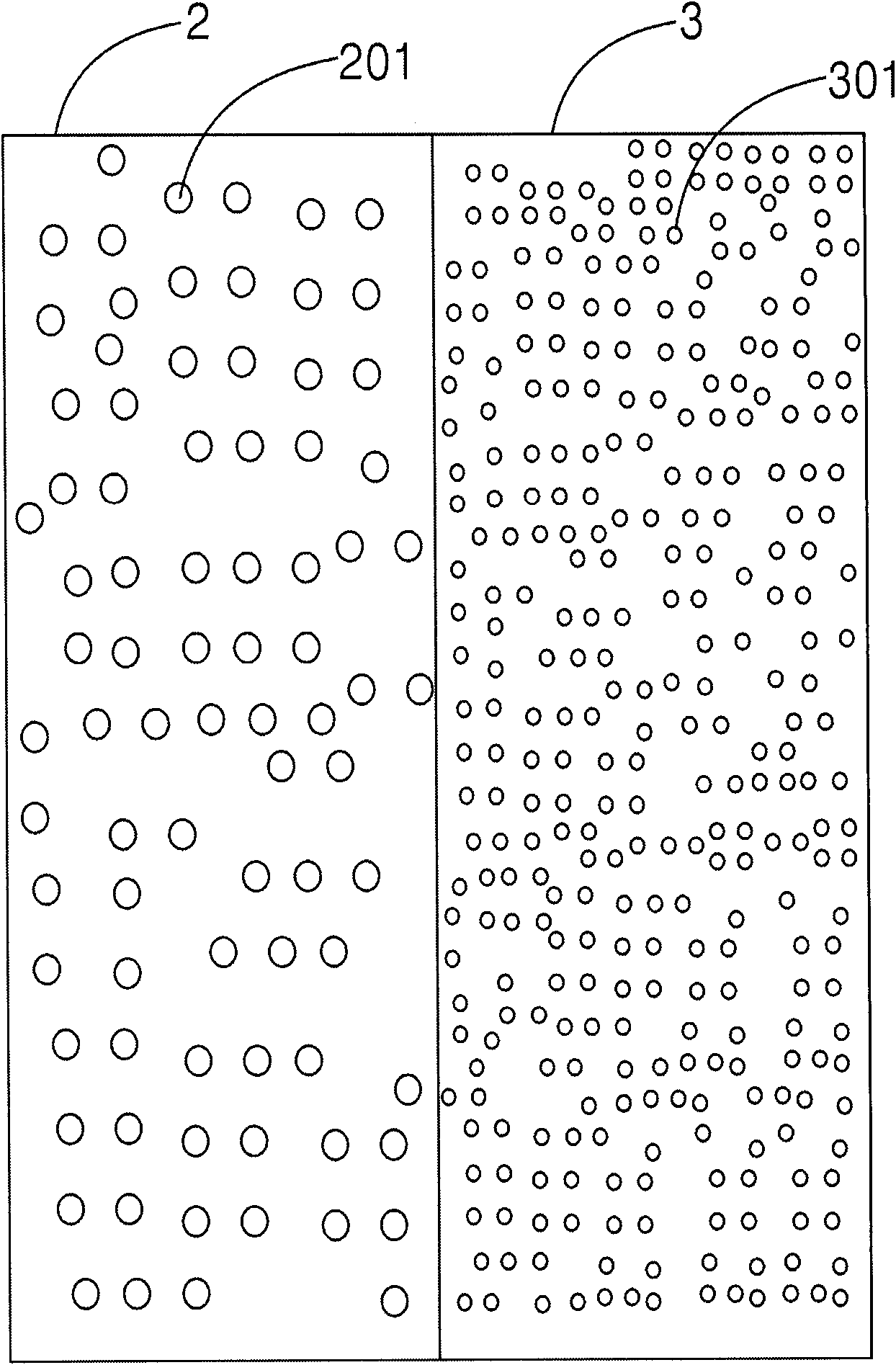

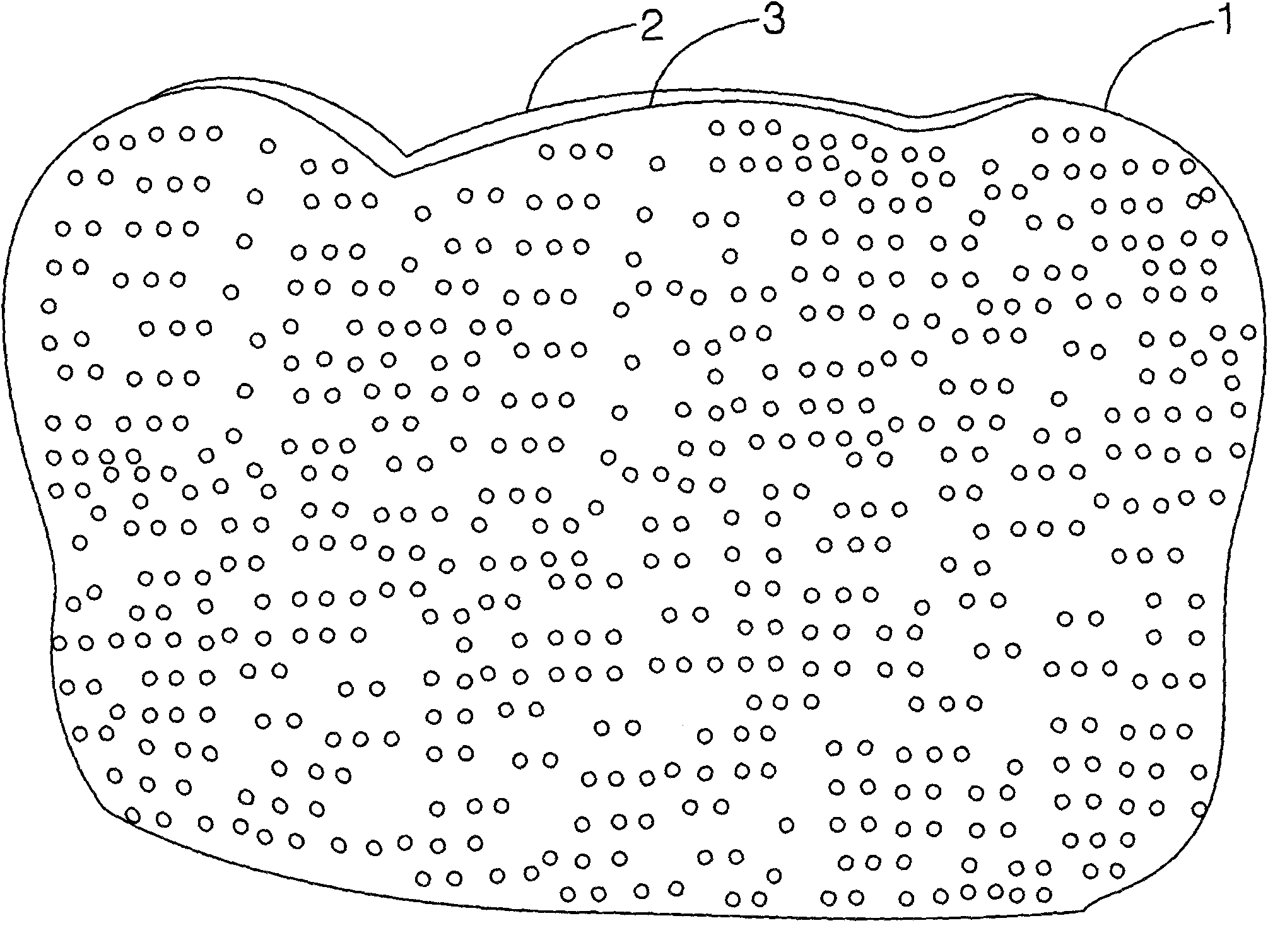

Double-sided heterogeneous glucomannan sponge and manufacturing method thereof

InactiveCN101816525ASimplify complex proceduresShorten production timeBathroom accessoriesColloidVolumetric Mass Density

The invention provides a double-sided heterogeneous glucomannan sponge and a manufacturing method thereof. The sponge comprises a first sponge and a second sponge. The manufacturing method comprises the following steps of: preparing a glucomannan mixture, heating the glucomannan mixture for a certain time to form first colloid, covering the first colloid on the un-reacted glucomannan mixture, further heating the first colloid and the un-reacted glucomannan mixture to make the un-reacted glucomannan mixture form second colloid, and sticking the first colloid and the second colloid on a joint face so that the first colloid and the second colloid are relatively combined to integrally form the double-sided heterogeneous glucomannan sponge. The first sponge and the second sponge are manufactured in different reaction time so that the interiors of the two sponges have different hole densities, and the double-sided heterogeneous glucomannan sponge with two surfaces with different roughness degrees can be applied to different textures of human bodies and achieve double effects of cleaning and maintenance.

Owner:GUANGZHOU CITY LITI TRADING

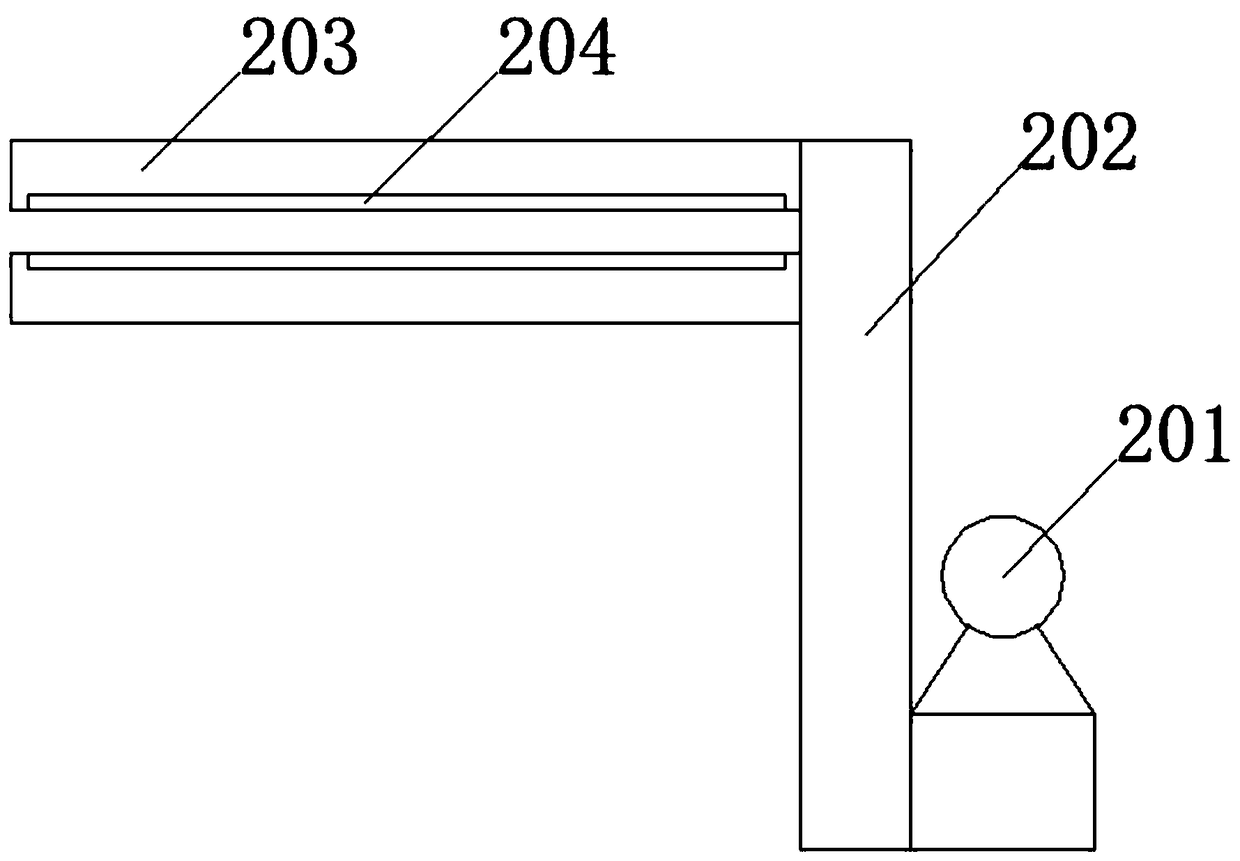

Long gauze drying device with pre-drying

InactiveCN108895801AFully dryAchieve drynessDrying gas arrangementsDrying machines with progressive movementsLaboratory ovenEngineering

The invention provides a long gauze drying device with pre-drying, which relates to the technical field of the long gauze drying device. Which is provided with a pre-drying long gauze drying device, including the rack, A feeding rotating shaft is movably installed on the left side of the top of the rack, A cooking device is fixedly installed on the top of the rack, a pre-drying device is fixedly installed on the top of the rack, an air inlet pipe is fixedly installed on the top of the pre-drying device, an air inlet port is arranged on the right side port of the air inlet pipe, and an oven isfixedly installed on the top of the rack. Which is provided with a pre-drying long gauze drying device, contacting the drying air with waste heat in the drying device with the air inlet pipe connectedto the pre-drying device through the first air duct and the second air duct, In this way, the waste heat inside the drying device can be transferred to the pre-drying device for pre-drying the long gauze, and the long gauze can be pre-dried while being extruded by the upper pressing shaft and the lower pressing shaft, so that the long gauze can be dried more fully and thoroughly.

Owner:江西美宝利实业有限公司

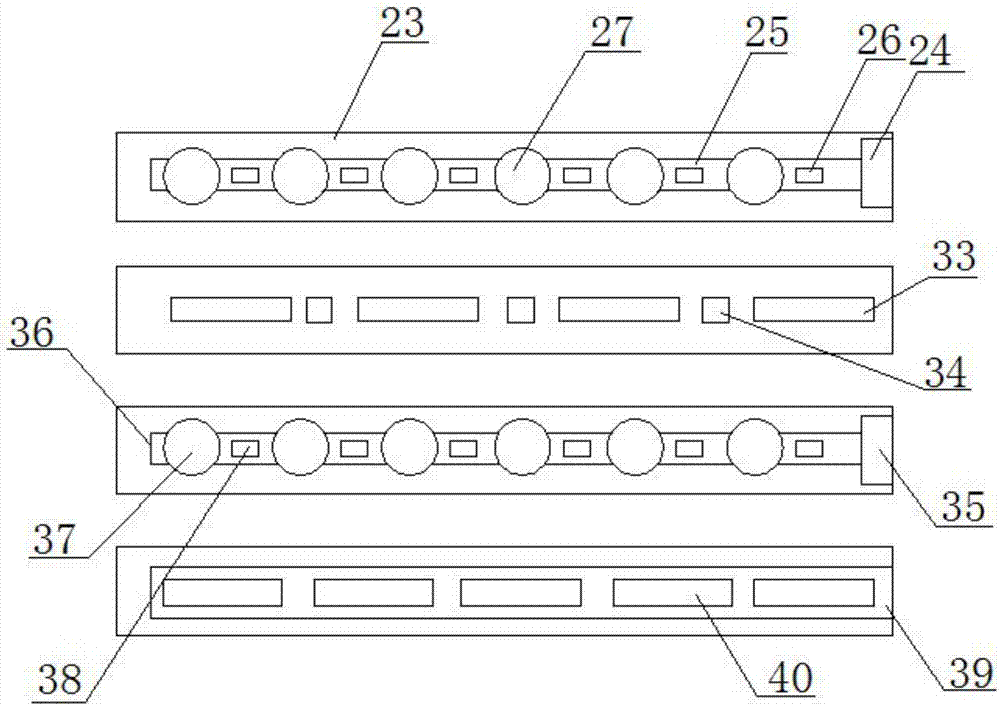

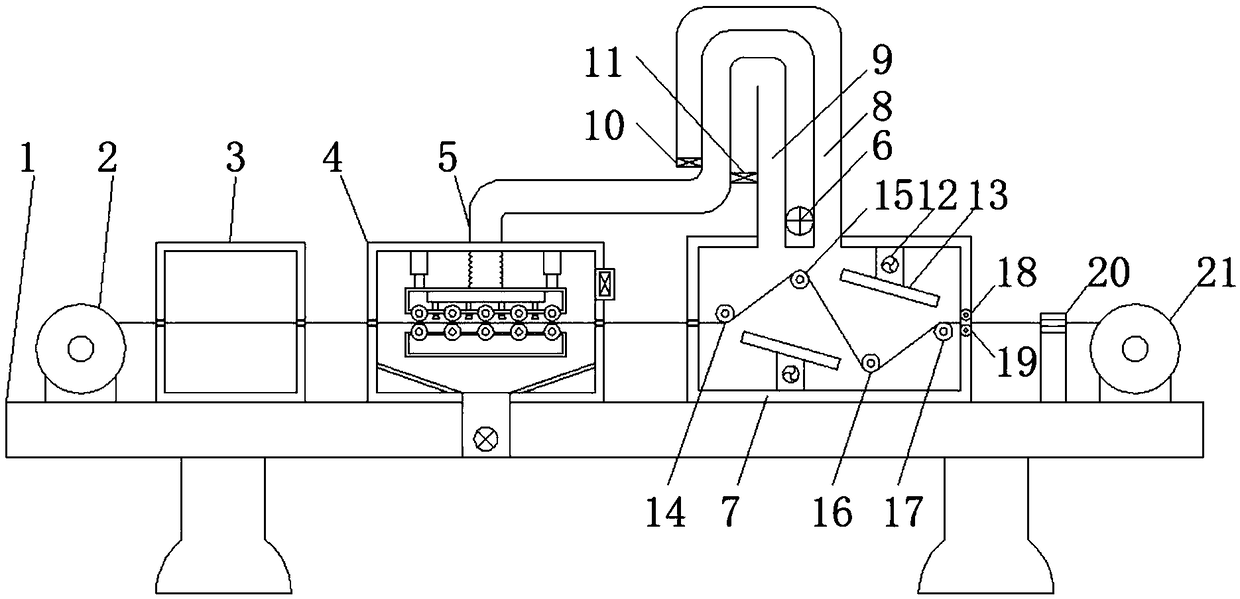

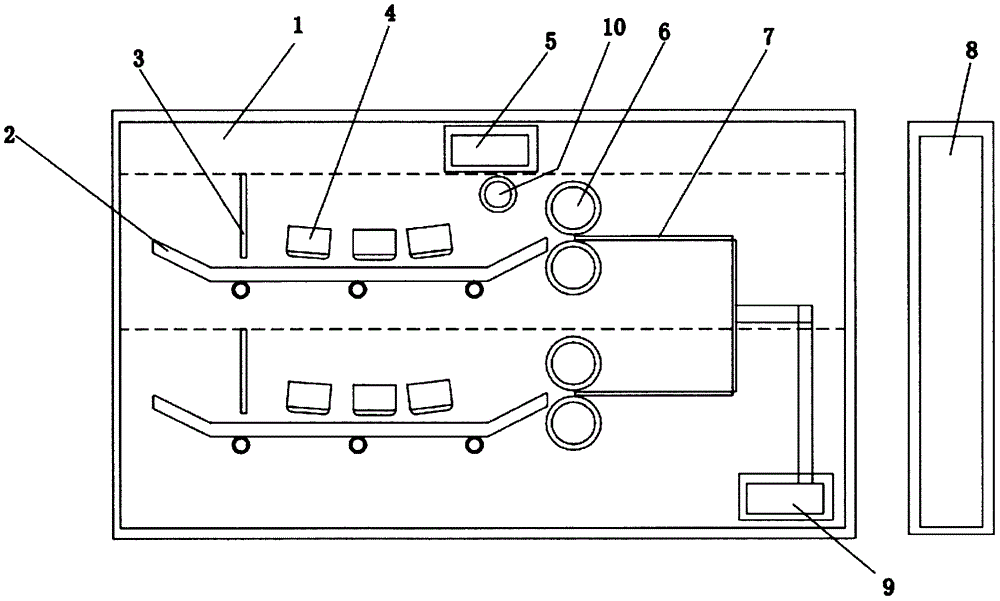

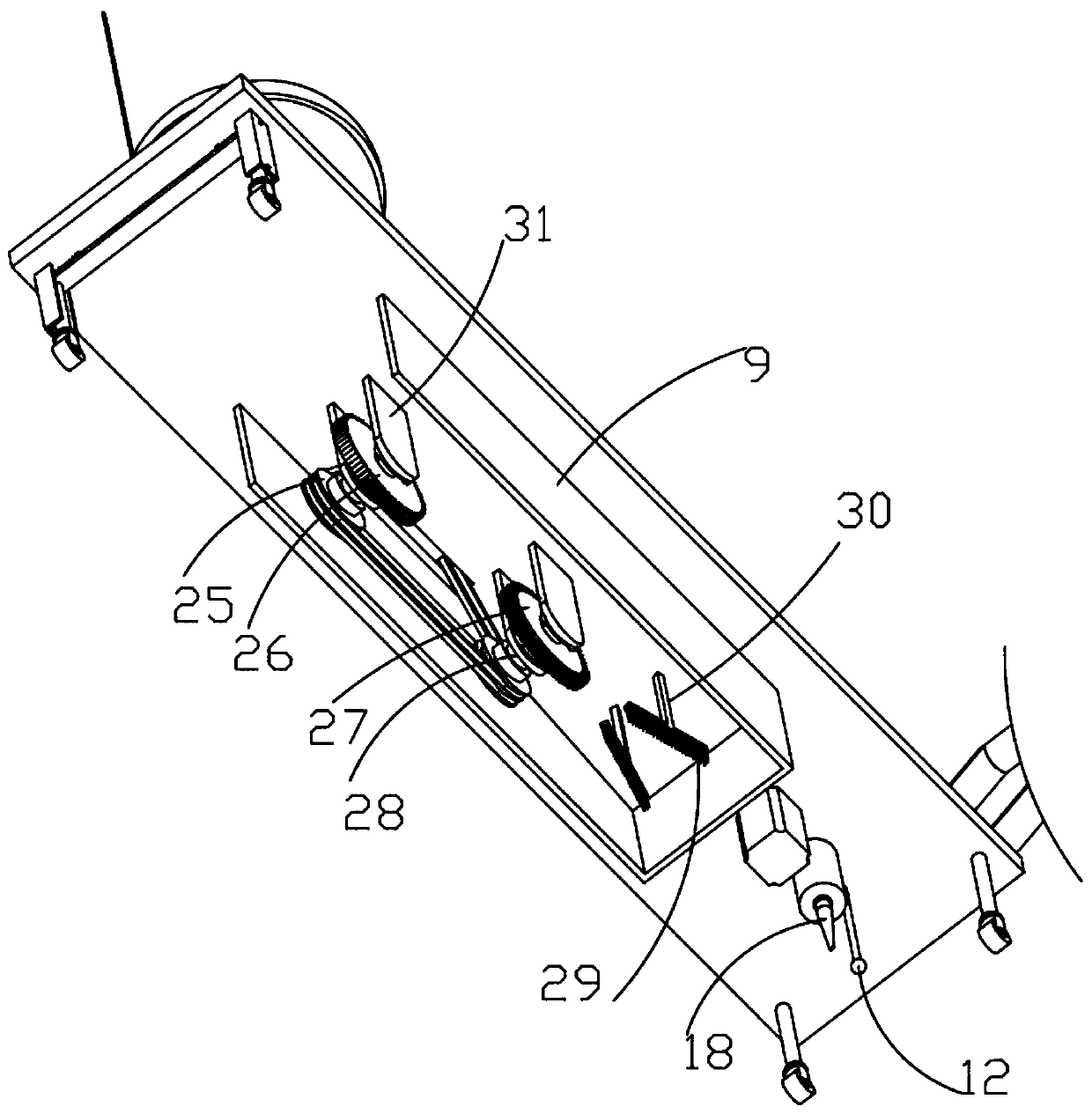

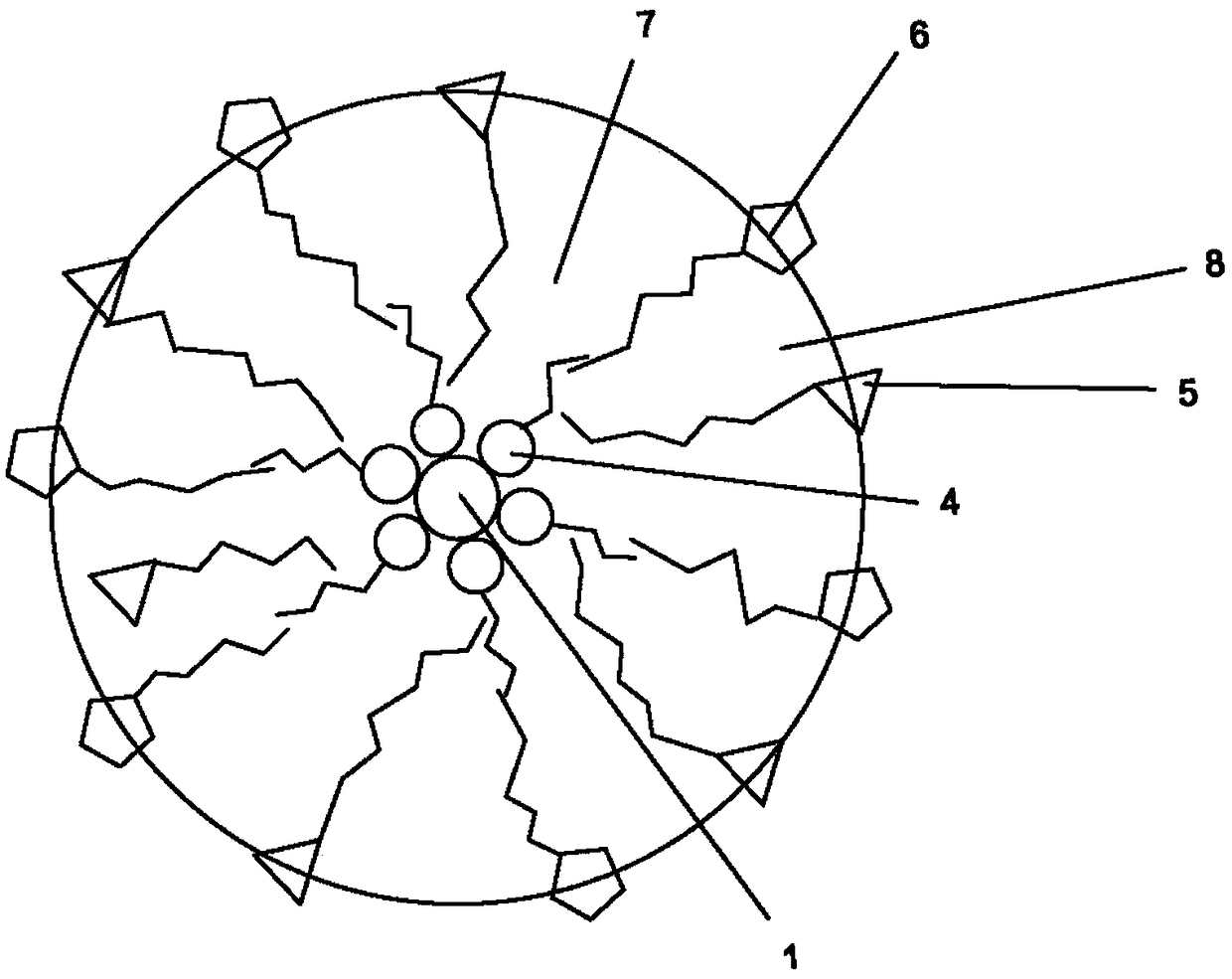

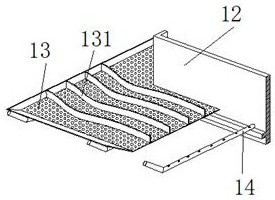

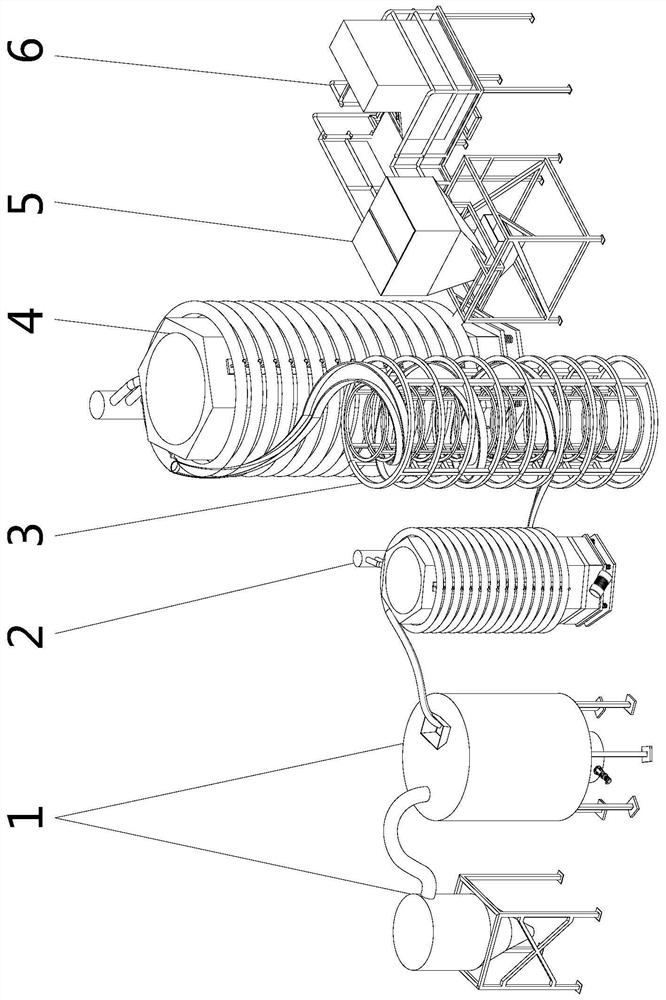

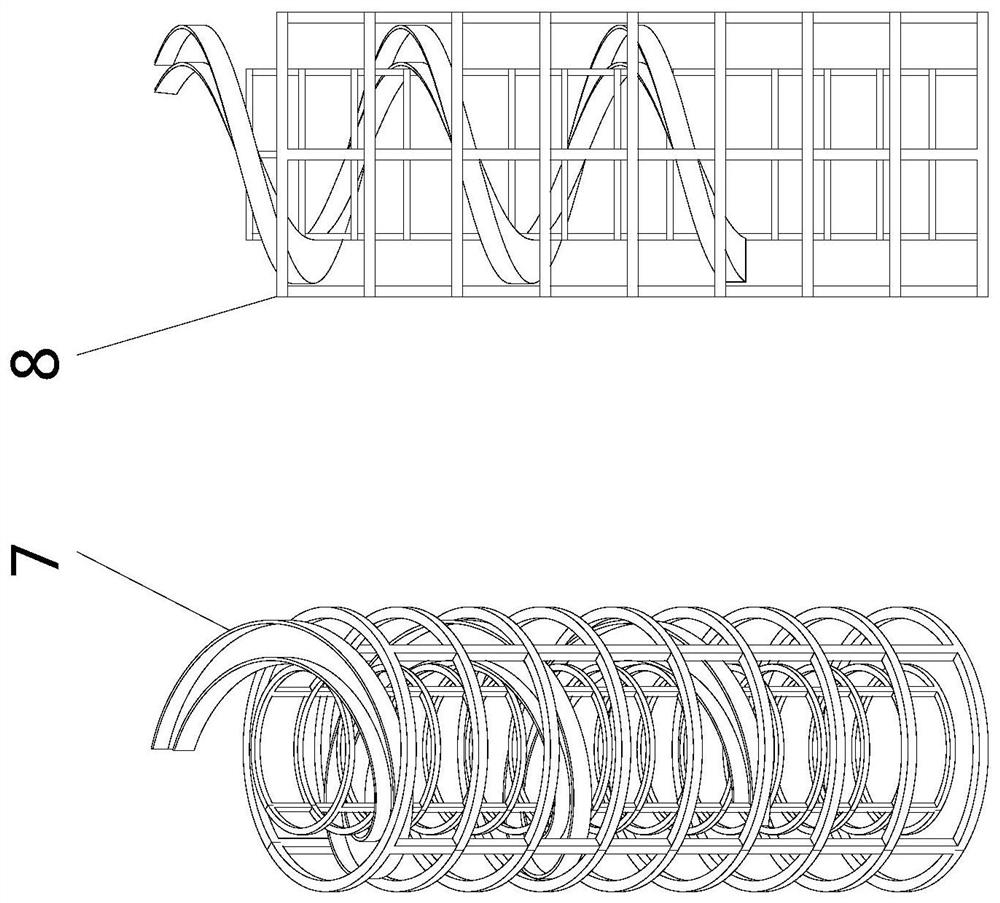

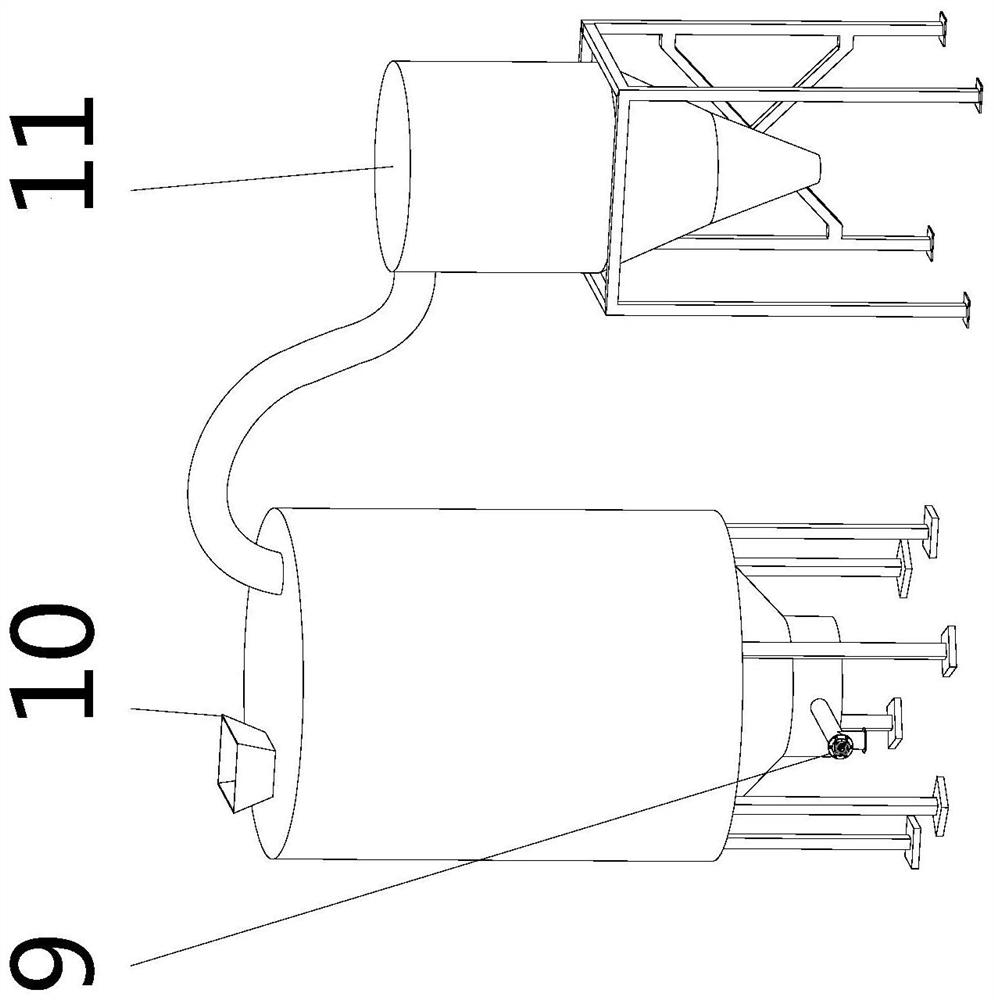

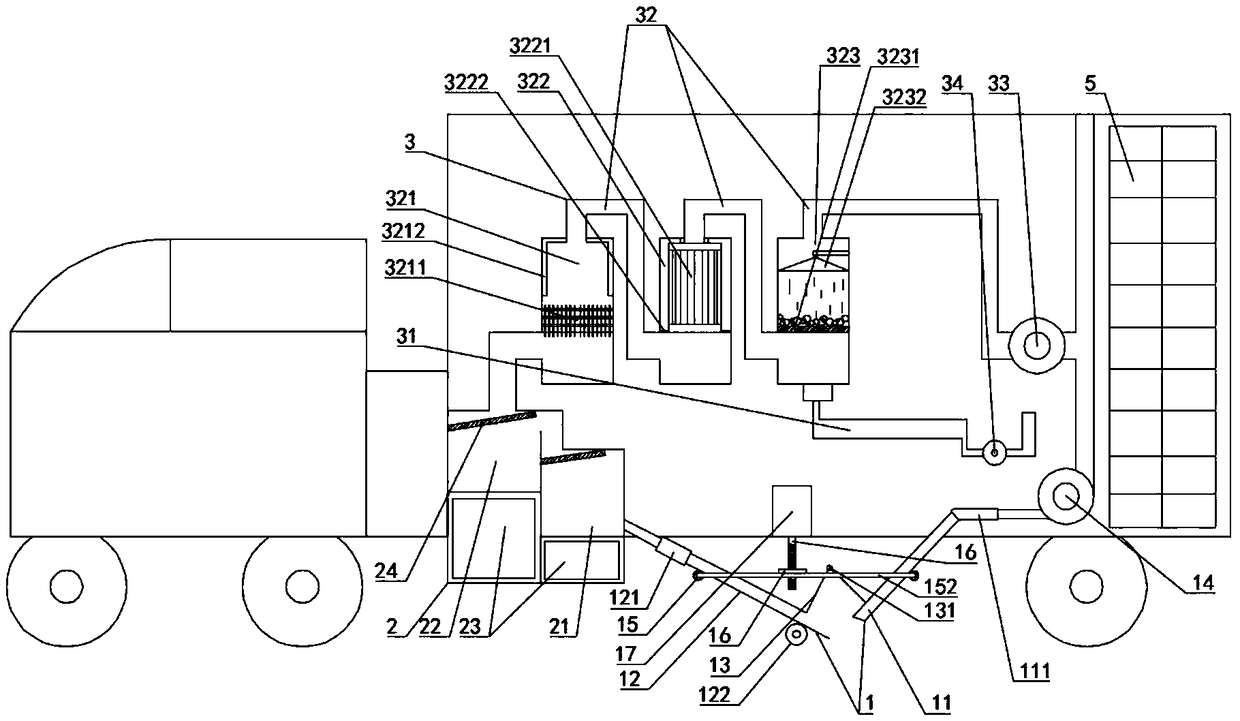

Automatic natural casing processing system

ActiveCN105685194AImprove cleanlinessEasy for workers to operateAnimal intestine cleaningProcess engineeringAssembly line

The invention discloses an automatic natural casing processing system which is characterized by comprising a stander, a plurality of groups of assembly lines supported on the stander and a PLC programming system for controlling the assembly lines, wherein each assembly line comprises a material feeding trough, a distance measurement mechanism, a casing burr scraping mechanism, a salt scattering mechanism and a sleeve shrinkage mechanism; and the multiple groups of assembly lines share a water storage mechanism or independently adopt a water storage mechanism. A worker can operate the automatic natural casing processing system easily; the machine cost is low, and the automatic natural casing processing system is simple in structure; the labor is saved; and the economic benefit is greatly enhanced, and popularization is facilitated.

Owner:江苏亚亮机械科技有限公司

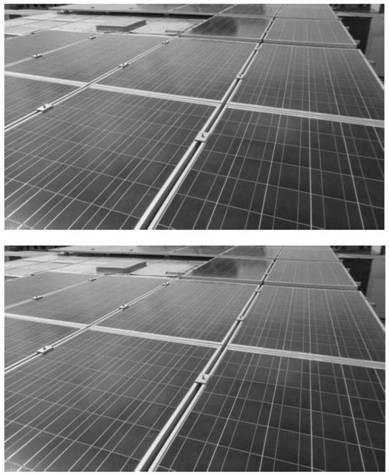

Solar panel cleaning system based on machine vision

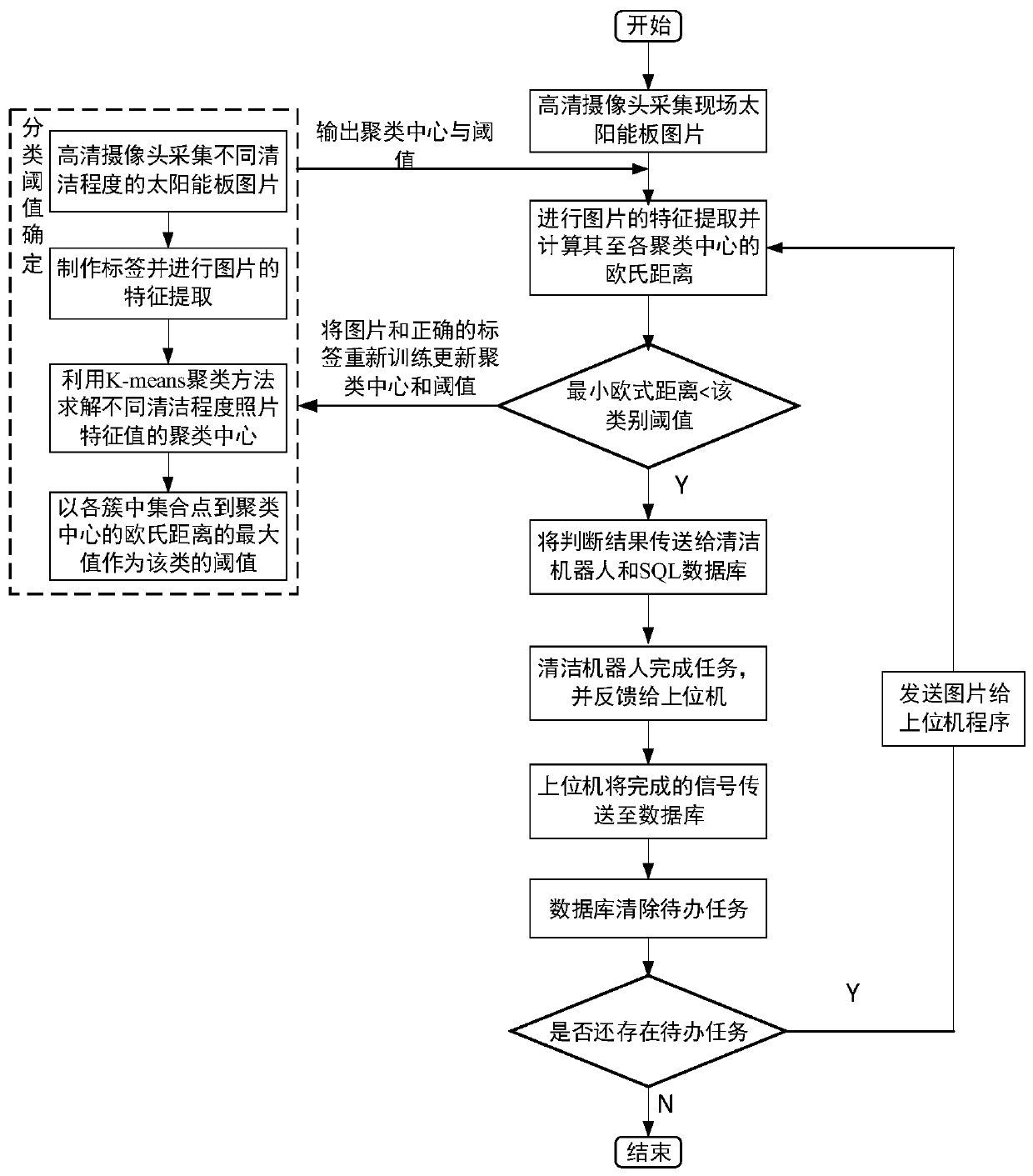

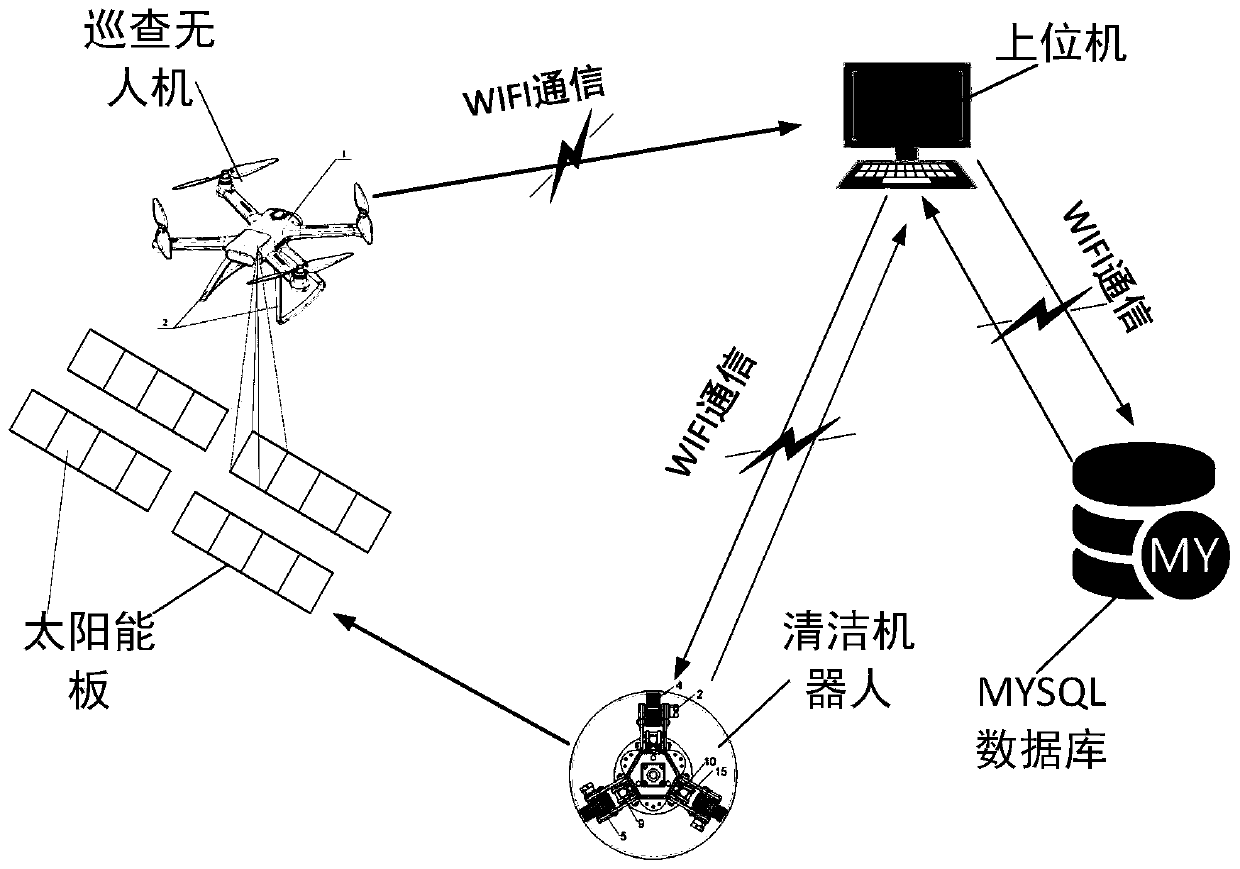

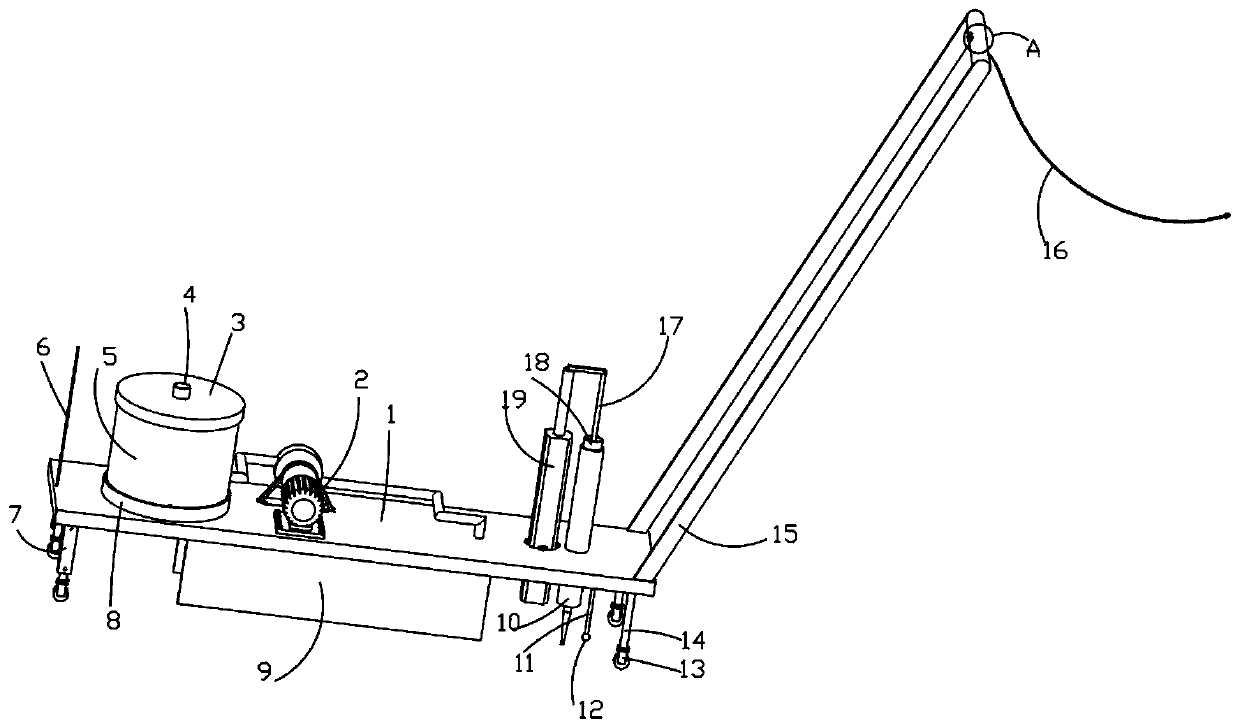

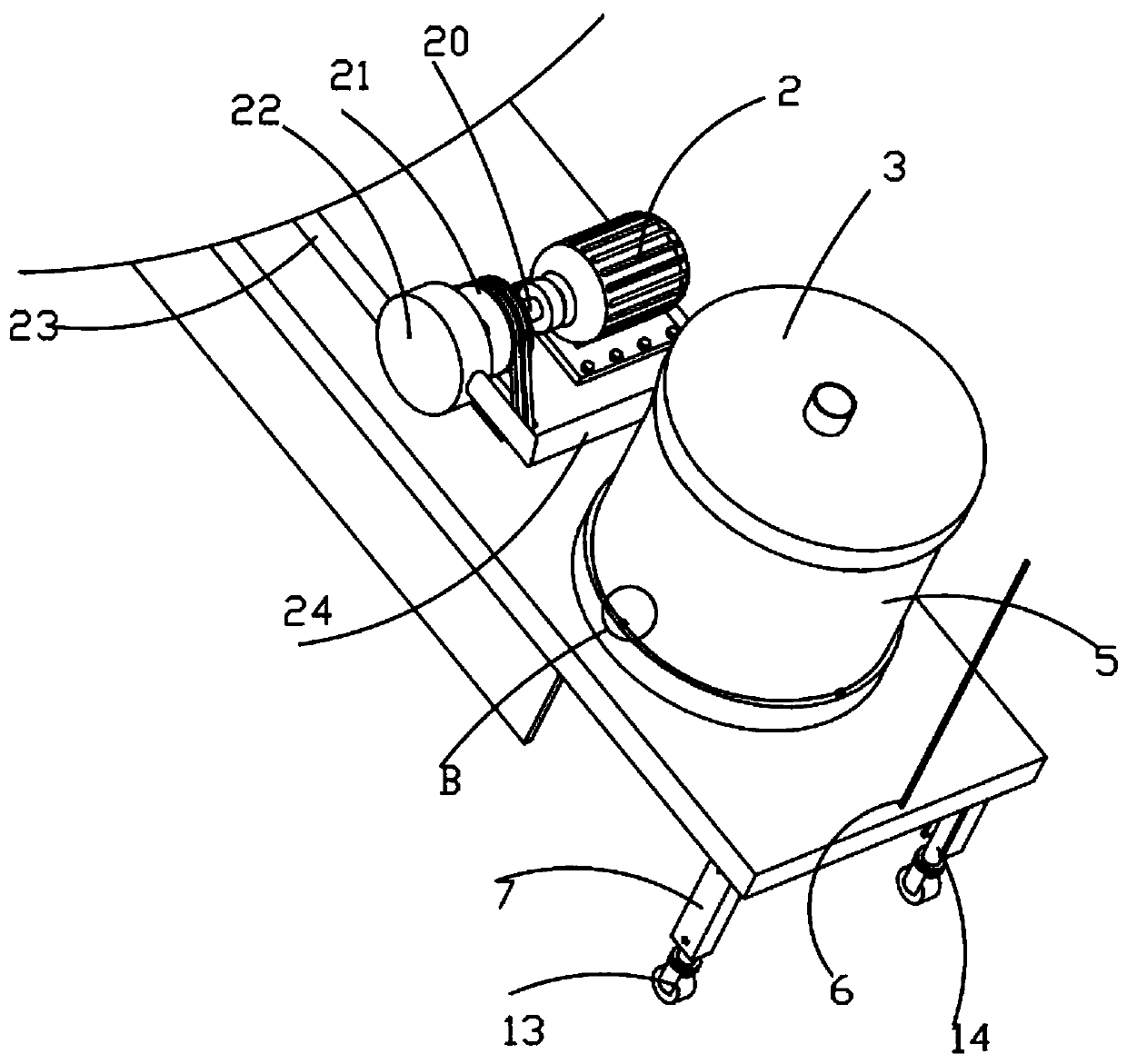

PendingCN111563467AImprove generalization and recognition accuracyAchieve cleanlinessData processing applicationsPhotovoltaicsEngineeringReal-time computing

The invention discloses a solar panel cleaning system based on machine vision. The method comprises the following steps: step 1, collecting on-site solar panel photos, and uploading the photos to an upper computer through WIFI; step 2, performing multi-dimensional feature vector extraction on the photosby an upper computer program; step 3, calculating the Euclidean distance between the multi-dimensional feature vector and each predetermined clustering center; step 4, comparing the minimum Euclidean distance with a predetermined threshold value of the category; step 5, enabling acleaning robotto complete the task and feed back the task to the upper computer; step 6, enabling the upper computer to send the completed signal to a database through WIFI; and step 7, enabling the database to clear away a to-do task and check whether the to-do task exists at the moment, if yes, sending the data to the upper computer program again, executing the step 2 and otherwise, finishing the whole closed-loop process. The cleaning of the solar panel is effectively realized, and power generation efficiency is improved.

Owner:JINLING INST OF TECH

Decorative joint filling device for decoration and using method thereof

ActiveCN111535558AGuaranteed integrityImprove bonding effectDirt cleaningCleaning using toolsBar pressingDrive motor

The invention relates to a decorative joint filling device for decoration and a using method thereof. The decorative joint filling device comprises a bottom plate, a driving motor and an electric pushing rod, wherein the bottom plate is provided with a circular ring, the driving motor, a hollow drum, the electric pushing rod, a mounting cylinder and a push handle; the circular ring is provided with an air filtration structure; the air filtration structure is provided with a hose; the hose is connected to the hollow drum; the hollow drum is provided with a rotating shaft, fan blades and an airinlet pipe; the right end of the air inlet pipe is arranged at the bottom of the bottom plate; the driving motor is connected to the rotating shaft; the rotating shaft is provided with a driving beltpulley; the driving belt pulley is provided with a belt; the belt is provided with a driven belt pulley; the driven belt pulley is provided with a rotating rod; the rotating rods are provided with a cutting disk and a rotating disk; the rotating disk is provided with bristles; the rotating disk is provided with a dust pushing structure; the dust pushing structure is provided with a dust accumulation structure; the mounting cylinder is provided with a decorative joint filler cylinder; the electric pushing rod is provided with an L-shaped pressing rod; the bottom plate is provided with a straight rod; and the straight rod is provided with a pressing ball. The decorative joint filling device for decoration and the using method thereof have the advantages of realizing the cleanliness in cut joints, avoiding the influence of dust in the cut joints on decorative joint filler, improving the bonding effect of the decorative joint filler and tiles, and ensuring the integrity of decorative jointfilling.

Owner:河南瑞隆建设有限公司

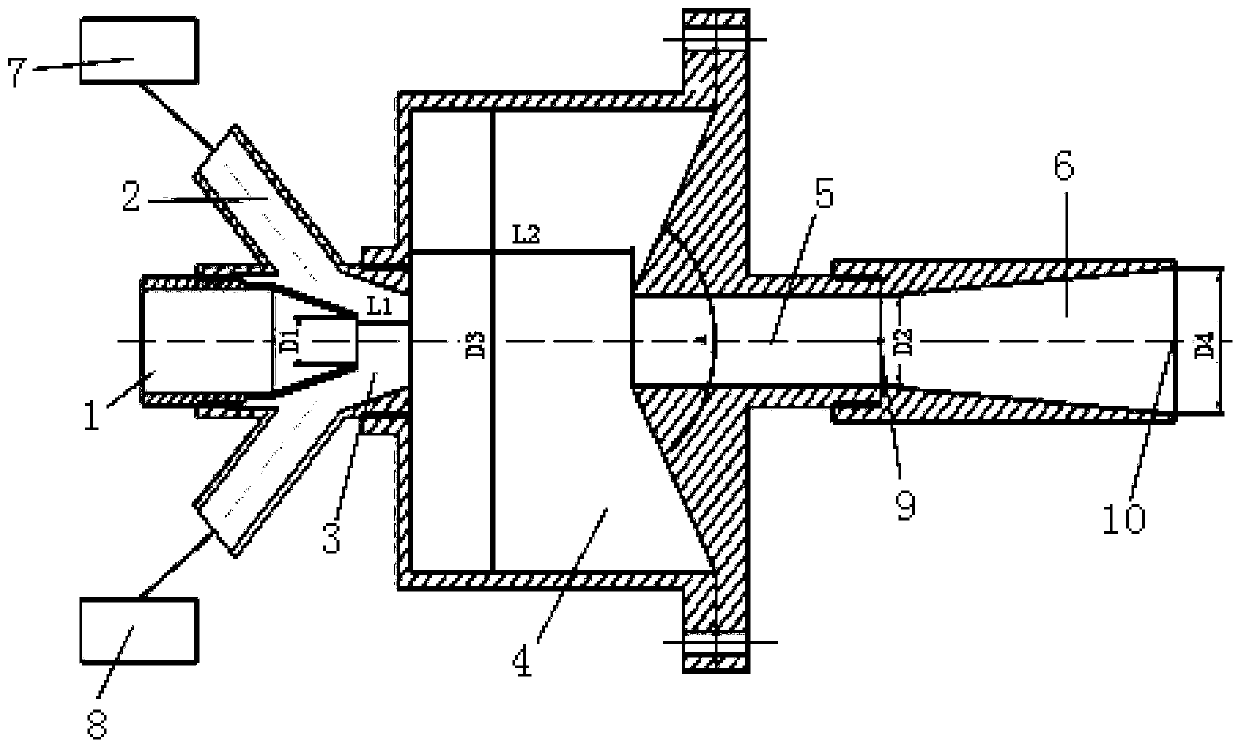

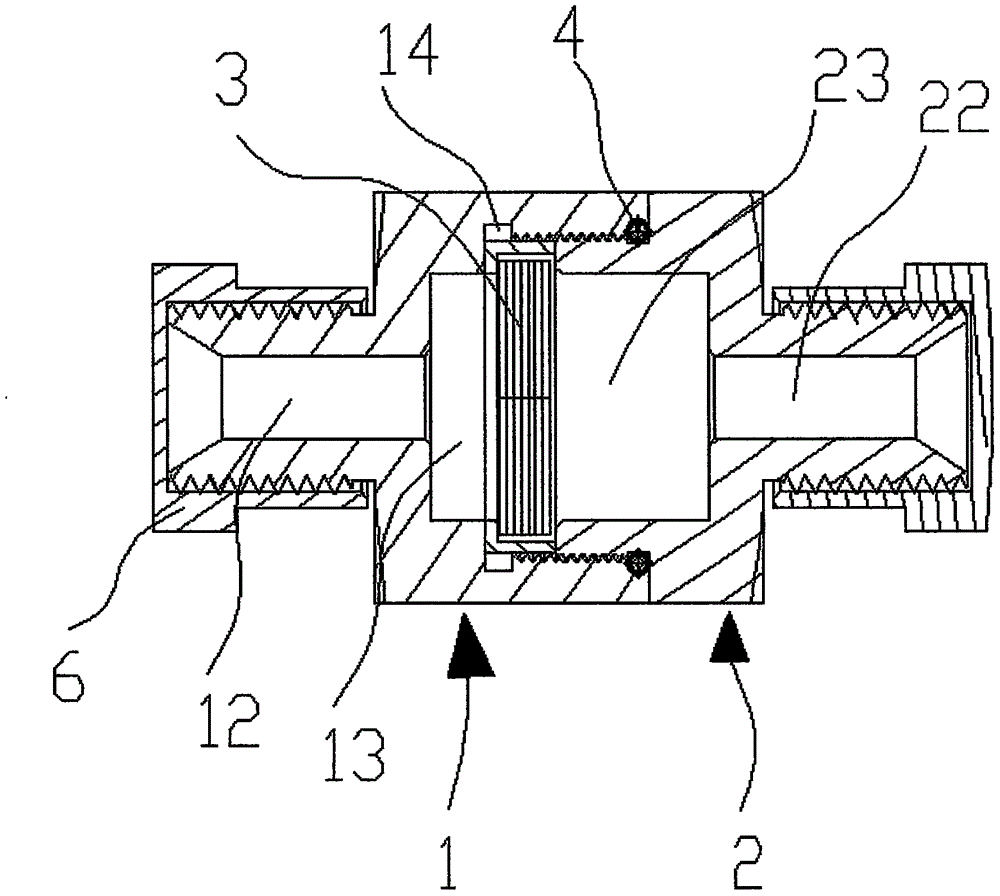

Cavitation jet-flow ozone degradation oxygenating device for marine product breeding

InactiveCN109824152AImprove efficiencyReduce length dimensionWater aerationSustainable biological treatmentMicroorganismCavitation

The invention relates to a cavitation jet-flow ozone degradation oxygenating device for marine product breeding. The device comprises a spray nozzle, an air suction chamber, air suction pipes, a self-excitation vibration chamber, pipework and a diffusion pipe; the outer side of the air suction chamber is provided with the air suction pipes and a liquid inlet, the spray nozzle is connected to the liquid inlet of the air suction chamber, and the air suction chamber is connected with an inlet of the self-excitation vibration chamber; the pipework is connected with an outlet of the self-excitationvibration chamber, and an inlet of the diffusion pipe is connected with an outlet of the pipework. A water pump pumps working water in an aeration tank, the working water is subjected to pressurization and then sprayed out from the spray nozzle, ozone is sucked into the air suction chamber through the air suction pipes and mixed with the water, the mixture enters the self-excitation vibration chamber to form a pulse cavitation jet flow, and finally the liquid-gas mixture is discharged through the diffusion pipe. According to the cavitation jet-flow ozone degradation oxygenating device, a constant jet flow is changed into a pulse jet flow, the capacity of gas entrainment of the airflow is improved, the cavitation jet flow is generated, oxygenating is completed, microorganisms in the waterare removed for achieving the function of oxygenating and cleaning at the same time, the ozone can be degraded through the cavitation jet flow, and the mass transfer efficiency of oxygen is improved.

Owner:SHANDONG UNIV

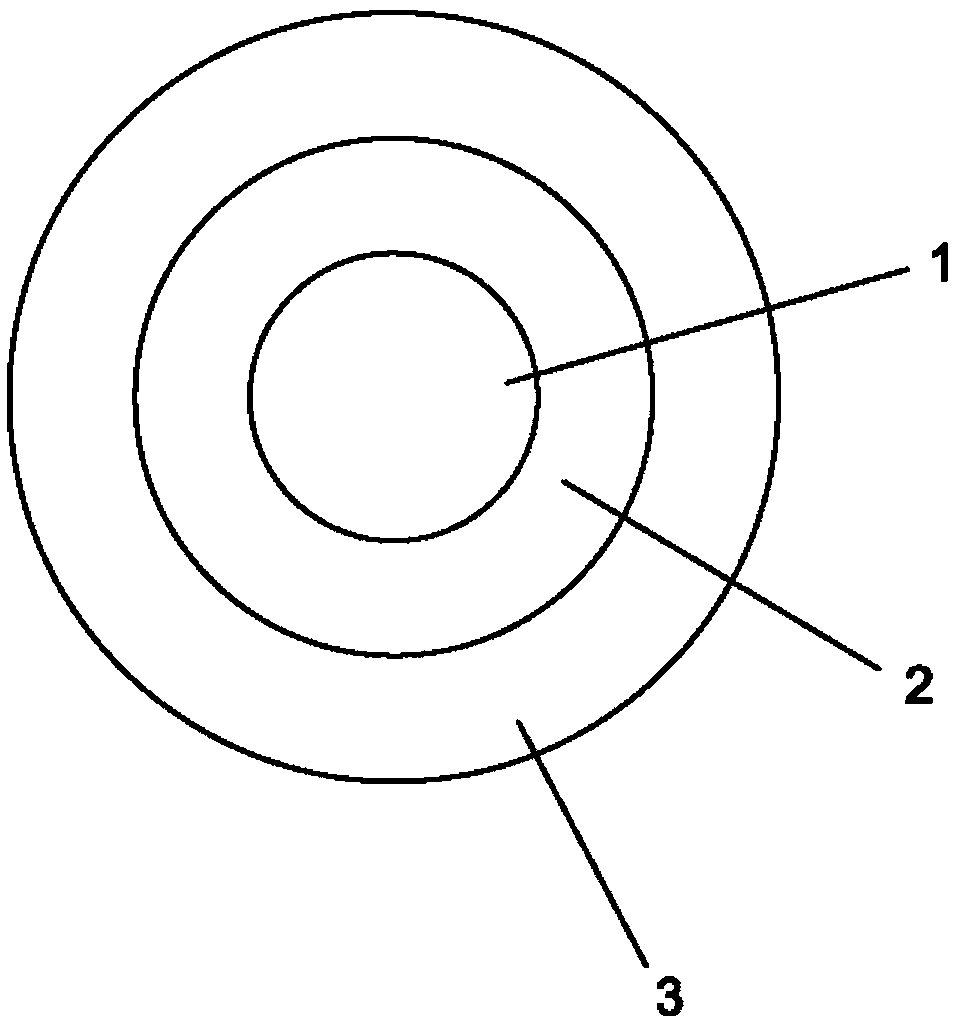

Soap-base compound and preparation method and application thereof

ActiveCN108587823AIncrease surface areaFully dispersedCosmetic preparationsToilet preparationsPolyolCore shell

The invention aims to provide a soap-base compound firstly. The soap-base compound has a multi-layer core-shell structure and a stable structure; the invention aims to provide a preparation method ofthe soap-base compound secondly, and the prepared soap-base compound has a stable structure and stable properties; the invention aims to provide application of the soap-base compound thirdly. The soap-base compound has a core-shell structure, a main component of a shell layer is soap, an emulsifier, polyol and water are further included, and a core material comprises water and polyol; and the soap-base compound has a short period of saponification time and mild conditions, and the prepared soap-base compound has a stable structure, stable properties and a wide application range.

Owner:广州浪奇日用品有限公司 +1

Agricultural fish fry hatching pond device

ActiveCN111631176AAchieve water changeAchieve cleanlinessClimate change adaptationPisciculture and aquariaFisheryWater flow

The invention discloses an agricultural fish fry hatching pond device, and relates to the technical field of agriculture. The problems that garbage in a pond is accumulated at the bottom in the roe hatching process, cleaning is difficult, and the hatching rate of fish fries is affected are solved. The device specifically comprises a pool body, a plurality of water inlet pipes of a three-way structure are fixedly installed at the end of the pool body, two water inlet valves are fixedly installed at the ends of the water inlet pipes, a plurality of drainage pipes of a three-way structure are fixedly installed at the other end of the pool body, and two drainage valves are fixedly installed at the ends of the drainage pipes. Roes fall into the upper portion of the hatching tray in an accelerated mode through water potential, water flows in and out of the middle layer in the hatching stage, garbage generated by big fishes above can be washed away while pond water is replaced, a valve at thelower end is opened regularly, water flows in and out downwards, garbage at the bottom of a pond is washed away, various water inlet and outlet modes can achieve the effects of changing and cleaningwater in the pond, and the hatching survival rate of fish fries is increased.

Owner:雷州海茂水产种业科技有限公司

Tooth paste containing artemisia rupestris extract and preparation method thereof

ActiveCN103655301AAvoid breedingPlay a protective effectCosmetic preparationsToilet preparationsMedicinal herbsDisease

The invention discloses a tooth paste containing an Artemisia rupestris extract. The tooth paste comprises an Artemisia rupestris extract, calcium carbonate, glycerin, sodium lauryl sulfate, carboxymethyl cellulose, aspartame, and other auxiliary components. The invention has the benefits that the tooth paste makes full use of traditional Uyghur nationality folk technology on health care, and utilizes the efficacy of resisting bacterium, resisting virus, and resisting allergy of national herbs and traditional Chinese medicine; Artemisia rupestris extract is mixed with other auxiliary components, according to Uyghur medicine and traditional Chinese medicine theories, to form the tooth paste which can resist bacterium, resist virus, resist allergy, and clear heat-toxin, is suitable for long-term use, can improve the capacity of a human body to resist bacterium and resist virus, can prevent disease entering from a mouth, and has the effect of clearing an oral cavity and protecting teeth.

Owner:URUMQI YI ZHI HAO BIOTECH

Vertical vibration conveying and drying integrated device

PendingCN111912212AReduce consumptionReduce wearDrying gas arrangementsDrying solid materialsVertical vibrationVertical plane

The invention relates to the technical field of material transportation, in particular to a vertical vibration conveying and drying integrated device. The device comprises a feeding structure, a discharging structure, a material conveying structure and a heater. The material conveying structure comprises two or more vertical conveying pipelines and a driver, and every two adjacent vertical conveying pipelines are connected in series in the material conveying direction. The vertical conveying pipelines are driven by the driver to do horizontal plane circular motion and vertical plane up-and-down vertical motion. A feeding hole at the lower part of the material conveying structure is communicated with the feeding structure, and a discharging hole at the upper part of the material conveying structure is communicated with the discharging structure. The heater is used for heating the materials in the vertical conveying pipelines. By means of the structure of the vertical conveying pipelinesand the heater, after-production drying can be achieved while grains are vibrated and vertically conveyed, the labor intensity of workers can be effectively reduced, the grain conveying and drying efficiency is improved, the investment cost of a grain conveying and drying system is reduced, a traditional grain conveying and drying mode is changed, and rapid grain conveying is guaranteed.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Novel efficient air-flowing type floor cleaning vehicle

PendingCN108824312APrevent overflowImprove work efficiencyCombination devicesElectrostatic separationWater storage tankRechargeable cell

The invention relates to a novel efficient air-flowing type floor cleaning vehicle. The novel efficient air-flowing type floor cleaning vehicle comprises a blowing-sucking device, a settling device, an air purifying mechanism, a water purifying mechanism and a rechargeable battery pack, wherein the blowing-sucking device comprises an air blowing passage plate and an air sucking passage plate, theair blowing passage plate and the air sucking passage plate are in V-shaped arrangement, the air blowing passage plate and the air sucking passage plate are fixedly connected with sealing plates, thebottom of the air sucking passage plate is provided with a roller, the air blowing passage plate is connected with a high pressure draught fan, the settling device is connected with the air sucking passage plate and the air purifying mechanism respectively, the air purifying mechanism comprises a sewage collection tank and an air purifying device, the sewage collection tank is communicated with the air purifying device, the air purifying device is connected with the settling device, the air purifying device is connected with an exhaust fan, the sewage collection tank is connected with a firstwater pump, the water purifying mechanism comprises a sewage filtering device, a clear water storage tank and a second water pump, the sewage filtering device is connected with the first water pump, the second water pump is connected with the air purifying device, and the rechargeable battery pack provides powder for the high pressure draught fan, the exhaust fan , the first water pump and the second water pump.

Owner:曹梅君

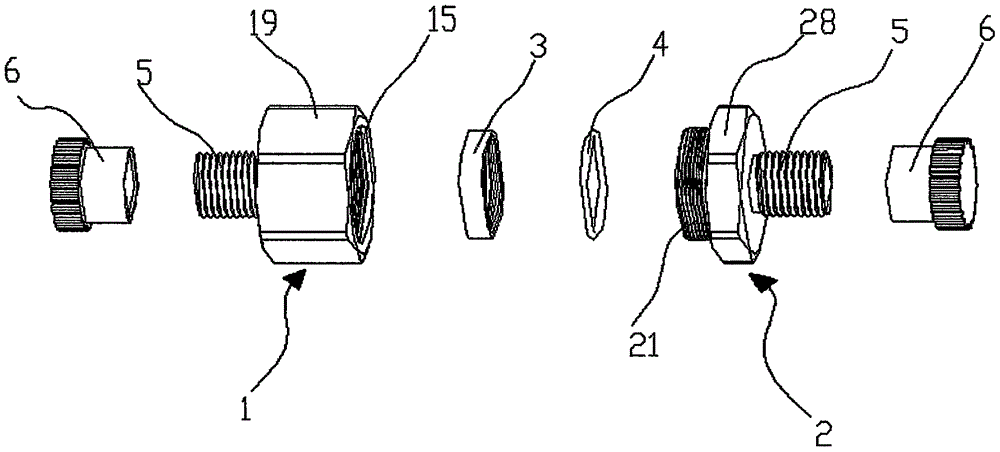

Gas path blockage prevention device of negative pressure system for hospital

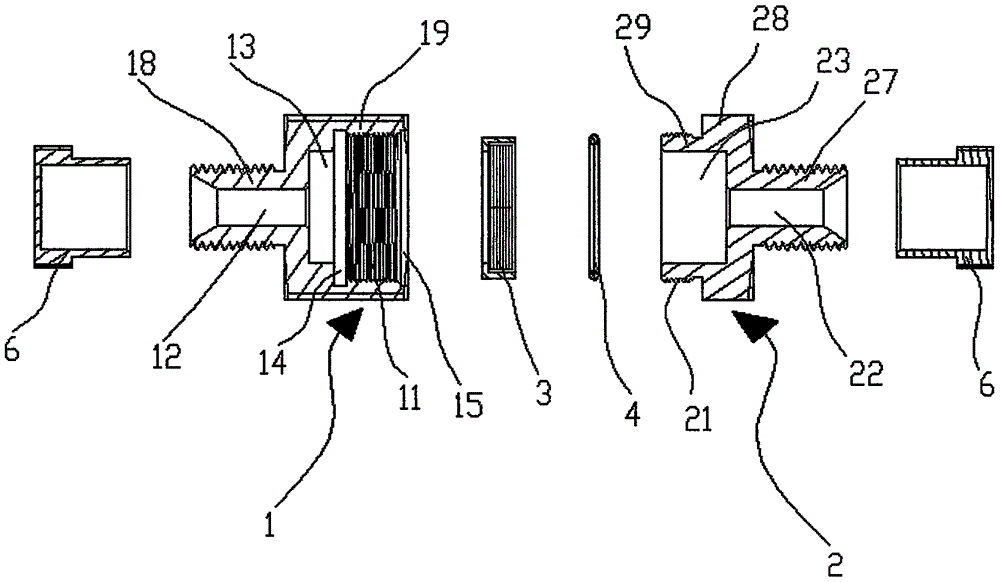

ActiveCN106310402AAchieving tightnessAchieve cleanlinessIntravenous devicesSuction devicesPressure systemEngineering

The invention discloses a gas path blockage prevention device of a negative pressure system for a hospital. The gas path blockage prevention device comprises a front cover and a rear cover, wherein the rear part of the front cover is internally provided with first internal threads, and the front part of the rear cover is provided with first external threads; the first external threads are matched with the first internal threads, so that the front part of the rear cover can be arranged in the rear part of the front cover; the front end of the first internal threads in the front cover is provided with a filter screen device; the rear end of the filter screen device is in contact with the front end of the rear cover; the middle part of the rear cover is protruded outwards; the protruded middle part is positioned behind the first external threads; a seal ring is arranged between the rear end of the first internal threads and the middle part of the rear cover. Under the condition that the negative pressure system absorbs blood and medical dirt with a small area, the gas path blockage prevention device is capable of realizing effective filtering and cleaning, achieving the blockage prevention effect, and achieving the effects of clear blockage point clearing targets and simplicity and convenient in clearing under the condition that blockage and insufficient air pressure are caused since the negative pressure system repeatedly absorbs the blood and the medical dirt with a small area or large area.

Owner:NINGBO MEIDIER MEDICAL EQUIP TECH CO LTD

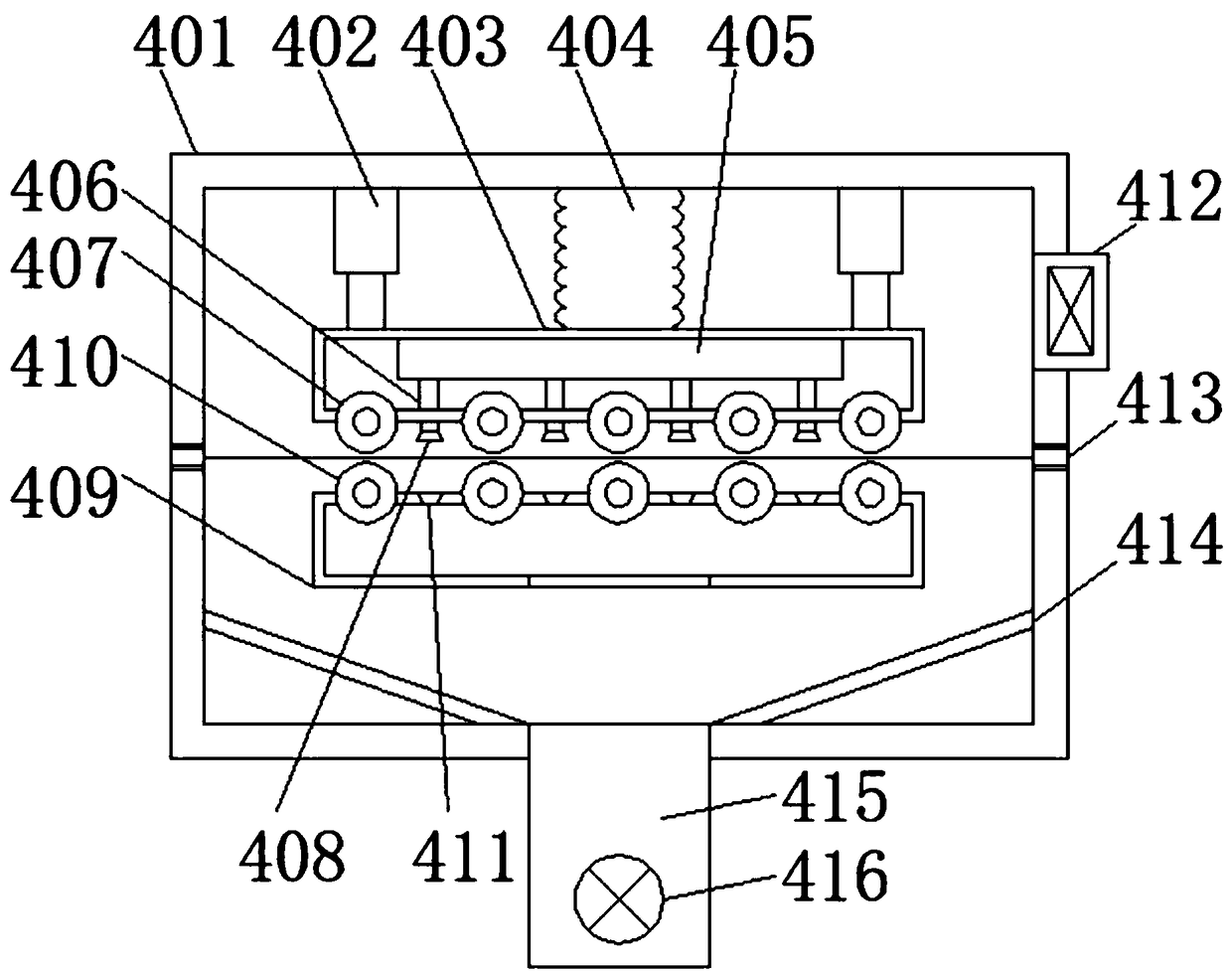

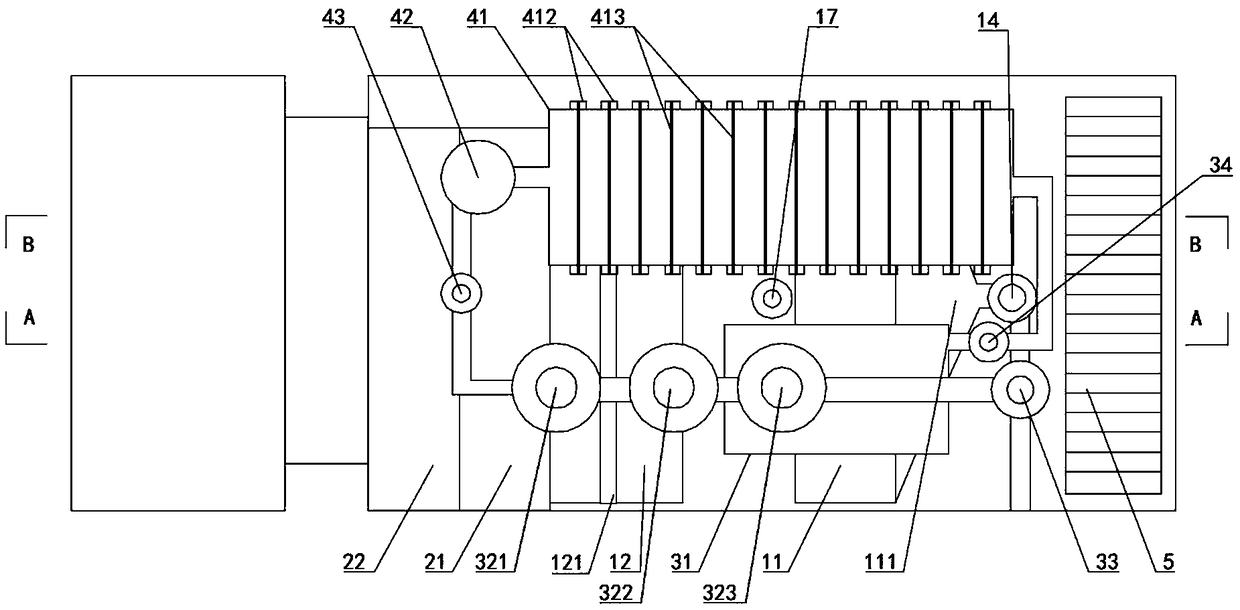

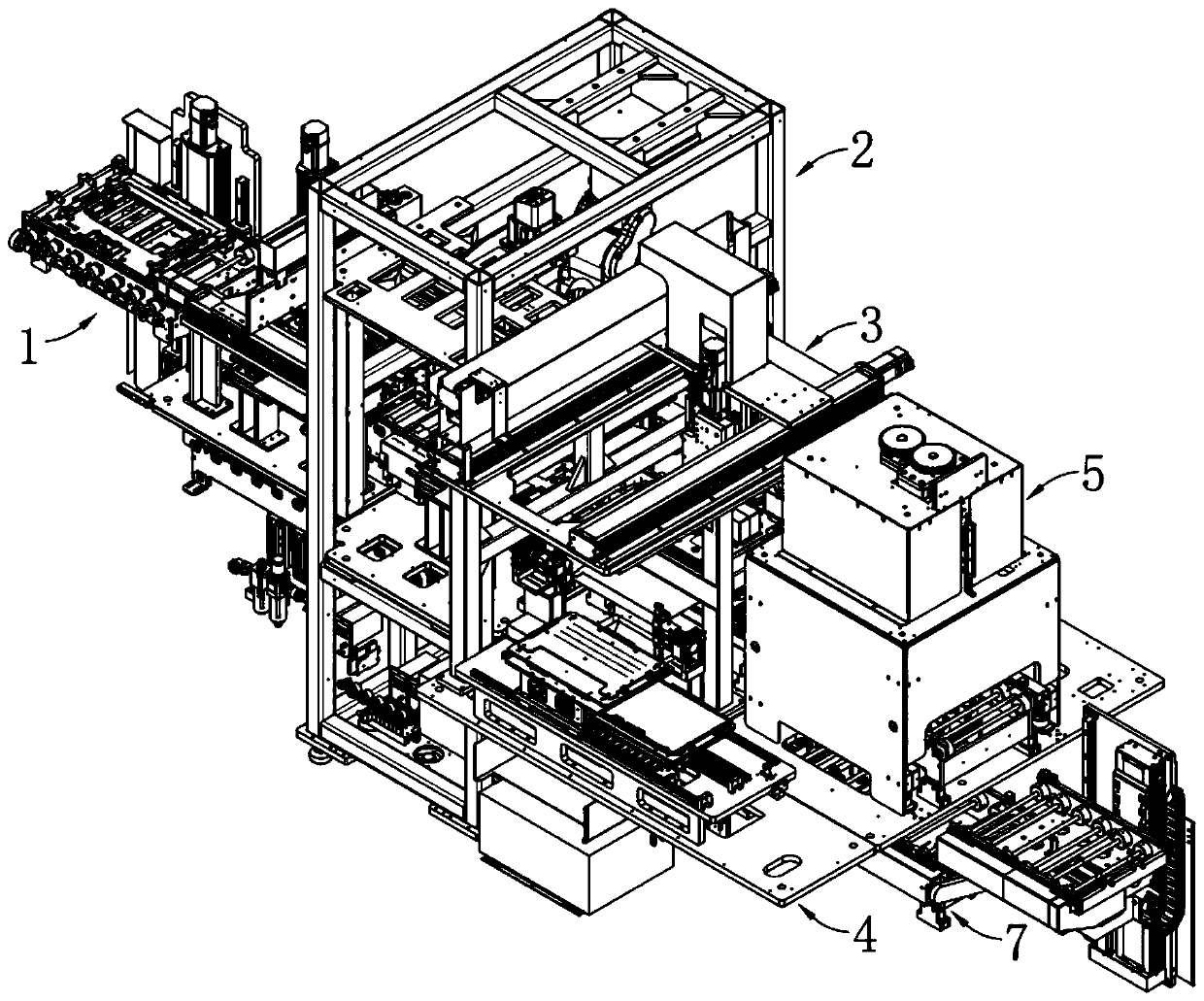

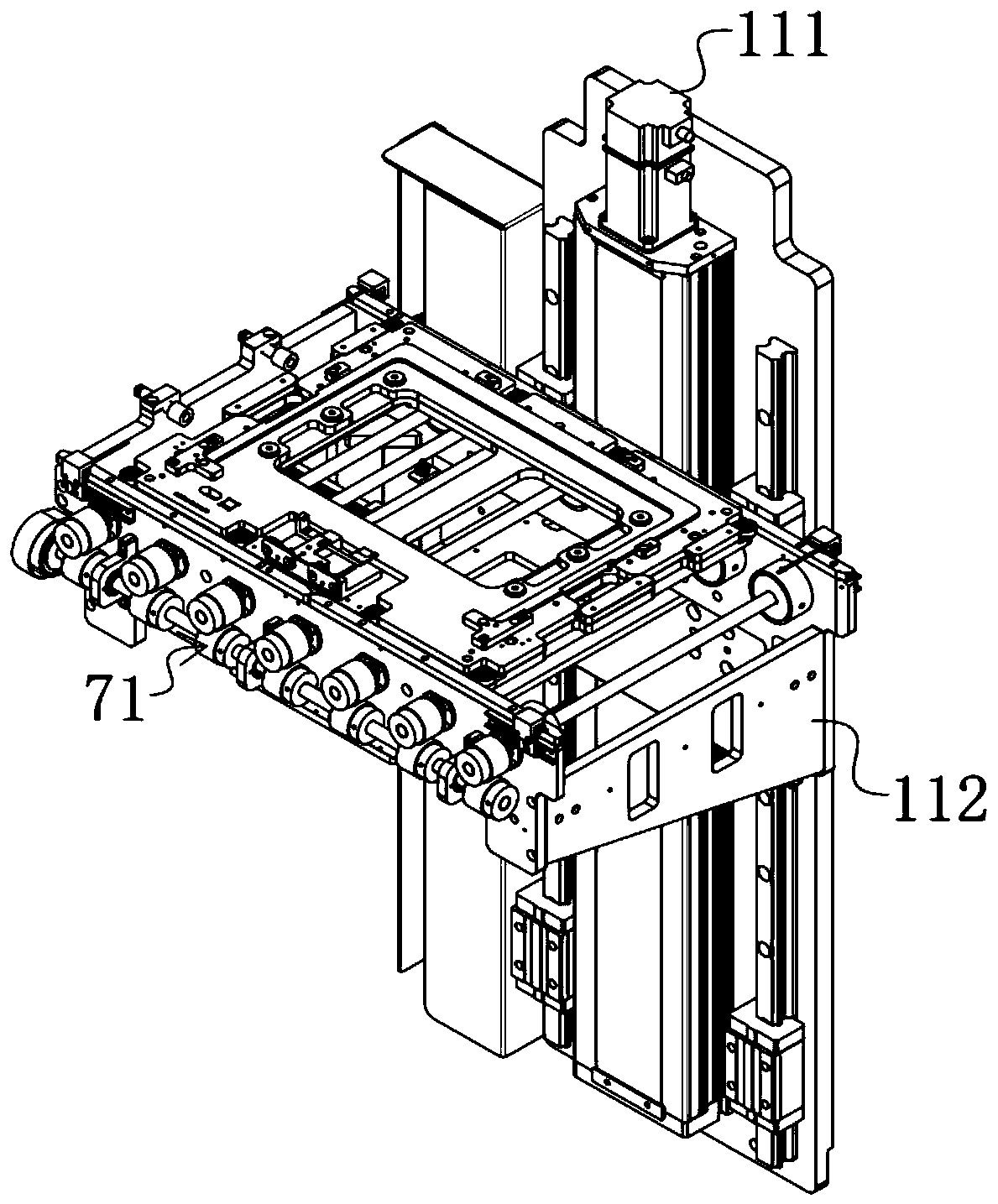

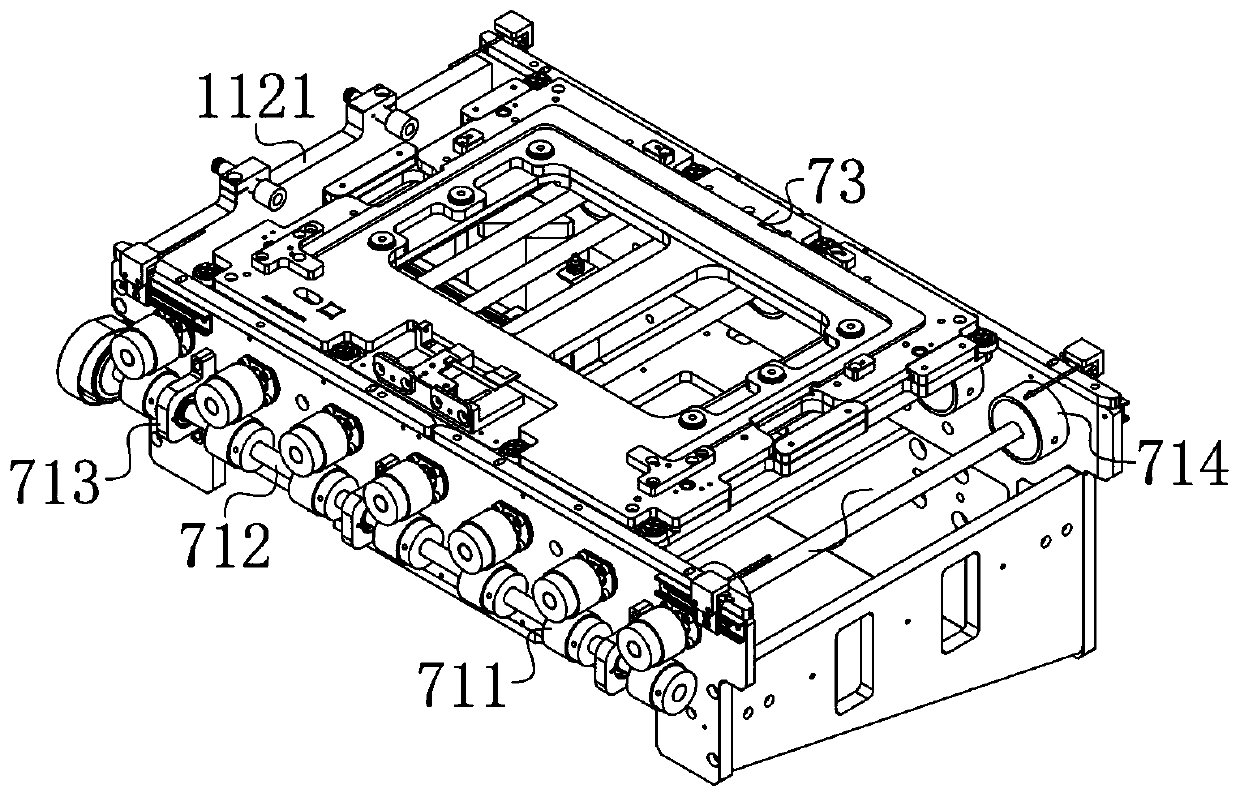

Assembly line for liquid crystal screens

The invention provides an assembly line for a liquid crystal screen. The device comprises a cleaning device body, a pressing device, a feeding mechanism and an assembly line mechanism, the assembly line mechanism comprises a plurality of conveying line bodies and a carrier, and a conveying channel of the assembly line mechanism is formed by splicing the conveying line bodies, so that the carrier sequentially move to the cleaning device body, the feeding mechanism and the pressing device along the conveying channel in the assembly line mechanism; a shell is fixedly supported on the carrier; thecleaning device body internally comprises a cleaning part, and the surface of the shell is cleaned through the cleaning part. The feeding mechanism is used for conveying the liquid crystal display panels to the carrier, so that the liquid crystal display panels are stacked on the shell; the pressing device presses and fixes the shell and the liquid crystal panel which are stacked in the carrier,so that the shell and the liquid crystal panel are fixedly connected to form an integrated liquid crystal screen, and the assembly line is convenient to use, simple in structure and convenient to maintain.

Owner:BOZHON PRECISION IND TECH CO LTD

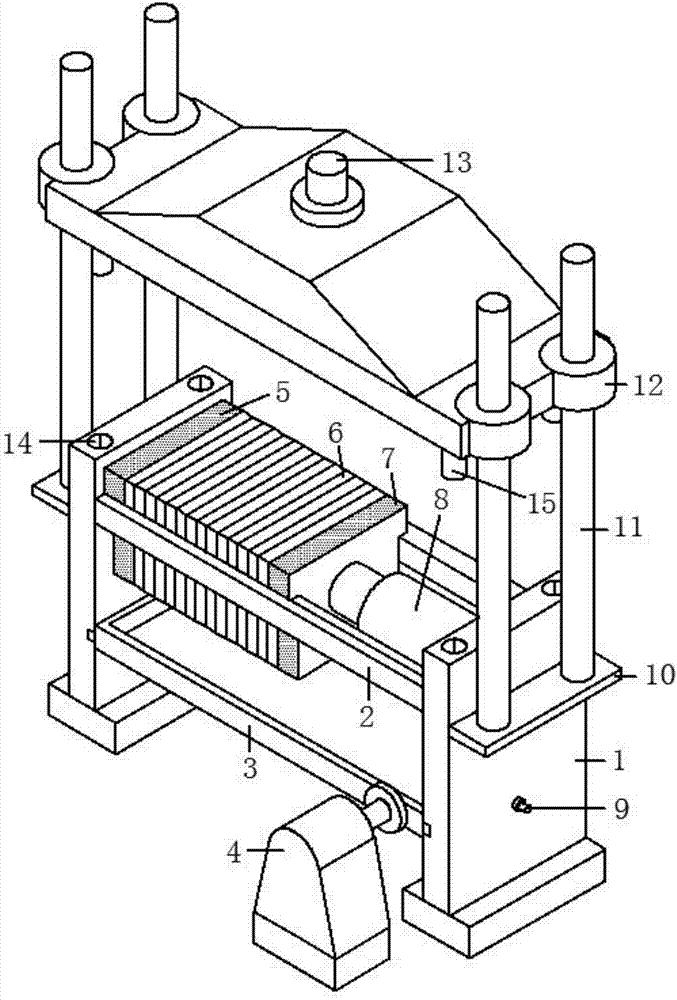

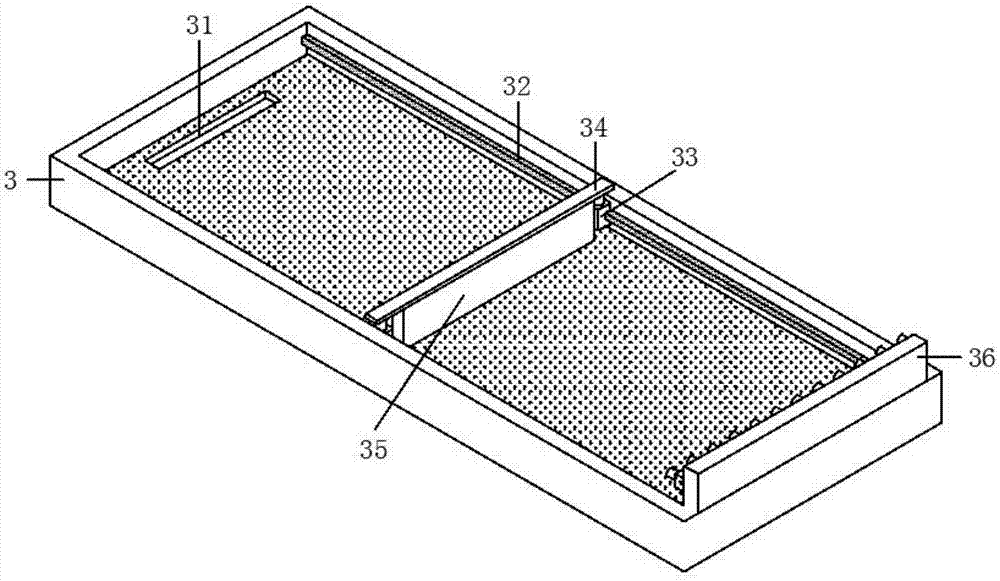

Box type filter press with automatic vibration and beating device

InactiveCN107970652AReasonable structural designReduce labor intensityHollow article cleaningDirt cleaningReciprocating motionEngineering

The invention discloses a box type filter press with automatic vibration and beating device. The box type filter press comprises two sets of support plates arranged in parallel, and a support frame and a liquid collection tank are arranged between the two sets of support plates. The front side wall of the liquid collection tank is provided with the vibration and beating device. The top of the support frame is provided with a passive extrusion plate, a filter cake and an active extrusion plate sequentially from left to right in a clamping connection way, the passive extrusion plate is fixed onthe left support plate, the right side of the active extrusion plate is provided with a hydraulic push rod, the right end of the hydraulic push rod is fixed on the right support plate, and the right side wall of the right support plate is provided with a water delivery pipe. The structure of the box type filter press is reasonable in design, can achieve effects of cleaning material residues and dye residues through an electric sliding block driving a brush to make reciprocating movement in the liquid collection tank, and reduces influences of waste gas generated in a press filtration process on operators by using a gas collection hood and a suction pump communicating with the gas collection hood to extract the waste gas generated in the press filtration process into a gas purification device.

Owner:安徽融创化工科技股份有限公司

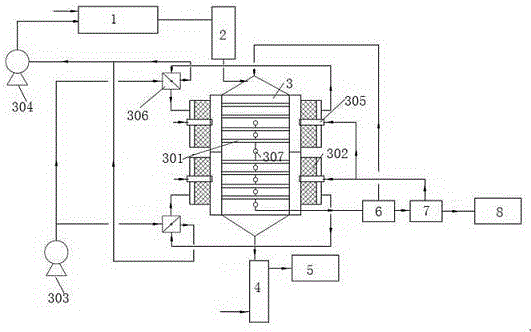

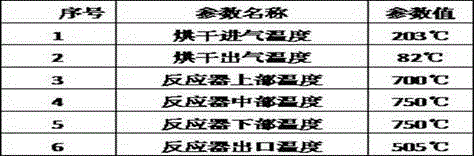

Regenerative garbage pyrolysis power generation system and method thereof

PendingCN106497586AEasy to cleanSimple designSpecial form destructive distillationIncinerator apparatusCarbonizationProcess engineering

The invention belongs to a clean garbage disposal technology, and particularly relates to a regenerative garbage pyrolysis power generation system and a method thereof. In allusion to the problems in the prior art, the invention provides the regenerative garbage pyrolysis power generation system and the method thereof. The regenerative garbage pyrolysis power generation system comprises a chain plate-type dryer, a hopper and a regenerative pyrolysis reactor, wherein the hopper is connected with the chain plate-type dryer. The regenerative garbage pyrolysis power generation system and the method thereof are different from other garbage disposal technologies with too high cost or a complicated process; a built-in regenerative radiant tube is used as a heating source, and through reasonable arrangement of the regenerative radiant tube, reasonable control over the temperature of the reactor is achieved; the design of the radiant tube can be simplified, so that the investment cost is reduced; dioxin is not produced, so that the regenerative garbage pyrolysis power generation system is environment-friendly, and combined with the comprehensive utilization of garbage byproducts, clean and effective garbage recycling disposal is achieved. Meanwhile, a continuous carbonization process is achieved, the process is simple, the production efficiency is higher and the production cost is reduced.

Owner:SHENWU TECH GRP CO LTD

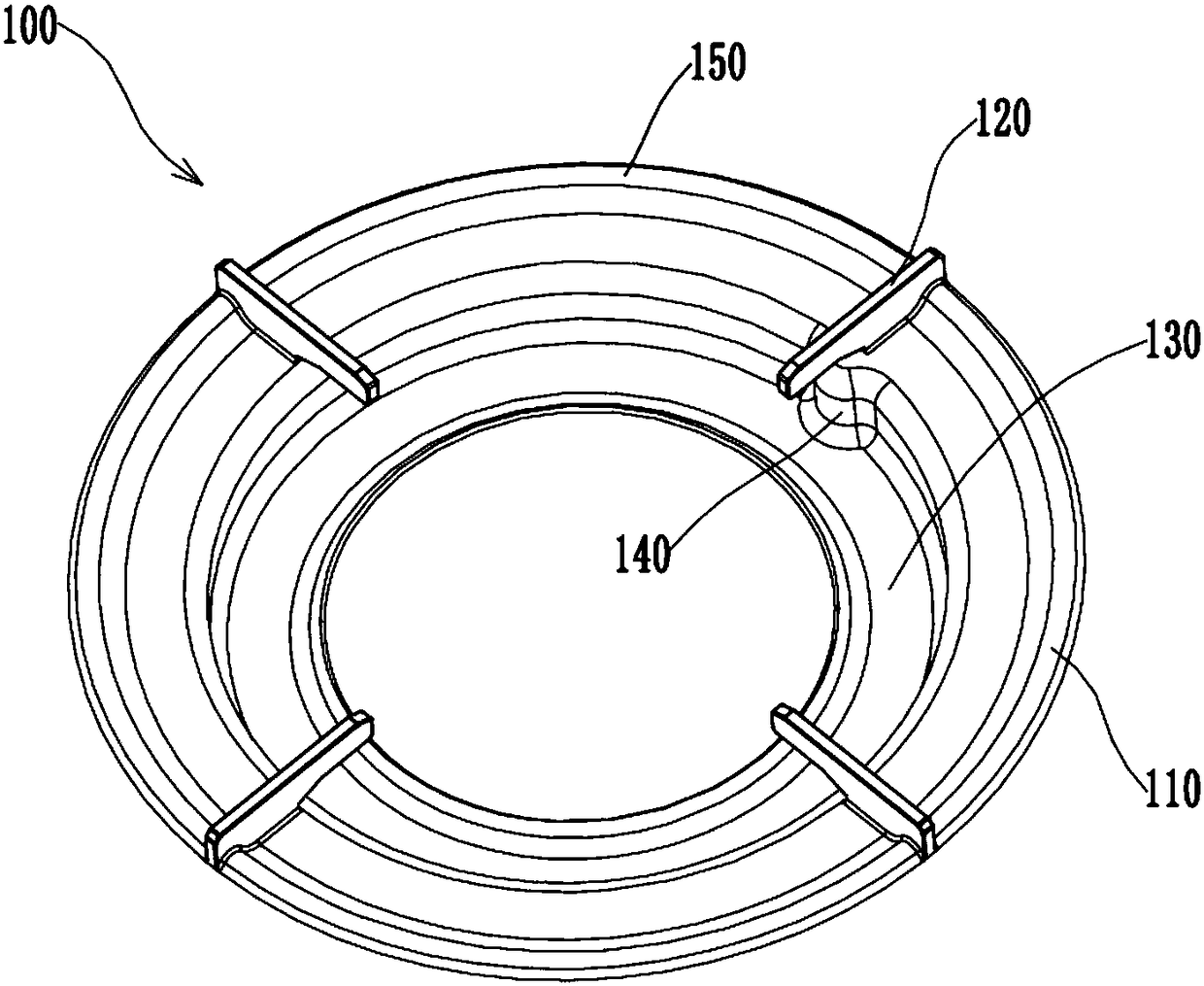

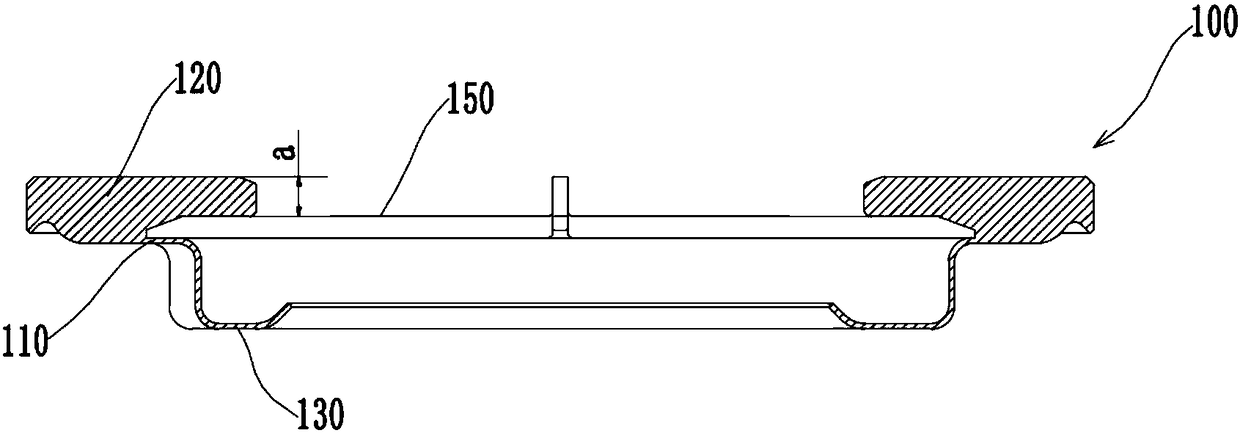

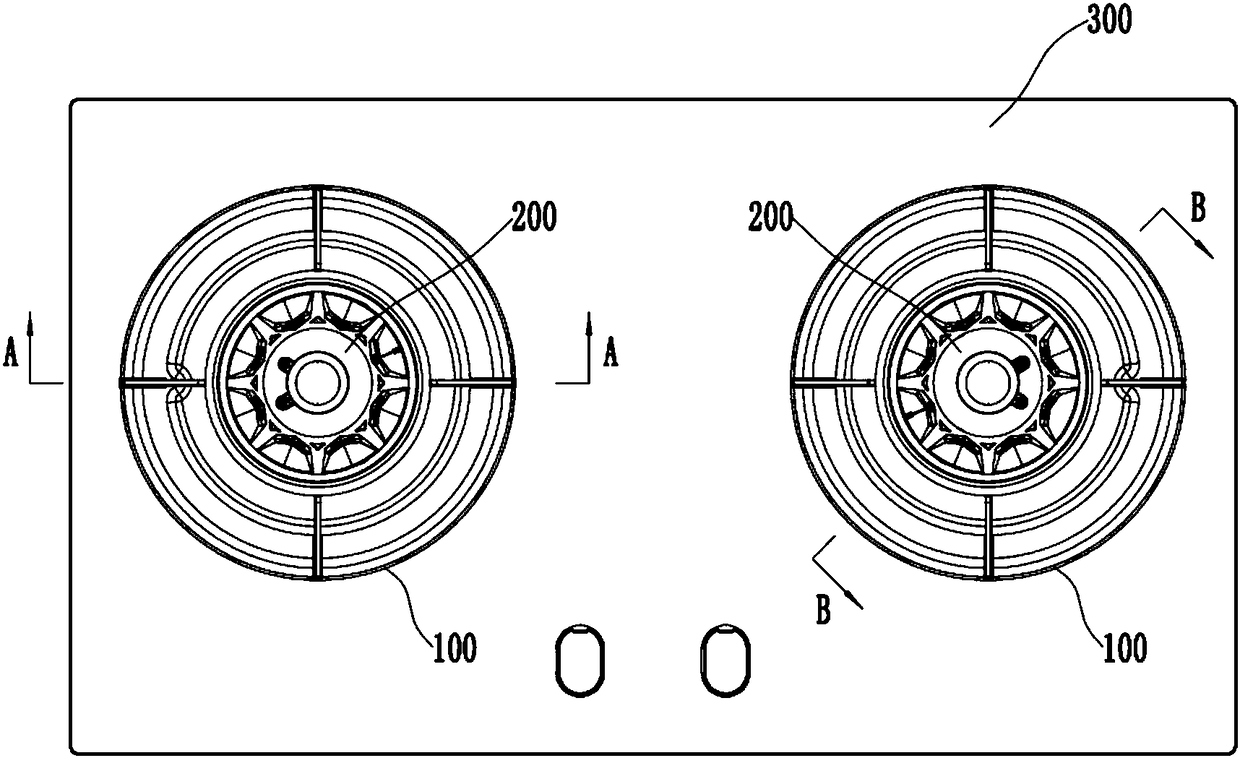

Pot rack and gas range

PendingCN108488852AIncrease surface areaAbundant storageDomestic stoves or rangesStoves/ranges topsEngineeringMechanical engineering

The invention provides a pot rack and a gas range, relates to the technical field of kitchen ranges and aims at solving the problems of low thermal efficiency and inconvenient cleaning of gas ranges in the prior art. The pot rack comprises a pot rack bottom ring and a plurality of foot pieces fixedly arranged on the bottom ring of the pot rack that are suitable for supporting the pot, wherein themiddle part of the bottom ring of the pot rack is sunken downwards to form a sinking table, and the sinking table is provided with a horizontal section extending towards the central direction of the bottom ring of the pot rack. The gas range comprises the pot rack. The pot rack and the gas range are used for improving the thermal efficiency of the gas range. The pot rack is used to realize the storage of most of the boiling overflow liquid so as to pour the boiling overflow liquid by taking the pot rack.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

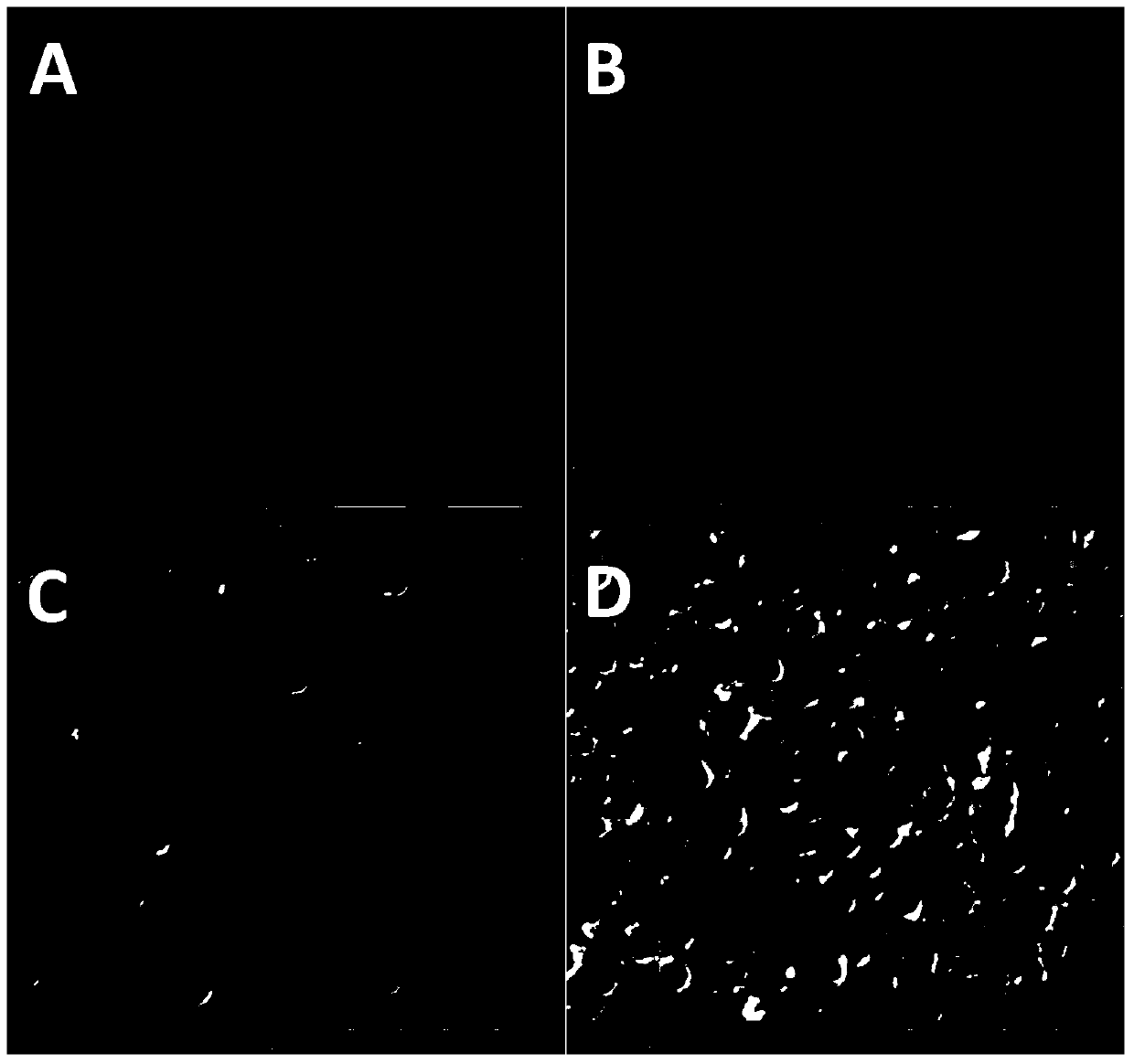

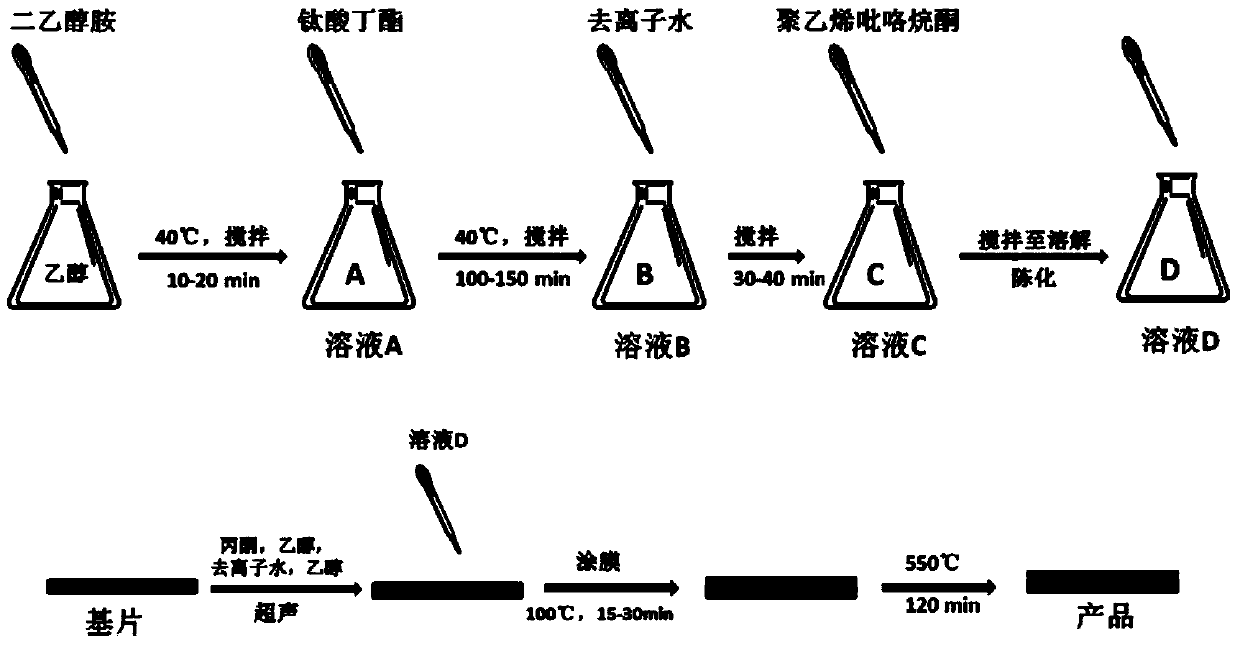

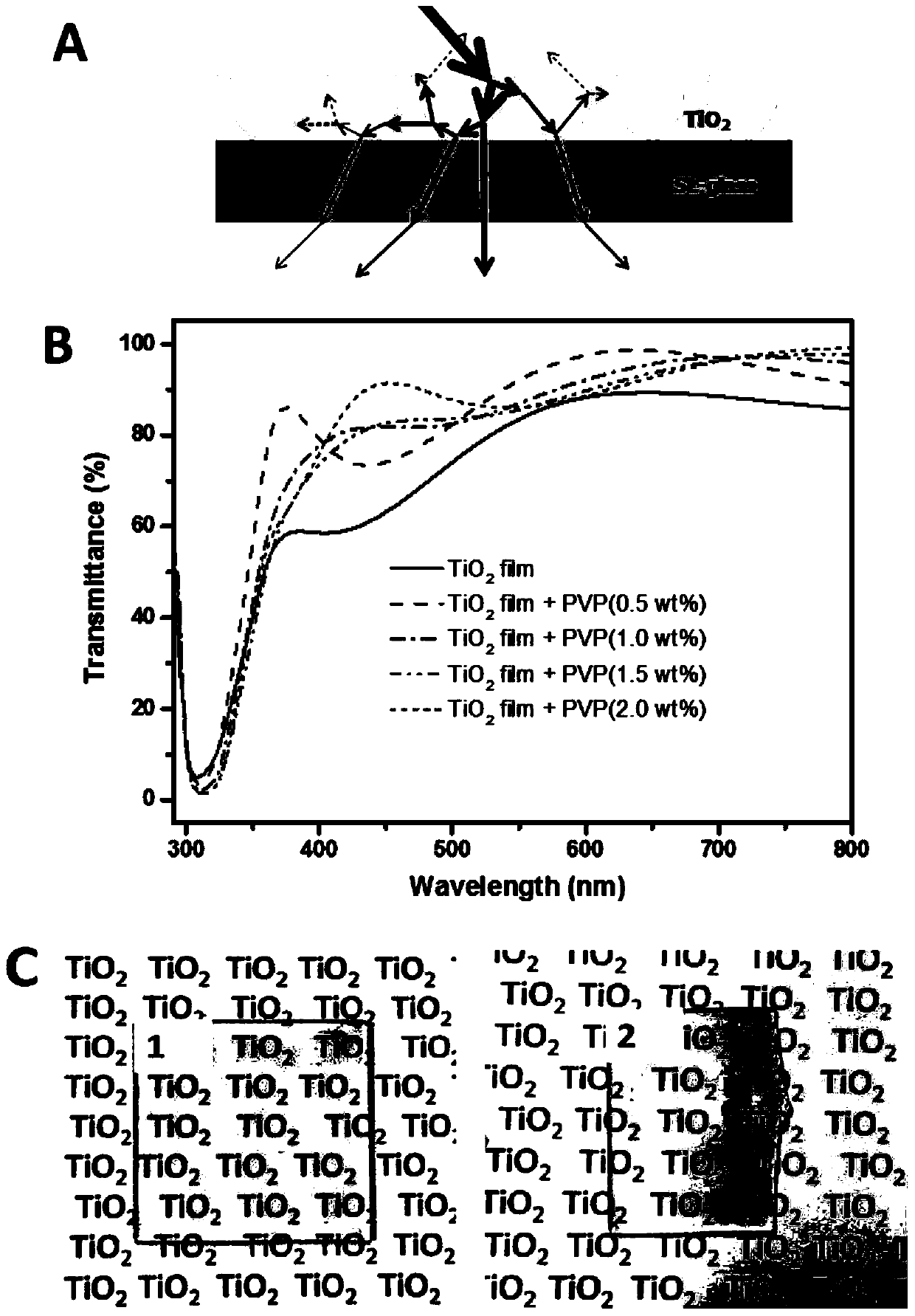

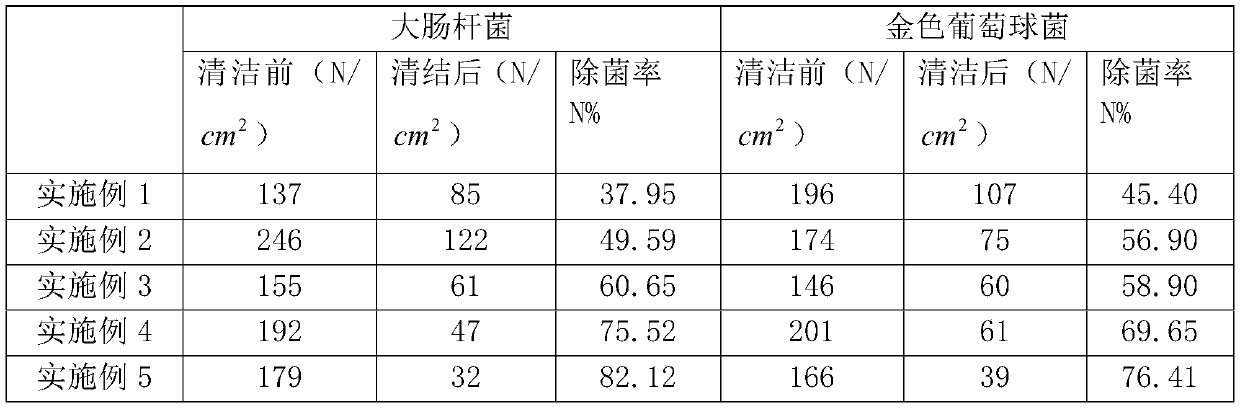

Preparation method of titanium oxide film and titanium oxide film

The invention provides a preparation method of a titanium oxide film and a titanium oxide film. The preparation method comprises the following steps: 1) preparation of titanium oxide precursor; and 2) film coating and after-treatment. The preparation method is simple in preparation technique and can implement large-scale production.

Owner:卜艳茹

Antibacterial treatment method of down jackets

InactiveCN111058209AImprove cleanlinessKeep healthySucessive textile treatmentsBiochemical fibre treatmentWarm waterPharmaceutical drug

The invention relates to an antibacterial treatment method of down jackets. First, the down jackets are subjected to hot-air heating by a hot air fan to increase the fluffiness of inner down; then thedown jackets are soaked in hot water to initially clean the down jackets; then the down jackets are steam cleaned, and the down jackets are cleaned and washed with no dead corners by high frequency steam; and finally, drug residues on clothes are washed away, and drying and sorting are carried out. The cleanliness of the down in the down jackets is increased by using a hot air blowing fluffy-warmwater soaking-steam cleaning method, the defect that cleaning dead corners exist by using a traditional cleaning method is overcome, meanwhile, the high-frequency high-temperature steam is instantlysprayed and covering washing is carried out, the effects of sterilization and cleaning are achieved while the clothes are damaged, and the health of wearers is ensured.

Owner:ANHUI GUIGU E COMMERCE

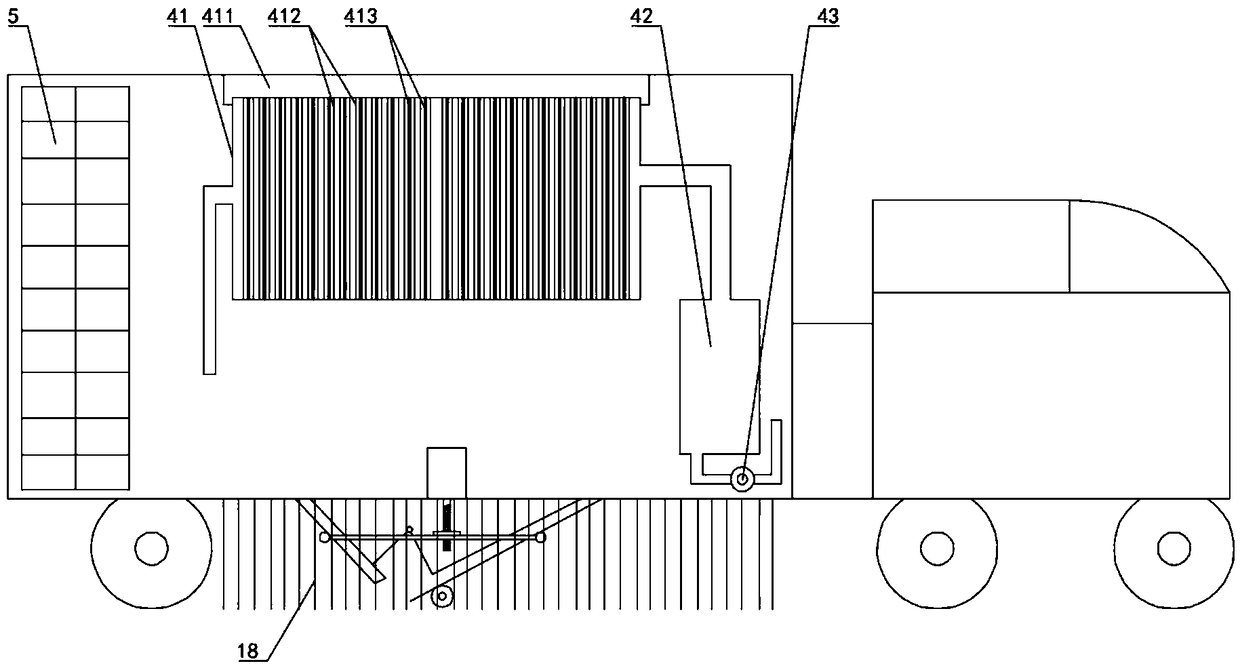

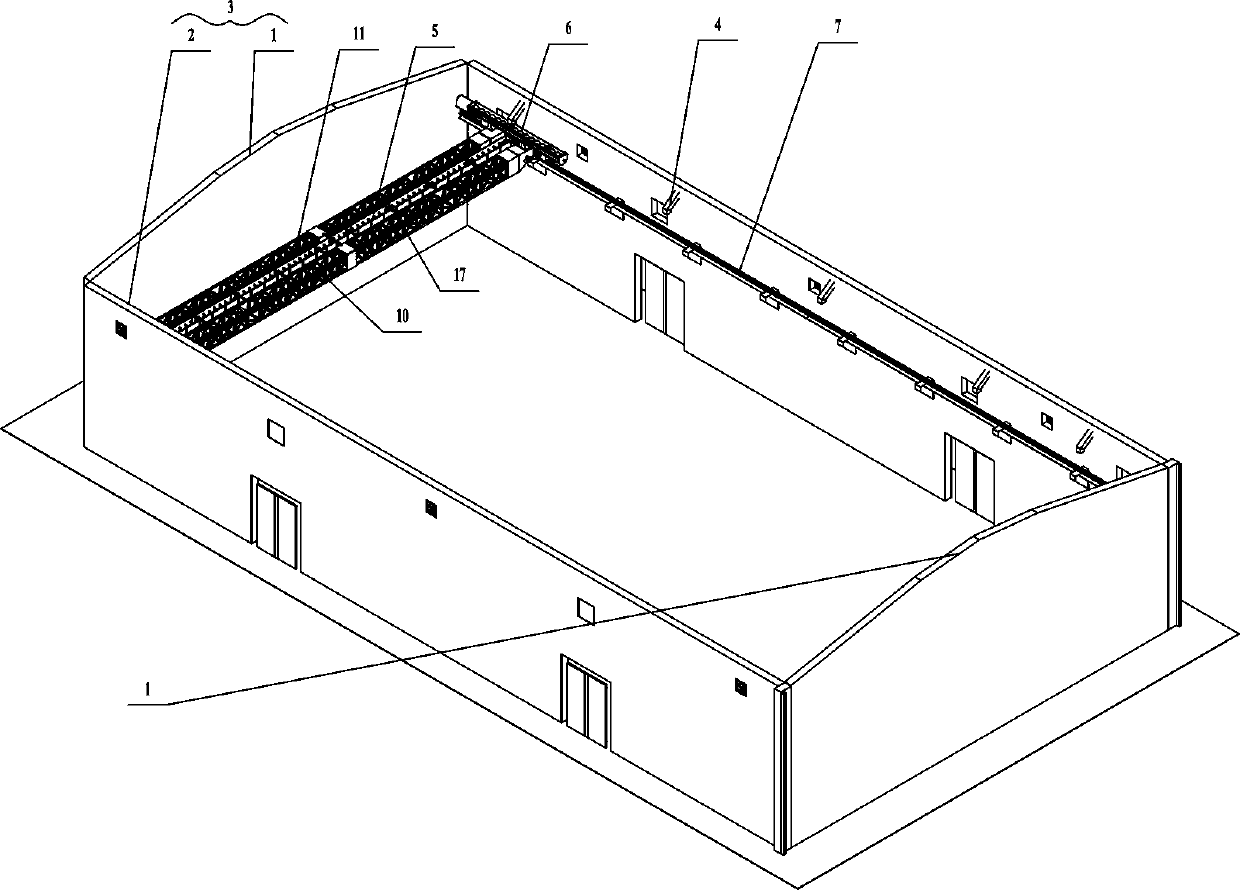

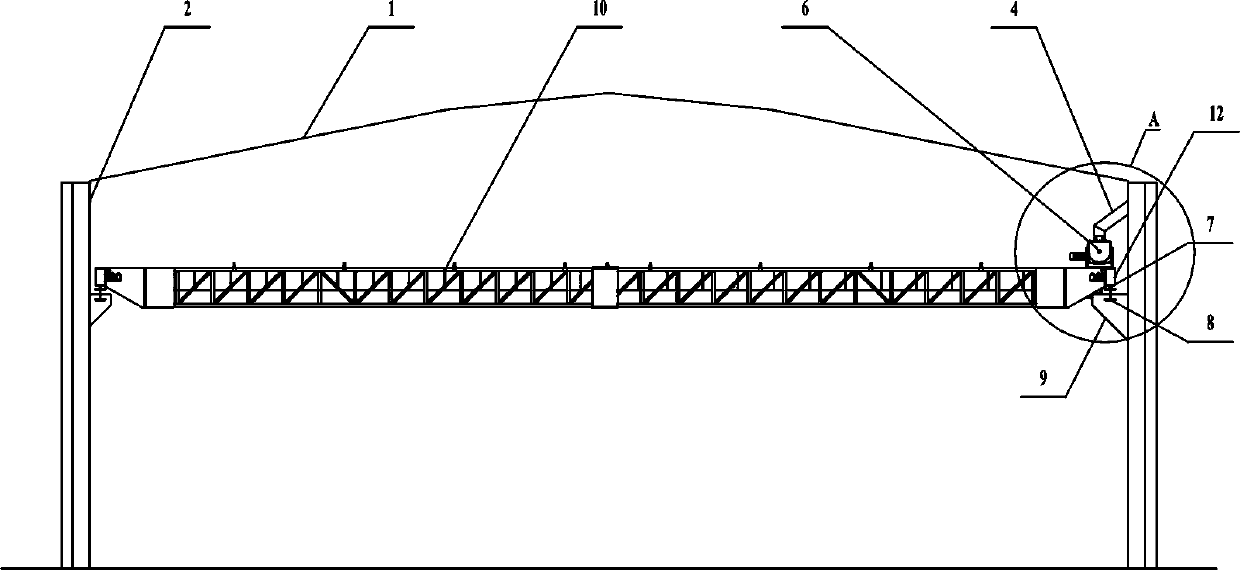

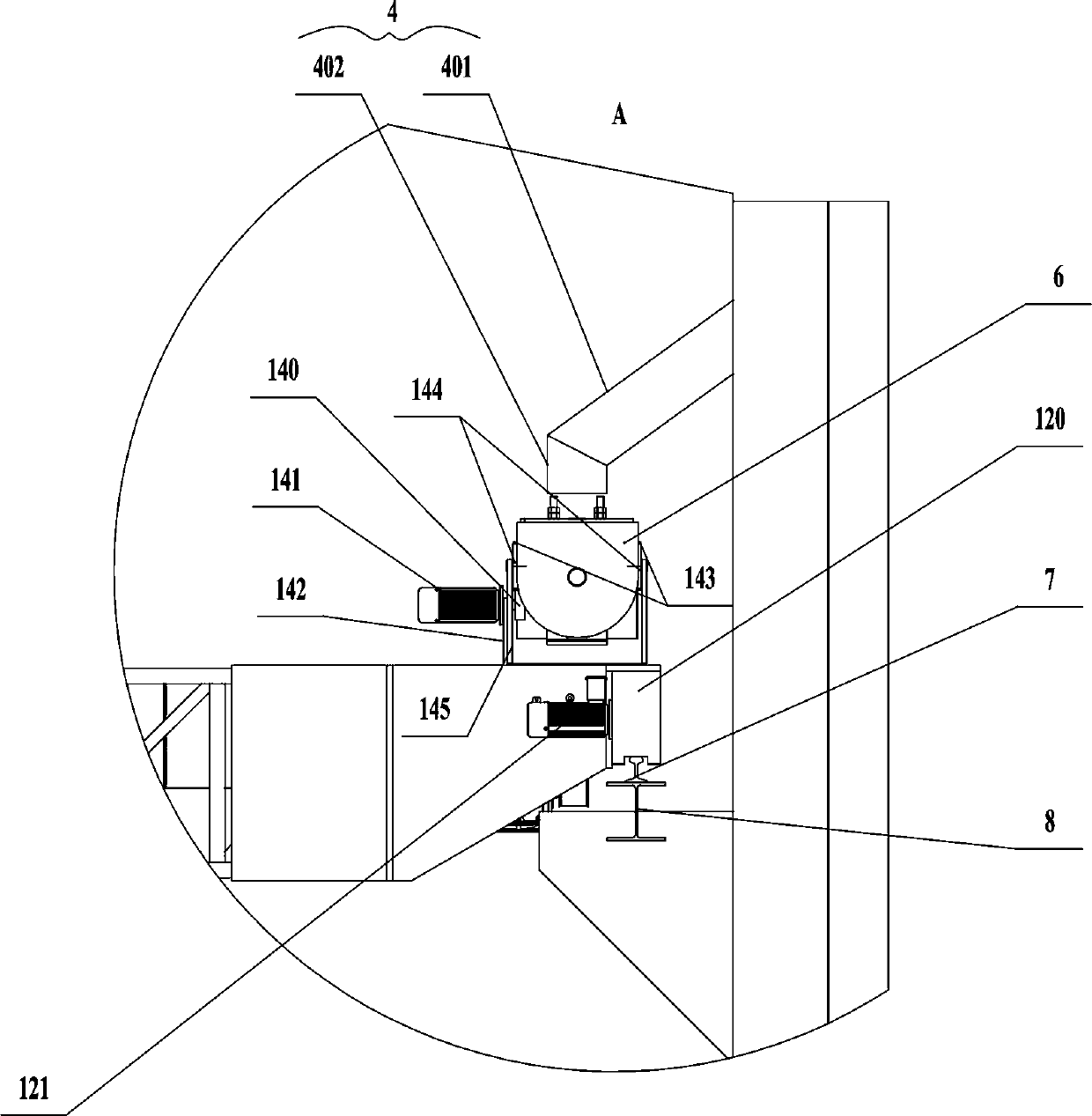

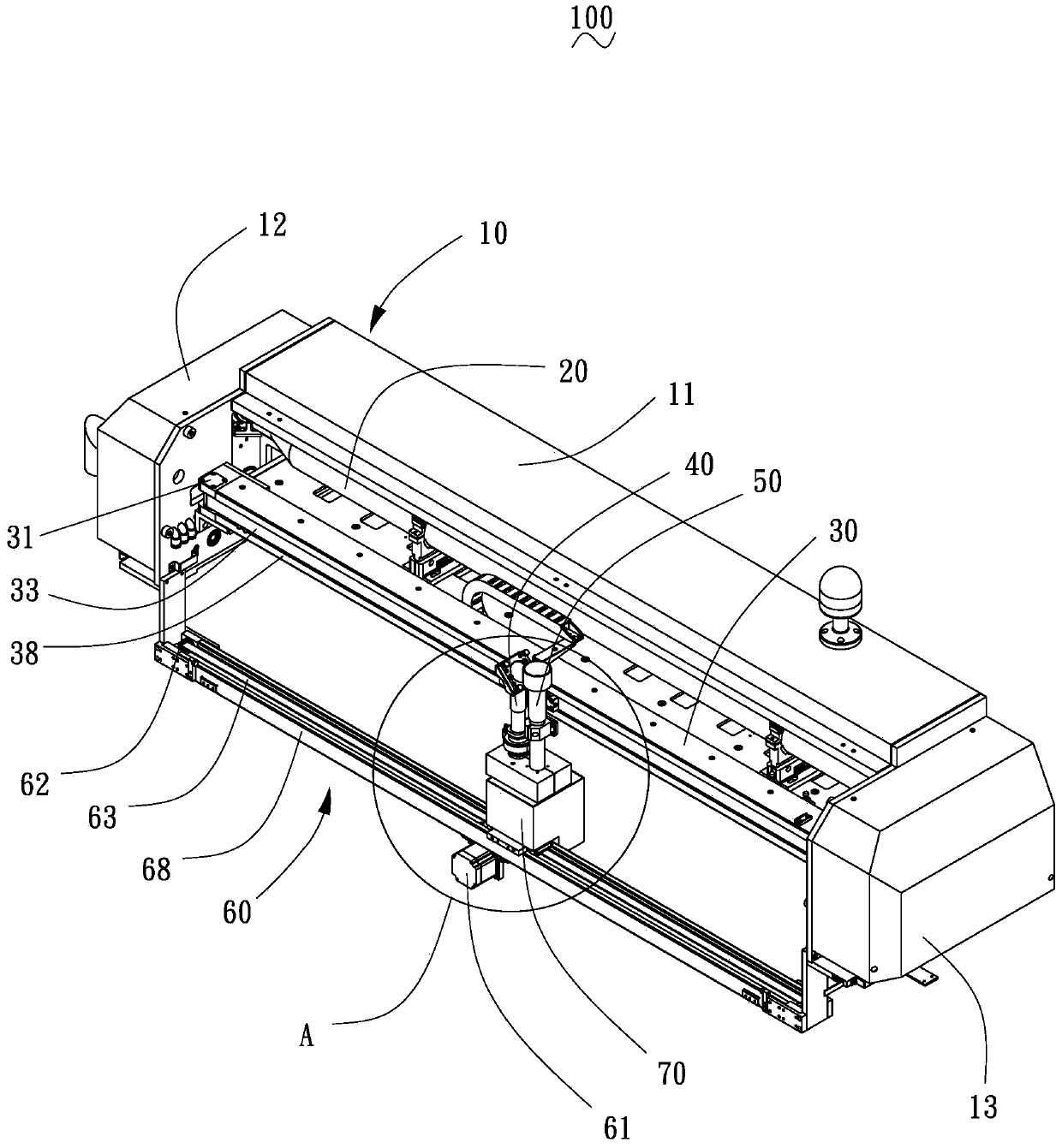

Waterfall type warehousing and distributing device and method for flat warehouse

PendingCN111302098AGuaranteed continuous warehousingRealize warehouse layoutLoading/unloadingGrain storageMechanical engineering

The invention belongs to the technical field of grain storage, and particularly relates to a waterfall type warehousing and distributing device and method for a flat warehouse. The waterfall type warehousing and distributing device for the flat warehouse comprises the flat warehouse defined by gable walls and eave walls, and further comprises a plurality of grain inlets, a warehousing reciprocating spiral, a spiral distributing device and a central controller, wherein the grain inlets are formed in the eave wall of one side of the flat warehouse side by side at intervals, the warehousing reciprocating spiral is parallel to the eave walls and positioned below a discharge port of any grain inlet; the spiral distributing device is parallel to the gable walls and is positioned below warehousing reciprocating discharging ports; the central controller is respectively in control connection with the warehousing reciprocating spiral and the spiral distributing device; two ends of the spiral distributing device are movably arranged on the eave walls at two sides, and the warehousing reciprocating spiral is movably arranged above the end part of the spiral distributing device. According to the waterfall type warehousing and distributing device and method for the flat warehouse, the grain warehousing and distributing operation efficiency can be greatly improved, the labor intensity and thecost of workers are reduced, and the intelligent, clean, efficient and unmanned grain warehousing and distributing operation of the flat warehouse can be effectively realized.

Owner:郑州中粮科研设计院有限公司

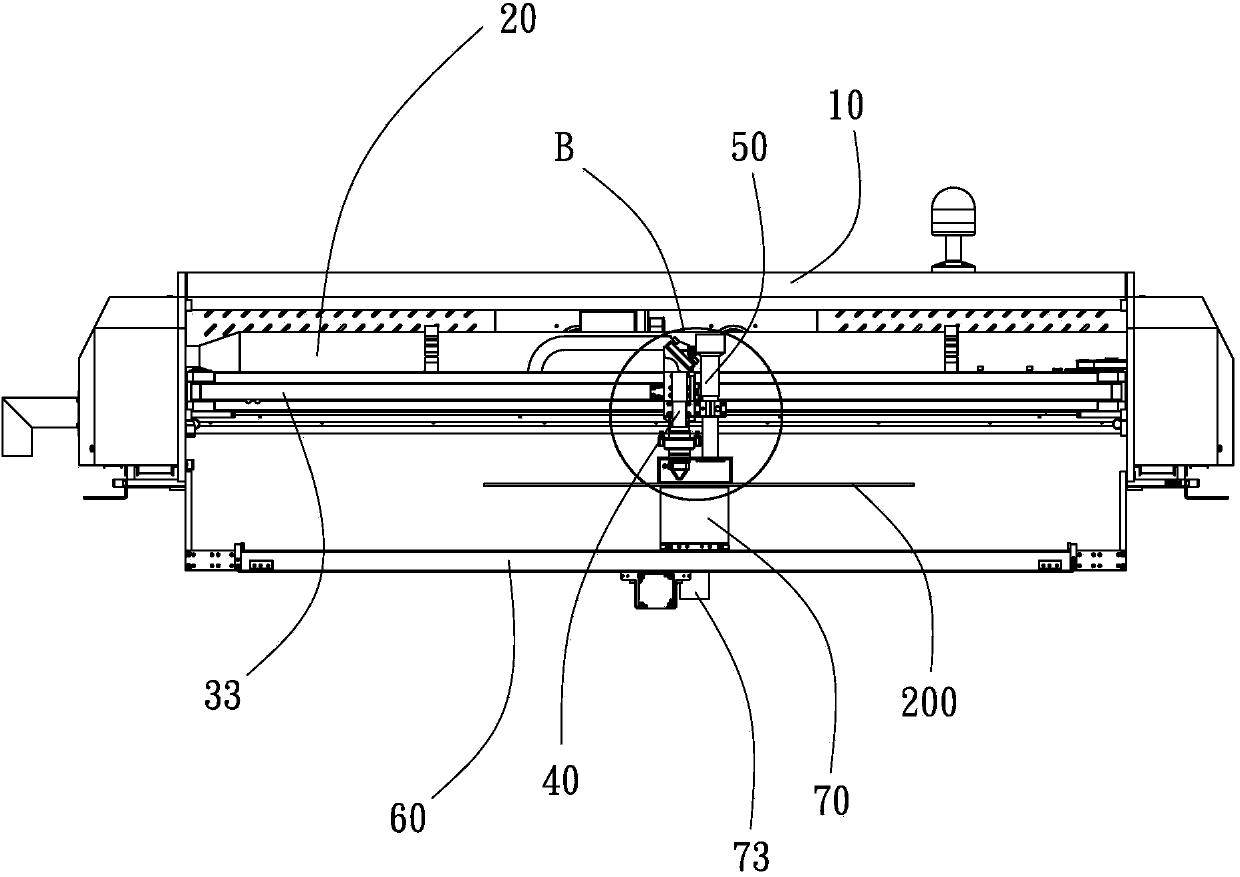

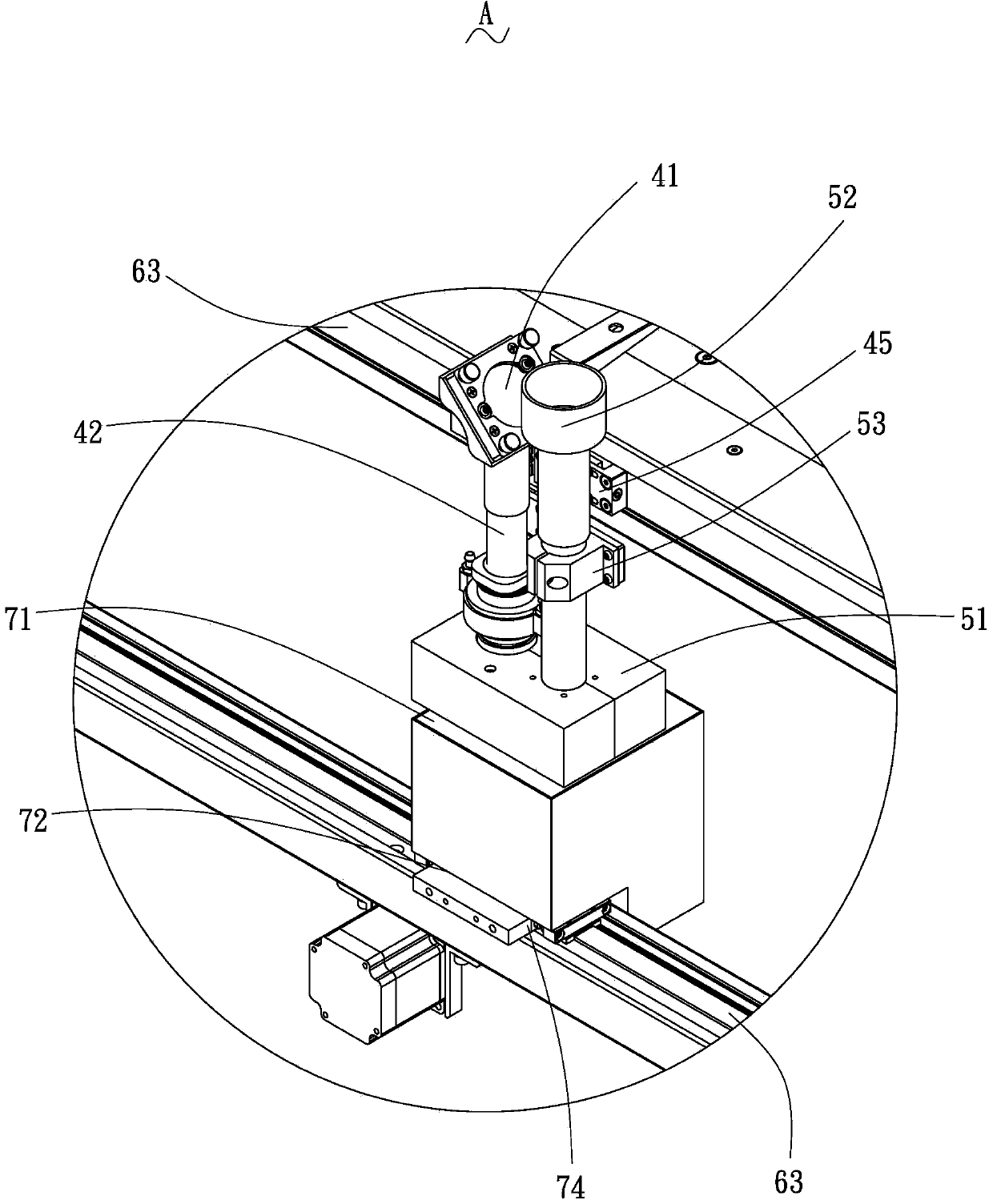

Laser cutting machine with up and down exhaust system

ActiveCN103737183AAvoid pollutionAchieve cleanlinessLaser beam welding apparatusPulp and paper industryLaser cutting

A laser cutting machine with an up and down exhaust system comprises a machine frame, a laser tube, a first movement device, a cutting device, an upper exhaust device, a second movement device and a lower exhaust device; the cutting device comprises a cutting head; the upper exhaust device comprises an upper cover, an exhaust tube and a fixing part which is connected with the exhaust tube and the cutting device; the upper cover covers the cutting head; the bottom surface of the upper cover is provided with the opening so as to face the top surface which covers materials to be cut; the lower exhaust device comprises the suction opening, the locking portion and the air outlet; the suction opening is formed at the top of the lower exhaust device; the locking portion is arranged on one side of the bottom of the lower exhaust device; the air outlet is formed in the other side of the bottom of the lower exhaust device; the suction opening faces the bottom surface which covers the materials to be cut; the locking portion is connected with the second movement device; the synchronous movement of the lower exhaust device, the cutting head and the upper cover is driven by the second movement device. According to the laser cutting machine with the up and down exhaust system, the laser cutting machine and the cutting device move synchronously through the upper exhaust device and the lower exhaust device and accordingly the smoke which is cut out through the materials to be cut is sucked up and down simultaneously and accordingly the clean and safe effect can be achieved.

Owner:GUANGDONG HANS YUEMING LASER GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com