Soap-base compound and preparation method and application thereof

A compound and soap-based technology, applied in chemical instruments and methods, surface-active non-soap compounds and detergent compositions, soap detergent compositions, etc., can solve the problem of high energy consumption, inability to adapt to industrial production needs, low reaction efficiency, etc. problems, to achieve the effect of increasing the reaction rate, stabilizing the soap-based compound, and increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further elaborated below by specific examples.

[0036] The soap base compound described in each embodiment of the present invention is prepared by the following method:

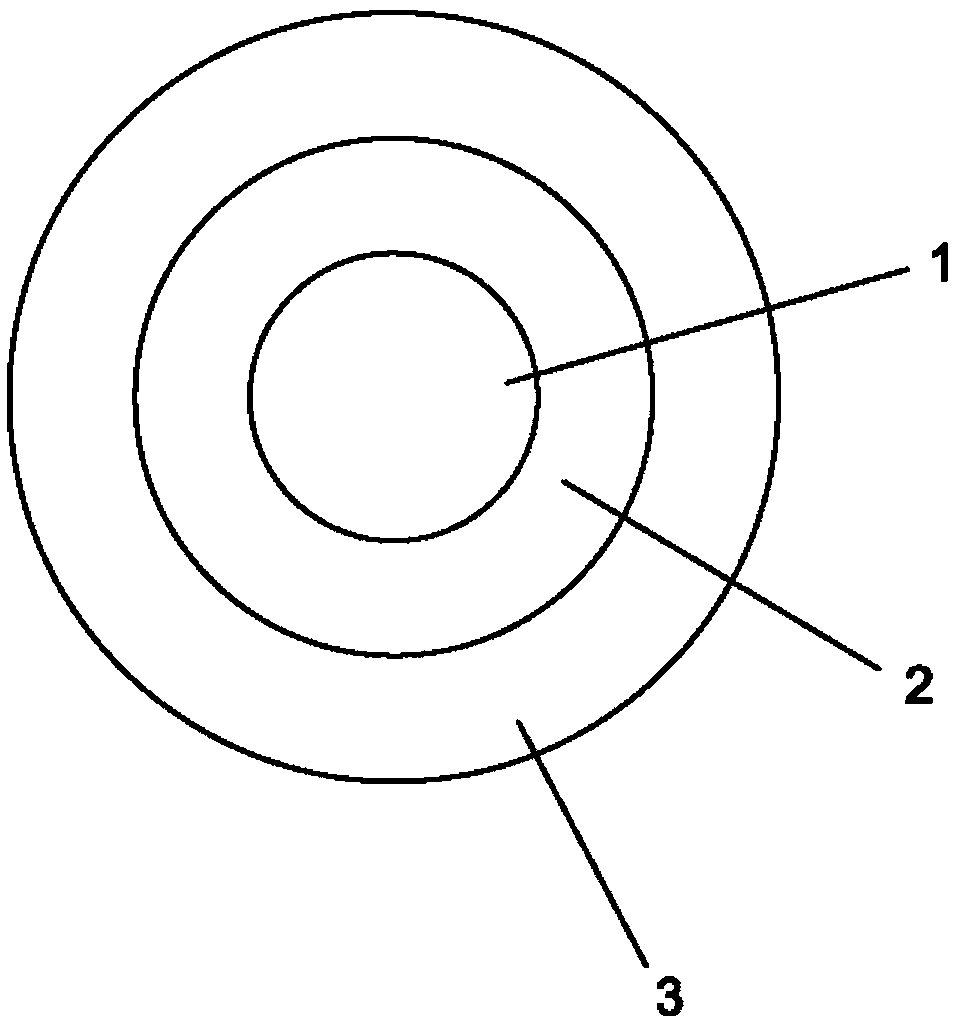

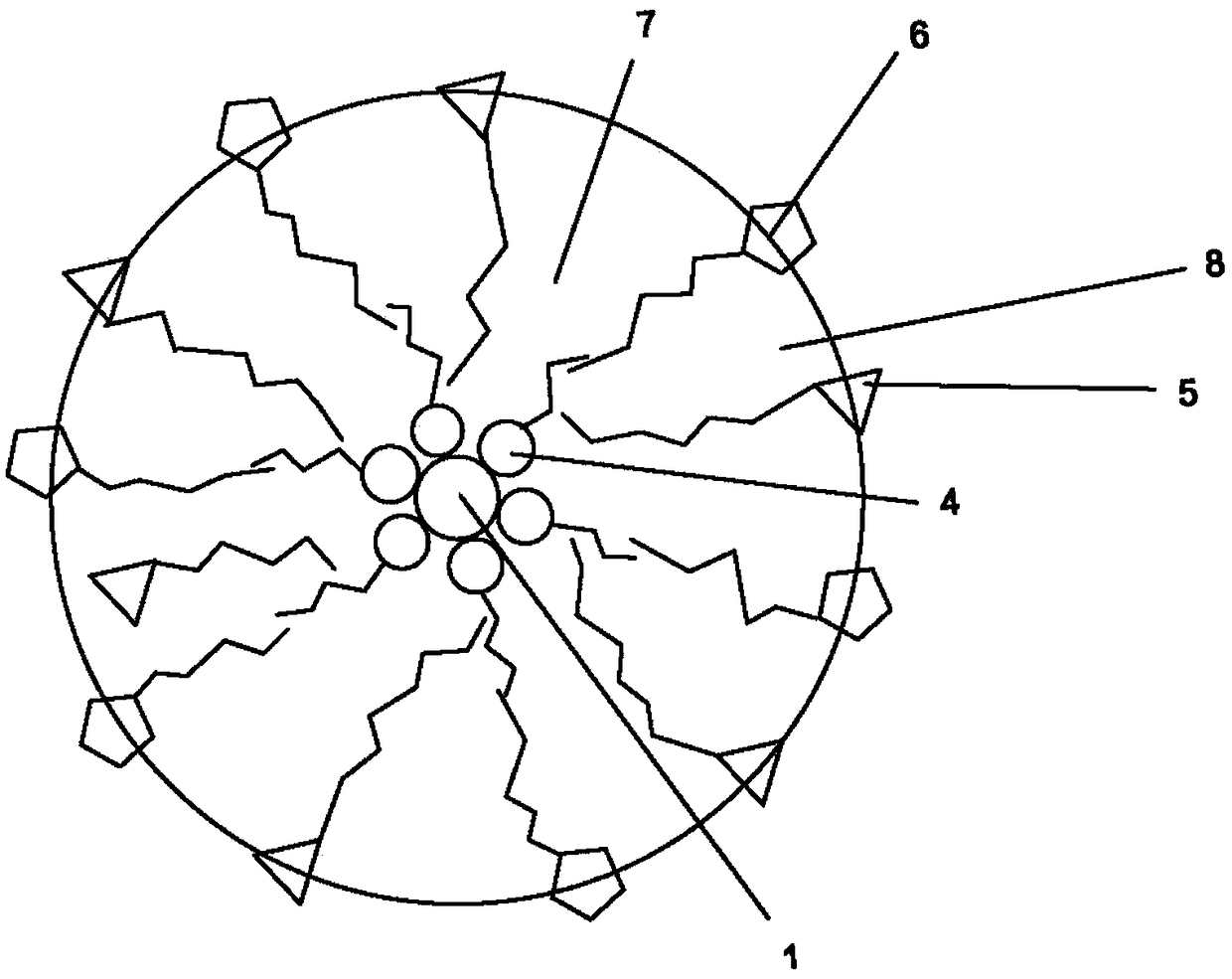

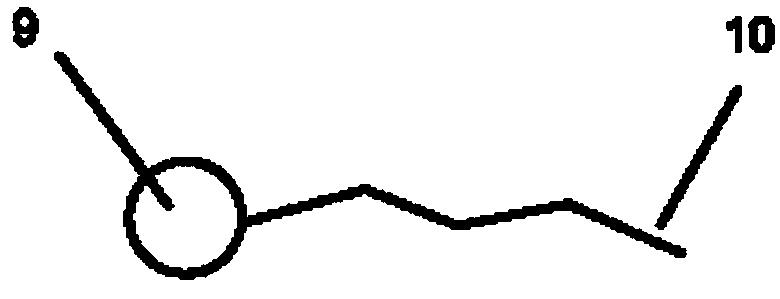

[0037] 1) Mix oil and emulsifier with HLB value < 6 evenly to obtain oil phase, mix water and polyols evenly to obtain water phase A, after fully stirring, slowly add water phase A to oil phase and continue to stir for emulsification , obtain emulsion a, emulsion a is the emulsion of water-in-oil structure;

[0038] 2) Mix polyol, emulsifier with HLB value>15, and water evenly to obtain water phase B, add the emulsion a obtained in step 1) into water phase B under stirring and continue to stir for emulsification to obtain emulsion b, emulsion B is the emulsion of water-in-oil-in-water structure;

[0039] 3) Mix the alkali metal hydroxide and water to obtain an alkali metal hydroxide solution, and then add the emulsion b obtained in step 2) into the alkali metal hydroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com