Cavitation jet-flow ozone degradation oxygenating device for marine product breeding

A mariculture, ozone degradation technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water aeration, etc., can solve the problem that microorganisms are difficult to effectively remove, and can not achieve both oxygenation and cleaning, and oxygen mass transfer efficiency. It can improve the theoretical power efficiency and oxygen utilization rate, reduce energy consumption, and improve the overall mass transfer coefficient of oxygen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

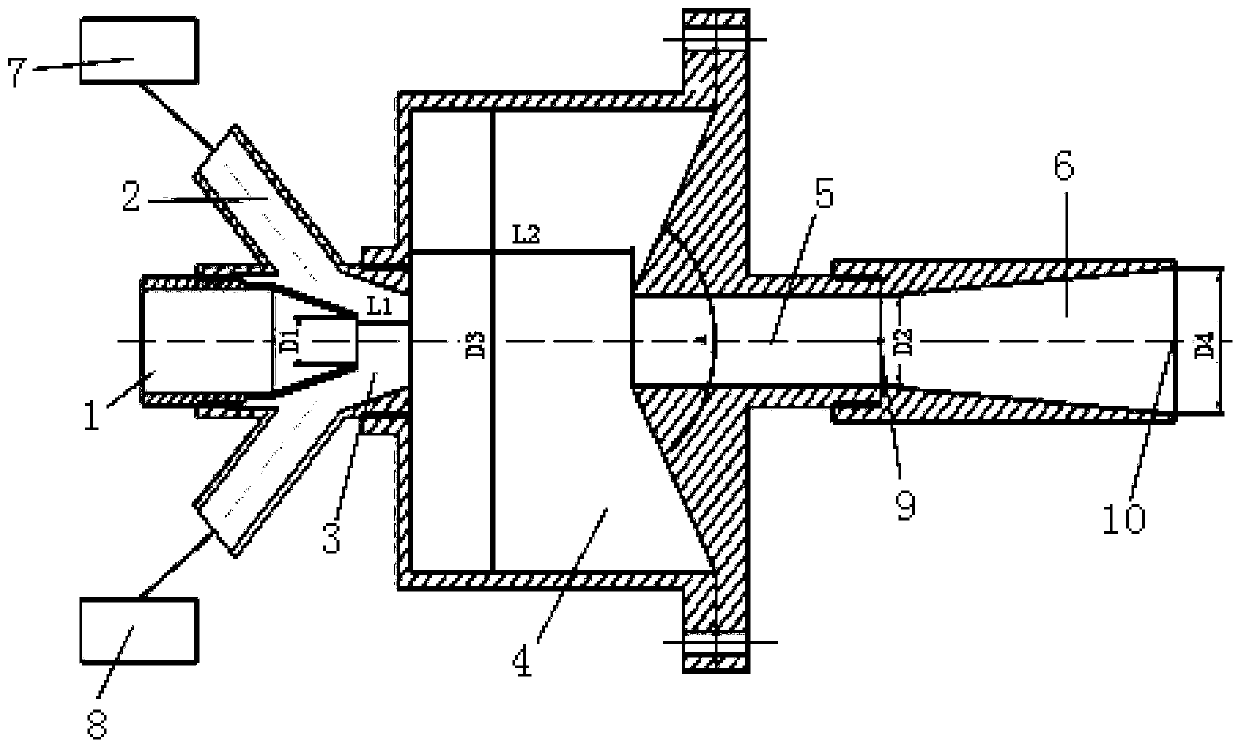

[0017] The cavitation jet ozone degrading oxygenation device of the present invention is used for mariculture, and its structure is as follows figure 1 As shown, it includes a nozzle 1, a suction chamber 3, a suction pipe 2, a self-excited oscillation chamber 4, a throat pipe 5 and a diffuser pipe 6. The outside of the suction chamber 3 is provided with two suction pipes 2 and a liquid inlet. The nozzle 1 is connected to the liquid inlet of the suction chamber 3 and is located inside the suction chamber 3 . The two-way suction pipes 2 are respectively connected with the first ozone generator 7 and the second ozone generator 8 . The suction chamber 3 and the inlet of the self-excited oscillation chamber 4 ( figure 1 in the left end) connection. Throat 5 and the outlet of self-excited oscillation chamber 4 ( figure 1 The right end of the ) connection. The diffuser pipe 6 is connected to the throat pipe 5 .

[0018] There are many factors that affect the working performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com