Preparation method of titanium oxide film and titanium oxide film

A titanium oxide film, titanium oxide technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of unsuitability for large-area and mass production of titanium oxide film, poor repeatability and uniformity, and long time consumption. Improve the utilization of sunlight, uniform aperture and density, smooth surface without cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention provides a simple, fast and low-cost chemical preparation method of a novel nano-porous titanium oxide film structure material.

[0032] details as follows:

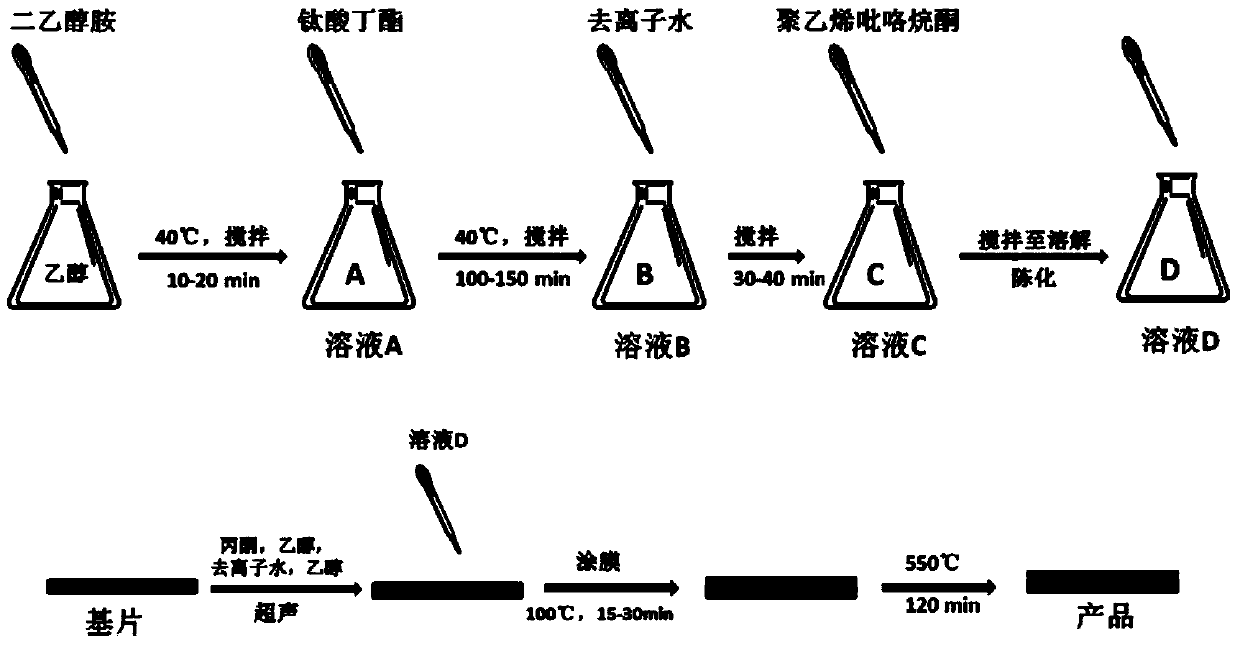

[0033] The first step, the preparation of titanium oxide precursor (such as figure 2 shown)

[0034] 1) Add diethanolamine dropwise to the stirring ethanol, the molar ratio is diethanolamine:ethanol=1:31.2, and stir at 40°C for 10-20 minutes to obtain solution A.

[0035] 2) Add butyl titanate to the above solution drop by drop, the molar ratio is butyl titanate:diethanolamine=1:1.62, and continue to stir at 40°C for 100-150 minutes to obtain solution B.

[0036] 3) Slowly add deionized water dropwise to the above system, the molar ratio is butyl titanate: water = 1:1.26, seal and stir for about 30-40 minutes to obtain light yellow transparent precursor solution C.

[0037] 4) Add a certain mass fraction of polyvinylpyrrolidone (molecular weight Mw=55000) to the light yellow transparent precursor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com