Antibacterial treatment method of down jackets

A treatment method and technology for down jackets, which are applied in the processing of textile materials, continuous processing of textile materials, fiber processing, etc., can solve the problems of structural damage and difficulty in sterilization of down jackets, and achieve the effect of ensuring health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

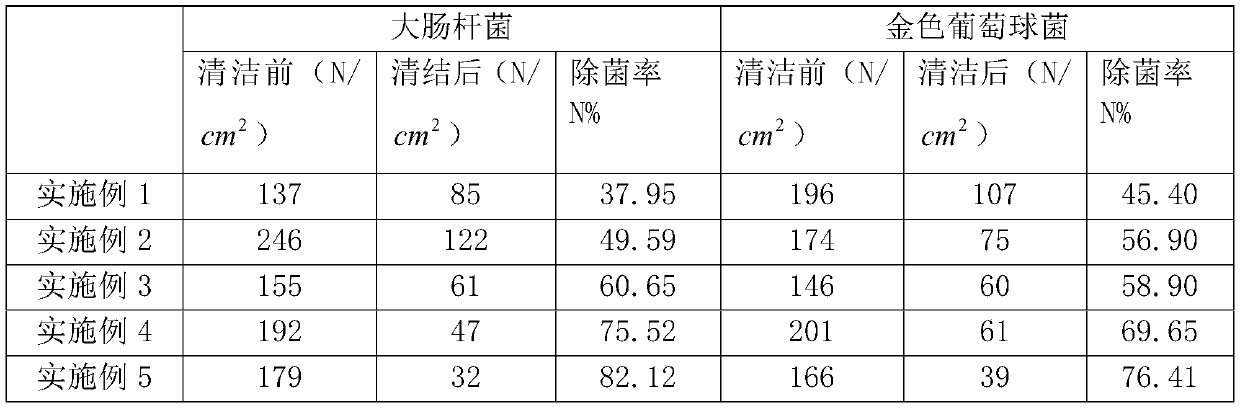

Examples

Embodiment 1

[0016] An antibacterial treatment method for down jackets, comprising the following steps:

[0017] a. Hang the down jacket that needs to be processed on the rack, and heat the down jacket through the multi-directional hot air blower; the blowing temperature of the hot air blower is divided into three types: 10-20°C, 30-40°C and 40-50°C Gear position, the down jacket is heated through the three gears of the hot air blower in sequence, the heating time is 10-20 minutes, and the interval between each gear is 2-5 minutes.

[0018] b. Soak the down jacket heated in step a in warm water containing a leavening agent, and shake off excess water after the down jacket expands as a whole; the leavening agent is a sodium tripolyphosphate solvent with a mass percentage of 10-15% , the water temperature of warm water is controlled at 40-60°C, and soaked continuously for 10-20 minutes.

[0019] c. Hang the dehydrated down jacket in step b in the disinfection tank, and steam wash the down j...

Embodiment 2

[0022] An antibacterial treatment method for down jackets, comprising the following steps:

[0023] a. Hang the down jacket that needs to be processed on the rack, and heat the down jacket through the multi-directional hot air blower; the blowing temperature of the hot air blower is divided into three types: 10-20°C, 30-40°C and 40-50°C Gear position, the down jacket is heated through the three gears of the hot air blower in sequence, the heating time is 10-20 minutes, and the interval between each gear is 2-5 minutes.

[0024] b. Soak the down jacket heated in step a in warm water containing a leavening agent, and shake off excess water after the down jacket expands as a whole; the leavening agent is a sodium tripolyphosphate solvent with a mass percentage of 10-15% The warm water also contains Andrographis paniculata poached liquid with a mass percentage of 5-10%, the temperature of the warm water is controlled at 40-60° C., and the soaking is continued for 10-20 minutes.

...

Embodiment 3

[0028] An antibacterial treatment method for down jackets, comprising the following steps:

[0029] a. Hang the down jacket that needs to be processed on the rack, and heat the down jacket through the multi-directional hot air blower; the blowing temperature of the hot air blower is divided into three types: 10-20°C, 30-40°C and 40-50°C Gear position, the down jacket is heated through the three gears of the hot air blower in sequence, the heating time is 10-20 minutes, and the interval between each gear is 2-5 minutes.

[0030] b. Soak the down jacket heated in step a in warm water containing a leavening agent, and shake off excess water after the down jacket expands as a whole; the leavening agent is a sodium tripolyphosphate solvent with a mass percentage of 10-15% , the water temperature of the warm water is controlled at 40-60°C, continuously soaked for 10-20 minutes, and the warm water also contains 10-15% by mass of sodium tripolyphosphate solvent and 5-10% by mass of Ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com