Preparation method of transparent thermal insulation self-cleaning coating

A self-cleaning and coating technology, applied in the direction of coating, can solve the problems of difficult to ensure the uniform stability of the coating, the decline of material performance, and inconvenient application, and achieve excellent self-cleaning performance, good thermal insulation performance, and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of photocatalyst

[0033] Mix 68g of tetrabutyl titanate, 20.8g of tetraethyl orthosilicate and 40g of absolute ethanol evenly, and add dropwise to a mixture containing 68% by volume of nitric acid 1g, water 6g, absolute ethanol 328g and acetoacetone 20g. The solution was stirred at 70° C. for 8 hours at a stirring speed of about 3000 rpm, and cooled to obtain anatase-type nano-titanium dioxide sol with a particle size of 10-50 nm.

[0034] (2) Preparation of thermal insulation powder dispersion

[0035] Disperbyk-110 10g, antifoaming agent GPE 0.5g and volume percentage are 339.5g of ethanol 339.5g of 95% to mix evenly, under high-speed stirring (stirring speed is 2500-3500 rev / min) in gained mixed solution, add antimony tin oxide (grain diameter 20-80nm) 150g, stirred for 30 minutes, and then ultrasonically dispersed for 30 minutes.

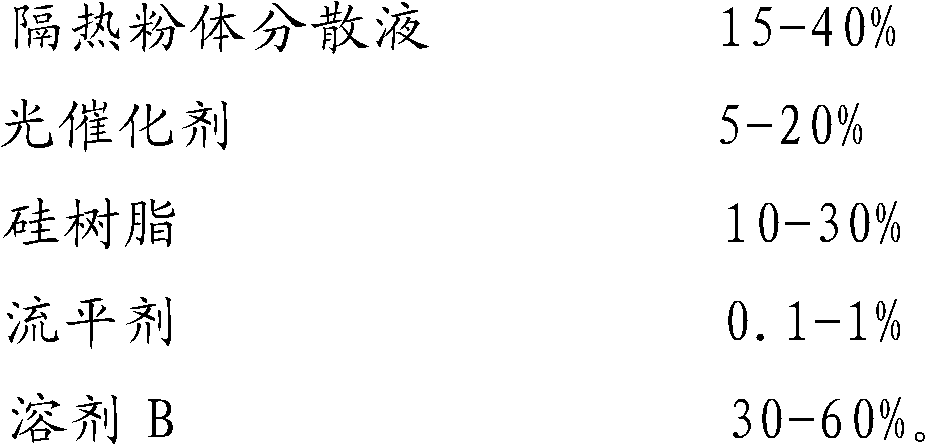

[0036] (3) Prepare 500g of transparent heat-insulating self-cleaning paint, and the consumption of each component is ...

Embodiment 2

[0046] (1) Preparation of photocatalyst

[0047] Mix 68g of tetrabutyl titanate, 33g of tetraethyl orthosilicate and 50g of absolute ethanol, and add dropwise to the mixed solution containing 2g of nitric acid, 6g of water, 328g of absolute ethanol and 30g of acetoacetone with a volume percentage of 68% , stirred at 50° C. for 12 hours, and cooled to obtain anatase-type nano-titanium dioxide sol with a particle size of 20-50 nm.

[0048] (2) Preparation of thermal insulation powder dispersion

[0049] Disperbyk-180 5g, antifoaming agent GPE 3.5g and volume percentage are 95% ethanol 369g to mix uniformly, under high-speed stirring (stirring speed is 2900-4000 rev / min) in gained mixed solution, add antimony tin oxide (particle diameter 20-60nm) 125g, stirred for 60 minutes, and then ultrasonically dispersed for 40 minutes.

[0050] (3) Prepare 500g of transparent heat-insulating self-cleaning paint, and the consumption of each component is as follows:

[0051] Photocatalyst: 7...

Embodiment 3

[0061] (1) Preparation of photocatalyst

[0062] Mix 51g of tetrabutyl titanate, 30g of tetraethyl orthosilicate and 30g of absolute ethanol evenly, and add dropwise to a mixed solution containing 0.5g of nitric acid with a volume percentage of 68%, 3g of water, 180g of absolute ethanol and 15g of acetylacetone , stirred at 80° C. for 15 hours, and cooled to obtain anatase-type nano-titanium dioxide sol with a particle size of 30-50 nm.

[0063] (2) Preparation of thermal insulation powder dispersion

[0064] Mix 8 g of Disperbyk-180, 1 g of defoamer DF-4164 and 291 g of ethanol with a volume percentage of 95%, and add indium tin oxide (grain diameter 30-70nm) 200g, stirred for 90 minutes, and then ultrasonically dispersed for 15 minutes.

[0065] (3) Prepare 500g of transparent heat-insulating self-cleaning paint, and the consumption of each component is as follows:

[0066] Photocatalyst: 75g

[0067] Thermal insulation powder dispersion: 100g

[0068] Methyl silicone r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com