Vertical vibration conveying and drying integrated device

A vertical vibration and drying technology, applied in the directions of vibrating conveyors, drying gas arrangement, drying solid materials, etc., can solve the problems of unfavorable rapid grain transportation and postpartum drying, spending a lot of time and resources, and achieving unsatisfactory results. Reduce equipment failure rate and equipment investment cost, facilitate maintenance and cleaning, and have the effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

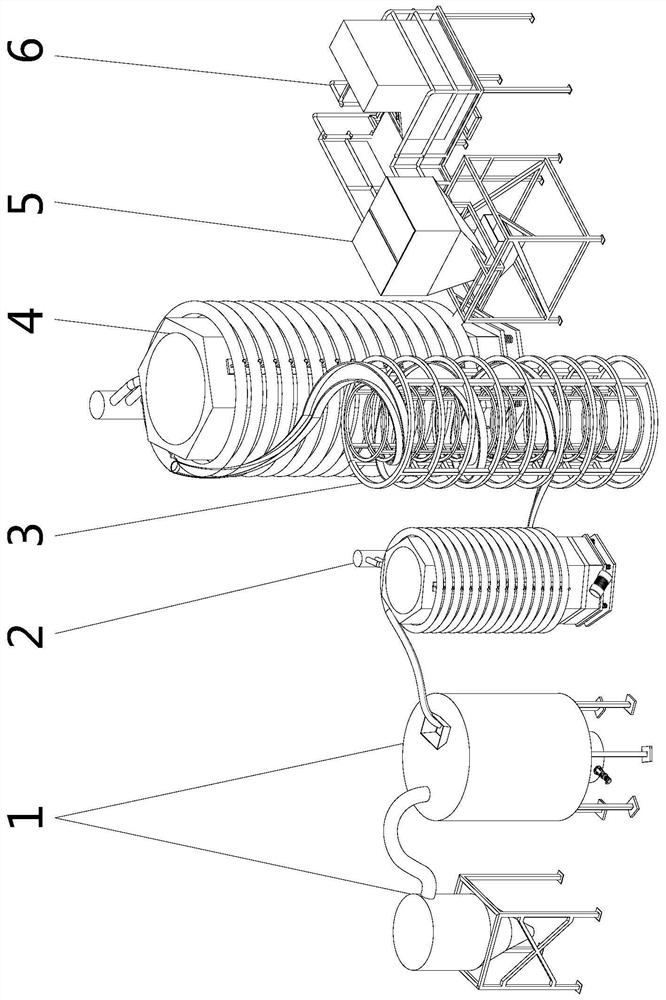

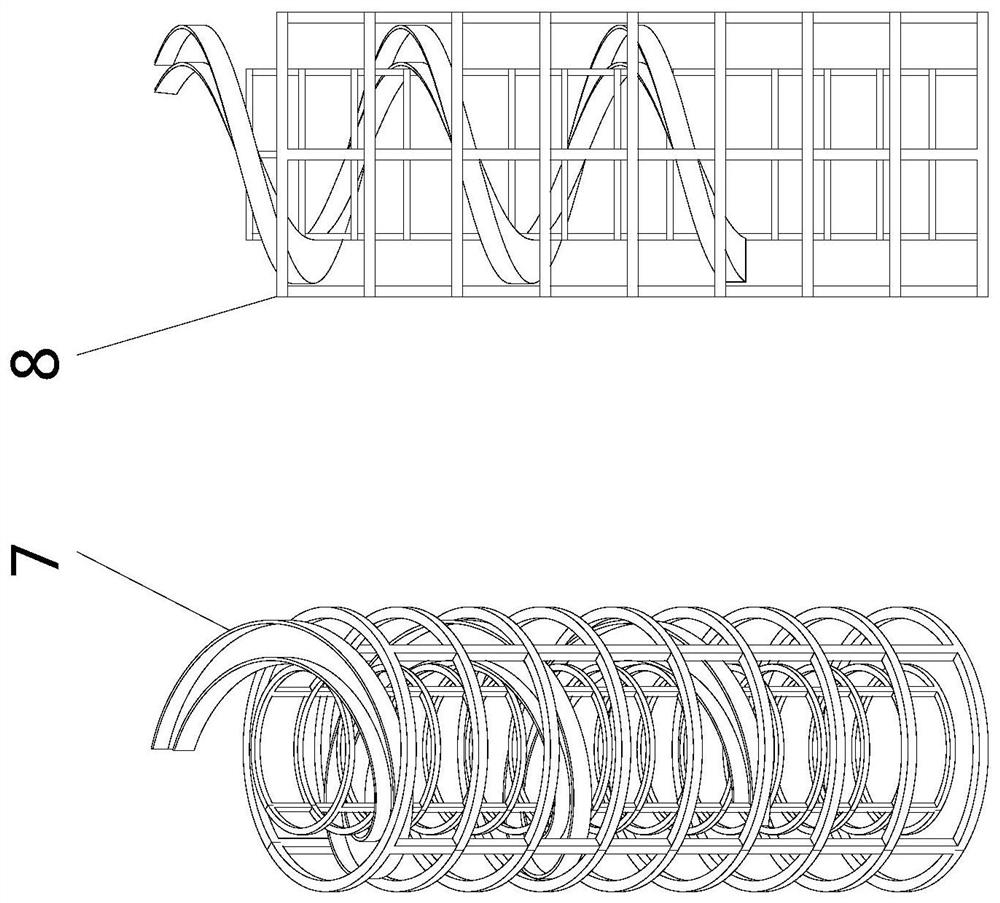

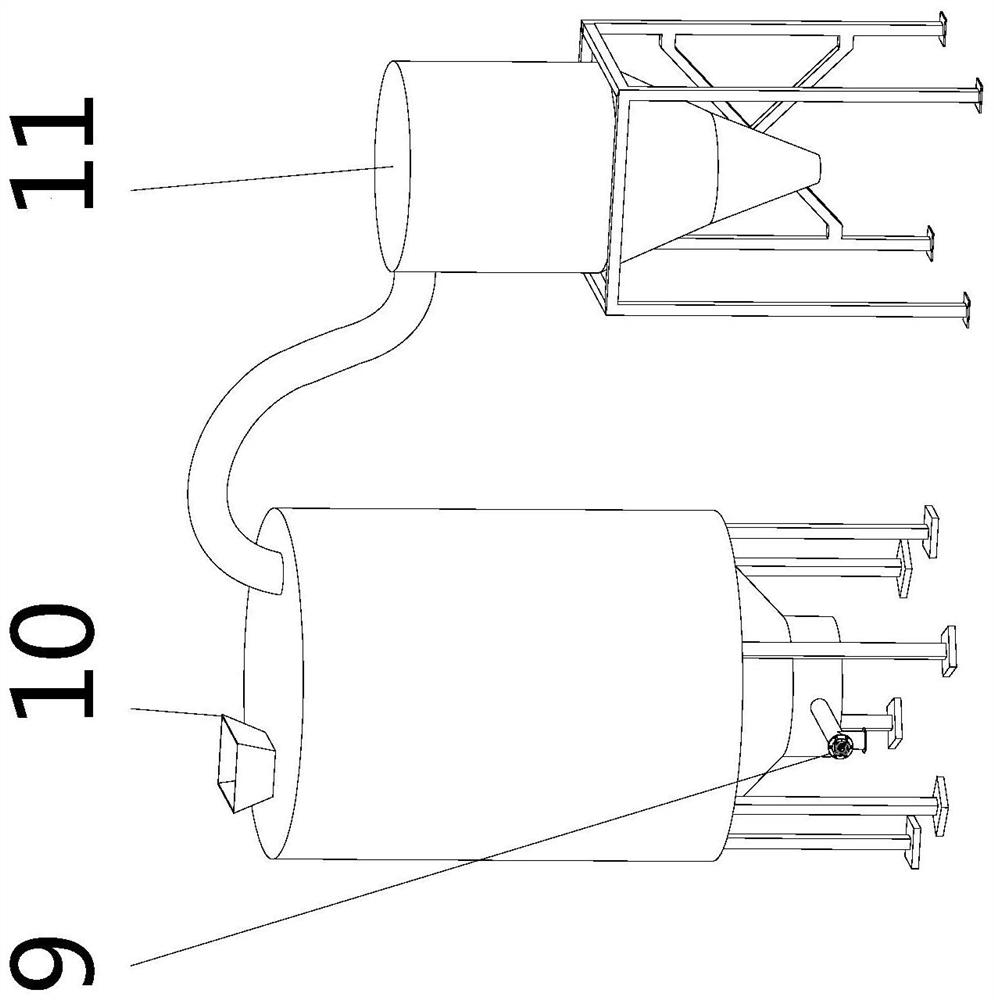

[0034] The present invention provides an integrated device for vertical vibration conveying and drying, which includes: a material feeding structure 5 and a material discharging structure; The pipelines are connected in series in the material conveying direction; the vertical conveying pipelines are driven by the driver to perform circular movement on the horizontal plane and vertical movement up and down on the vertical plane; The material structure is connected; the heater is used to heat the material in the vertical conveying pipeline.

[0035] The structure of the vertical conveying pipe and the heater enables the post-production drying of the grain while vibrating an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com