Patents

Literature

503results about How to "Automate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

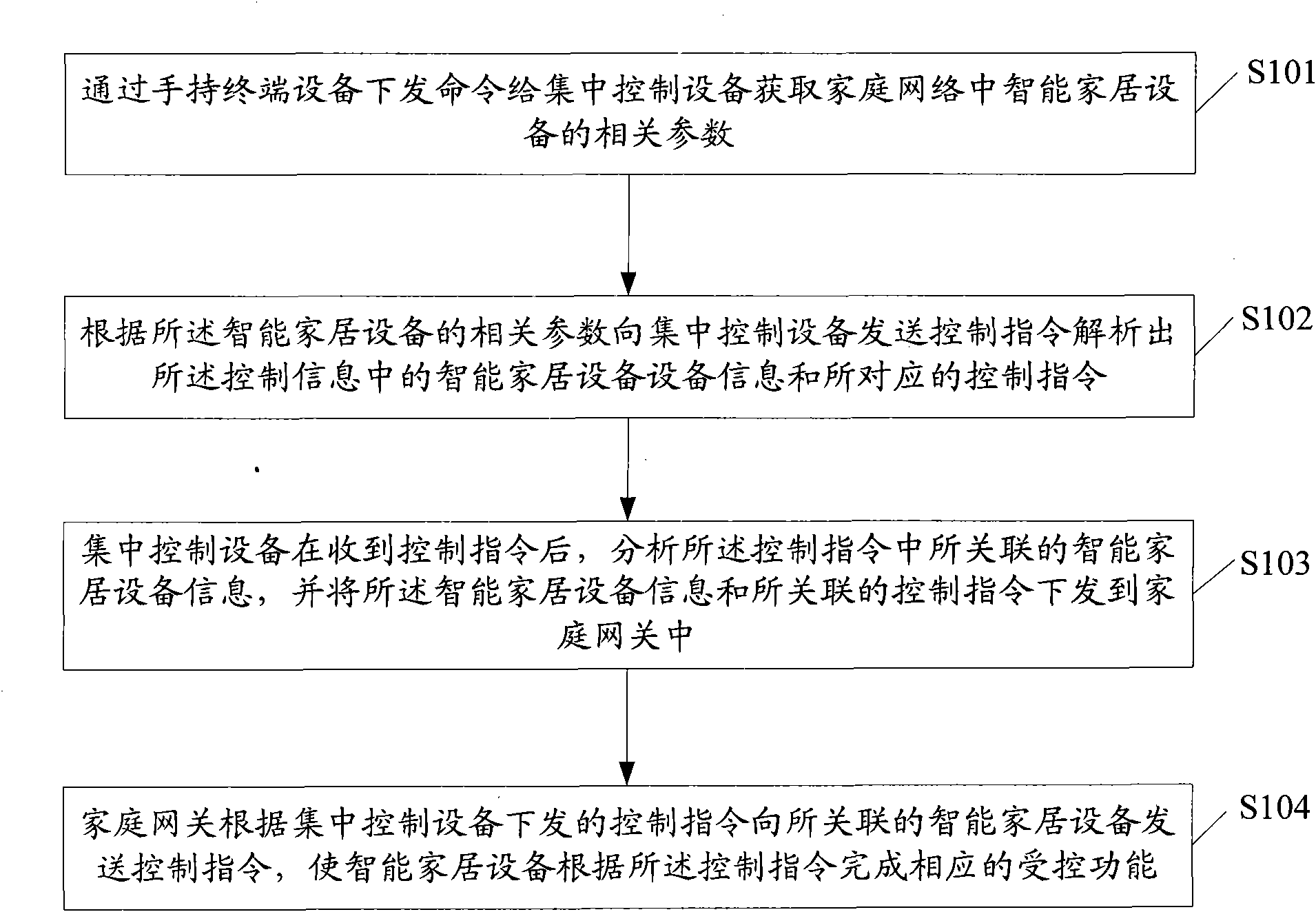

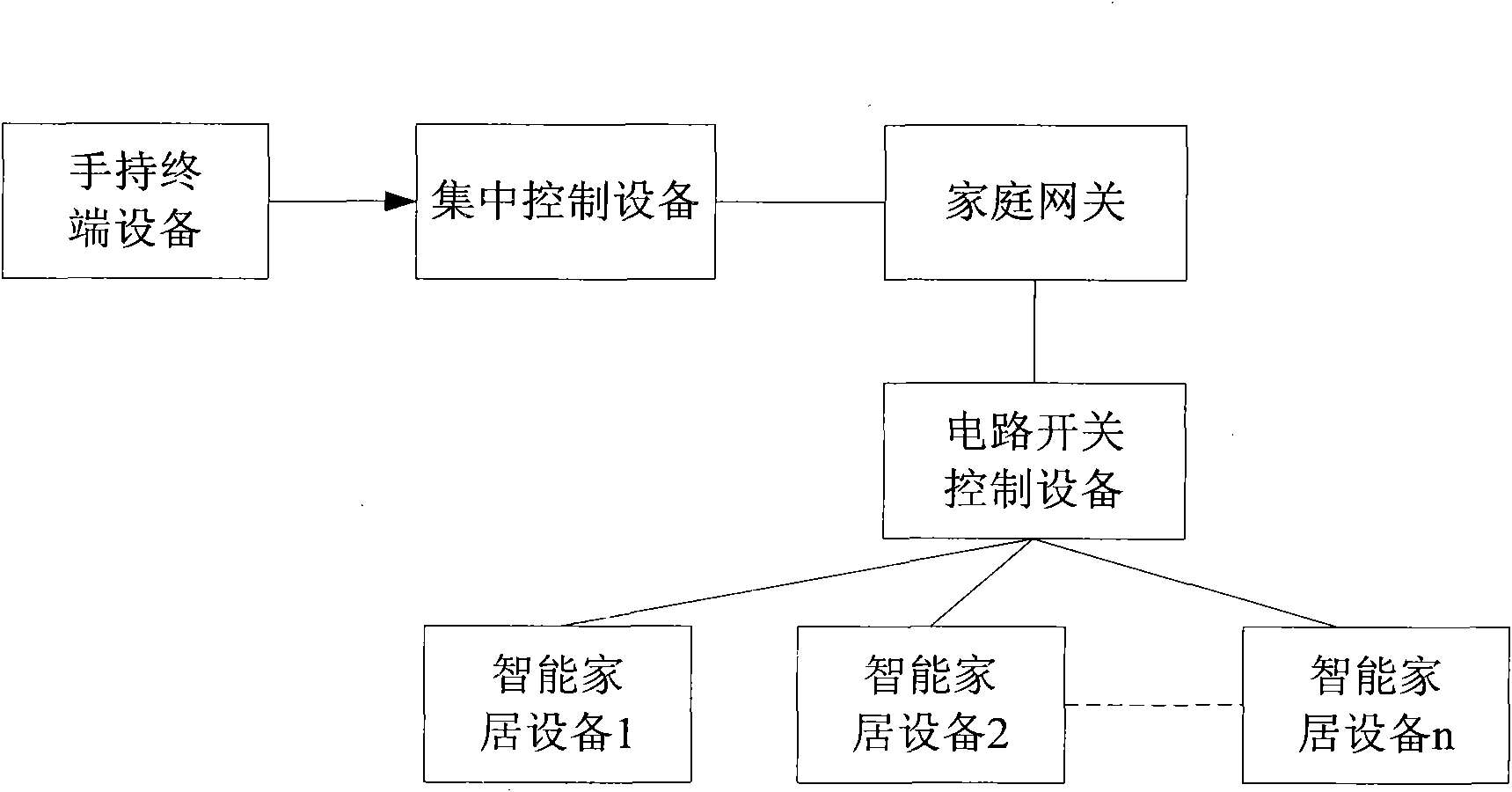

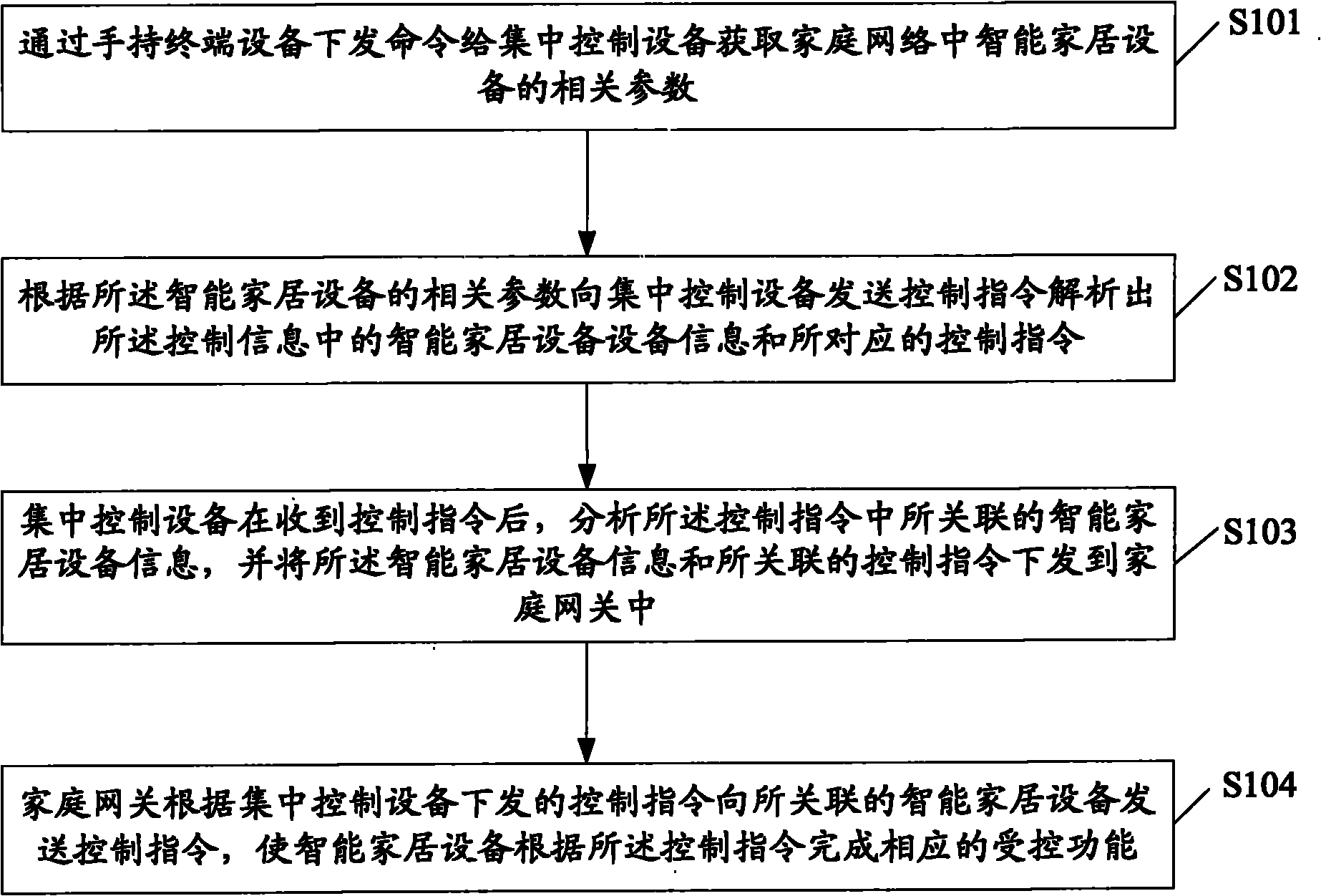

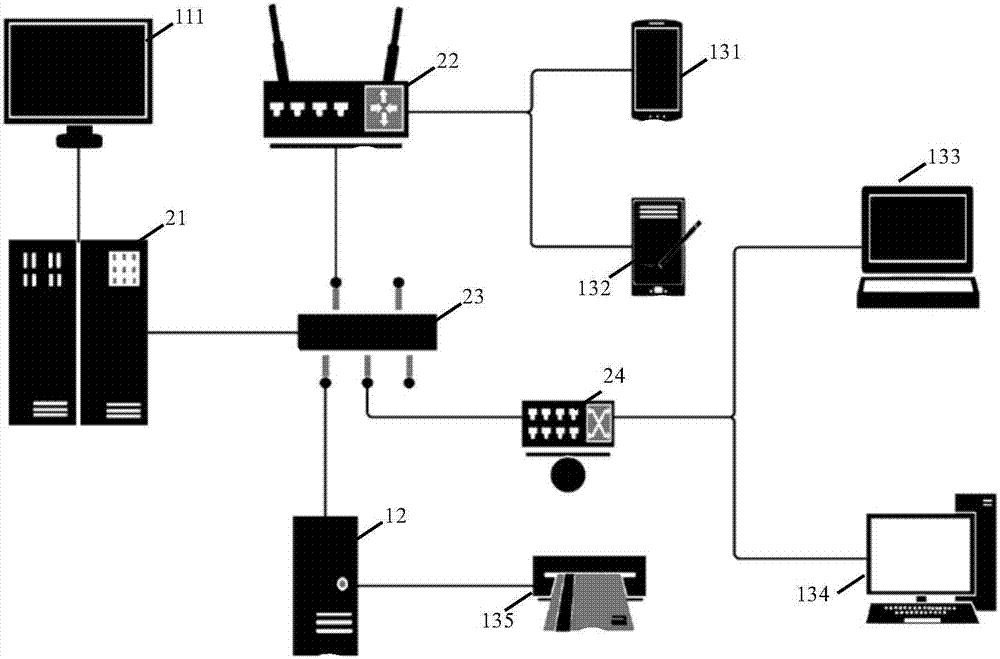

Interactive method for controlling intelligent home equipment and home network system

InactiveCN101848126AAutomateEasy to useTransmission systemsData switching by path configurationEmbedded systemControl function

The embodiment of the invention discloses an interactive method for controlling intelligent home equipment, which comprises the following steps: sending a command to a central control device through a handheld terminal device to get the relevant parameters of the intelligent home equipment in a home network; transmitting a control command to the central control device central control device based on the relevant parameters of the intelligent home equipment; the central control device analyzing the relevant information of the intelligent home equipment in the control command after receiving the control command, and sending the relevant information of the intelligent home equipment and the relevant control command to a home gateway; and the home gateway sending the control command to the relevant intelligent home equipment according to the control command sent by the central control device, thereby making the intelligent home equipment finish the corresponding controlled function according to the control command. The embodiment of the invention also discloses a system. Moreover, the embodiment of the invention can facilitate the use of all intelligent home equipment for the user, thereby making all the household electrical appliances realize automation in a higher sense.

Owner:SUN YAT SEN UNIV

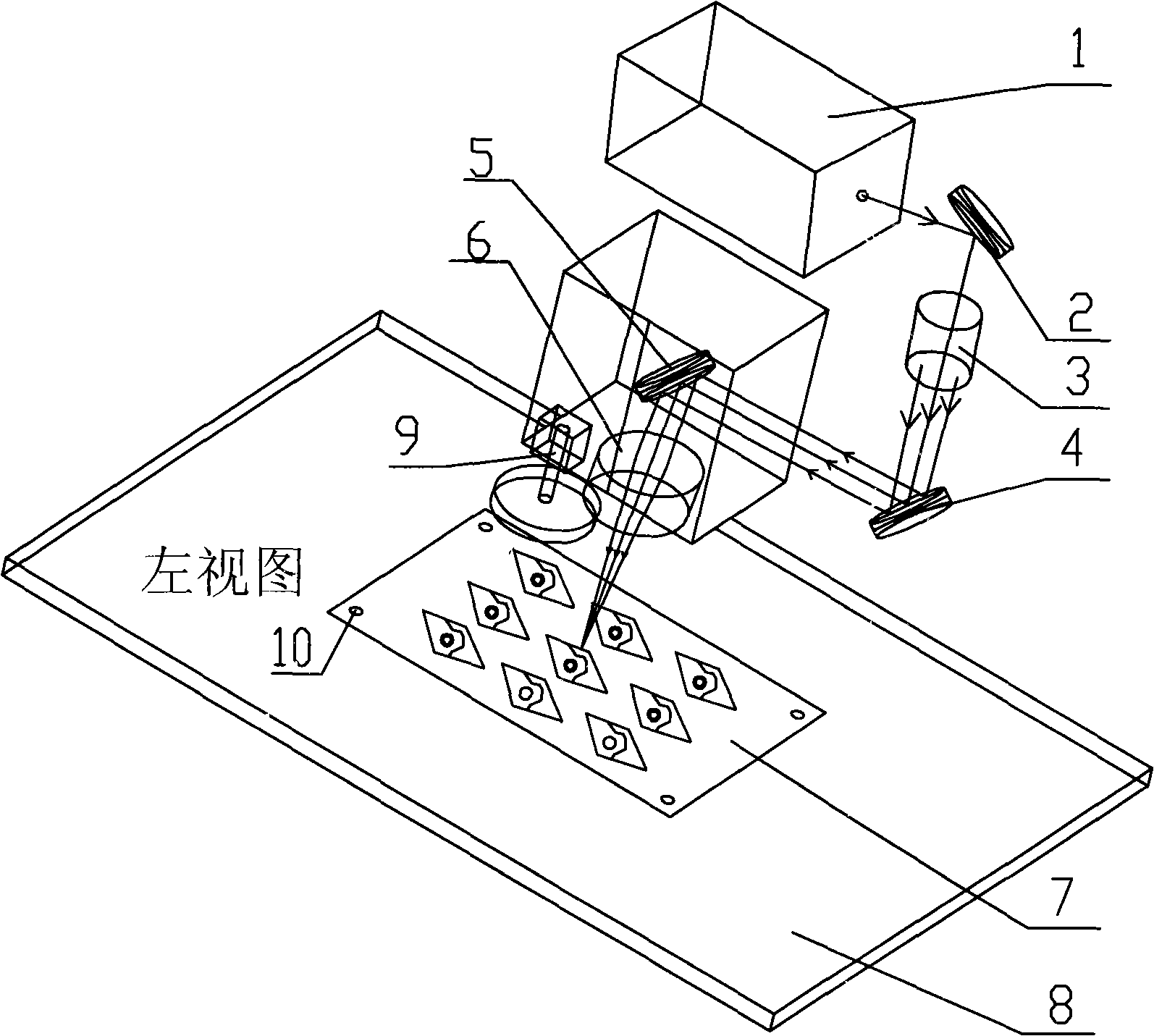

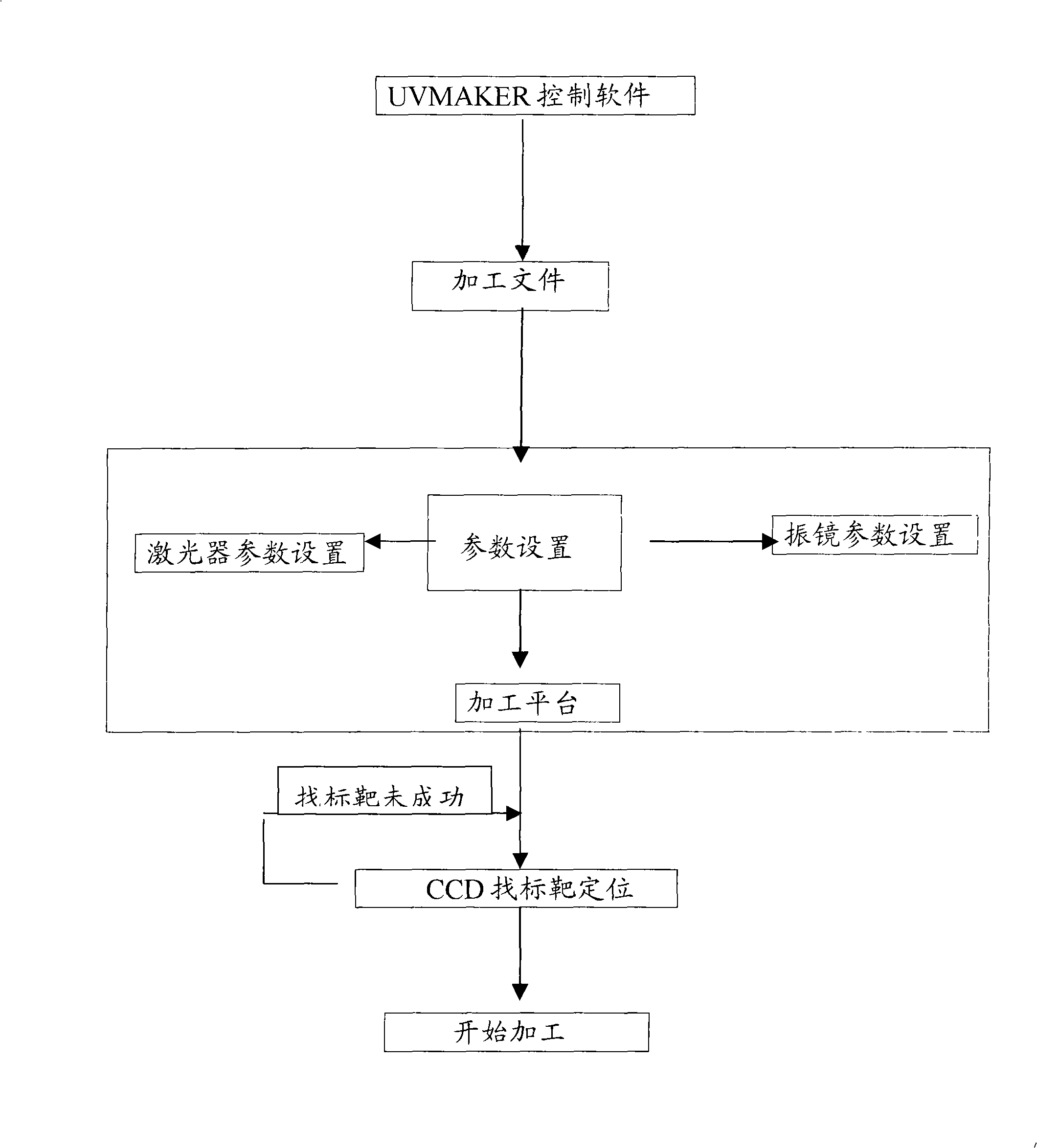

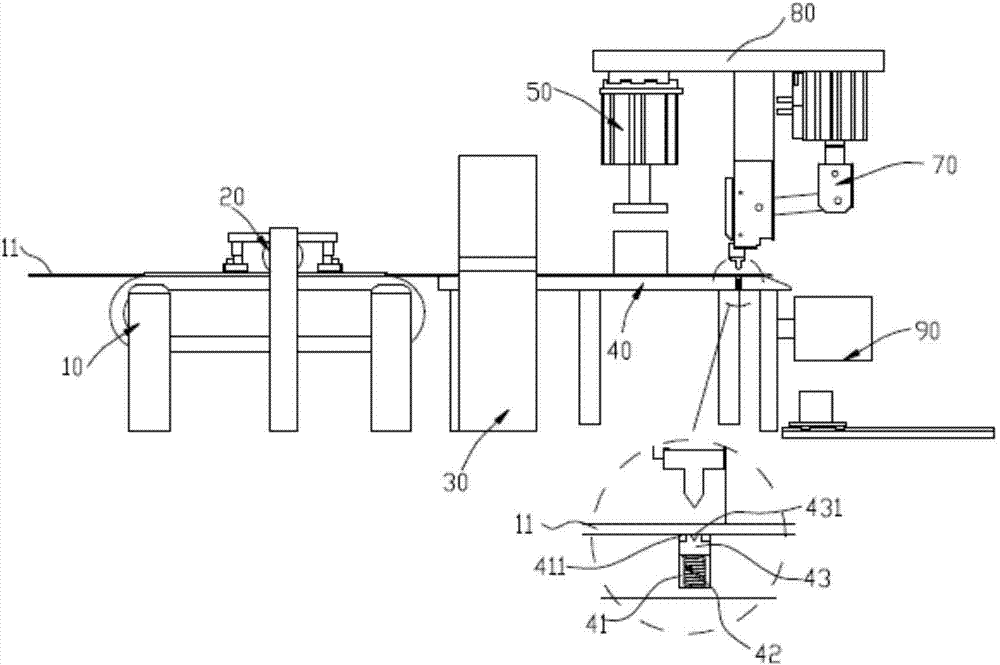

Laser device for cutting

ActiveCN101288921AGood cutting effectAutomateWork holdersLaser beam welding apparatusLaser cuttingEngineering

The invention discloses an FPC (Flexible Printed Circuit) laser cutting device, consisting of a laser focus scanning system, a control system and a vacuum platform system. The cutting device of the invention improves the FPC formation accuracy and saves processing time and cost.

Owner:HANS CNC SCI & TECH

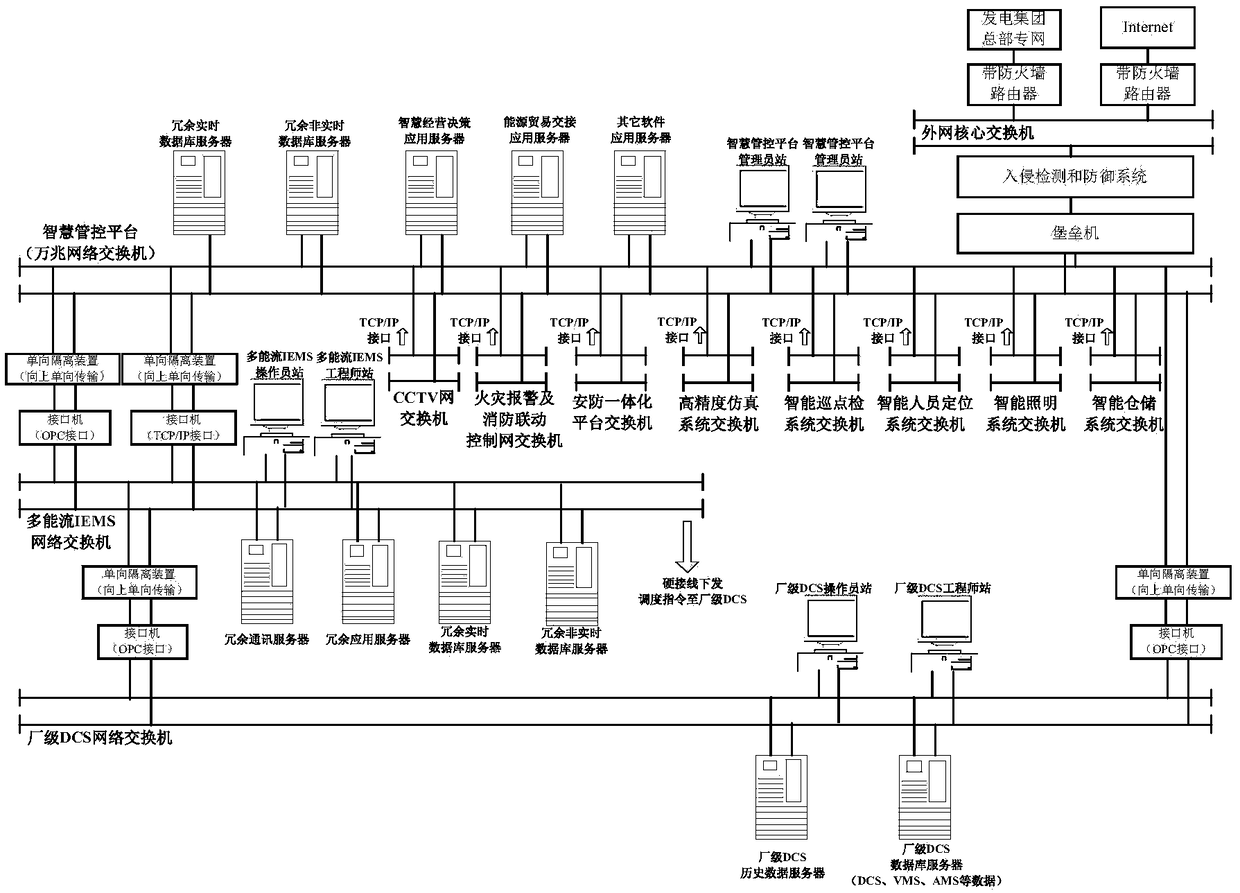

Smart power plant integrated monitoring and management system

PendingCN108762224AReal-timeRealize visualizationTotal factory controlProgramme total factory controlAutomatic controlSmart power

The invention discloses a smart power plant integrated monitoring and management system which comprises a smart management and control platform, a multi-energy flow IEMS network switch and a factory-level DCS; a smart management and control platform comprises a 10 Gigabit network switch, a server and a smart management and control platform administrator station; the server comprises a redundant real-time data server, a redundant non-real-time database server, a smart business decision-making application server, an energy trade transition application server and other software application servers; the server and the smart management and control platform administrator station are connected with the 10 Gigabit network switch; the factory-level DCS has two ways to upload externally; and the multi-energy flow IEMS network switch has two ways of upward interfaces. The system has the benefits that: a linkage application case after intelligent subsystems are accessed is planned, so that the design integrity of the smart power plant is stronger; combined with a DCS control system, the extension of automatic control range to the automatic control of the whole process operation is realized; and the smart power plant is endowed with the ability to integrate with the overall design of upper-level smart parks and smart cities.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

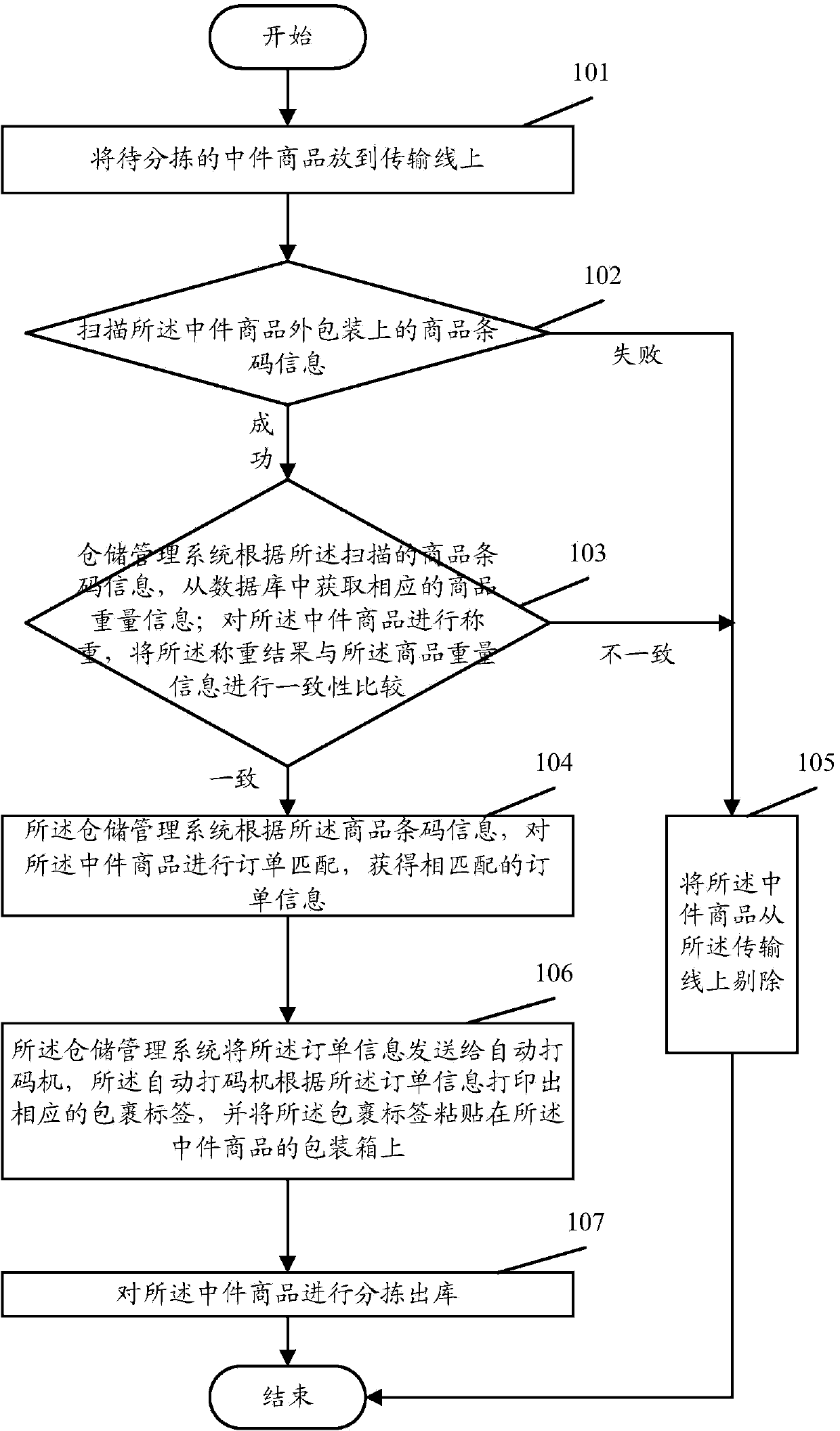

Commodity ex-warehouse method

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

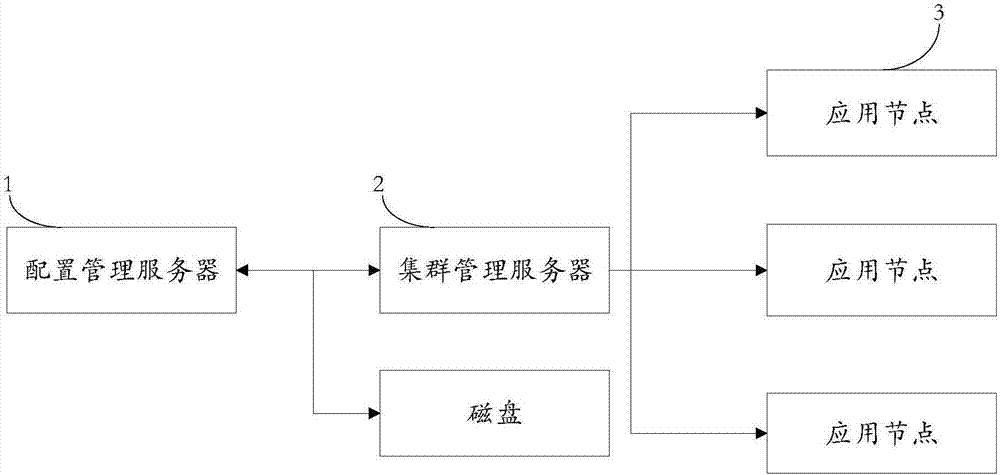

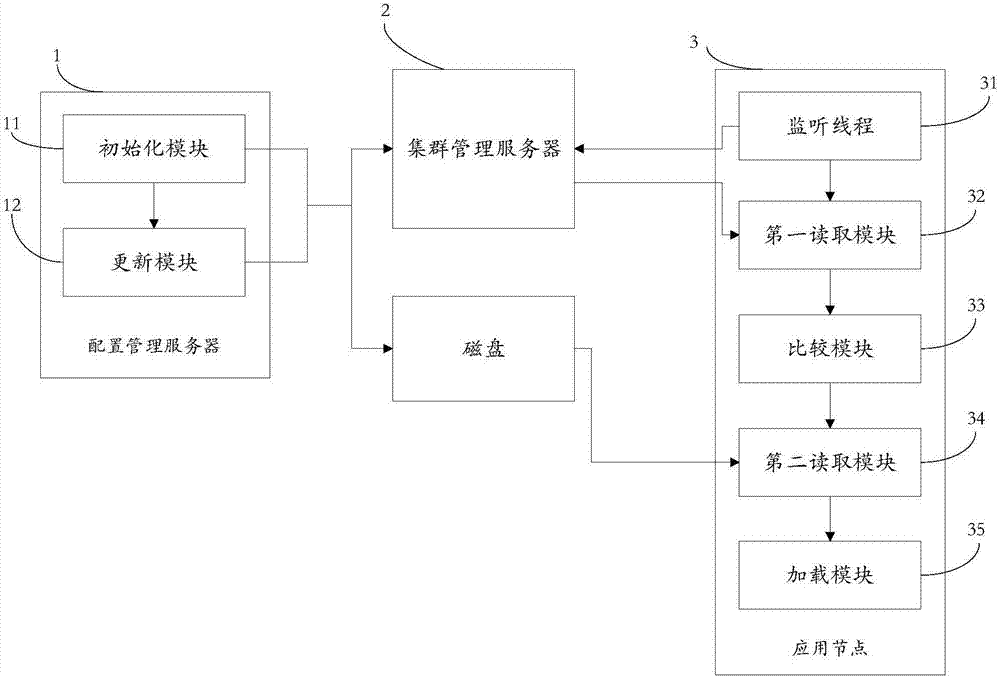

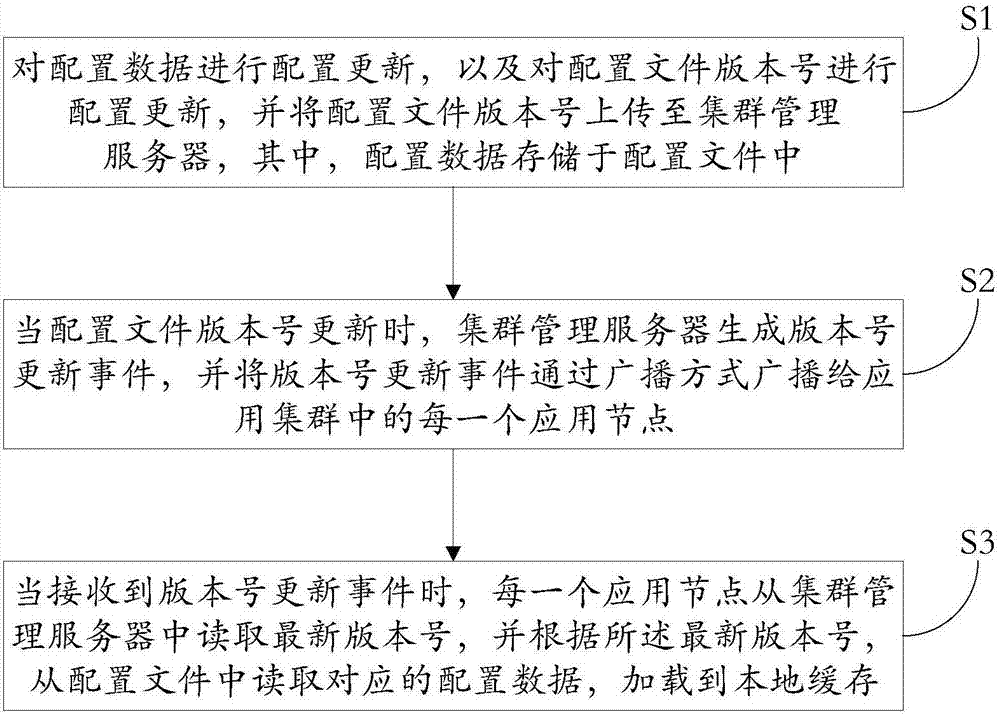

Configuration data dynamic updating system and method based on application cluster

The invention relates to a configuration data dynamic updating system and method based on an application cluster. The system and method has the advantages that a configuration file version number scheme is introduced; configuration data is classified and managed through a configuration file version number based on a cluster management server; the cluster management server informs application nodes of a version number change event when the configuration file version number changes; after learning the version number change event through monitoring, the application nodes acquire the latest version from the cluster management server, read configuration data corresponding to the latest version number, analyze the configuration data, assemble the analyzed data into local cache objects, and update local caches to complete dynamic updating of the configuration data; and only the configuration file version number is stored on the cluster management server, and the specific configuration data is stored through discs, so that limits from a memory of the cluster management server are removed, and the dynamic updating of massive data can be achieved.

Owner:北京思特奇信息技术股份有限公司

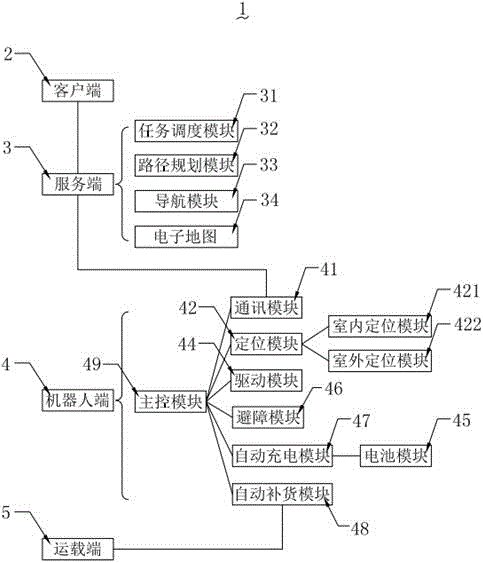

System for automatically conveying mobile robots

PendingCN106584466AAutomateReduce human inputProgramme-controlled manipulatorDistribution systemRoute planning

The invention provides a system for automatically conveying mobile robots. The system for automatically conveying the mobile robots comprises client ends, a service end, robot ends and conveying ends. The service end comprises a task scheduling module, a route planning module and a navigation module. Each robot end comprises a master control module, a communication module, a location module, a driving module, a battery module and the like. By means of the system for automatically conveying the mobile robots, the technical problems that in the prior art, distribution modes are inconvenient to implement, and automated distribution systems are incomplete are solved.

Owner:湖南天特智能科技有限公司

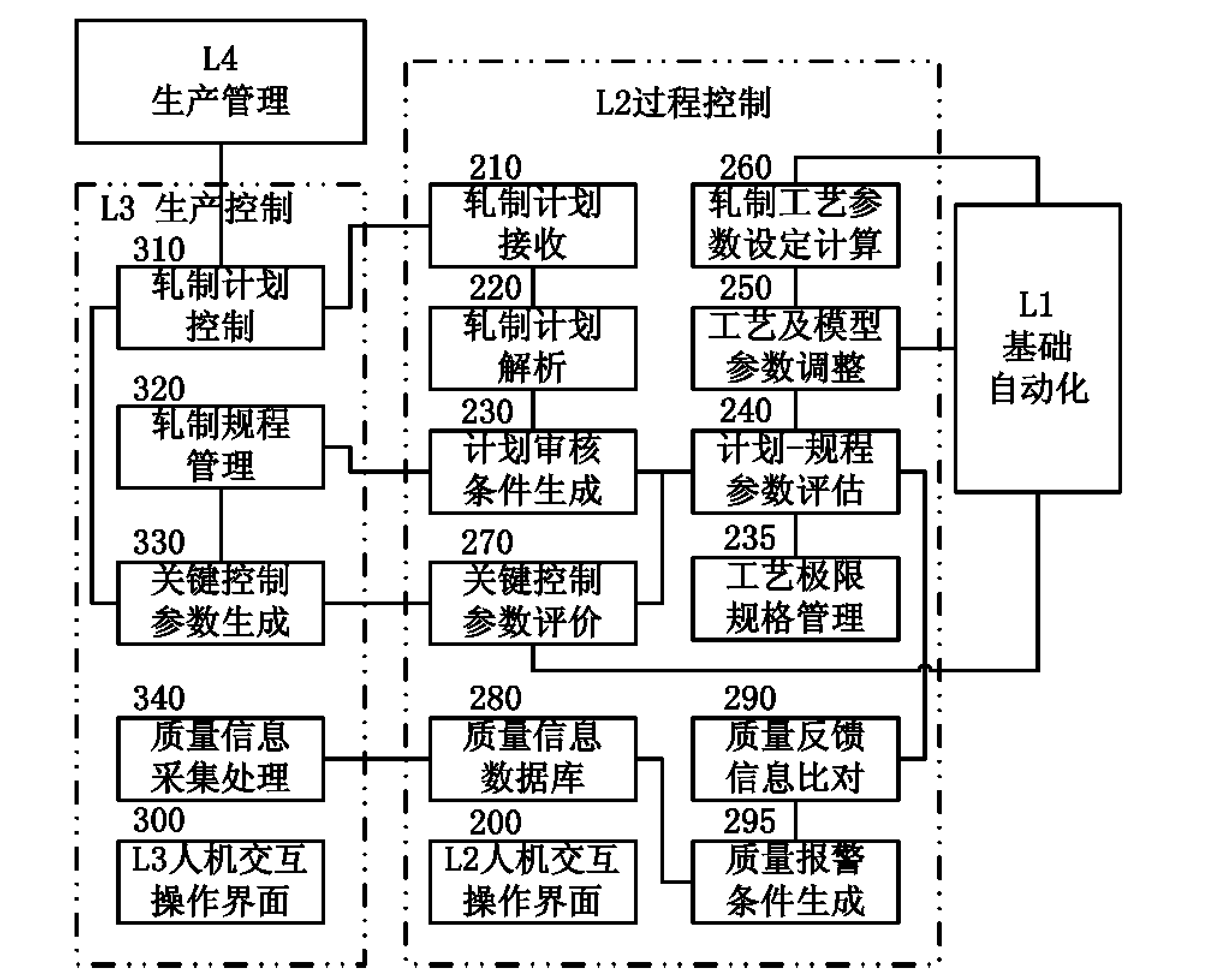

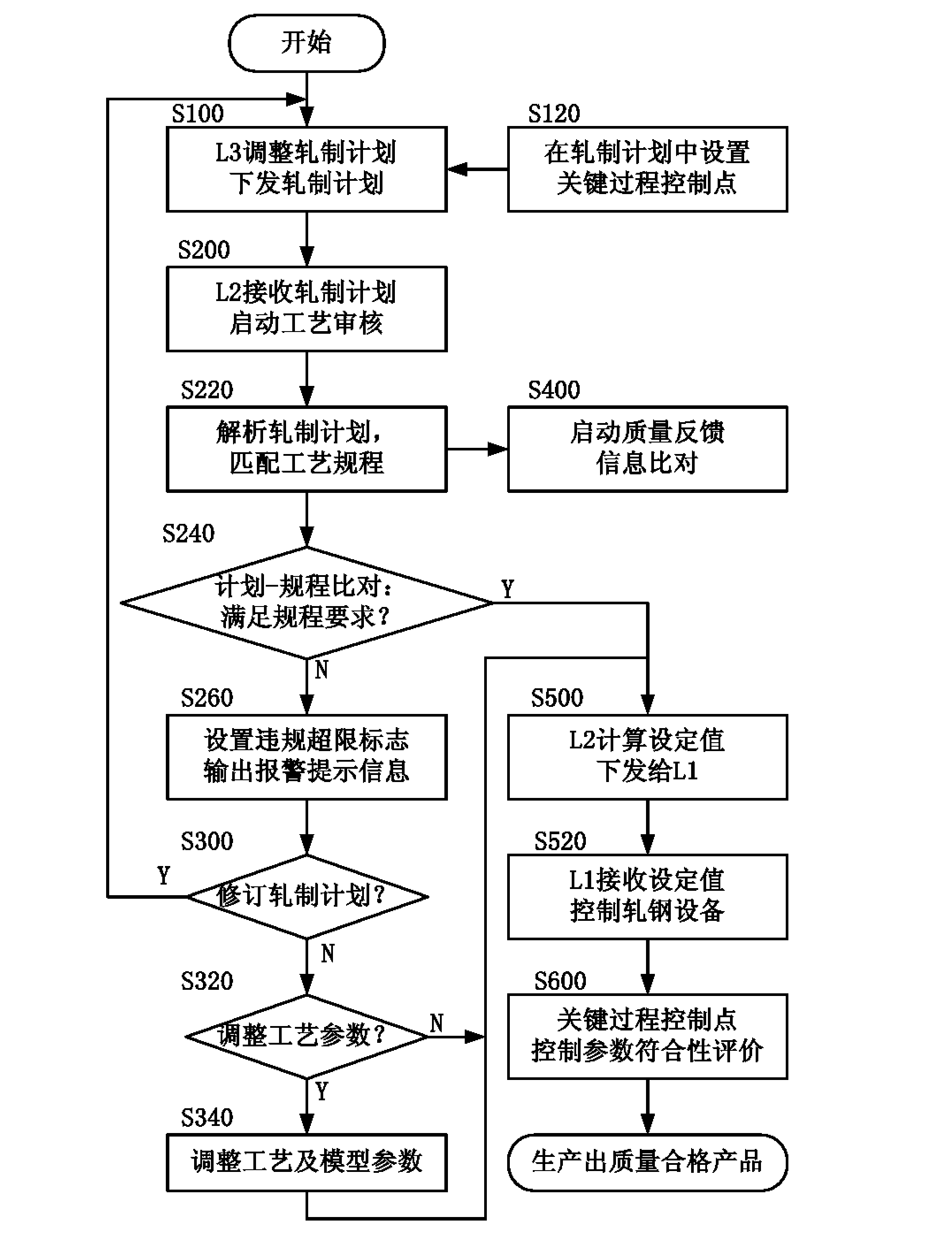

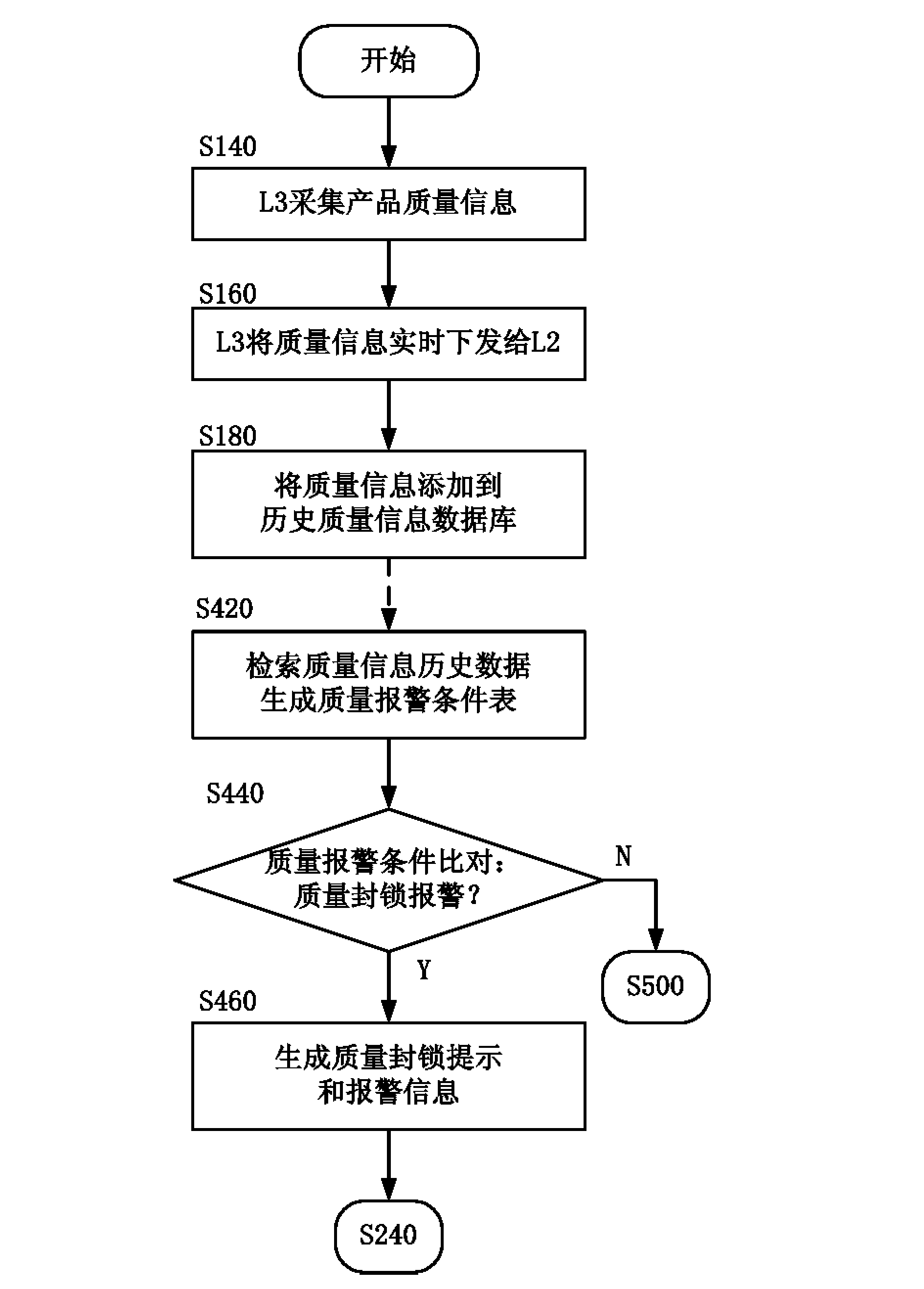

Online rolling plan dynamic pre-analysis and self-adjustment system and method

ActiveCN102591286AAutomateImprove efficiencyTotal factory controlProgramme total factory controlPlan analysisModel parameters

The invention relates to CIM (Computer Integrated Manufacturing) applicable for overall factory control and discloses an online rolling plan dynamic pre-analysis and self-adjustment system and method having quality information feedback. The online rolling plan dynamic pre-analysis and self-adjustment system comprises a rolling plan analysis module, a plan review condition generation module and a plan-regulation parameter evaluation module, wherein a rolling regulation management module and the rolling plan analysis module are connected to the plan-regulation parameter evaluation module through the plan review condition generation module; and the e plan-regulation parameter evaluation module is connected to a rolling technical parameter setting and calculating module through a technology and model parameter adjustment module. The method comprises the steps of: analyzing the rolling plan; comparing the rolling plan with the rolling regulation; screening regulation items; generating a plan review condition table and setting a rule-breaking and limit-exceeding mark; and displaying limit specification of the technology and prompting and automatically adjusting technological parameters. According to the online rolling plan dynamic pre-analysis and self-adjustment system and method, disclosed by the invention, automatic plan review is realized, plan reviewing efficiency is improved and the problem that plan defects cannot be discovered in time and exactly due to missed detection and misjudgment of artificial review can be avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

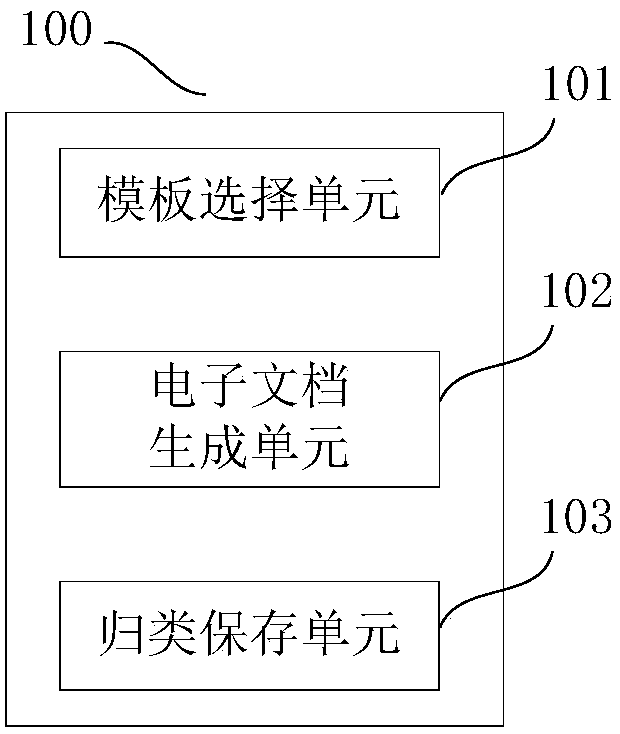

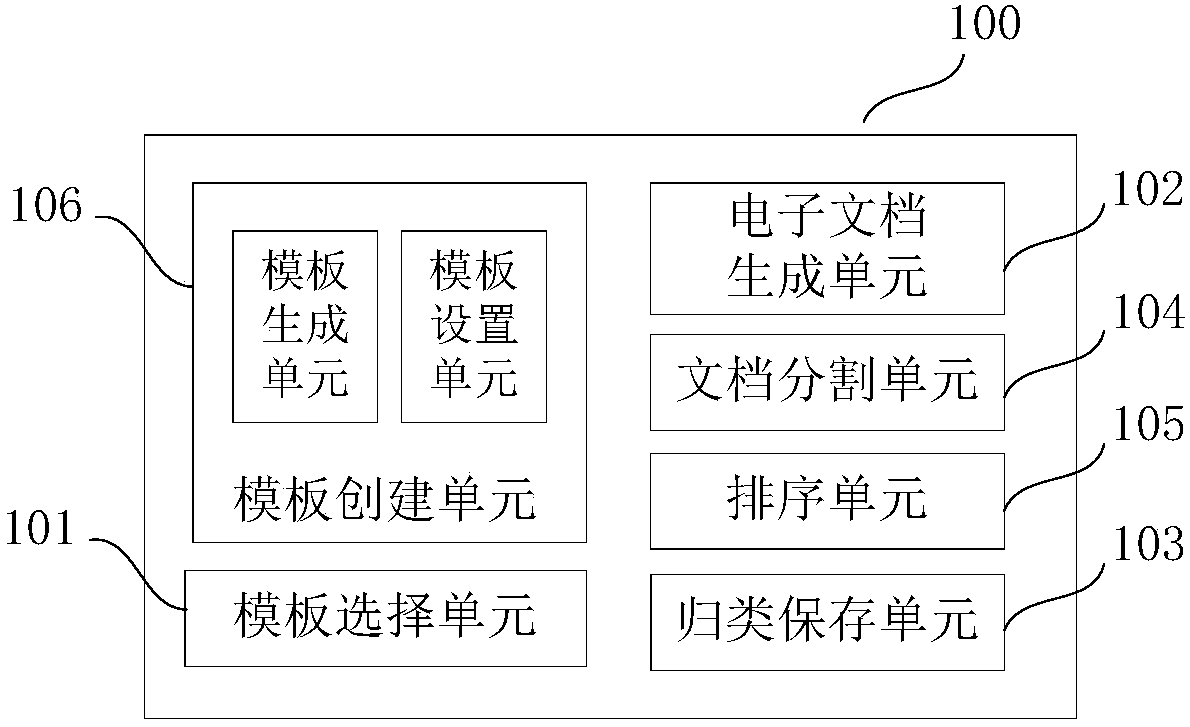

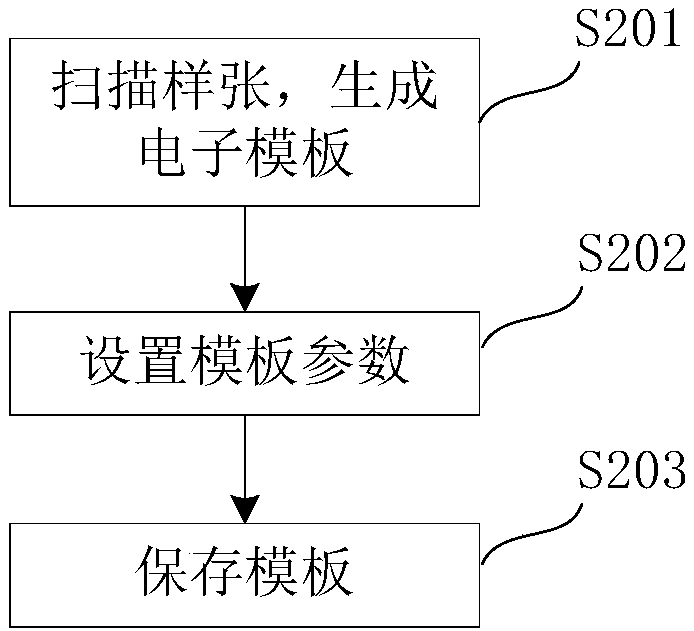

Batch document scanning and sorting apparatus and method, medium and device

InactiveCN107908745AImprove filing efficiency and accuracyRealize fully automatic classificationSpecial data processing applicationsDocument management systemsElectronic documentDigital document

The invention relates to a batch document scanning and sorting apparatus. The apparatus comprises a template selection unit used for selecting an electronic template from a preconfigured template library, an electronic document generation unit used for scanning an original manuscript to generate an electronic document, and a classification storage unit used for identifying type information of theelectronic document according to template parameters of the selected electronic template, automatically creating a classification directory according to the type information and storing the electronicdocument in the directory. In addition, the invention relates to a batch document scanning and sorting method, a medium and a device. By presetting a template automatic sorting process, full-automatic archiving of documents scanned in batch is realized.

Owner:RICOH IMAGING TECH SHANGHAI CO LTD

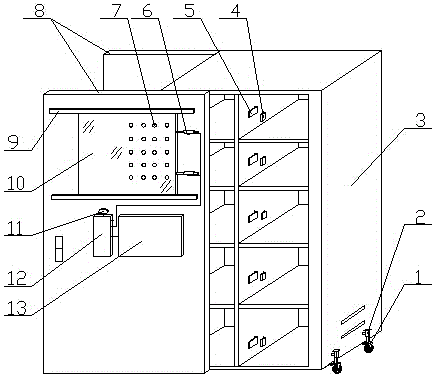

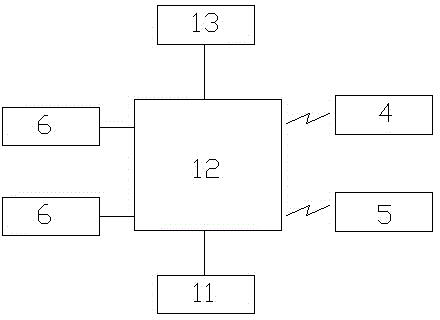

Monitoring system and method for file cabinet for file management

InactiveCN104523035AAutomateImprove management efficiencyBook cabinetsFittingAutomatic controlManagement efficiency

The invention discloses a monitoring system and method for a file cabinet for file management. The file cabinet comprises a cabinet body and cabinet doors installed on the front side and the back side of the cabinet body, wherein the interior of the cabinet body is divided by a vertical plate installed in the middle and a plurality of evenly-distributed transverse plates into a plurality of file storage spaces. Compared with the prior art, in cooperation with the specific monitoring method, an automatic control system is additionally arranged in the structure, so that automation of file management is accordingly achieved; the management efficiency is improved; meanwhile, the integrity of files is guaranteed, and the quality of the overall file management work is further guaranteed. On this basis, sliding wheel devices are installed at the four corners of the cabinet body through connecting rods, so that the file cabinet is conveniently moved, the efficiency is further guaranteed, and the wide application value and the wire market prospect are achieved.

Owner:QINGDAO UNIV

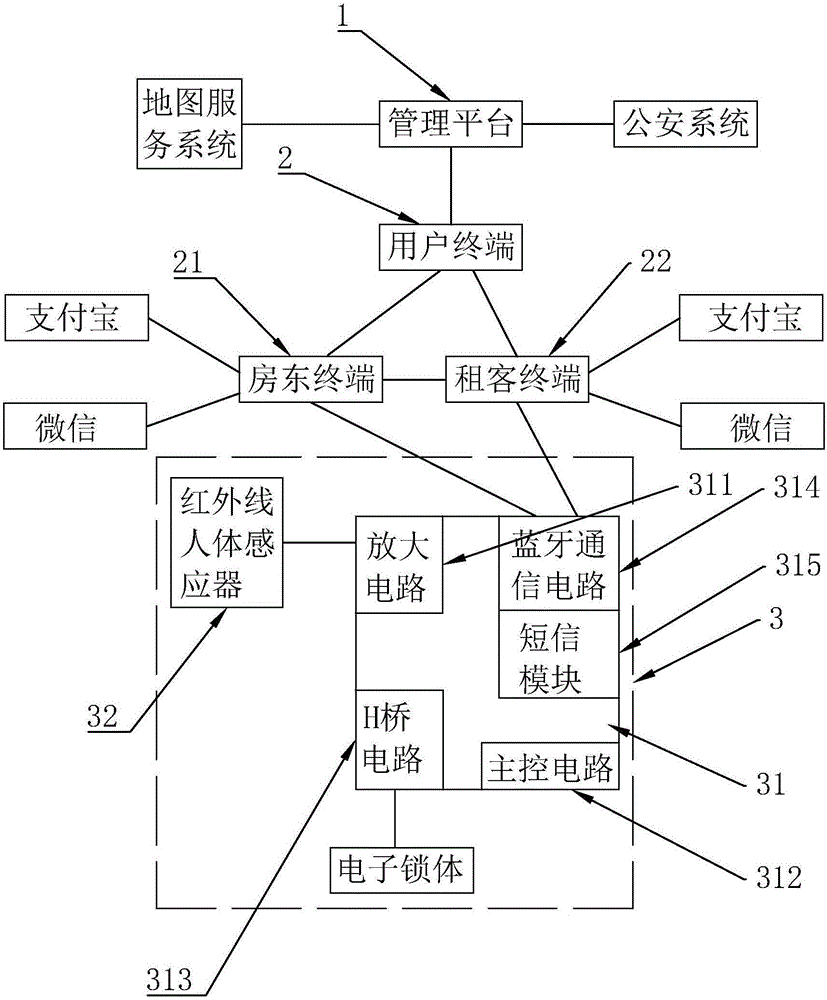

Rental housing management system and method

InactiveCN106127627AAutomateEfficient storageData processing applicationsIndividual entry/exit registersService systemEngineering

The invention discloses a rental housing management system, and the system comprises a management platform, wherein the management platform stores rental housing data, tenant information data and rent data, is coupled to an external public security system, and is also coupled to an external map service system; user terminals which comprises a landlord terminal and a tenant terminal; and a plurality of entrance guard devices which are respectively disposed on the door of each rented house, and communicates with the landlord terminal and the tenant terminal. The system can cooperate with the public security system through the setting of the management platform, so as to judge whether a tenant is a criminal offender or not. The system also can achieve the automation of payment through the setting of the landlord terminal and the tenant terminal, and solves a problem in the prior art.

Owner:WENZHOU UNIV OUJIANG COLLEGE

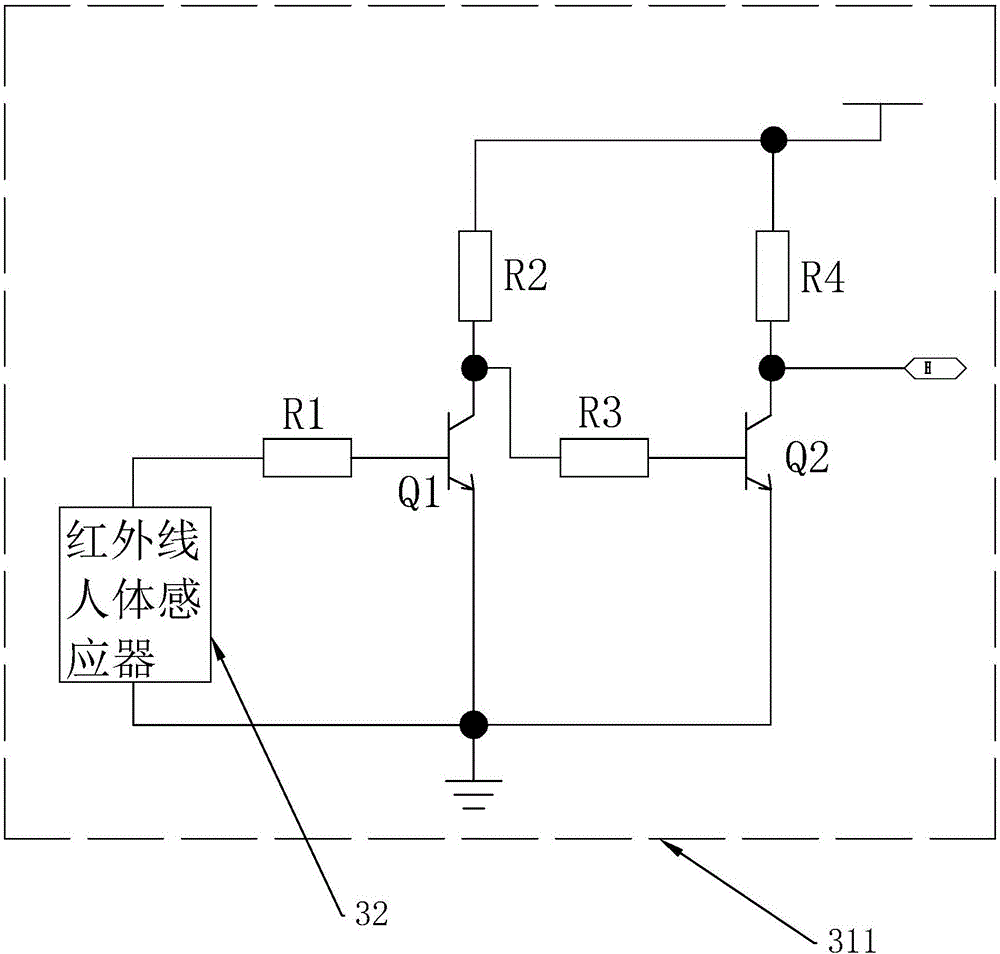

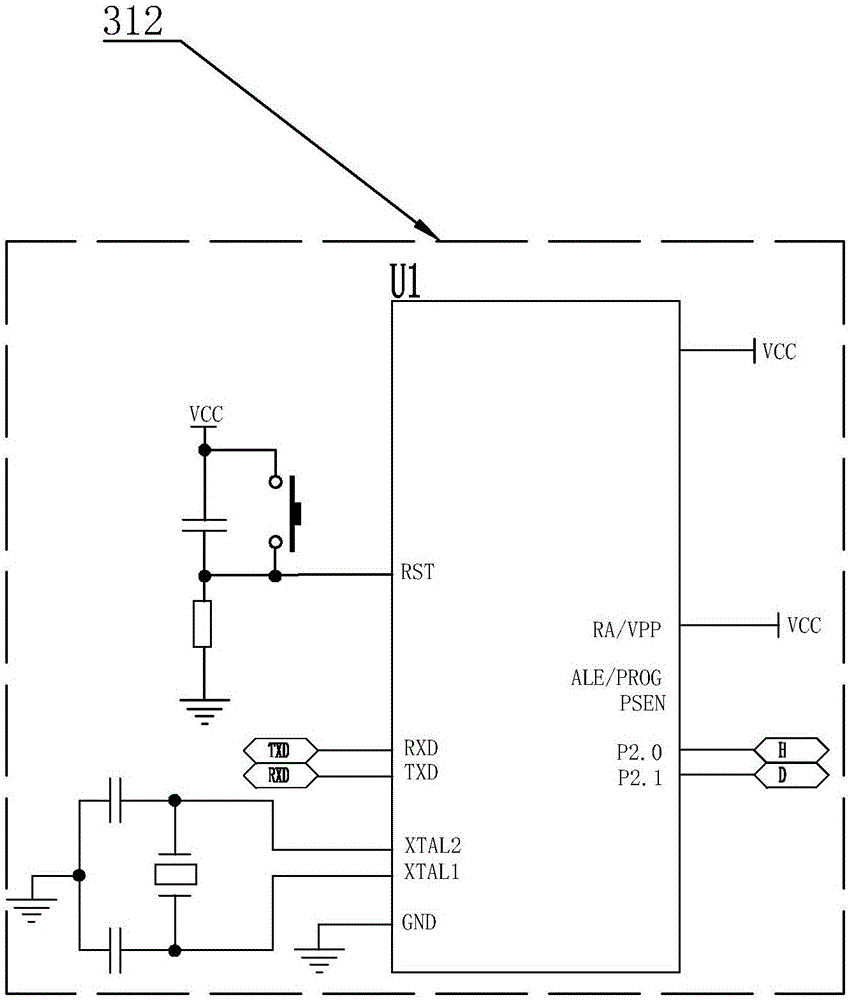

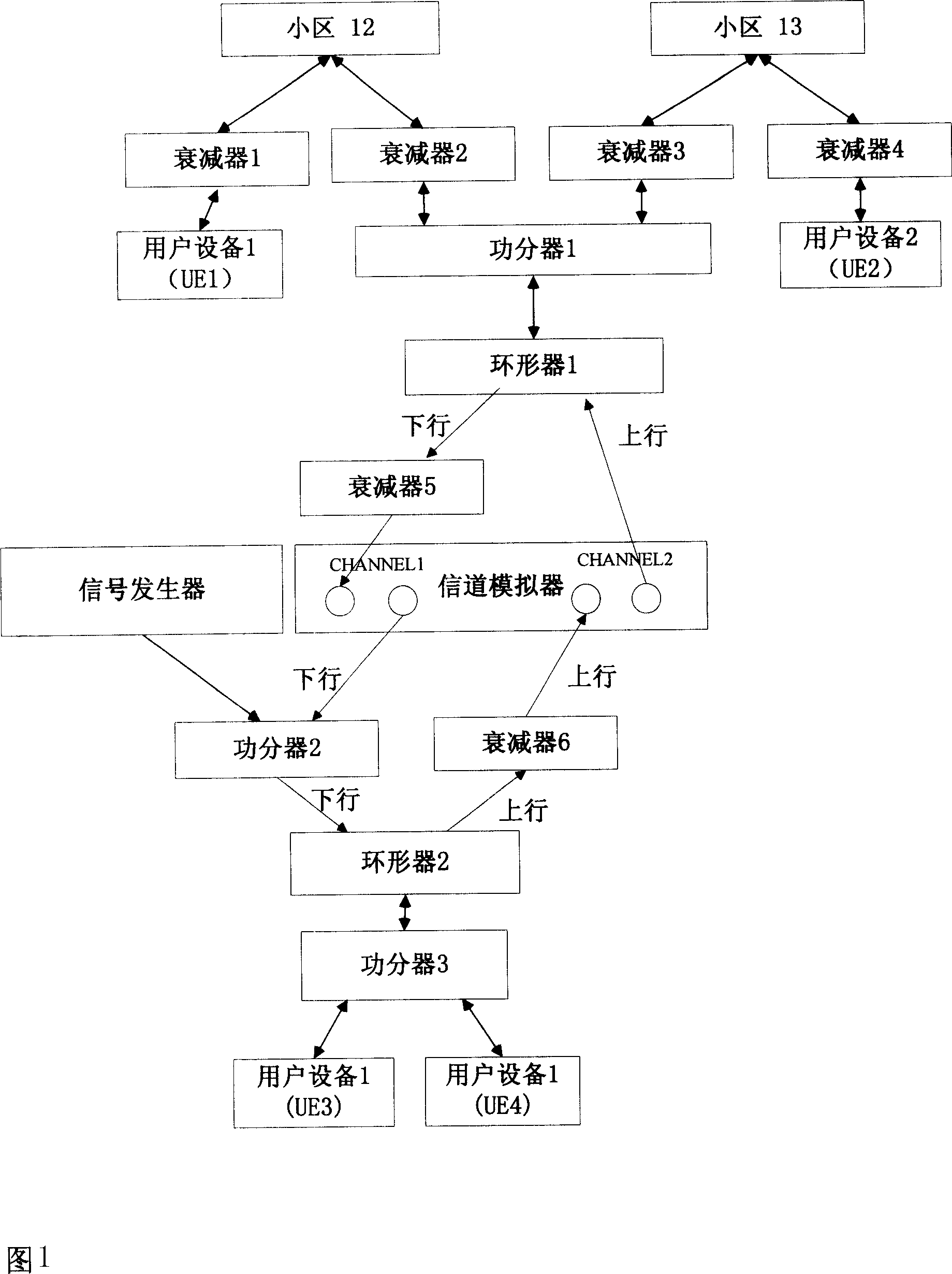

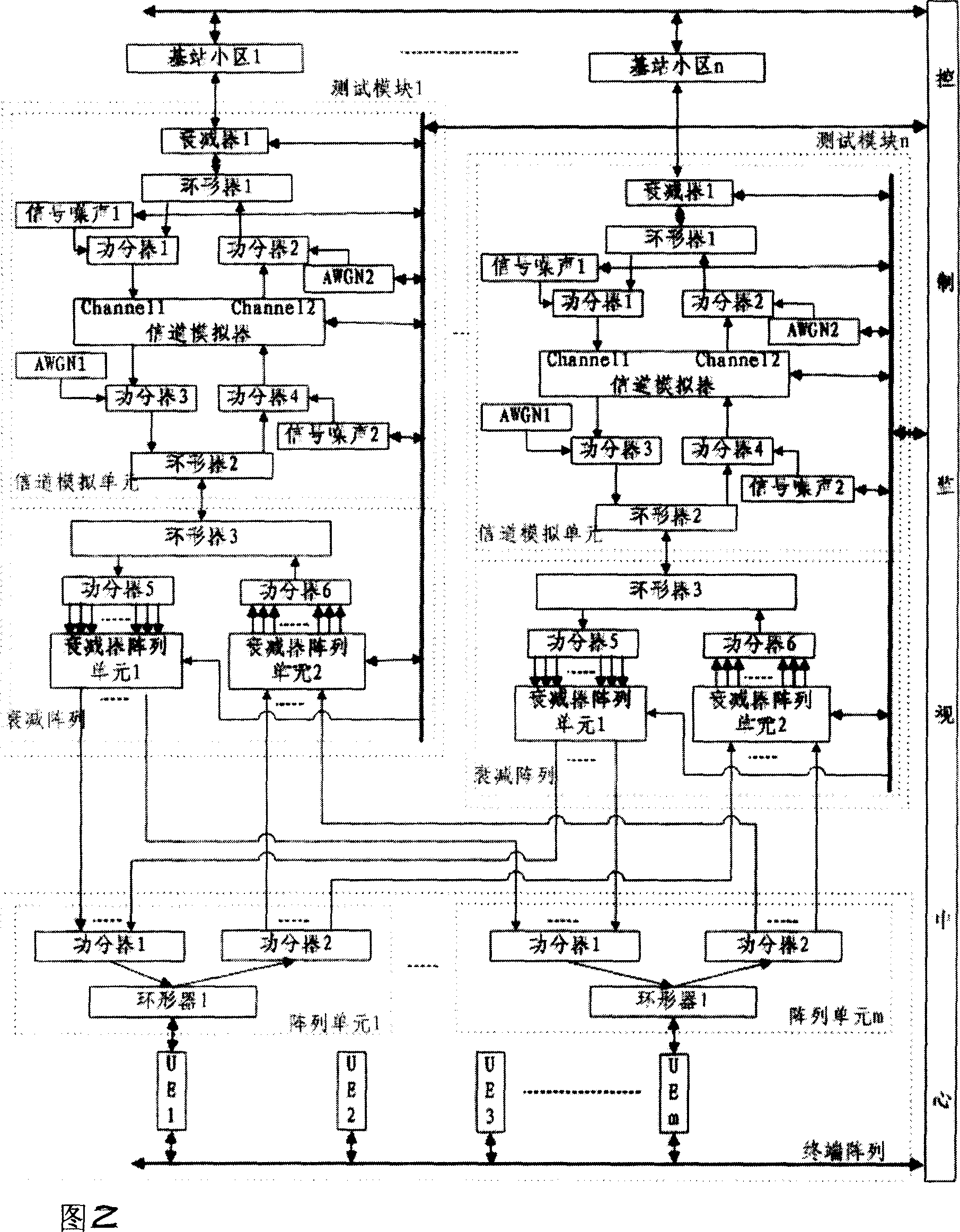

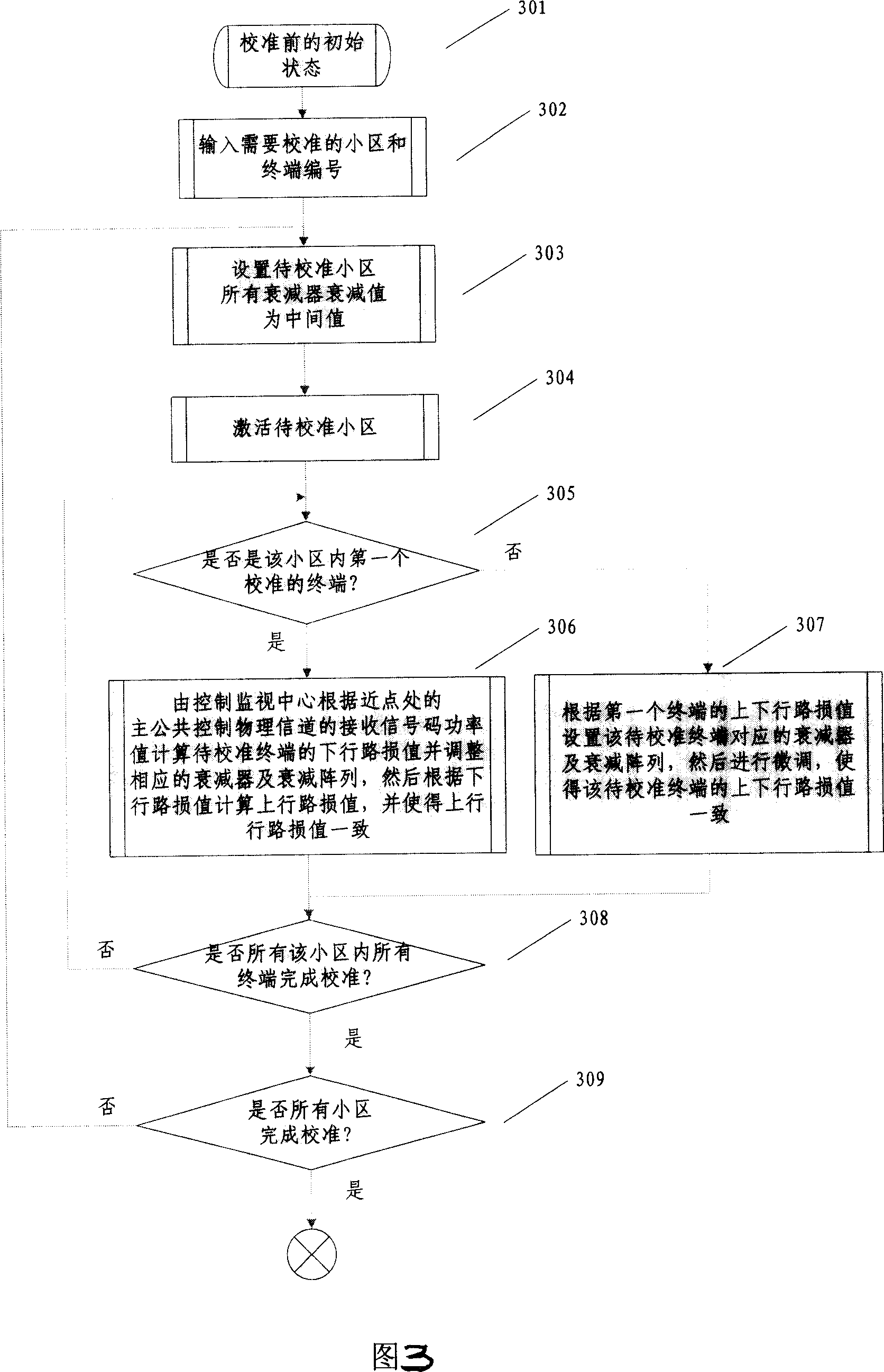

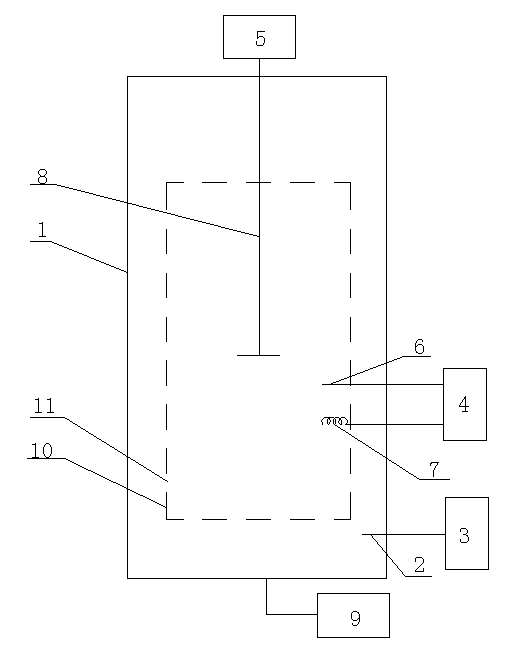

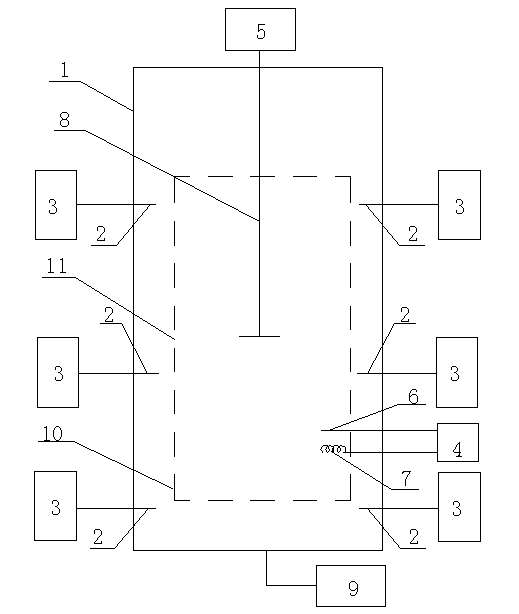

An automatic test method and device of the radio resource management performance

ActiveCN101056446AAutomateReduce manual involvementRadio/inductive link selection arrangementsTransmission monitoringUltrasound attenuationRadio resource management

The invention relates to an automatic testing method and device in a PRM performance test, the method soloves disadvantages of errors and law efficiency when testing in a manually constructed testing entironment. The device includes one or more channel simulation units, one or more attenuation arraies, one or more terminal array units, a control monitoring centre which provides an interface for users to programme test scripts based on testing examples, for outside, and controls adjustable devices via a standard interface, for inside. A testing method corresponding to the device is proposed, which comprises an automatic aligning step and an automatic testing step which are performed by the control monitoring centre according to a receiving signal code power value of a main common control physical channel at a near point and a characteristic that uplink and downlink path loss are symmetrical. The technic of the invention completely replaces manually testing manner in a current technic, is capable of simulating an actual circumstance of a network more accurately and factually, and performing a test with multi-RRM algorithm interaction.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Device and method for extracting algal polysaccharide by ultrasonic-assisted extraction

The invention relates to a device and a method for extracting algal polysaccharide by ultrasonic-assisted extraction. The device comprises an extraction reactor, ultrasonic generators and a temperature controlling device, wherein the extraction reactor is internally provided with an extraction tube for placing materials to be extracted; a plurality of through holes are formed in the periphery of the wall of the extraction tube; and more than one ultrasonic generator is arranged. The method comprises the following steps of: crushing kelps, sargassum fusiforme or undaria pinnatifida; adjusting ultrasonic power, a material-liquid ratio, temperatures and time and precipitating an extracting solution by ethanol; filtering to obtain rough algal polysaccharide; purifying the rough algal polysaccharide by utilizing DEAE (Diethyl-Aminoethanol) cellulose column chromatography; and finally, spraying and drying or freezing and drying to obtain an algal polysaccharide pure product. The method disclosed by the invention is simple and is easy to operate; the time consumed by extracting the algal polysaccharide through the method disclosed by the invention is short, and the purity of the algal polysaccharide is high and can be up to be more than 98%; and therefore, not only can the cost be saved and the energy consumption be reduced, but also the automation is easy to realize and the extraction efficiency can be improved.

Owner:ZHEJIANG YUXIANG BIOLOGICAL SCI & TECH

Rotary type opening-tying and cramping integrated device

ActiveCN104512575AGood sealing effectAutomateWrapper twisting/gatheringCultivating equipmentsAluminiumCulture mediums

Owner:临沂高新物业管理有限公司

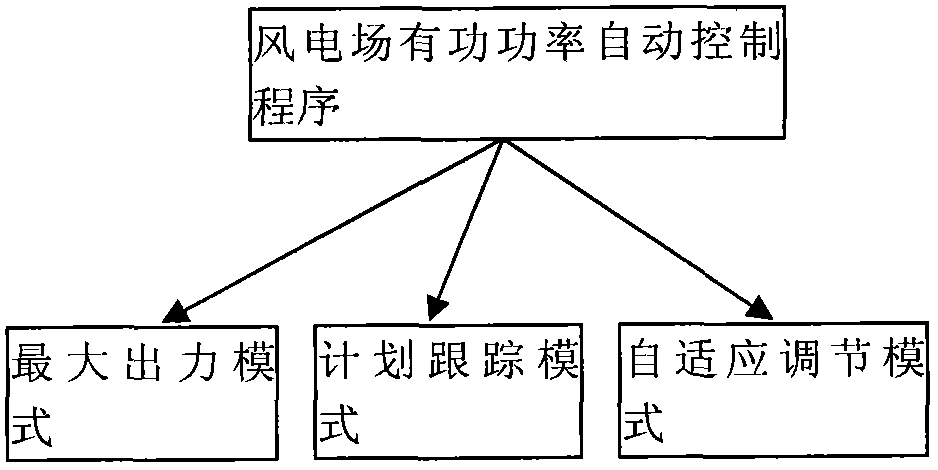

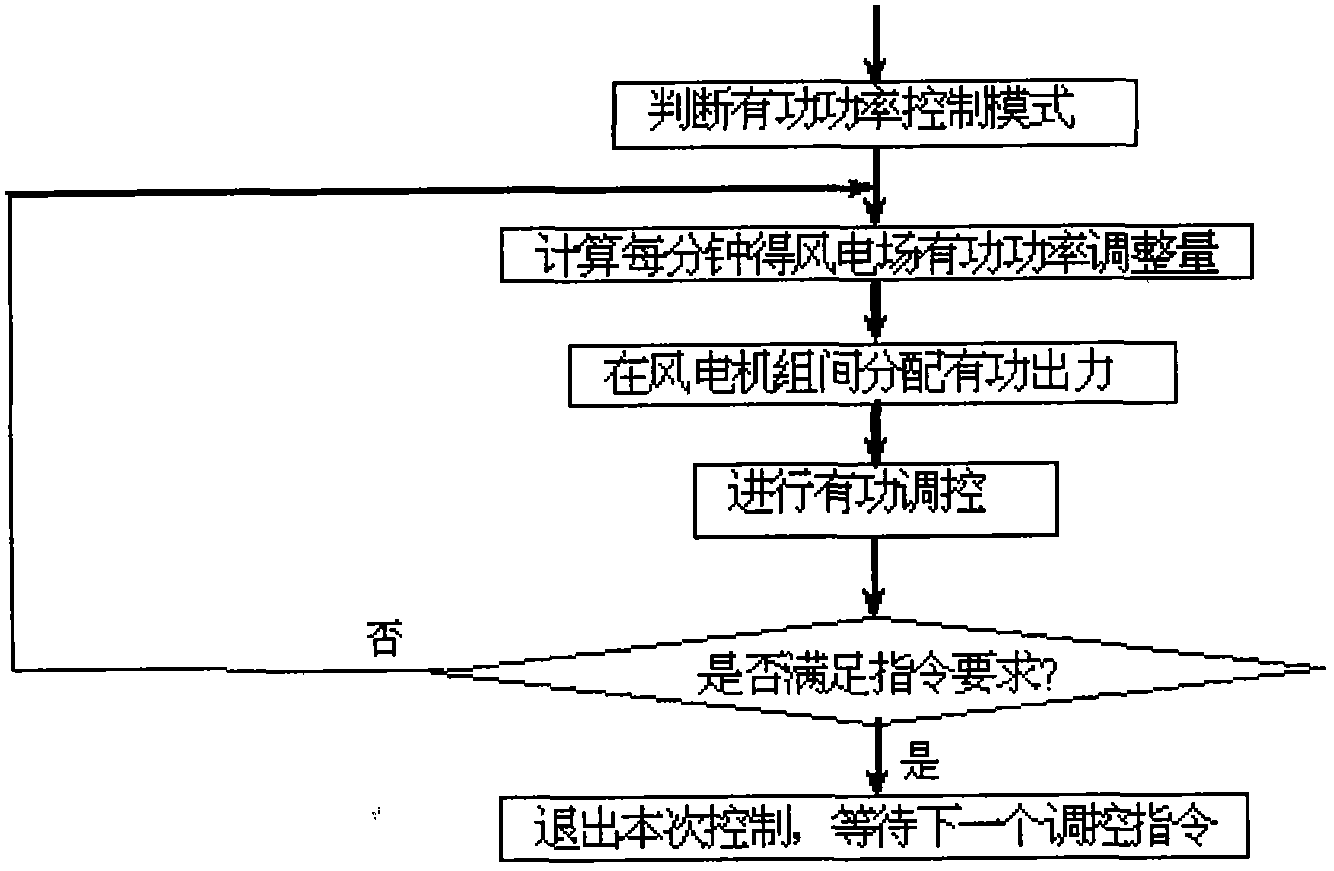

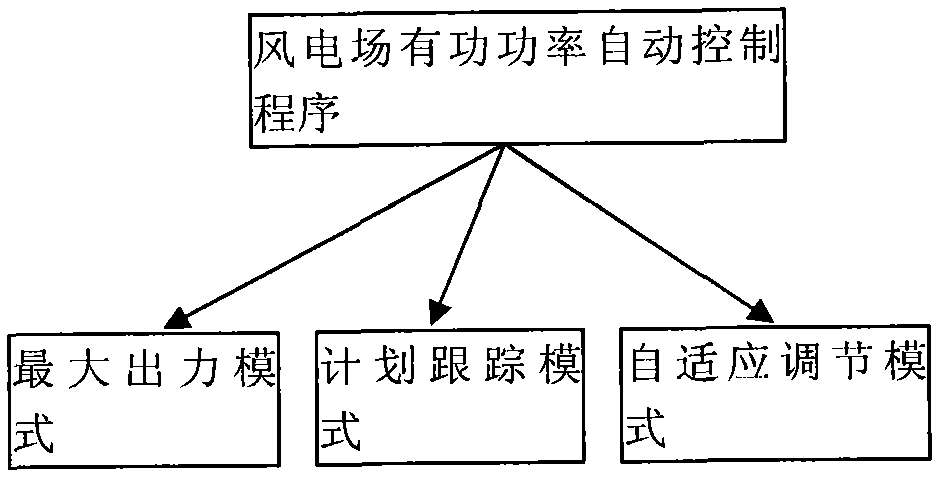

Automatic control method of wind electric active power for wind farm monitoring system

InactiveCN101917023APowerful wind power automatic control functionAutomateSingle network parallel feeding arrangementsReactive power adjustment/elimination/compensationAutomatic controlSelf adaptive

The invention discloses an automatic control method of wind electric active power for a wind farm monitoring system. The method is characterized by comprising the following steps of: (1) maximum output mode control; (2) plan and track mode control; and (3) adaptive adjustment mode control. The method has the advantages of ensuring good connection with a dispinterface of the power grid in China, contributing to coordinating and cooperating the wind farm connected with the power grid with the connected regional power grid to run and improving the automatic control and the management and operation level of the wind farm, along with powerful real-time power output function and operating control function of the wind farm accessed power grid.

Owner:STATE GRID ELECTRIC POWER RES INST

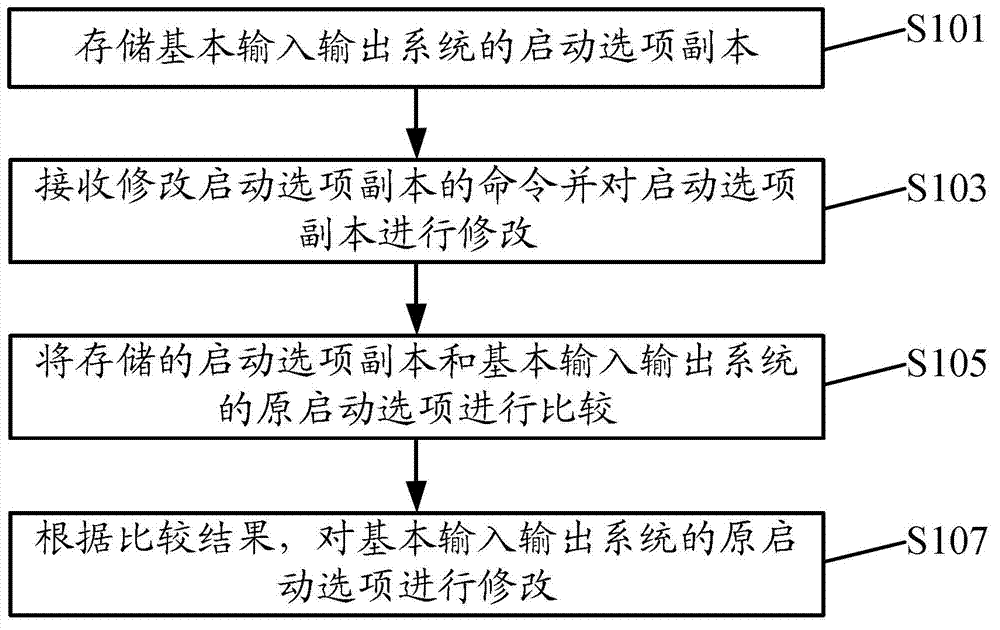

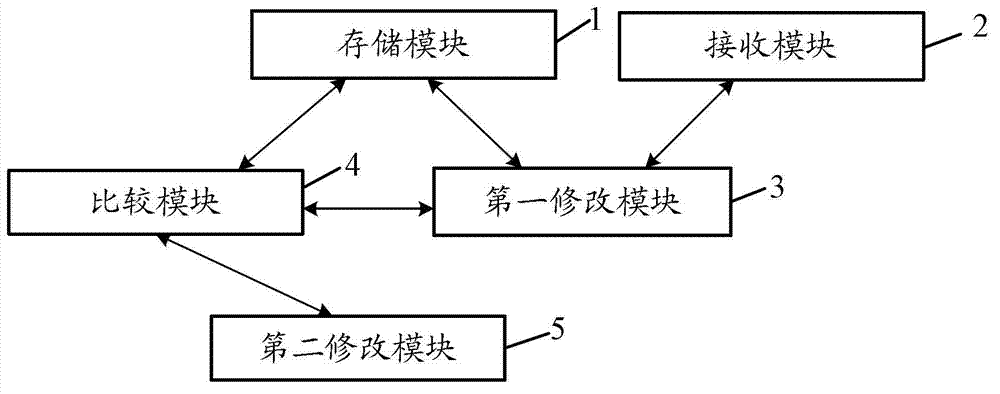

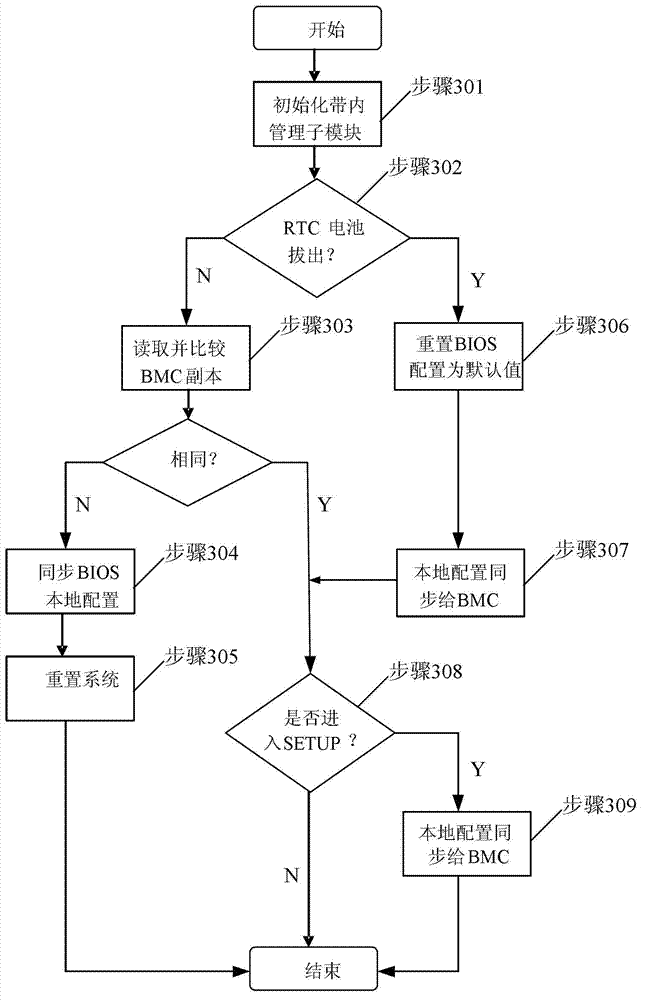

Method and device for modifying system configuration

ActiveCN102831022AAutomateImprove work efficiencyError detection/correctionSystem configurationScripting language

The invention discloses a method and a device for modifying system configuration. The method comprises the following steps: storing a startup option copy of a base input and output system; receiving and modifying orders of the startup option copy, and modifying the startup option copy; comparing the stored startup option copy with the original startup options of the base input and output system; and modifying the original startup options of the base input and output system according to the compared results. The method comprises the following steps of storing a startup option copy of a base input and output system; receiving and modifying orders of the startup option copy, and modifying the startup option copy; comparing the stored startup option copy with the original startup options of the base input and output system; and modifying the original startup options of the base input and output system according to the compared results. Therefore, the proposal can call scripting language, is highly automatic and improves the working efficiency of a computer.

Owner:DAWNING INFORMATION IND BEIJING +1

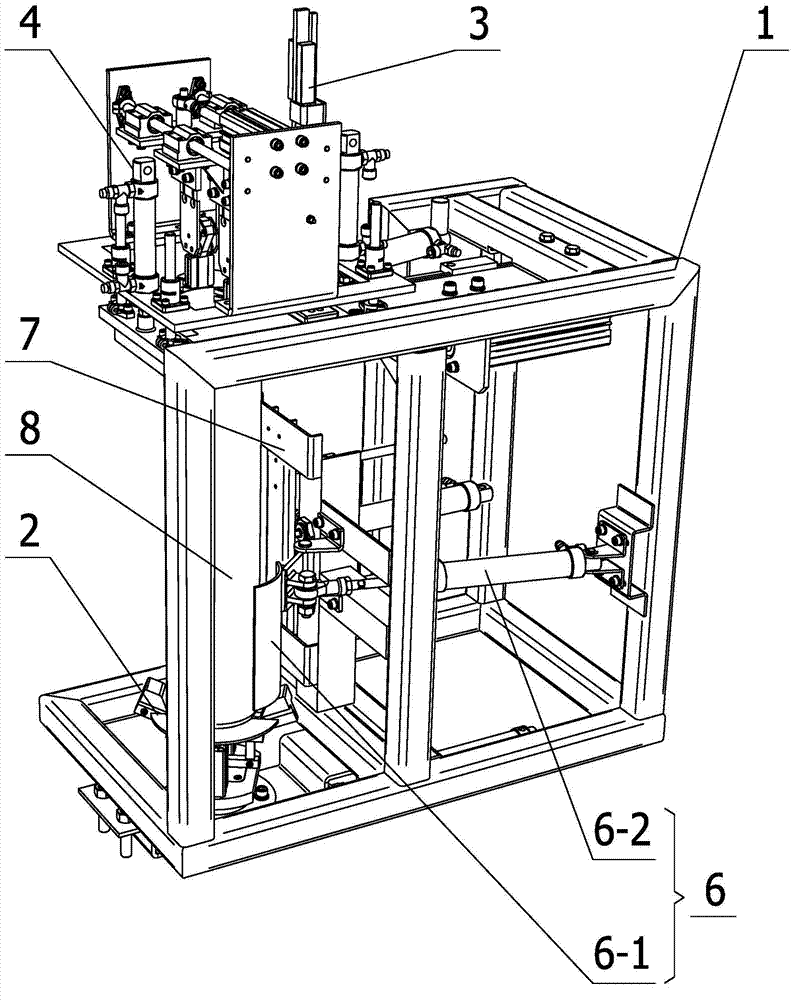

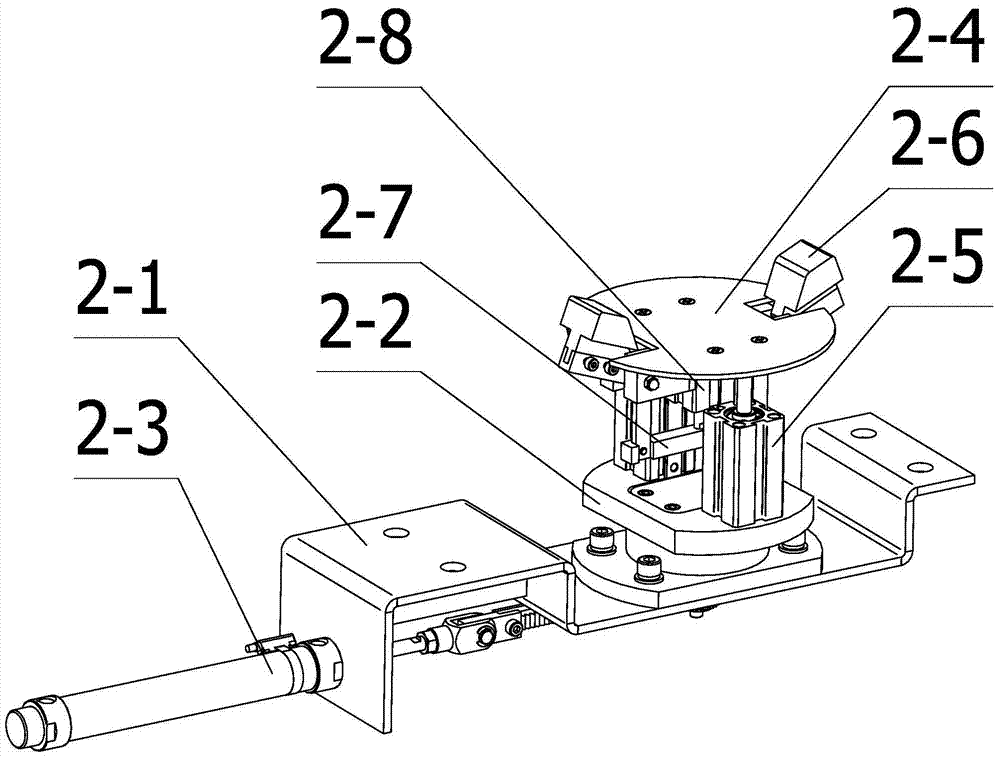

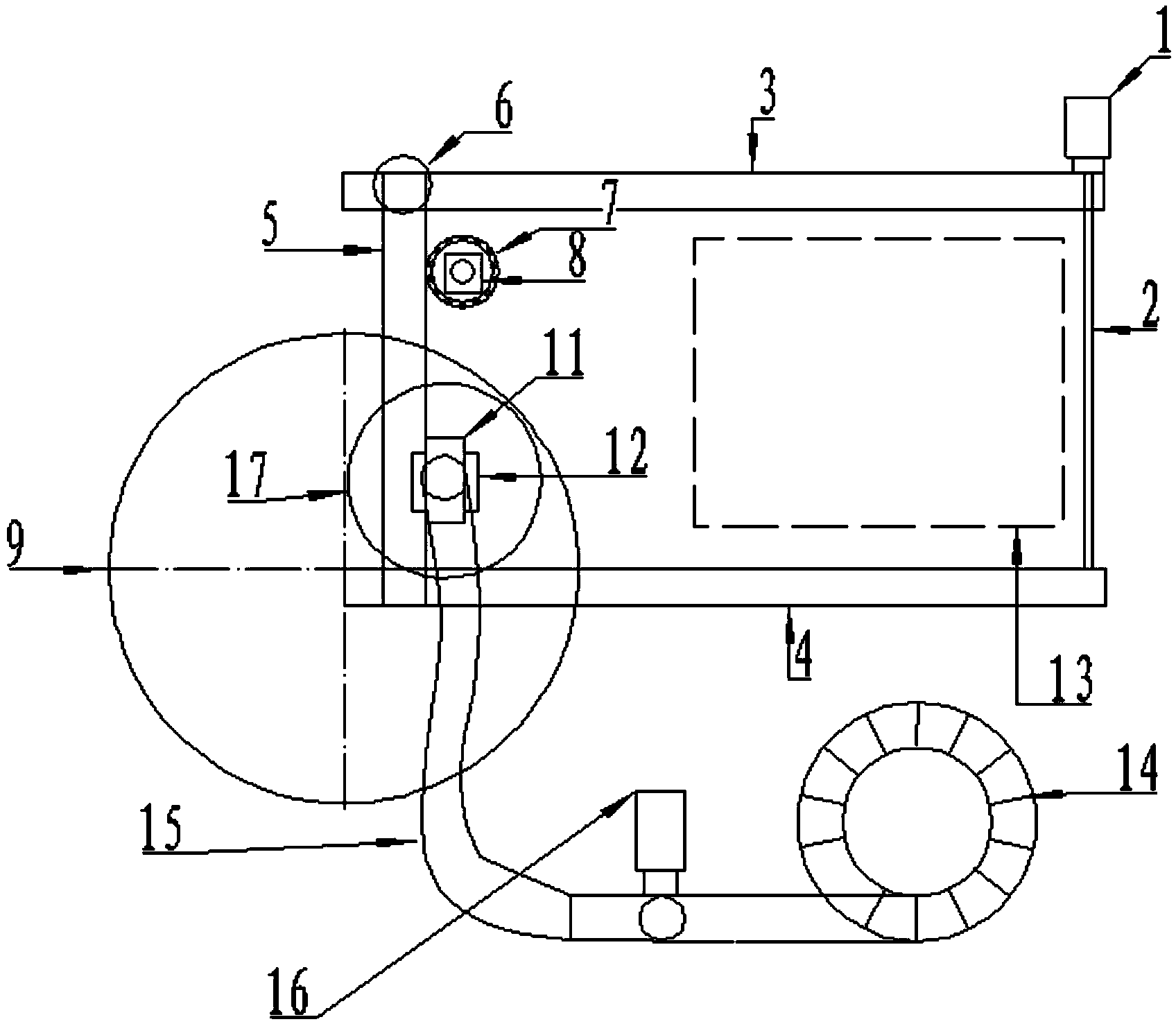

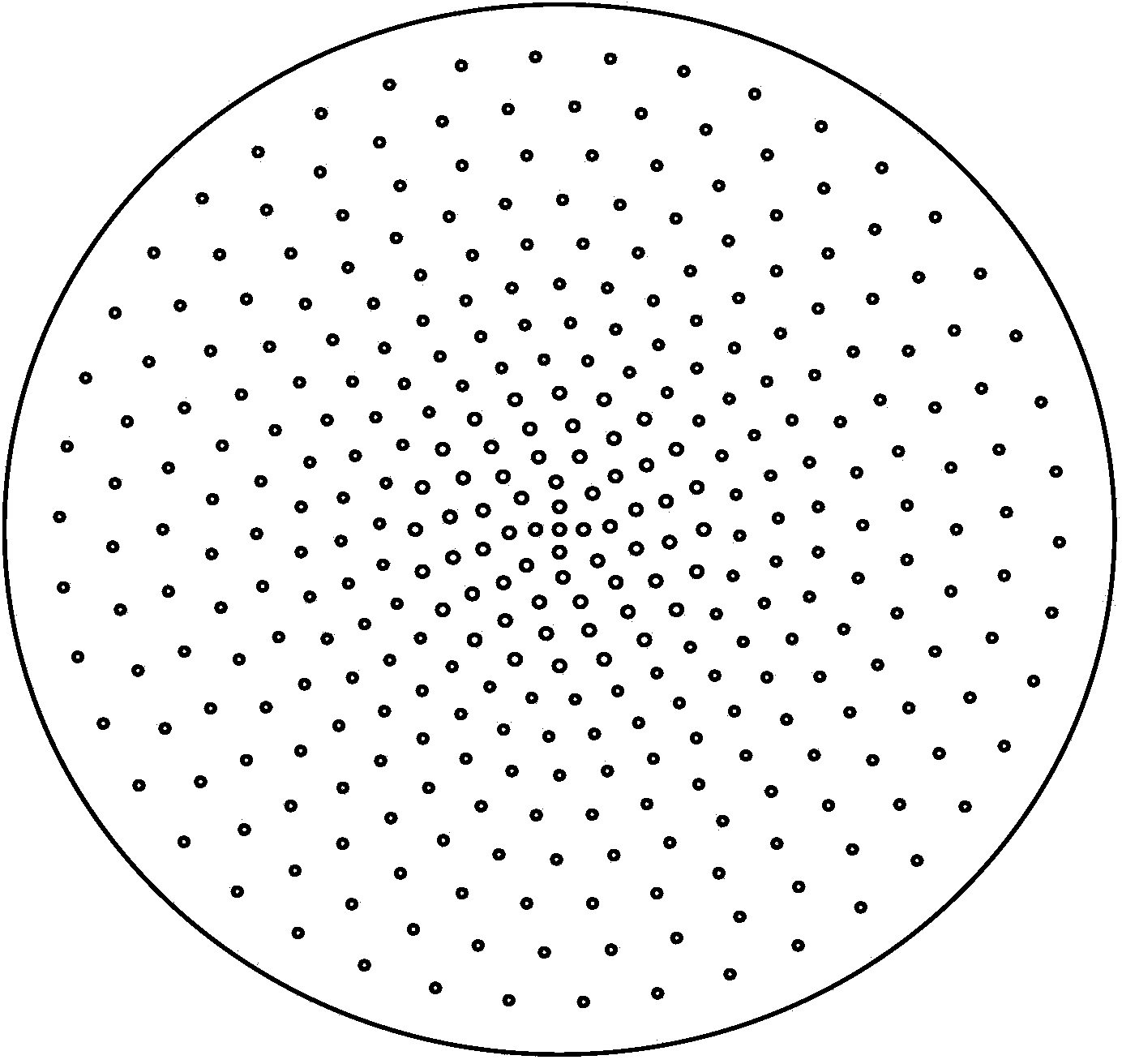

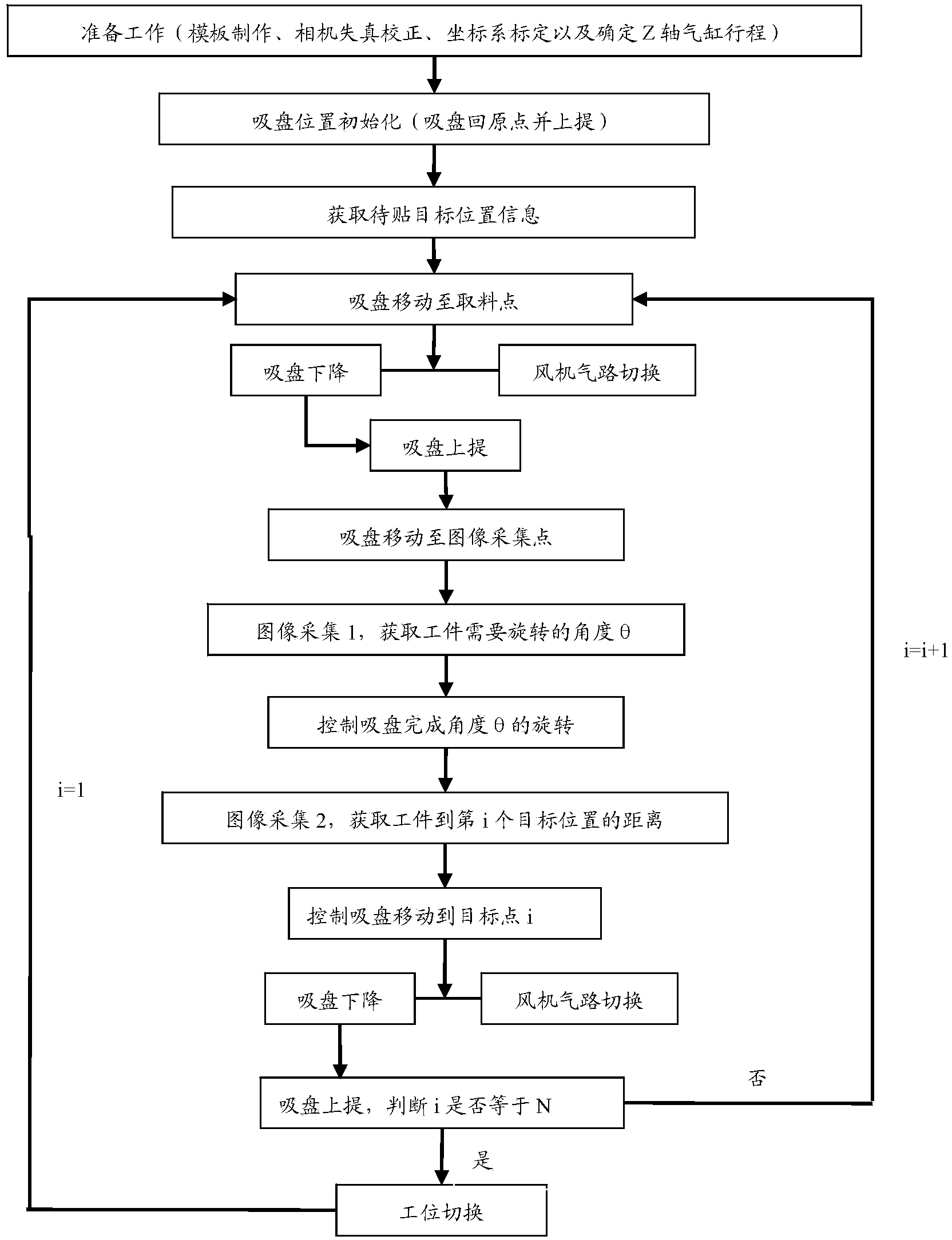

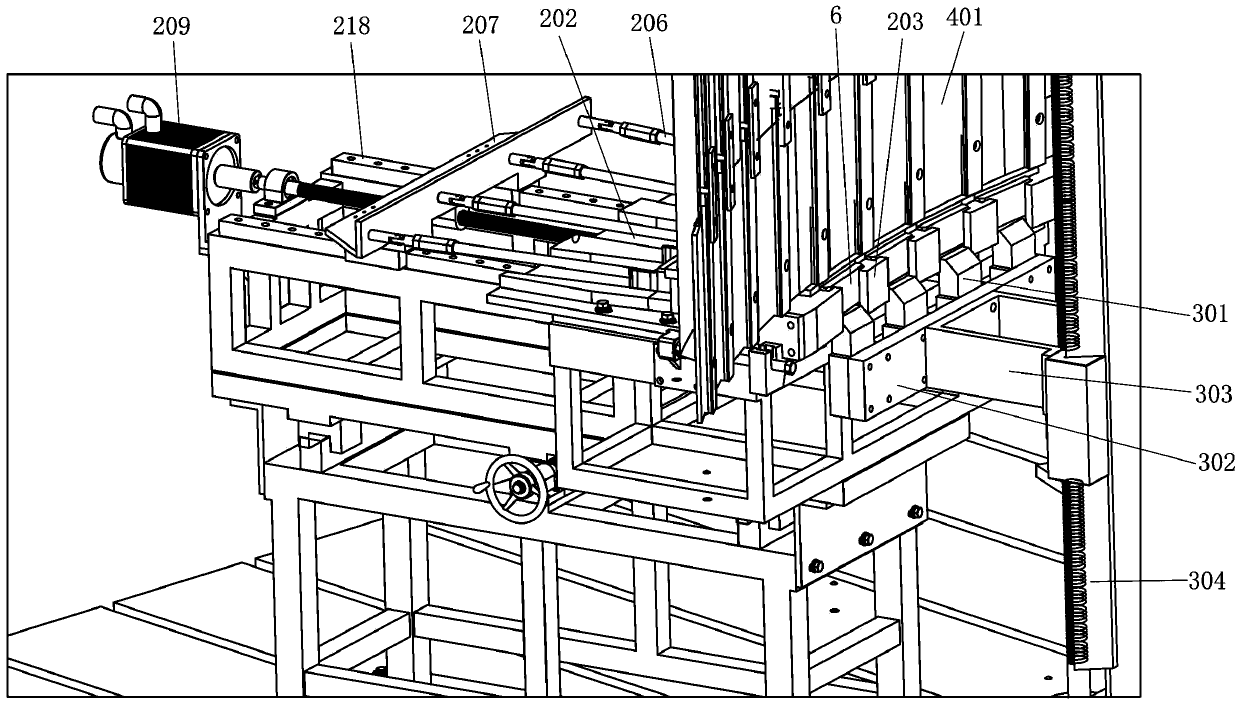

Automatic mounting system

The invention provides an automatic mounting system comprising a feeding mechanism, a workpiece taking and mounting mechanism, a sucking disc driving mechanism, an image collector, and a controller. The feeding mechanism comprises a feeding platform; the feeding platform is provided with stations; and the stations are used for placing workpieces. The workpiece taking and mounting mechanism comprises a sucking disc and a negative pressure system, wherein the sucking disc is used for getting / putting the workpieces, the sucking disc is provided with a plurality of dot matrix holes, and the negative pressure system is connected with the sucking disc and controls the sucking disc to absorb / drop the workpieces. The sucking disc driving mechanism is used for driving the sucking disc to move. The image collector is used for collecting workpiece images. The controller is used for correcting the workpiece images, and according to the deviation value and deviation angle between the workpiece images obtained after correction and a target position image, controlling the sucking disc driving mechanism to move and rotate until the workpiece is moved to the target position, and then, controlling the sucking disc to move up and down, and thus mounting of the workpiece is realized. The automatic mounting system can carry out automatic mounting on flexible workpieces or air-permeable workpieces which are irregular in shapes; and the automatic mounting system has the advantages of high mounting precision and high mounting efficiency.

Owner:TSINGHUA UNIV

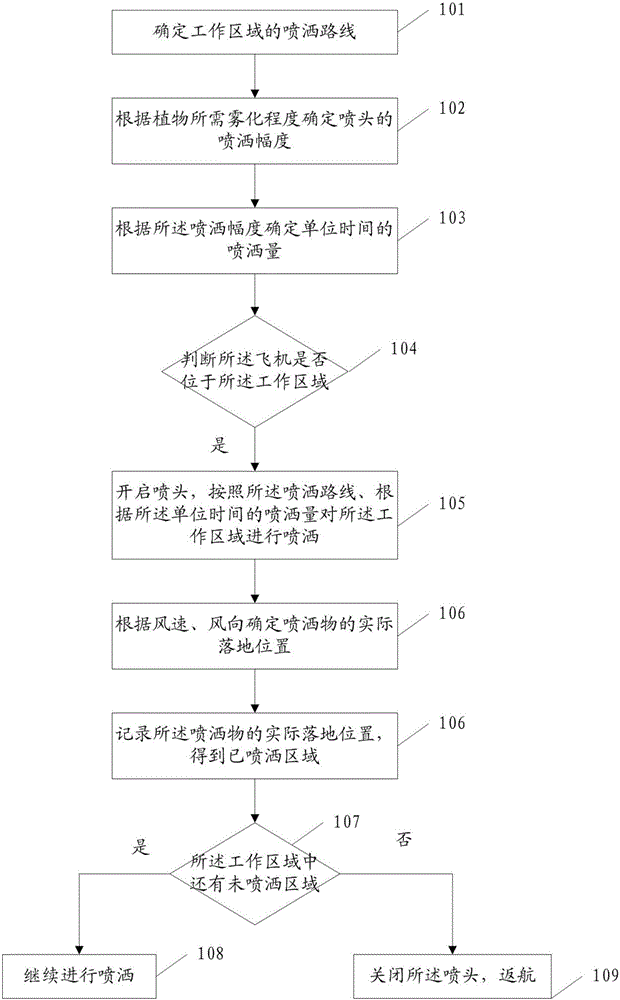

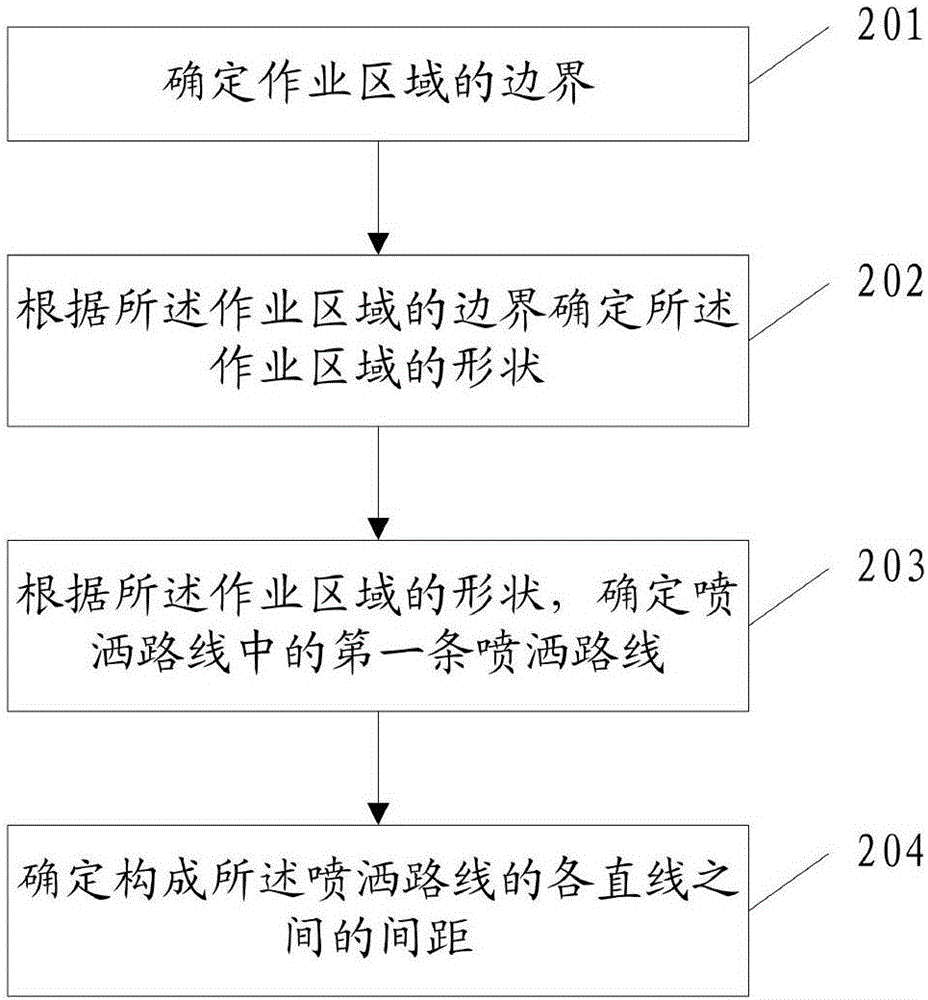

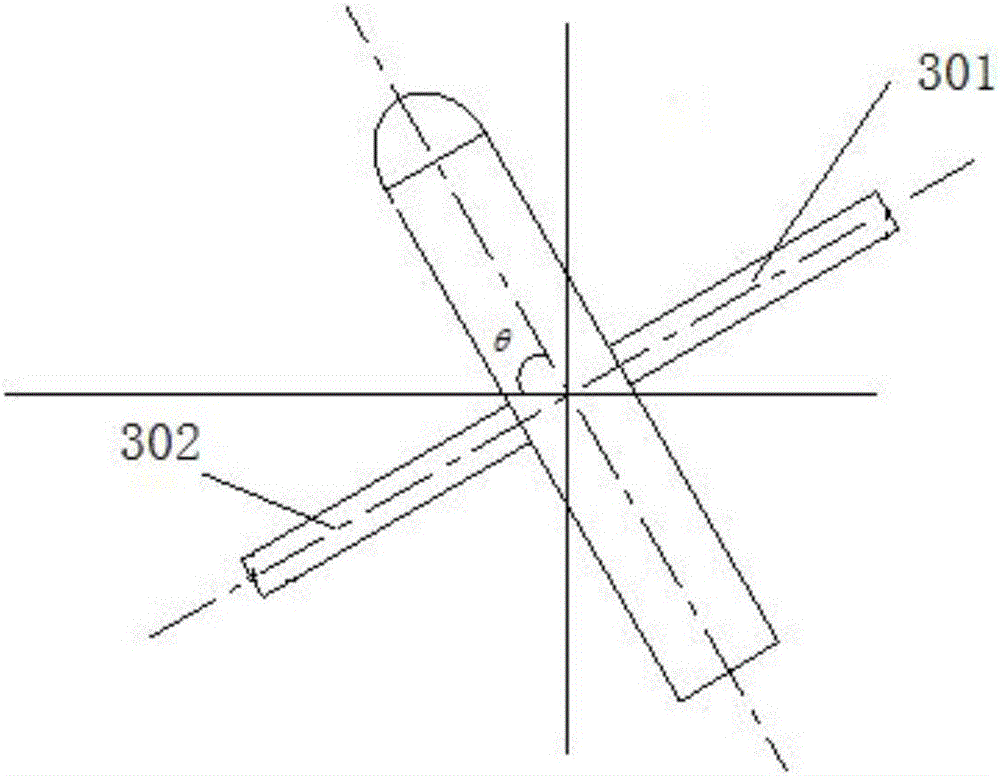

Intelligent sprinkling method and intelligent sprinkling system for airplane

InactiveCN106335641AAutomateFully automatedAircraft componentsLaunching weaponsAirplaneSmart control

The invention discloses an intelligent sprinkling control method and an intelligent sprinkling control system for an airplane. The method comprises the following steps of: determining a sprinkling route of a work area; determining the sprinkling amplitude of a spray head according to the required atomization degree of plants; determining the sprinkling quantity in unit time according to the sprinkling amplitude; judging whether the airplane is positioned in the work area or not; if the airplane is positioned in the work area, performing sprinkling on the work area according to the sprinkling route and the sprinkling quantity in unit time; determining the actual landing position of a sprinkling agent according to the wind speed and the wind direction; recording the actual landing position of the sprinkling agent so as to obtain the sprinkled area; judging whether a non-sprinkled area exists in the work area or not; if a non-sprinkled area exists in the work area, further performing sprinkling; and if no non-sprinkled area exists in the work area, closing the spray head, and returning back. The intelligent sprinkling method and intelligent sprinkling system provided by the invention are capable of realizing automatic and intelligent sprinkling on the work area.

Owner:JIANGXI TIANXIANG GENERAL AVIATION CO LTD

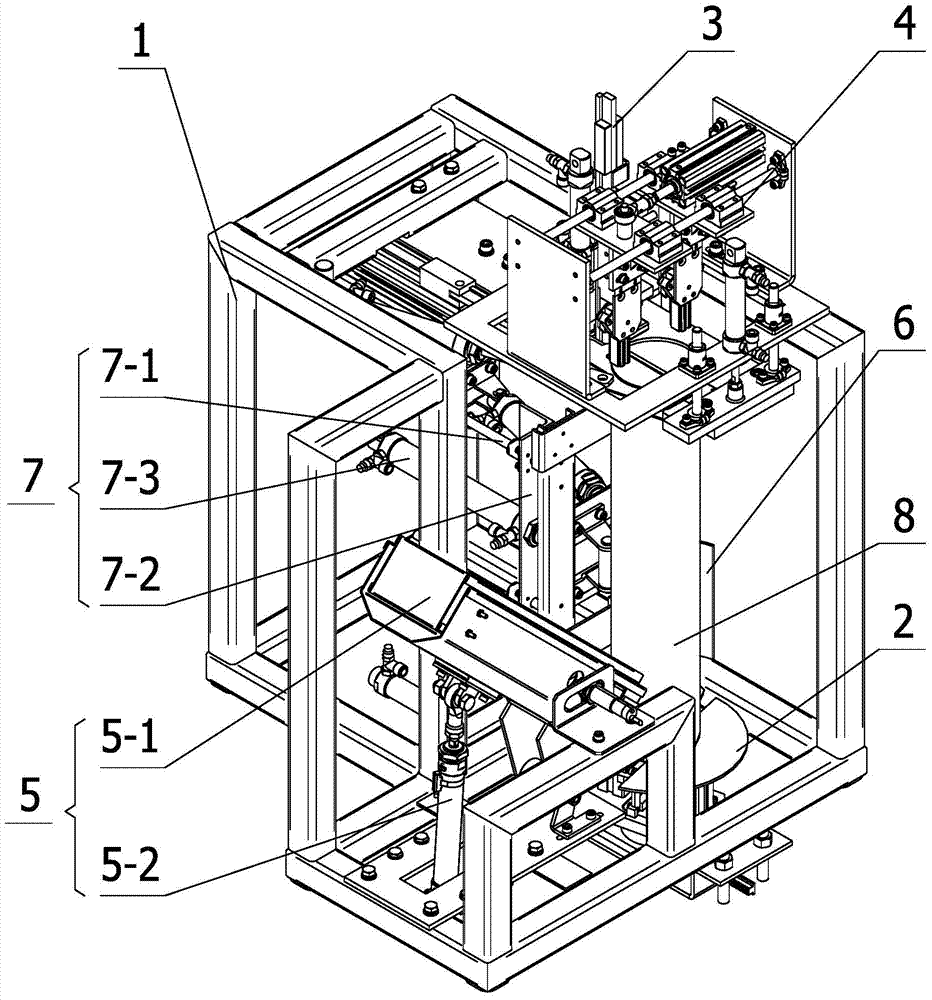

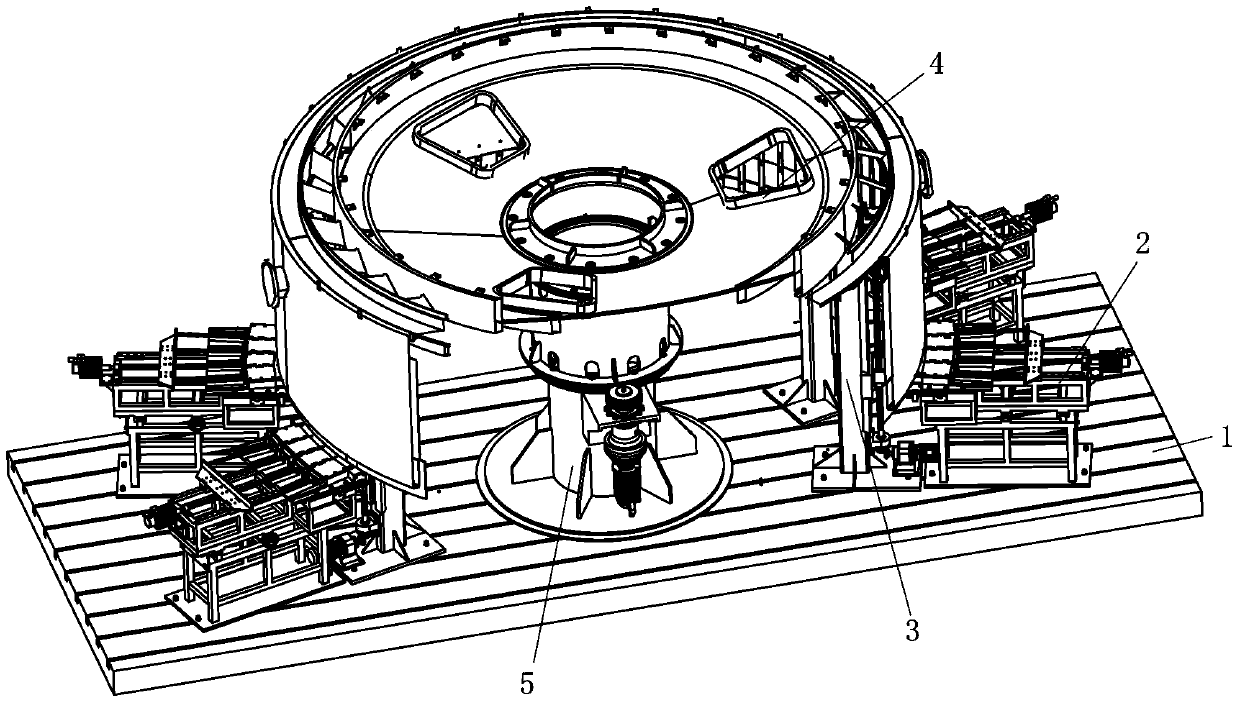

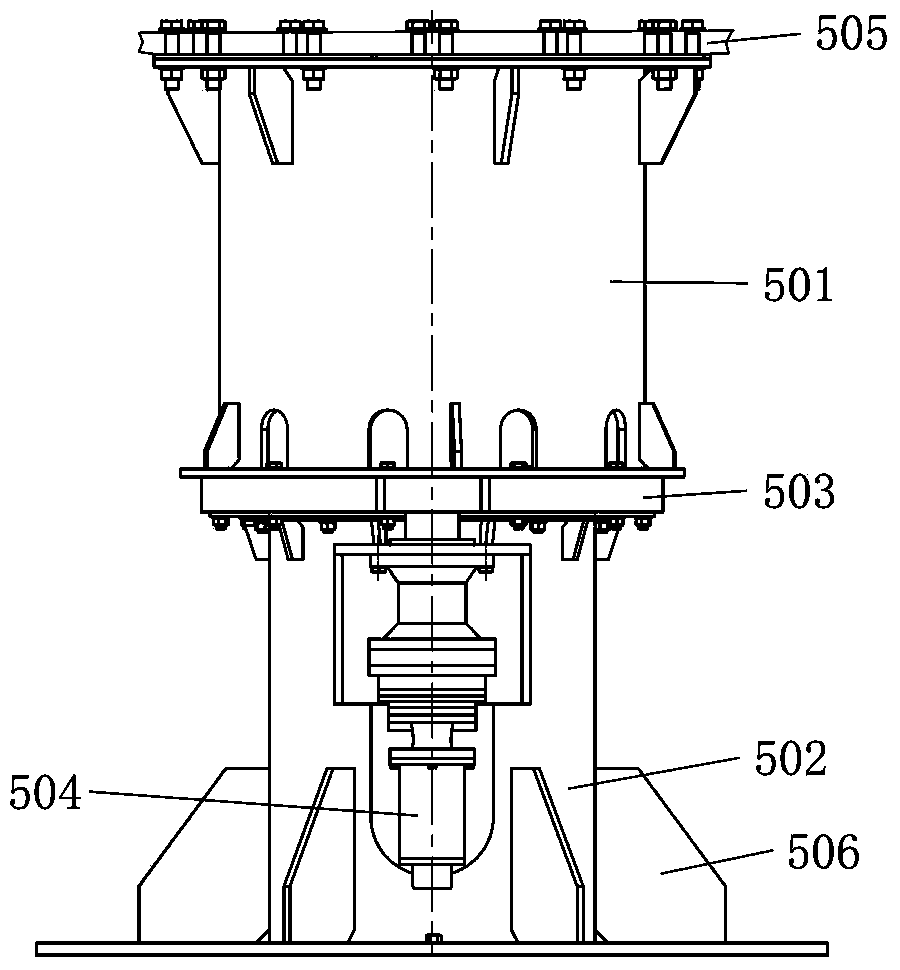

Automated magnet assembling device for wind power generator set

ActiveCN103633792AAutomateImprove assembly efficiencyManufacturing stator/rotor bodiesMagnetEngineering

The invention discloses an automated magnet assembling device for a wind power generator set. The automated magnet assembling device comprises a support device for being fixed with a rotor of the wind power generator set and driving the rotor to rotate, feeders arranged outside the rotor, pushing-in devices arranged inside the rotor, and a control system for controlling the rotation of the rotor, the operation of the feeders and the operation of the pushing-in devices, wherein the feeders comprise supports, feeding slots arranged on the supports and pushing assemblies for pushing magnets to be assembled along the feeding slots; one end of each feeding slot is positioned below a magnetic yoke of the rotor; the feeding slots correspond to magnet assembling slots on the magnetic yoke to push the magnets to be below the magnet assembling slots; the pushing-in devices can push the magnets to preset positions in the magnet assembling slots. The automation of the magnet assembling process is realized by the automated magnet assembling device, the investment of manpower in the assembling process is reduced, and the assembling efficiency and precision are improved.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

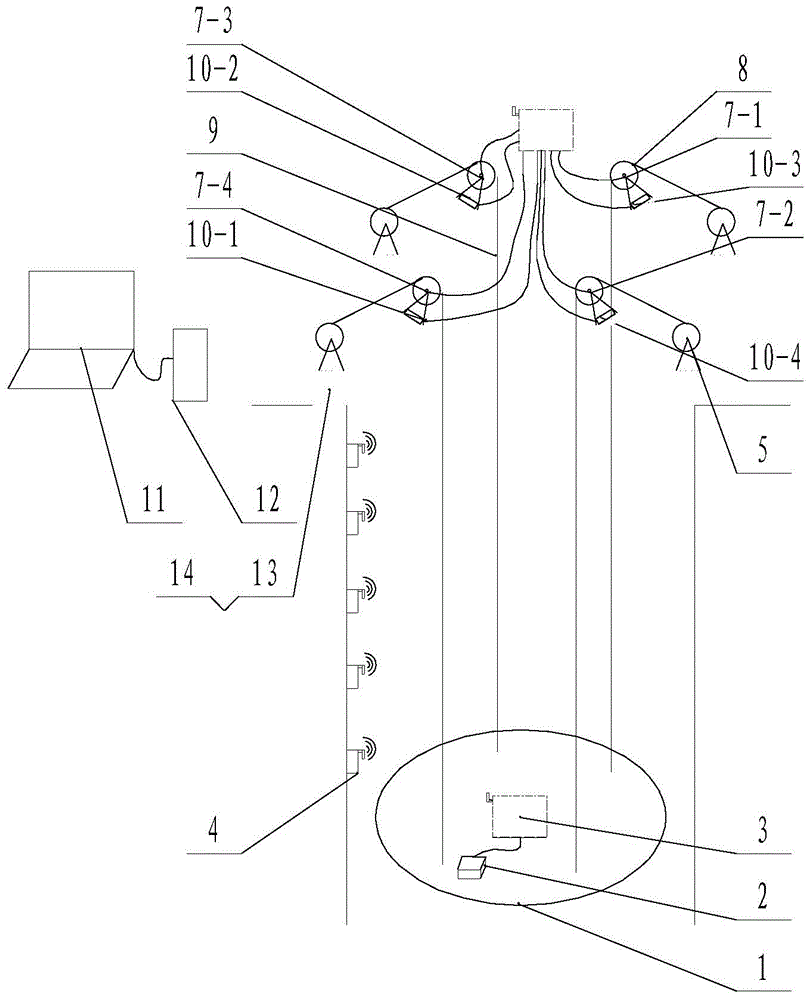

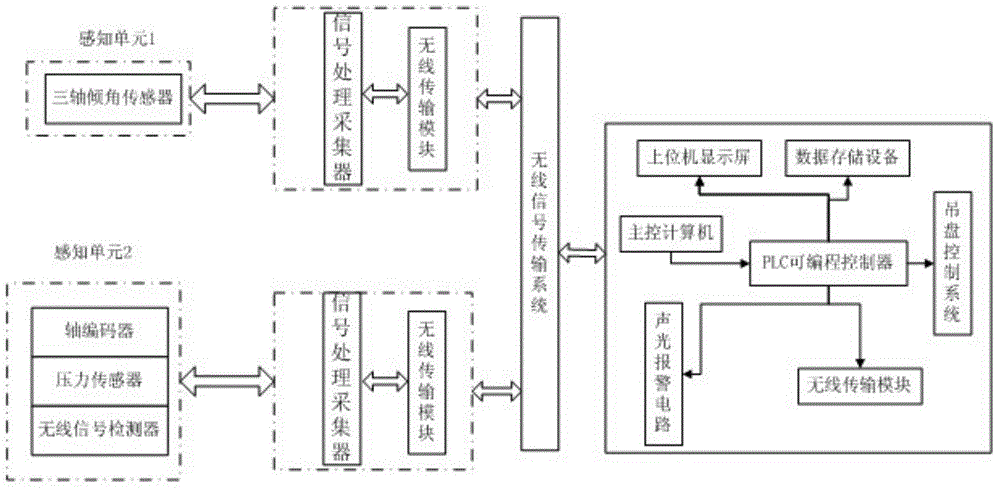

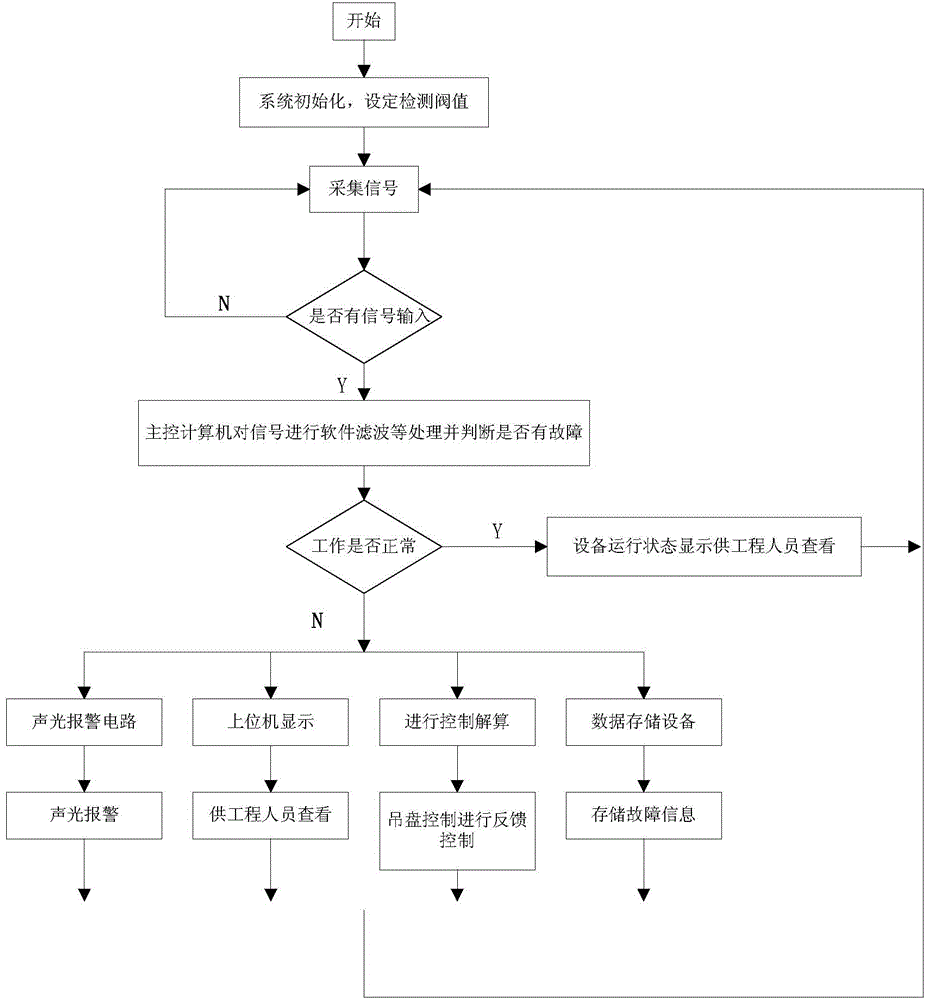

Operation fault monitoring system and method of construction vertical shaft hanging scaffold winch

The invention discloses an operation fault monitoring system and method of a construction vertical shaft hanging scaffold winch, and belongs to an operation fault monitoring system and method of a winch. The operation fault monitoring system comprises a first sensing unit, a first signal processing and acquiring unit, a second sensing unit, a second signal processing and acquiring unit, a wireless signal transmitting system arranged on the wall of a construction vertical shaft, and a PLC centralized control center which is controlled in a control room, wherein the first sensing unit and the first signal processing and acquiring unit are arranged on a hanging scaffold; the second sensing unit and the second signal processing and acquiring unit are arranged on a main head sheave main shaft and a main head sheave base; the first sensing unit comprises a three-axis tilt angle sensor, the second sensing unit comprises a shaft encoder, a pressure sensor and a wireless signal strength detector; the first signal processing and acquiring unit and the second signal processing and acquiring unit comprise signal processing and acquiring devices; the wireless signal transmitting system comprises a wireless mesh node and a controller; the centralized control center comprises a main control PLC, human-machine interaction equipment, an audible and visual alarm circuit and data storage equipment. The operation fault monitoring system has the advantages that an operation fault of the construction vertical shaft hanging scaffold winch can be detected and eliminated, and the safe and stable operation of the construction vertical shaft hanging scaffold winch are realized.

Owner:CHINA UNIV OF MINING & TECH

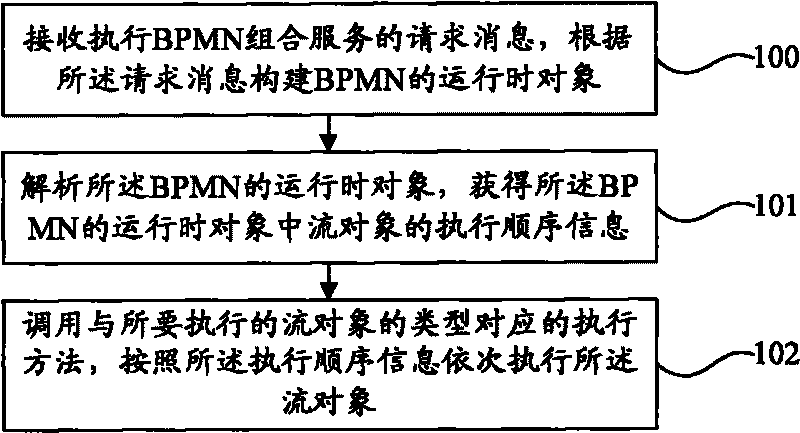

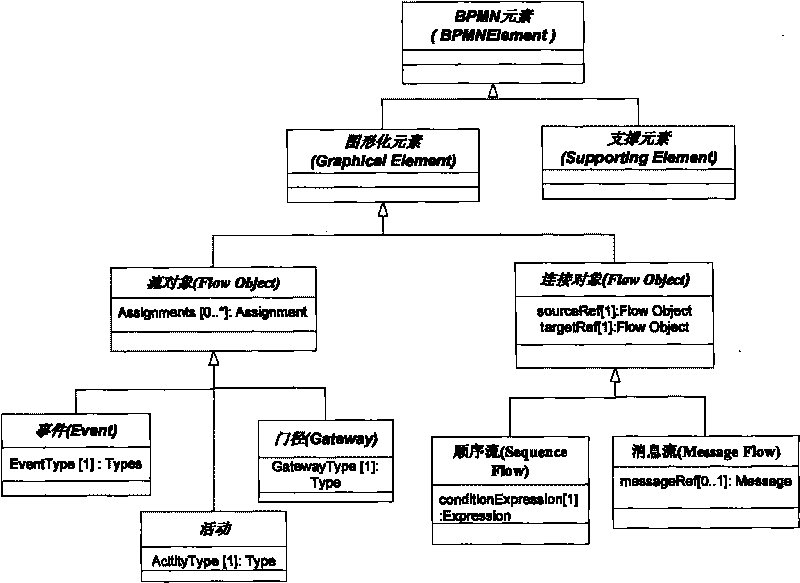

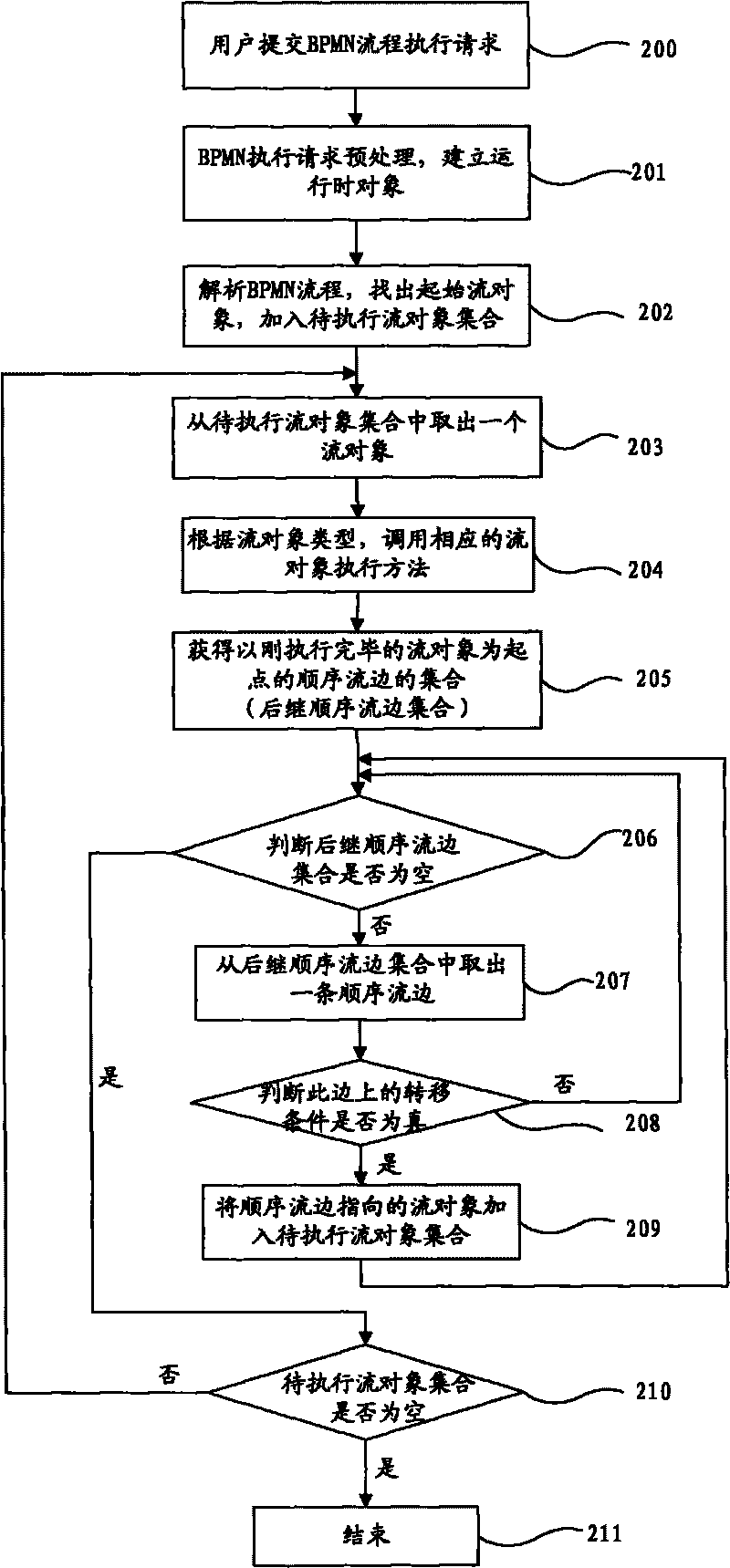

Execution method of BPMN composition service and execution device thereof

InactiveCN101695080AOvercoming Semantic MismatchesAutomateTransmissionGraphical modelBusiness process modeling

The invention provides an execution method of BPMN composition service and an execution device thereof. The execution method includes steps of receiving a query message of executing BPMN composition service to construct runtime objects of BPMN according to the query message, analyzing the runtime objects of the BPMN to acquire execution sequence information of streamed objects in the runtime objects of the BPMN, calling an execution method corresponding to types of the to-be-executed streamed objects, and then sequentially executing the steamed objects according to the execution sequence information. By analyzing the streamed objects and the sequence flow in a BPMN graphical model to acquire the execution sequence of the steamed objects and executing relative action according to semantics of flow objects in the BPMN, direct interpretation and execution of the BPMN flow are realized, and semantic compatibility and unity of a business conceptual model, a business process model and a business execution model and execution automation of the BPMN are realized.

Owner:BEIHANG UNIV

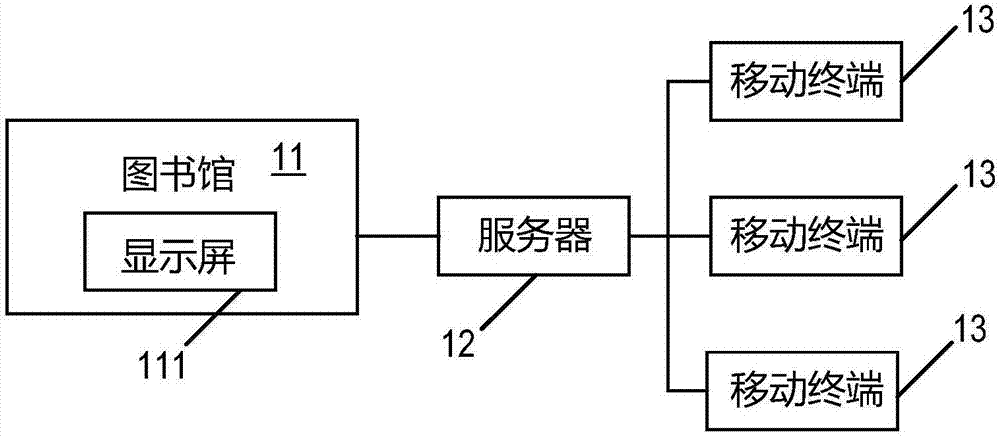

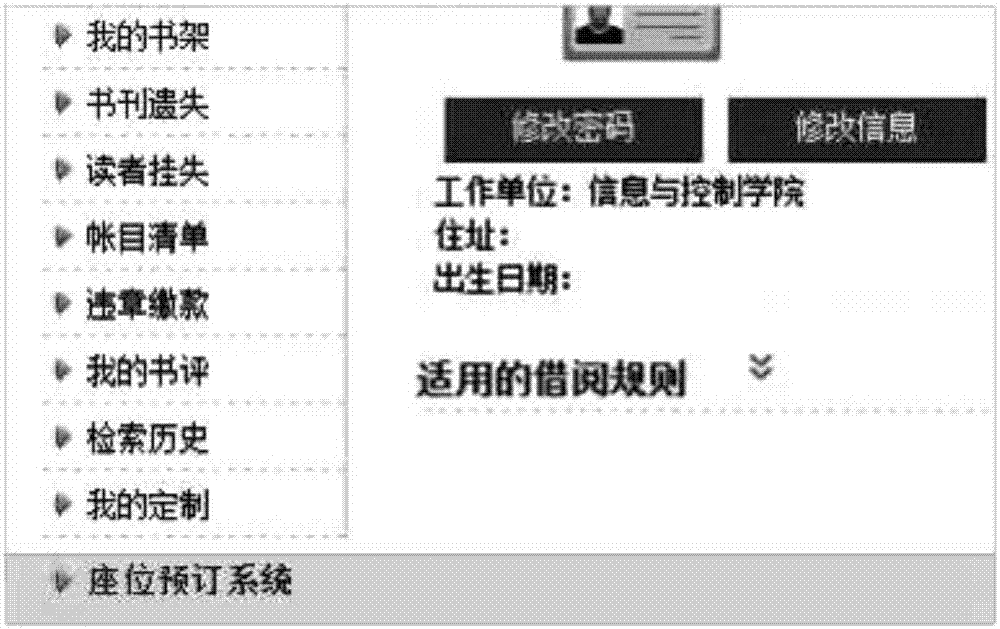

Library reading seat management system and management method thereof

InactiveCN107392339AAutomateImprove management efficiency and effective utilizationReservationsCo-operative working arrangementsManagement efficiencyManagement system

The present invention relates to a library reading seat management system and a management method thereof. The system comprises a mobile terminal, a server and a display screen; the mobile terminal and the display screen are connected with the server through a wireless network, the display screen is arranged at a library, the mobile terminal is configured to receive the user identity information and reserved information of a reading seat; the server is configured to verify whether the identity information is registered in the library or not and lock the target reading seat; the display screen is configured to display verification codes of the target reading seat; and the server determines that the target codes input by the user are matched with the verification codes or not, if yes, the user is prompted to use the target reading seat. The library reading seat management system and the management method thereof improve the management efficiency and effective utilization rate of the reading seats in the library, reduce the waste of manpower resource and are simple in whole structure, easy to deploy and high in expandability.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

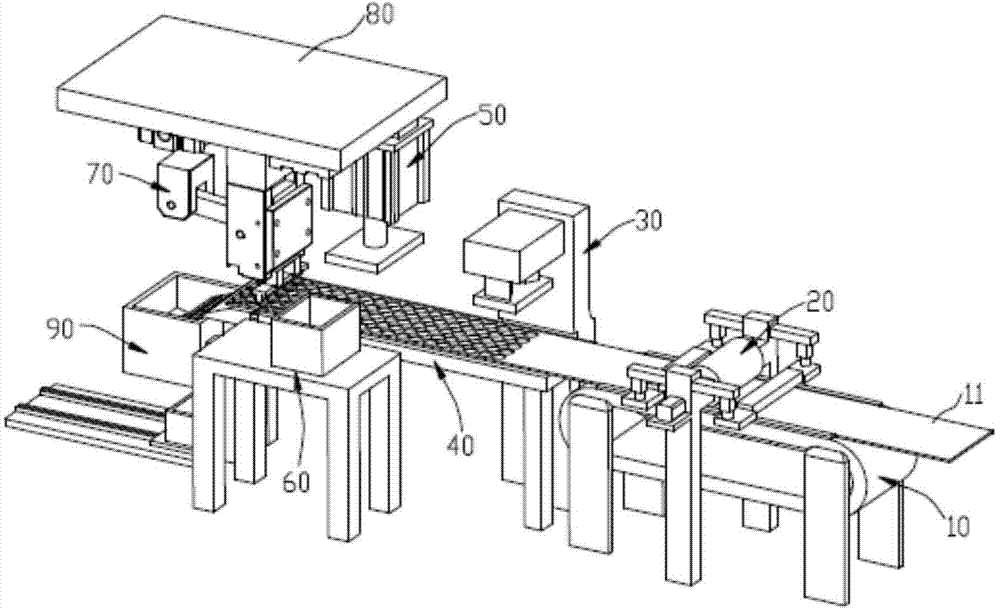

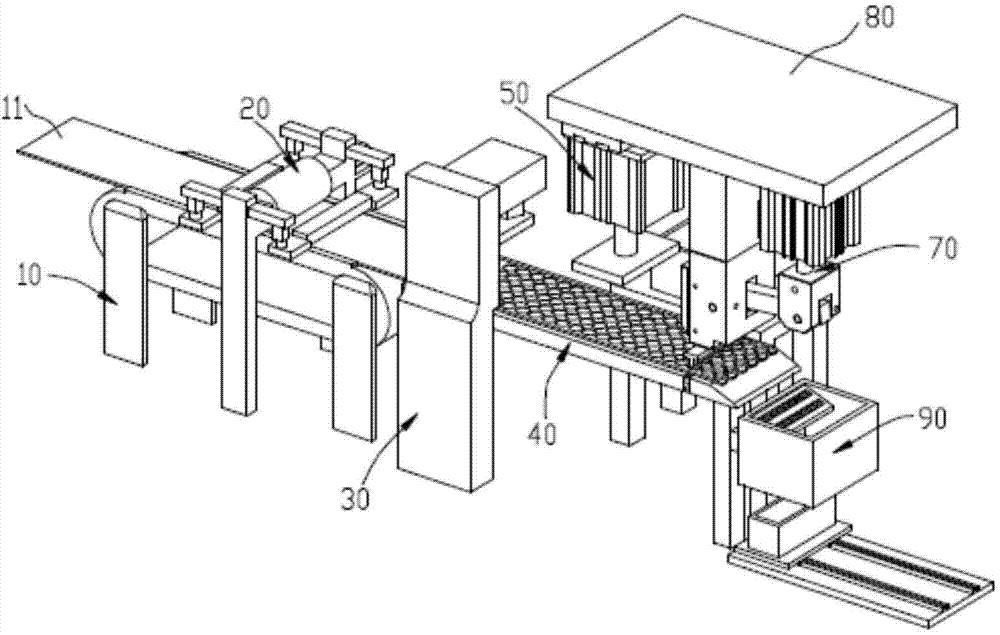

Novel punching production line

ActiveCN104759515AQuality assuranceProtect the bladeMetal-working feeding devicesStripping-off devicesSteel platesScrap

The invention discloses a novel punching production line. The novel punching production line comprises a transmission belt device used to drive a steel plate to move, a sweeping unit arranged above the transmission belt device and used to clean the steel plate, a punching platform arranged at a discharge end of the transmission belt device, a punching machine arranged on one side of the punching platform, an adsorption unit arranged right above the punching platform through an installation plate and located on one side of the punching machine, far away from the transmission belt device, a finished product unit arranged on the other side of the punching platform and used to place a finished product, a material cutting unit arranged right above the punching platform through the installation plate and located on one side of the adsorption unit, far away from the transmission belt device and a scrap clearing unit arranged at a discharge end of the punching platform, wherein the installation plate is fixedly arranged above the punching platform. The novel punching production line can achieve automatic punching, fetching, cutting and scrap clearing, effectively reduces labor intensity of a worker, and improves production efficiency.

Owner:东莞市钮纽实业有限公司

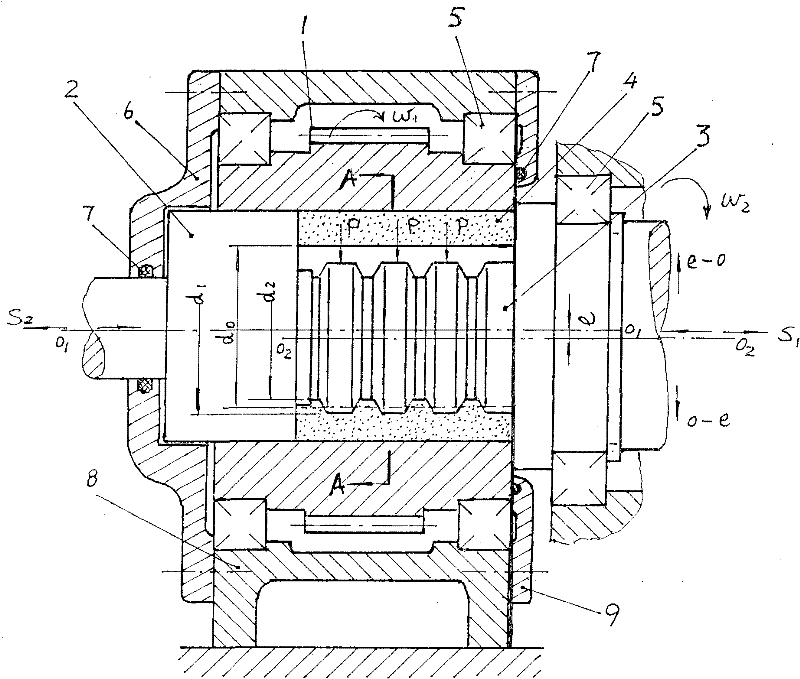

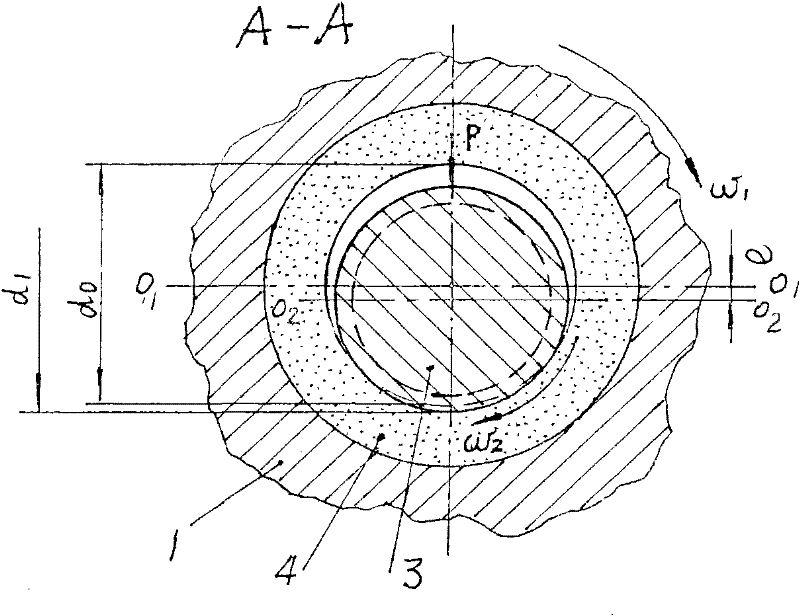

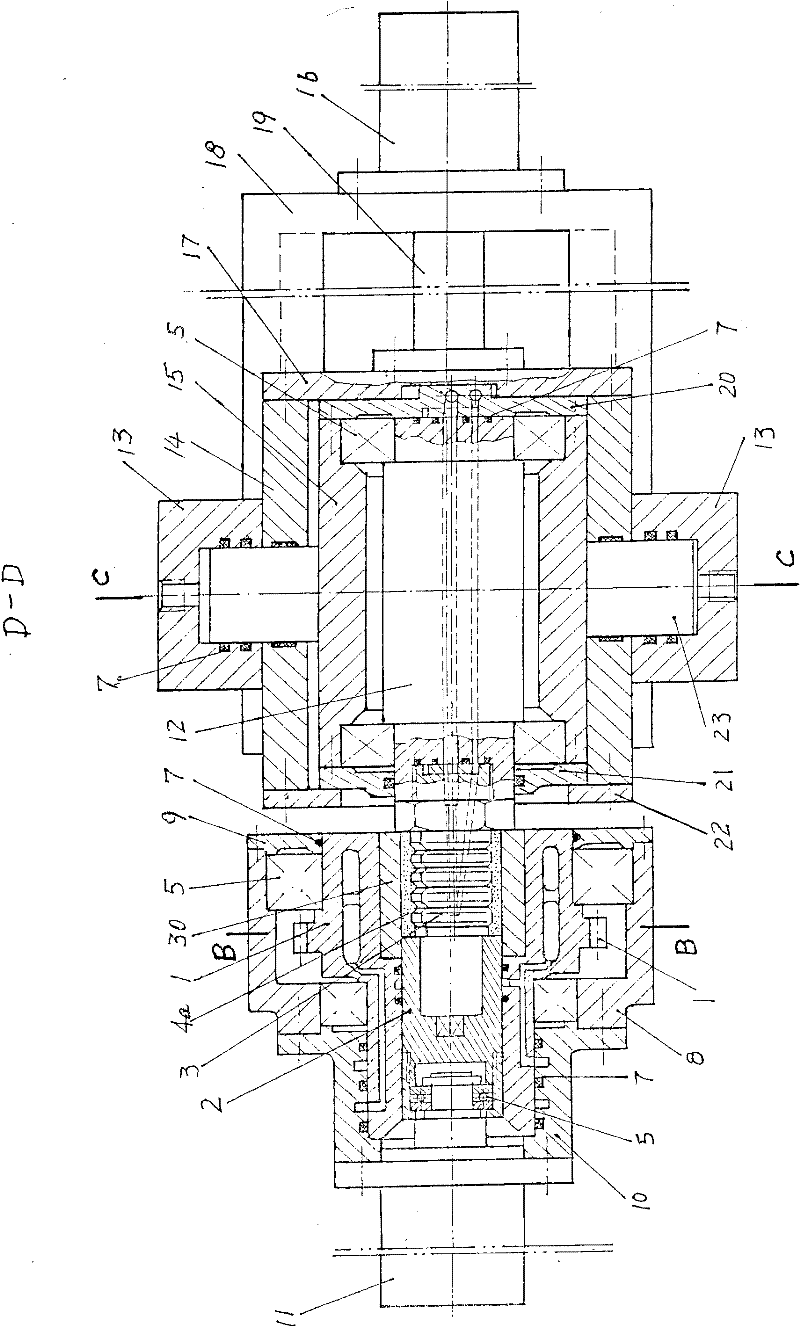

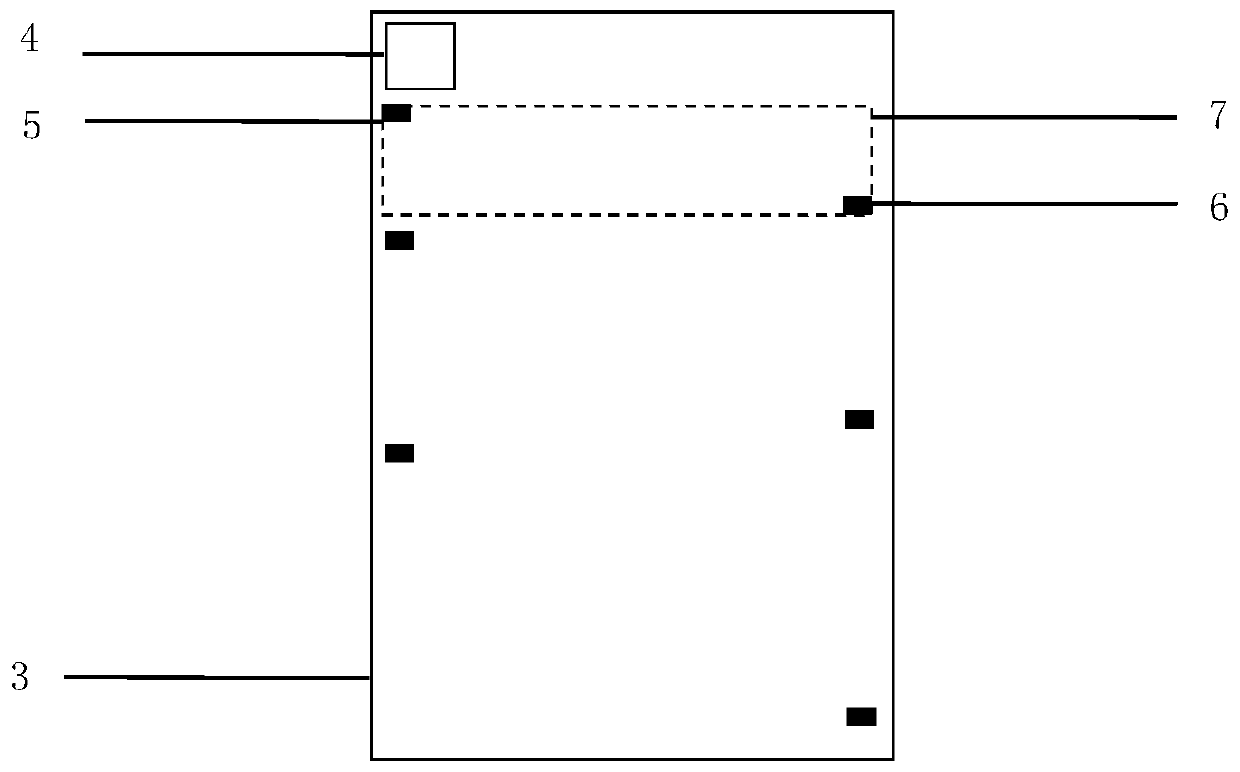

Compound mill

The invention discloses a compound mill. A roller (1) is positioned on a base (8) through bearings (5), a cylindrical space is arranged inside the roller (1), one end of the roller (1) is closed by a stopper (2), the other end of the roller (1) is firstly provided with a tubular blank (4) and extends into a roll shaft (3) with an annular groove, a die comprises the roller (1), the stopper (2) and the roll shaft (3), the roller (1) drives the blank (4) to rotate at an angular speed 1 under the drive of external force, friction force is generated between the roll shaft (3) and the blank (4) by means of pressure P, and the roll shaft (3) rotates at an angular speed 2 and further has the functions of axial reciprocation and radial reciprocation. When the axis O2-O2 of the roll shaft (3) is misaligned with the axis O1-O1 of the roller, the blank (4) is embedded by the aid of offset, and the inner wall of the blank (4) is broached and shrunk in compound milling and extrusion, so that the blank (4) becomes a qualified workpiece with an external cylindrical surface and an internal annular groove. Afterwards, the roll shaft (3) radially returns, stops rotating and axially returns, the stopper advances (pushes the workpiece out of the roller) and returns, all technical processes for machining one workpiece are continued to be completed rapidly and automatically by means of mechanical, electrical and hydraulic integration, production efficiency is improved, labor intensity is reduced, chipless machining is realized, and metal materials are saved.

Owner:袁正敏

Automatic stem cell culture system

InactiveCN108102914AAutomateIncrease productivityBioreactor/fermenter combinationsBiological substance pretreatmentsAir cleaningEngineering

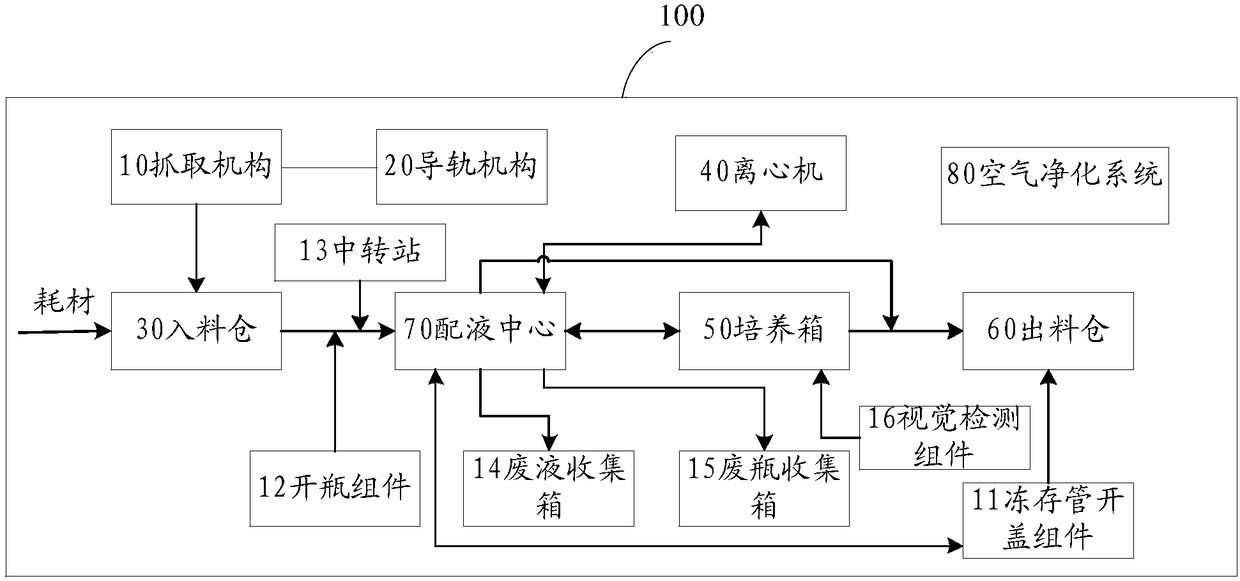

The invention discloses an automatic stem cell culture system which comprises a grabbing mechanism, a guide rail mechanism, a feed bin, a centrifuge, an incubator, a liquid distribution center, a discharge bin and an air purifying system, wherein the feed bin is used for feeding consumable material for single culture of stem cells; the grabbing mechanism is used for grabbing and placing a cultureflask; the guide rail mechanism is used for driving the grabbing mechanism to move; the centrifuge is used for centrifuging the stem cells in the culture flask; the incubator is used for culturing thestem cells to obtain a finished product of stem cells; the liquid distribution center is used for inoculating an empty culture flask with seed stem cells in the culture flask in the feed bin, and concentrating all finished products of stem cells to be collected when single batch is finished and sub-packaging in freezing tubes; the discharge bin is used for transferring out the freezing tubes containing the finished products of stem cells; the air purifying system is used for purifying air of internal environment for the stem cell culture. The system disclosed by the invention can realize automation of stem cell culture and improve the culture efficiency.

Owner:CELLAUTO BIOLOGICAL AUTOMATION CO LTD

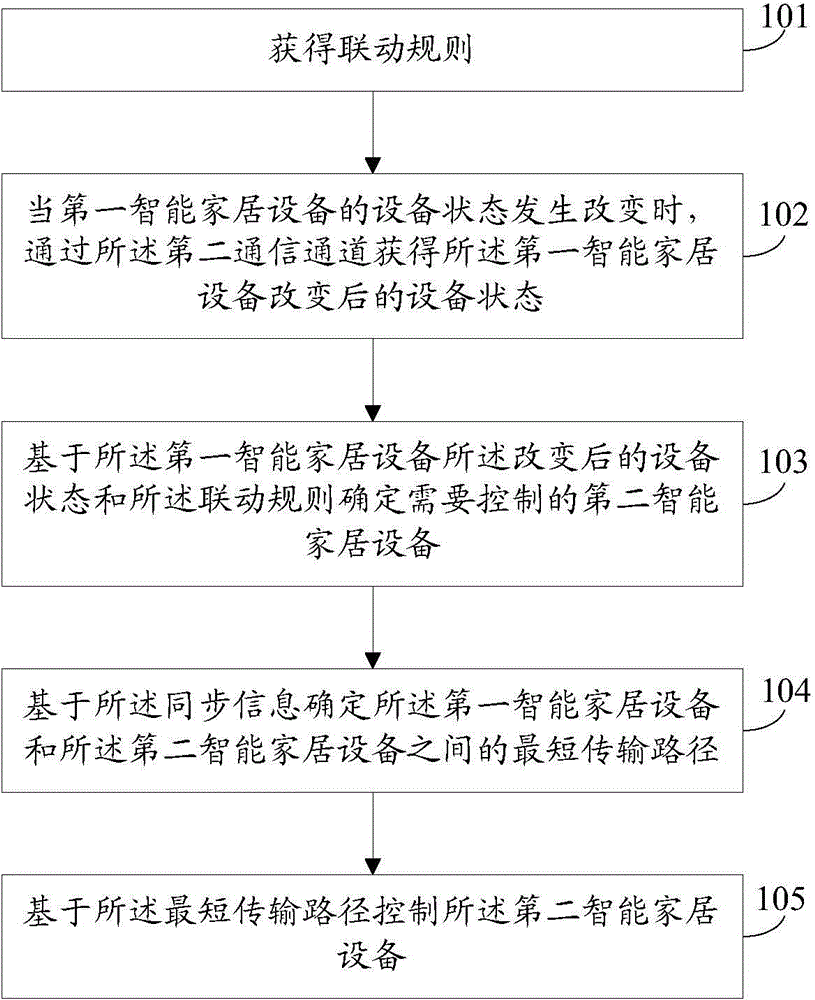

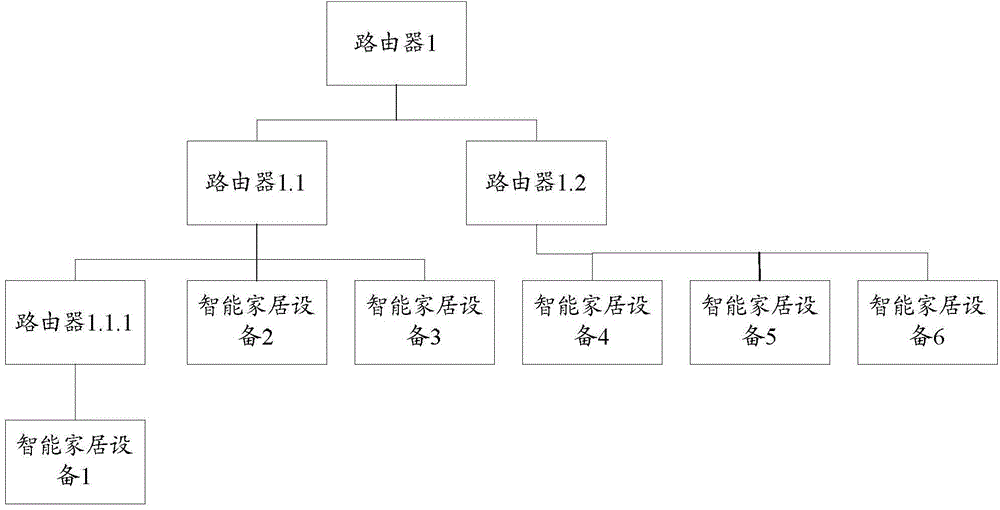

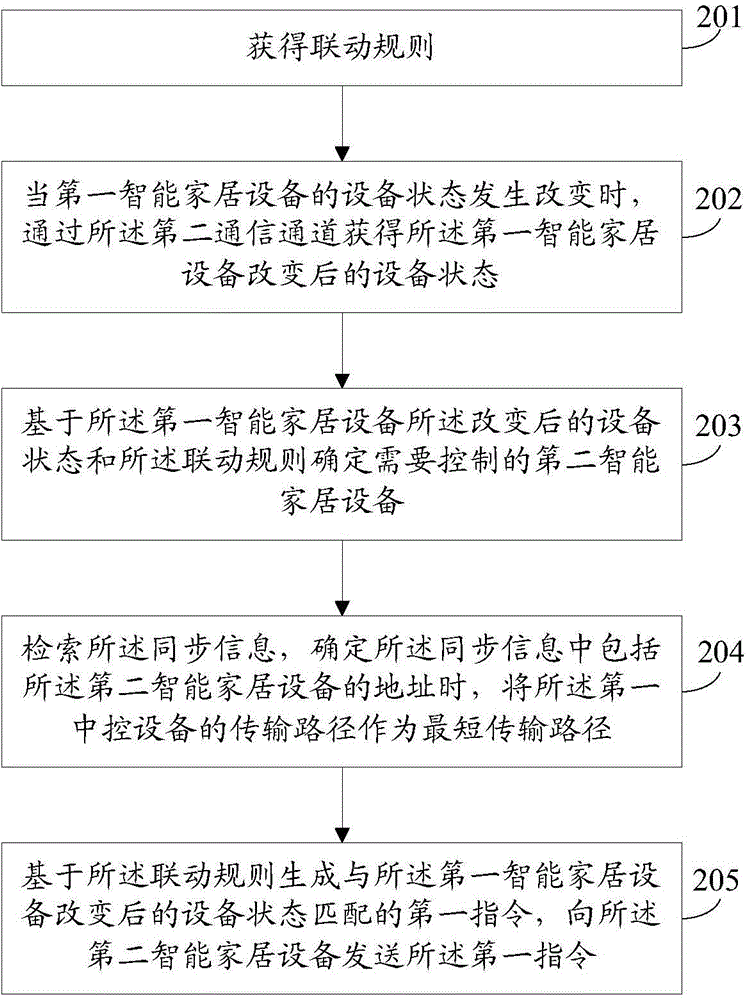

Control method and first central control device

The invention discloses a control method and a first central control device. The control method is characterized in that a linkage rule can be acquired; when a device state of a first intelligent household appliance is changed, a second communication channel is used to acquire the device state of the first intelligent household appliance after the change; based on the device state of the first intelligent household appliance after the change and the linkage rule, a second intelligent household appliance required to be controlled can be determined; based on the synchronization information, the shortest transmission path between the first intelligent household appliance and the second intelligent household appliance can be acquired; the shortest transmission path is the transmission path between the central control devices of the multi-stage control system; and based on the shortest transmission path, the second intelligent household appliance can be controlled.

Owner:LENOVO (BEIJING) CO LTD

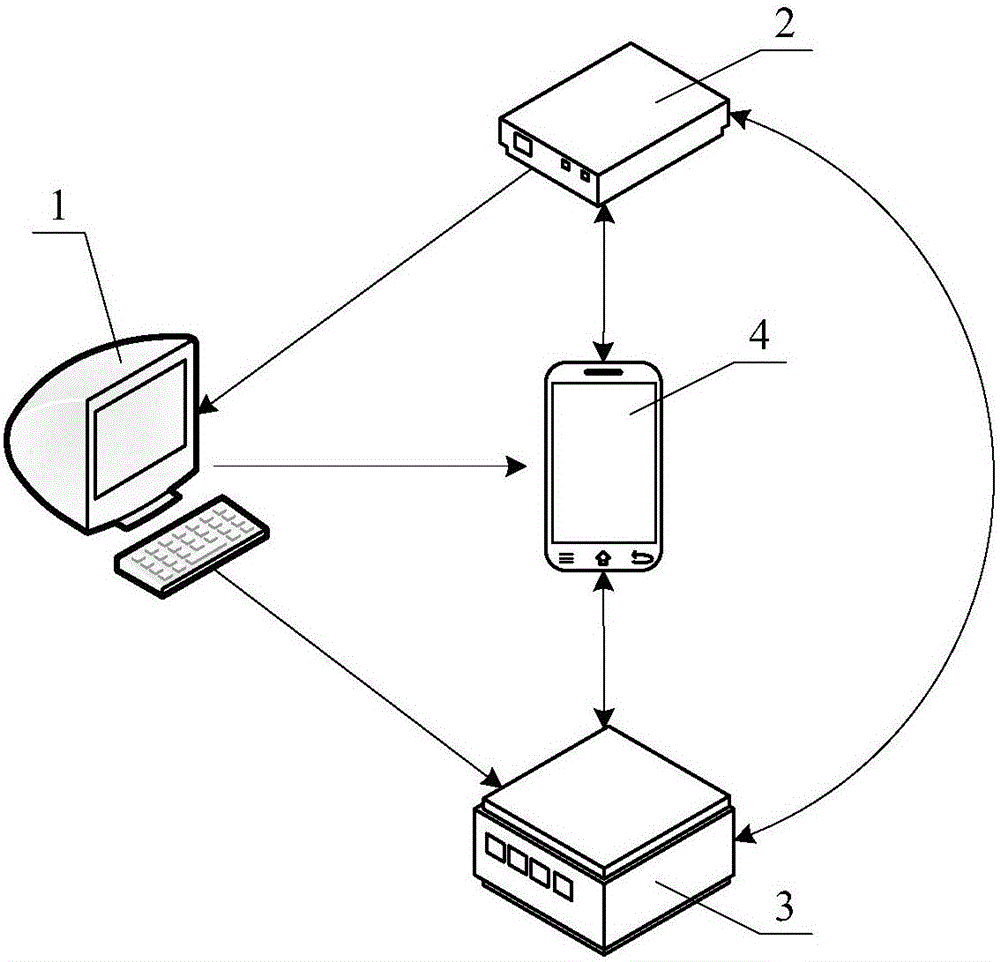

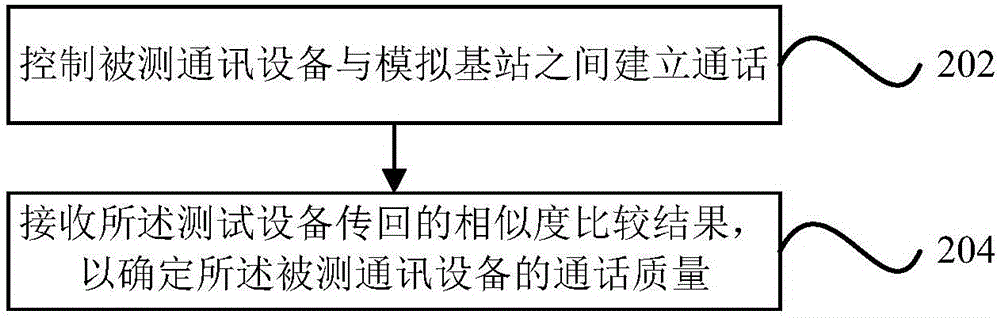

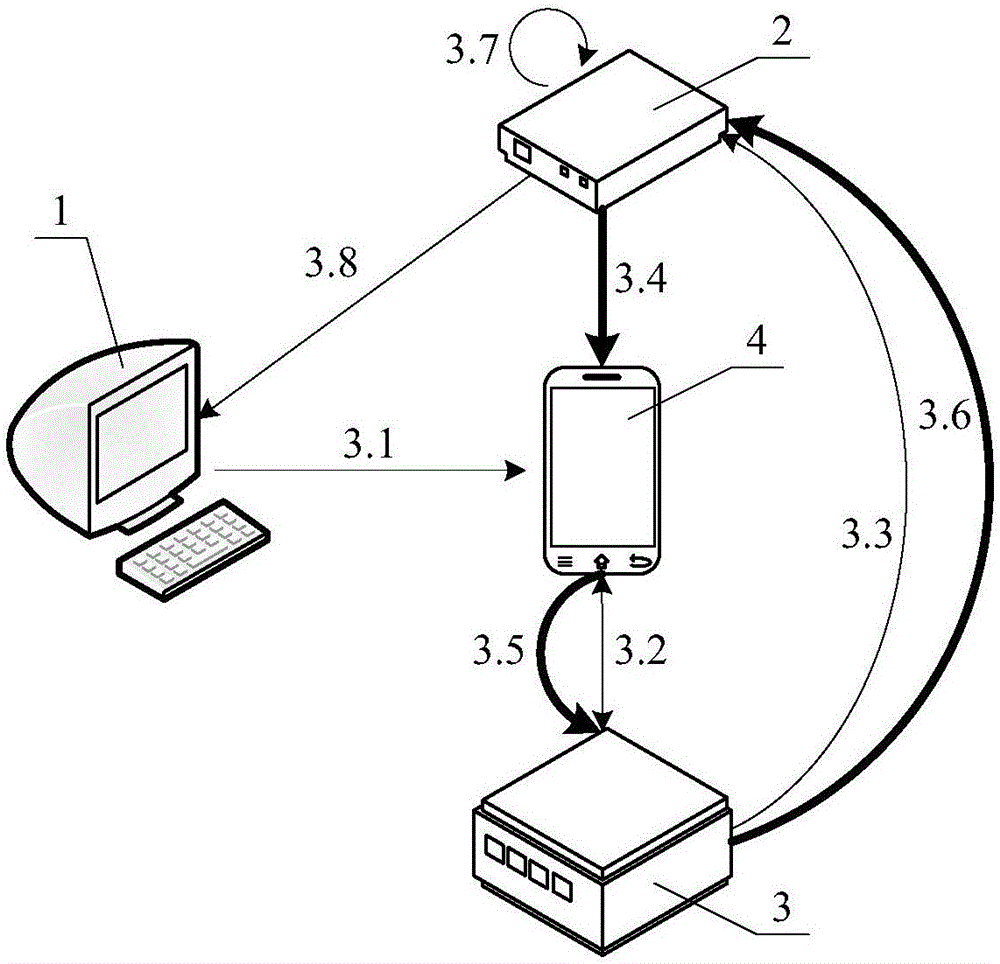

Call quality testing system, call quality testing method and call quality testing device

ActiveCN106504770AEliminate the effects ofImprove test efficiencyTransmitters monitoringReceivers monitoringAudio frequencyAutomatic testing

The invention relates to a call quality testing system, a call quality testing method and a call quality testing device. The call quality testing system comprises control equipment, testing equipment, a simulated base station and tested communication equipment. The control equipment transmits a call instruction to a random one selected from the tested communication equipment and the simulated base station so that the selected one initiates a call to the other one and furthermore the other one is preconfigured to an automatic answering mode, thereby establishing communication between the tested communication equipment and the simulated base station; supplying a standard audio to the other one by the testing equipment after the call is established so that the call is processed by the tested communication equipment for obtaining a testing audio in transmitting the call from the selected one to the other one, and the call is further transmitted back to the testing equipment; performing similarity comparison on the testing audio and the standard audio, and transmitting a result back to the control equipment. The call quality testing system, the call quality testing method and the call quality testing device can realize automatic testing on the call quality of the communication equipment, thereby performing call adjustment on the communication equipment.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

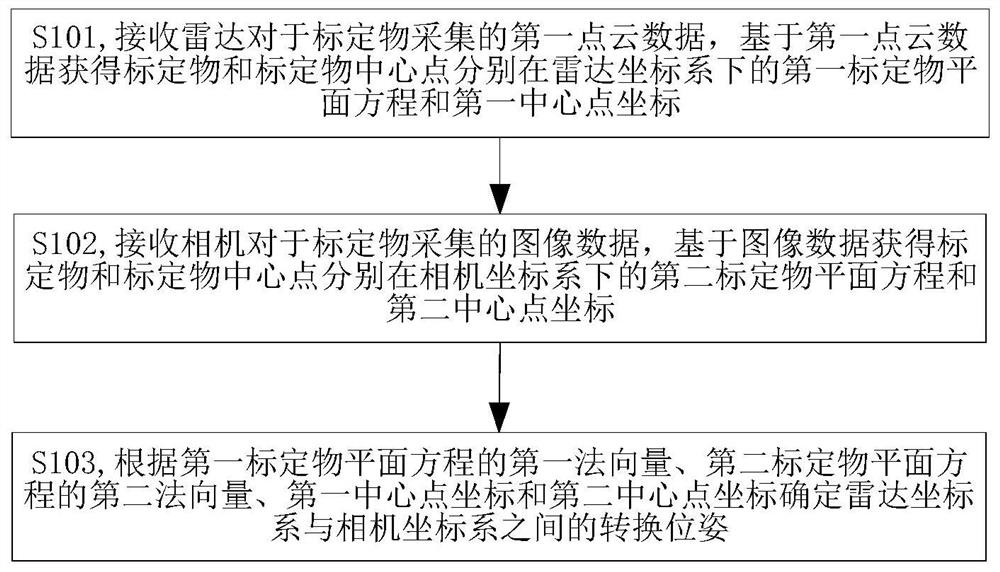

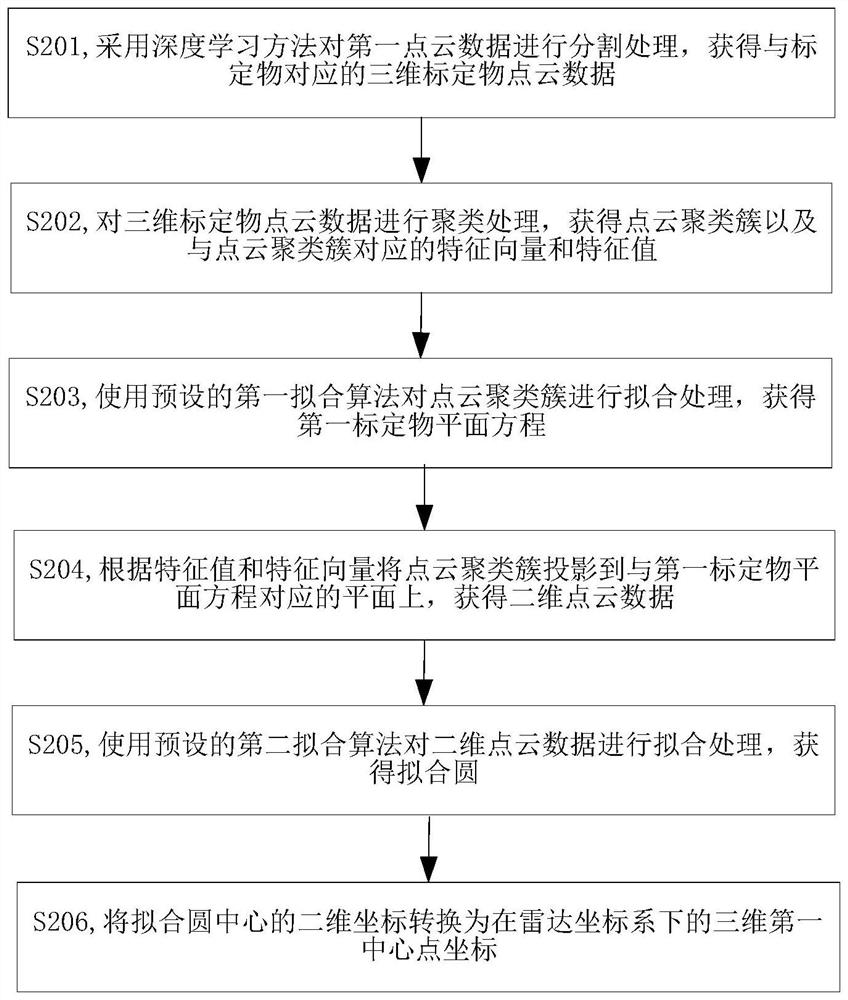

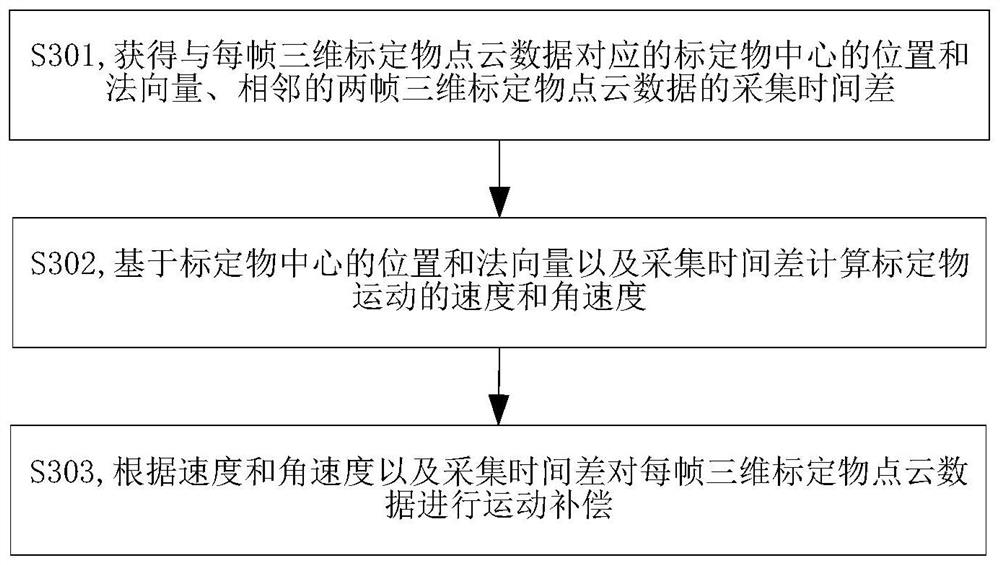

Method and device for determining conversion pose between radar and camera and electronic equipment

PendingCN112180362AAutomateReduce manual involvementImage enhancementImage analysisCalibration resultEngineering

The invention provides a method and a device for determining a conversion pose between radar and a camera, electronic equipment and a storage medium, and relates to the technical field of images. Themethod comprises the steps of acquiring a first calibration object plane equation and a first center point coordinate of a calibration object and a calibration object center point under a radar coordinate system based on first point cloud data acquired by radar; obtaining a second calibration object plane equation and a second center point coordinate of the calibration object and the calibration object center point under the camera coordinate system based on the image data collected by the camera; and determining a conversion pose between the radar coordinate system and the camera coordinate system according to the first normal vector of the first calibration object plane equation, the second normal vector of the second calibration object plane equation, the first center point coordinate and the second center point coordinate. According to the method and the device, the electronic equipment and the storage medium, automation of the calibration process is achieved, manual participationof the calibration process is reduced, the degree of dependence on the calibration board state and the external environment is low, and calibration results are stable.

Owner:BEIJING HORIZON ROBOTICS TECH RES & DEV CO LTD

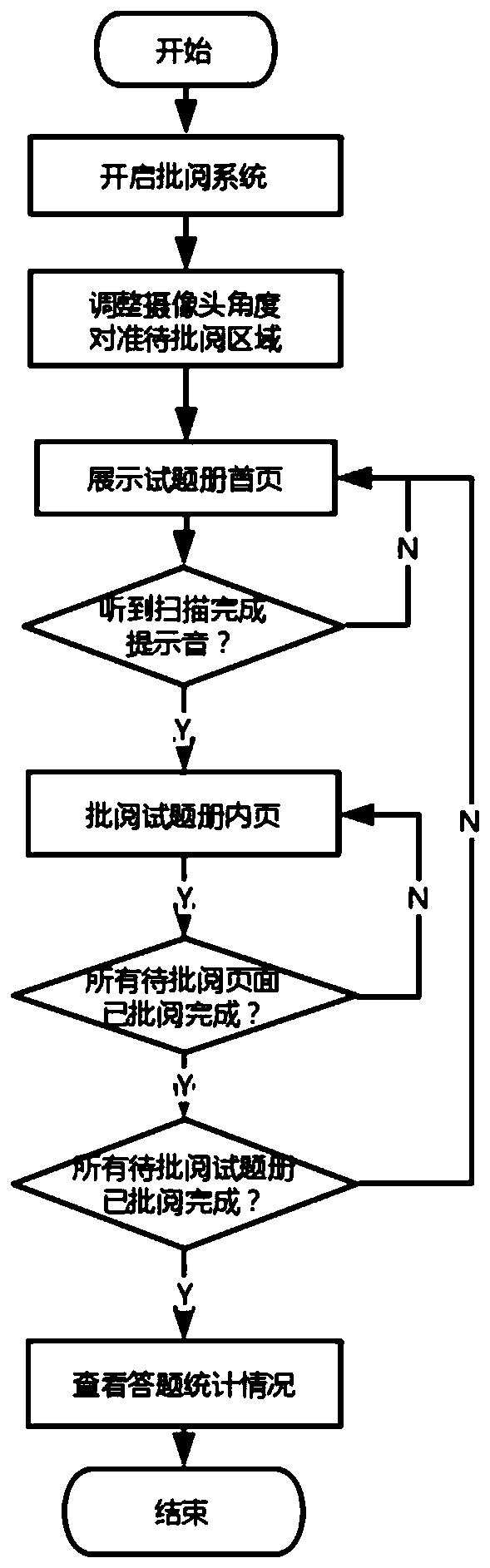

Wrong question set generation and answer statistics system and method based on review identification

PendingCN110597806AWill not affect the habit of paper reviewShorten the timeDatabase updatingCharacter and pattern recognitionTablet computerSystem configuration

The invention relates to a wrong question set generation and answer statistics system and method based on review recognition. The wrong question set generation and answer statistics system comprises afeature test question book, a personal terminal, and a corresponding upper computer function module, wherein the feature test question book is a paper test question book comprising a feature two-dimensional code and a test question segmentation mark point; the personal terminal comprises a PC with a camera, a notebook computer, a tablet personal computer or a mobile phone and the like; and the upper computer function module comprises an image processing unit, a data analysis unit, a wrong question database, an answering condition database and a statistics and display unit. The wrong questionset generation and answer statistics system judges the manual reading condition of a teacher and counts the answering condition of students to form an error question set for the teacher and the students to use by scanning the characteristic test brochure at regular time through a camera on the personal terminal, so as to improve the teaching and learning efficiency. Compared with the prior art, the wrong question set generation and answer statistics system has the advantages of no influence on the reading habit of teachers, high efficiency, convenience in operation, low system configuration requirement and the like.

Owner:SHANGHAI JIAN QIAO UNIV

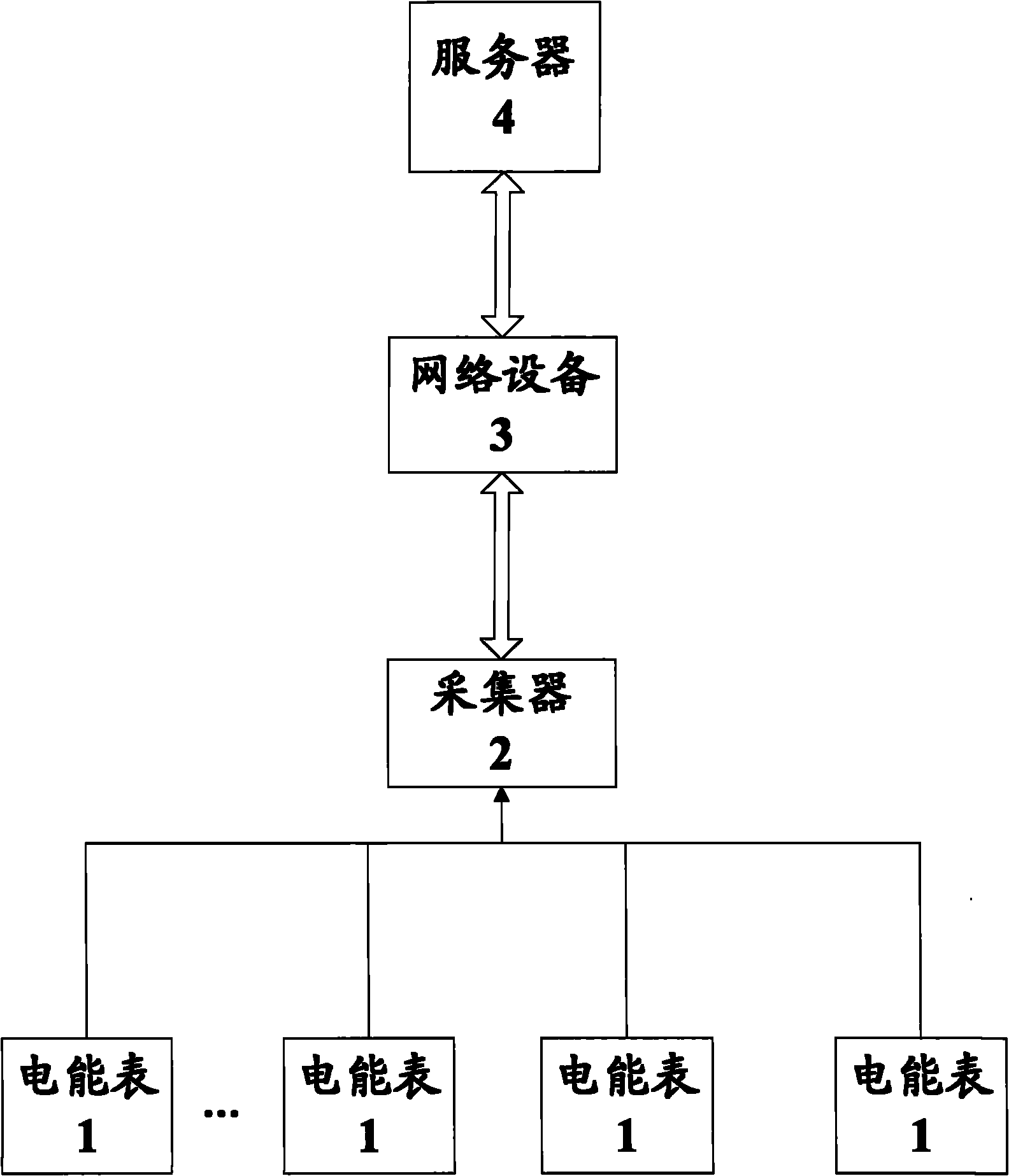

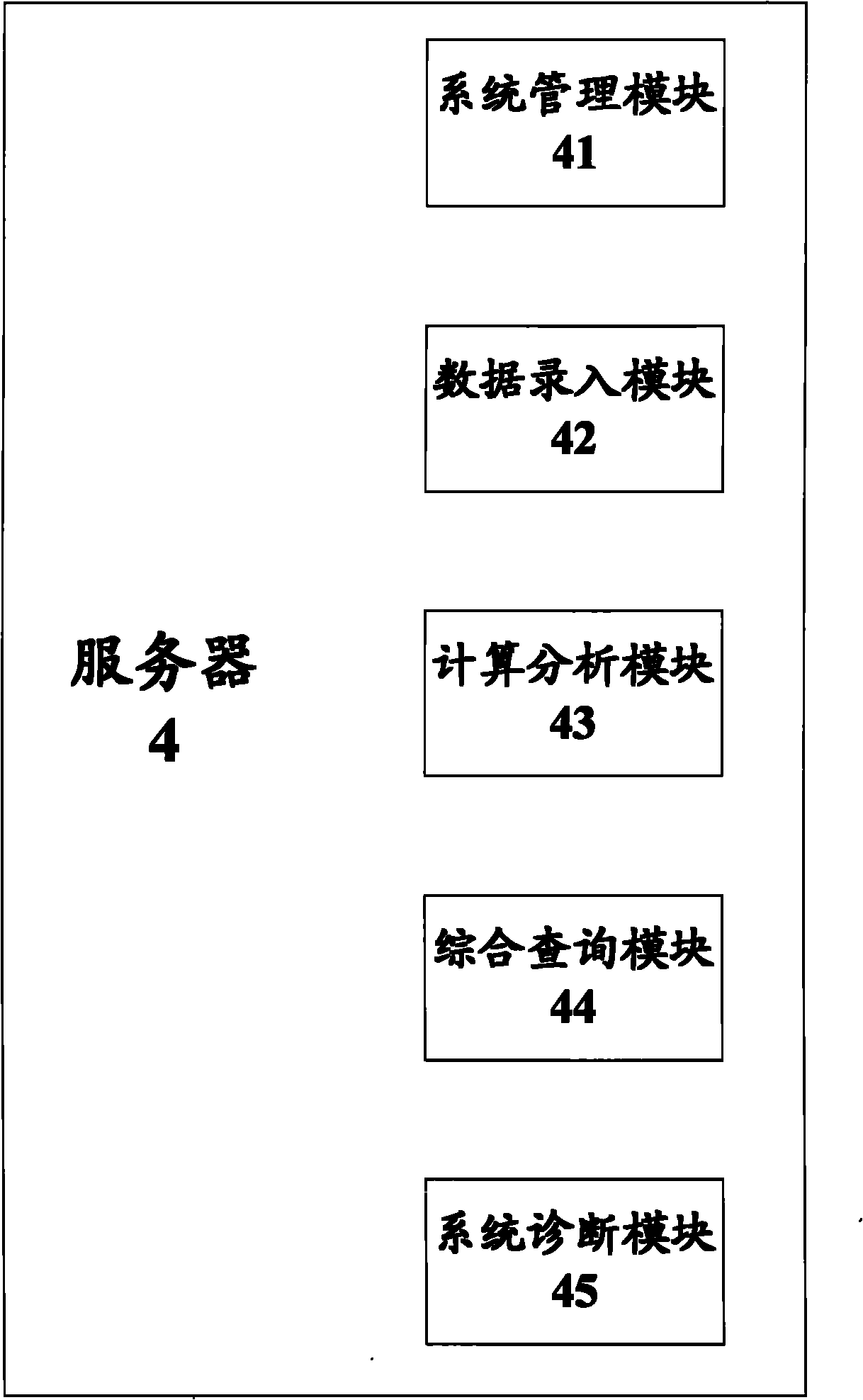

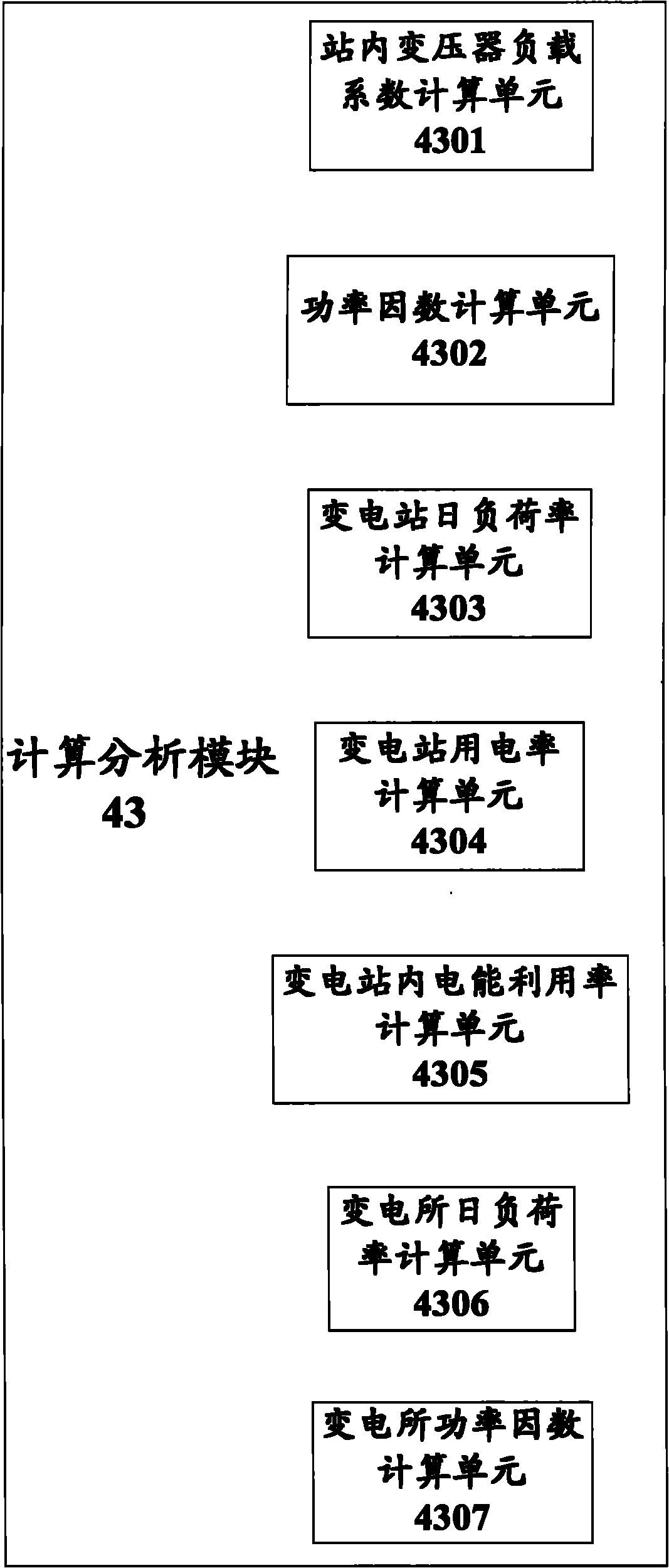

Electric energy monitoring system

ActiveCN101771275AAutomateFully consider real-timeSpecial data processing applicationsAc network circuit arrangementsSoftware designAutomotive engineering

The invention discloses an electric energy monitoring system, comprising an electric energy meter, a collector, a network apparatus and a server. The electric energy meter is used for detecting the electric energy data of each electric energy metering point; the collector is connected with the electric energy meter and used for collecting the electric energy parameter of each electric energy meter; the network apparatus is connected with the collector, and the electric energy data collected by the collector is transmitted to the server; and the server is used for receiving the electric energy data as well as calculating and processing the electric energy data. The electric energy monitoring system fully considers the real-time, the accuracy and the efficiency of the data collection, and uses an advanced hardware / software design scheme to realize automation, intelligent and networking for data collection analysis.

Owner:CHINA SHENHUA ENERGY CO LTD +1

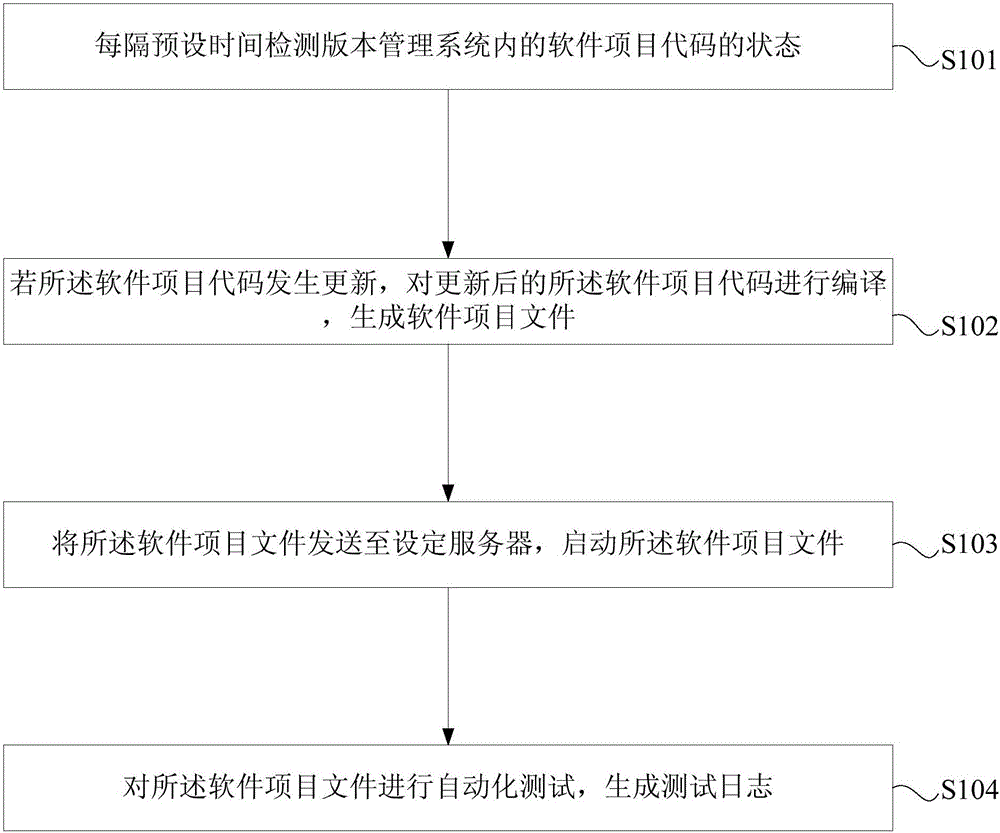

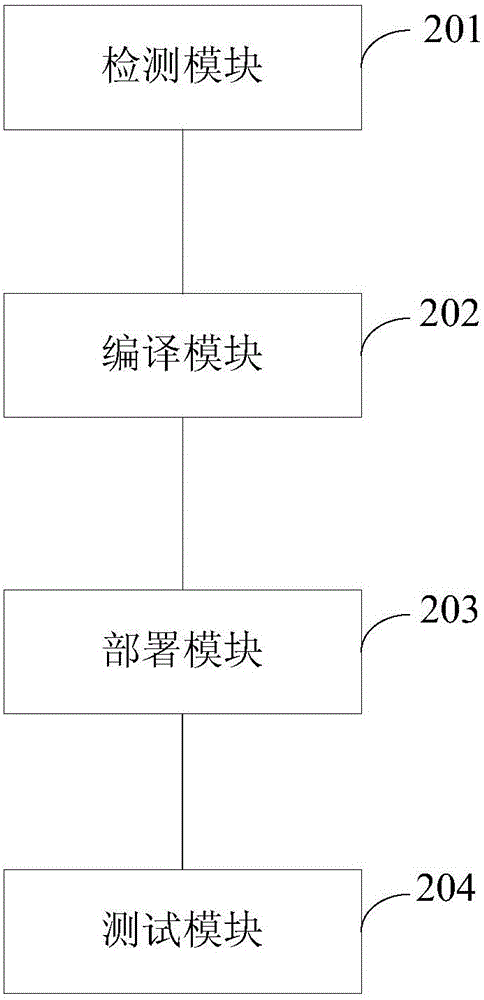

Continuous software project integration method and device

InactiveCN105955749AAutomateCommission integration efficiencySoftware maintainance/managementSoftware testing/debuggingManagement systemVersion management

The invention discloses a continuous software project integration method and device. The method comprises the following steps: detecting the state of a software project code in a version management system at set intervals; if the software project code is updated, compiling the updated software project code so as to generate a software project file; sending the software project file to a set server and starting the software project file; and carrying out automatic test on the software project file so as to generate a test log. By applying the continuous software project integration method and device provided by the invention, the integration efficiency of continuous software project integration can be well enhanced.

Owner:BEIJING VENUS INFORMATION SECURITY TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com