Patents

Literature

115results about How to "Good cutting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

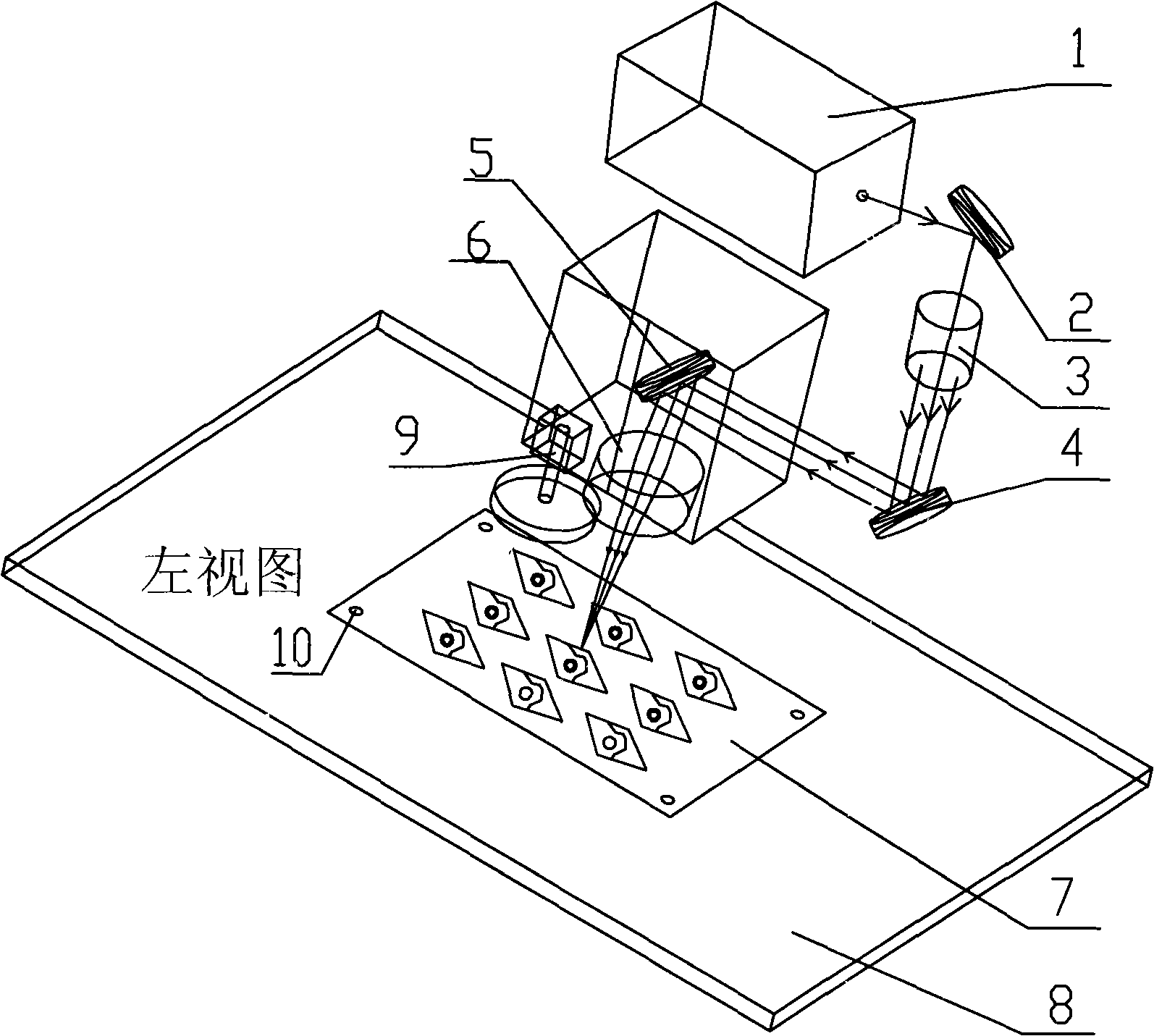

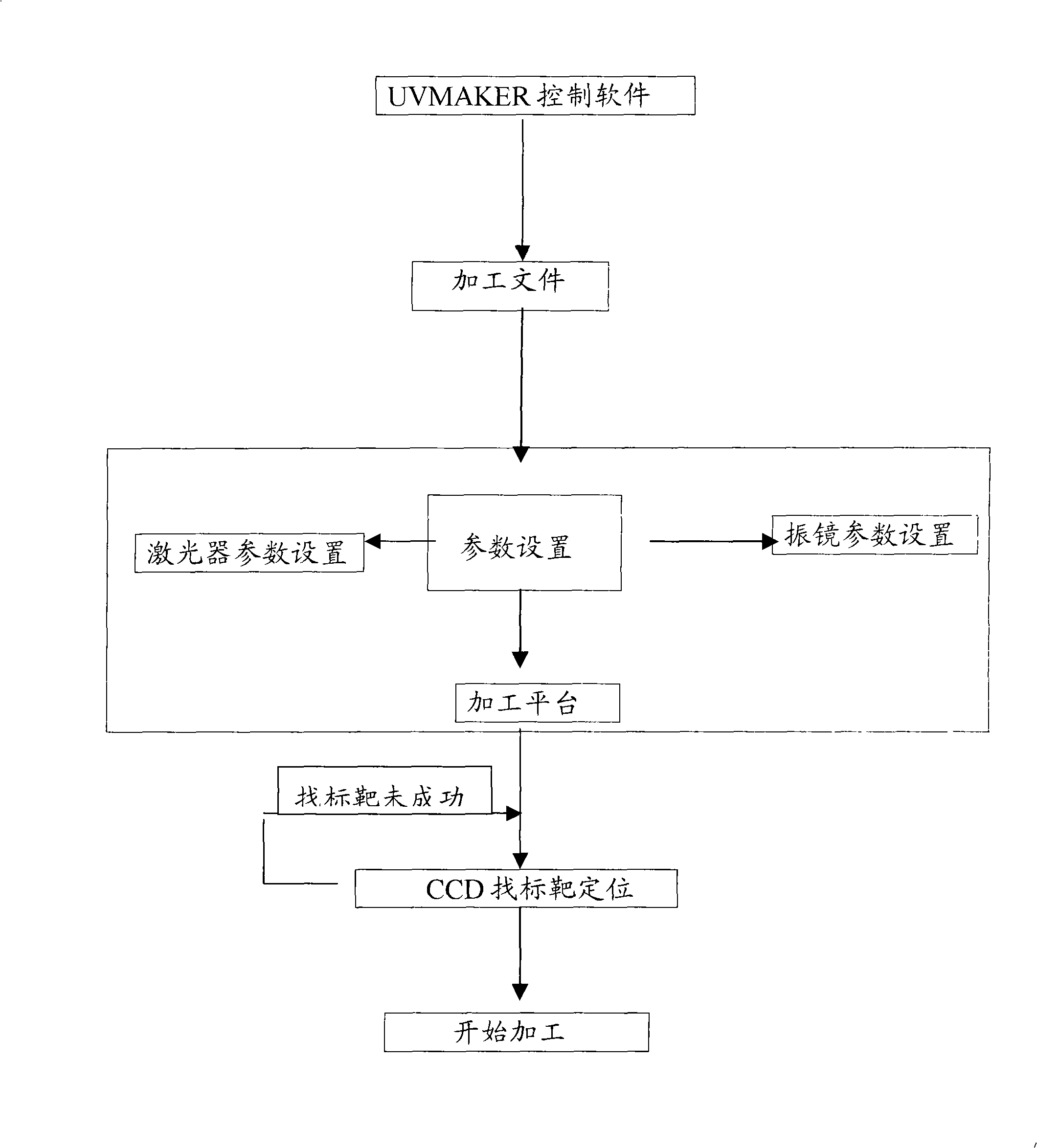

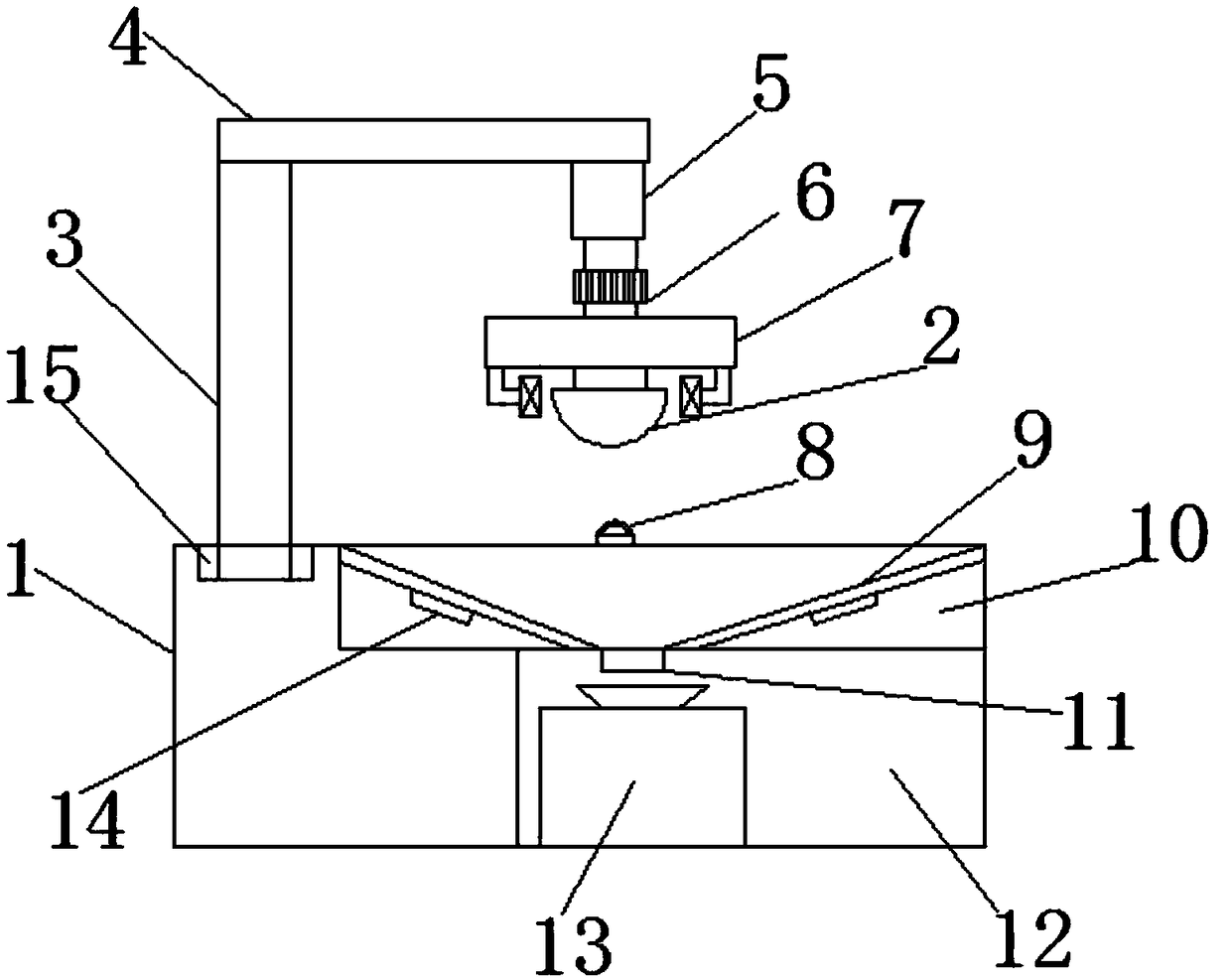

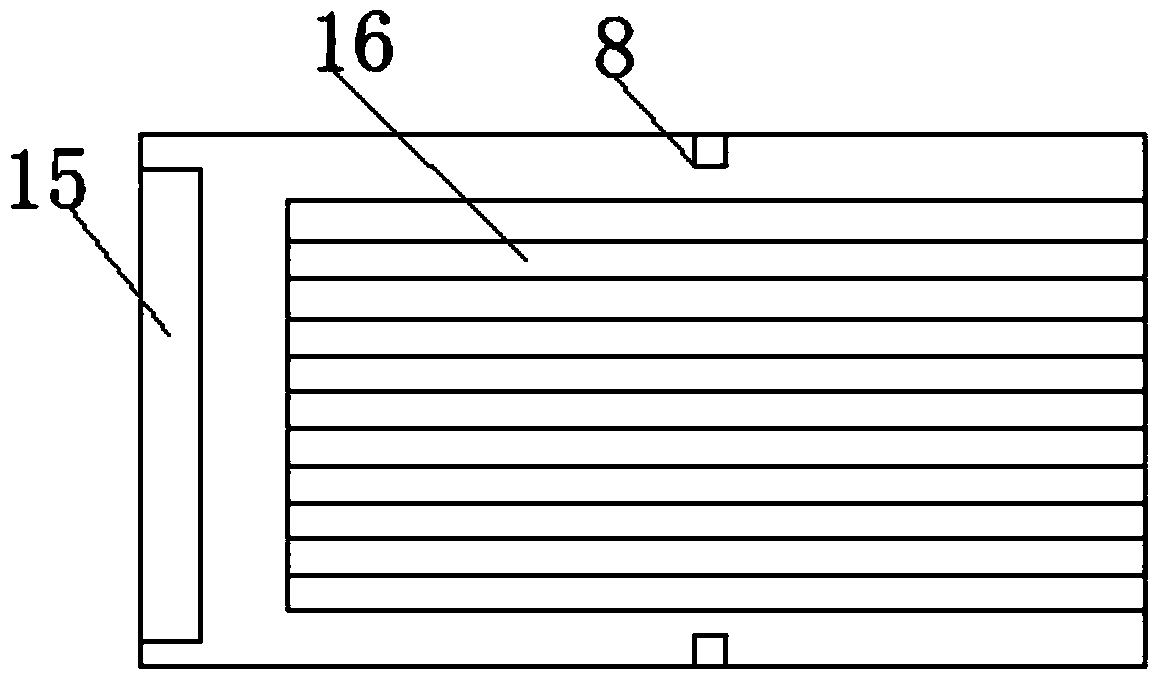

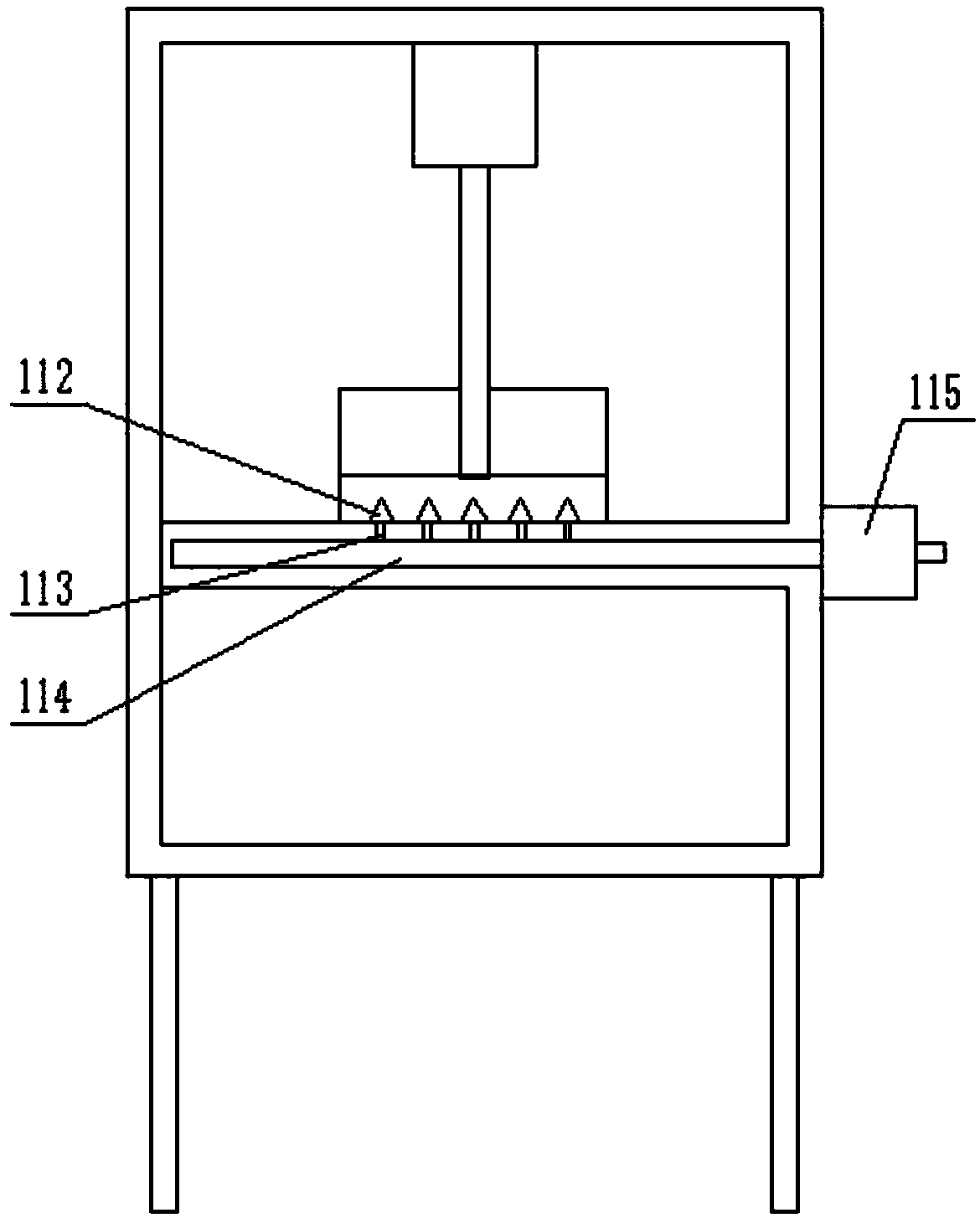

Laser device for cutting

ActiveCN101288921AGood cutting effectAutomateWork holdersLaser beam welding apparatusLaser cuttingEngineering

The invention discloses an FPC (Flexible Printed Circuit) laser cutting device, consisting of a laser focus scanning system, a control system and a vacuum platform system. The cutting device of the invention improves the FPC formation accuracy and saves processing time and cost.

Owner:HANS CNC SCI & TECH

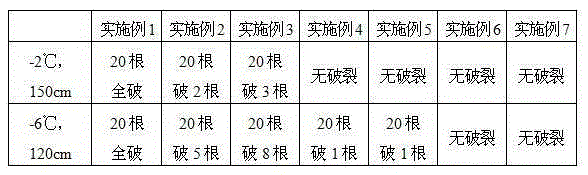

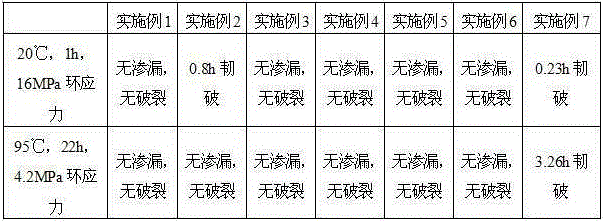

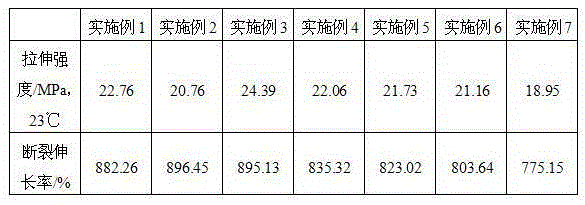

Preparation method for polypropylene-toughened impact-resistant tubular product

The invention relates to a preparation method for a polypropylene-toughened impact-resistant tubular product. The preparation method comprises the following steps: A, weighing raw materials in parts by mass: 100 parts of polypropylene, 5-30 parts of a polyolefin toughening agent, 5-10 parts of inorganic filler, 0.01-1.0 part of an antioxidant and 0.01-1.0 part of an ultraviolet adsorbent; B, drying: drying the raw materials at 60-80 DEG C; C, preparing a premix: after mixing the polypropylene, the polyolefin toughening agent and the inorganic filler in a certain proportion, stirring the raw materials in a low-speed stirrer to be stirred for 10-12 minutes, then adding the antioxidant and the ultraviolet adsorbent, and continuously stirring the mixture for 2-5 minutes; and D, extruding the tubular product: feeding the prepared premix into a single screw extruder, controlling the processing temperature at 160-210 DEG C, controlling the rotating speed of the screw at 60-90 rpm, and extruding the toughened and modified polypropylene tubular product.

Owner:YONGGAO CO LTD

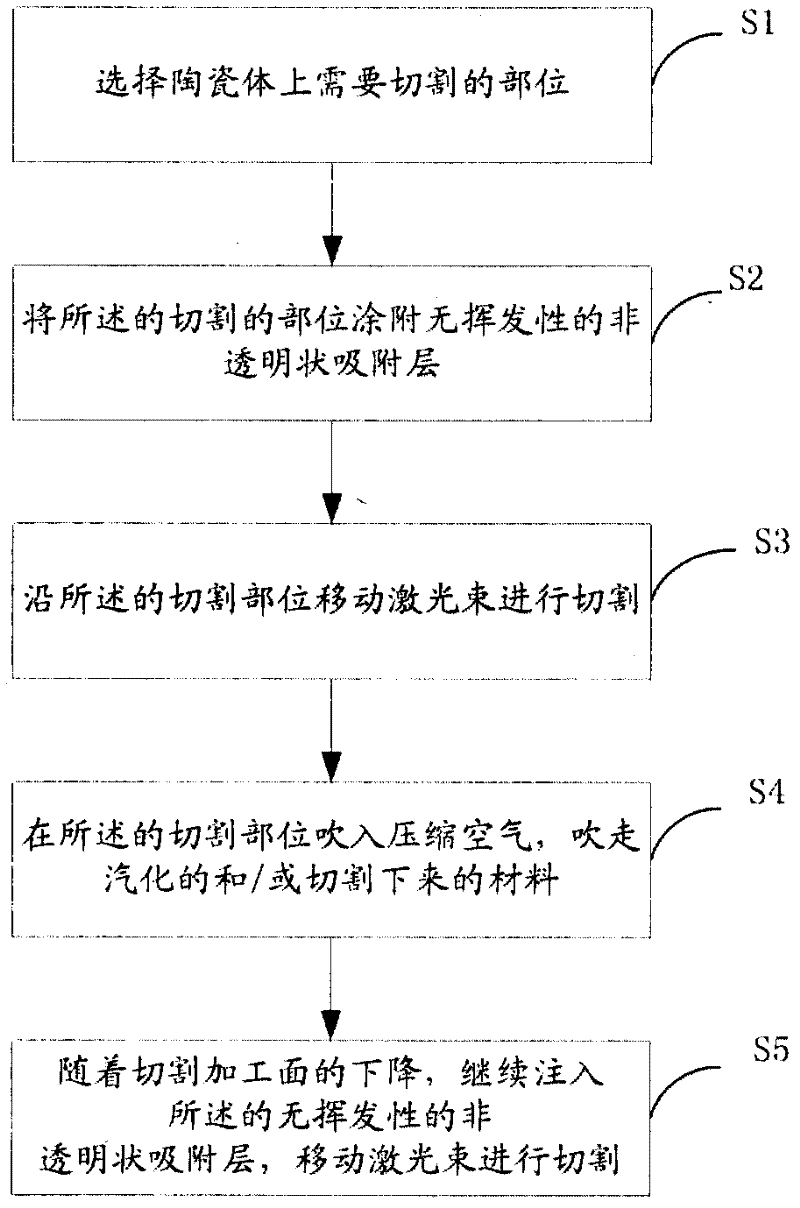

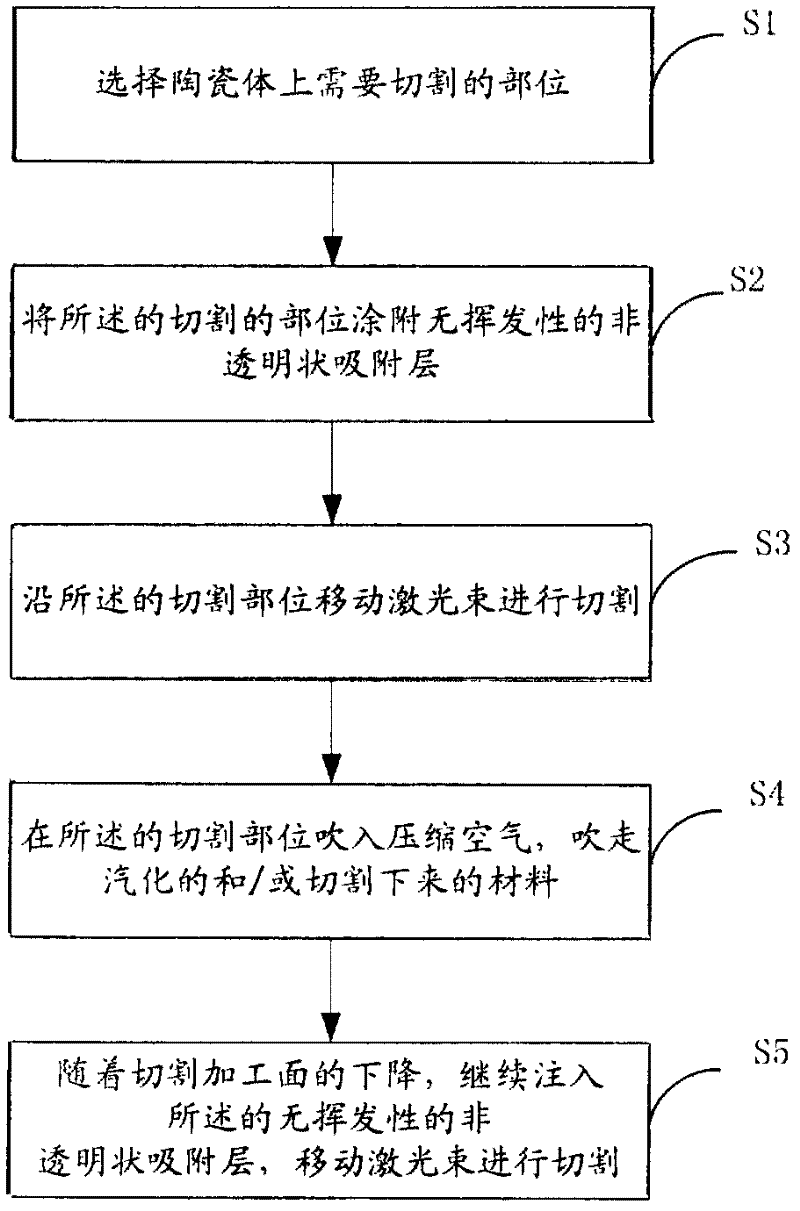

Method for cutting ceramic by laser

InactiveCN102513707AImprove cutting efficiencyGood cutting effectLaser beam welding apparatusLaser beamsMetallurgy

The invention discloses a method for cutting ceramic by laser, which includes: S1, selecting portions of ceramic required to be cut; S2, coating a non-volatile non-transparent adsorption layer onto the portions to be cut; and S3, cutting along the portions to be cut by moving a laser beam. Since the adsorption layer used in the method can adsorb laser energy, cutting efficiency can be improved.

Owner:SHENZHEN MUSEN TECH

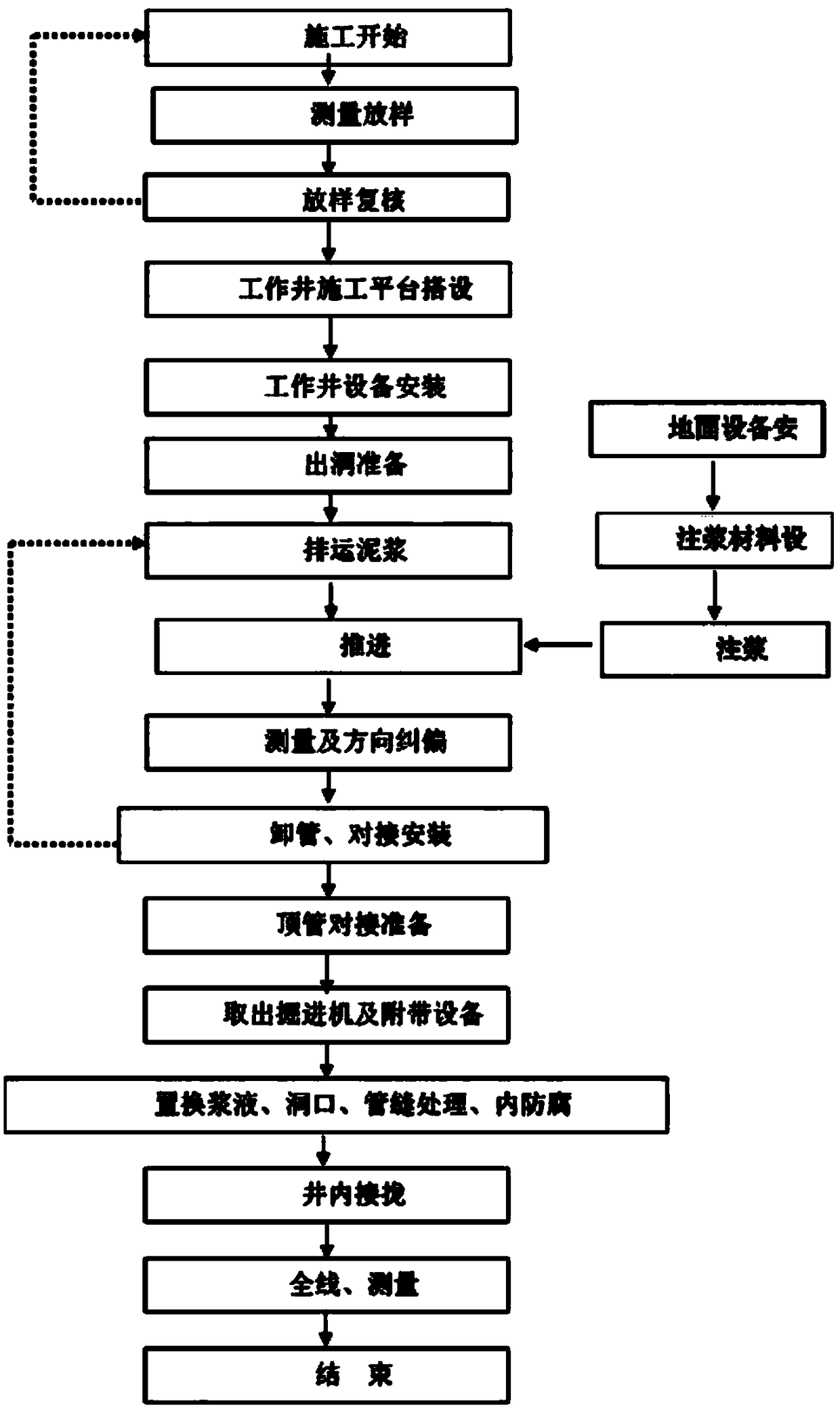

Pipe jacking construction method in complex terrain environment

InactiveCN109372532AReduce disturbanceReduce extrusion stressBuilding constructionsOrganic fertilisersTerrainEarth pressure balance

The invention discloses a pipe jacking construction method in a complex terrain environment. A panel type 3.5m large cutter head earth pressure balance pipe jacking heading machine is adopted; cut soil enters a muddy water cabin from gaps of a main cutting edge; soil in the muddy water cabin is broken into mud under the joint action of a stirring bar behind a cutter head and muddy water; and the water and earth pressure of excavation surfaces is balanced by controlling the mud and water pressure and the mud weight of the muddy water cabin, so that the excavation surfaces are always in a stablestate. As for sections with poor soil quality and a large buried depth of pipelines, or sections located in a prosperous region with buildings (structures) or traffic trunks above and strict restrictions on displacement and groundwater by surrounding environments, the large-diameter earth pressure balance pipe jacking method is easy and safety in construction, high in quality, low in investment and short in construction period, extrusion of surrounding pipelines and settlement of the ground are effectively controlled, and smooth operation of ground transportation is ensured while important underground pipelines are protected during construction.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

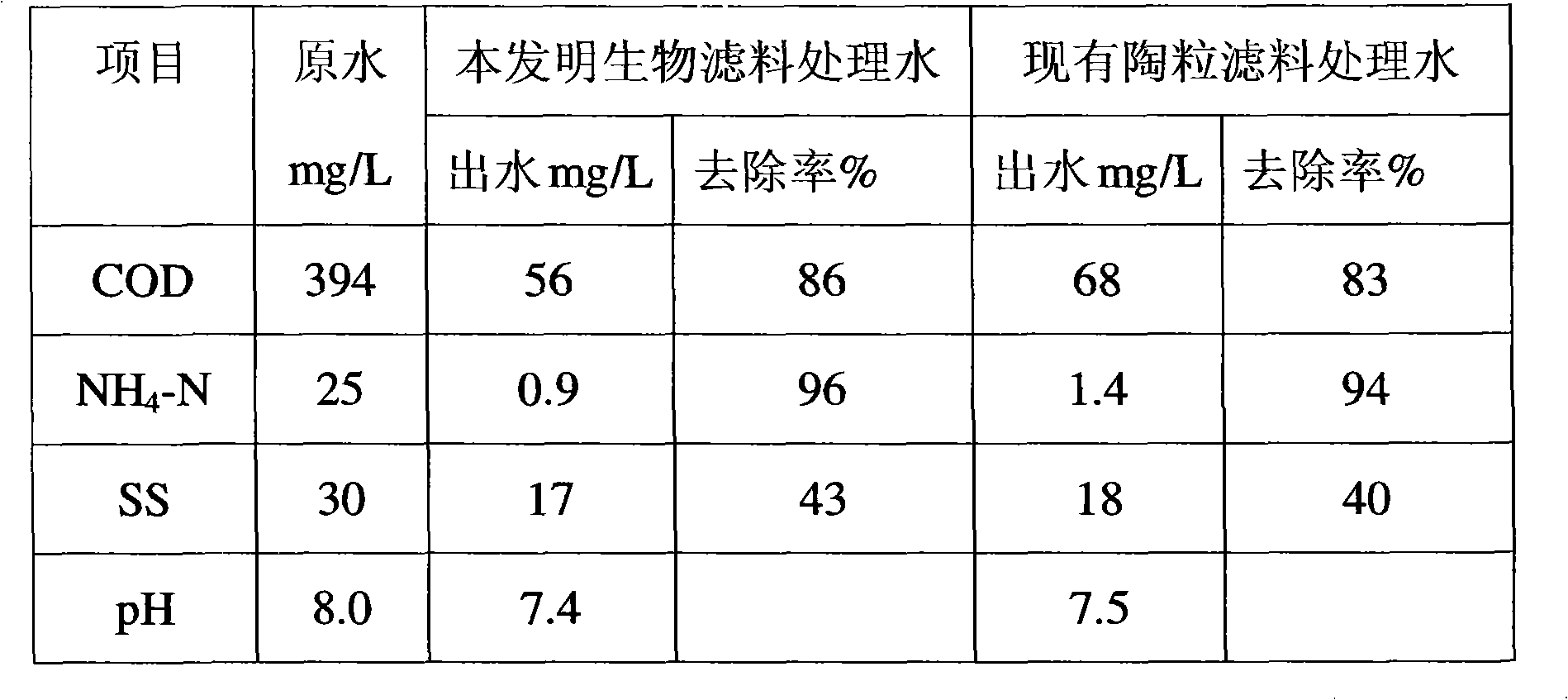

Biological filter material and preparation method

InactiveCN101293768AGood cutting effectLow granulation equipment and costSustainable biological treatmentBiological water/sewage treatmentWater qualityVoid volume

The invention discloses a biological filtering material and a preparation method thereof. The biological filtering material is prepared from clay 70-80 wt%, fly ash 15-25 wt%, raw coal 3-5 wt% and pore forming agent 0.2-3 wt% by pulverizing clay into 100 mesh; mixing dry powders of clay, fly ash, raw coal and pore forming agent; mixing with water 18 wt% and pelletizing; drying; calcining at 1,050-1,200 DEG C in a kiln; taking out; cooling; sieving; and selecting particles with the diameter of 4-10mm. The biological filtering material has good shearing effect to gas and water, and can prevent bubble aggregation; and compared with ceramsite filtering material, its oxygen utilization is improved by 20-30%. Biomembrane grows the surface of the filtering material and the internal surfaces of pores in a great amount, so influence of backwashing on the internal surfaces of the pores is not great and the quality fluctuation of the discharged water after backwashing is also small. The filtering material is almost spherical and has low pelletizing requirement, and the cost of a pelletizing device and a pelletizing process is relatively low. The prepared filtering material has high strength and void volume.

Owner:广州市金龙峰环保设备工程股份有限公司

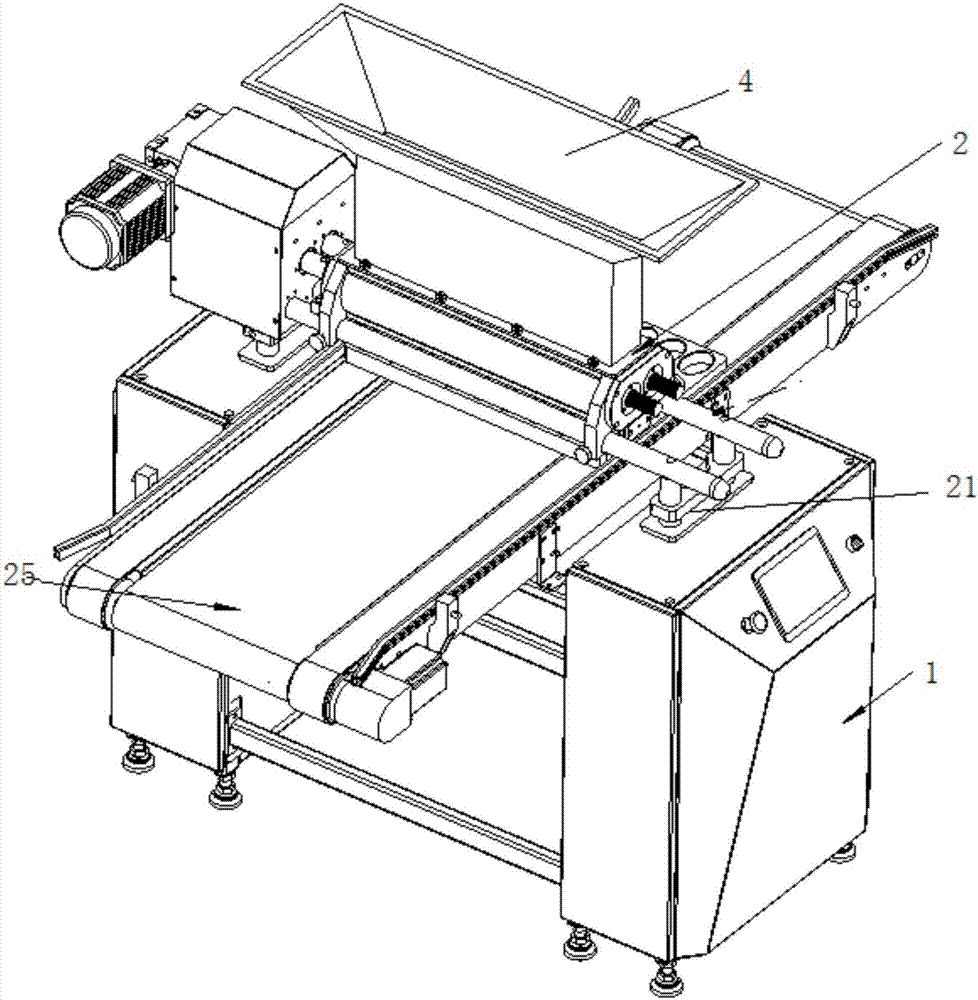

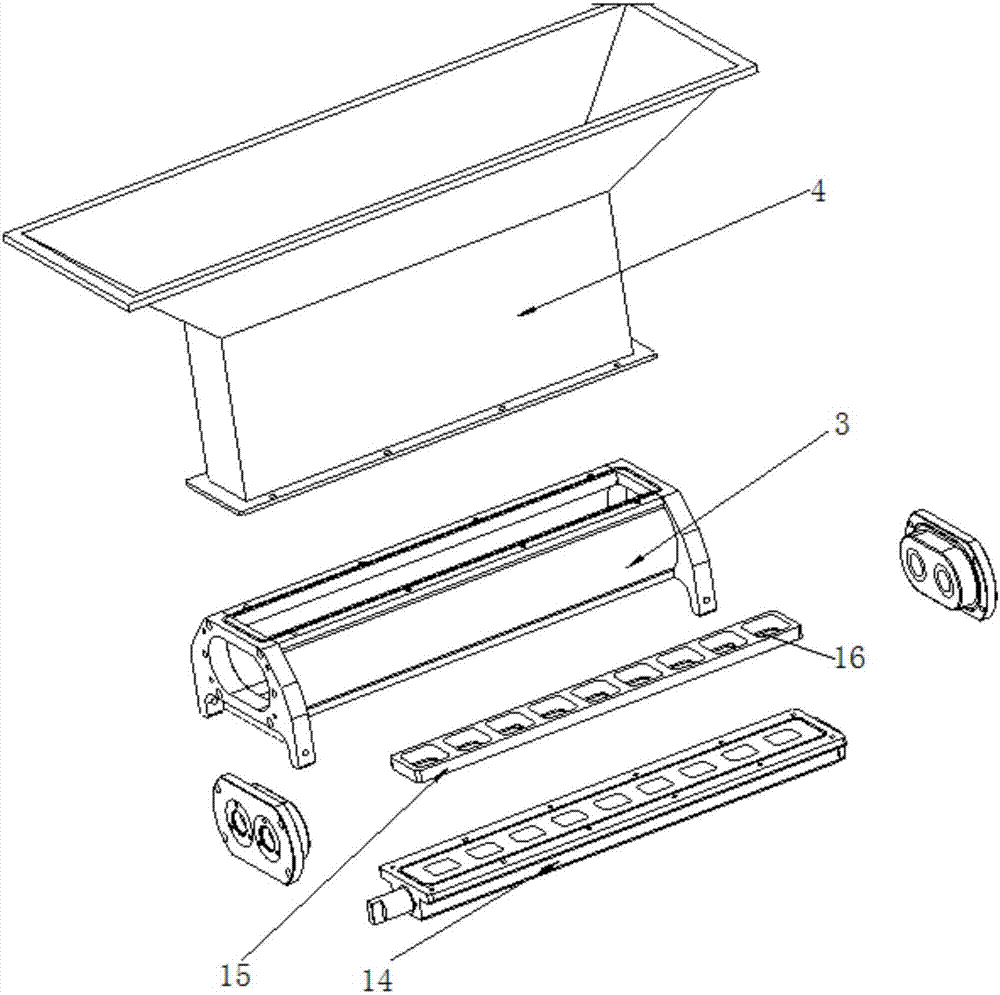

Grouting machine

ActiveCN106879659AUniform discharge scaleGood cutting effectDough dividingBaking plantsEngineeringManufacturing line

The invention discloses a grouting machine, which comprises a rack, wherein the rack is provided with a liftable pump body mechanism; the pump body mechanism comprises a pump body; the top of the pump body is provided with a hopper communicating with a feeding inlet in the pump body; a feed roller mechanism for conveying slurry is rotationally arranged in the pump body; a material closing base is arranged at the bottom of the pump body; a material cavity is arranged in the material closing base; a feeding hole and a discharge hole are formed in the top and the bottom of the material closing base separately; a material closing shaft is rotationally arranged in the material cavity; and material guide openings corresponding to the feeding hole and the discharge hole are formed in the material closing shaft. The grouting machine can be connected with a cake production line for use, can be used as a single machine, and is high in production efficiency and high in yield. Two structures are adopted by the material closing base and can be exchanged to meet different product requirements. Slurry dripping or trailing is avoided. A cake material is completely separated from a feed gate through material returning, material cutting and fast raising during material extrusion, no residue is formed and the slurry dripping or trailing can be avoided.

Owner:ANHUI ZHONGLE FOOD MACHINERY

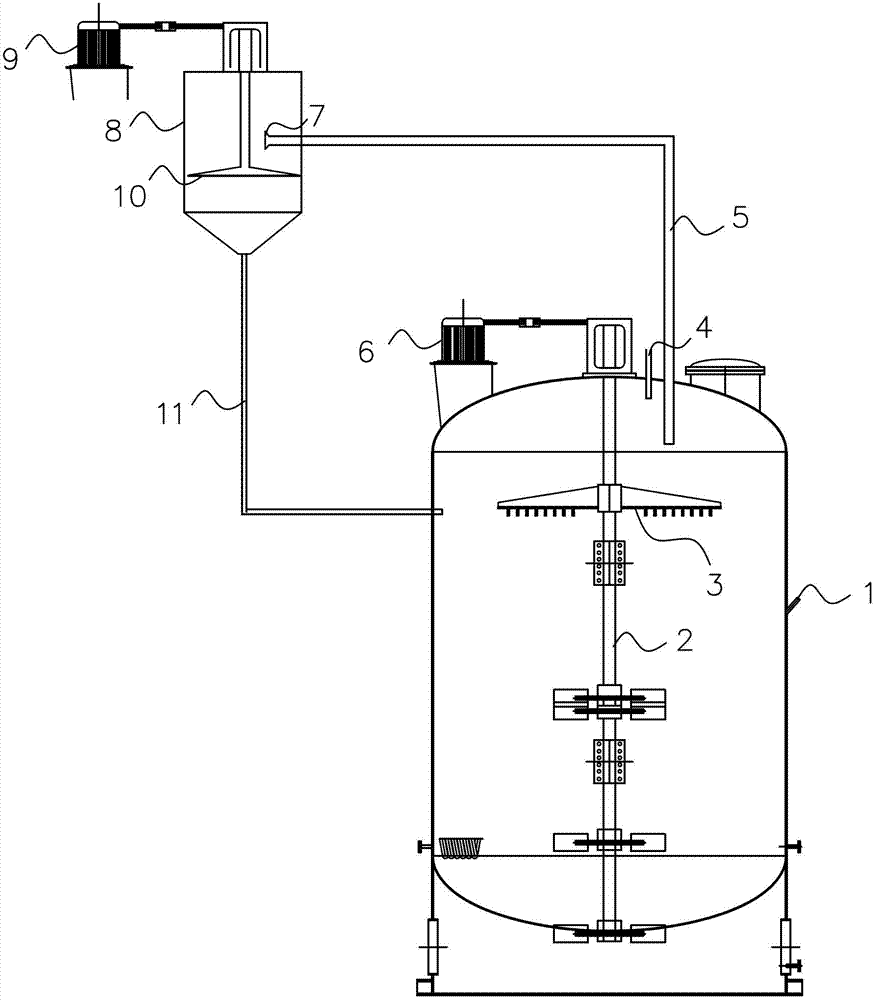

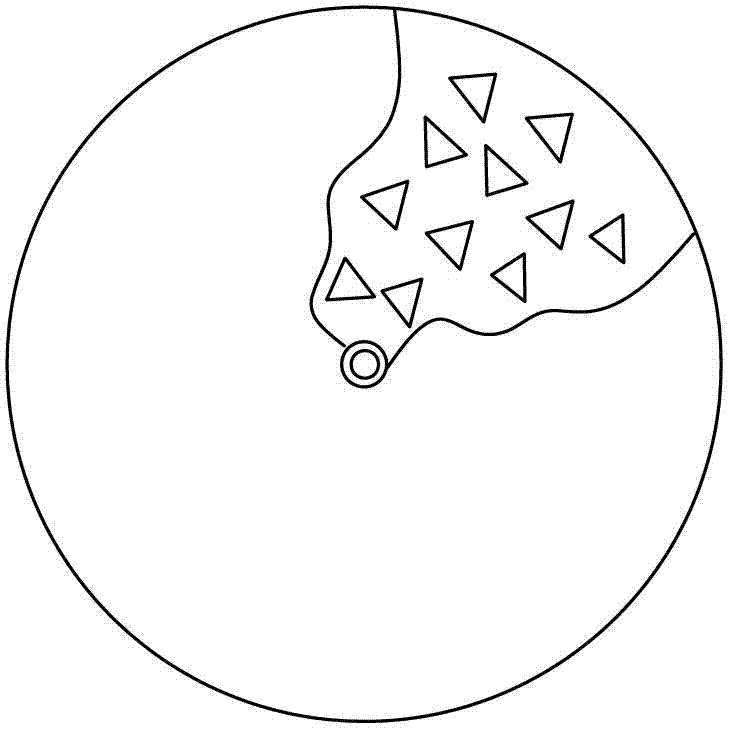

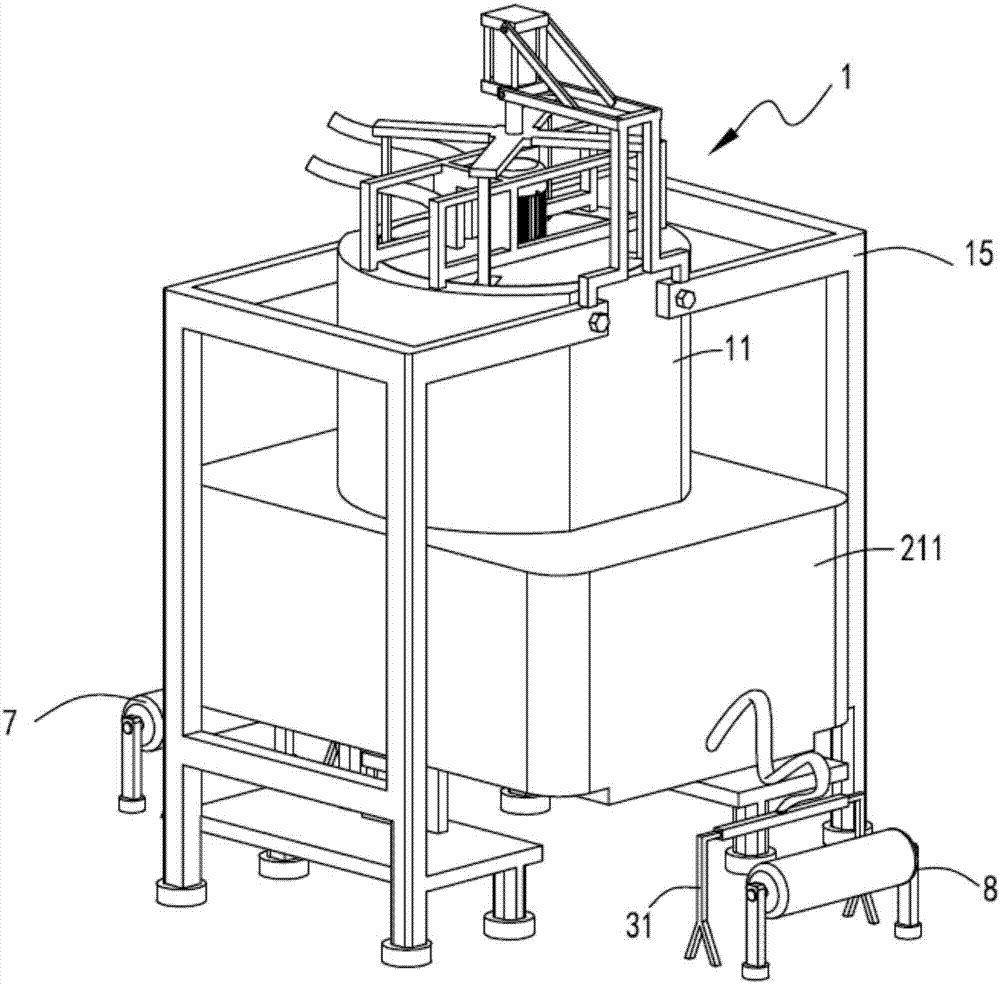

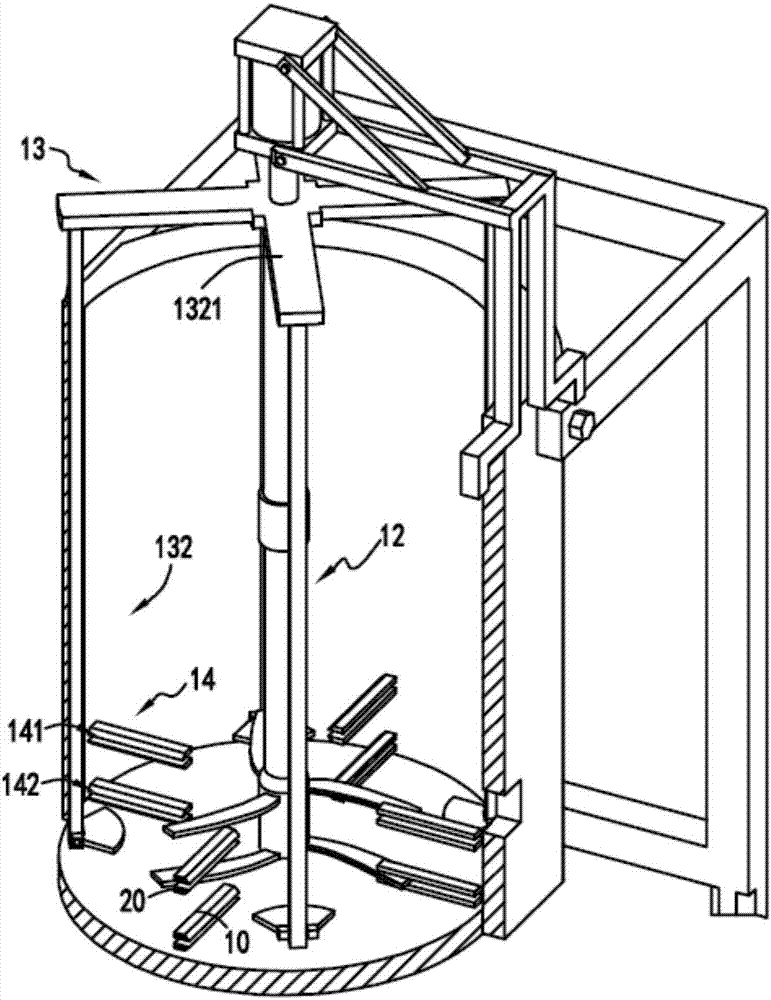

Fermentation liquid compound defoaming device

InactiveCN102925340AGood cutting effectImprove foam breakageBioreactor/fermenter combinationsBiological substance pretreatmentsItaconic acidAgricultural engineering

The invention discloses a fermentation liquid compound defoaming device, relates to the field of itaconic acid fermentation tanks and is used for solving the defoaming problem during the fermentation process of itaconic acid. The fermentation liquid compound defoaming device comprises a fermentation tank body, wherein a stirring shaft is arranged in the fermentation tank body, a rake type defoaming paddle is mounted on the stirring shaft, the stirring shaft is driven by a first motor, an exhaust pipeline is arranged at the upper part of the fermentation tank body, and the fermentation liquid compound defoaming device is characterized in that rake teeth at the bottom of the rake type defoaming paddle are irregularly arranged like a triangle, and one angle of the rake teeth is consistent with the rotation direction of the stirring shaft; and a foam collecting pipeline which leading foam to outside is arranged above the rake type defoaming paddle in the fermentation tank body, the foam collecting pipeline is connected with a defoaming device outside a tank, and the defoaming device outside the tank is connected with the fermentation tank body via a material liquid return pipe. Due to the adoption of a compound defoaming technology which adopts the rake type defoaming paddle and a multi-layer filter screen for defoaming and adopts stirring blades in an outer tank body for defoaming, defoaming can be performed timely, rapidly and thoroughly.

Owner:JINAN HUAMING BIOCHEM

Once grinding technology of steel ball for high-grade car transmission shaft

InactiveCN101514726AReduce surface defectsGood cutting effectOther chemical processesLapping machinesLiquid waterDrive shaft

The invention discloses a once grinding technology of a steel ball for a high-grade car transmission shaft, which includes cold heading process, smooth grinding process, heat treatment process, hard grinding process, reinforcement process, secondary hard grinding process and fine grinding process, and is characterized in that two fine grinding processes after the secondary hard grinding process are combined into one fine grinding process. The fine grinding process includes steps of adjusting the present once grinding technology to standard of G10 grade ball, carrying out circulation liquid water grinding on a grinder, and increasing grinding amount to the steel ball to 30MM-35MM. Stage of steel ball produced by employing the technology reach to G28, so that the steel ball is suitable for high-grade car transmission shaft, and the two processes are modified to one process by the processing technology, thereby increasing production efficiency.

Owner:JIANGSU LIXING GENERAL STEEL BALL

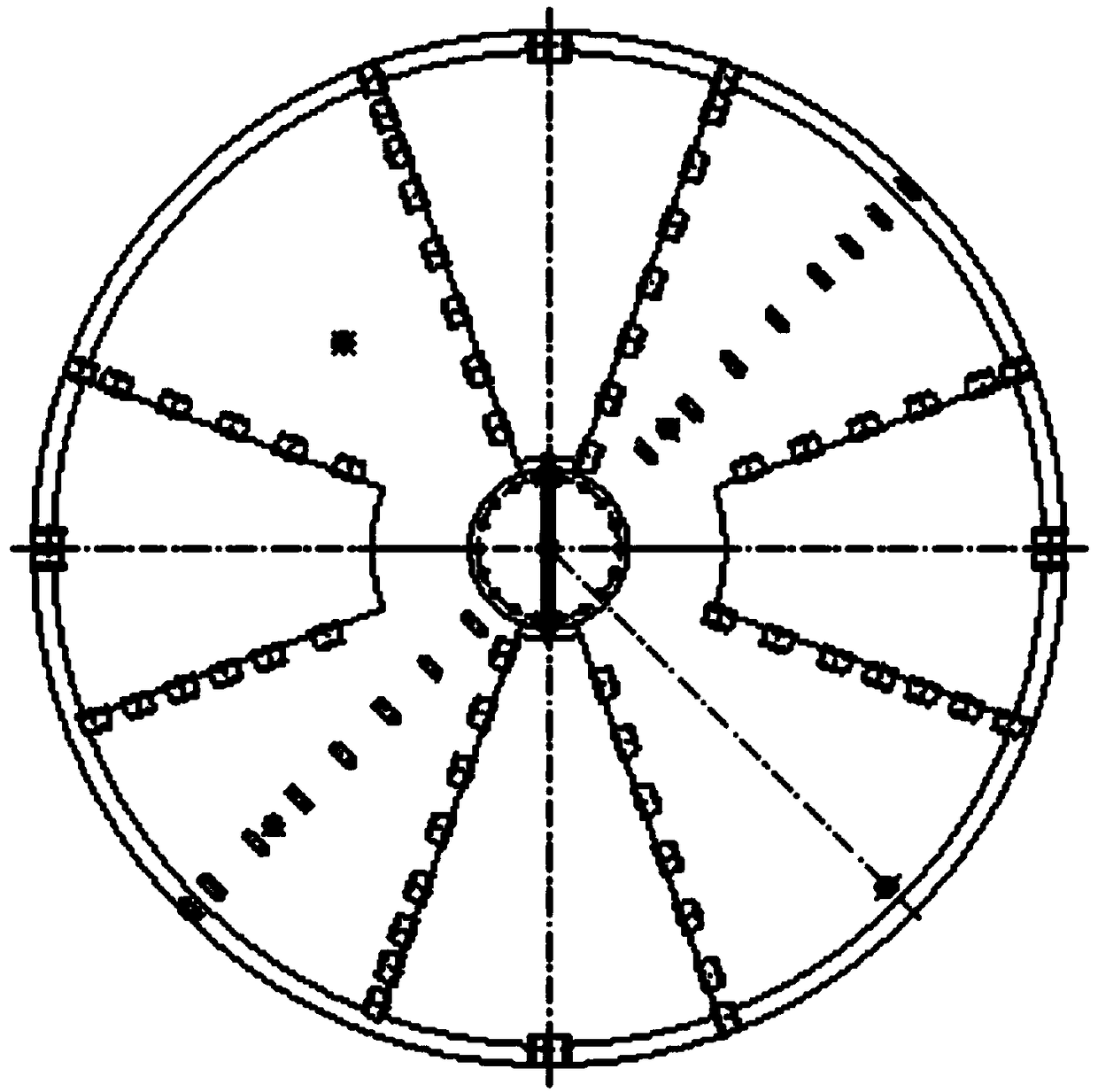

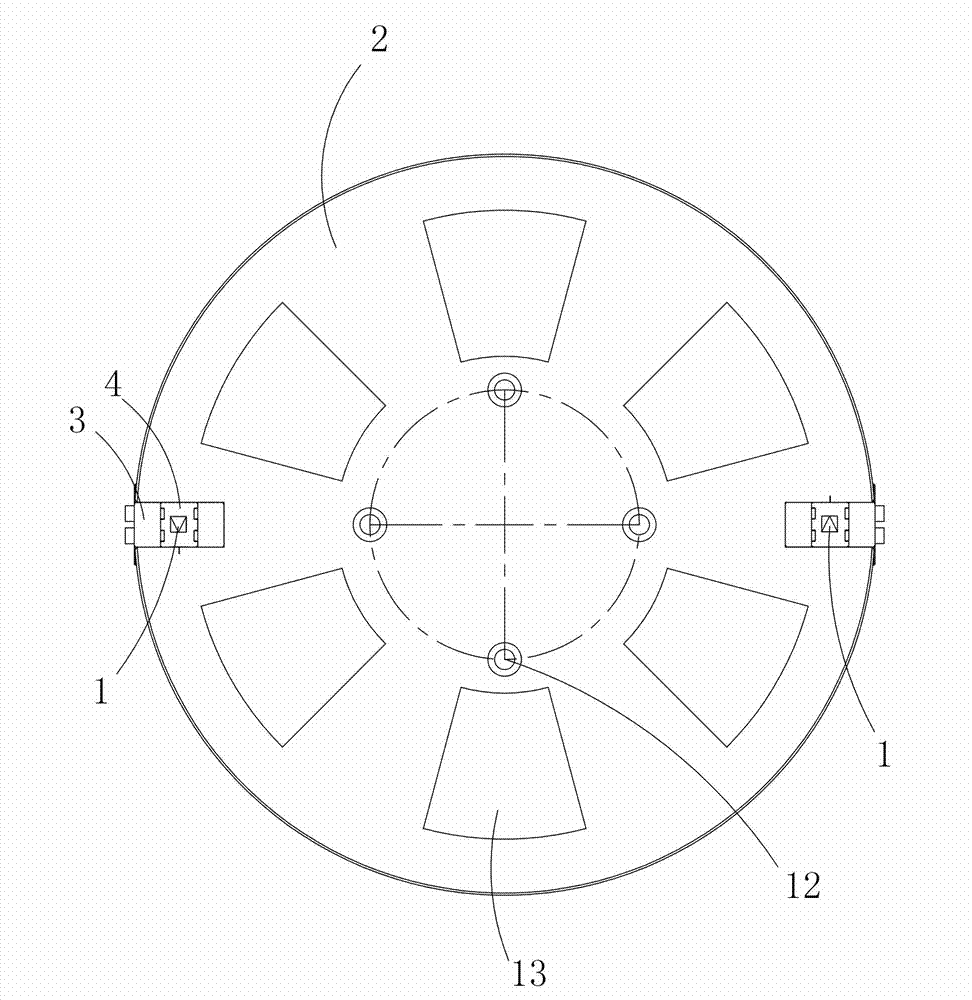

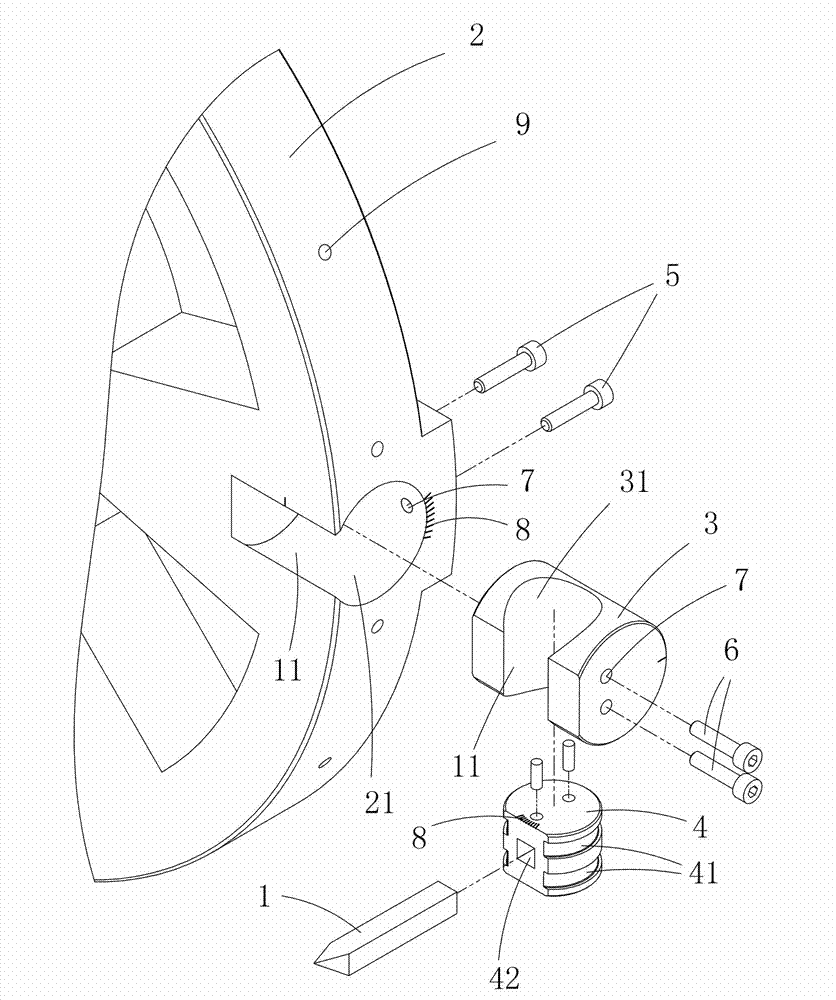

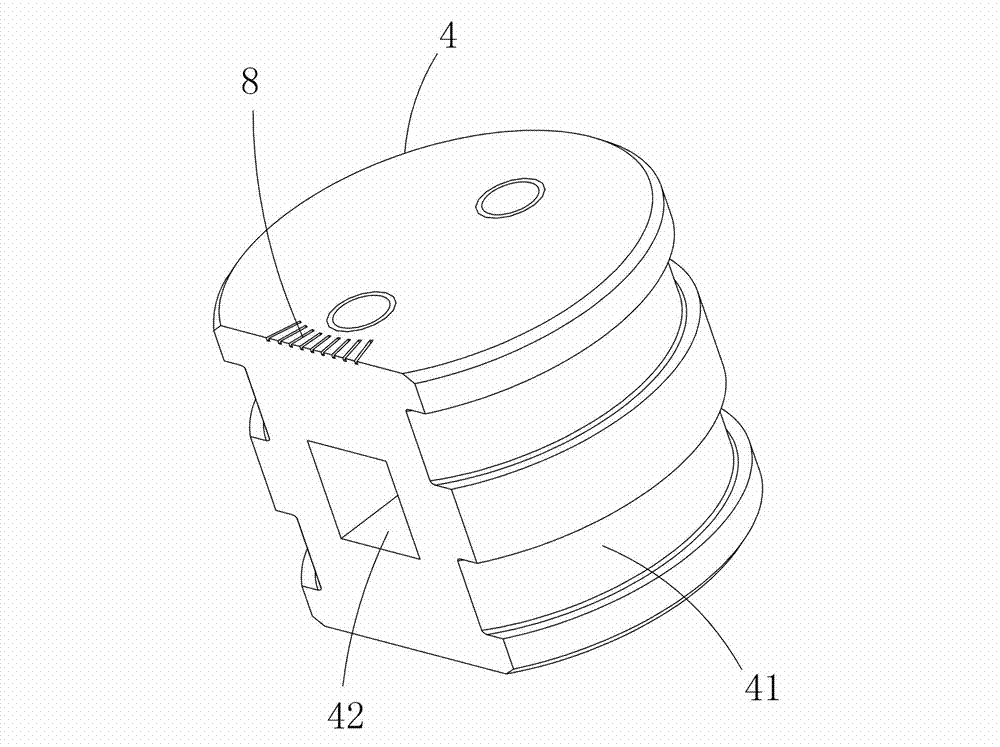

Fly cutter plate for processing large-size optical elements by single-point diamond milling method

ActiveCN102765139AGood cutting effectAvoid damageFine working devicesGlass severing apparatusEngineeringLarge size

The invention discloses a fly cutter plate for processing large-size optical elements by a single-point diamond milling method. The fly cutter plate comprises a fly cutter plate body, a diamond cutter and a cylindrical front angle adjusting block for mounting the diamond cutter, wherein a cylindrical groove is arranged on the fly cutter plate body and is arranged in the radial direction of the fly cutter plate body; and the front angle adjusting block can be rotationally sleeved in the cylindrical groove and is fastened and located through a first fastening piece. The fly cutter plate is simple in structure and convenient to adjust, can flexibly adjust the front cutting angle of the diamond cutter and improves the cutting effect.

Owner:NAT UNIV OF DEFENSE TECH

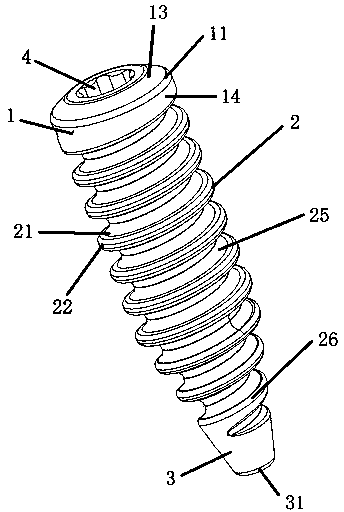

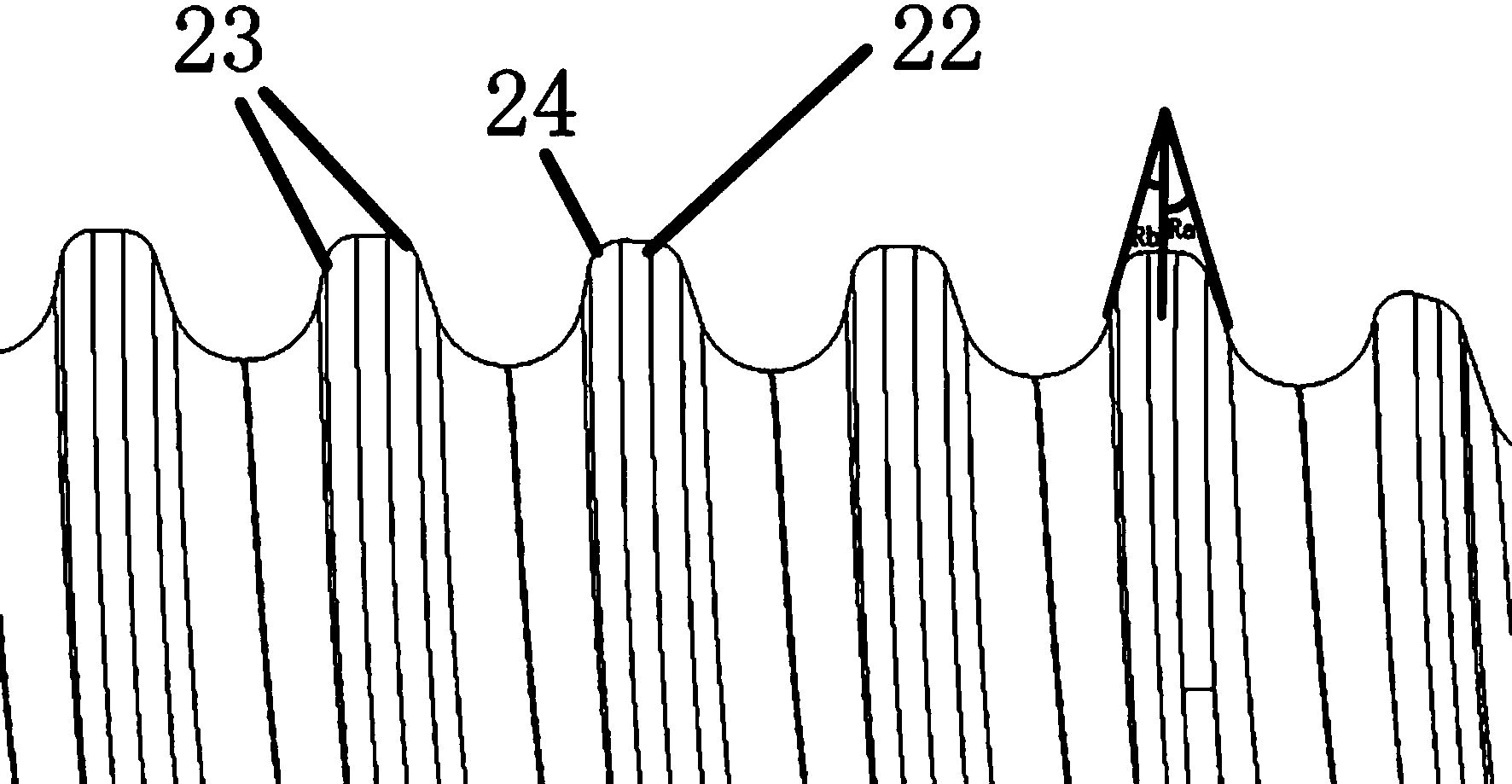

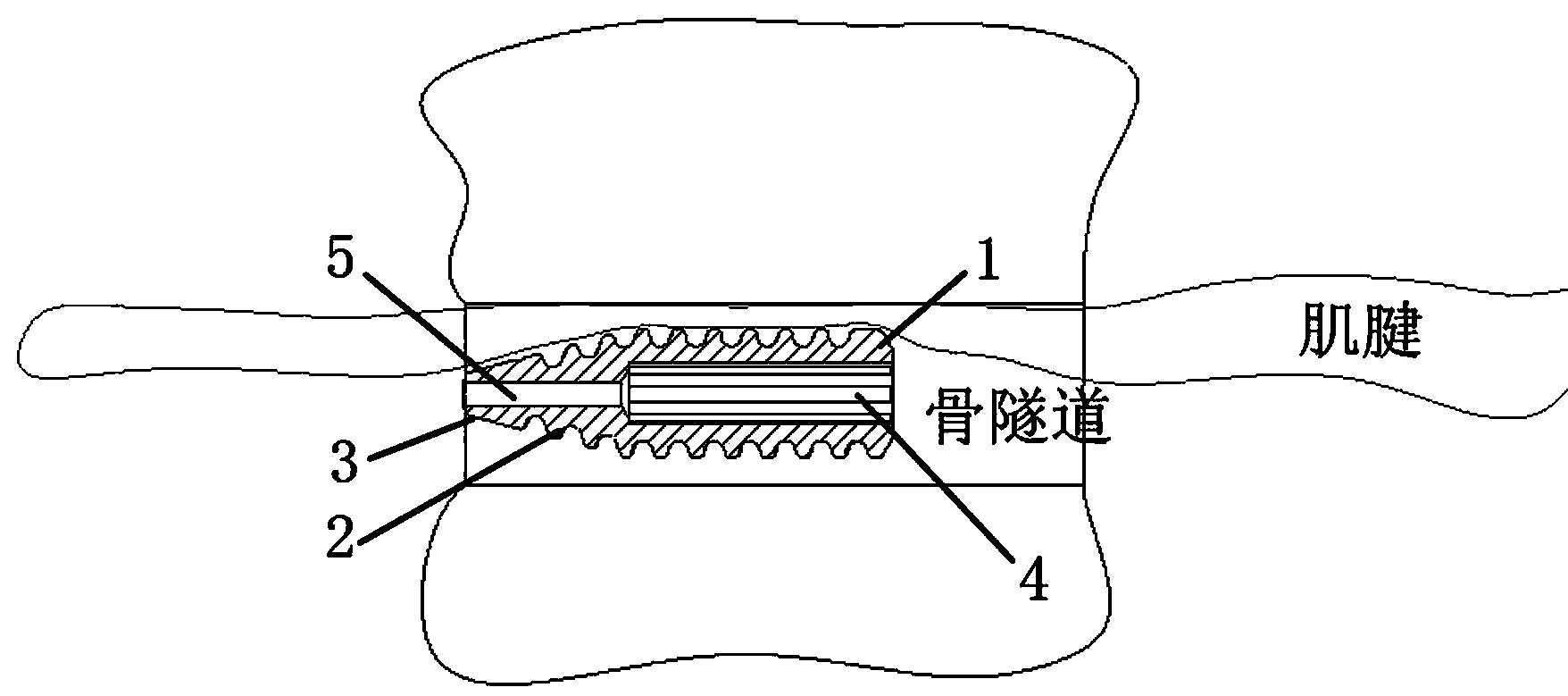

Interference screw for department of orthopaedics

The invention provides an interference screw for the department of orthopaedics. The interference screw for the department of orthopaedics comprises a head end, a threaded section and a tail end, wherein the head end, the threaded section and the tail end are fixedly connected in sequence; the outer surface of the head end and the outer surface of the tail end are smooth. The interference screw for the department of orthopaedics aims to overcome the defects in the prior art, is used for rebuilding and restoring an articular ligament, enhances connection firmness, reduces the cutting effect on muscle tendons and improves the treatment effect on the rebuilt ligament.

Owner:GUANGDONG HONGZHI BIOTECHNOLOGY CO LTD

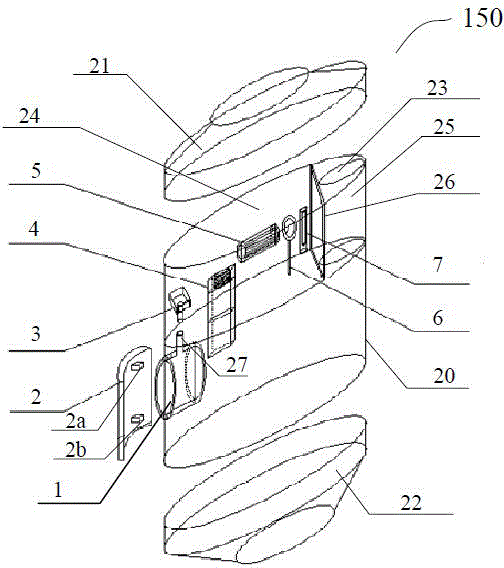

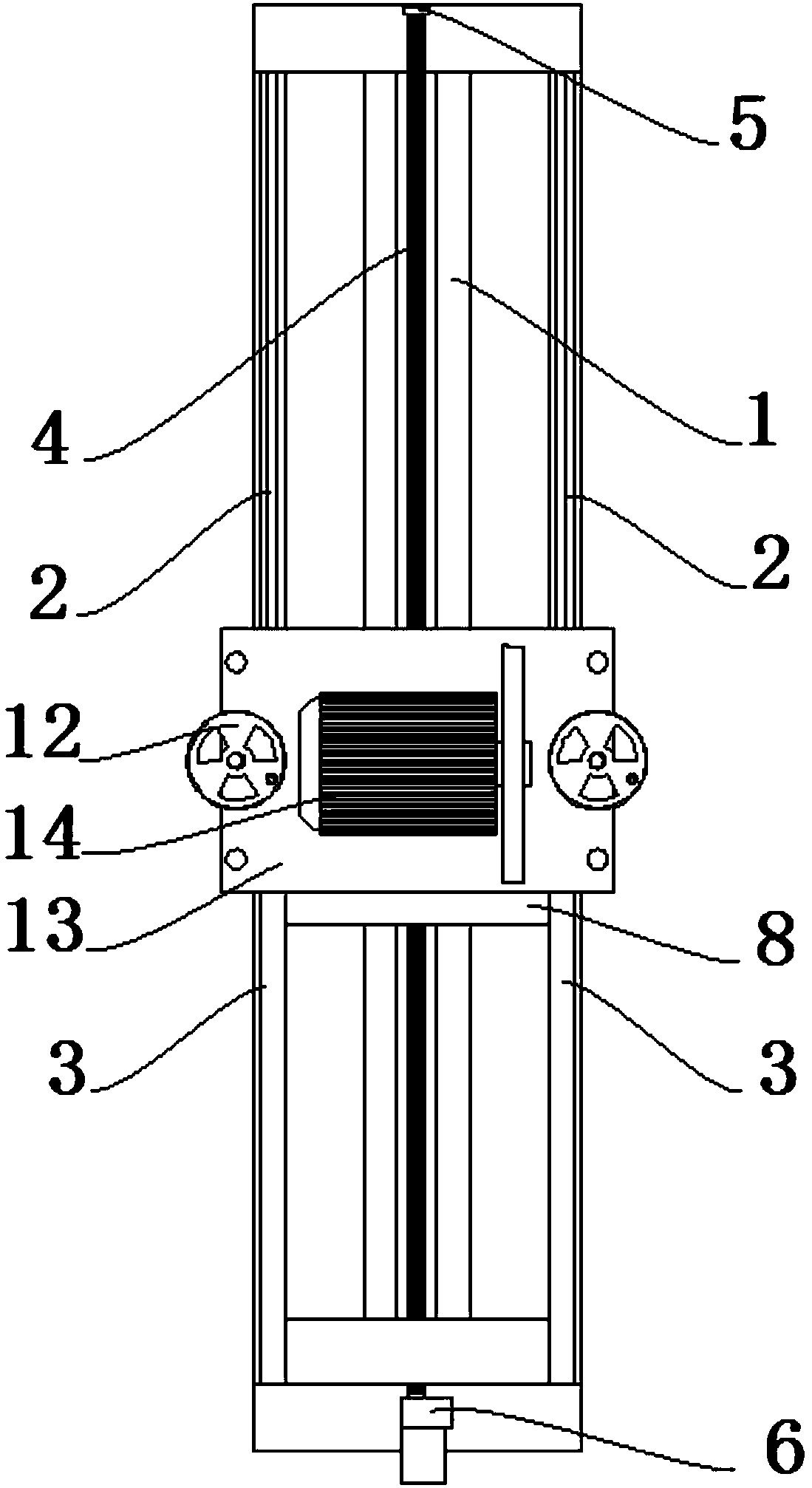

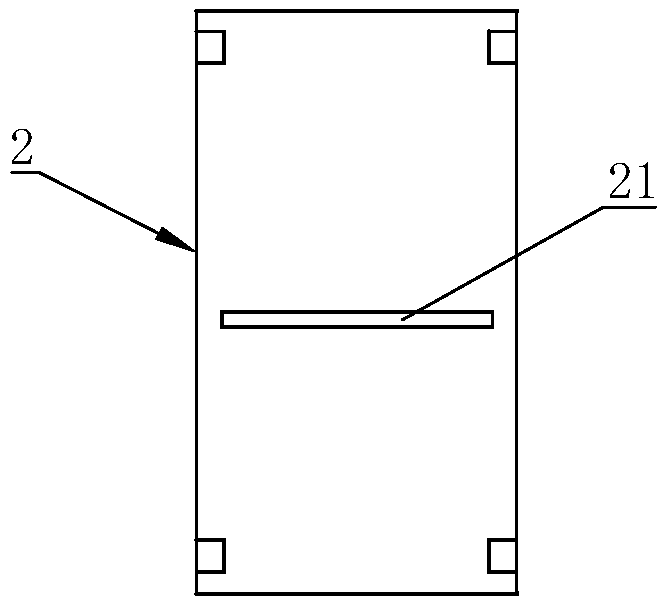

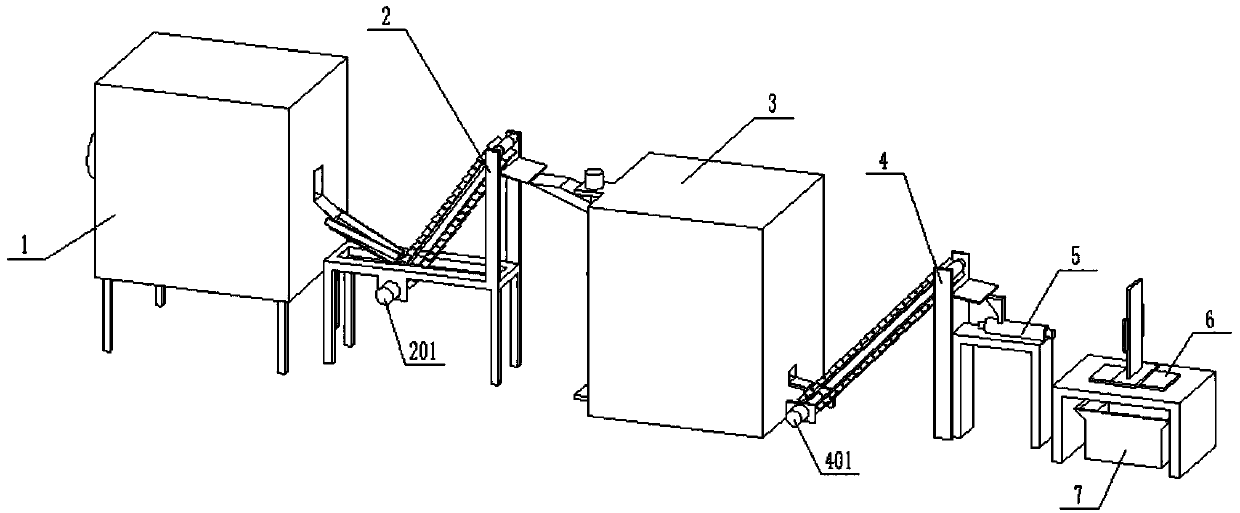

Production device of flame-retardant power line

InactiveCN108597678AGood cutting effectGood flexibilityReduction of cables/conductors sizeScrapElectricity

The invention discloses a production device of a flame-retardant power line. The production device comprises a base and a cutting knife, wherein a slide chute is embedded into one side of the upper surface of the base; an upright post is arranged in the slide chute; the upright post is connected with the slide chute in a sliding manner; an upper mold base is connected with the upper end of the upright post in a welding manner; an electric push rod is arranged on the lower surface of the upper mold base and is fixedly connected with the upper mold base; and a motor is arranged at one end of theelectric push rod. According to the production device, the cutting knife can be timely cooled by using cooling fans through arranging the cooling fans at two sides of the cutting knife, so that the phenomenon that a knife body is adhered to a plastic protective cover on the power line to affect the cutting effect due to overheating of the knife body is prevented and a good cutting effect is ensured; and through embedding a dust collecting groove into the base, dust and scraps generated when the surface of the base is cut can fall into the dust collecting groove to be collected through a cutting groove and can fall into a dust collecting box through cooperation of a dust guide plate in the dust collecting groove and a vibrating plate, so that the condition that the base is clean and tidy is ensured.

Owner:浙江海宁普赛自动化科技有限公司

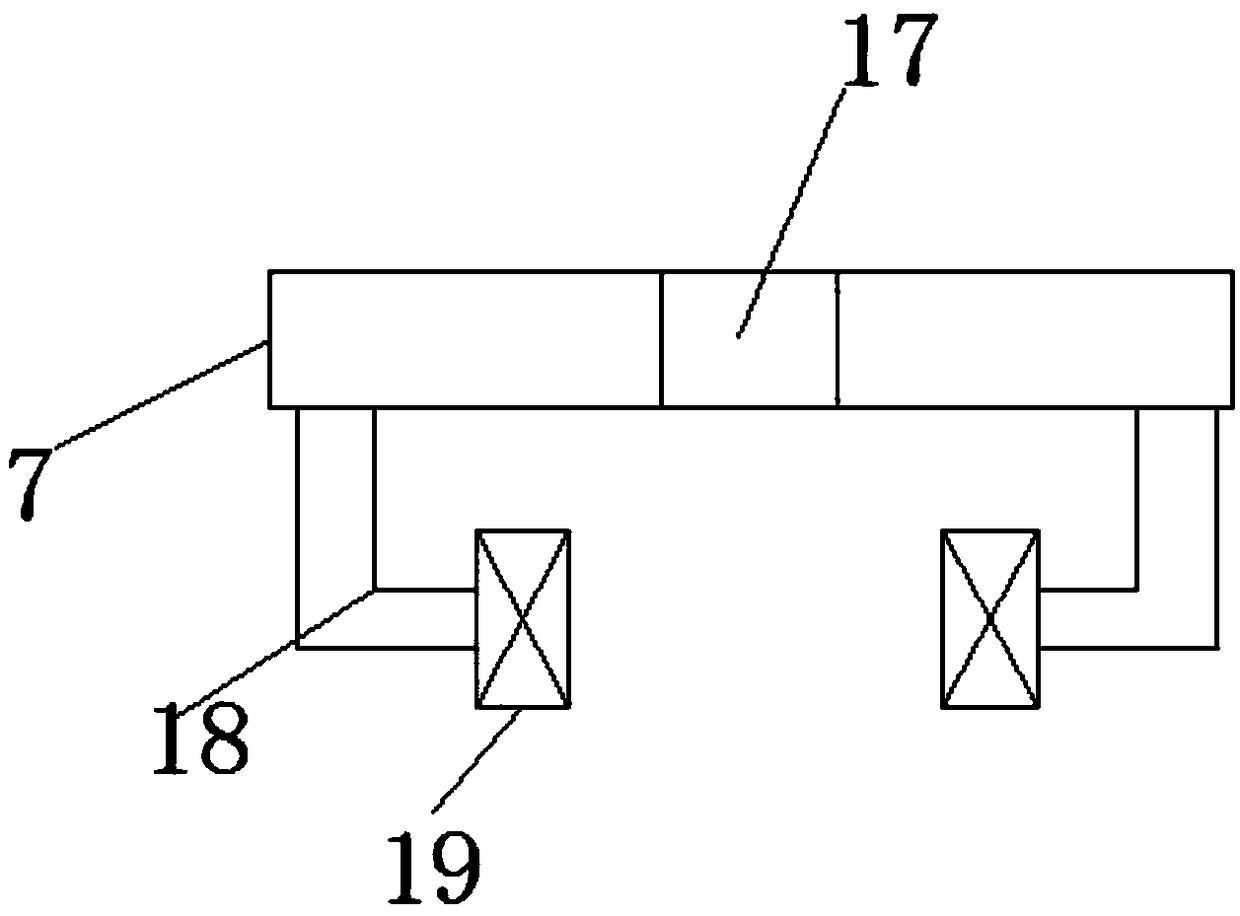

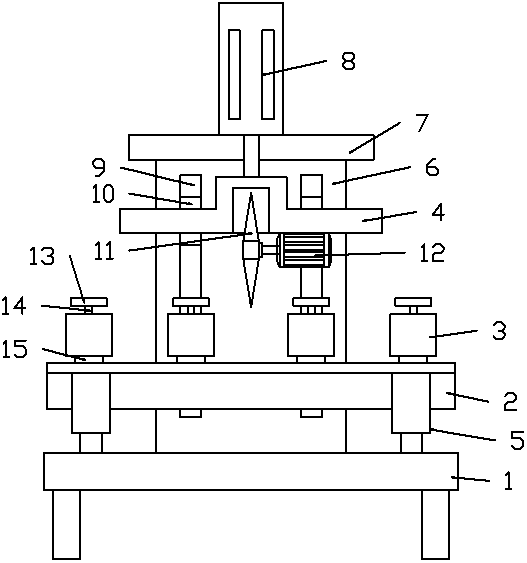

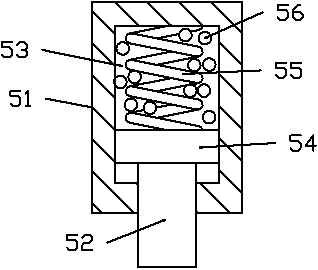

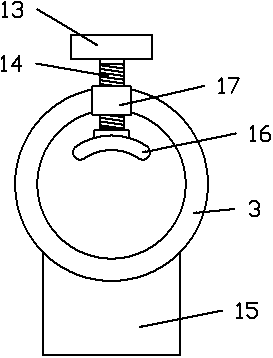

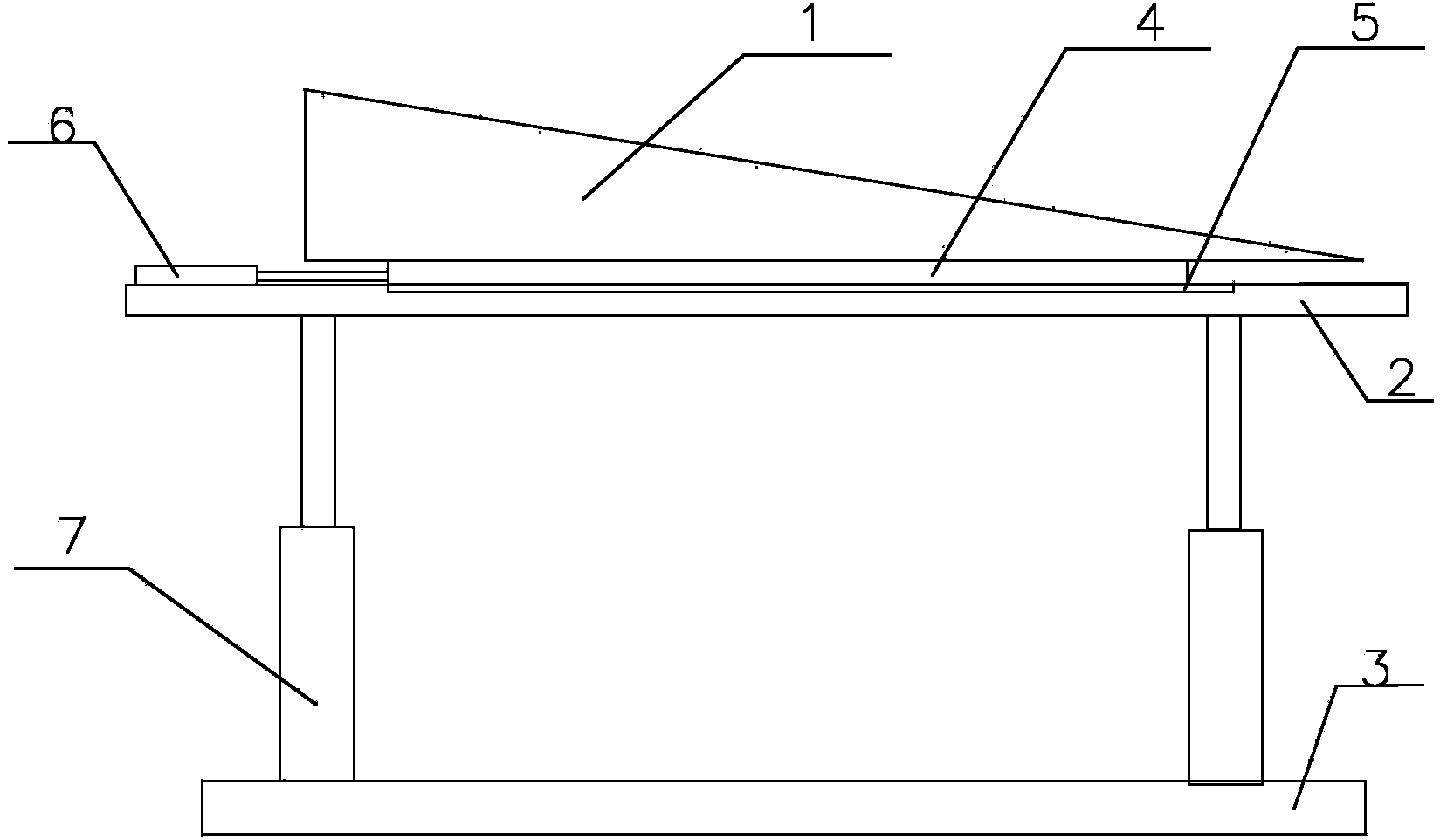

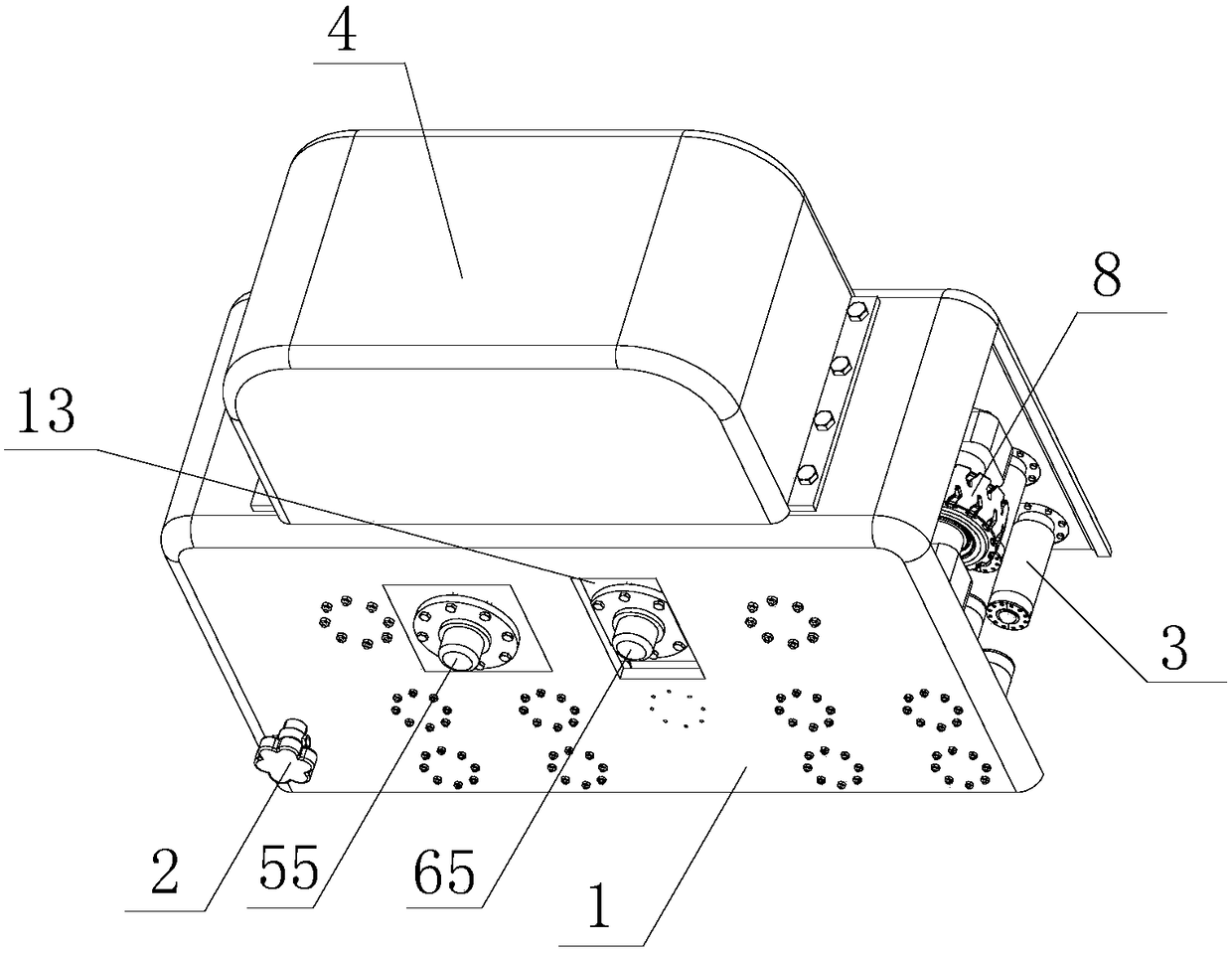

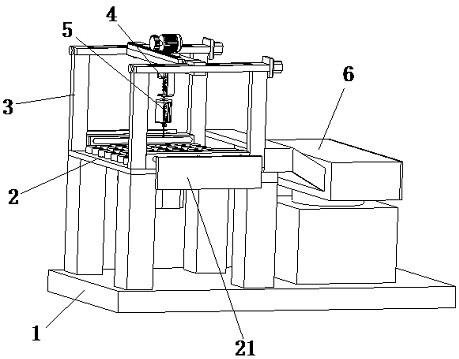

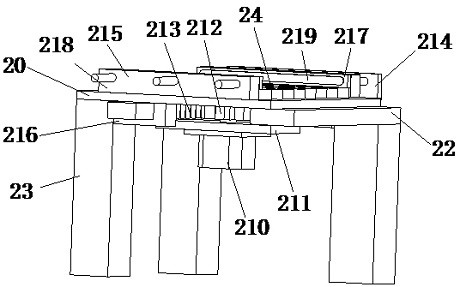

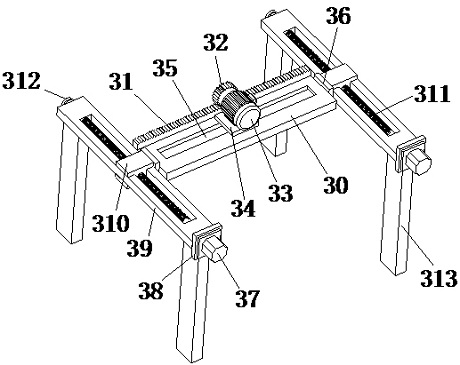

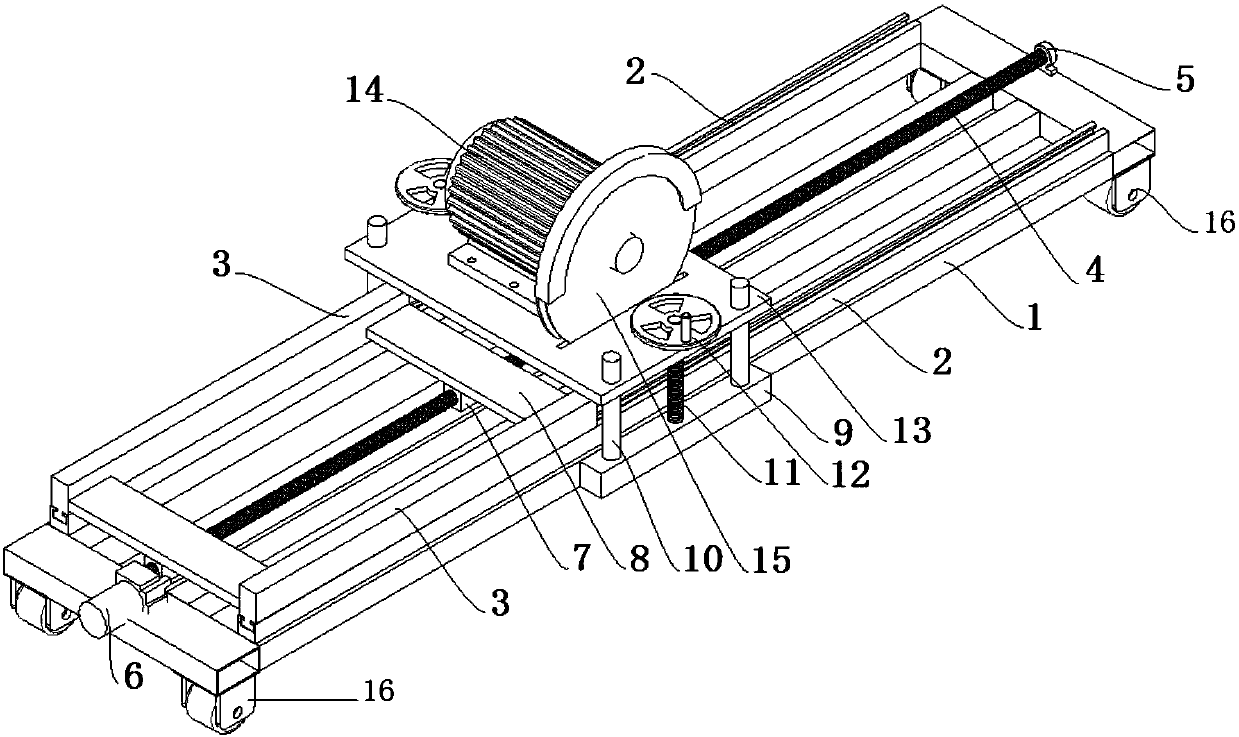

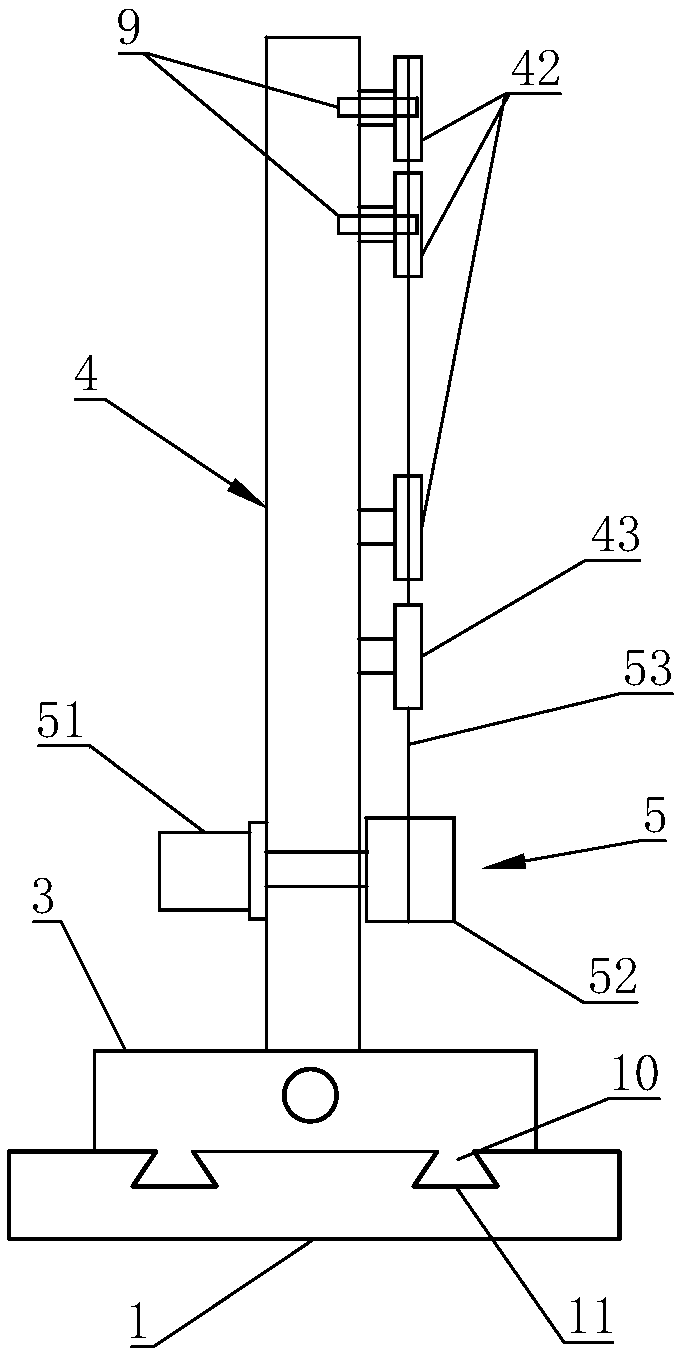

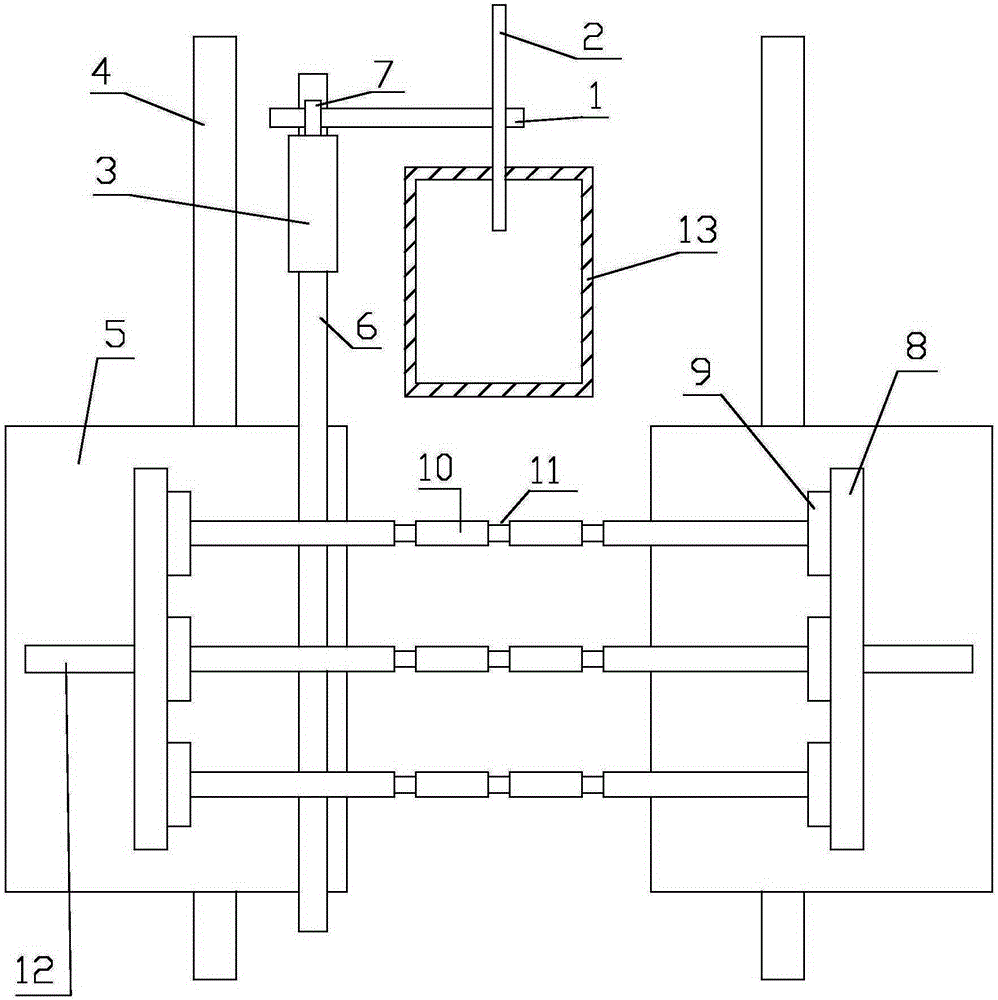

Vibration and noise reduction type cutting device for building construction pipe fitting

InactiveCN108356580AGood cutting effectHigh precisionFeeding apparatusLarge fixed membersNoise reductionArchitectural engineering

The invention discloses a vibration and noise reduction type cutting device for a building construction pipe fitting. The vibration and noise reduction type cutting device for the building construction pipe fitting comprises a machine frame, a working platform, a lifting plate, vibration and noise reduction bases, a fixing vertical plate, hydraulic cylinders, a cutting wheel and clamping mechanisms. The working platform is erected above the machine frame through the vibration and noise reduction bases arranged at the bottom end of the working platform. Four groups of clamping mechanisms are symmetrically and fixedly arranged at the top of the working platform. The fixed vertical plate is fixedly installed at the top of the rear side of the machine frame in a welding mode. A supporting topplate is horizontally and fixedly erected at the top of the fixed vertical plate. The hydraulic cylinders are fixedly installed at the middle of the supporting top plate. The lifting plate is horizontally and fixedly installed at the bottom ends of piston rods on the hydraulic cylinders. A motor is fixedly installed at the bottom of the lifting plate, and the cutting wheel is fixedly installed onan output shaft of the motor. The vibration and noise reduction type cutting device for the building construction pipe fitting has simple structure, convenient use, good cutting effect, high precision, good vibration and noise reduction effect, and high practicability.

Owner:黄健森

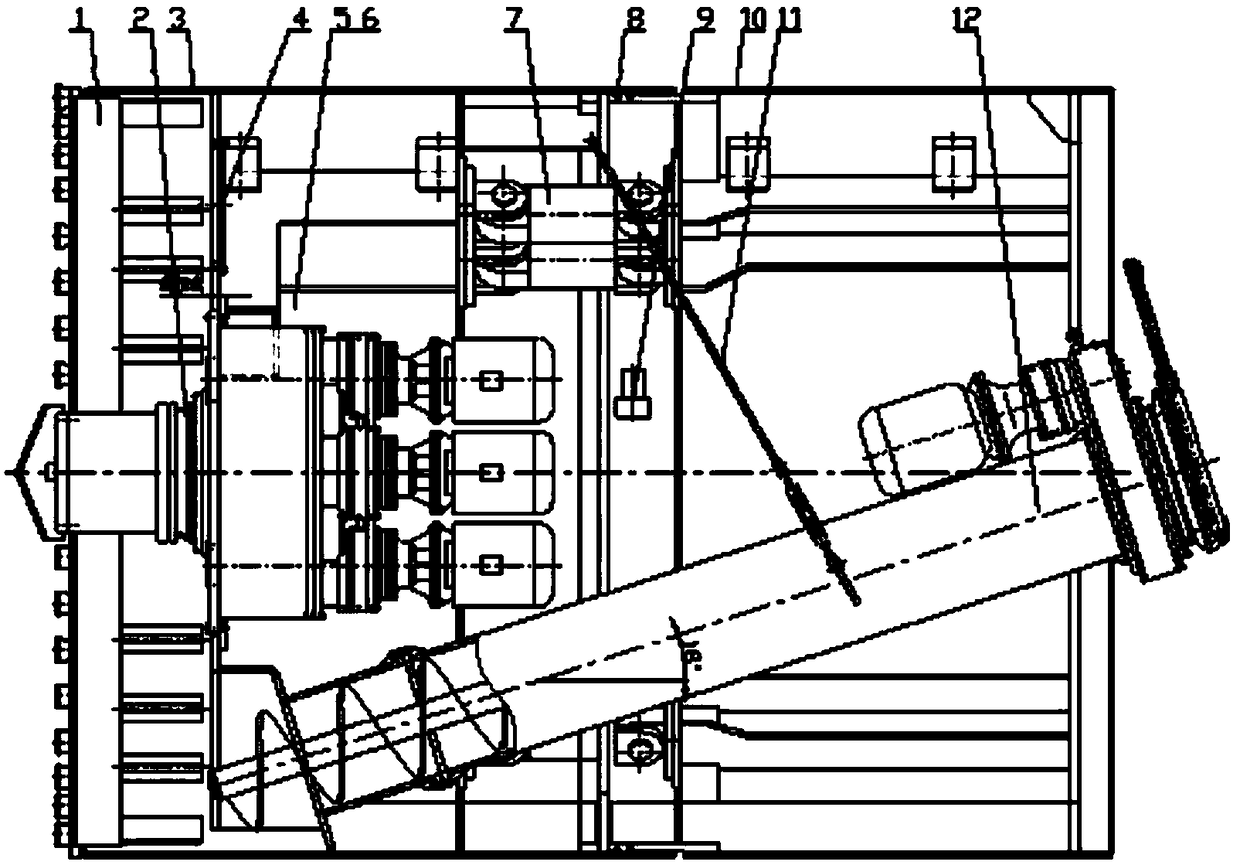

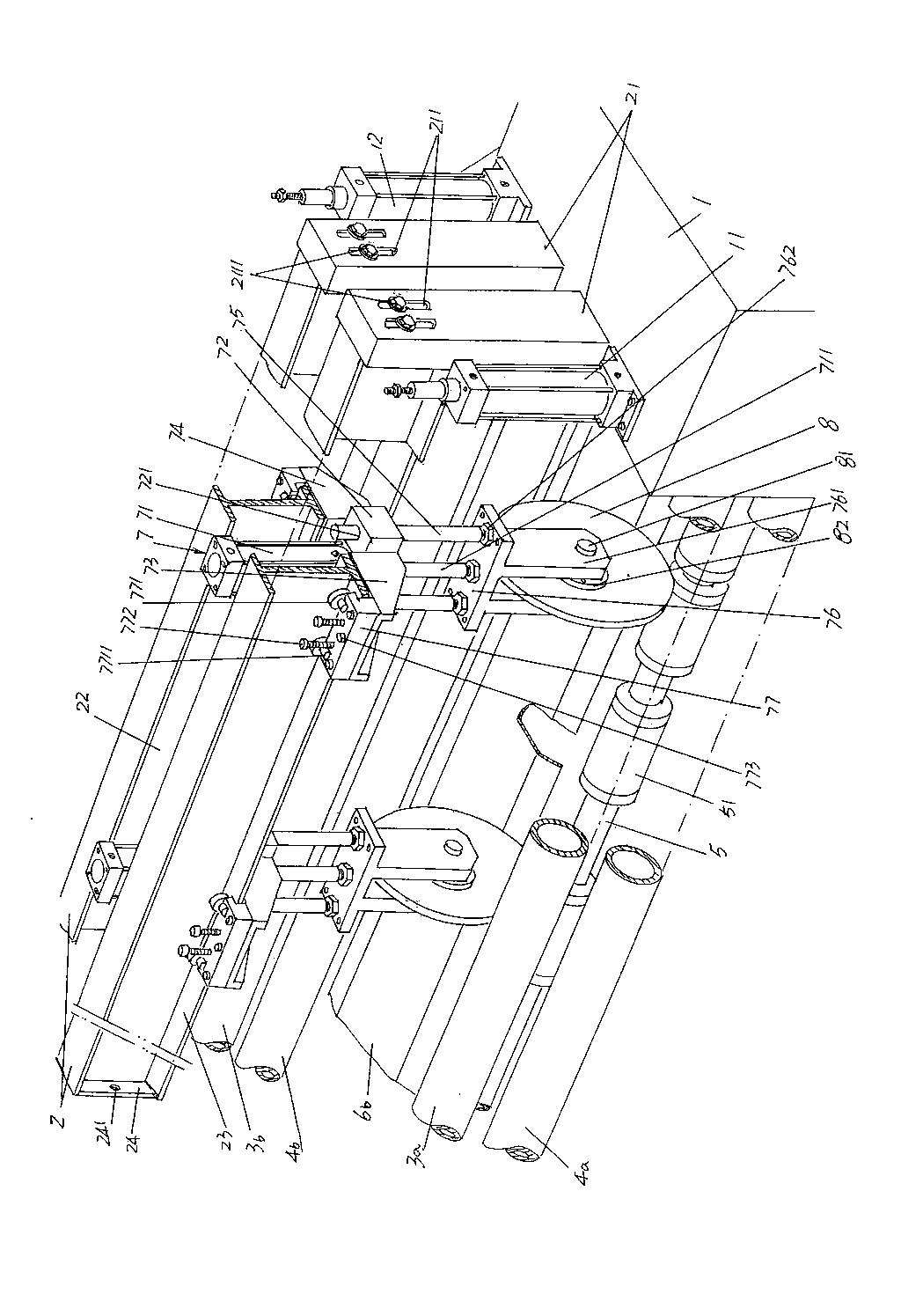

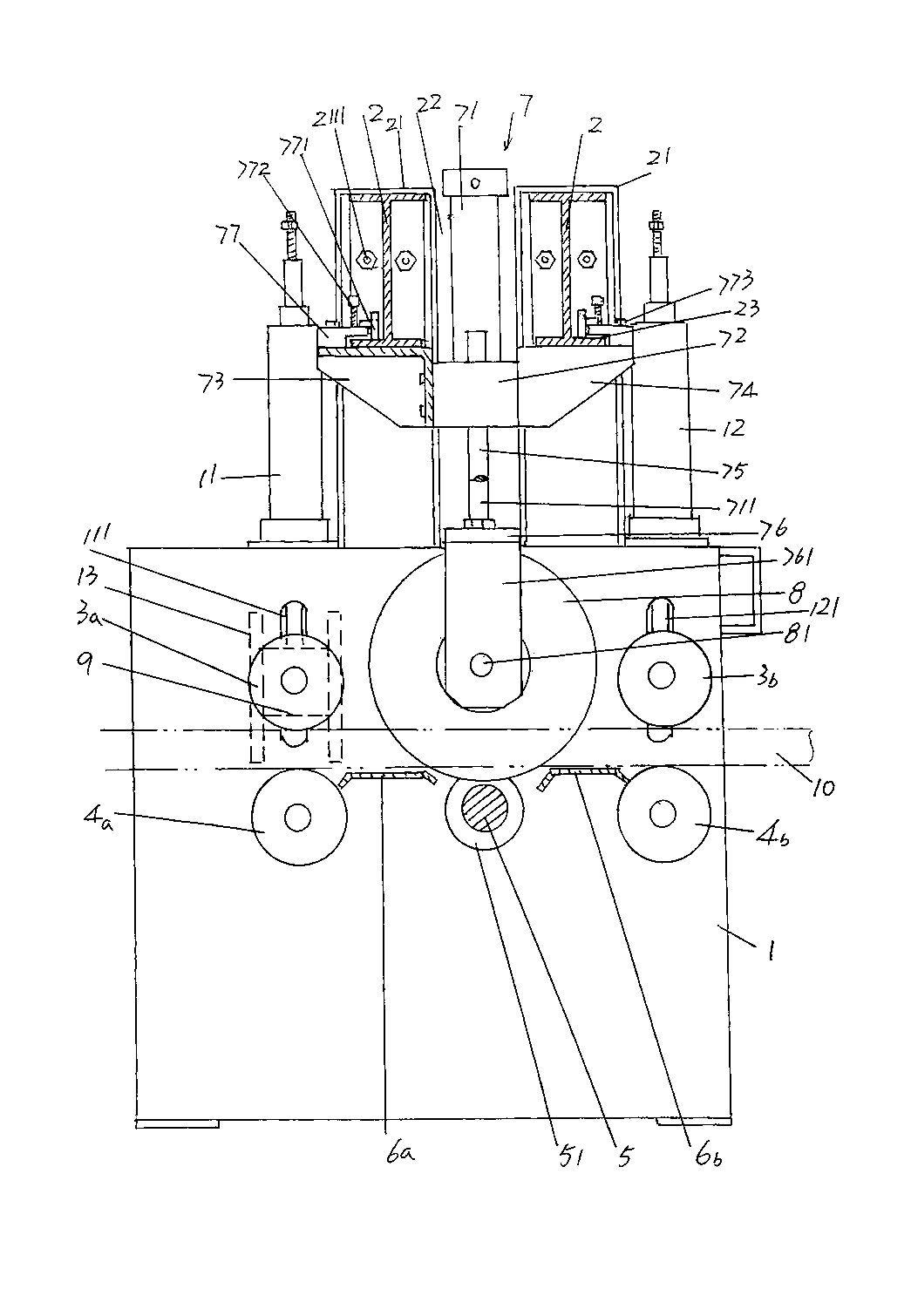

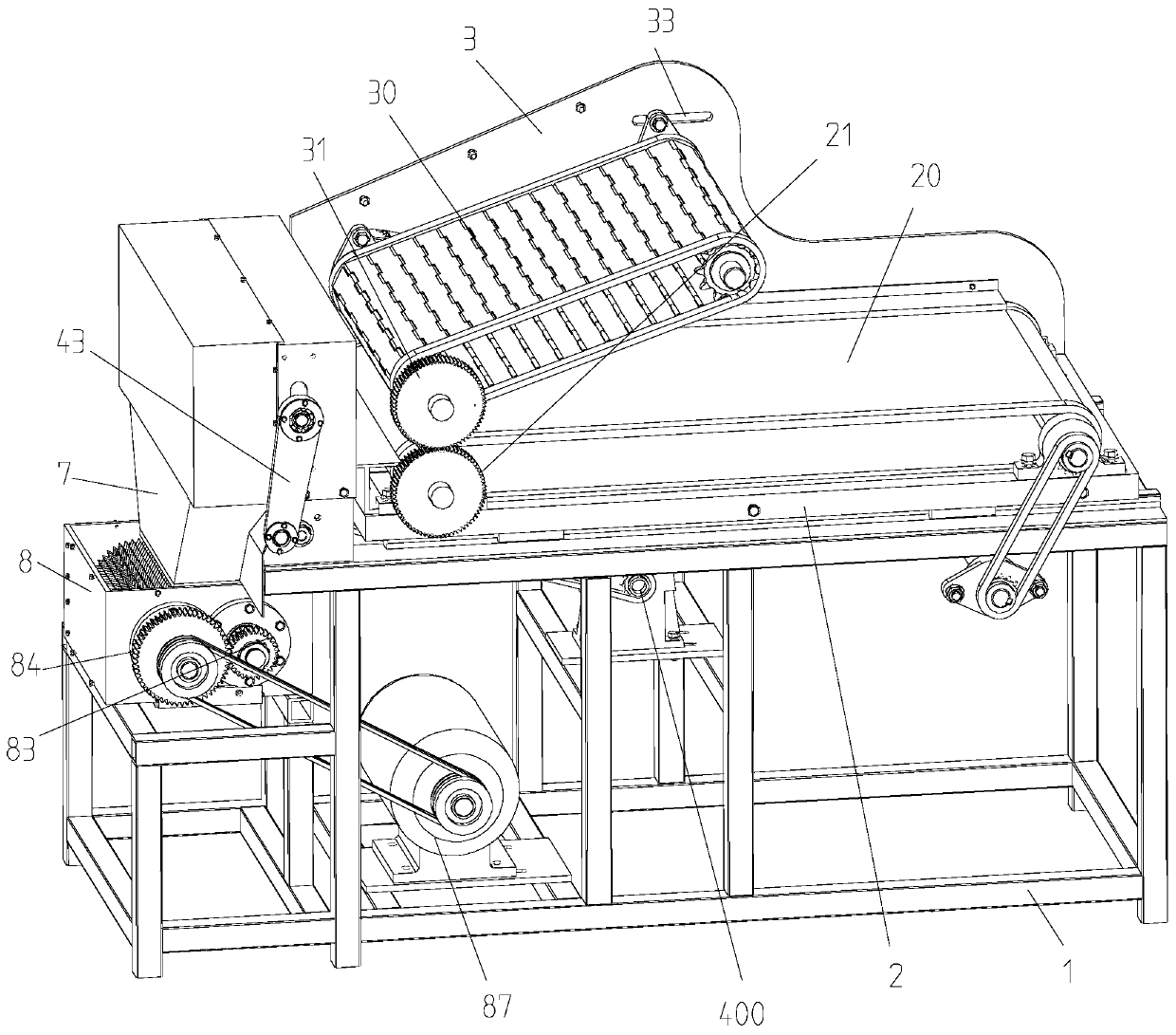

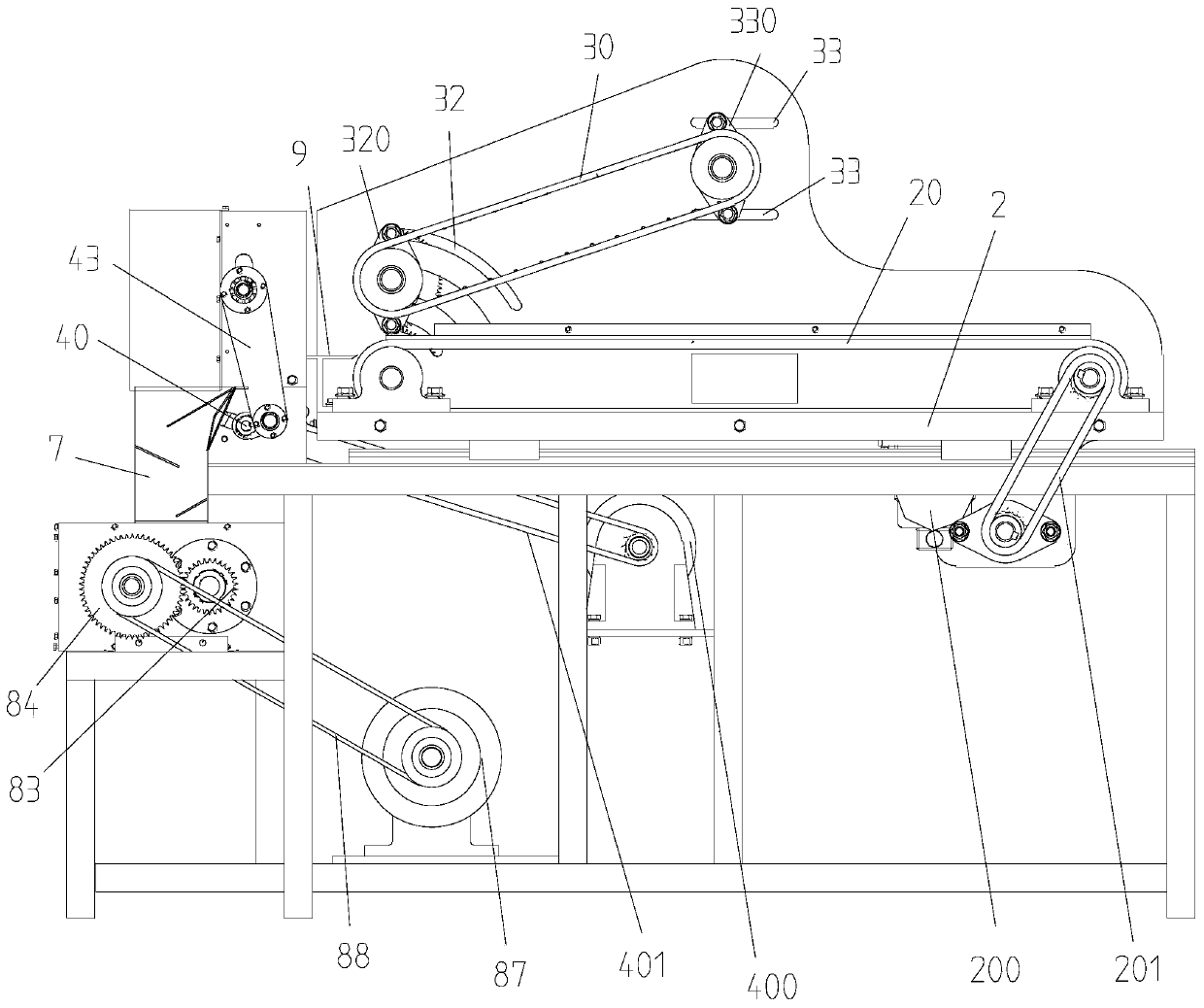

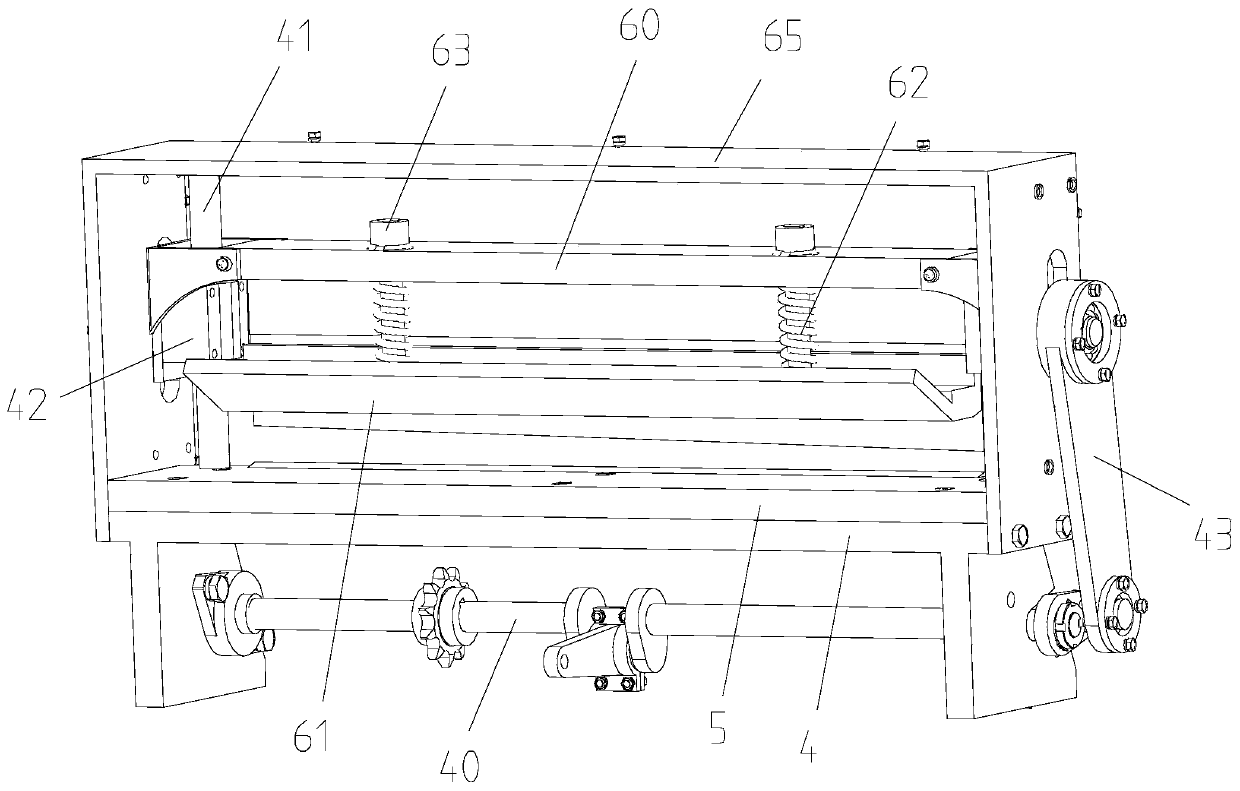

Cutting machine for nonwoven cellucotton screen cloth

The invention discloses a cutting machine for nonwoven cellucotton screen cloth, belonging to the technical field of nonwoven machinery. The cutting machine comprises a pair of bases, a pair of beams and a group of cutter head lifting mechanisms, wherein adjustment acting cylinders of a cloth inlet side upper pressure roller are arranged at one ends of the upper parts of the pair of the bases respectively; adjustment acting cylinders of a cloth outlet side upper pressure roller are arranged at the other ends of the upper parts of the pair of the bases respectively; a fixed beam upright post is fixed at the two ends of each of the pair of beams; an acting cylinder abdicating cavity is formed by a space between the pair of beams; the two ends of the cloth inlet side upper pressure roller are connected with the adjustment acting cylinders of the cloth inlet side upper pressure roller; the two ends of the cloth outlet side upper pressure roller are connected with the adjustment acting cylinders of the cloth outlet side upper pressure roller; the two ends of each of a cloth inlet side lower guide roller and a cloth outlet side lower guide roller are supported on the pair of bases; the two ends of an anvil roller are supported on the pair of bases; a group of anvil sleeves are sleeved and fixed on the anvil roller; the tow ends of each of a front cloth guide plate and a rear cloth guide plate are fixed between the pair of bases; the group of cutter head lifting mechanisms are arranged on the pair of beams in a fitted manner; and a cutter head is arranged on each cutter head lifting mechanism. According to the cutting machine for nonwoven cellucotton screen cloth disclosed by the invention, the requirements of rolling while cutting are satisfied, the cutting for nonwoven cellucotton meshes of different gram weights or thicknesses can be coped; and the rolling is convenient and safe.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

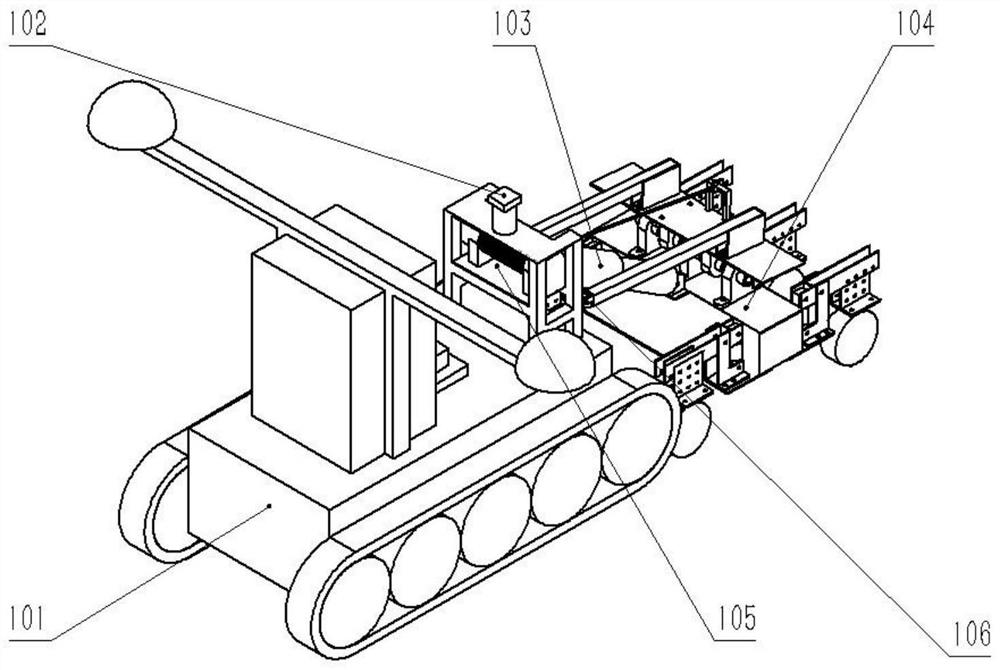

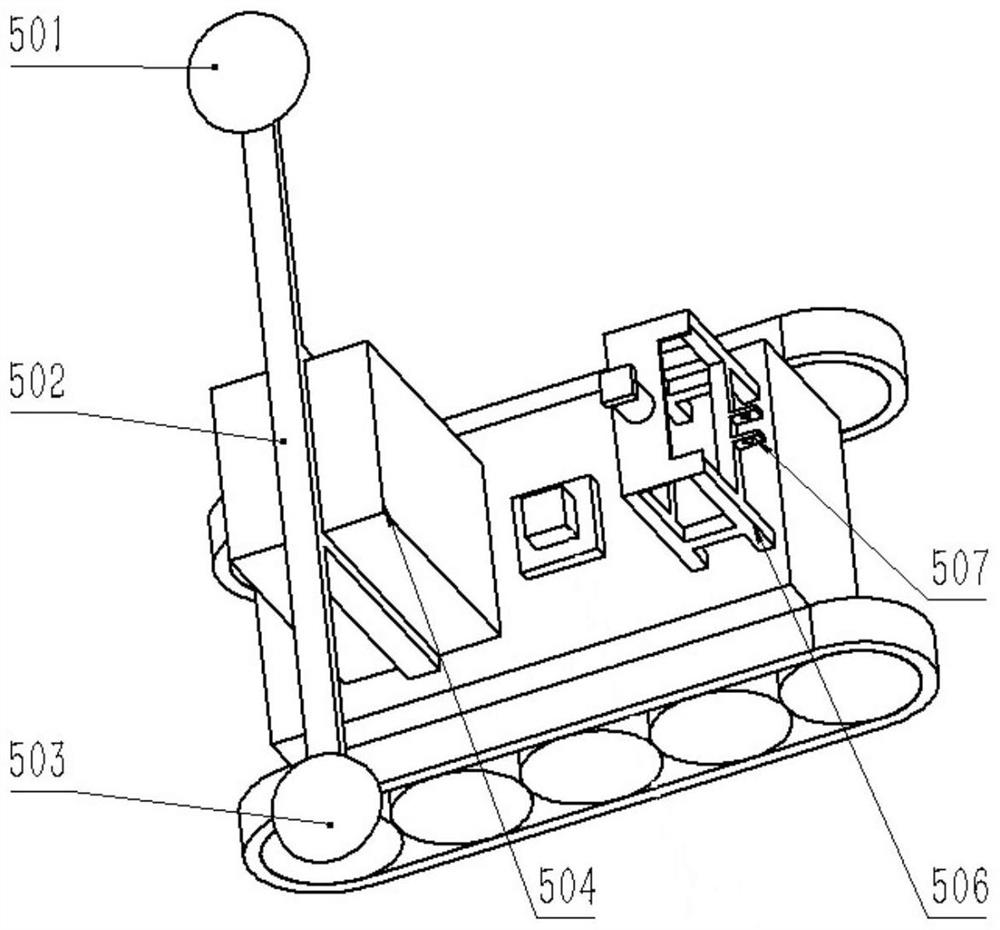

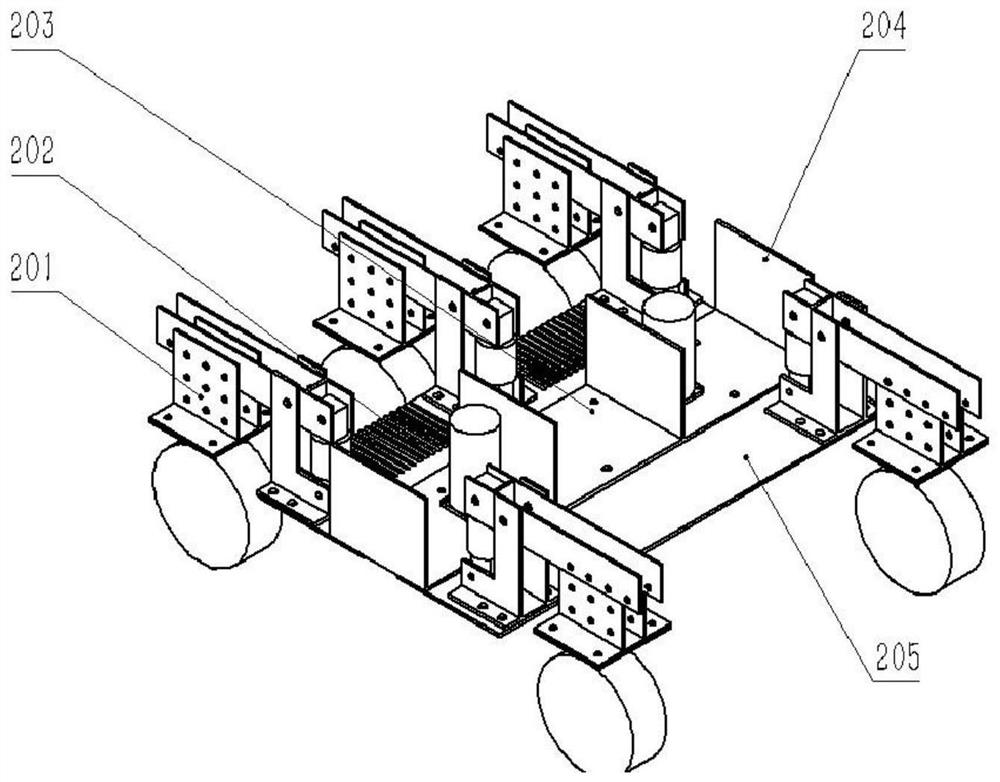

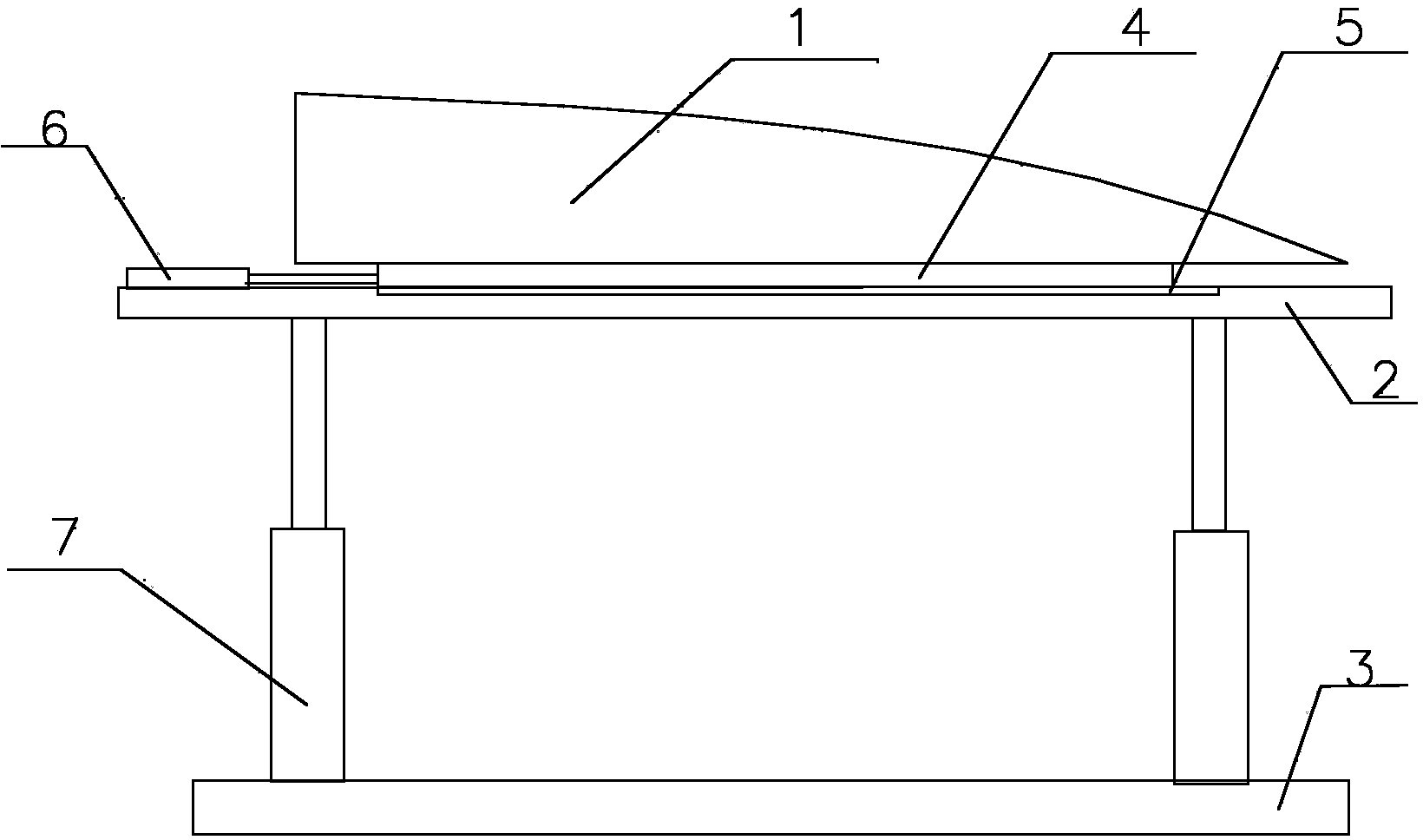

Hillside orchard profiling autonomous obstacle avoidance mower and control method thereof

ActiveCN111713245ANo damageFully absorb impact energyVehicle body stabilisationUnderstructuresCompliant mechanismElectric machinery

The invention provides a hillside orchard profiling autonomous obstacle avoidance mower and a control method thereof. Through cooperation of a push rod motor and a rotating pair, multi-angle cutting is achieved, and energy consumption needed by mowing operation is reduced; a connecting rod is arranged and is matched with an upper base bearing, a lower base bearing and a base connecting optical axis to form a flexible mechanism, the flexible mechanism interacts with the push rod motor, profiling operation is achieved, the mower can conduct ground profiling mowing operation on a complex orchardterrain as a whole, and the cutting effect is better than that of a traditional mower; and by adopting a right-angle bypassing obstacle avoidance mode, precise obstacle avoidance of the mower is achieved, and the operation purpose of not excessively depending on operators is achieved. The hillside orchard profiling autonomous obstacle avoidance mower can conduct ground profiling multi-angle mowingoperation, is good in cutting effect and has the advantages of being high in safety and operation reliability, intelligent, efficient, capable of saving energy, environmentally friendly and the like.

Owner:JIANGSU UNIV

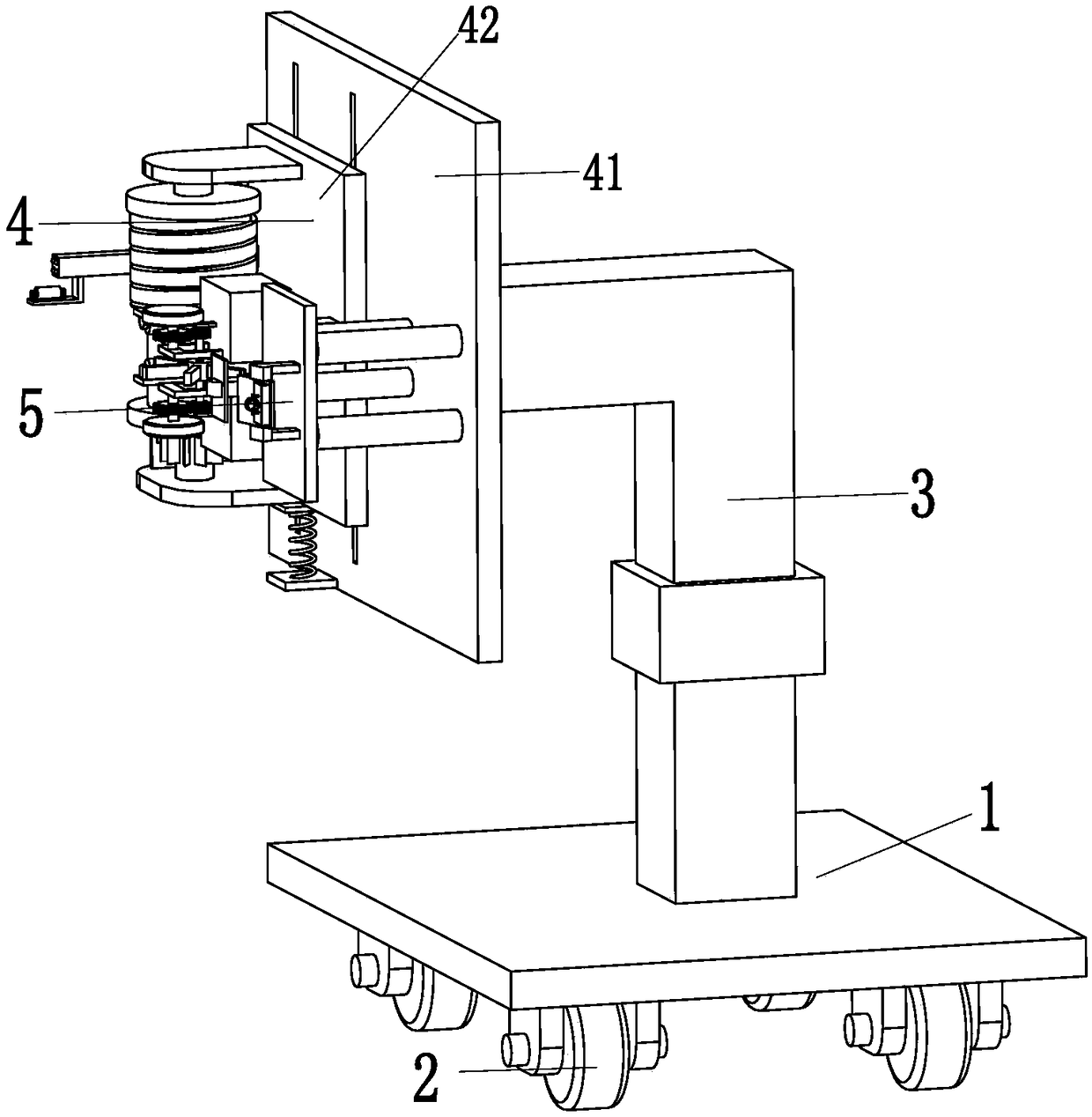

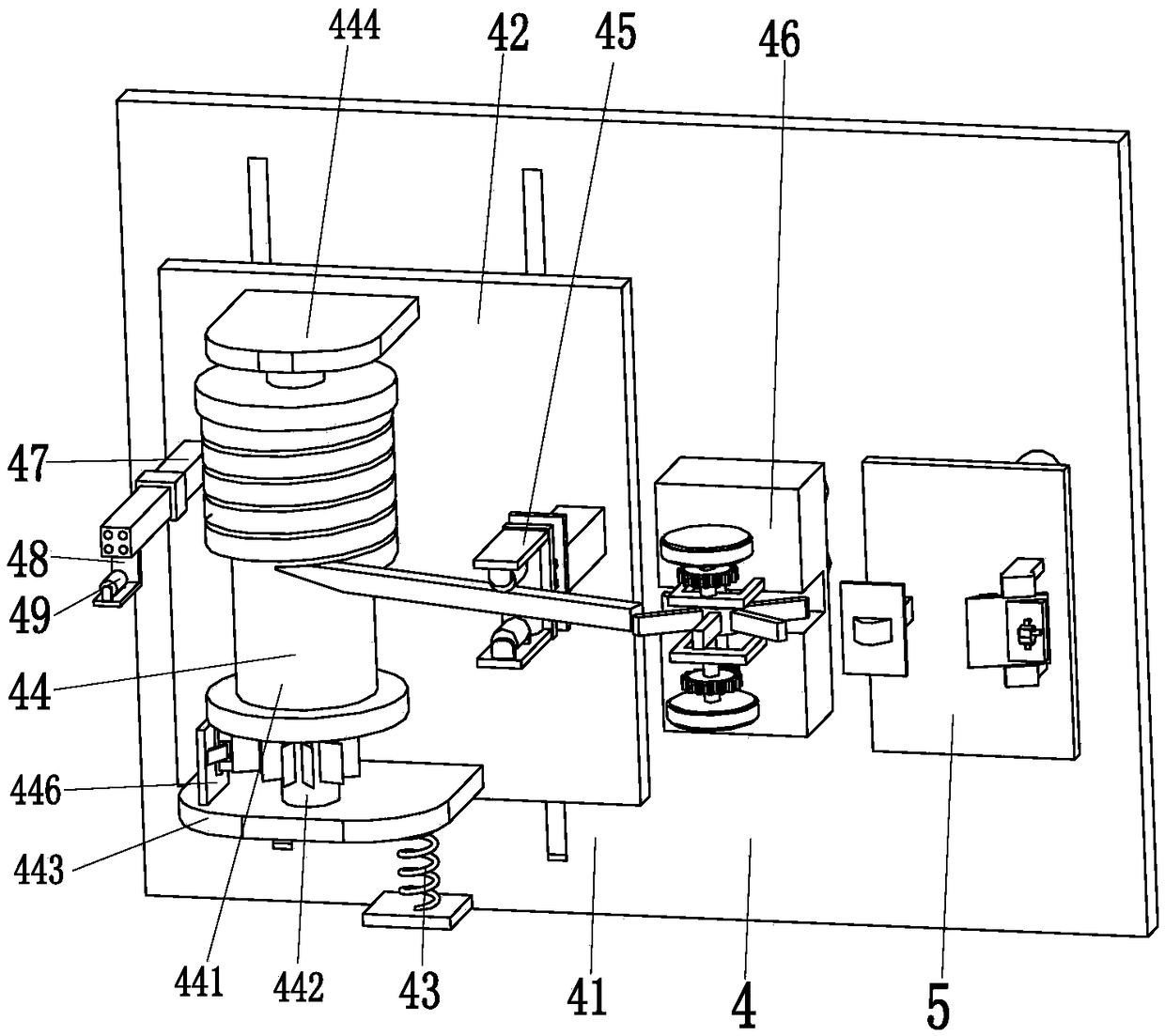

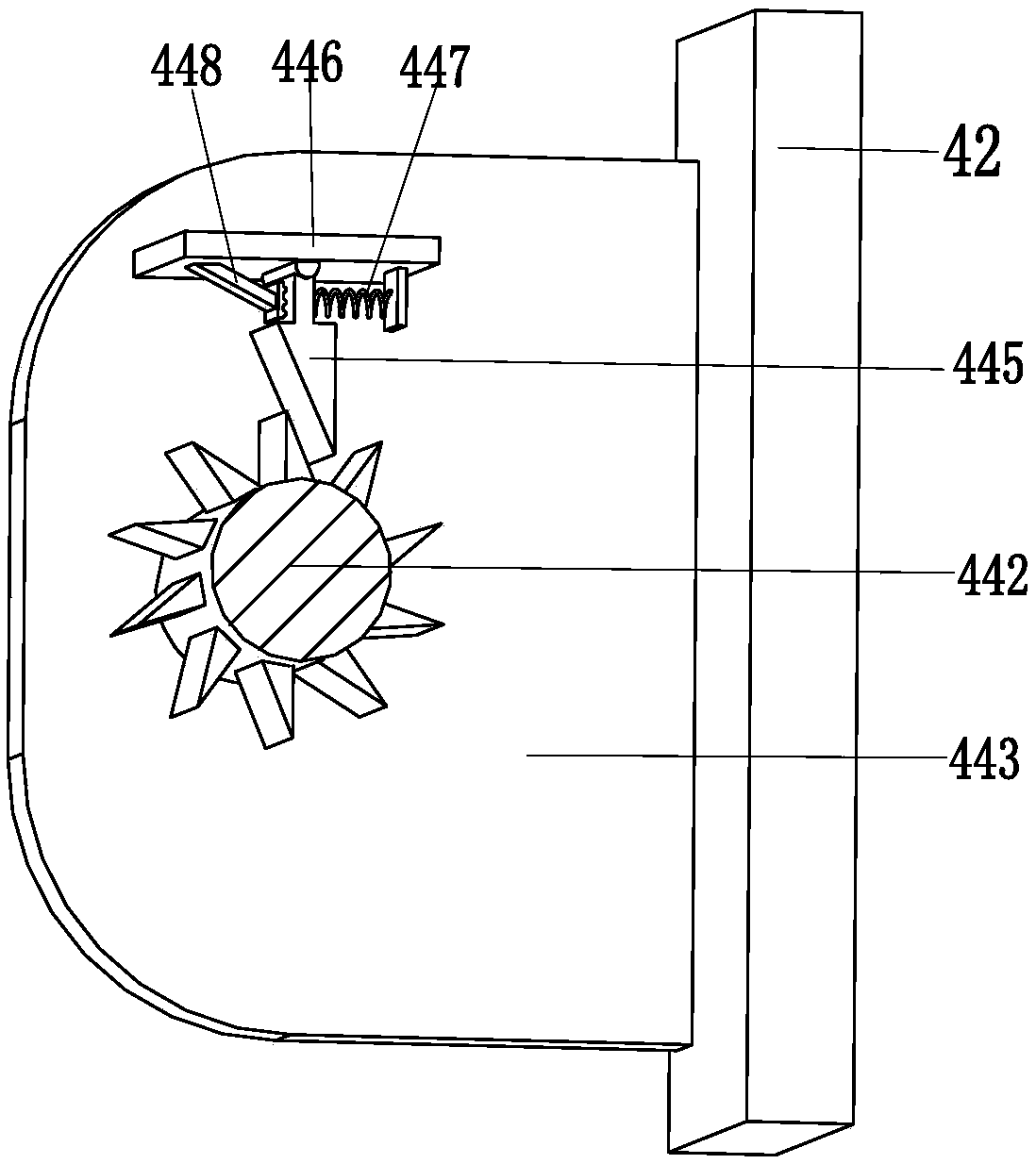

Building wall surface decoration construction equipment used for dry-hanging stone

ActiveCN109057283AGood cutting effectImprove cutting effectBuilding constructionsEquipment useArchitectural engineering

The invention relates to building wall surface decoration construction equipment used for dry-hanging stone. The equipment comprises a supporting bottom plate, moving wheels, a telescopic frame, a filling device and a cutting device, moving wheels are symmetrically installed on the bottom of the supporting bottom plate, the telescopic frame is installed on the top of the supporting bottom plate, the middle of the telescopic frame is of a telescopic structure, the filling device is installed on the left end of the telescopic frame, and the cutting device is connected with the front end of the filling device. By means of the equipment, the existing difficult problems of the failing of automatic delivery of foam seam embedding strips, the potential safety hazards of the friction fracturing when the foam seam embedding strips are delivered, manual operation needed for pressing the foam seam embedding strips into stone seams, the failing of performing straightening on the foam seam embedding strips when the foam seam embedding strips are filled, the failing of performing synchronous cutting when the foam seam embedding strips fill the seams, poor cutting effect on the foam seam embedding strips and the like when seam filling is conducted by using the dry-hanging stone are solved.

Owner:龙元明筑科技有限责任公司

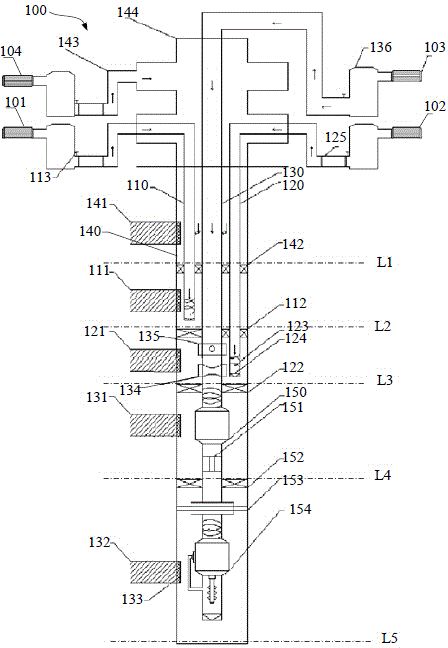

Multi-media separated injection system suitable for mine field complex oil reservoir

ActiveCN104948149AEnhanced overall recoveryImprove sealingFluid removalPetroleumPetroleum engineering

The invention provides a multi-media separated injection system and method. A multi-media separated injection pipe column device comprises a first passageway, a second passageway, a third passageway and a fourth passageway, wherein the first passageway is provided with a first pipeline for injecting a first medium to a first-depth well section, the second passageway is provided with a second pipeline for injecting a second medium to a second-depth well section, the third passageway is provided with a third pipeline for injecting a third medium to a third-depth well section, two decenter injection proration devices connected in series are arranged at the bottom of the third pipeline, the fourth passageway is provided with a fourth pipeline which can contain the first pipeline, the second pipeline and the third pipeline, and a first single-pipe packer, a second single-pipe packer, a three-pipe packer and a double-pipe packer are contained in the fourth pipeline. The different media are injected to the well sections of different depths through the four passageways, and therefore the multiple media can be injected to the different sections at the same time, the borehole operation can be monitored in real time and adjusted instantly aboveground, the petroleum recovery efficiency is improved, and the system and method are suitable for production of a mine field complex oil reservoir.

Owner:NORTHEAST GASOLINEEUM UNIV

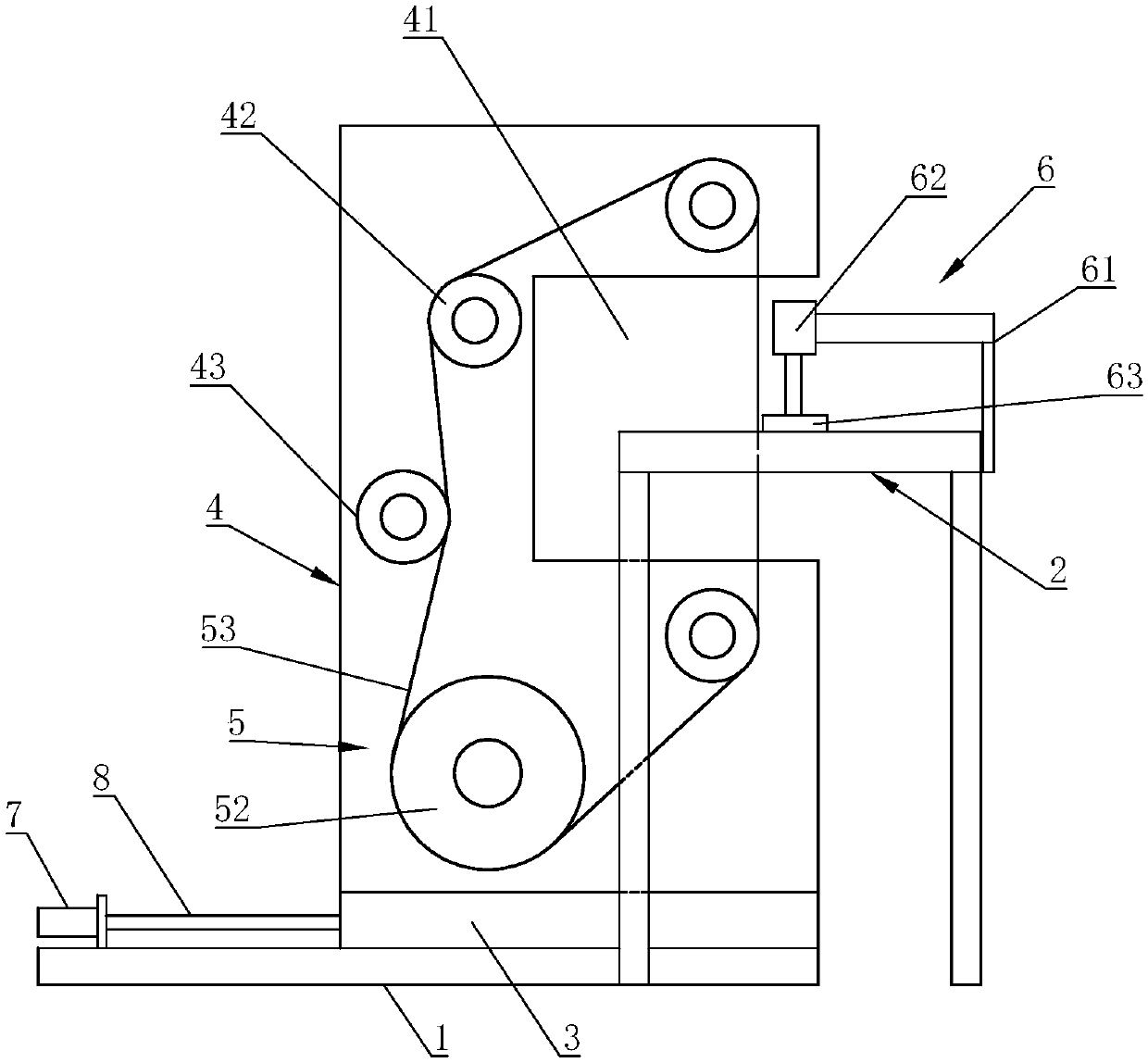

Dividing and cutting machine

InactiveCN103552100AImprove cutting effectGood cutting effectSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention relates to a dividing and cutting machine which comprises a cutting knife, a cross beam, a power device pushing the cross beam to move vertically and a support. The power device is fixed on the support, the cutting knife is arranged on the cross beam, the knife back of the cutting knife right faces the cross beam, a slide block and a slide rail are further arranged between the knife back and the cross beam, the slide block is fixedly connected with the knife back, the slide rail is arranged on the cross beam, and the slide block slides in the slide rail. A first hydraulic cylinder is further arranged on the cross beam, the operation direction of a piston rod of the first hydraulic cylinder is parallel to the cross beam and located on the same straight line with the slide rail, and the extending end of the piston rod of the first hydraulic cylinder is fixedly connected with the slide block. The cutting knife is longitudinally moved through the slide block, the slide rail and the first hydraulic cylinder and performs sliding type cutting, the improvement of the cutting effect is facilitated, and the cutting effect is good by changing a blade of the cutting knife and adopting a line-to-point cutting method.

Owner:CHANGZHOU WUJIN GUANGYU EMBOSSING ROLLER MACHINERY

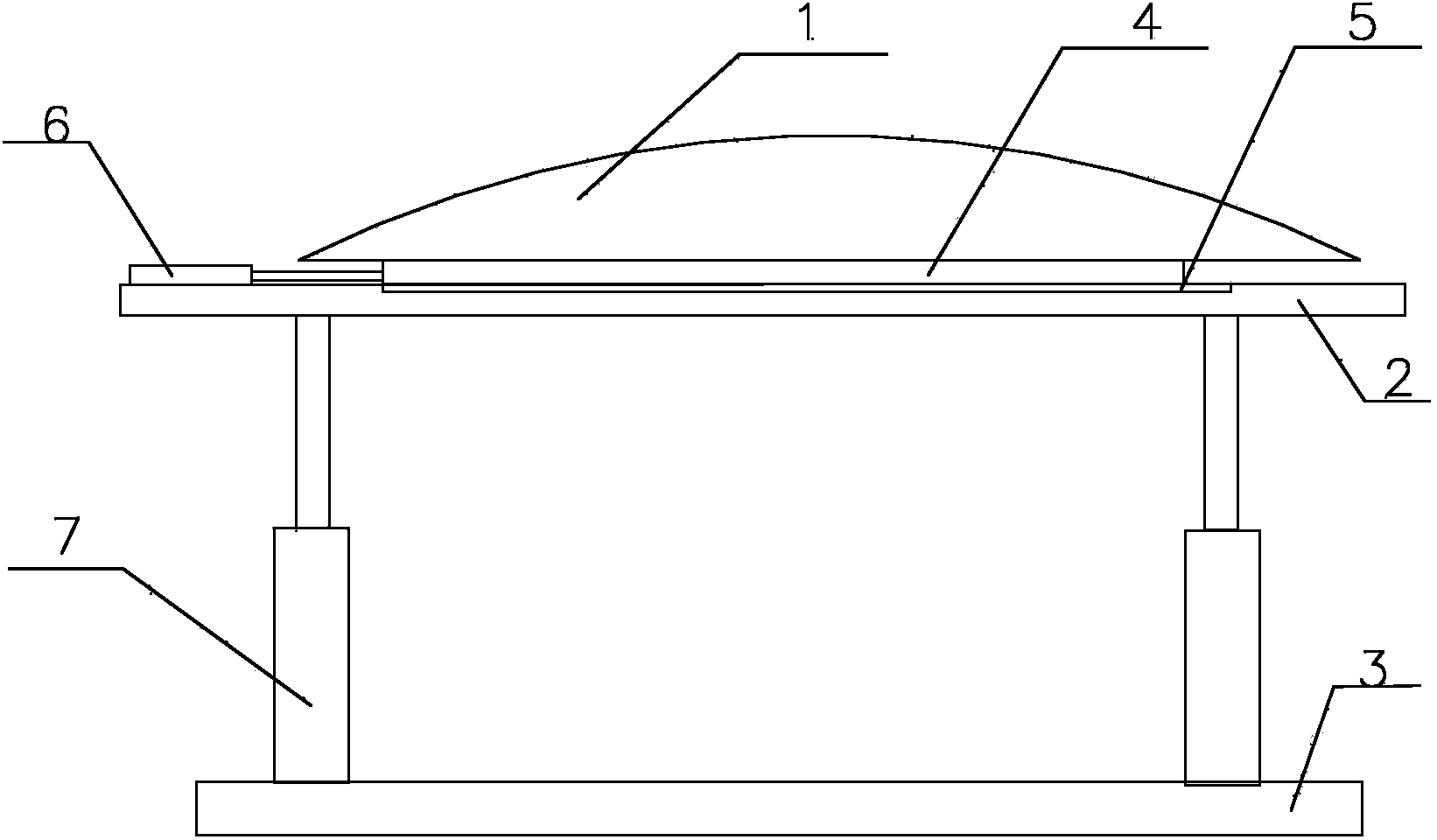

Automatic safe and environmental-friendly dedusting robot for steel drum intersecting line fracture surface polishing

ActiveCN108581703AGood cutting effectLabor savingEdge grinding machinesOther manufacturing equipments/toolsMagnetEngineering

The invention discloses an automatic safe and environmental-friendly dedusting robot for steel drum intersecting line fracture surface polishing. The safe and environmental-friendly dedusting robot for steel drum intersecting line fracture surface polishing comprises an equipment shell with a U-shaped cross section, wherein a first drive mechanism, a hobbing cutter wheel mechanism, a grinding wheel mechanism and a second drive mechanism are sequentially arranged in the U-shaped cavity of the equipment shell from front to back; multiple magnet blocks are distributed and fixed to positions, close to the hobbing cutter wheel mechanism and the grinding wheel mechanism, on a top wall of the inner part of the U-shaped cavity of the equipment shell; a group of branch splay wheel mechanism pressing against the outer side surface and the inner side surface of a steel drum in a rolling way is arranged at a position, located under the hobbing cutter wheel mechanism, in the equipment shell; and multiple ball bearing mechanisms pressing against the outer side surface and the inner side surface of the steel drum in a rolling way are further distributed and fixed onto two side walls of the innerpart of the equipment shell. According to the equipment provided by the invention, an intersecting line notch fracture surface can be automatically cut and polished smoothly without the need to be polished manually, so that the labor force is saved, and the production efficiency is improved.

Owner:汇氏生态环境医院(山东)有限公司

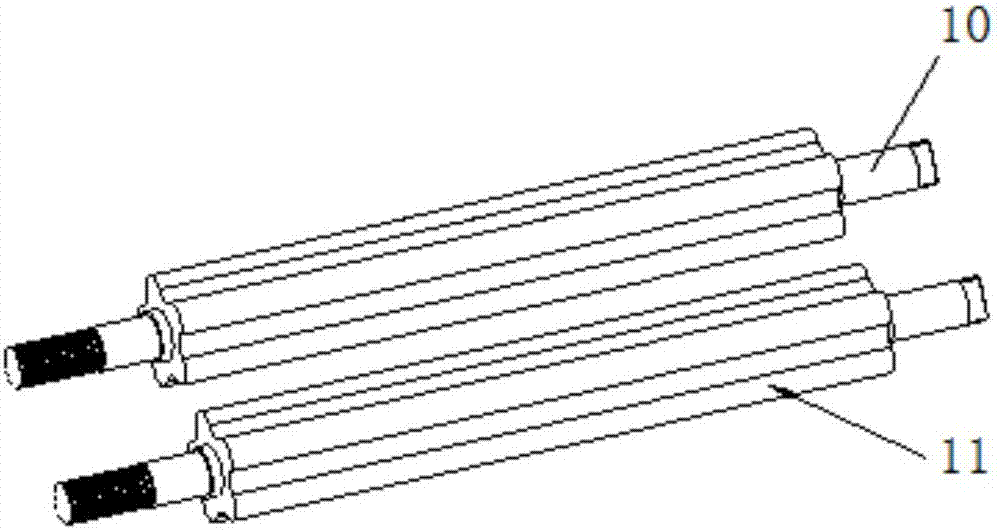

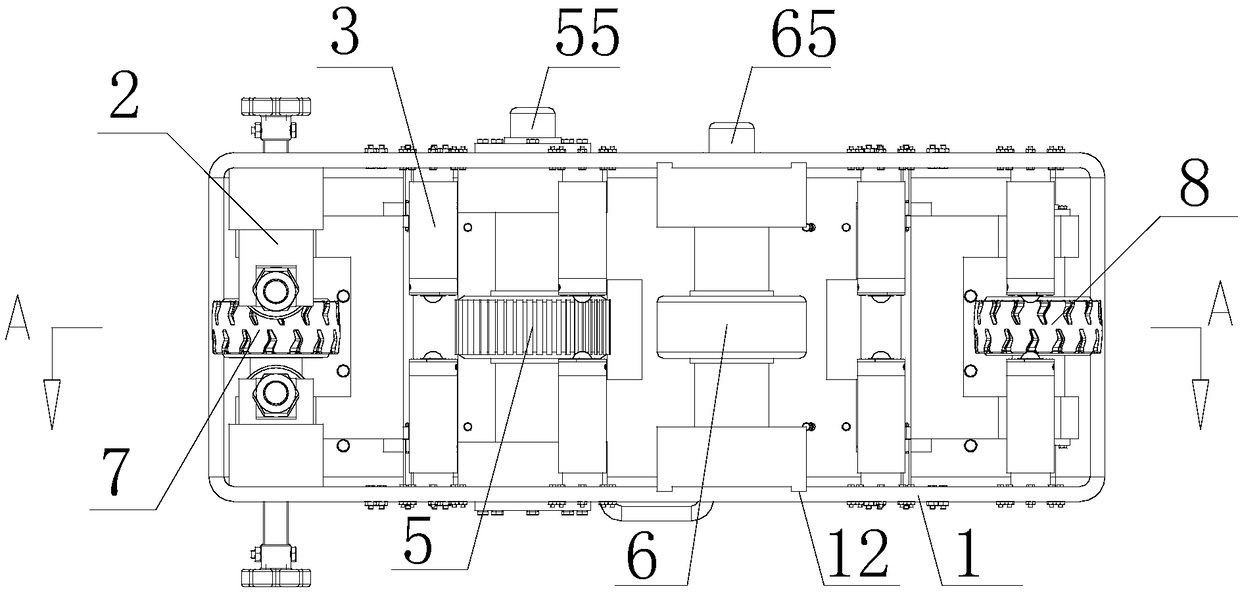

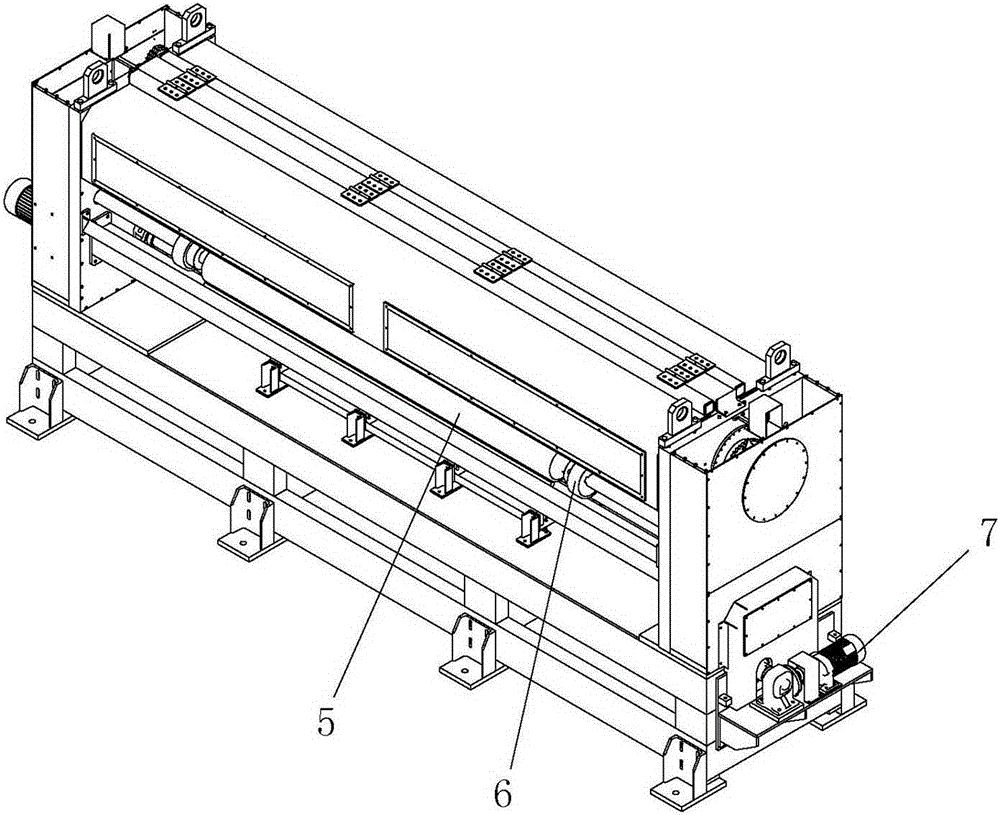

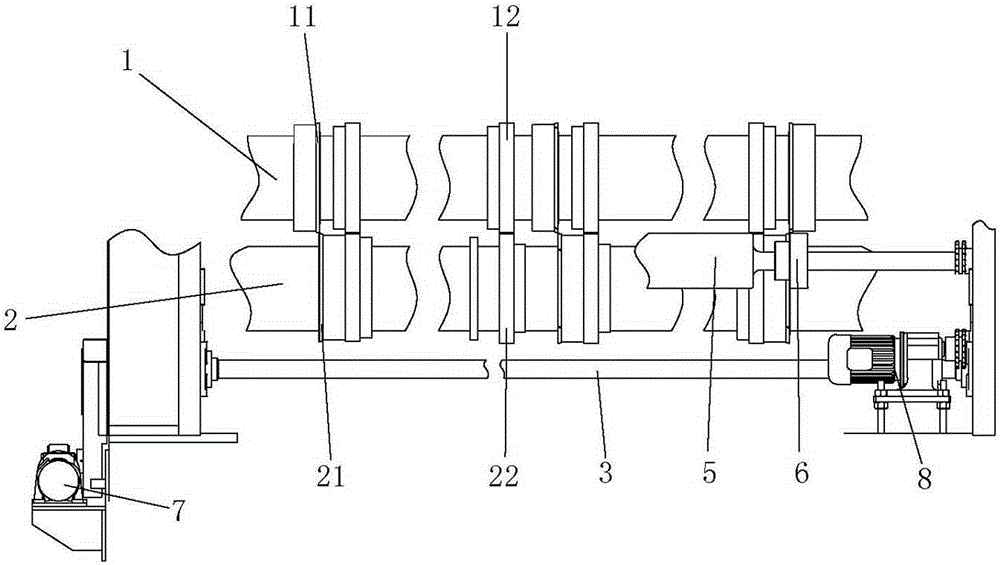

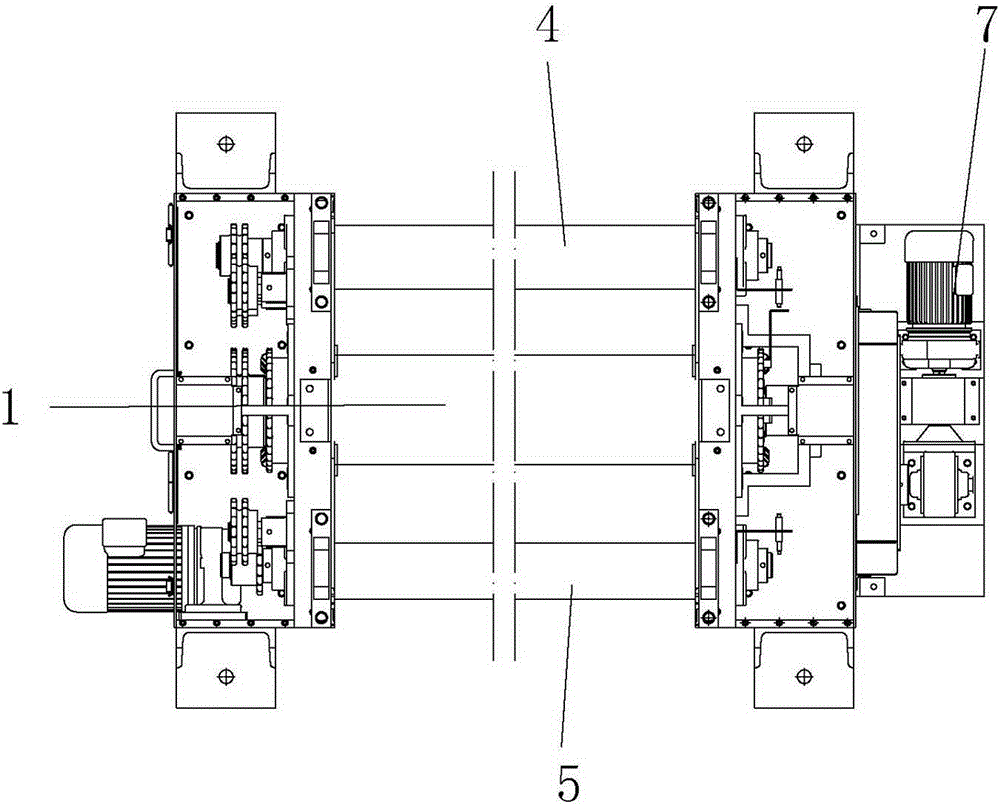

Slitting mill

The invention relates to a slitting mill, and belongs to the technical field of thin plate cutters. The slitting mill comprises an upper roller and a lower roller, and further comprises at least two upper ring cutters arranged on the upper roller and rotating with the upper roller, and at least two lower ring cutters arranged on the lower roller and rotating with the lower roller, wherein the upper roller and the lower roller are both rollers actively rotating; and each upper ring cutter and the corresponding lower ring cutter are opposite in edges to form a cutter set. Through mutual fit between the ring cutters mounted on the upper roller and the lower roller, the slitting mill can realize longitudinal cutting of various plates, can perform fixed-width treatment for the plates, can cut copper foil substrates, paper substrates, aluminum substrates and the like, and has the advantages of quick cutting speed and good cutting effect.

Owner:浙江安浦科技有限公司

Cutting device for gypsum brick production

PendingCN112571644AEasy to changeSave human effortWorking accessoriesStone-like material working toolsBrickMining engineering

The invention discloses a cutting device for gypsum brick production, and belongs to the technical field of gypsum brick cutting, The cutting device comprises a floor, a bearing assembly, a moving assembly, a lifting rotating assembly, a cutting assembly and a dust collection assembly, wherein the floor is laid on the horizontal plane, the bearing assembly is vertically installed on the floor, themoving assembly is vertically installed at the top of the bearing assembly, the lifting rotating assembly is installed at the bottom of the moving assembly, the cutting assembly is installed at the bottom of the lifting rotating assembly and located at the upper end of the bearing assembly, one end of the dust collection assembly is installed on the back face of the bearing assembly, and the other end of the dust collection assembly is arranged on the floor. According to the cutting device for gypsum brick production, gypsum bricks can be cut through the assemblies, the radian direction can also be changed in the cutting process, meanwhile, dust generated in the cutting process is absorbed, high-efficiency and high-level cutting can be achieved, dust can be prevented from polluting the production environment, and the cutting device is quite environmentally friendly.

Owner:常德环创力达环保科技有限公司

Construction method for building board cutting device

InactiveCN107824862ASmooth cutGood cutting effectShearing machinesMaintainance and safety accessoriesElectrical controlElectricity

The invention discloses a construction method for a building plate cutting device, which comprises the following steps: the first step is to fix the device at the setting station; the second step is to move the slider to the end of the device; the third step is to take a For building boards, fix the building boards on the slider; the fourth step is to measure the thickness of the building boards, and manually rotate the handwheel until the outer circle of the cutting piece on the motor mounting plate intersects with the bottom surface of the building boards; fifth The first step is to power on the device; the sixth step is to press the motor start button on the electrical control box; the seventh step is to press the DC motor forward start button on the electrical control box; Spray water at the cutting position; the ninth step, after the building board is cut, press the motor stop button and the DC motor stop button on the electrical control box; the tenth step, the device is powered off; the eleventh step, take out the cut building board . The incision after cutting the building plate of the invention is smooth, and the construction speed is accelerated.

Owner:罗艳春

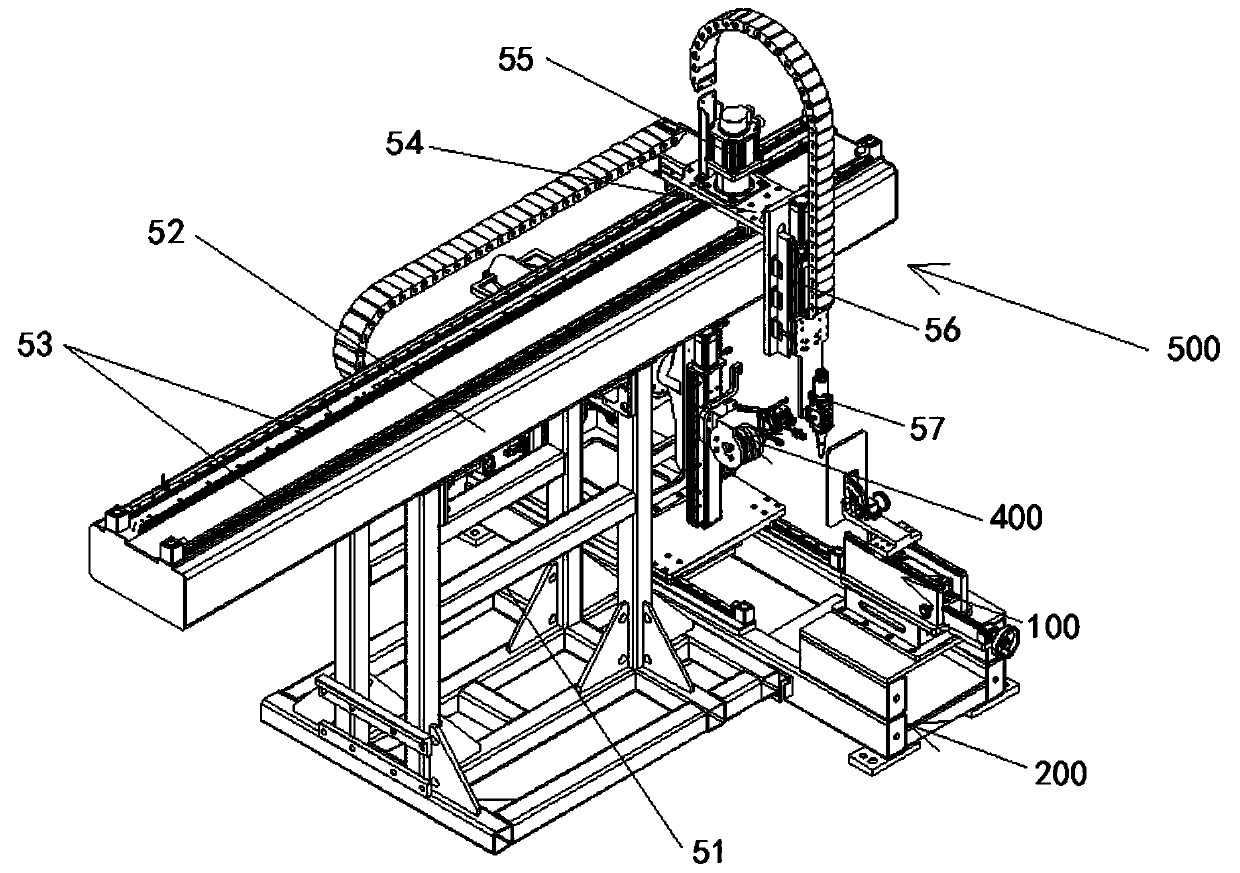

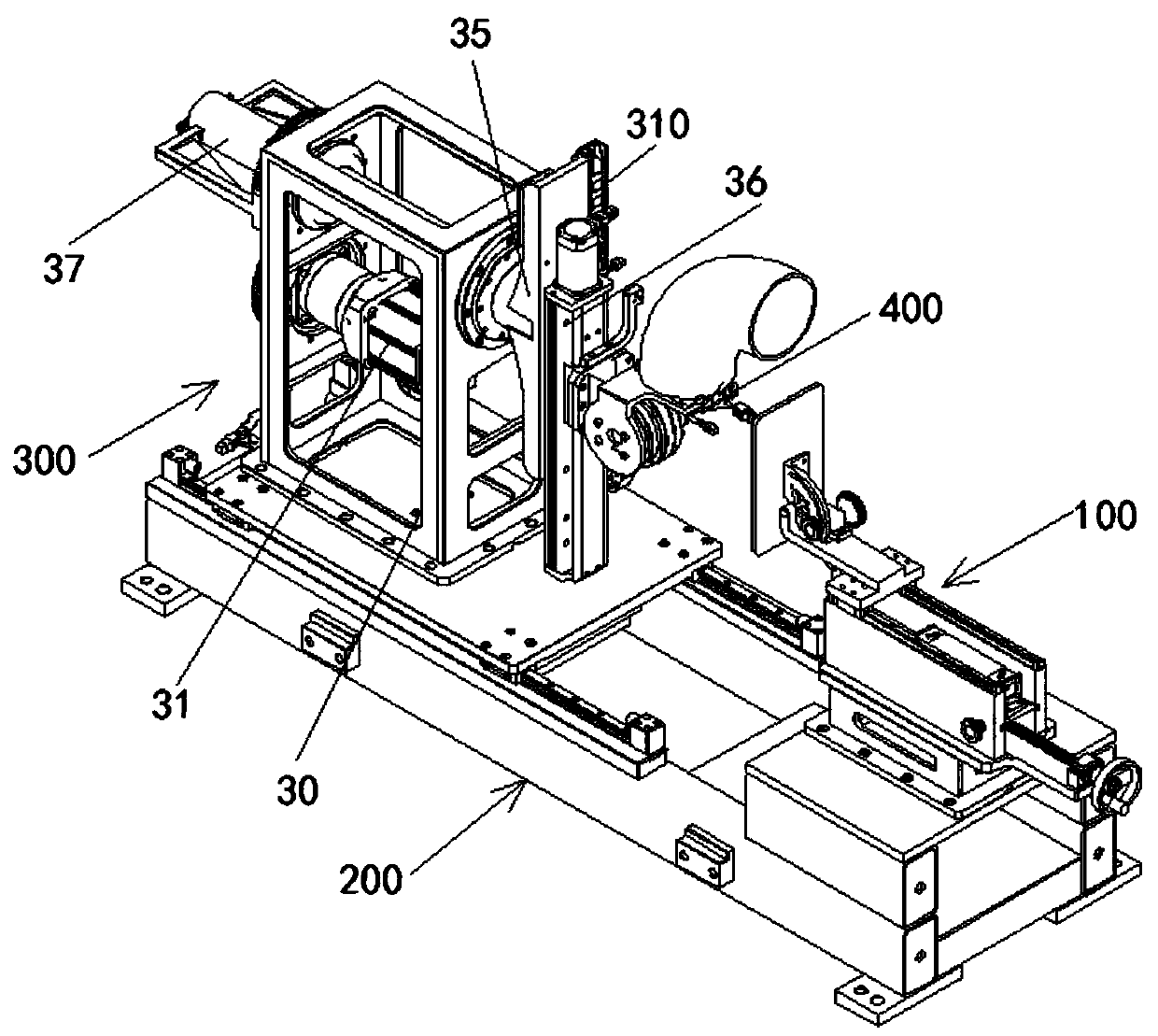

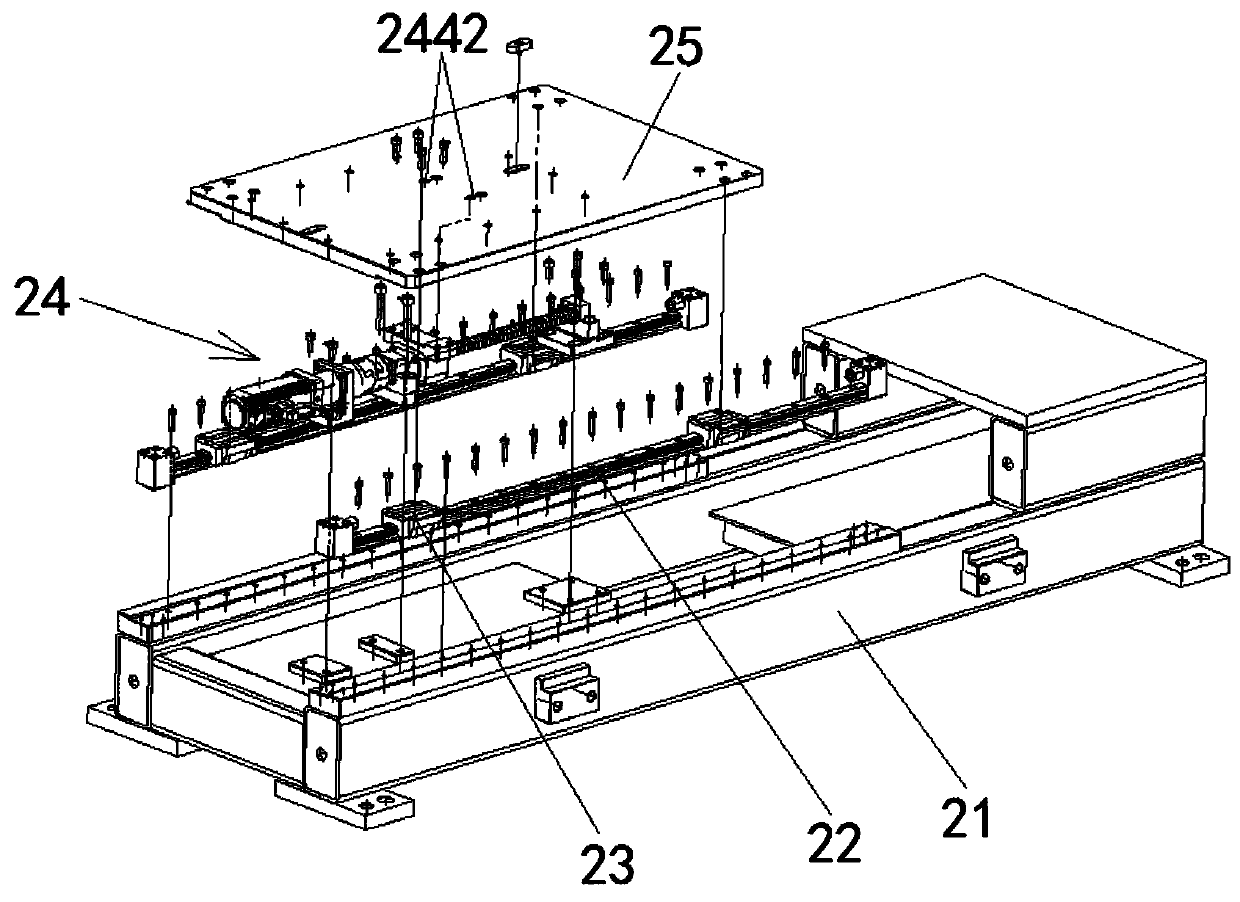

Steel pipe bend cutting device

PendingCN110193663AImprove cutting accuracyGood cutting effectLaser beam welding apparatusSteel tubeLaser cutting

The invention discloses a steel pipe bend cutting device comprising a sliding base assembly, a bend main shaft mounting assembly, an indexing system and a laser cutting assembly. The bend main shaft mounting assembly is mounted on the sliding base assembly, the indexing system is connected to the bend main shaft mounting assembly, and the laser cutting assembly is arranged on one side of the sliding base assembly. According to the steel pipe bend cutting device, a hollow main shaft rotates to drive a steel pipe bend installed on the indexing system to conduct rotary cutting; front-back-back motion of the sliding base assembly and up-and-back motion of a bend sliding module are used for finding a cutting center point of the bend; a second servo motor in the indexing system rotates to adjustthe bend cutting angle; left-and-right movement of a laser cutting head in the laser cutting assembly is used for finding the cutting center point; the cutting thickness is controlled by the up-and-down movement of the laser cutting head, arbitrary cutting of the steel pipe bend angle is achieved, and the advantages of being high in cutting precision, free of burrs and the like are achieved.

Owner:湖北峰佑高端装备制造有限公司

Rubber cutting machine

The invention discloses a rubber cutting machine. The rubber cutting machine comprises a base and a cutting platform, wherein a fixing seat is slidably arranged on the base, a support is fixedly arranged on the fixing seat, a notch for accommodating the cutting platform is formed in the part, corresponding to the cutting platform, of the support, a cutting device is arranged on the support, the cutting device comprises a diamond wire roller driven by a motor to rotate, a diamond wire is wound around the diamond wire roller, at least three guide wheels are arranged on the support, and the diamond wire on the diamond wire roller sequentially bypasses the three guide wheels to form a diamond wire loop; a threading groove is formed in the middle of the cutting platform, and the diamond wire between the two guide wheels at the upper front end of the support passes through the threading groove; and a pressing device is arranged on the cutting platform; and a servo motor is arranged on the base, a lead screw is fixedly connected to an output shaft of the servo motor, and the lead screw is in threaded connection with the fixing seat. The rubber cutting machine cuts rubber in order.

Owner:宁国市中英橡胶有限公司

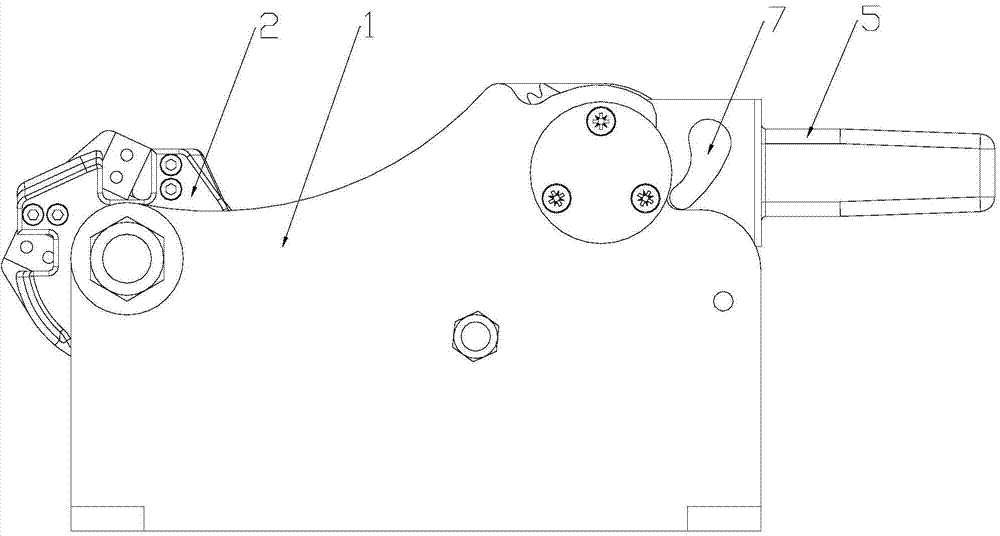

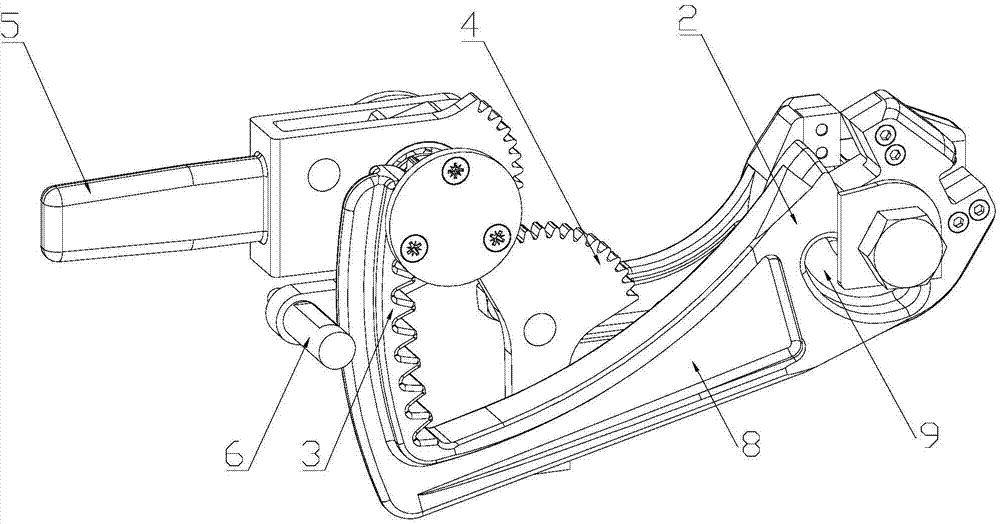

Ratchet type reinforcing steel bar cutter

The invention discloses a ratchet type reinforcing steel bar cutter comprising a base, a tool rest fixed to the base and a blade hinged to the tool rest. A ratchet gear is connected to the base in a rotatable mode. The blade is connected with a handle. The front end of the handle is in the shape of ratchet teeth, the ratchet teeth are meshed with the ratchet gear connected to the base. The lower portion of the handle is connected with an L-shaped shifting block. The other end of the L-shaped shifting block is tightly attached to the back of the blade. The rear end of the handle is in the shape which enables people to hold the handle by hand. The cutting edge portion of the blade is zigzag. A through hole and a groove which are used for reducing the weight are formed in the tool rest. Due to the fact that the ratchet structure is applied to the ratchet type reinforcing steel bar cutter, large shearing force can be obtained just through small human power, a good reinforcing steel bar shearing effect can be achieved, and production efficiency is high.

Owner:ZHANGJIAGANG TIANDA SPECIFIC CUTTER

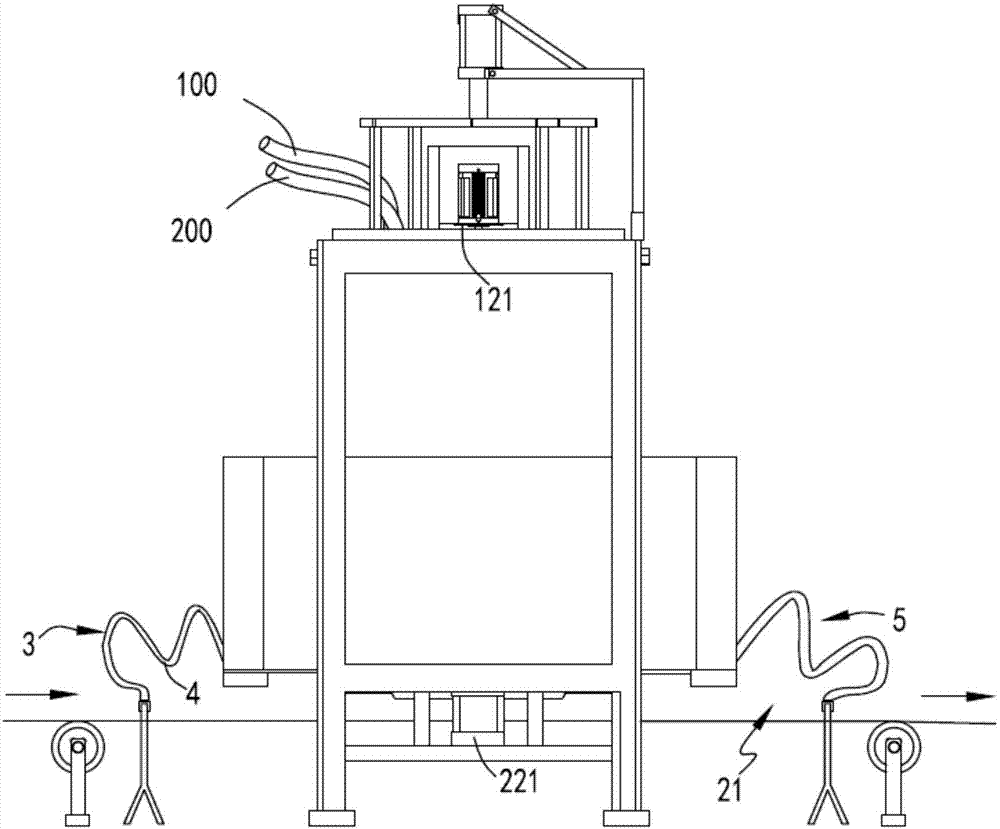

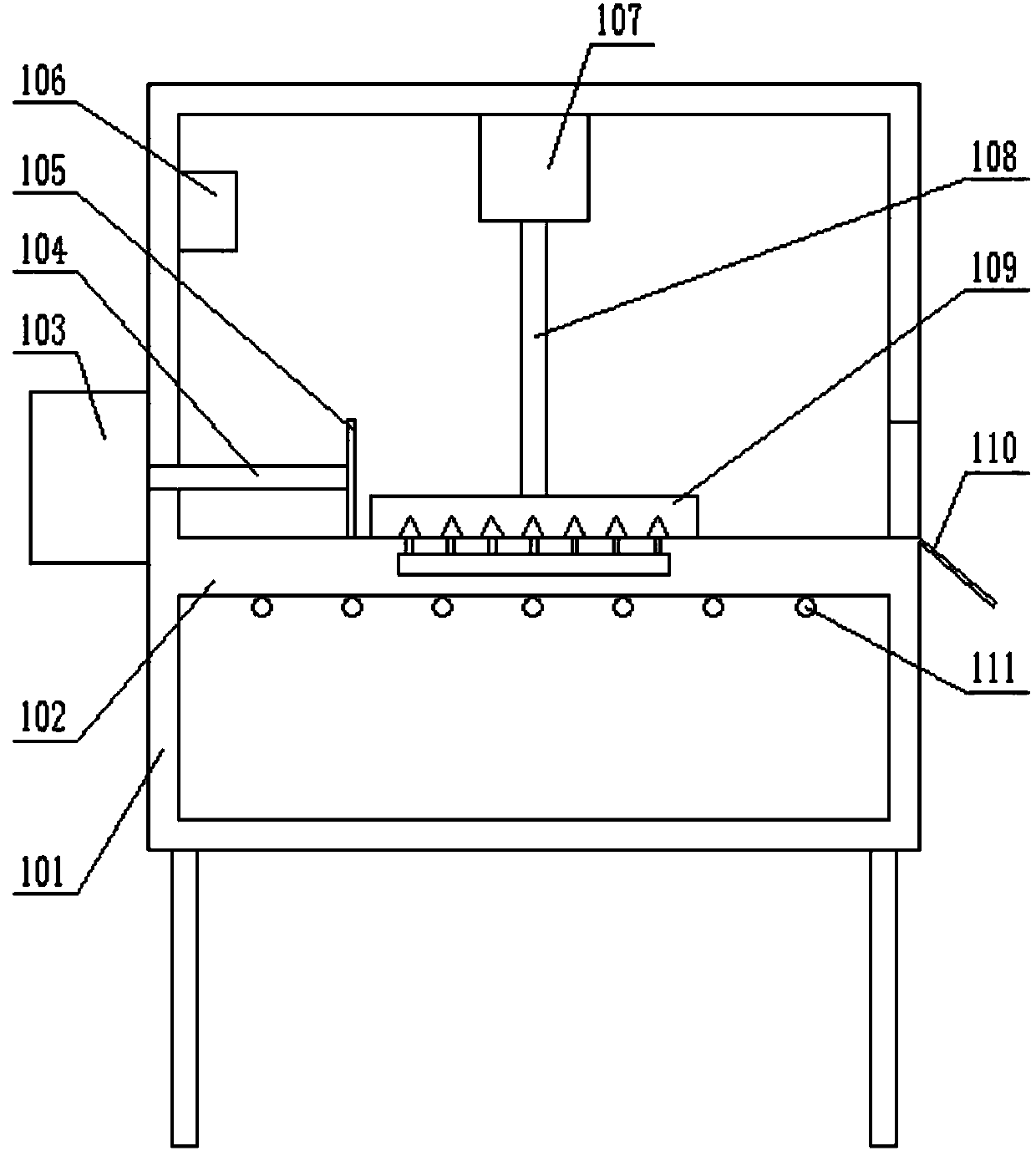

Automatic dosing and beating system

InactiveCN107366103AImprove chopping effectGood beating effectTextile treatment machine arrangementsTextile treatment by spraying/projectingTextile fiberPulp and paper industry

The invention relates to an automatic batching and beating system, comprising a beating part, the beating part includes a beating barrel, a rotating chopping mechanism and an agitating mechanism, the beating barrel is fixed on a bracket, and the inner wall of the beating barrel is provided with several cutter mechanisms along its circumferential direction , during the rotation of the rotating shredding mechanism, cooperate with the cutter mechanism to cut the fibers in the slurry, the stirring mechanism is arranged on one side of the cutter mechanism, and the stirring mechanism is used to stir the slurry up and down; the sizing part The sizing part includes a sizing mechanism arranged under the beating barrel and a control mechanism arranged under the sizing mechanism. The sizing mechanism is used to accept the slurry flowing out of the beating barrel and transmit it from the front and rear ends under the action of the control mechanism. Spraying the sizing solution twice on the textile fiber; the invention overcomes the problems of insufficient beating of the sizing material, poor fineness of the sizing material and uneven sizing of the sizing material.

Owner:HUZHOU CHENGXIN TEXTILE PRINTING & DYEING

Novel chopping type straw super crusher

The invention discloses a novel chopping type straw super crusher, which comprises a frame, wherein the upper end of the frame is movably connected with a conveying base, two sides of the conveying base are respectively provided with side mounting plates, the upper end surface of the conveying base is provided with a lower conveyor belt, an upper conveyor belt is arranged between the two side mounting plates at a position right above the lower conveyor belt, the upper conveyor belt and the lower conveyor belt are arranged at an acute angle, lower gears are arranged at two ends of a front rotating shaft of the lower conveyor belt, upper gears are arranged at two ends of the front rotating shaft of the upper conveyor belt, and are meshed with the lower gears. A fixed chopping table is arranged at one end of the frame close to the lower gear, a lower chopping knife is arranged at the upper end of the fixed chopping table, a crankshaft penetrates through the fixed chopping table, the two ends of the crankshaft are respectively connected with the two ends of the chopping knife through a chopping connecting rod, and a conveying base is connected with the crankshaft through a base connecting rod. A funnel is arranged at the oblique lower position of the fixed chopping table, and a crushing device is arranged below the funnel.

Owner:NANCHANG INST OF TECH

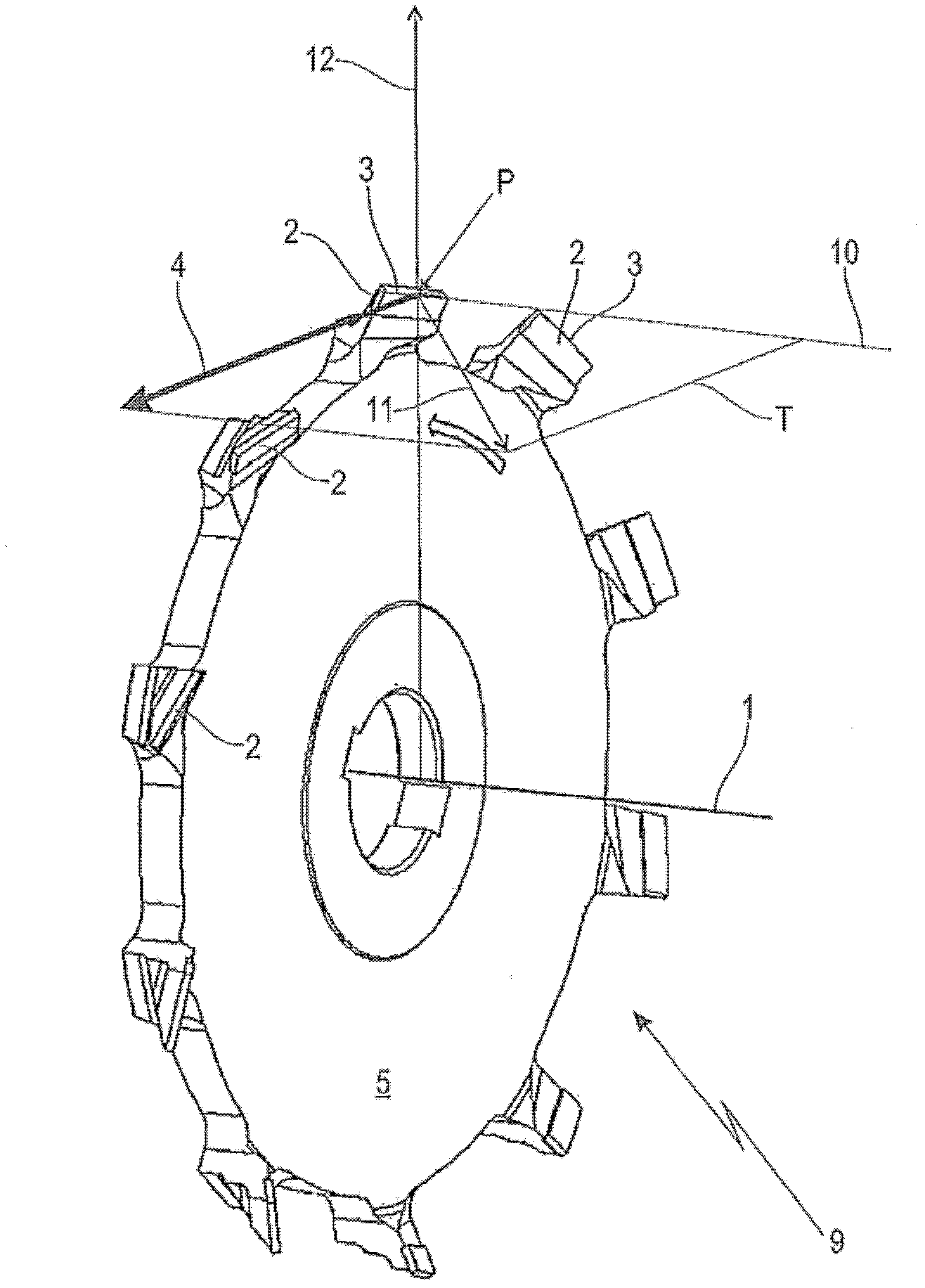

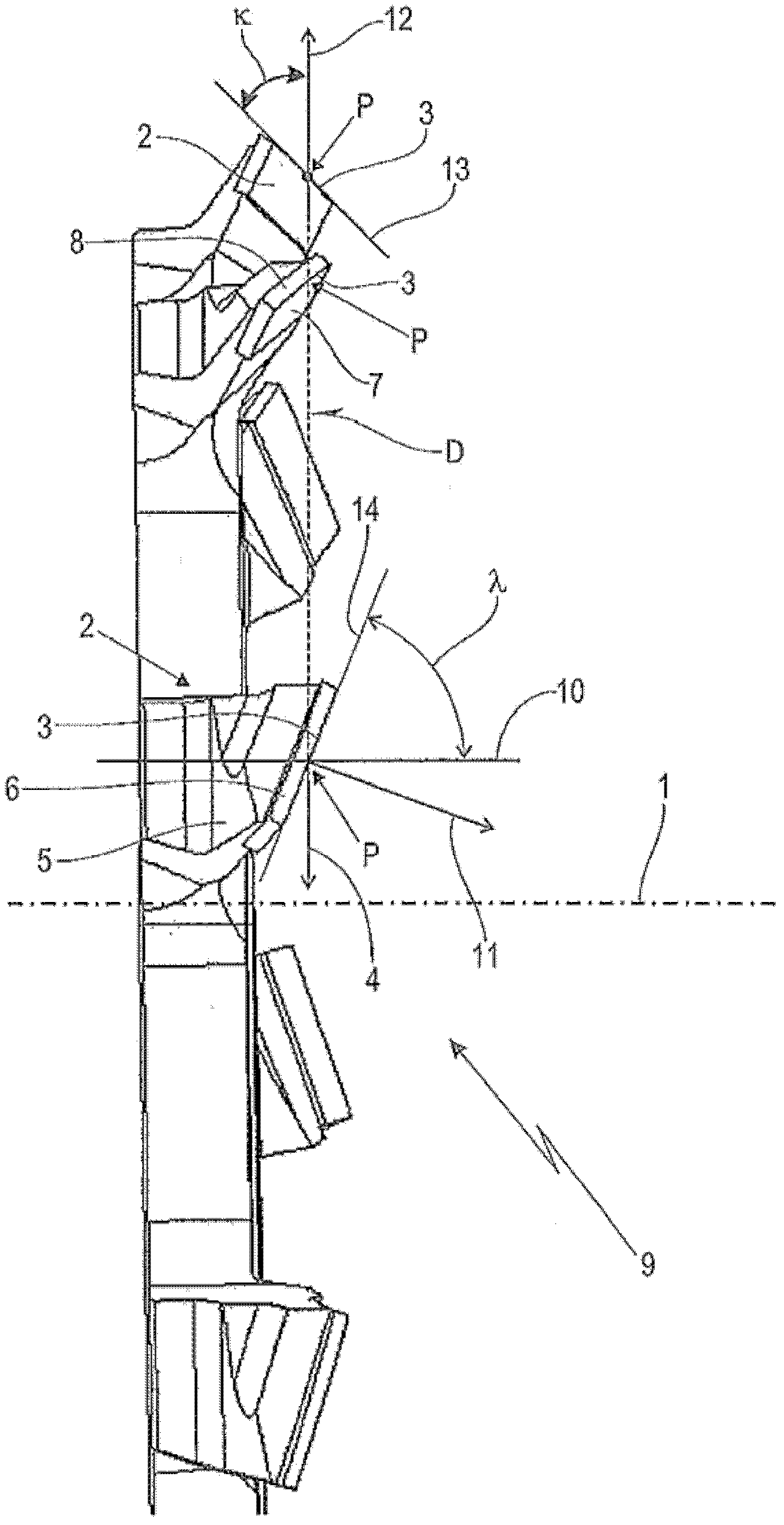

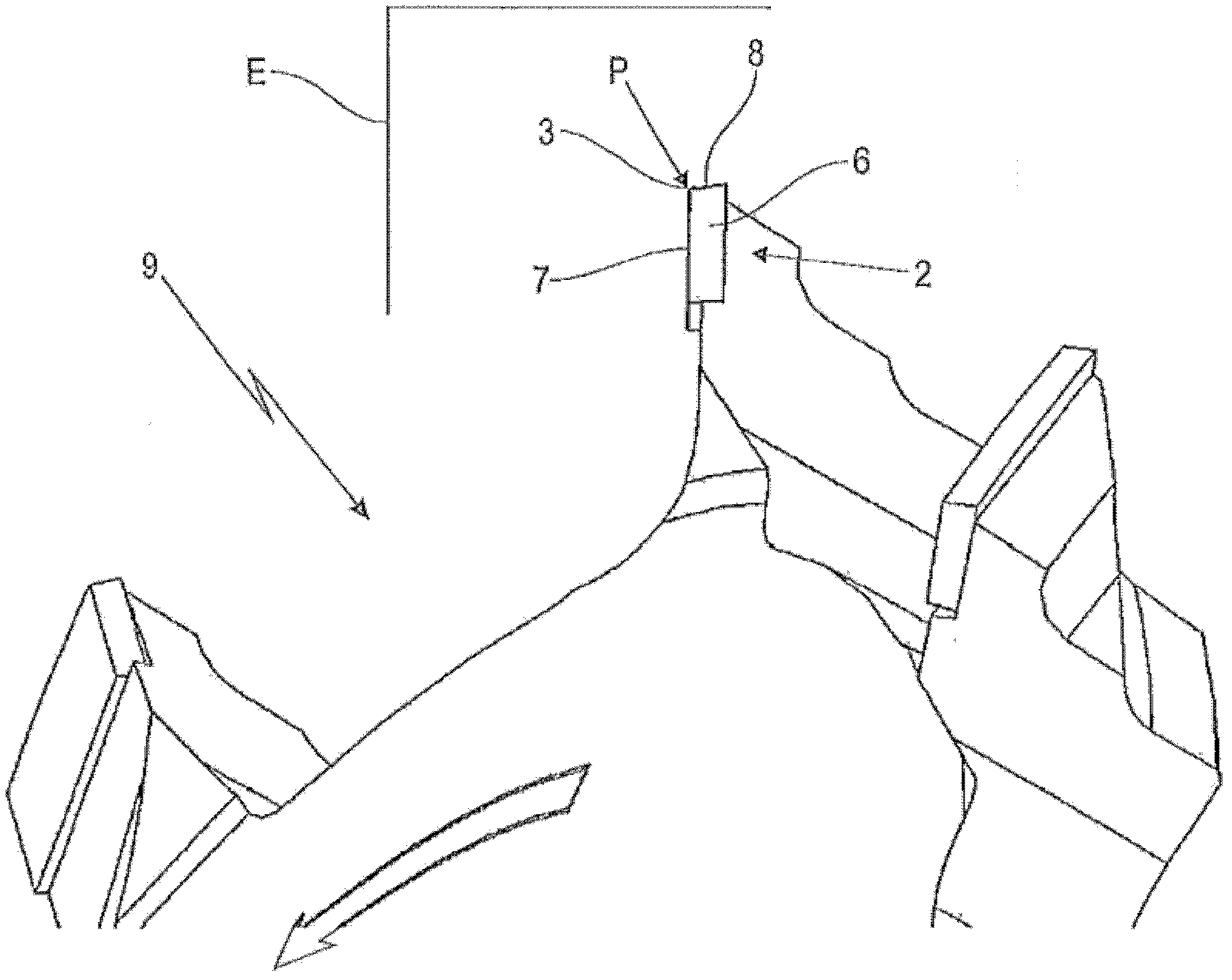

Processing cutting tool

InactiveCN102626794AExtended service lifeGood cutting effectMilling cuttersTurning toolsWedge angleEngineering

The invention refers to a Processing cutting tool (9) use for cutting and processing materials. The processing cutting tool is configured to be driven around a rotation axis (1) and has several cutting heads (2) with cutting edges (3) and at least one point (P) on the cutting edges (3). The cutting edges (3) are rotated about the rotation axis (1) to describe a cutting edge outline (13) circling the rotation axis (1). A rotation plane (D) is provided which comprises the at least one point (P) and is perpendicular to the rotation axis (1). A cross-section (E) of the cutting heads (2)are also provided which comprises the at least one point (P) and is perpendicular to the cutting edges (3). The cutting edges (3) form a crossed axis angle (lambda) relative to the rotation axis (1) on the at least one point (P). The cutting edge outline (13) form a tool cutting edge angle (kappa) relative to the rotation plane (D) at the at least one point (P). The cutting edges (3) at the point (P) and in the rotation plane (D) has an effective clearance angle (alpha eff), effective wedge angle (beta eff) and effective rake angle (gamma eff). The clearance angle (alpha eff) is no greater than zero DEG; the crossed axis angle (lambda) and the tool cutting edge angle (kappa) are coordinated such that effective clearance angle (alpha eff) is equal to or greater than zero DEG.

Owner:LEDERMANN

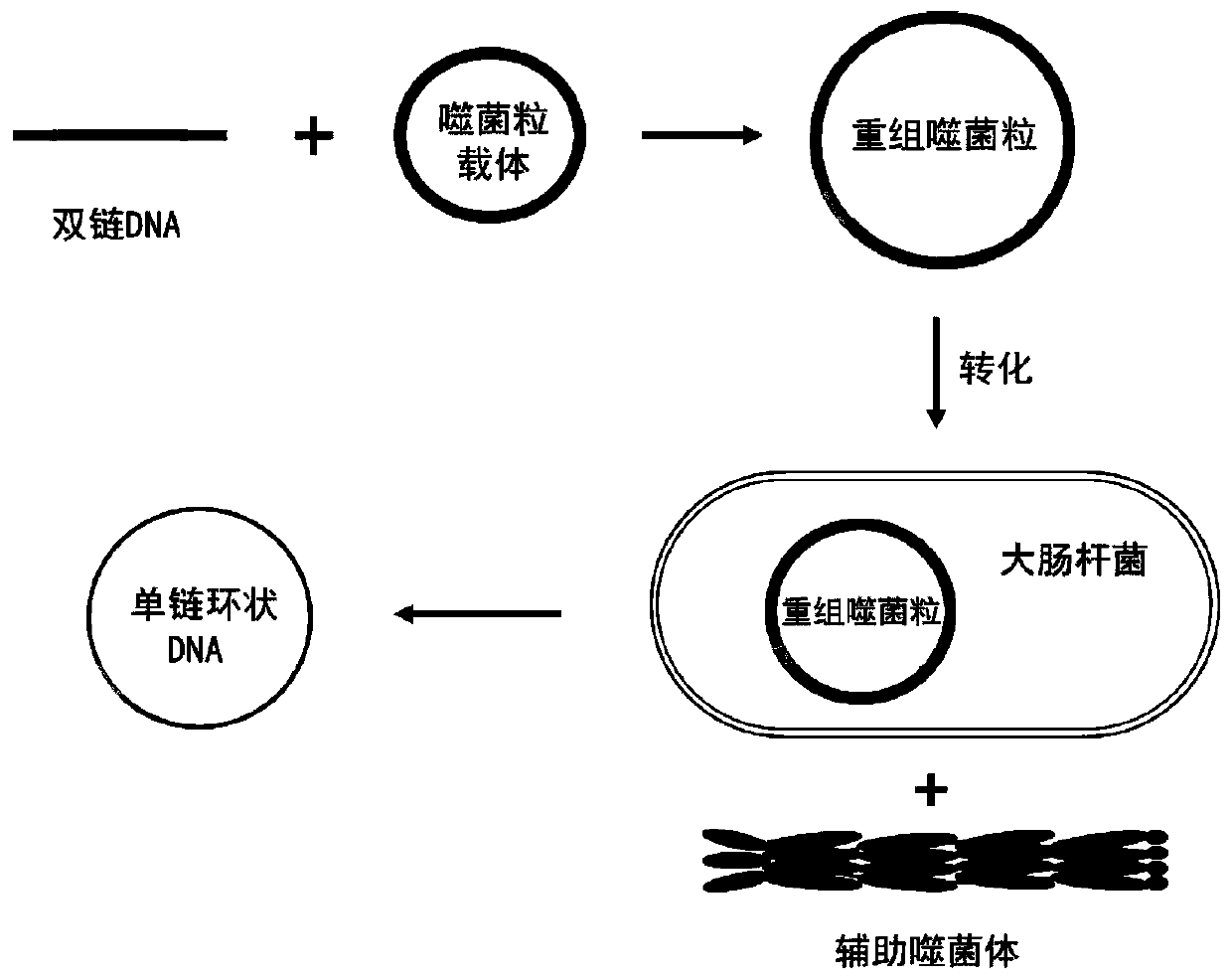

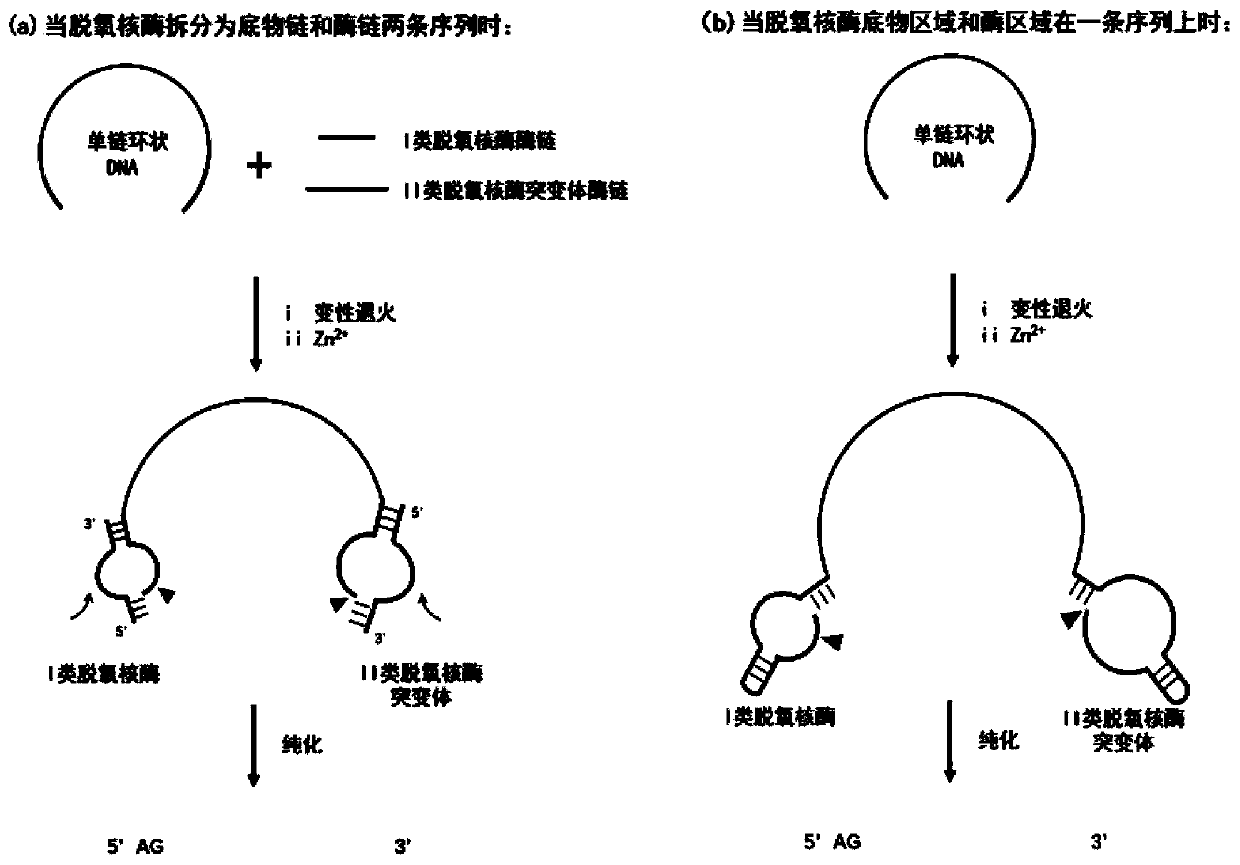

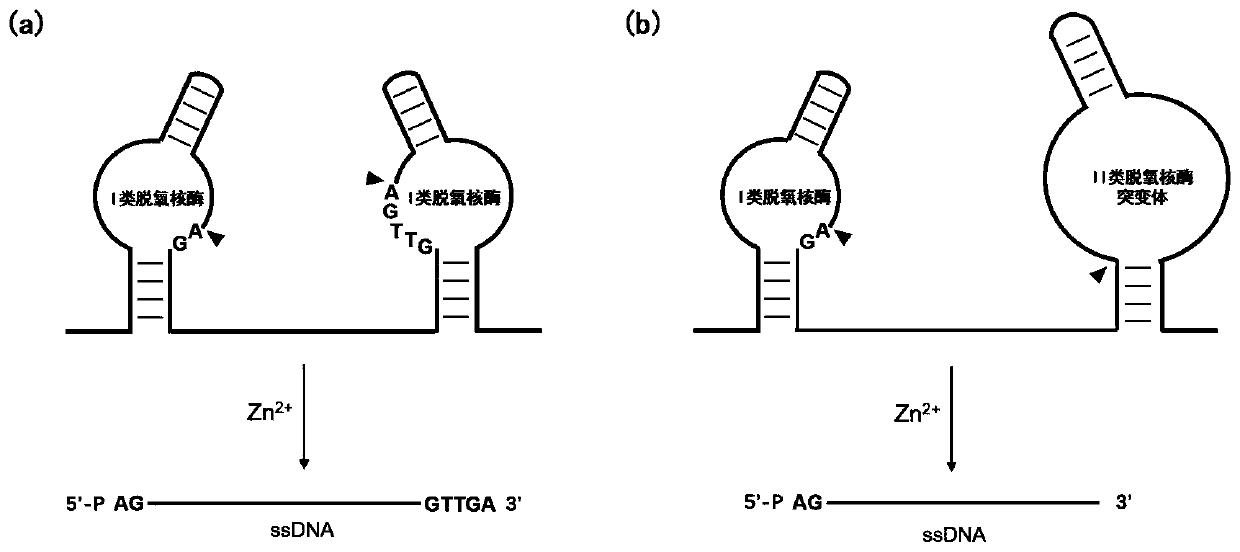

Preparation method of long single-chain DNA

The present invention discloses a method for efficiently preparing long single-chain DNA by means of class I and class II hydrolysable deoxyribozymes. The method mainly comprises steps of designing and constructing recombinant phagemids to obtain phagemid circular single-chain DNA, at the same time, the class I deoxyribozyme and class II deoxyribozyme mutants are used to cut the circular single-chain DNA, and the long single-chain DNA is obtained by purifying, recovering and enzyme digestion. The two types of the deoxyribozymes capable of rapidly hydrolyzing DNA are used to replace restrictionendonucleases, the preparation method realizes specific cleavage of the prepared DNA sequences by an assisted phage method in a low cost manner, and the single-chain DNA with any length and sequencesis prepared in a large amount, economic and high-purity manner.

Owner:FUNDAN UNIVERSITY SHANGHAI CANER CENTER

Equipment used for cutting polyvinyl chloride (PVC) pipe

InactiveCN105234979AGood cutting effectIngenious designMetal working apparatusUnit/actuationGear drive

The invention discloses equipment used for cutting a polyvinyl chloride (PVC) pipe. The equipment comprises a rotary shaft, a saw blade, a driven gear, two supporting frames, two sliding rods, two installation plates, a rack, two clamps and a driving unit. According to the equipment for cutting the PVC pipe, the pipe is clamped through the clamps, the installation plates are driven to move through the driving unit, then the rack, the driven gear and an external gear drive the rotary shaft and the saw blade to rotate, the saw blade is used for cutting the pipe, and the cutting effect is good. The driving unit drives the clamps to move and meanwhile drives the saw blade to rotate, the design is ingenious, and the structure is simplified. An annular groove is formed in each supporting rod, the saw blade is used for cutting the pipe in the annular groove areas, and the supporting rods are used for supporting the to-be-cut part of the pipe, so that the situation that the pipe is concaved during cutting, and the cutting quality is affected is avoided. The equipment used for cutting the PVC pipe is simple in structure and convenient to use.

Owner:安徽宁国市高新管业有限公司

Ice knife cutting method

InactiveCN107932755AGood cutting effectImprove efficiencyWorking accessoriesStone-like material working toolsWater recoveryWater pipe

The invention discloses a method for cutting ice blades, which includes making ice blades, storing ice blades, launching and cutting ice blades, which are respectively realized by an ice blade making device, an ice blade storage device and an ice blade launching device; the ice blade making device and the ice blade storage device A first conveying device is arranged between them, a second conveying device is arranged between the skate storage device and the skate launching device; a cutting table is arranged on one side of the skate launching device, and a cutting table is arranged below the cutting table. A filter recovery device, the filter recovery device communicates with the ice blade making device through a water pipe. The beneficial effect is that the device can sequentially realize the production, storage and launch of ice blades, and realize low-temperature cutting at room temperature by using the material of the high-speed ice blade device, which has good cutting effect and high efficiency; meanwhile, the crushed ice after cutting is recovered and recycled by the filter recovery device. Utilization can help save water resources and other technical effects.

Owner:湖南三五二环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com