Processing cutting tool

A technology for machining tools and cutting, which is used in wood processing appliances, manufacturing tools, rotary cutting tools, etc. It can solve the problem that the compromise solution is not always satisfactory, and achieve good cutting results, prolong service life, and reduce tool heads. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

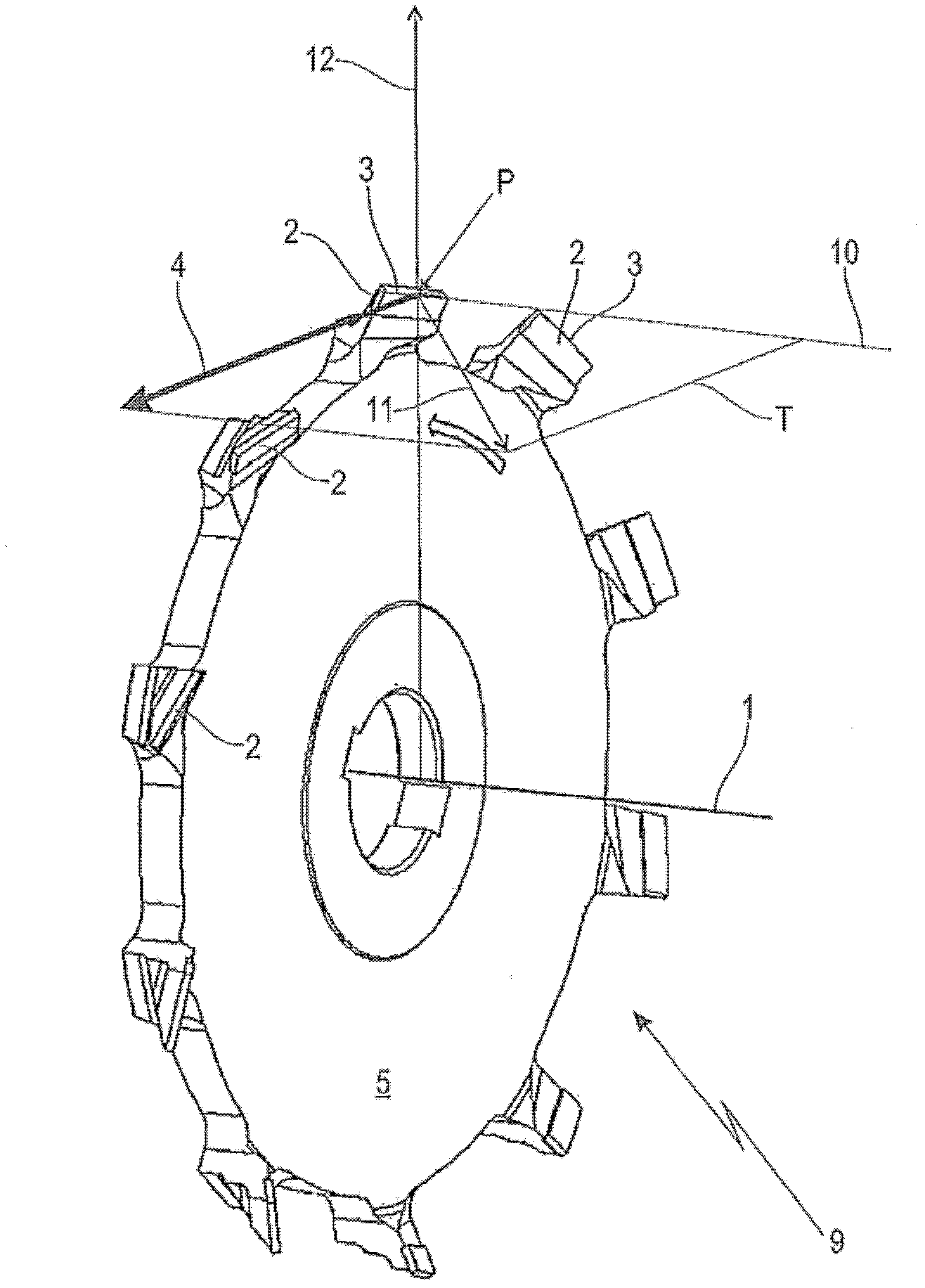

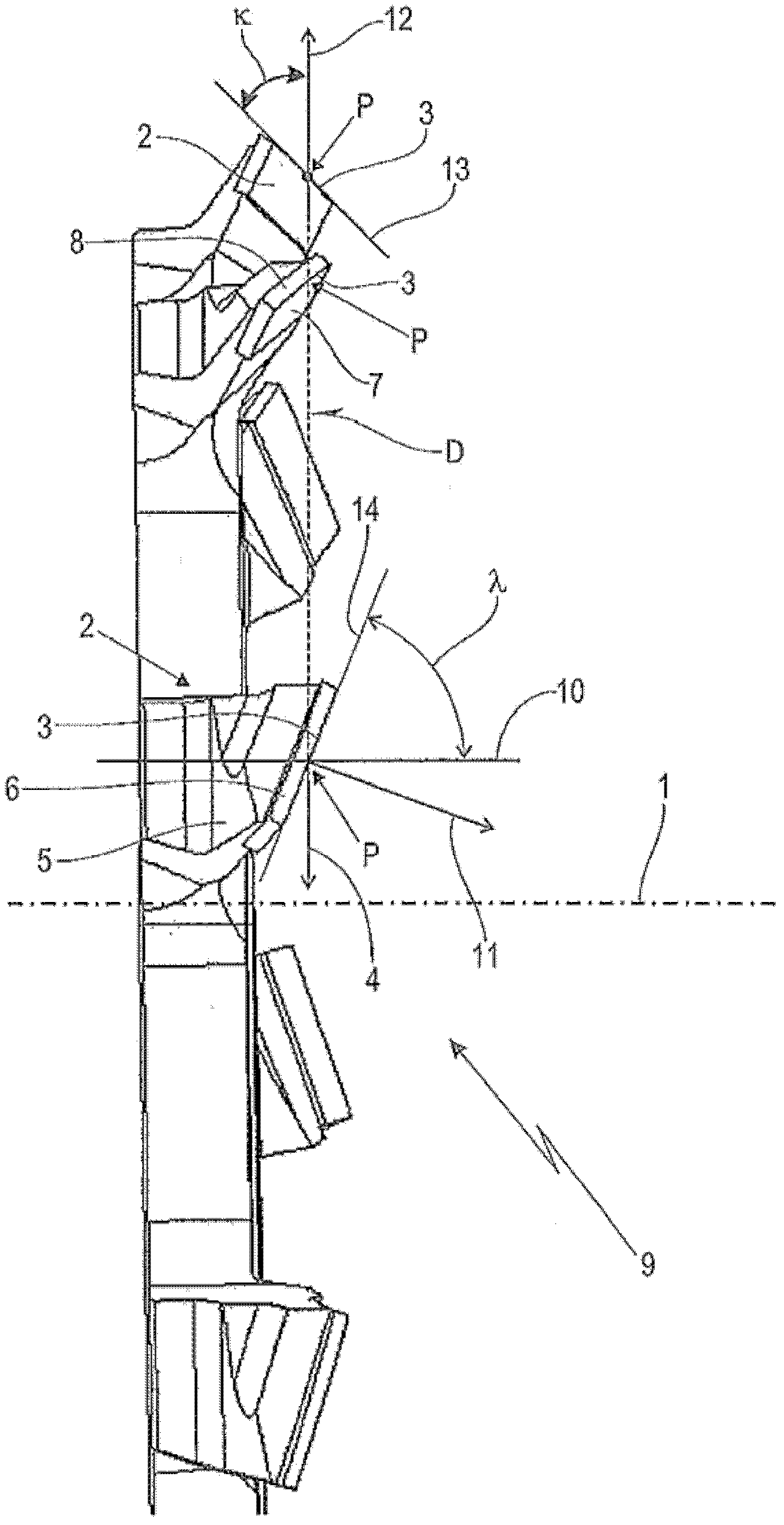

[0027] figure 1 An exemplary embodiment of a machining tool 9 according to the invention for material removal is shown in a perspective view, here the illustrated embodiment is provided for cutting wood or wooden materials. However, embodiments for any other material like especially metal, plastic and / or composite materials may also be suitable.

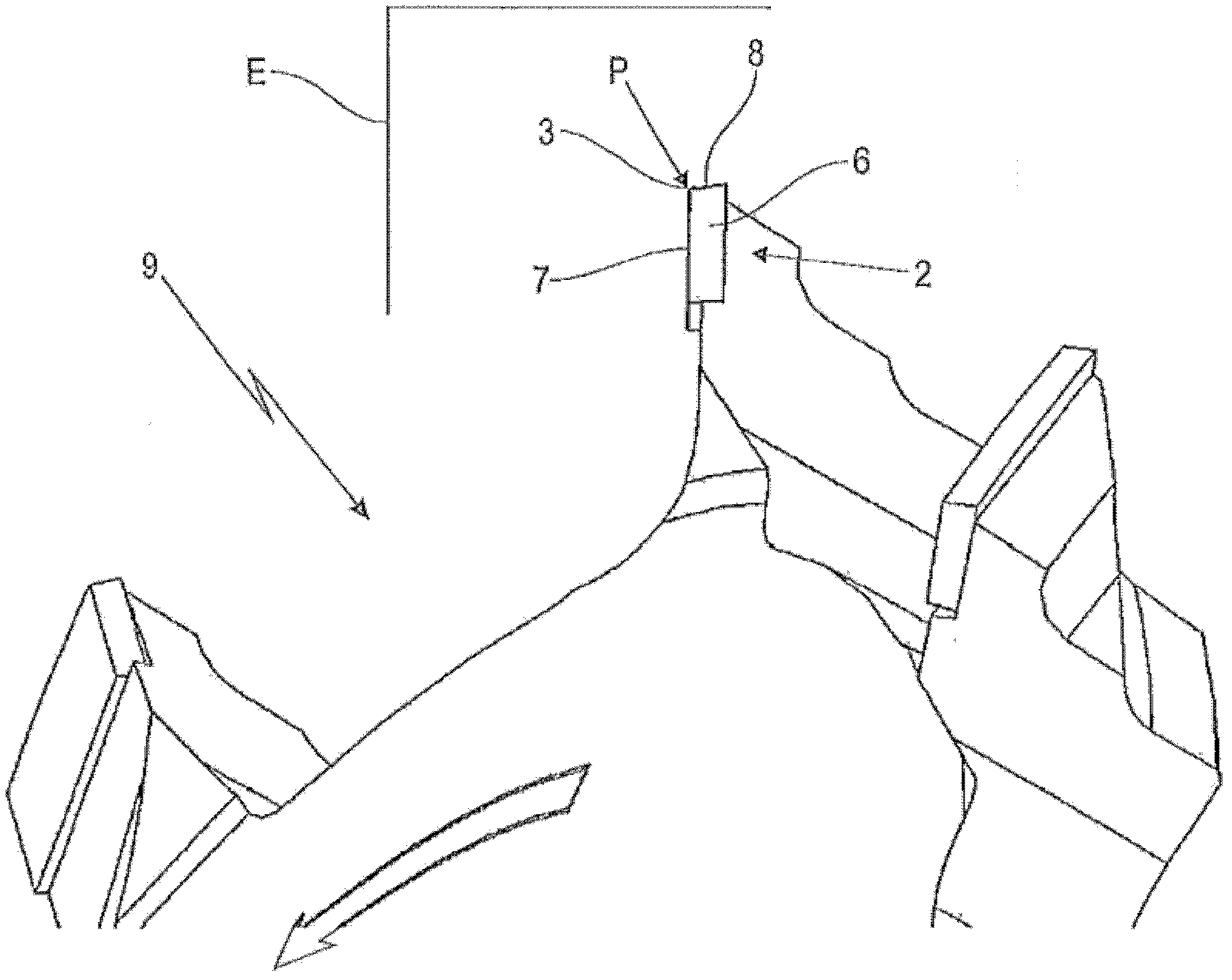

[0028] The machining tool 9 is provided for being driven in rotation about an axis of rotation 1 and for this purpose has a disk-shaped main body 5 , in the peripheral region of which a plurality of cutting heads 2 each having a cutting edge 3 are arranged. At least one cutter head is provided. In the illustrated embodiment, ten cutter heads 2 are evenly distributed around the body 5 .

[0029]Along each individual cutting edge 3 any point P can be chosen as a reference point. Starting from the axis of rotation 1 , a radial direction 12 passes through each point P of the cutting edge 3 . Due to the rotational movement of the mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com