Equipment used for cutting polyvinyl chloride (PVC) pipe

A PVC pipe and equipment technology, applied in metal processing and other directions, can solve the problem of unsatisfactory cutting effect, etc., and achieve the effect of good cutting effect, convenient use and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

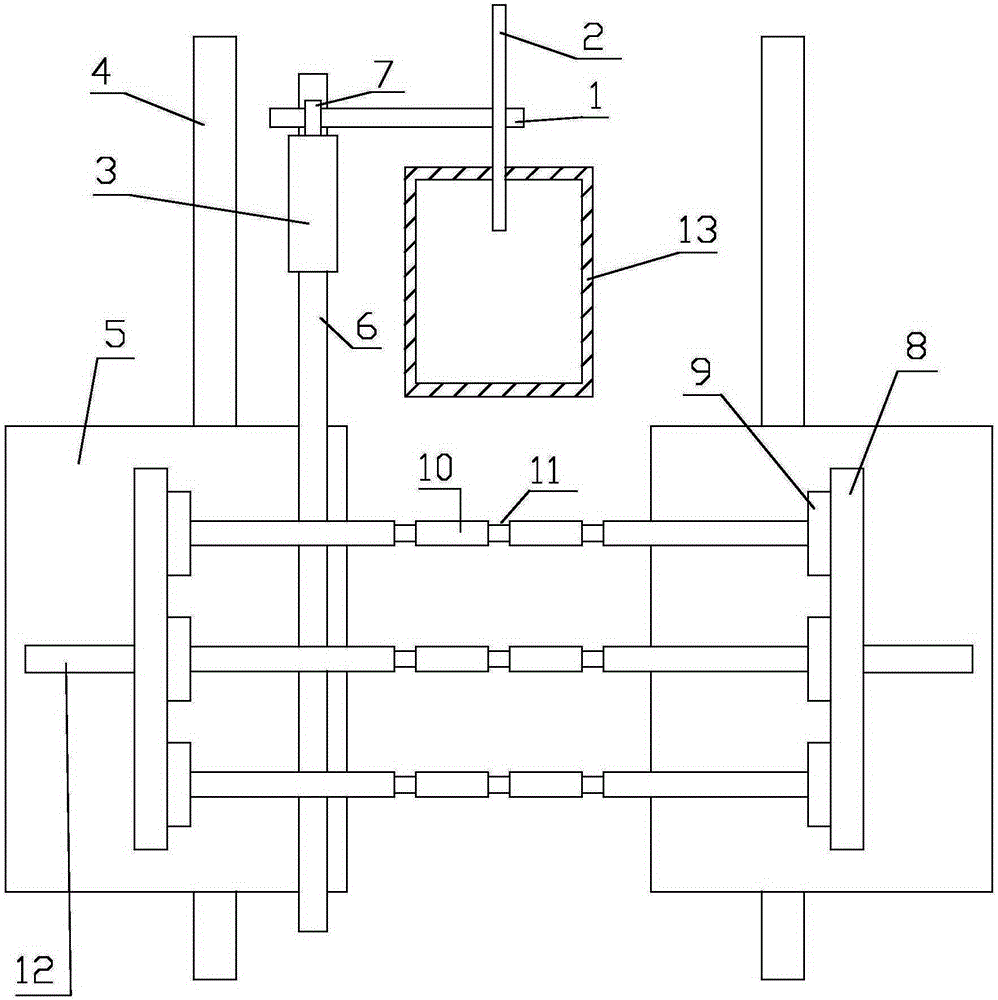

[0024] refer to figure 1 :

[0025] The present invention proposes a kind of equipment for cutting PVC pipes, including a rotating shaft 1, a saw blade 2, a driven gear 3, two brackets, two sliding rods 4, two mounting plates 5, racks 6, and two clamps , a drive unit, N support rods 10, and a collection box 13.

[0026] The axis of the rotating shaft 1 is arranged horizontally, and the rotating shaft 1 is provided with an external gear 7 , the axis of the external gear 7 coincides with the axis of the rotating shaft 1 .

[0027] The saw blade 2 is installed on the rotating shaft 1 , and the axis of the saw blade 2 coincides with the axis of the rotating shaft 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com