Patents

Literature

42results about How to "Avoid compromising cut quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

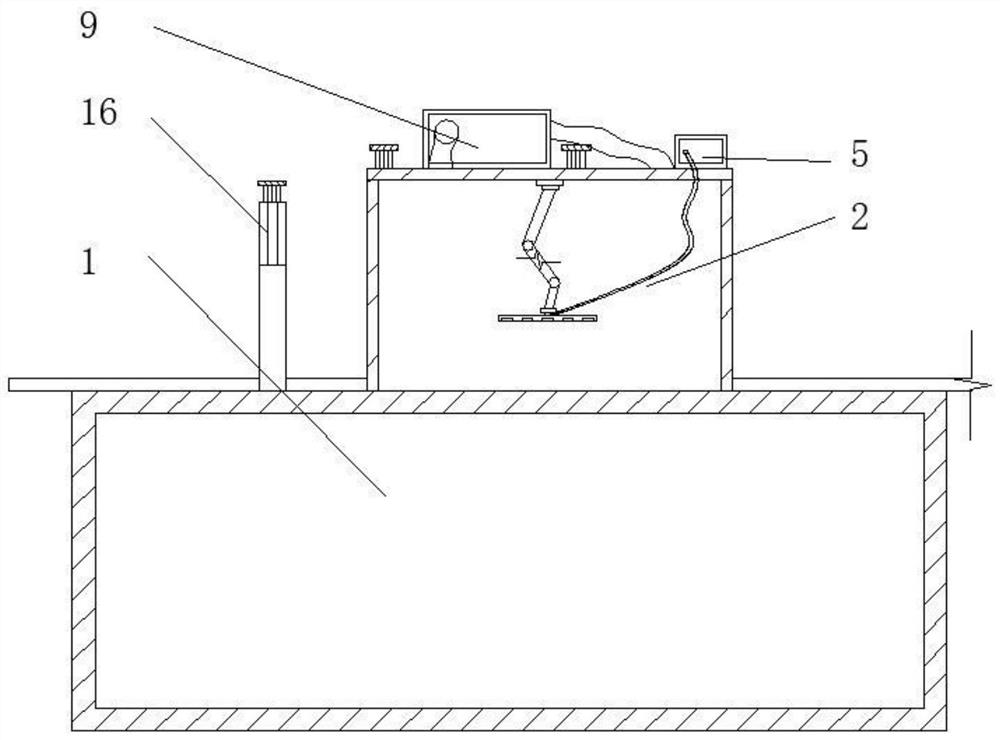

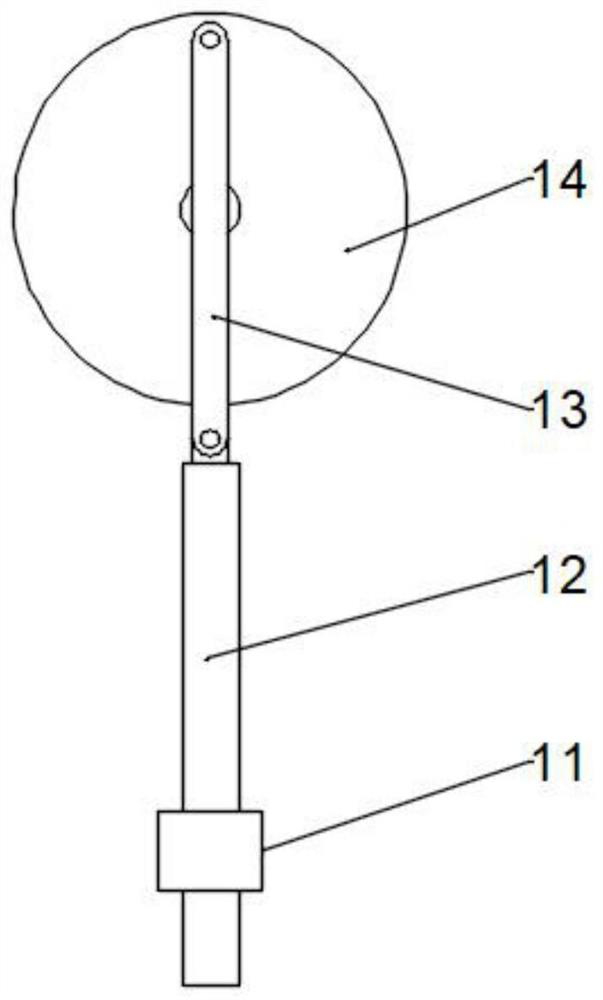

Cutting machine for producing chemical fiber

PendingCN107127804ASolve the problem of mildew affecting cuttingAvoid compromising cut qualityDrying gas arrangementsMetal working apparatusFiberSlag

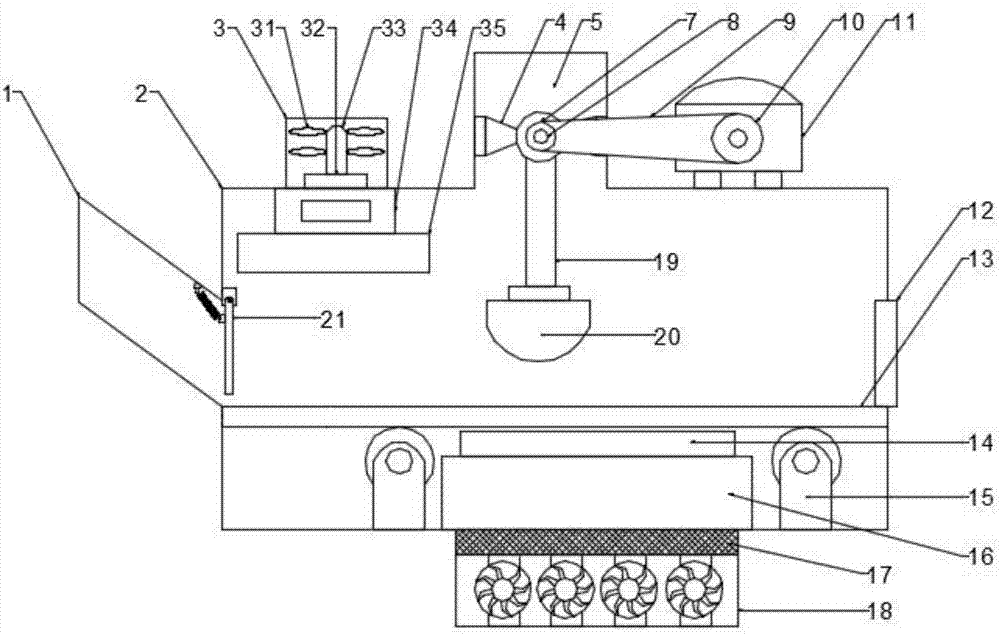

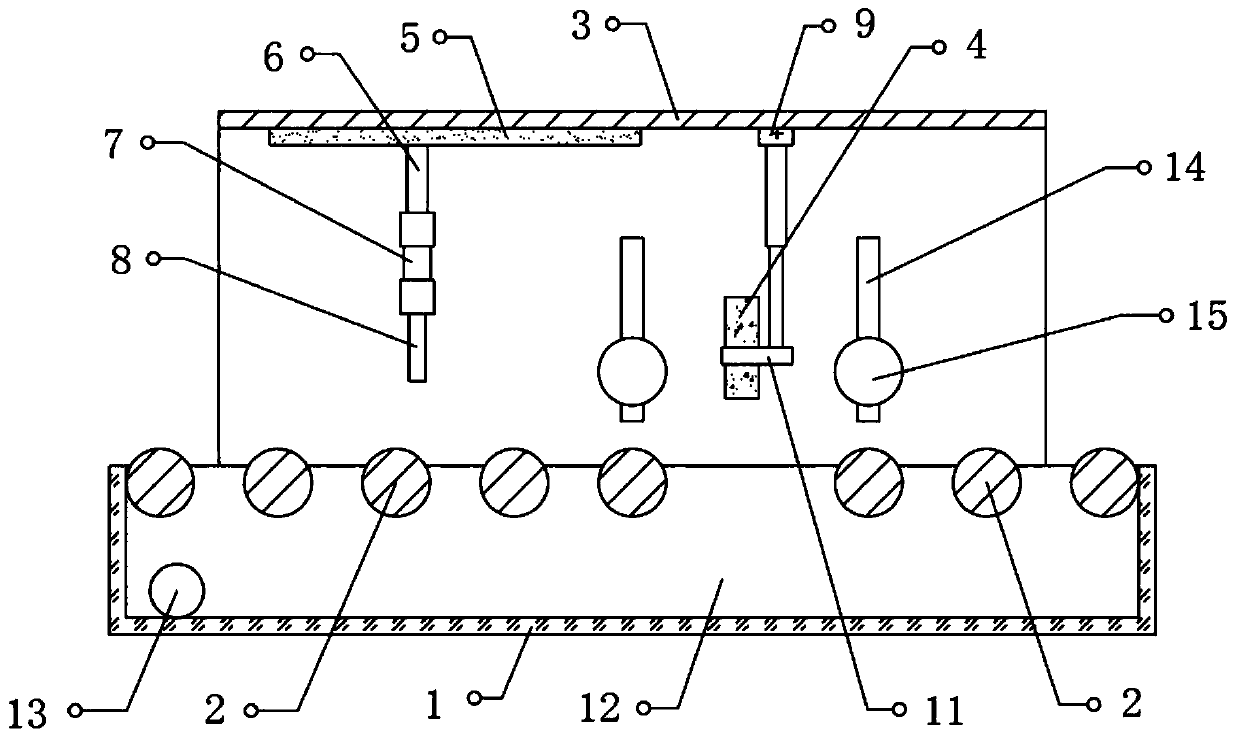

The invention discloses a cutting machine for producing a chemical fiber. The cutting machine comprises a cutting machine body, wherein a chemical fiber inlet pipe is arranged at the left side of the cutting machine body; a cutting device is arranged at the top of the cutting machine body; a rotating shaft is arranged in the cutting device and is provided with fixed sleeves which are arranged in an array; a fixed rod is arranged at the lower ends of the fixed sleeves; a cutting head is fixed at the lower end of the fixed rod; a conveyor belt is arranged on the cutting machine body at the lower end of the cutting device; a dust absorption cup is arranged at the lower end of the conveyor belt; a dust collection box is arranged at the lower end of the dust absorption cup; a filtering and adsorption net is fixed at the lower end of the dust collection box; and a ventilation device is arranged at the lower end of the filtering and adsorption net. According to the cutting machine for producing the chemical fiber, adjustment of the cutting length is facilitated, and the problem that the quality is affected due to the fact that chemical fiber slag generated in the cutting process of the chemical fiber is mixed into the cut chemical fiber can be effectively solved.

Owner:贵港市益福美农资有限公司

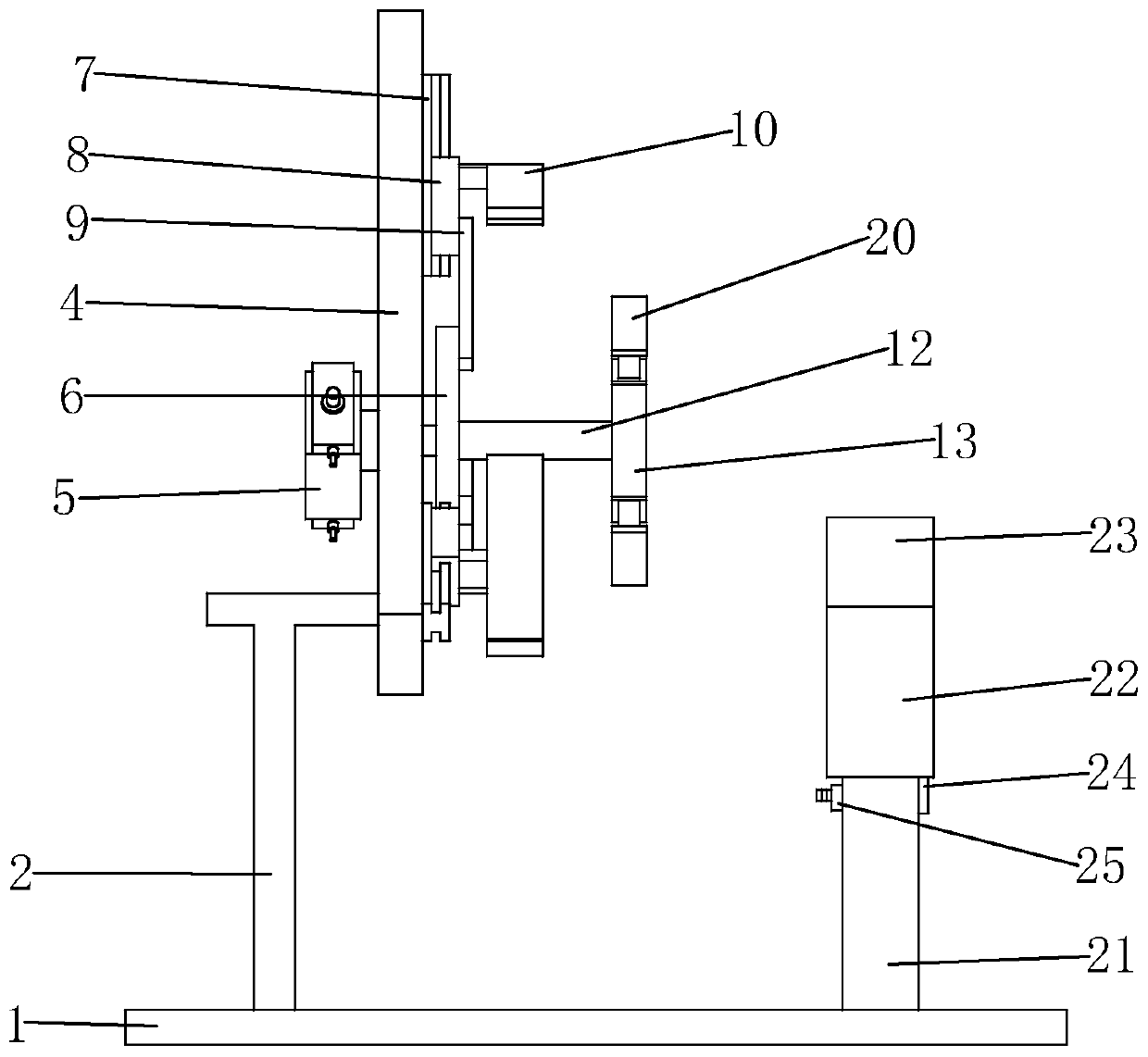

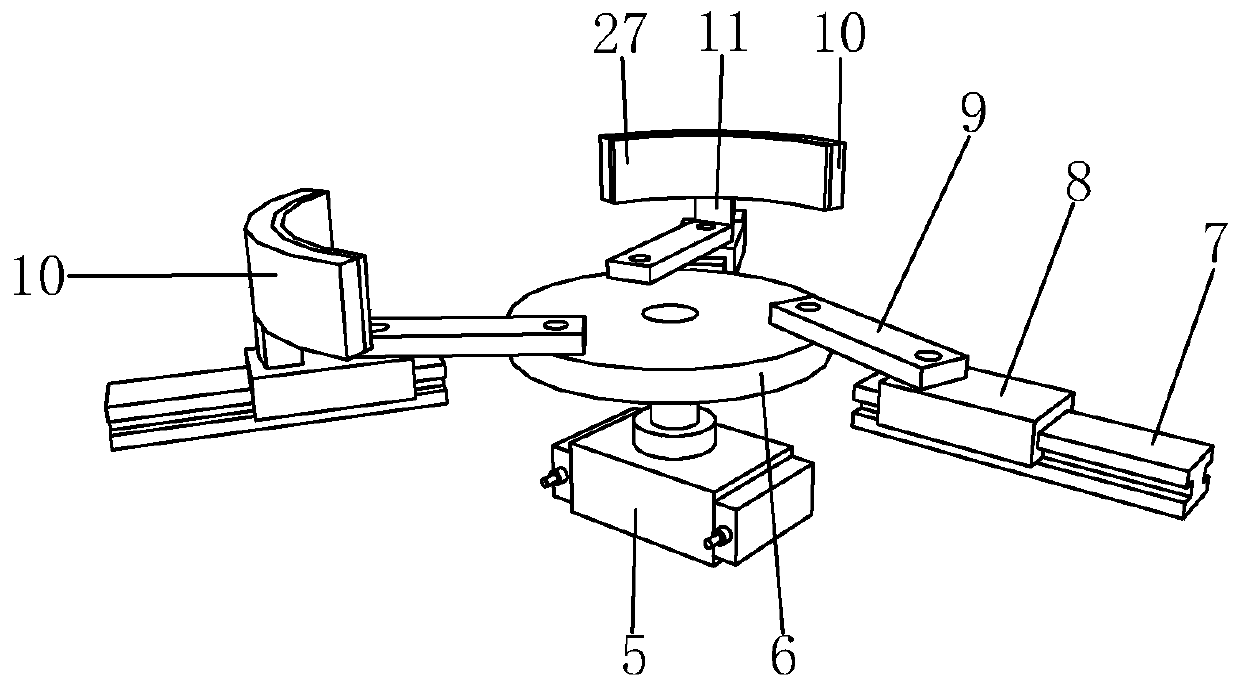

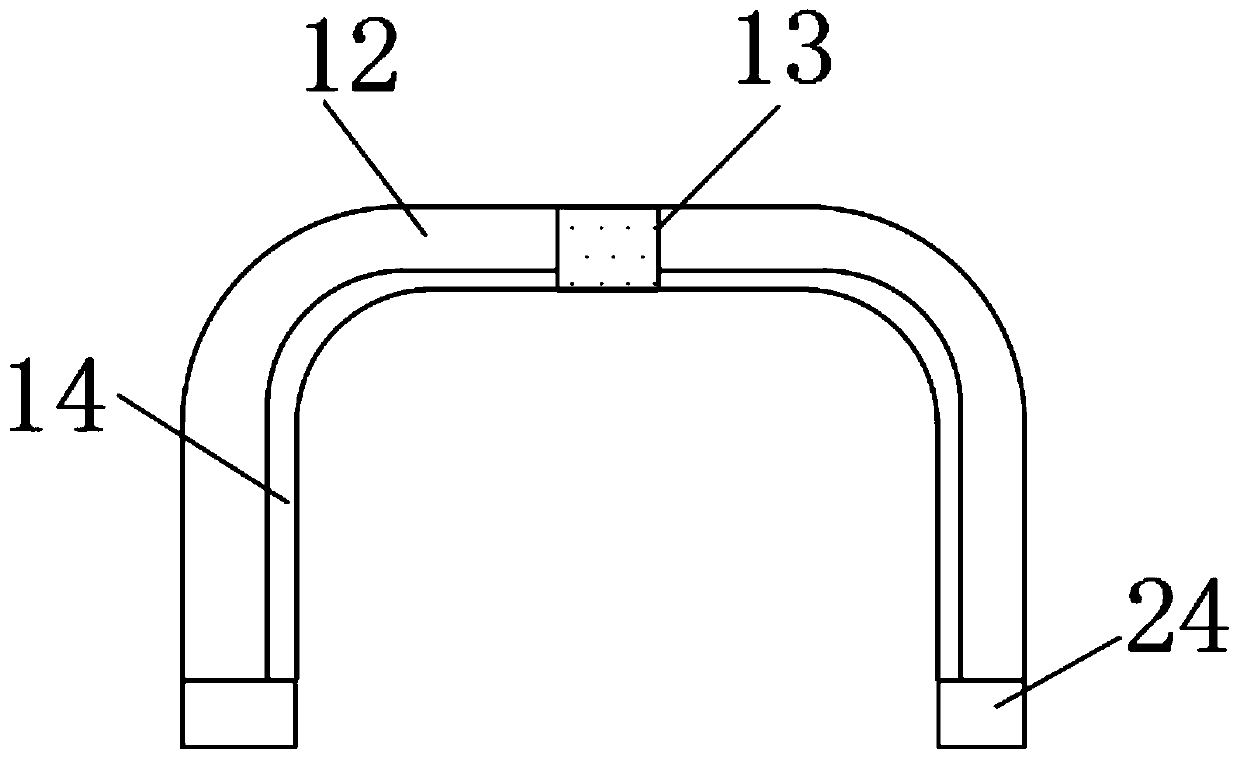

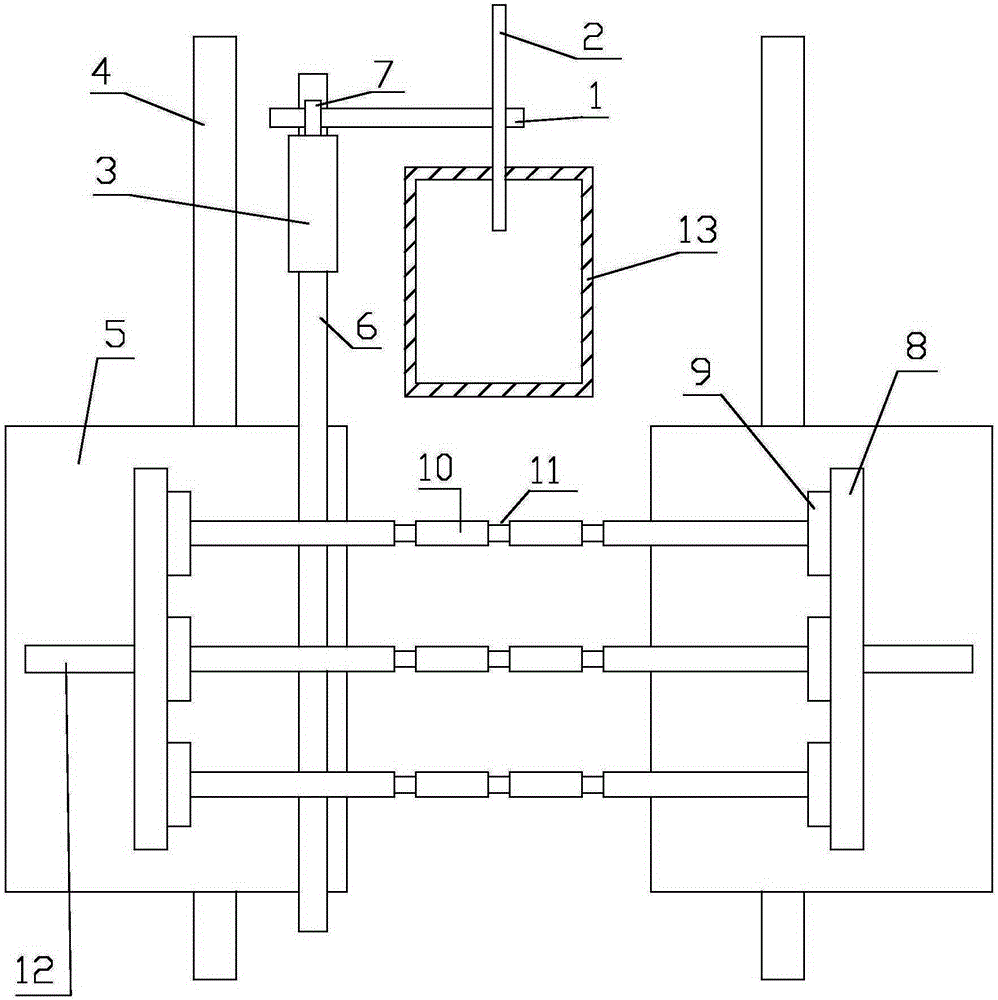

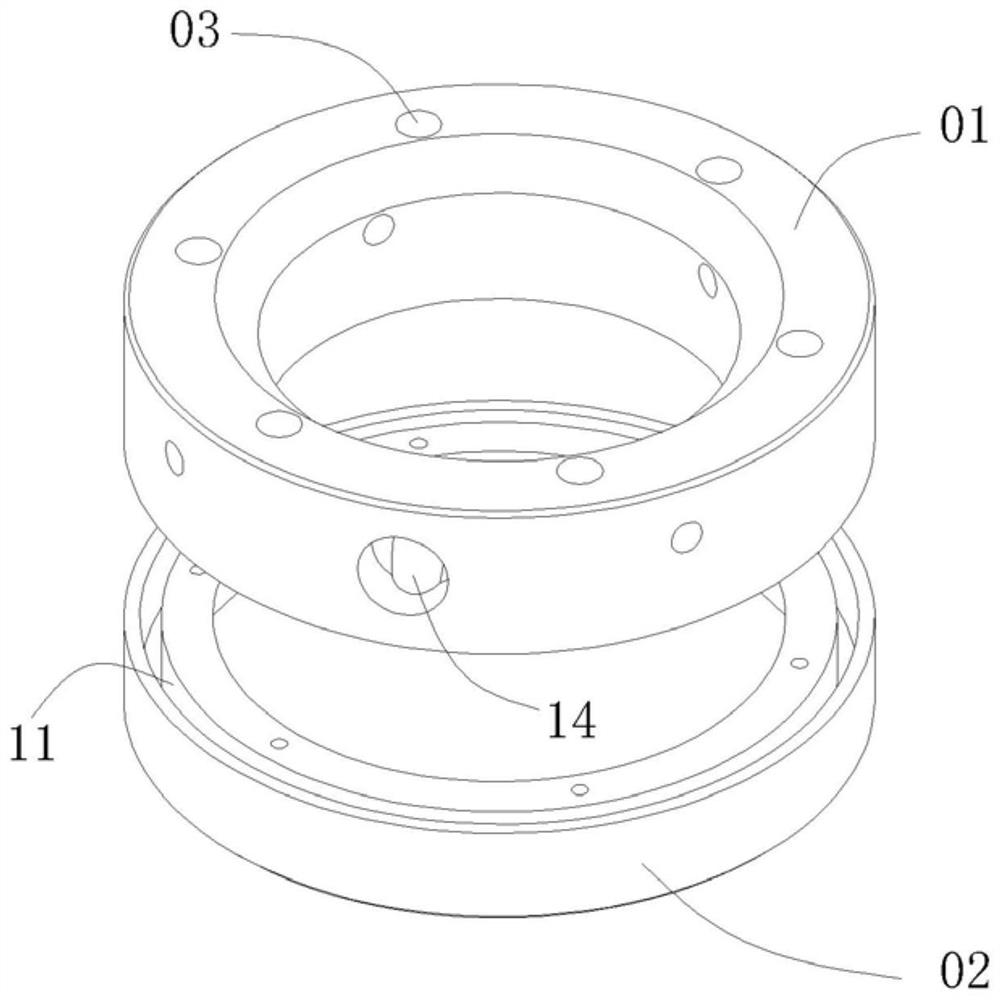

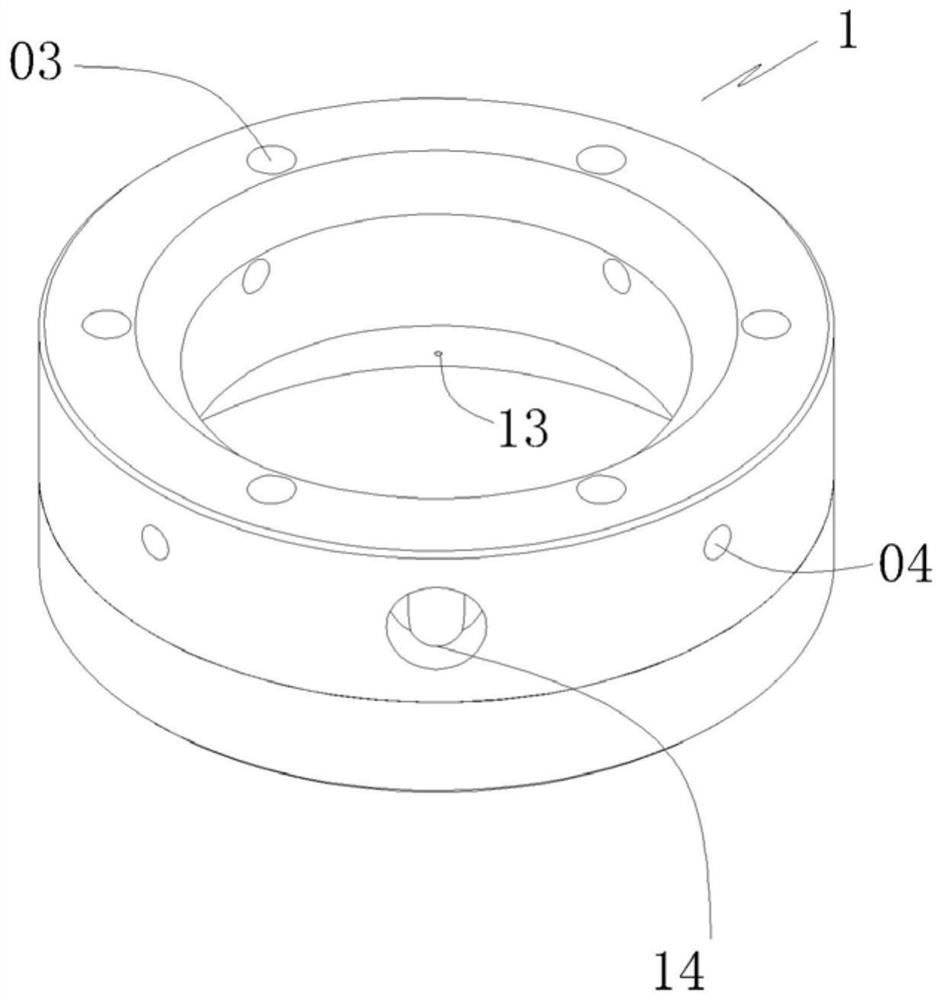

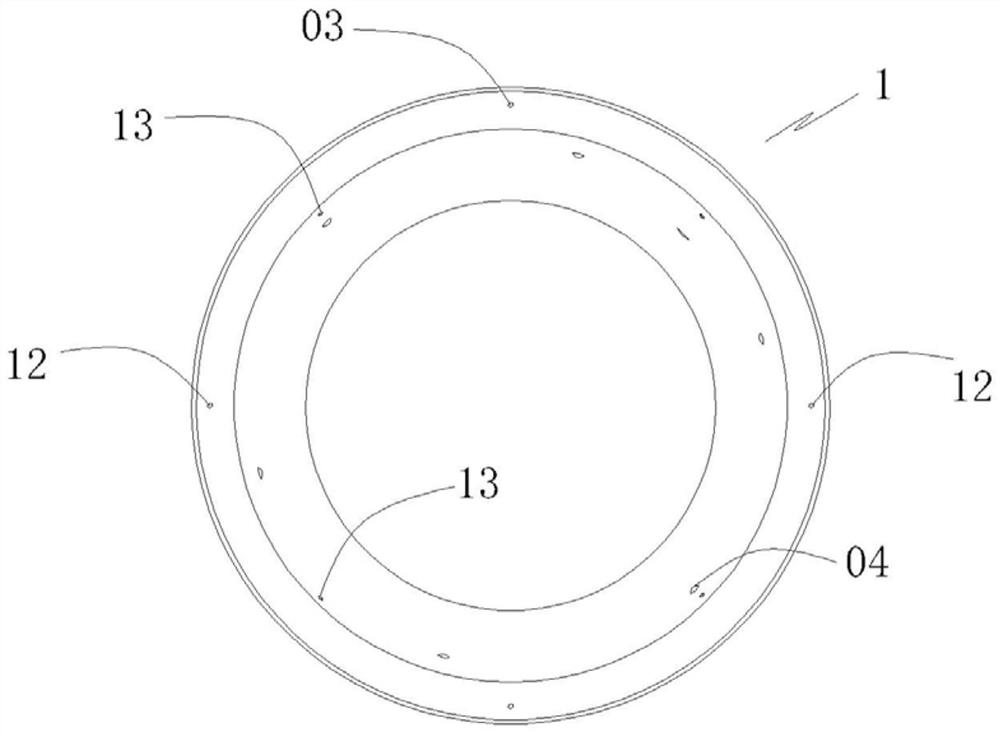

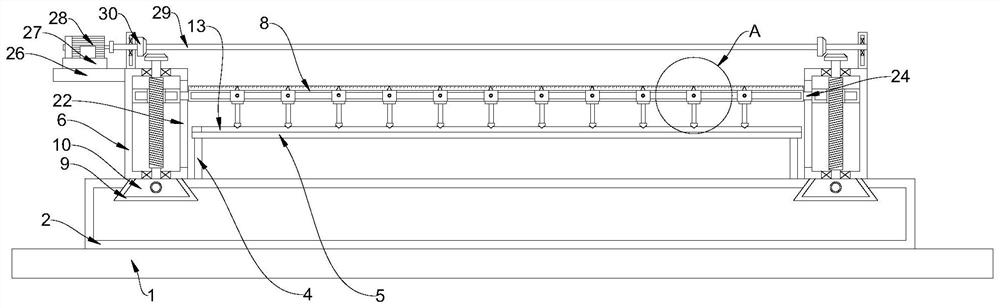

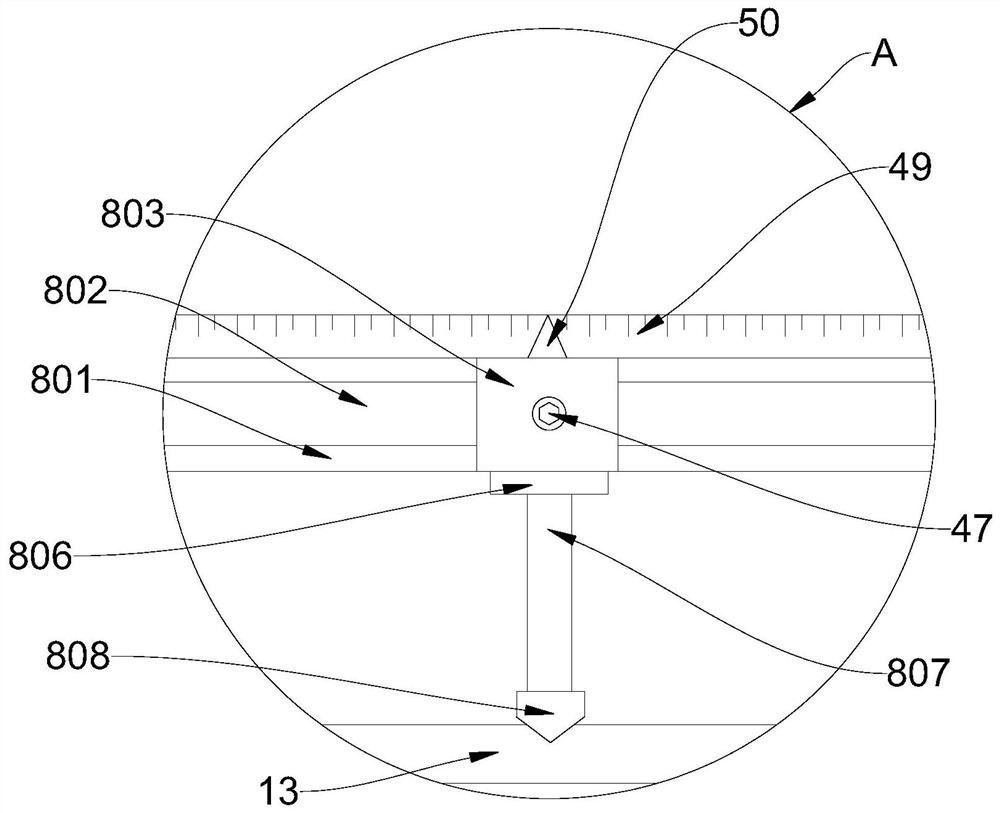

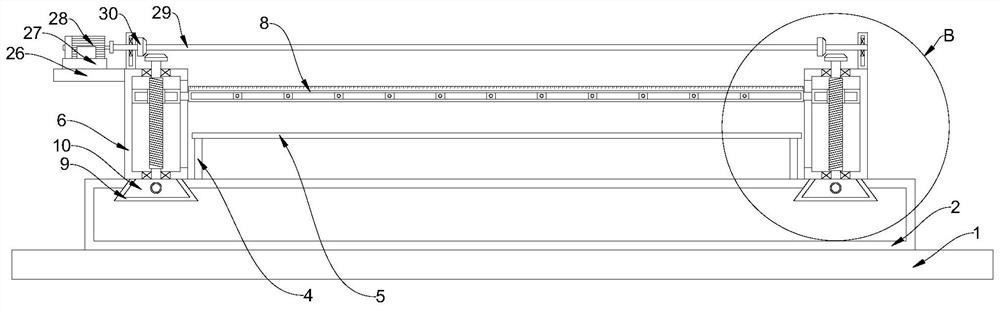

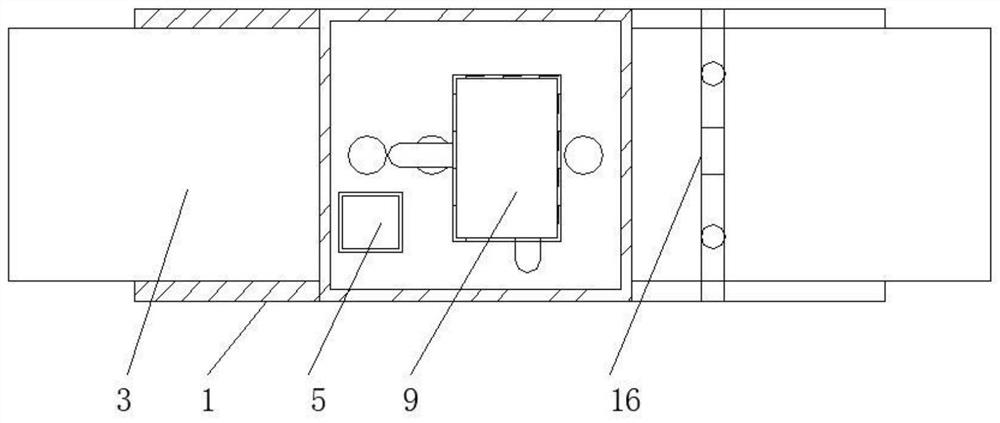

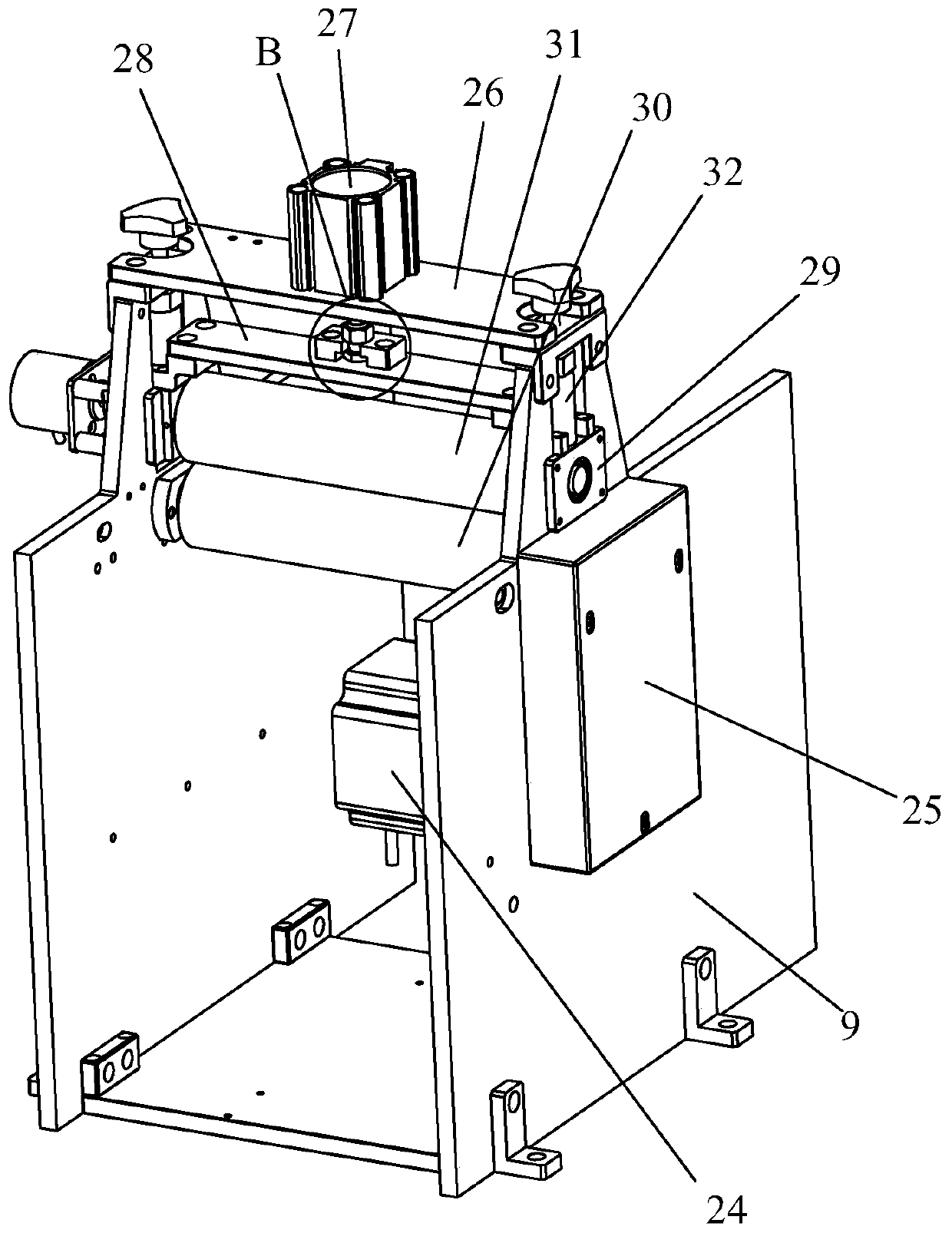

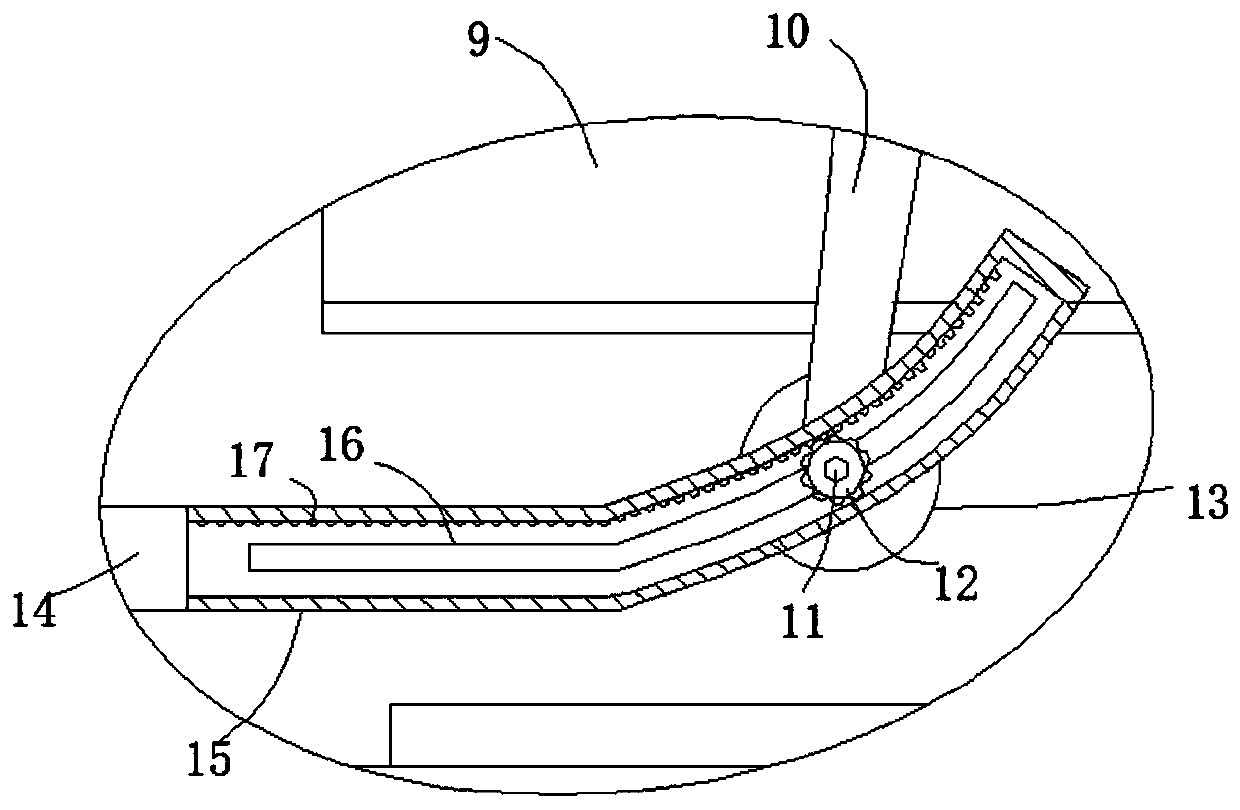

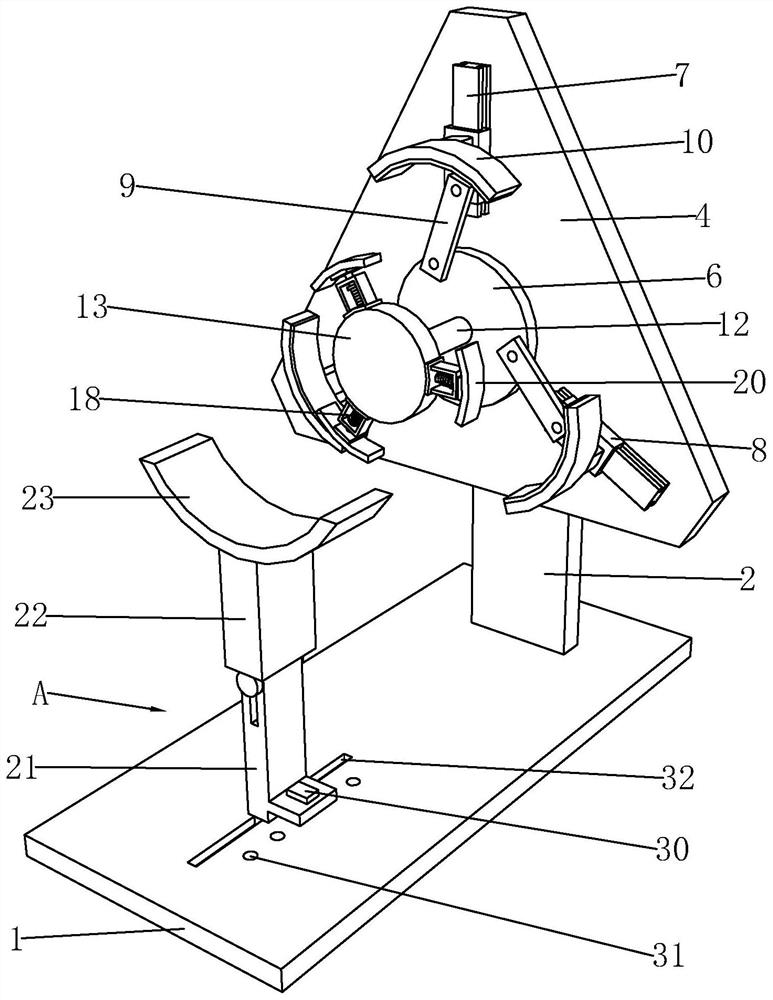

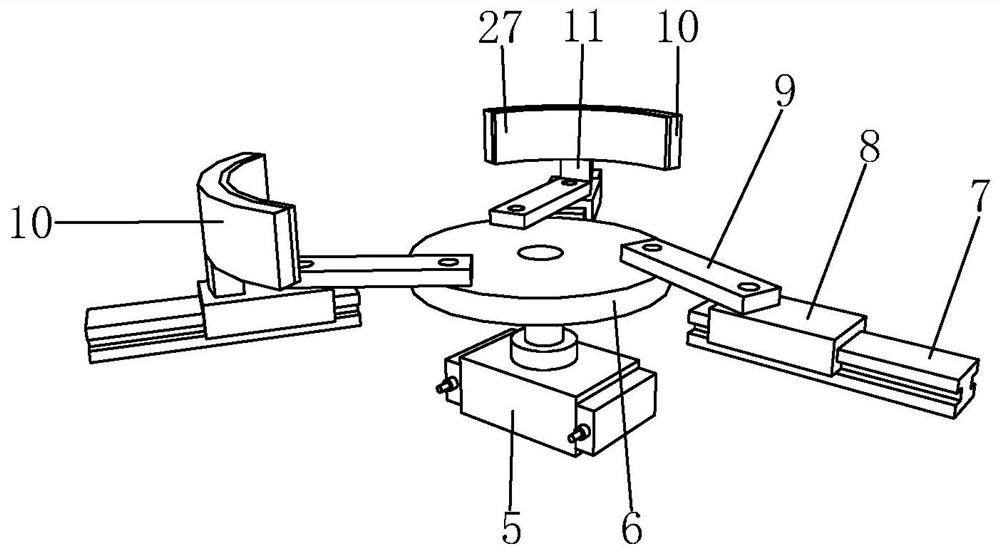

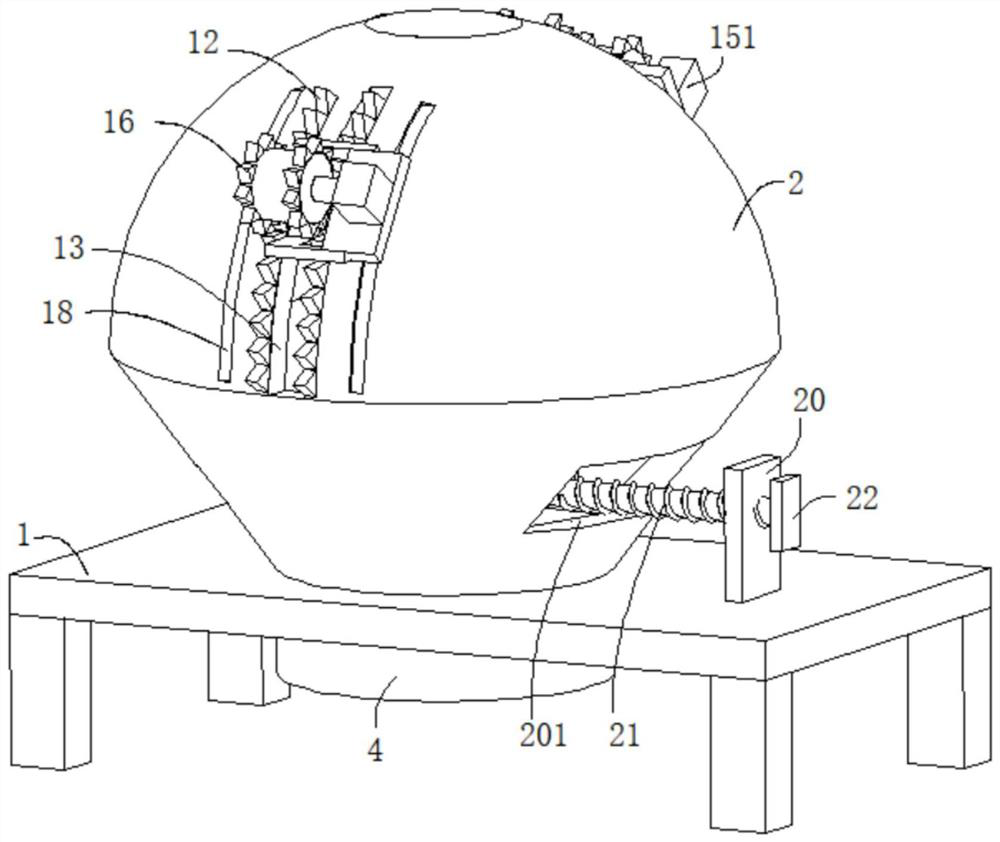

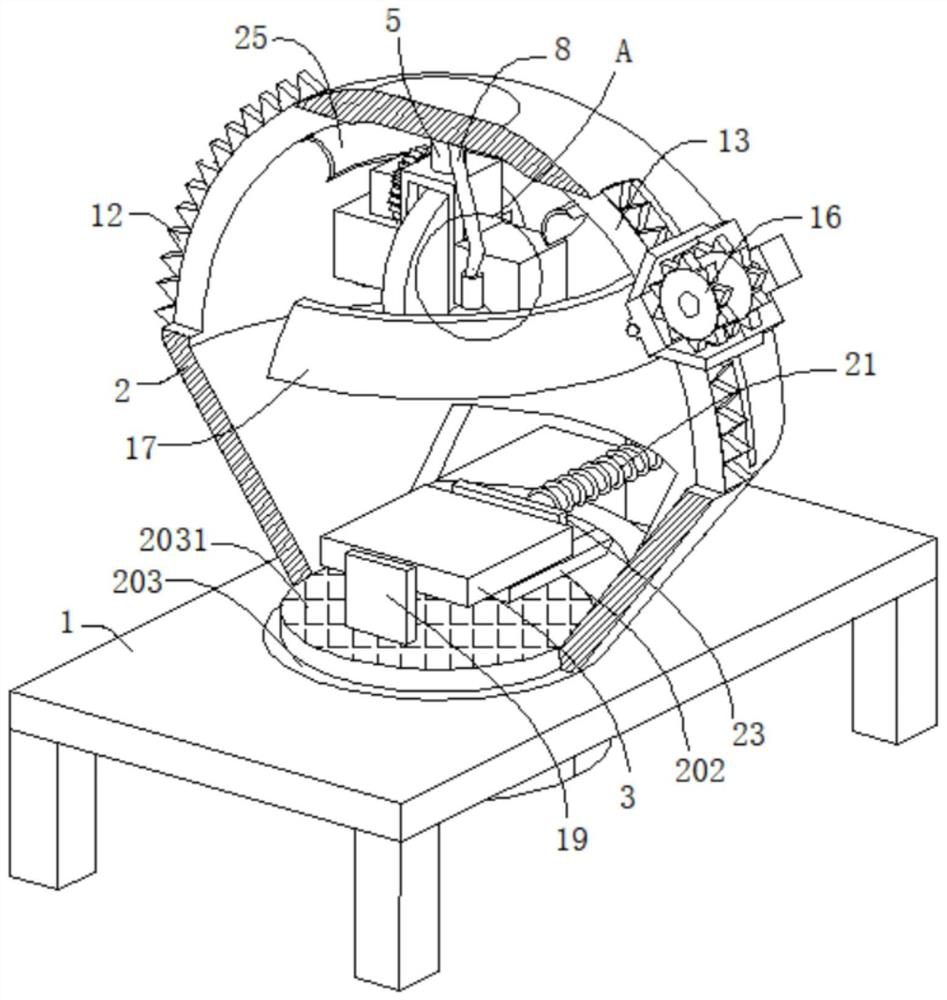

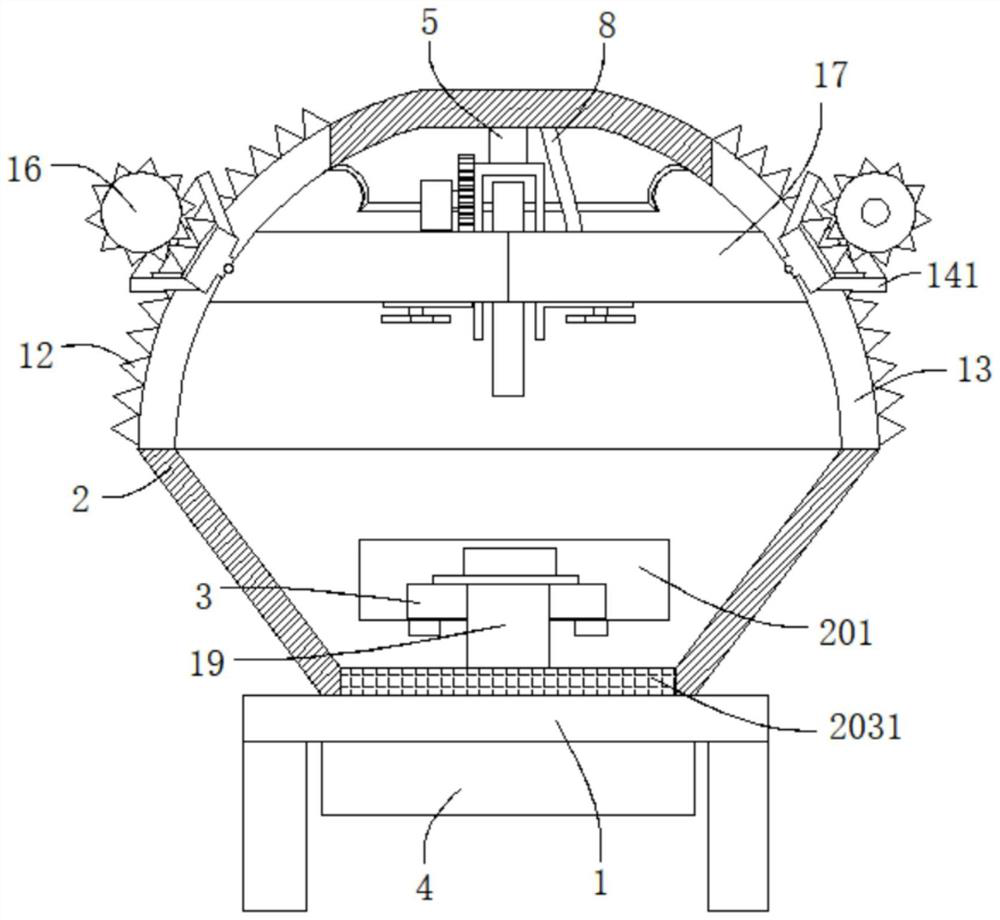

Operation table for cutting hardware pipe fitting

ActiveCN110450115AFlexible position adjustmentChange contact positionWork benchesPipe fittingArchitectural engineering

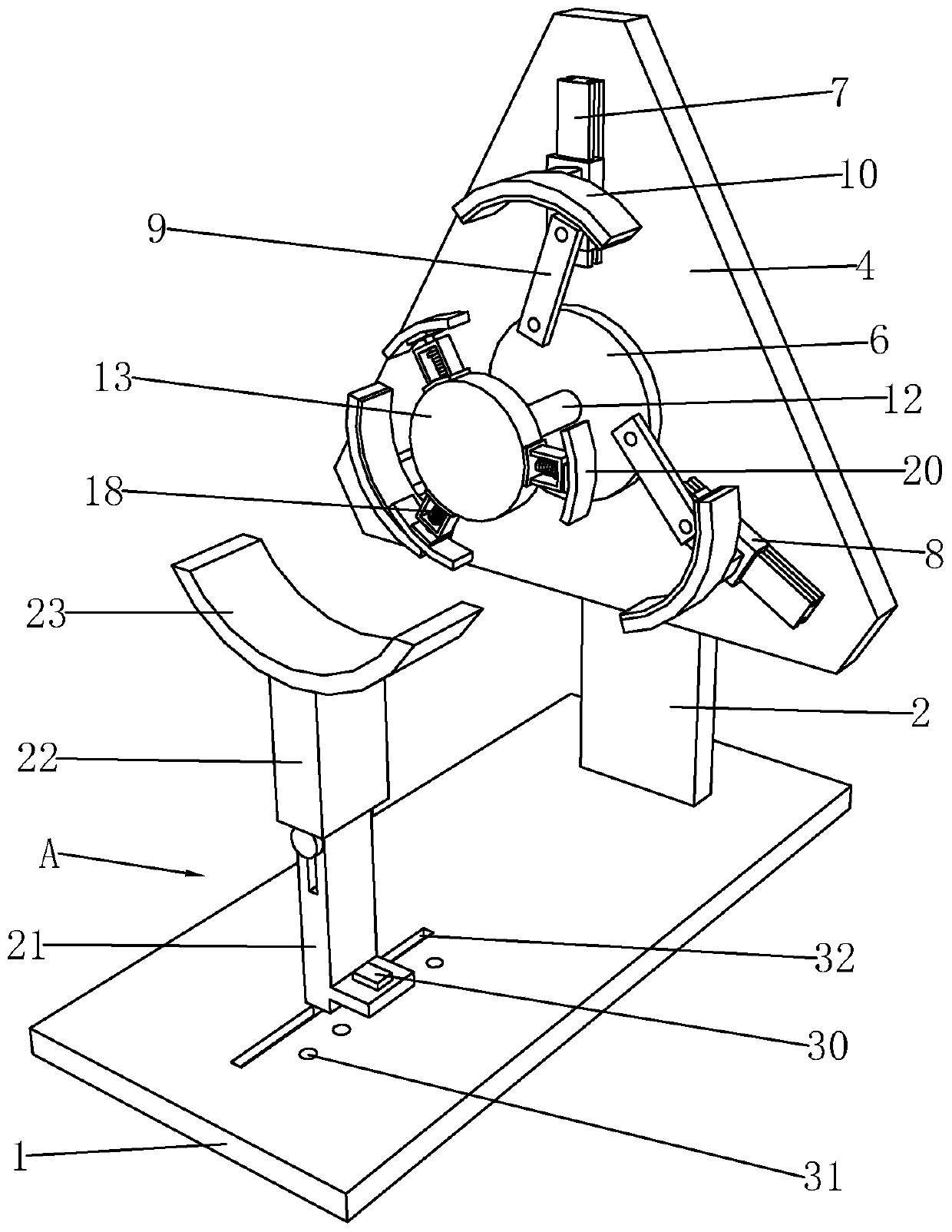

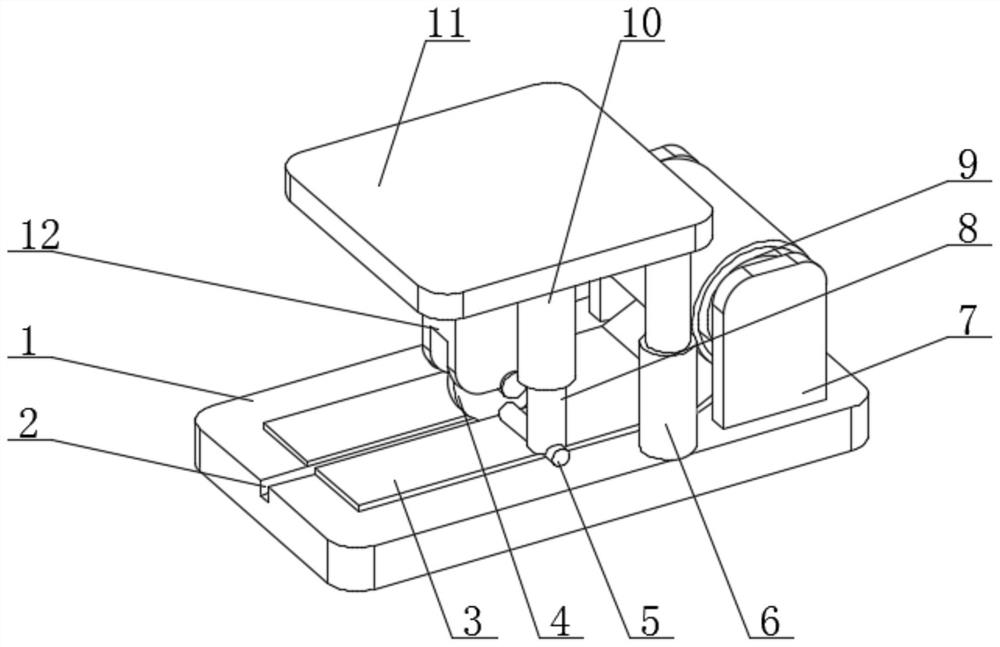

The invention discloses an operation table for cutting a hardware pipe fitting. The table comprises a supporting platform, wherein the supporting platform is provided with a bracket and a lifting frame, the bracket is provided with a mounting plate, the mounting plate is provided with a rotating air cylinder, a rotating disc and fixed guide rails, the rotating air cylinder is connected with the rotating disc, and the fixed guide rails are distributed around the center of the rotating disc; the fixed guide rails are slidably connected with guide blocks, wherein the portion between each guide block and the rotating disc is connected with a corresponding transmission rod, each transmission rod is connected with the eccentric position of the rotating disc, and the fixed guide rails are provided with arc-shaped clamping plates; the center of the rotating disc is provided with a fixed rod, wherein one end of the fixed rod is provided with a positioning disc, elastic seats are distributed around the positioning disc, and each elastic seat is provided with a corresponding arc-shaped pressing plate; and the lifting frame is close to the positioning disc, wherein the top end of the lifting frame is provided with an arc-shaped supporting plate. The operation table for the cutting hardware pipe fitting has the advantages of being novel in structure, suitable for cutting operation of hardware pipe fittings of different pipe diameters, wide in applicable range, and stable and reliable in placement, and accordingly cutting quality can be improved.

Owner:朱泽鹏

Machining-stable steel structure cutting device

InactiveCN110369803AImprove clamping effectImprove cutting effectPositioning apparatusMaintainance and safety accessoriesDrive motorEngineering

The invention provides a machining-stable steel structure cutting device, and relates to the technical field of steel structure machining. The machining-stable steel structure cutting device comprisesa support base; the top of the support base is connected with an electric push rod; the top of the electric push rod is connected with a support plate; a suspended frame box is mounted in the bottomcenter of the support plate; a driving motor is bolted to the bottom of the inner wall of the suspended frame box; and a cutting blade is welded on an output shaft of the driving motor. In the machining-stable steel structure cutting device, when the cutting blade is descended for cutting, steel structures can be fixedly clamped by lateral clamping blocks, and the clamping effect is improved by springs, so that the cutting effect of the steel structures is improved, and the influence on the cutting quality by shaking in the cutting process is prevented; meanwhile, no manual operation is neededin the clamping operation, so that the operation is more convenient; and the cutting places can be cooled in the cutting process, so that the influence on the cutting blade and the cutting places ofthe steel structures by high temperature is prevented, and the cutting quality is improved.

Owner:重庆宝高实业有限公司

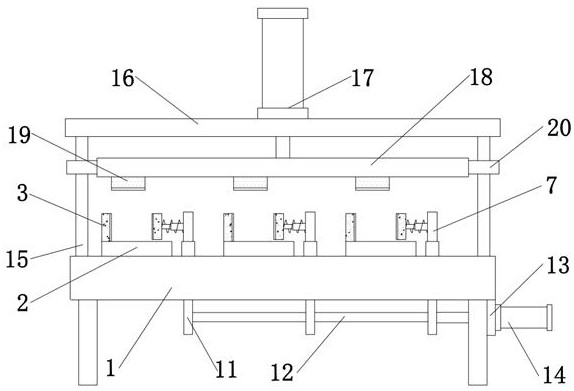

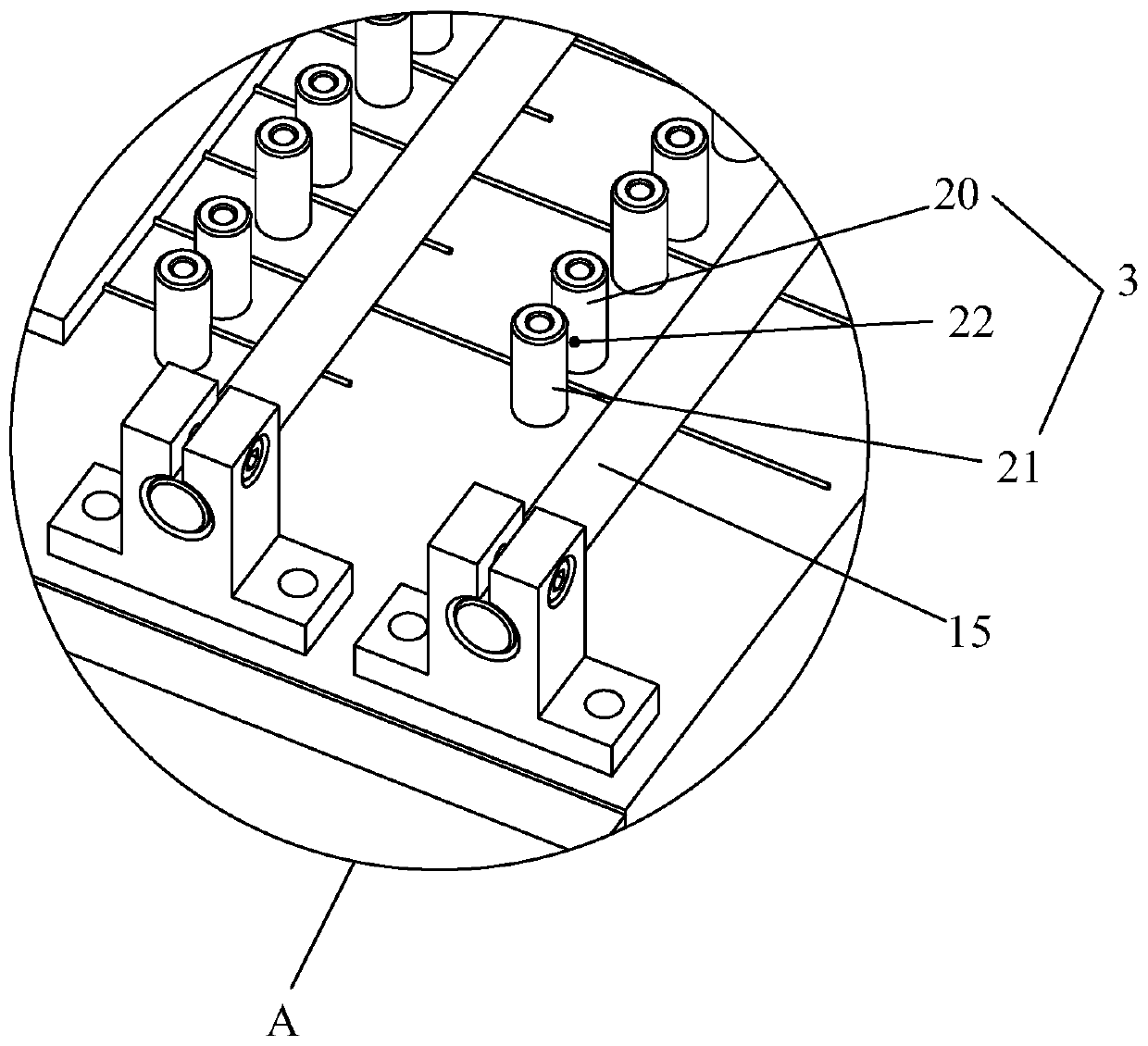

Aluminum profile cutting multi-station profile machining tool

InactiveCN111975415ARelieve pressureAvoid deformationPositioning apparatusMetal-working holdersClassical mechanicsStructural engineering

The invention relates to the technical field of aluminum profile machining, in particular to an aluminum profile cutting multi-station profile machining tool. The tool includes a working table, lowerpositioning seats are fixedly connected with the upper end of the working table, fixed limit plates are fixedly connected with the left sides of the upper ends of the lower positioning seats, rectangular groove holes are formed in the right sides of each group of the lower positioning seats on the working table, two groups of guide rods are fixedly connected in the rectangular groove holes, two groups of guide rods are connected with a moving seat together in a sliding mode, a side plate is fixedly connected with the upper end of the moving seat, two groups of expansion rods are fixedly connected with the left side of the side plate, and springs sleeve the outer sides of the expansion rods. According to the tool, profiles are compacted and fixed on the horizontal and vertical directions through the fixed limit plates, moving limit plates and upper positioning seats, the profiles are supported stably, the profiles are prevented from shaking during cutting so that the cutting quality isaffected, multiple groups of profiles are fixed and cut simultaneously, and the working efficiency can be improved.

Owner:郝海钧

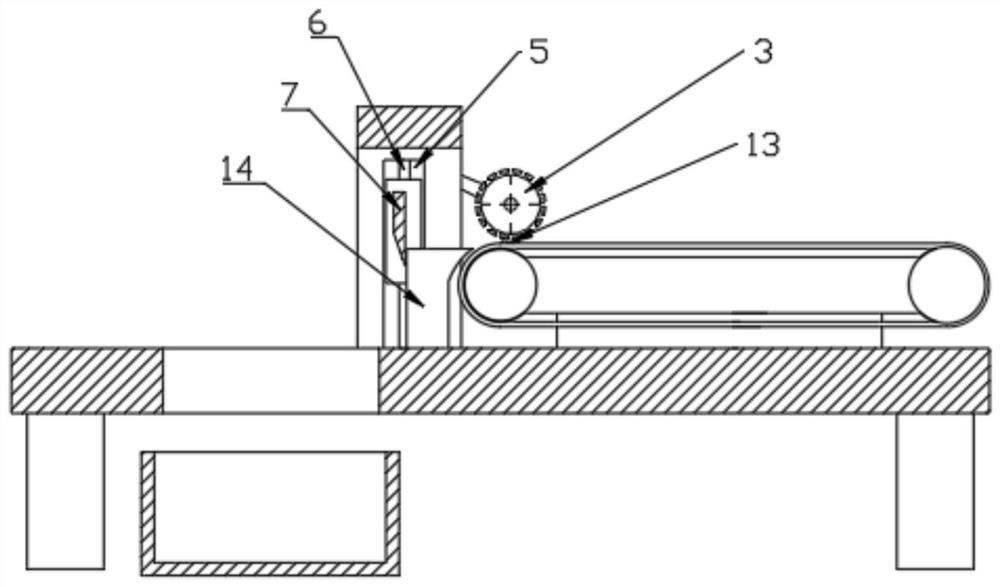

Equipment used for cutting polyvinyl chloride (PVC) pipe

InactiveCN105234979AGood cutting effectIngenious designMetal working apparatusUnit/actuationGear drive

The invention discloses equipment used for cutting a polyvinyl chloride (PVC) pipe. The equipment comprises a rotary shaft, a saw blade, a driven gear, two supporting frames, two sliding rods, two installation plates, a rack, two clamps and a driving unit. According to the equipment for cutting the PVC pipe, the pipe is clamped through the clamps, the installation plates are driven to move through the driving unit, then the rack, the driven gear and an external gear drive the rotary shaft and the saw blade to rotate, the saw blade is used for cutting the pipe, and the cutting effect is good. The driving unit drives the clamps to move and meanwhile drives the saw blade to rotate, the design is ingenious, and the structure is simplified. An annular groove is formed in each supporting rod, the saw blade is used for cutting the pipe in the annular groove areas, and the supporting rods are used for supporting the to-be-cut part of the pipe, so that the situation that the pipe is concaved during cutting, and the cutting quality is affected is avoided. The equipment used for cutting the PVC pipe is simple in structure and convenient to use.

Owner:安徽宁国市高新管业有限公司

A cooling water spray component for laser cutting, a spray device and a laser cutting machine

ActiveCN111230343BDoes not change the structureWill not affect normal workLaser beam welding apparatusEngineeringLaser cutting

Owner:株洲特装智能装备有限公司

Rapid cutting equipment for glass curtain wall and cutting method of the rapid cutting equipment

PendingCN112939437ABatch cutting is fast and efficientAdjustment works preciselyGlass severing apparatusManufacturing engineeringMechanical engineering

The invention discloses rapid cutting equipment for a glass curtain wall and a cutting method of the rapid cutting equipment, relates to the technical field of glass curtain wall cutting, and aims to solve the problems that an existing glass curtain wall plate is generally cut manually through a glass cutting knife to form scratches, only one glass panel can be cut through one-time operation when the cutting knife is used for cutting, but a high number of the glass curtain wall plates are required, and time is consumed during batch processing. A fixing seat is fixedly arranged on the upper end face of a base, connecting seats are fixedly arranged at the front end and the rear end of the fixing seat, the connecting seats are fixedly connected with the base, four supporting rods are fixedly arranged above the fixing seat, and a placing plate is fixedly arranged above the four supporting rods. First fixing boxes are arranged on the two sides of the placing plate correspondingly. Second fixing boxes are arranged above the connecting seats, and cutting mechanisms are arranged between the first fixing boxes and between the second fixing boxes correspondingly.

Owner:江苏华幕建筑科技有限公司

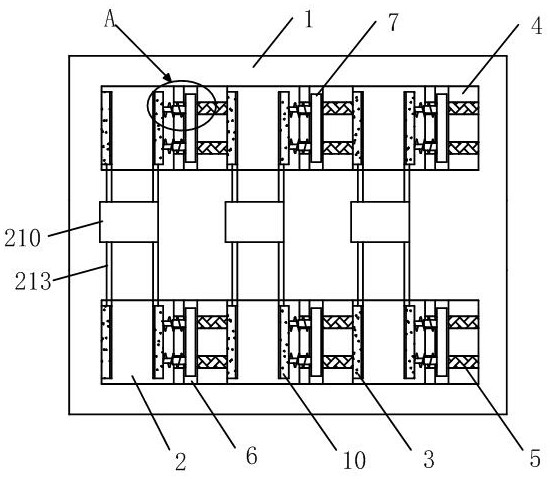

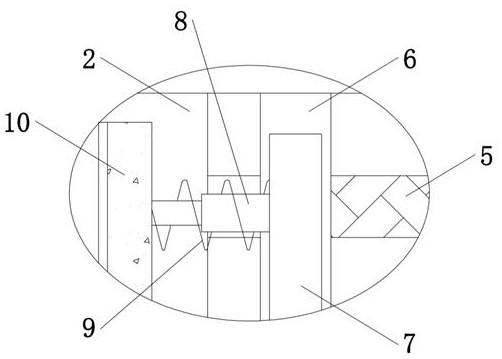

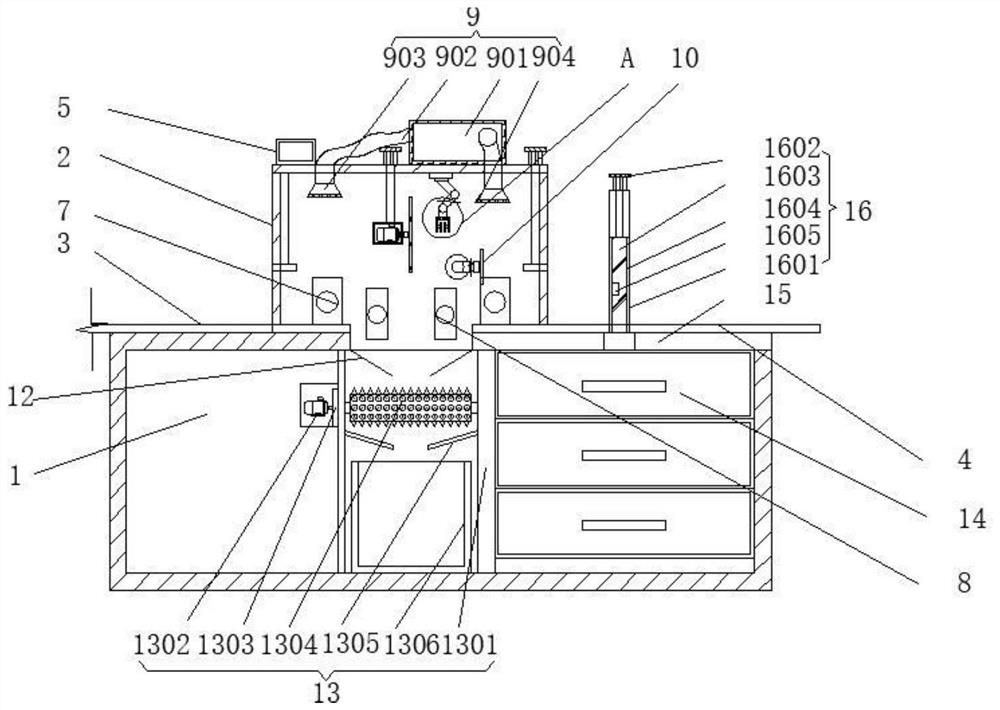

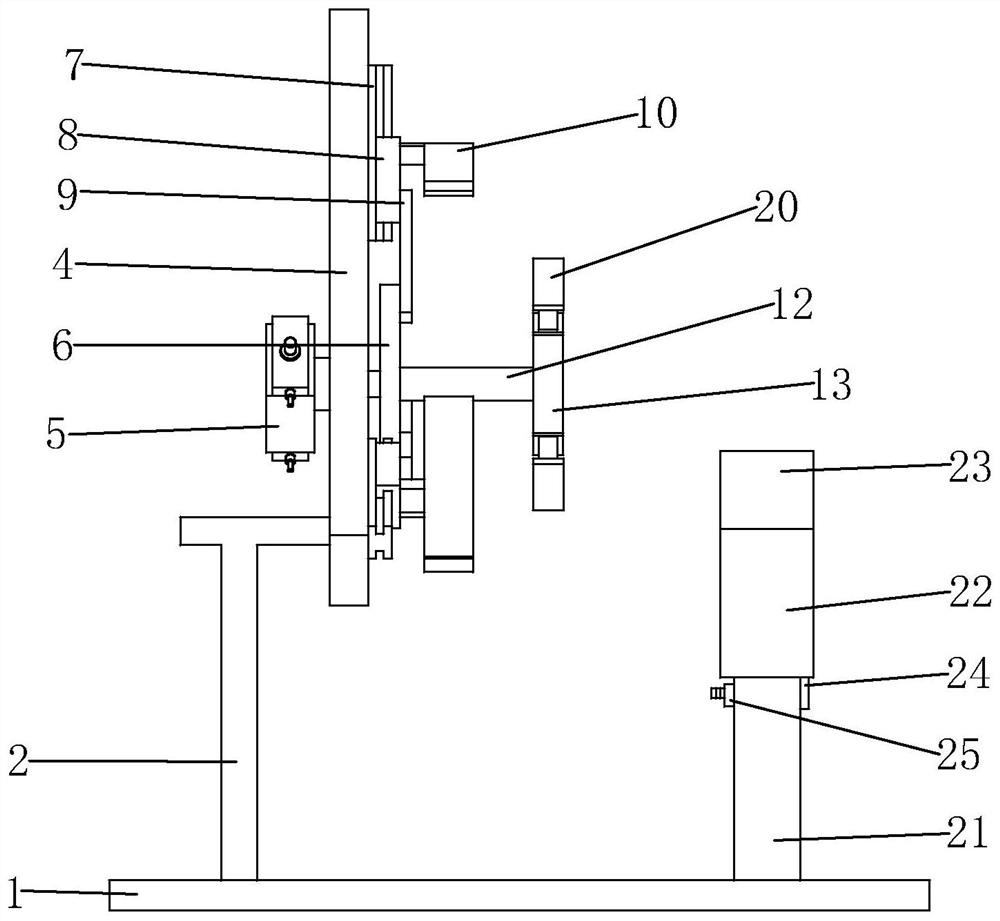

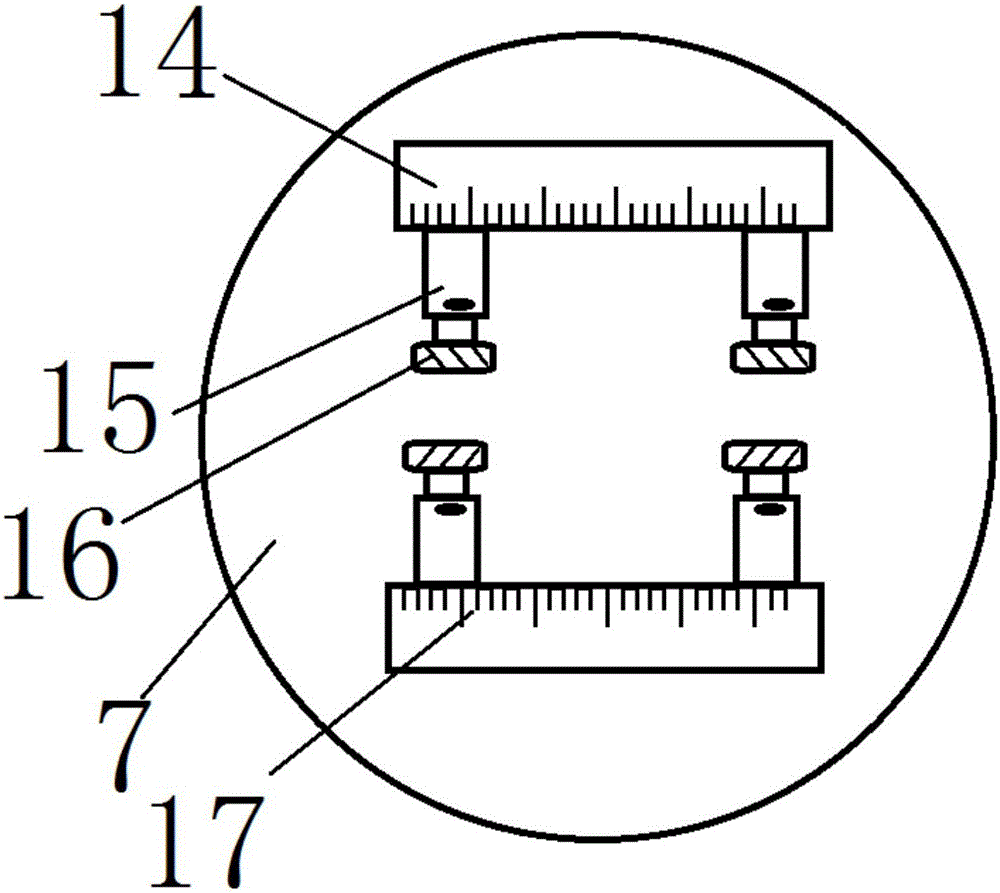

Positioning and cutting device for fabricated steel structure construction

ActiveCN113509976AImprove practicalityAvoid compromising cut qualityShearing machinesOther manufacturing equipments/toolsGrindingElectric machinery

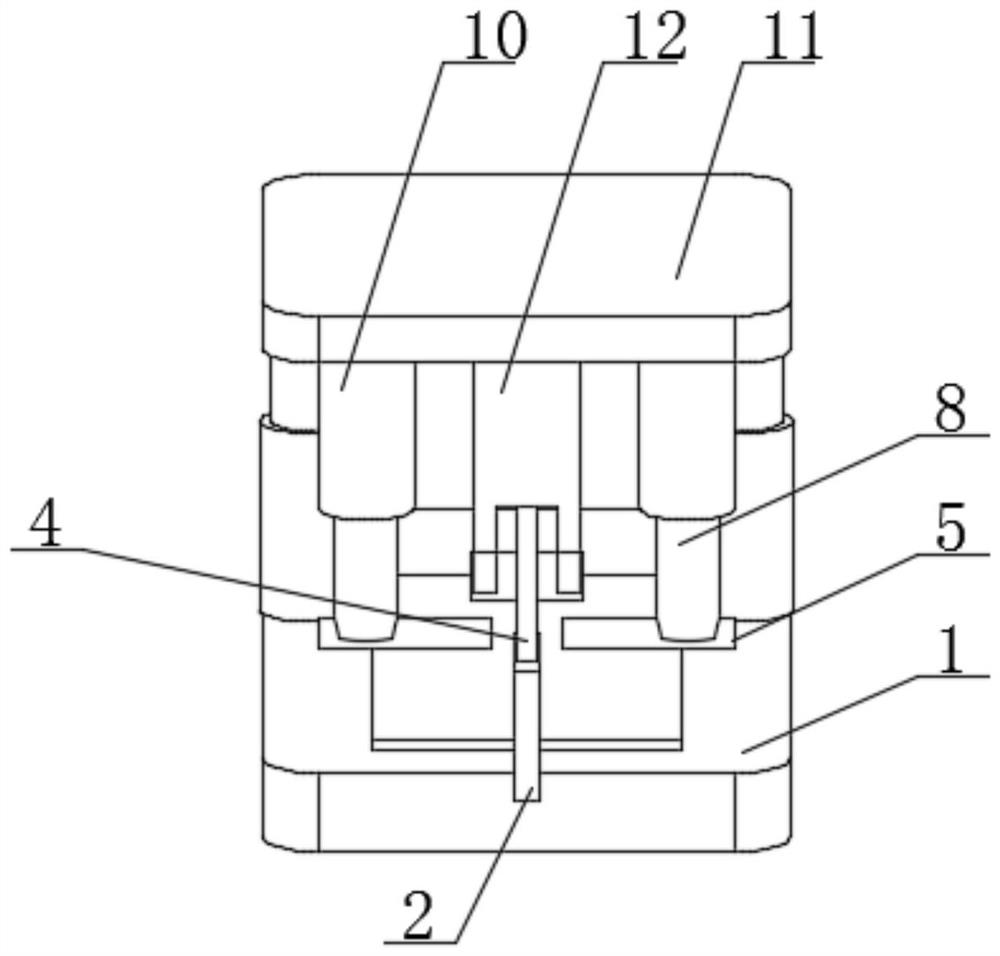

The invention discloses a positioning and cutting device for fabricated steel structure construction. The positioning and cutting device comprises a base, a grinding assembly, a knife grinding assembly, a material guide groove and a control box, wherein a first U-shaped plate is fixed on the upper side of the base, an air blowing assembly, a first auxiliary fixing assembly, a harmful gas treatment assembly and a third hydraulic cylinder are fixed on the upper side of the first U-shaped plate, the air blowing assembly is located on the left side of the harmful gas treatment assembly, a second driving motor is fixed on the lower side of the third hydraulic cylinder through a piston rod, the grinding assembly is used for grinding a steel structure after cutting, and the knife grinding assembly is used for grinding a cutting blade and a grinding blade. The positioning and cutting device for the fabricated steel structure construction has the advantages that different fabricated steel structures can be fixed in an assisted mode, large steel structure waste materials after cutting can be crushed and stored, chippings generated during cutting can be automatically cleaned, and the length of the fabricated steel structures can be accurately positioned.

Owner:徐州中煤汉泰建筑工业化有限公司

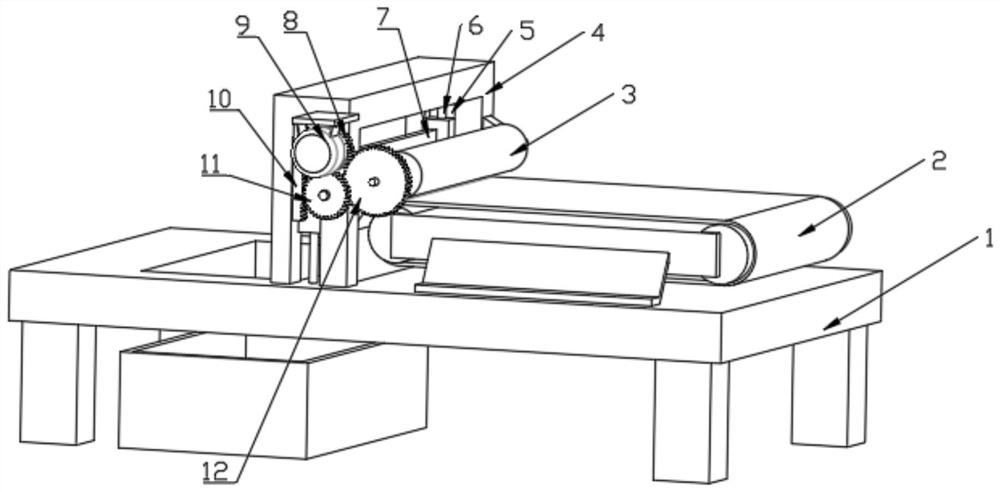

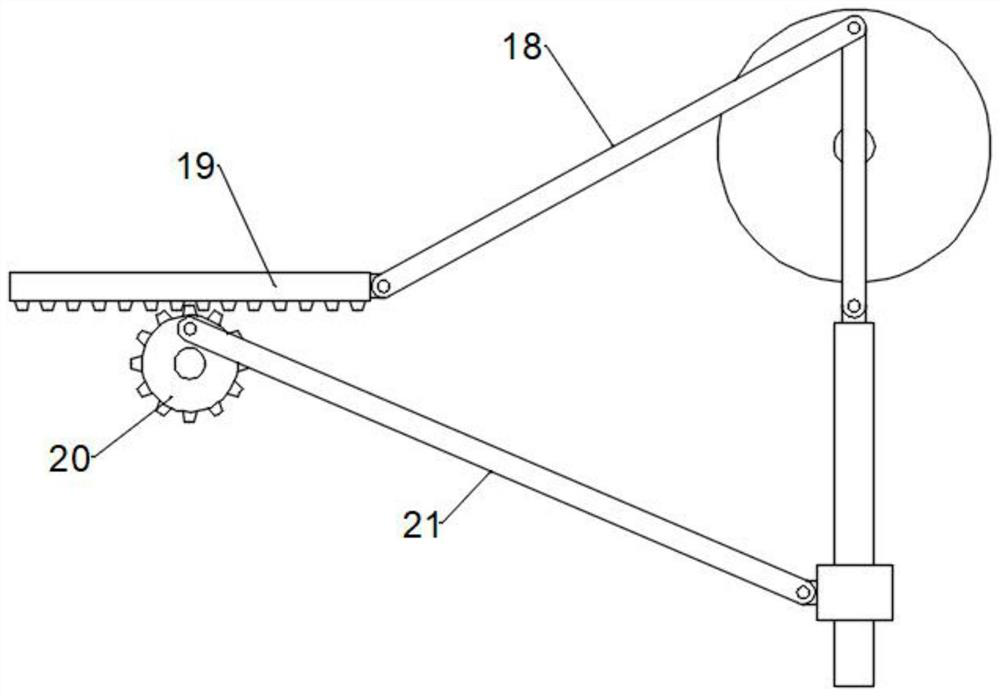

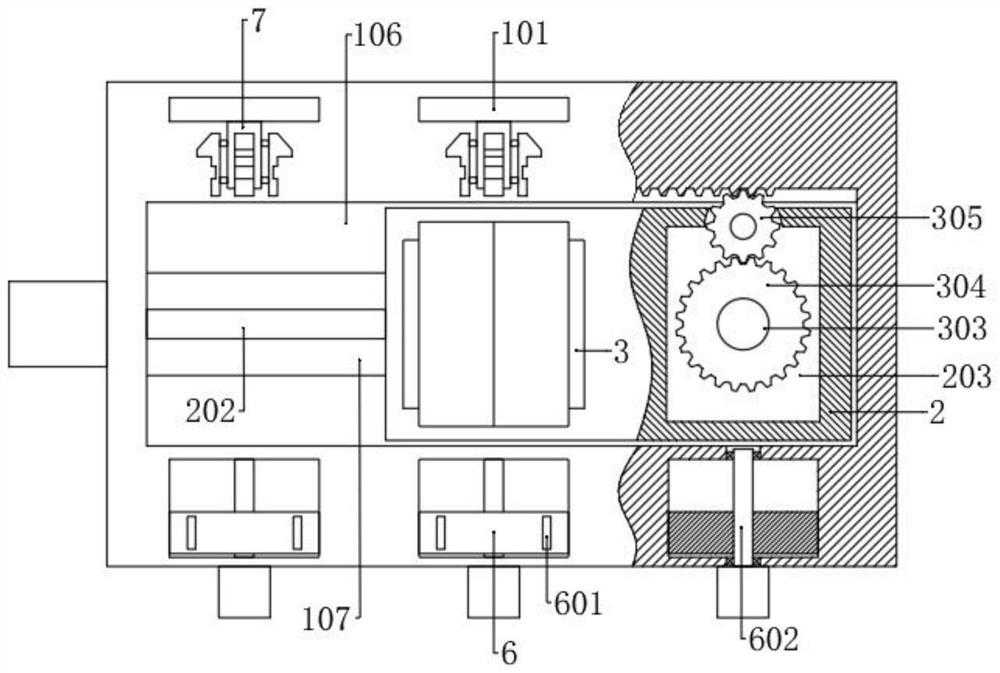

Traditional Chinese medicine cutting device

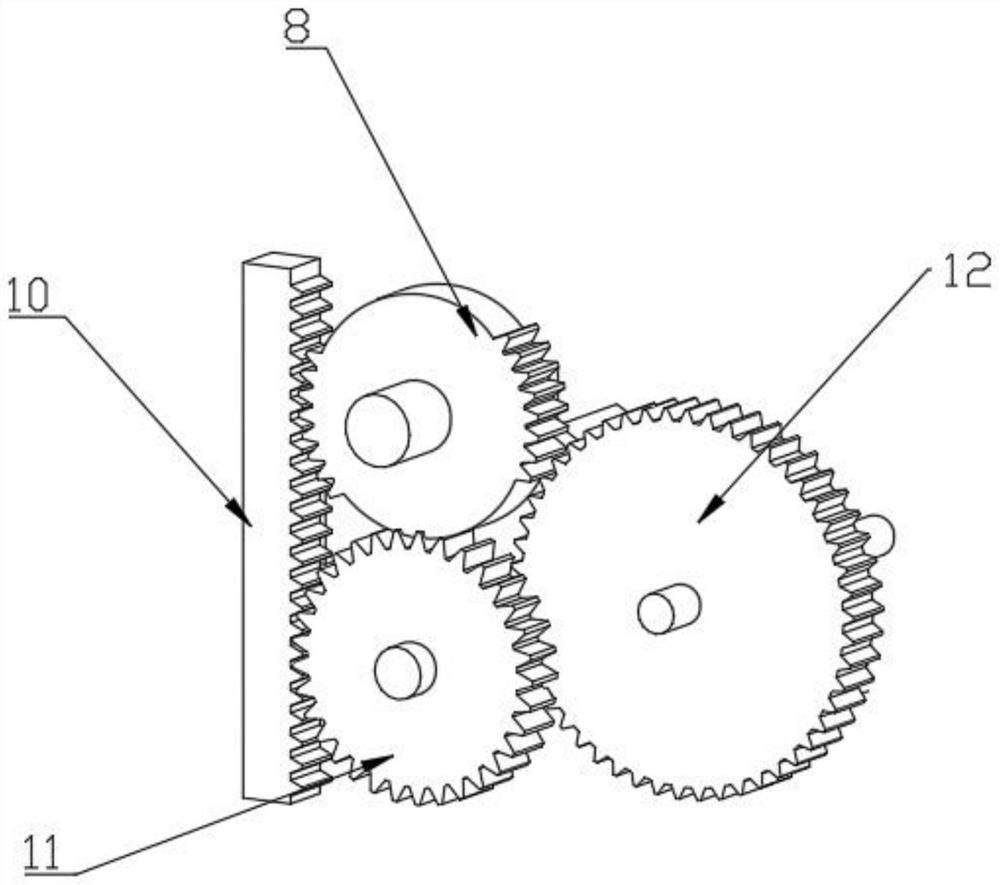

InactiveCN112123400AAvoid cutting obstructionSimple structureMetal working apparatusGear wheelIndustrial engineering

The invention is applicable to the technical field of traditional Chinese medicines, and provides a traditional Chinese medicine cutting device. The traditional Chinese medicine cutting device comprises a workbench, a cutting knife group, a conveying roller and a driving part; a mounting frame is mounted on the upper surface of the workbench; the cutting knife group is arranged on the mounting frame in a liftable manner and is used for cutting traditional Chinese medicine; the conveying roller is rotationally arranged on the mounting frame and used for conveying the traditional Chinese medicine; the driving part is mounted on the mounting frame and is connected with the conveying roller and the cutting knife group through a transmission part; and the transmission part comprises an incomplete gear, a rack, a transmission gear and a driven gear, the driven gear is coaxially and fixedly connected with the conveying roller, the incomplete gear is coaxially and fixedly connected with an output shaft of the driving part, the rack is fixedly connected with the cutting knife group, and the incomplete gear is alternately meshed with the rack, the transmission gear and the driven gear for transmission. The traditional Chinese medicine cutting device has the advantages of being simple in structure, convenient to operate, low in manufacturing cost, energy-saving, good in synchronism, highin applicability, high in cutting efficiency and good in safety.

Owner:SUZHOU LONGZE PHARM TECH CO LTD

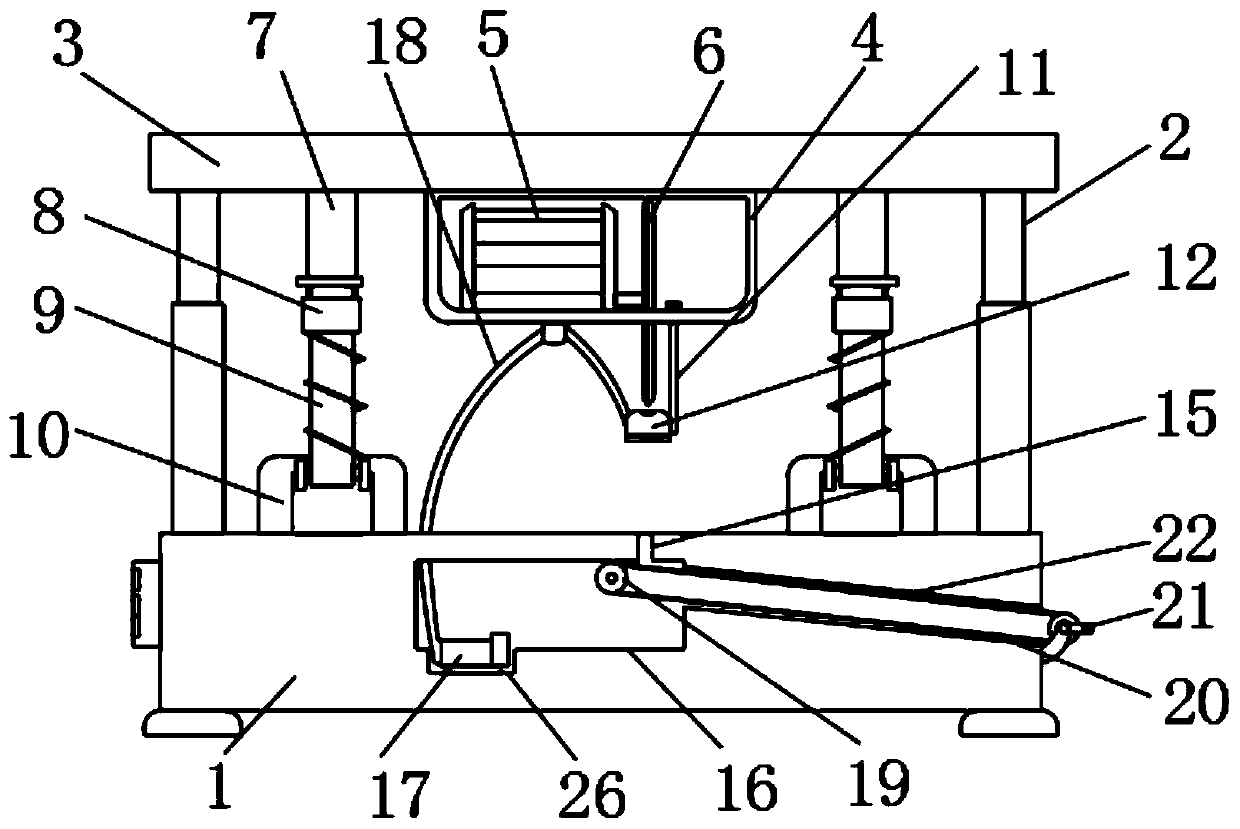

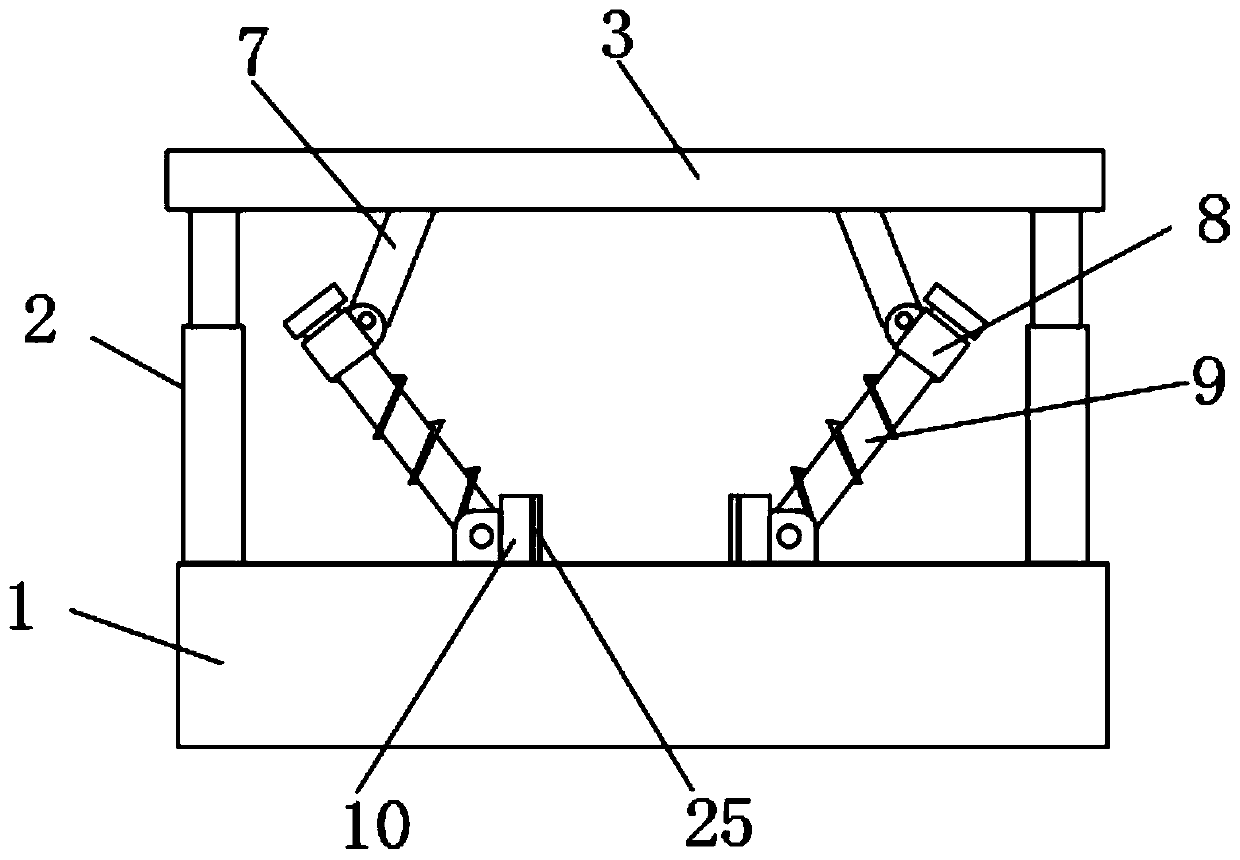

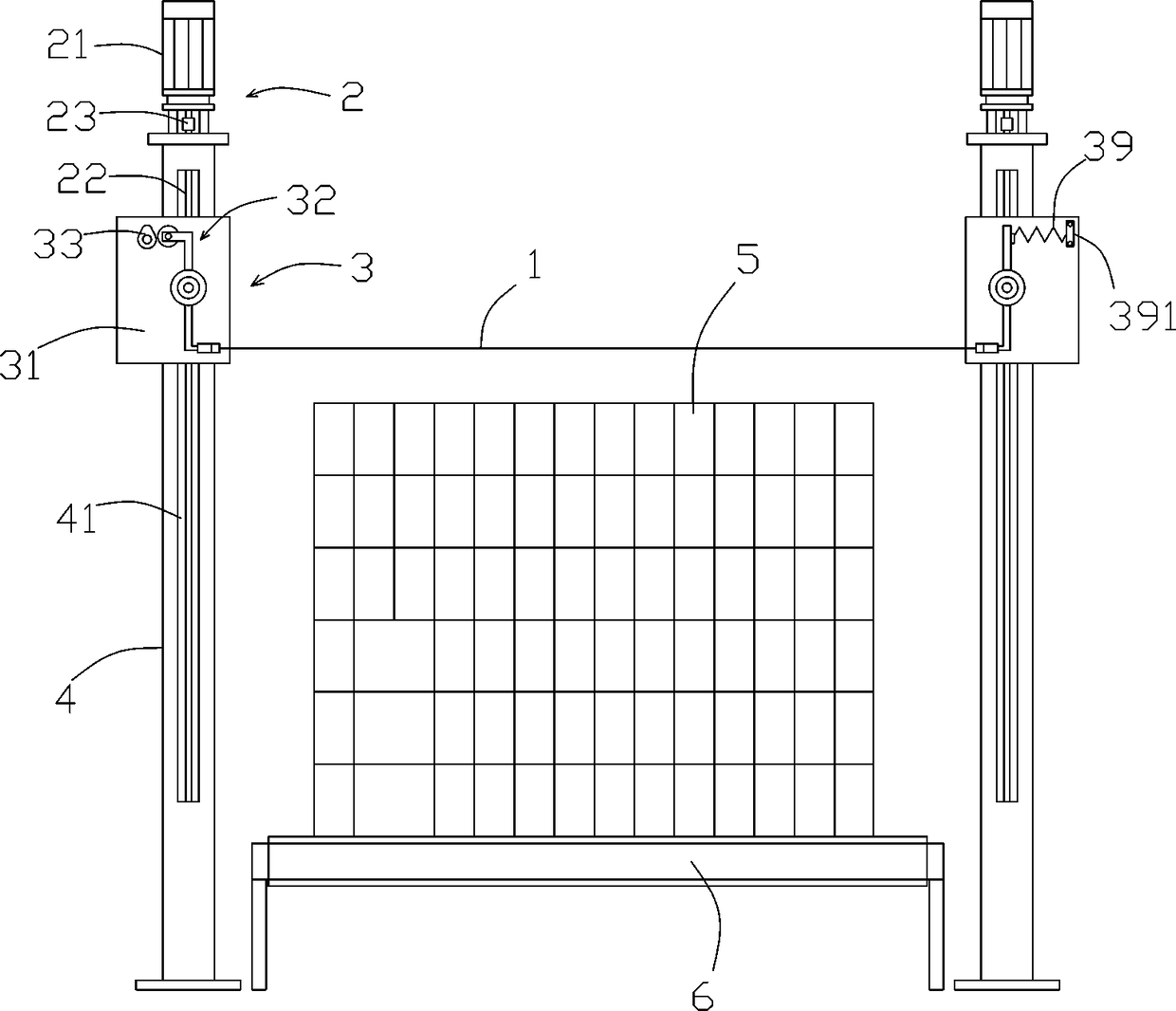

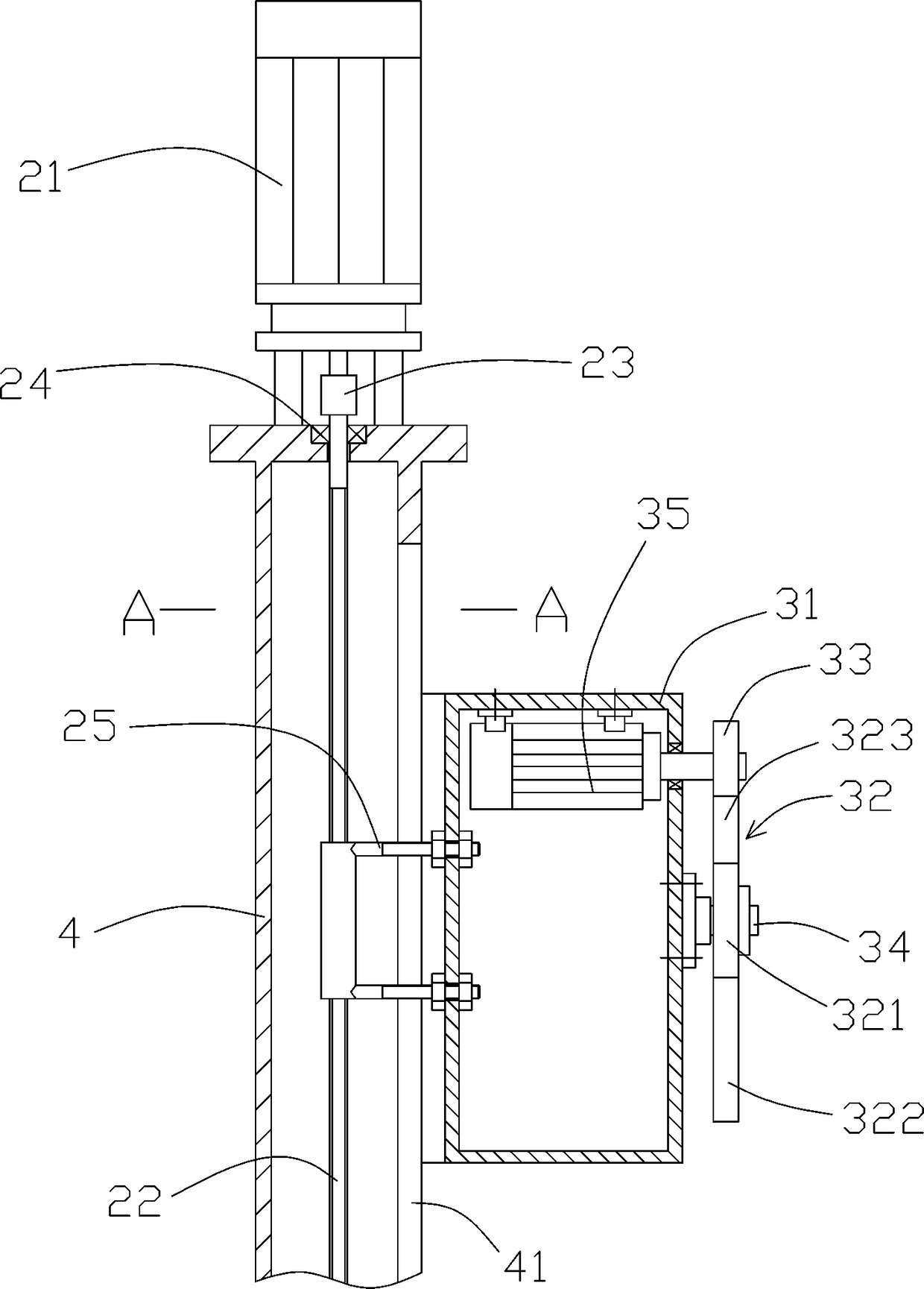

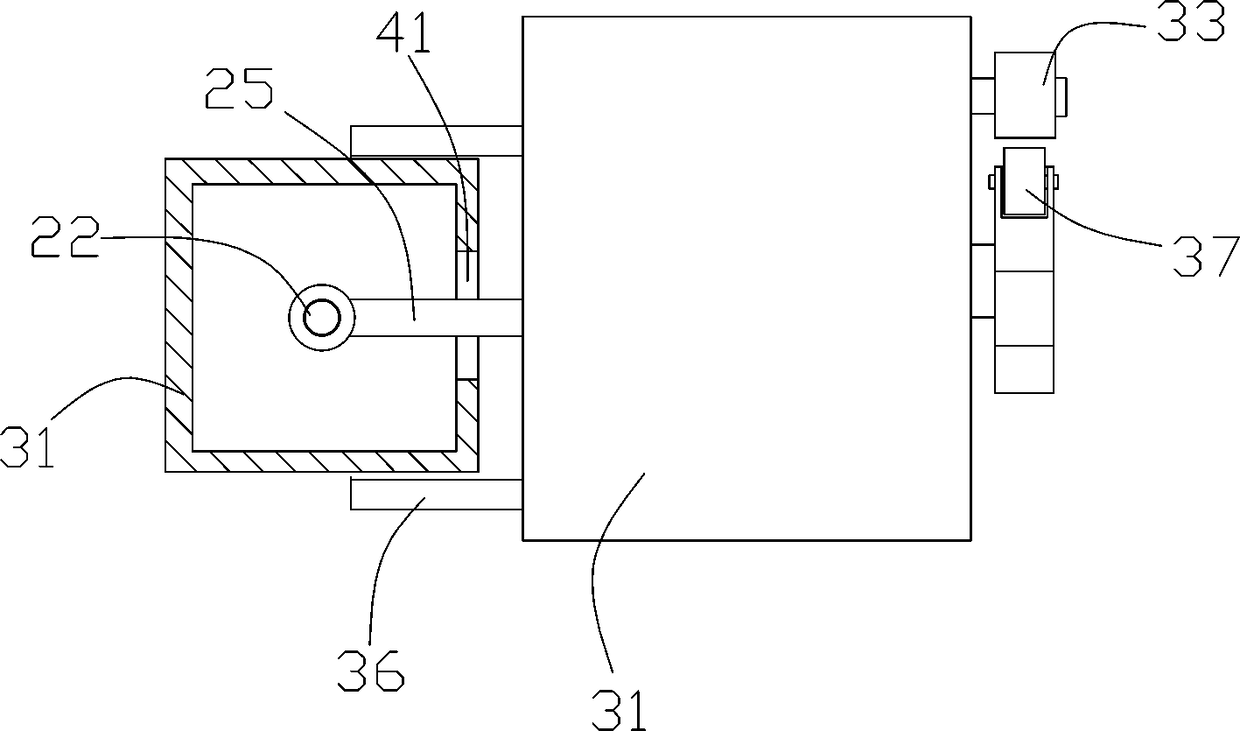

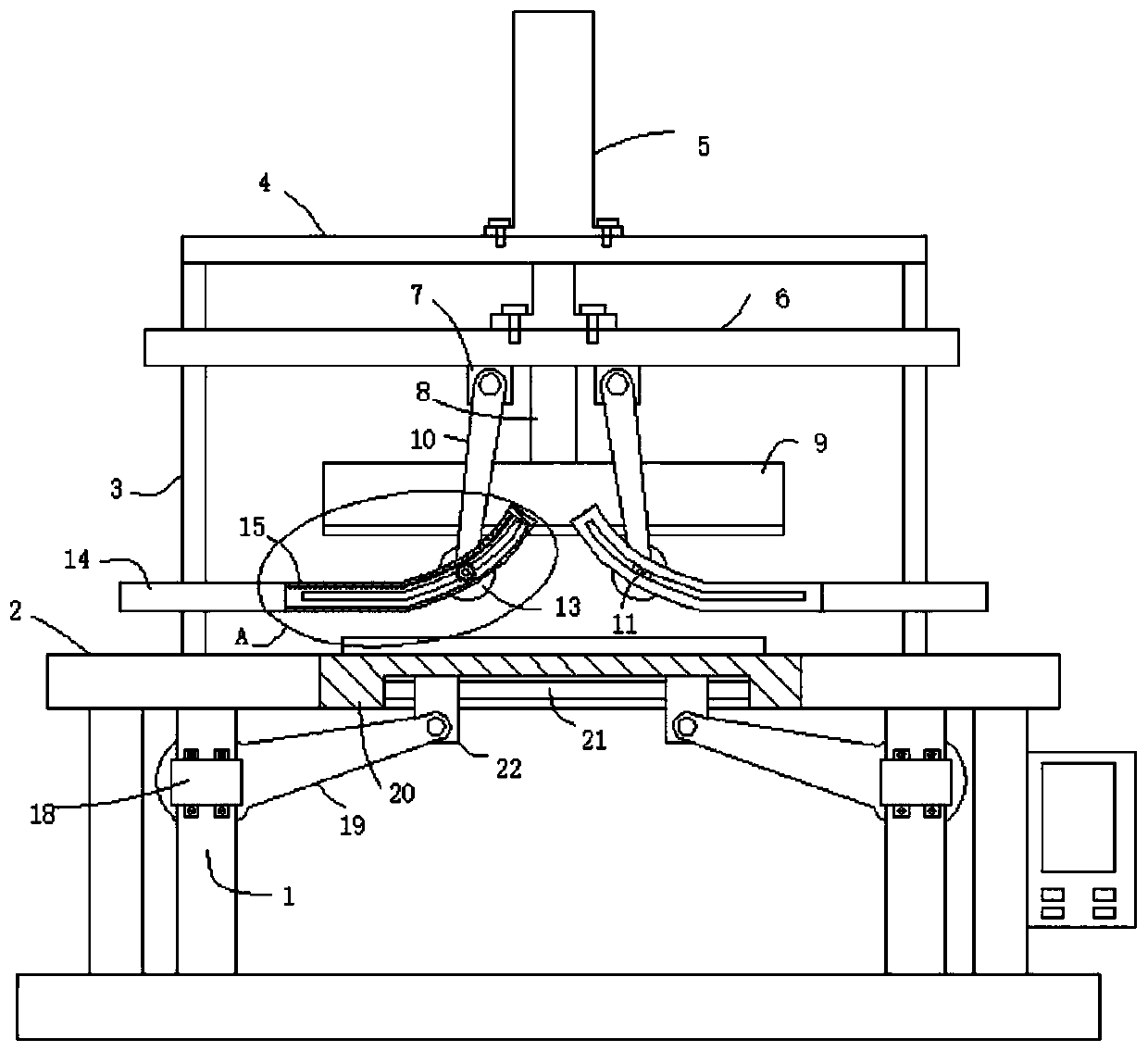

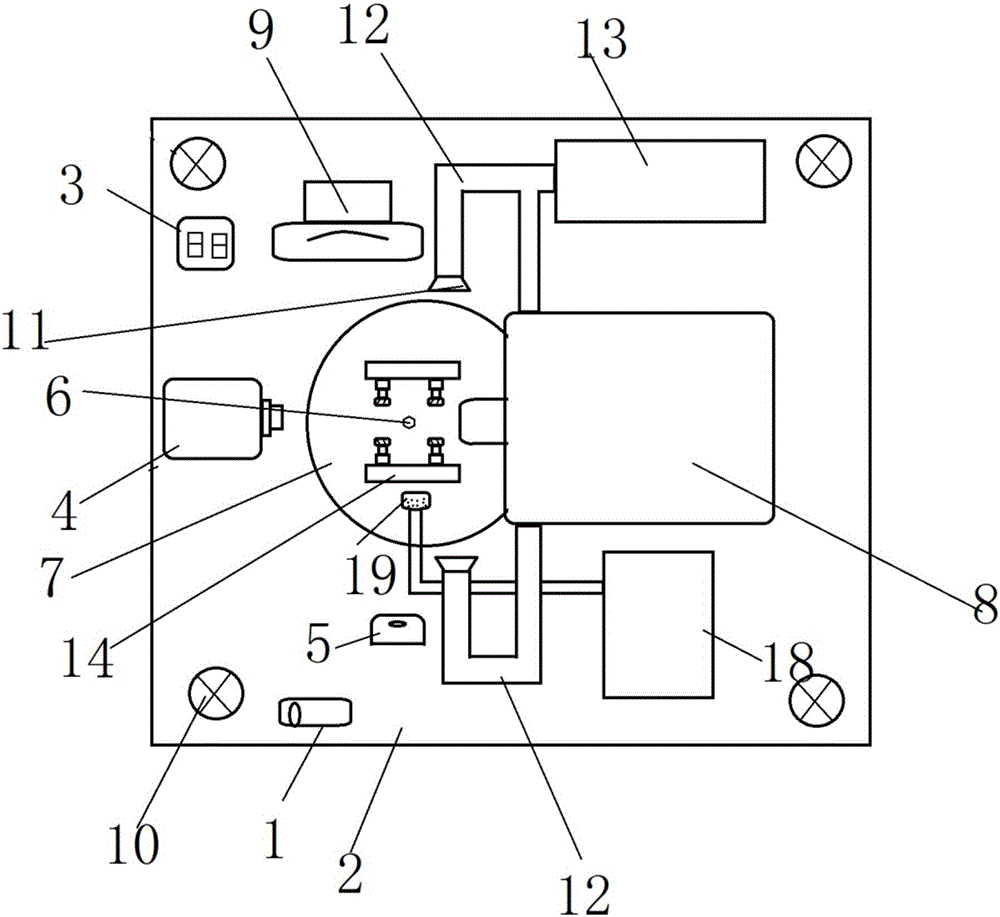

Concrete block repairing and cutting device

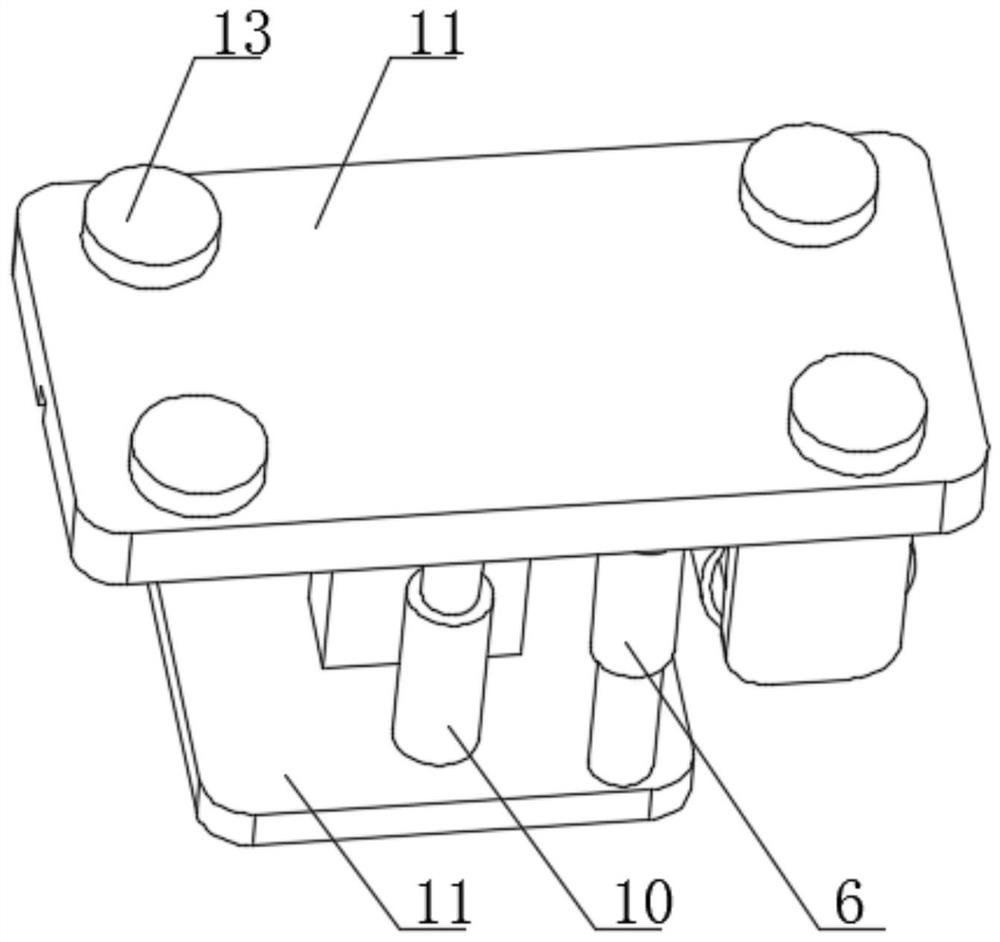

InactiveCN108656327AAvoid affecting the production scheduleAvoid compromising cut qualityCeramic shaping apparatusBall screwArchitectural engineering

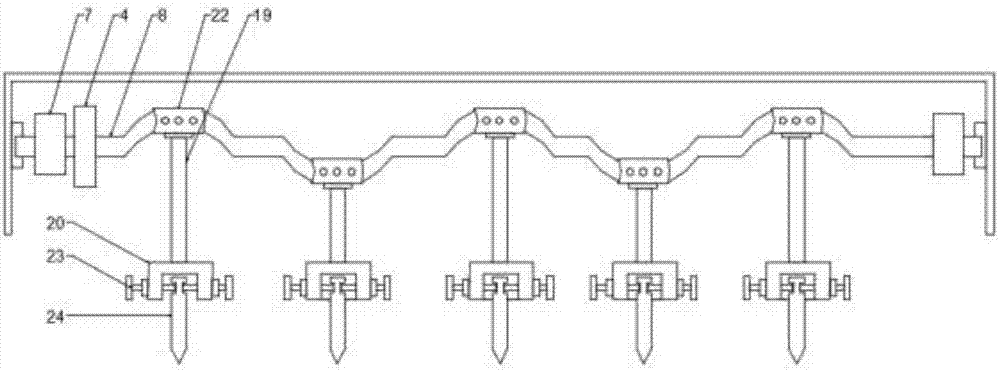

The invention provides a concrete block repairing and cutting device. The concrete blocking repairing and cutting device comprises a steel wire and two sets of cutting mechanisms symmetrically arranged on the two sides of a concrete block; vertical rods are internally hollow, and one sides of the vertical rods are provided with vertical openings; each driving part comprises a first motor arrangedat the upper end of the vertical rod and a ball screw connected in the vertical rod in a shaft mode, and first motor rotating shafts are connected with screws in ball screws, and each lifting part comprises a shell, the shells are connected with nuts in the ball screws through a plurality of connecting rods, wing plates are fixedly arranged on the two sides of the shells, the vertical rods are located between the two wing plates, shaft rods are fixed on the end faces of the shells, rocker arms are installed on the shaft rods, and the two ends of the steel wire are connected to the lower ends of the rocker arms in two sets of cutting mechanisms; and a second motor is arranged in the shell of one set of cutting mechanism, a second motor rotating shaft penetrates out of the shell and then isconnected with a cam, and the cam is used for pushing the rocker arms to swing left and right.

Owner:刘阳国

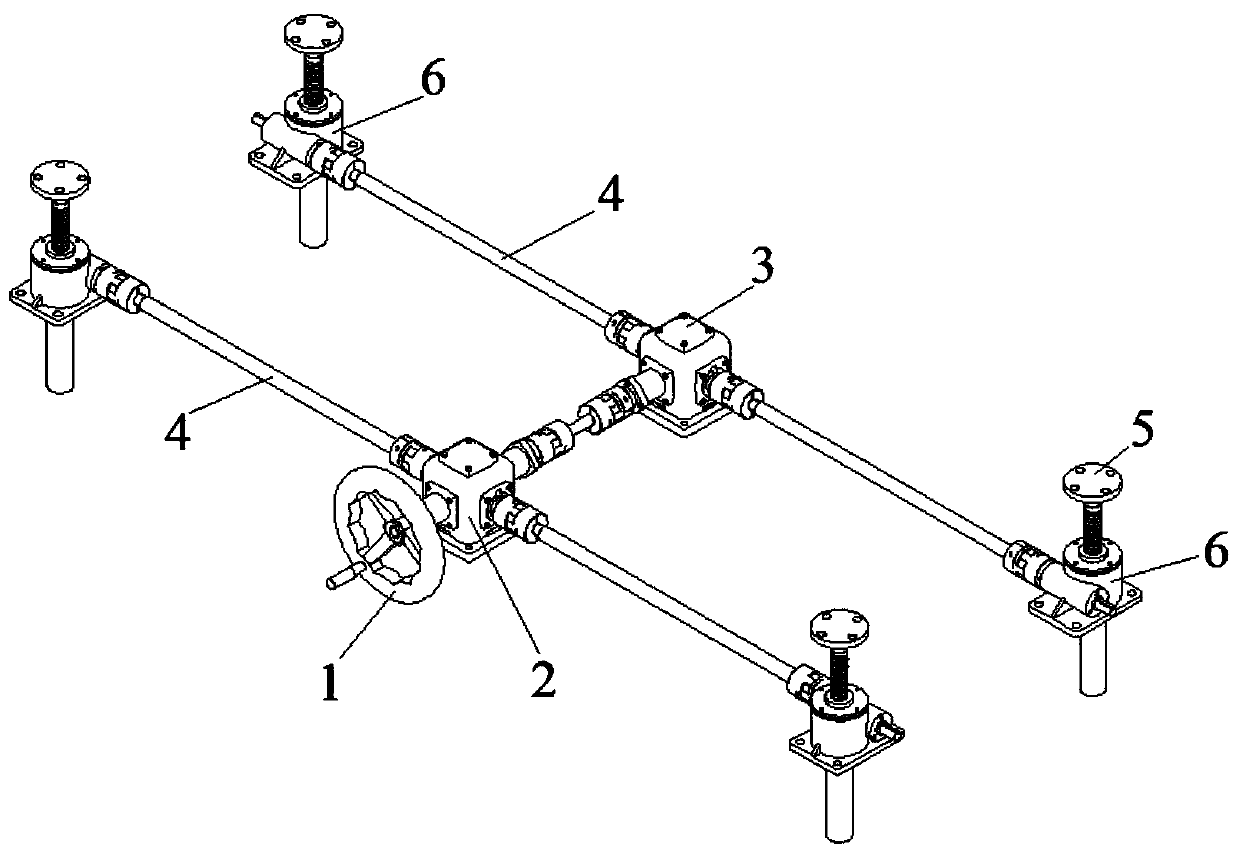

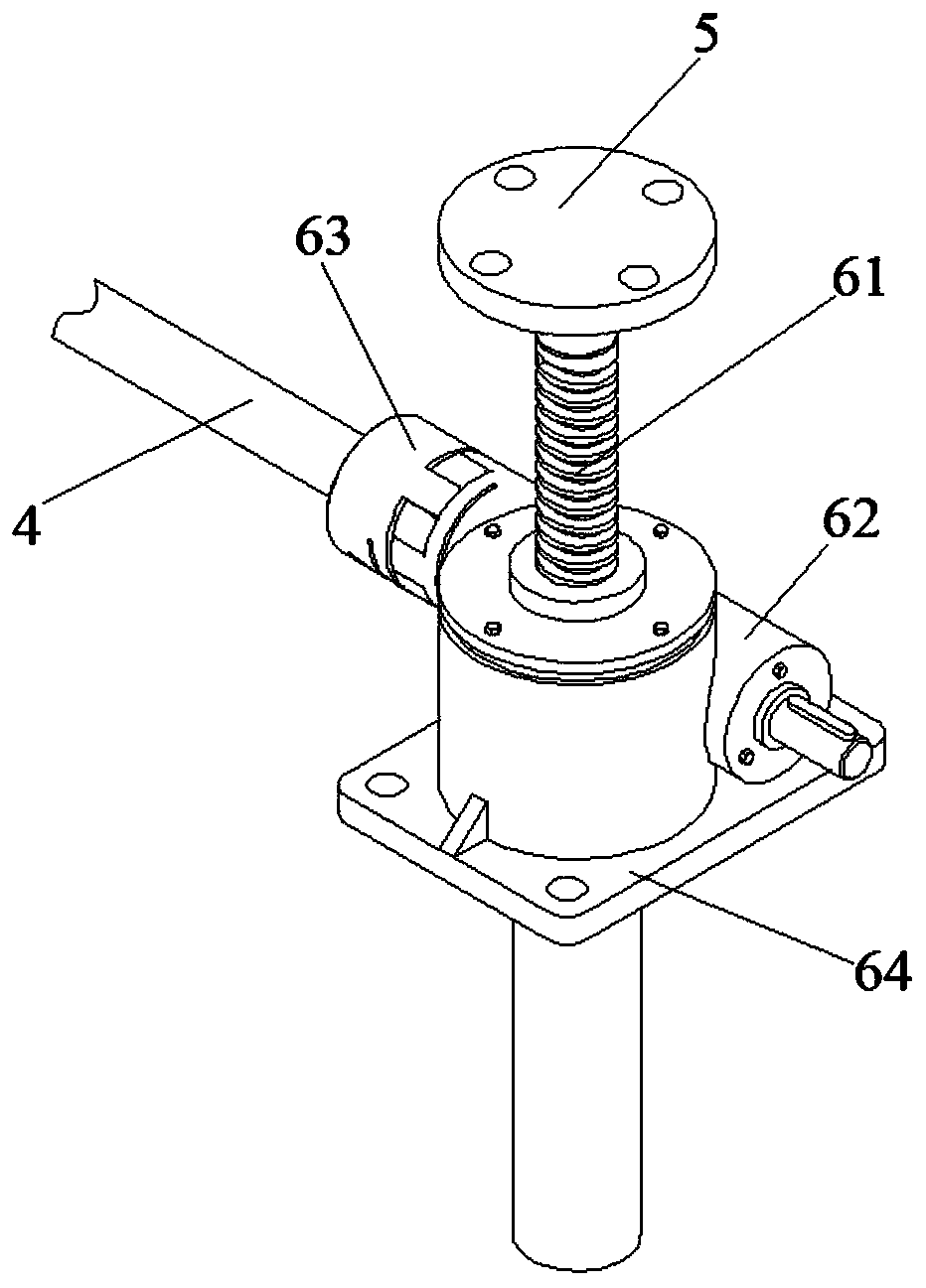

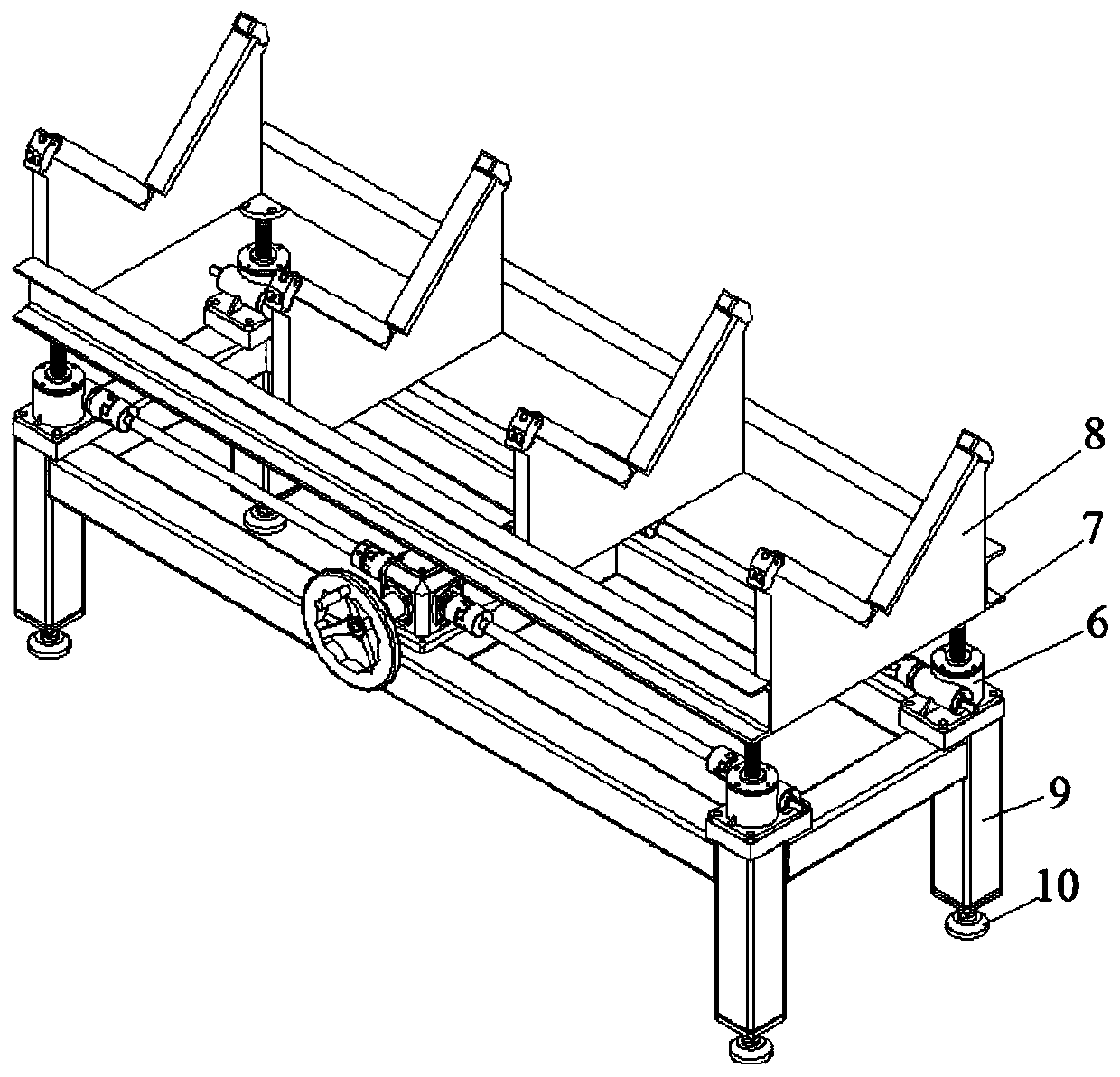

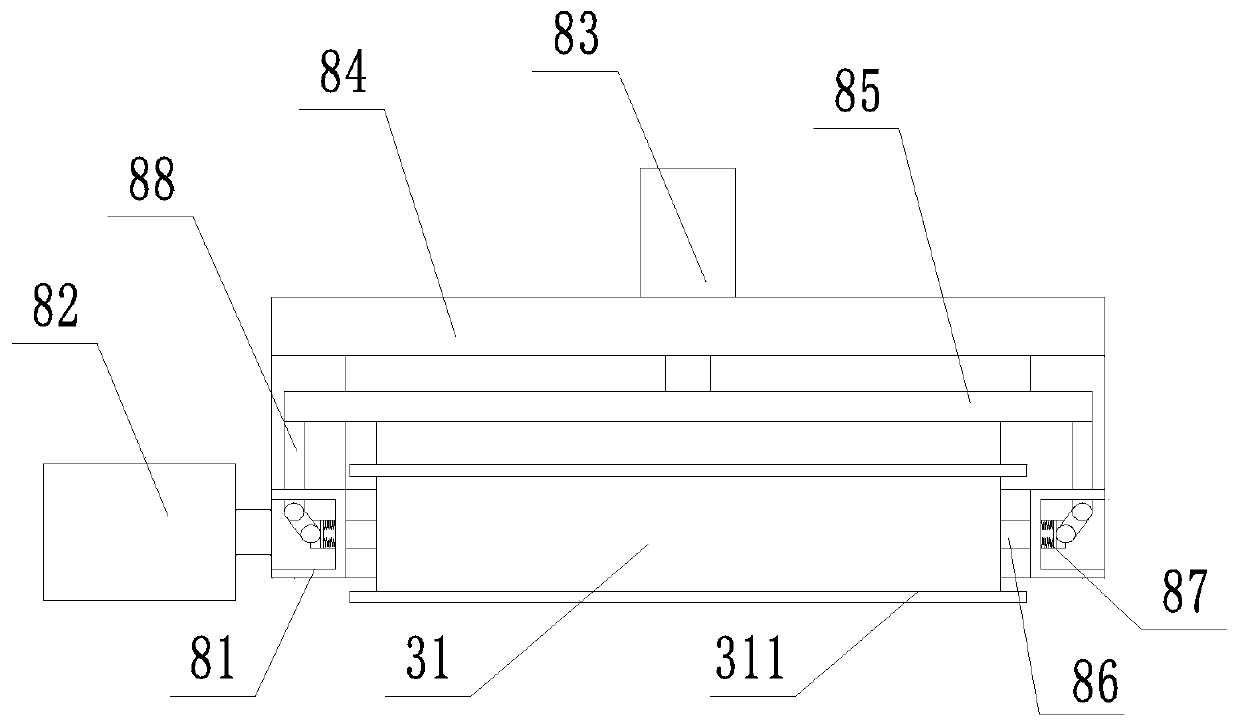

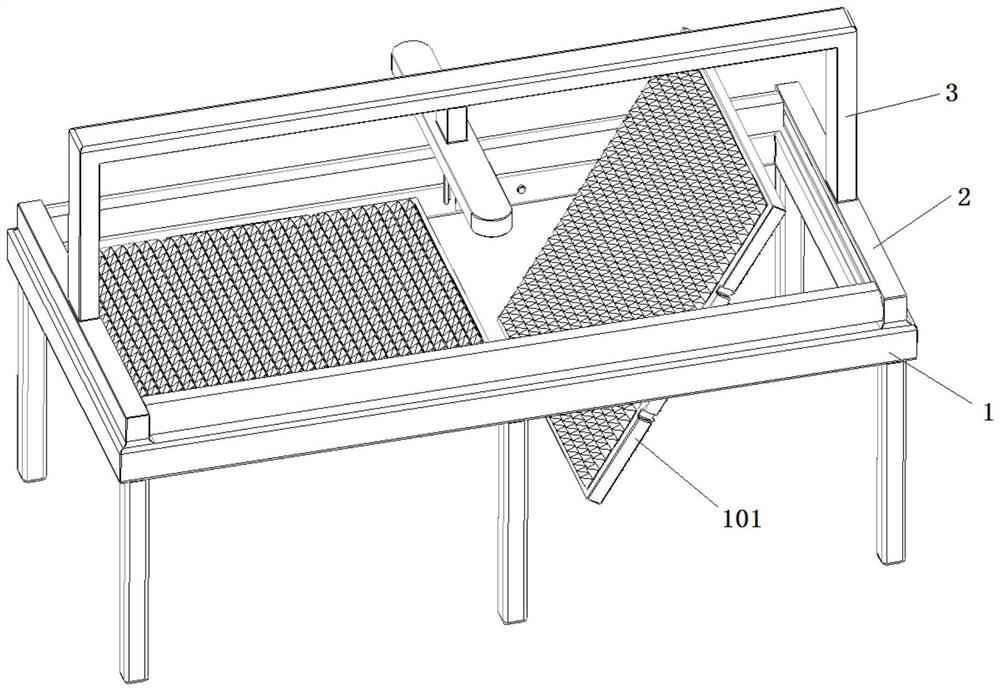

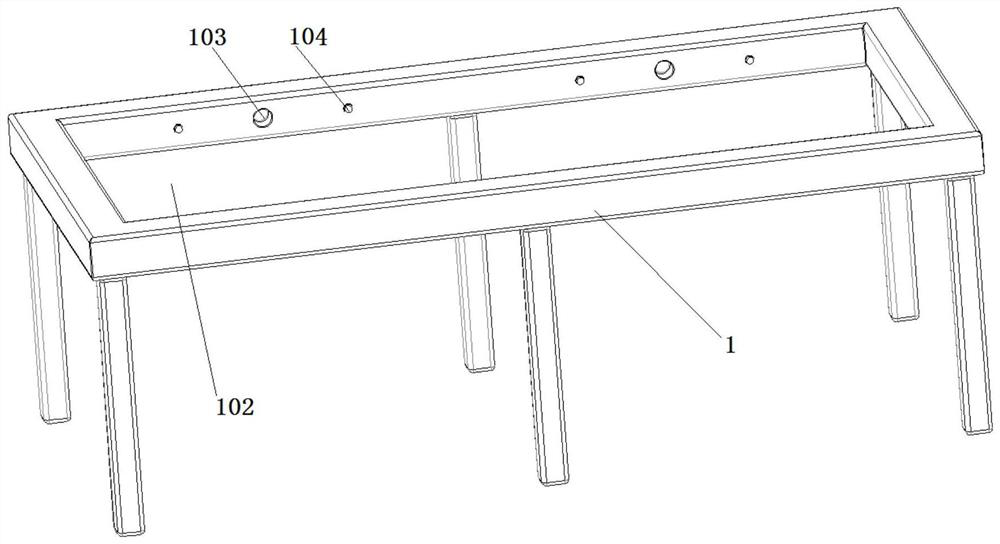

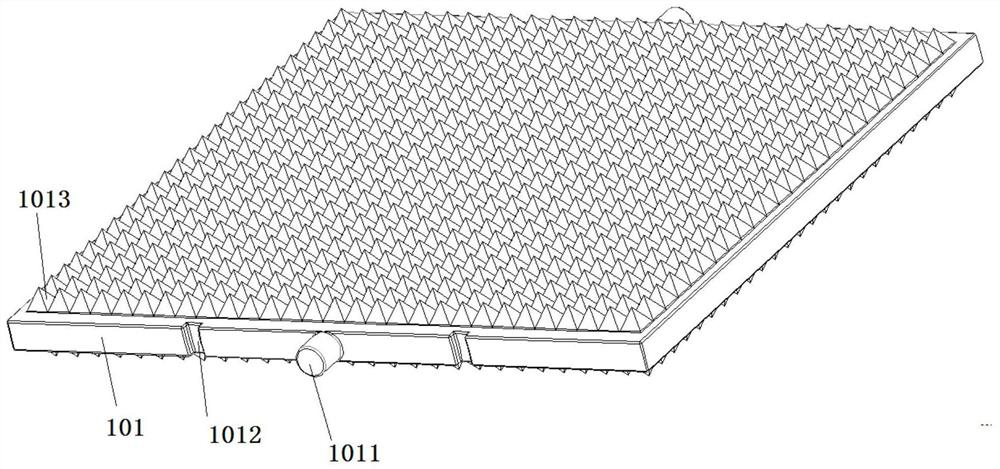

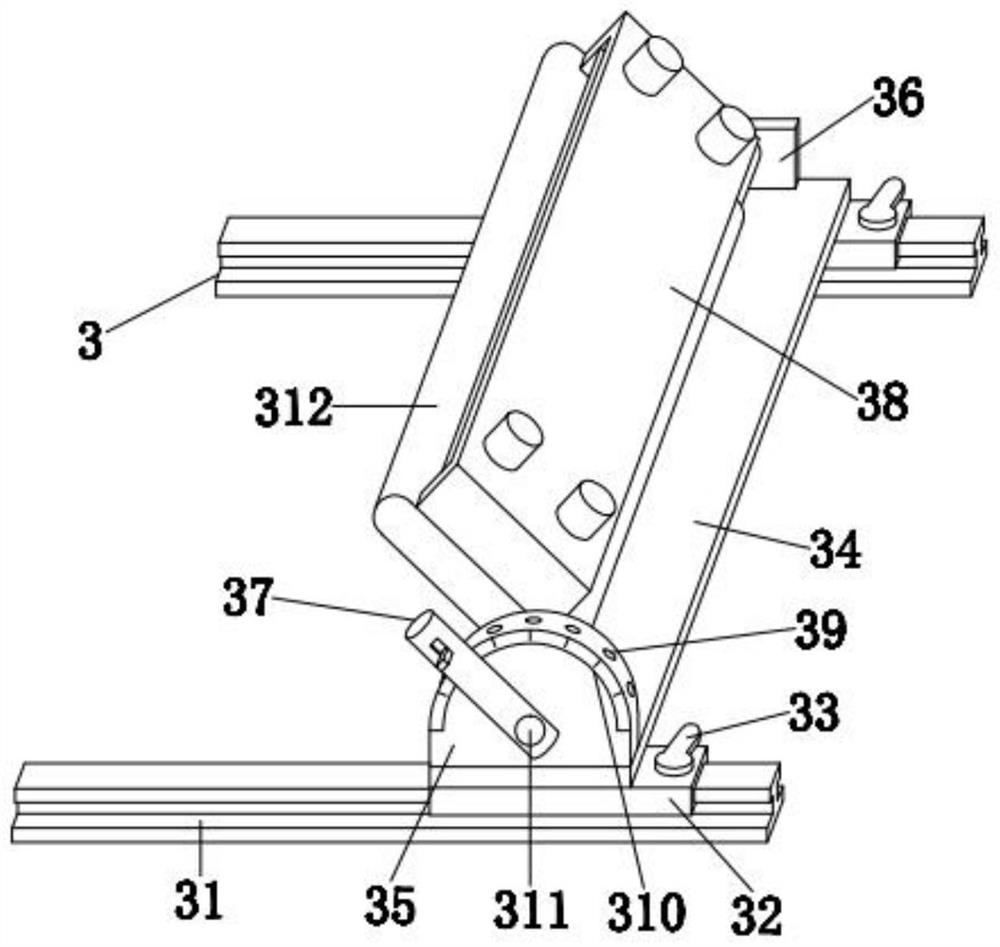

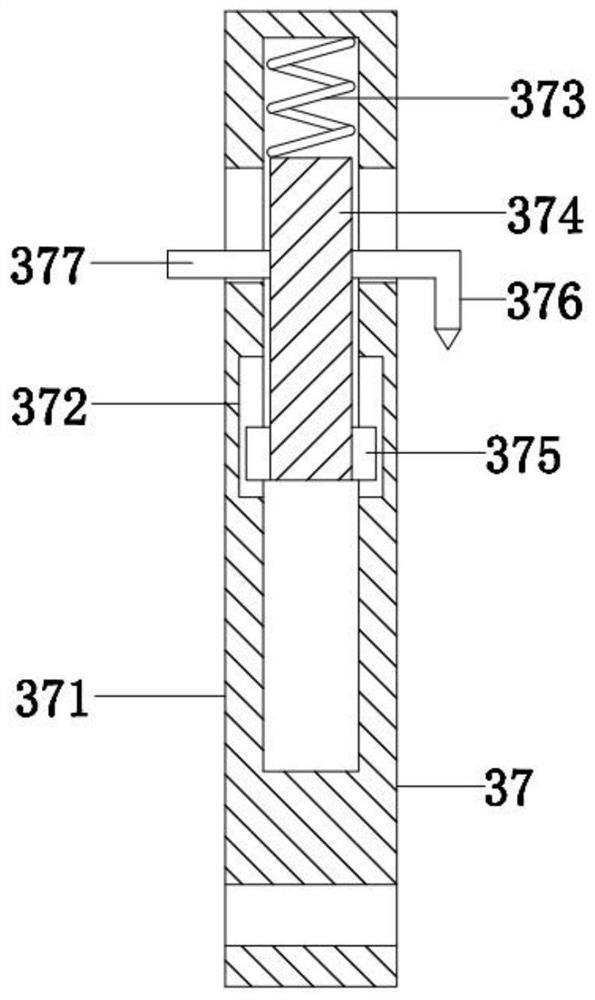

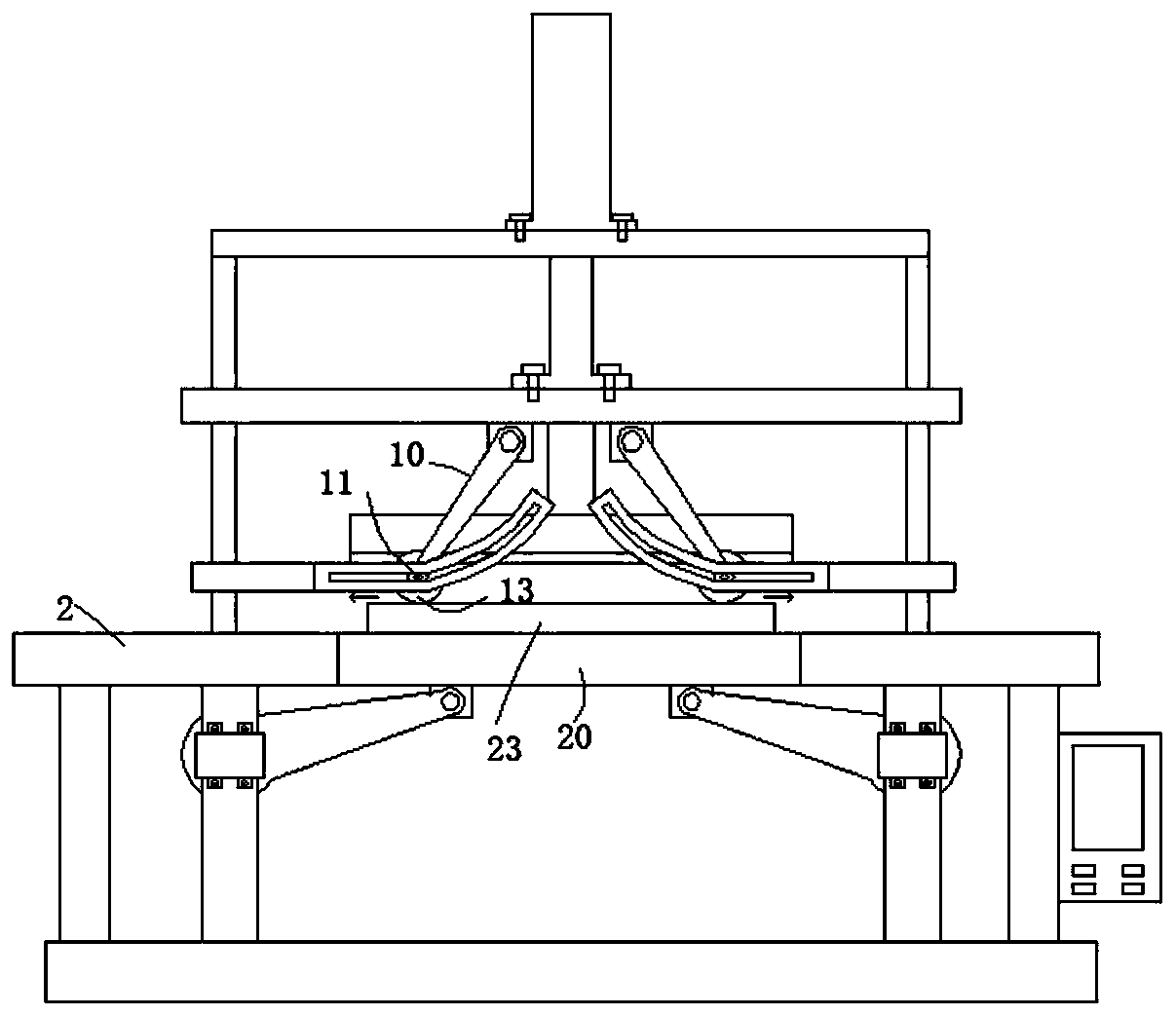

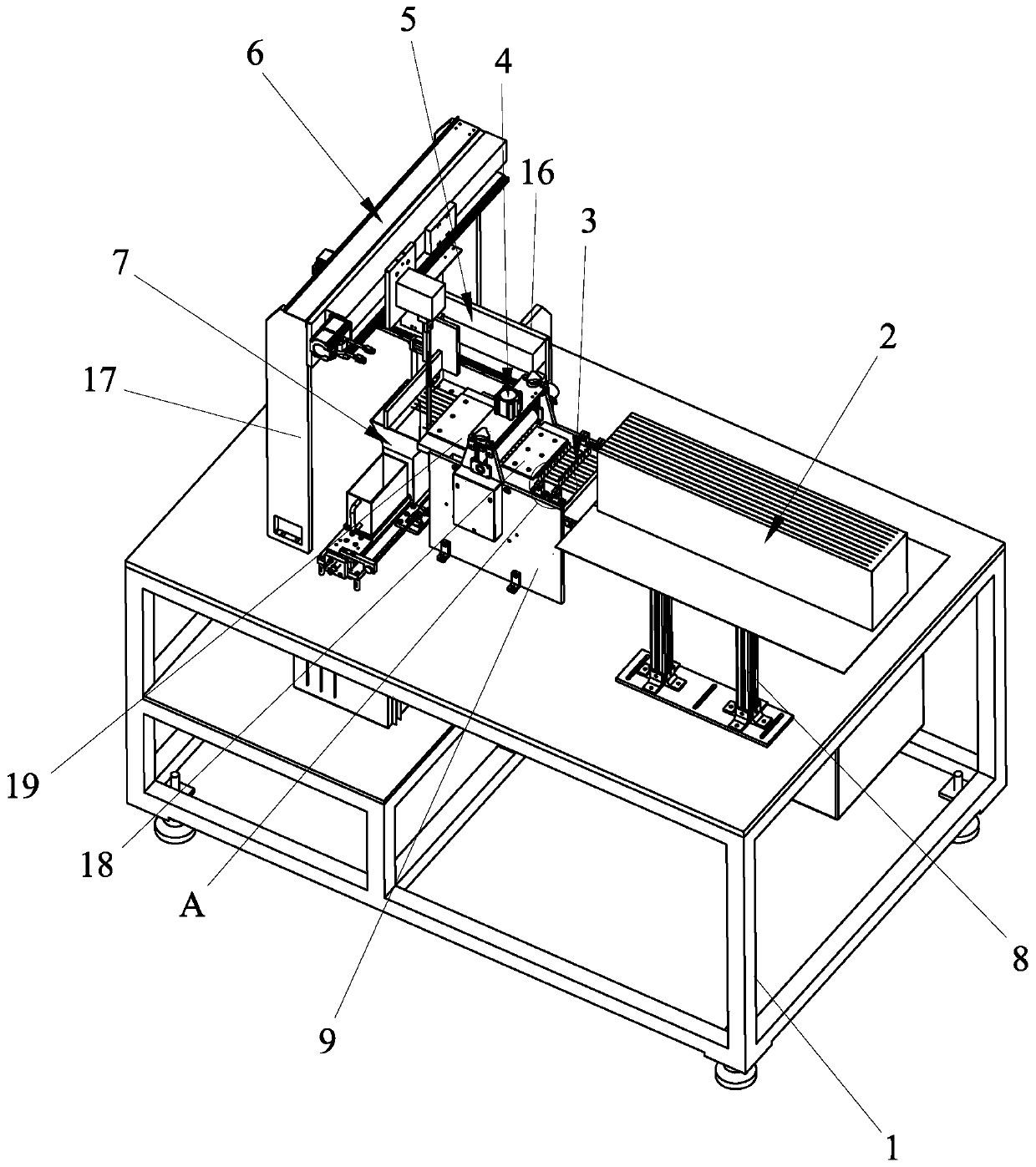

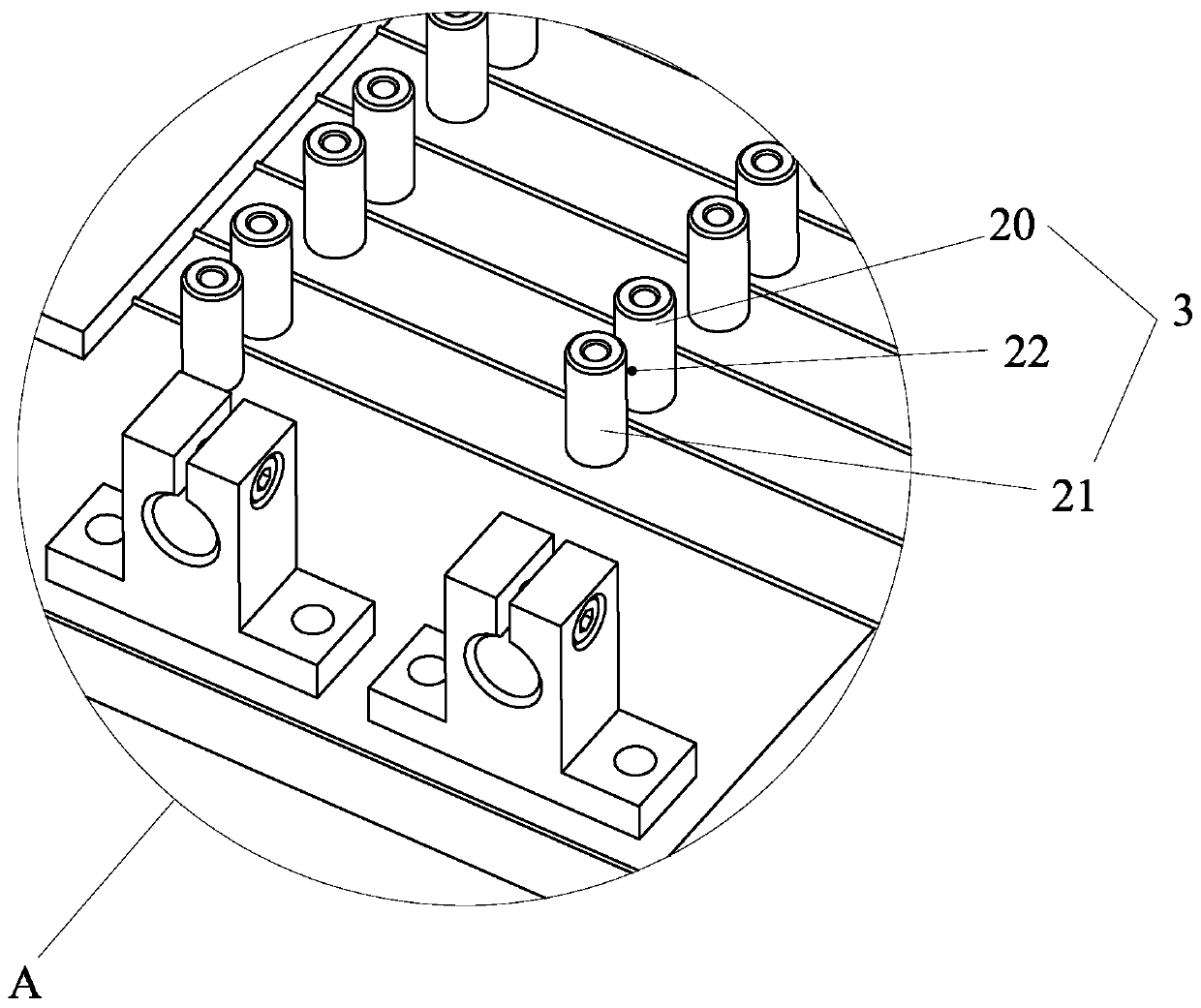

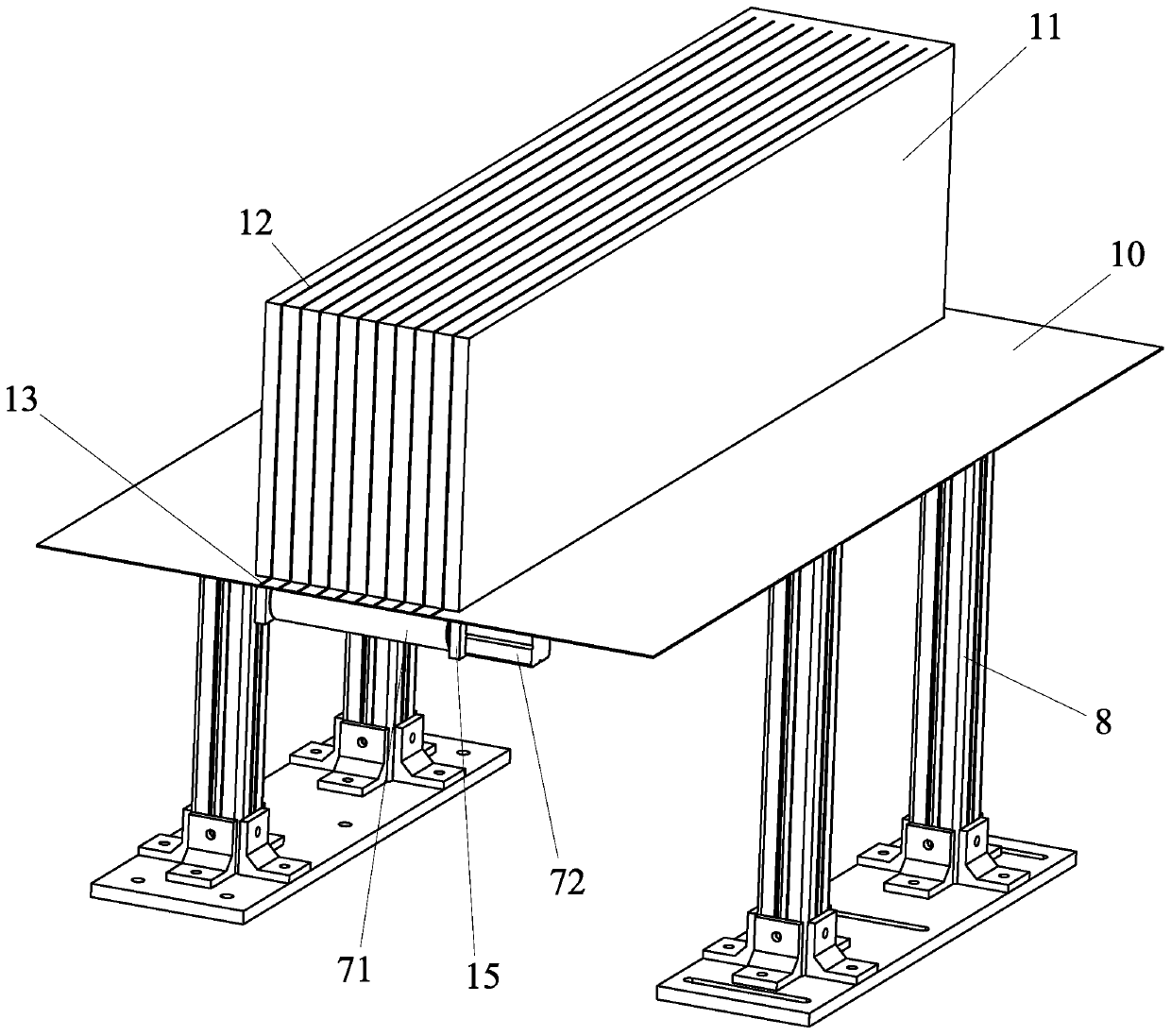

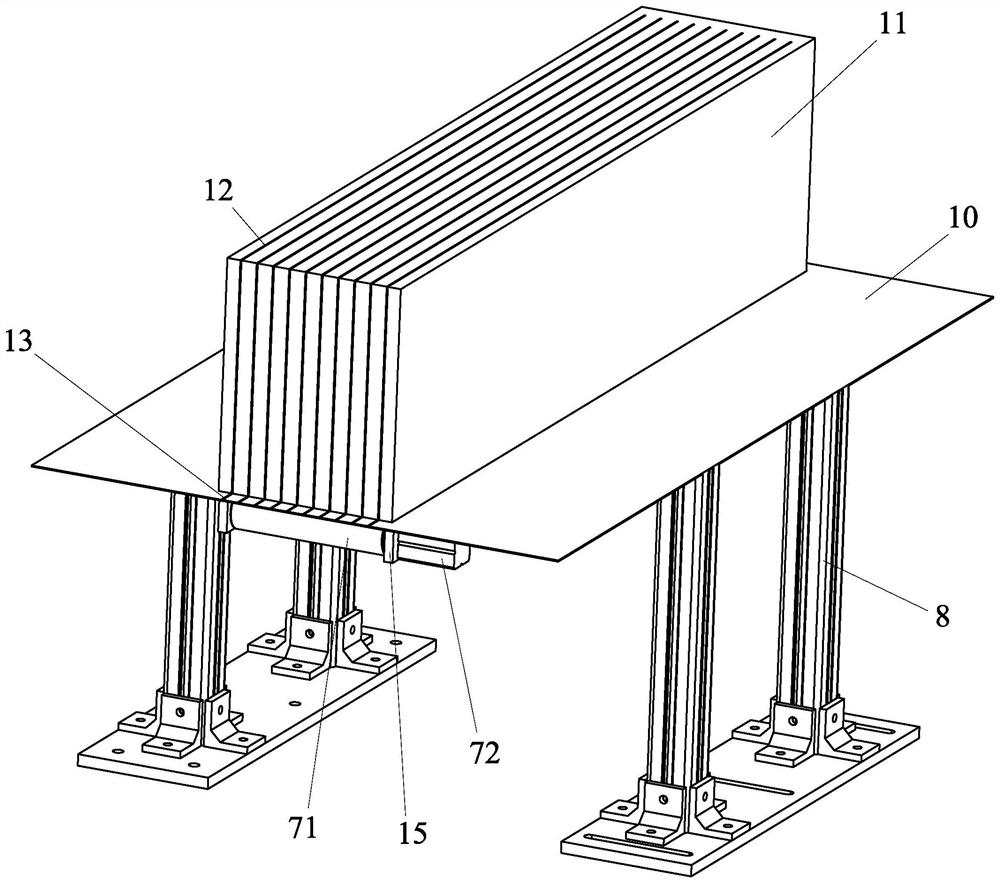

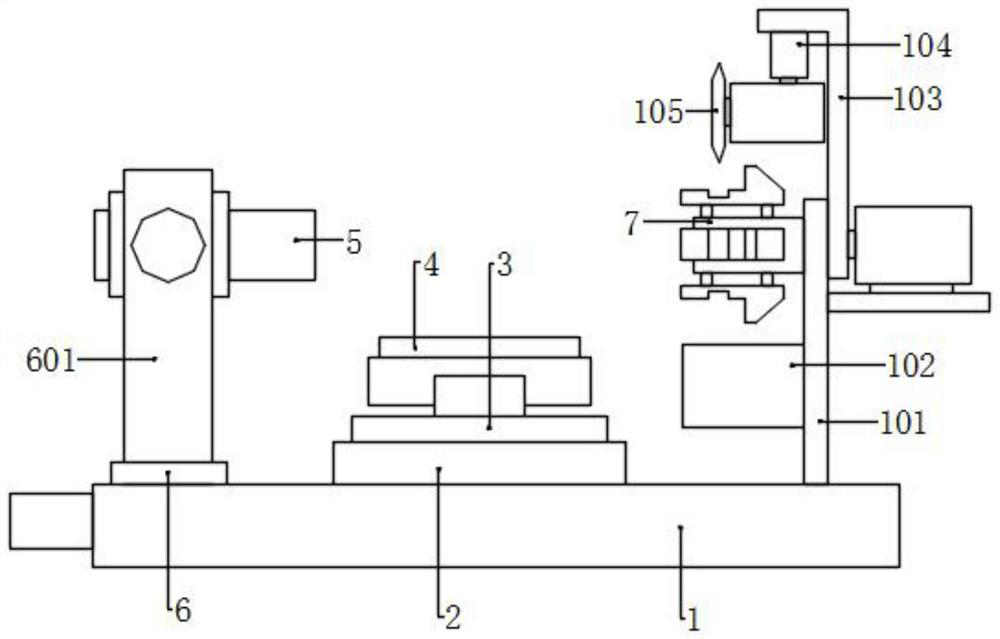

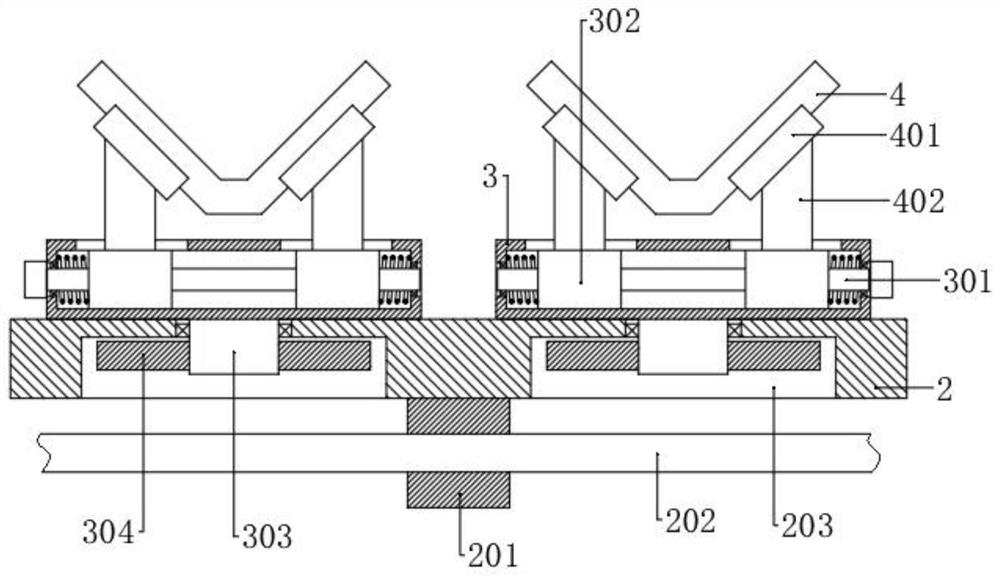

Lifting platform suitable for supporting feeding of large-pipe-diameter pipes

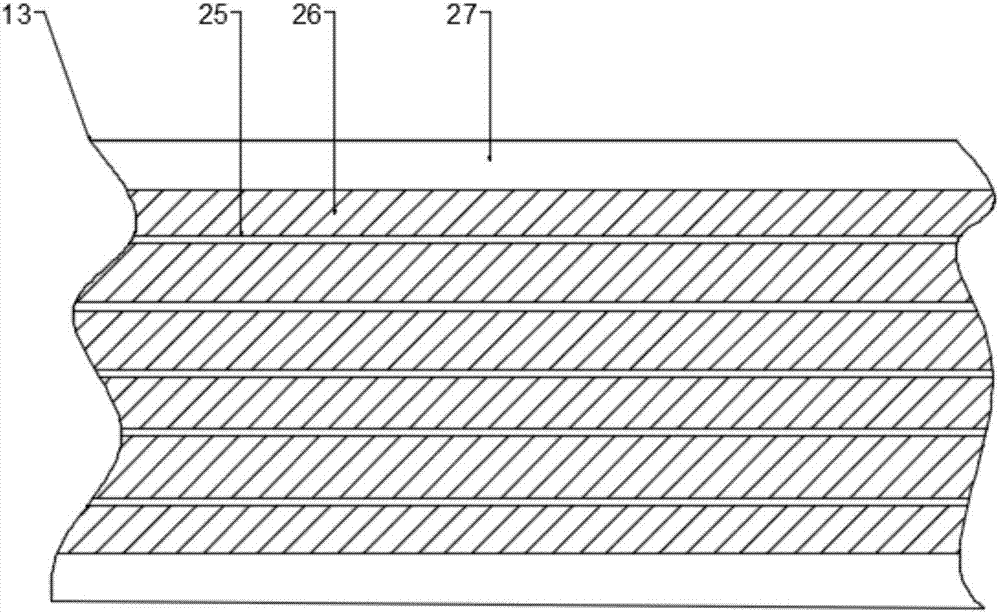

InactiveCN110900227AGuarantee processing quality and precisionSimple structureLifting framesMetal working apparatusStructural engineeringPower apparatus

The invention discloses a lifting platform suitable for supporting feeding of large-pipe-diameter pipes. The lifting platform belongs to the technical field of pipe machining equipment. The lifting platform comprises a power device, a steering gear I and a steering gear II, wherein the power device is connected with an input shaft of the steering gear I; connecting shafts are connected to output ends of the left and right sides of the steering gear I; an output end of the rear side of the steering gear I is connected with an input shaft of the steering gear II; output ends of the left side andthe right side of the steering gear II are connected with connecting shafts, and worm gear lead screw lifters are connected to the connecting shafts; and at least two sets of brackets used for supporting pipes are installed on the upper portions of the worm gear lead screw lifters. According to the lifting platform, a screw rod lifter is controlled to ascend or descend by means of the power device, and the height of the brackets can be adjusted, so that the axes of the pipes and the axis of a totally-enclosed plate-pipe all-in-one machine are at the same height, the machining quality and precision of the pipes are guaranteed, the universality is good, the manufacturing cost is low, the use is safe and reliable, the production operation efficiency can be improved, and the lifting platformcan be used as a pipe feeding support and used for supporting the pipes in the cutting process.

Owner:SHANDONG LEIMING CNC LASER EQUIP CO LTD +2

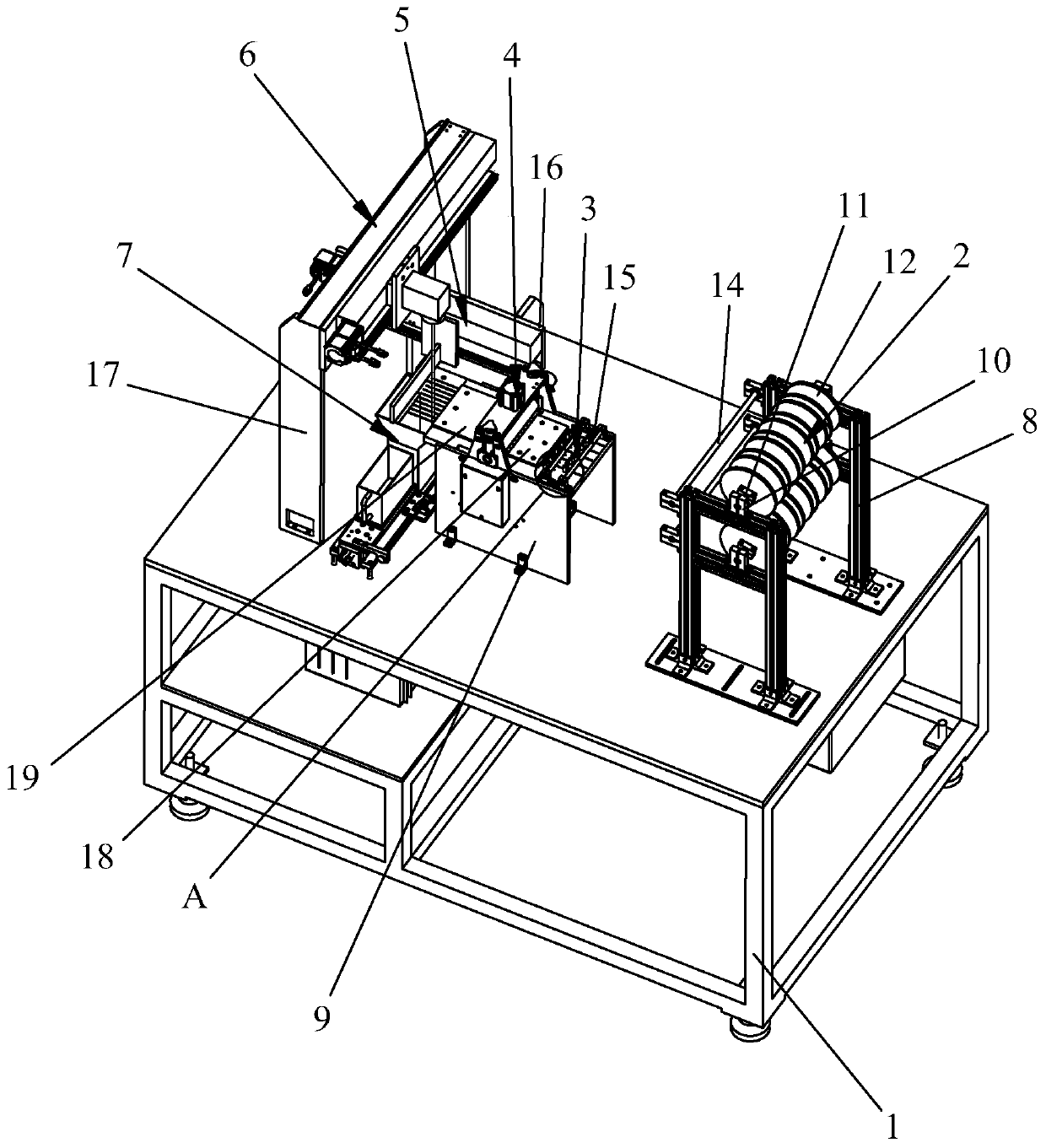

Stainless steel pipe cutting device for pen

ActiveCN110948037AQuick cutGuarantee the safety of lifeTube shearing machinesShearing machine accessoriesEngineeringStructural engineering

The invention discloses a stainless steel pipe cutting device for a pen. The device comprises a cabinet body, a winding mechanism, a guiding mechanism, a feeding mechanism, a size limiting mechanism,a cutting mechanism and a material receiving mechanism, wherein a fixing frame is arranged on the cabinet body, the winding mechanism is arranged on the fixing frame and is used for winding a stainless steel pipe, a supporting table is arranged on the position, located on one side of the fixing frame, of the cabinet body, the guiding mechanism and the feeding mechanism are arranged on the supporting table, the feeding mechanism pulls the stainless steel pipe and is guided through the guiding mechanism, and when the head end of the stainless steel pipe is conveyed above the material receiving mechanism and abuts against the size limiting mechanism, the cutting mechanism cuts the stainless steel pipe and the cut stainless steel pipe is collected through the material receiving mechanism. Thedevice has the advantages of high processing efficiency, good processing precision, high safety, and can guarantee the life safety of employees.

Owner:WENZHOU UNIVERSITY

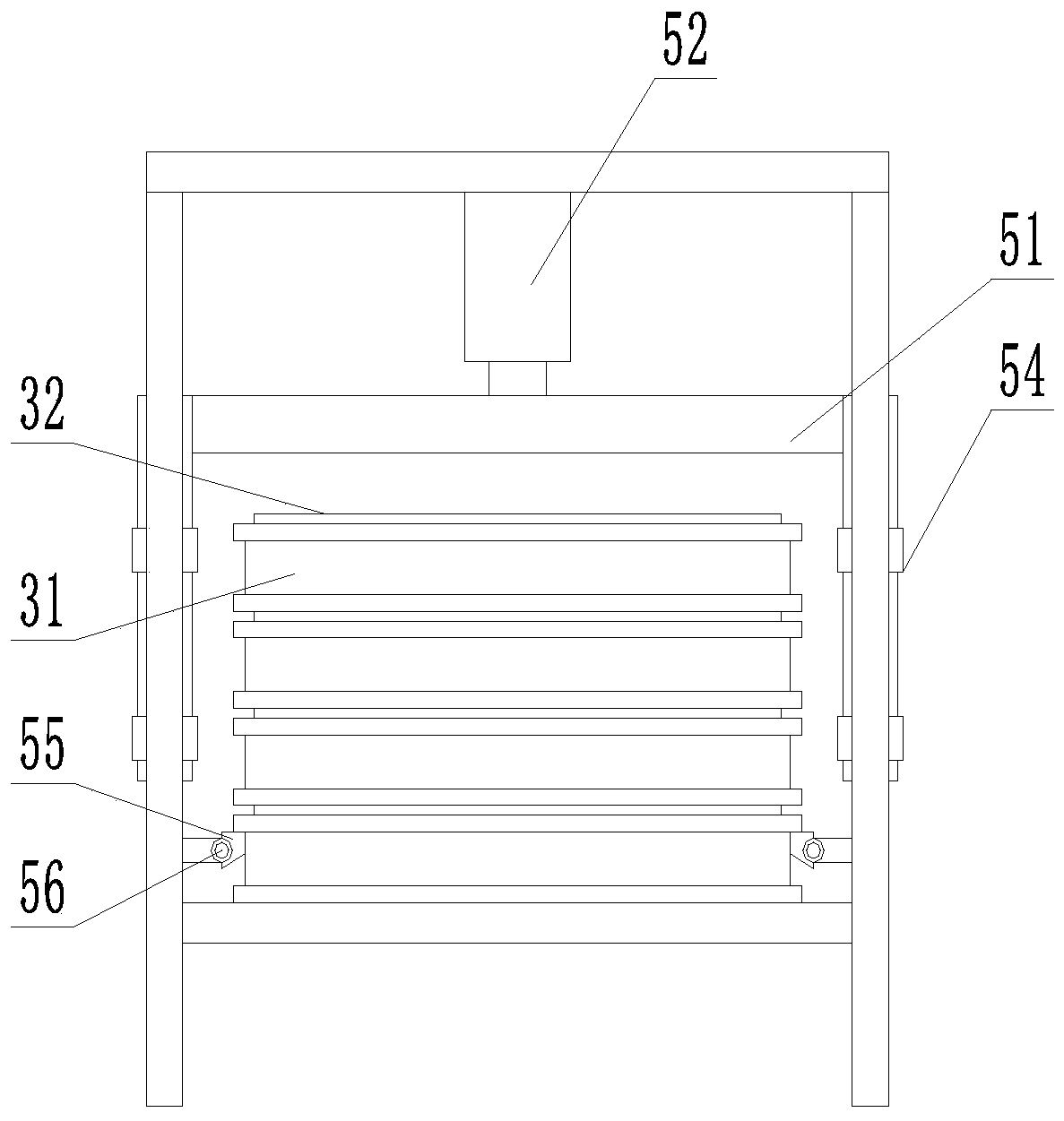

Full-automatic dried bean curd production system and dried bean curd production method

PendingCN111053122AGuaranteed production efficiencyLow costCheese manufactureFood scienceChemistryAgricultural engineering

The invention discloses a full-automatic dried bean curd production system and a dried bean curd production method, and belongs to the technical field of dried bean curd production equipment. A stacking piece moves on a guide piece in the vertical direction on a fixed frame; when a limiting plate is encountered, after counterclockwise rotation, resetting is realized under the action of a torsionalspring and the limiting plate is positioned between an upper limiting plate and a lower limiting plate; when the output end of a stacking driving part withdraws, the stacking part supports the limiting plate to enable a frame mold to reach a certain height, then the frame mold enters a next procedure to be squeezed for 15 times, and redundant water in the bean curd can be sufficiently dischargedthrough the frame mold and through holes in a frame cover plate.

Owner:JINCAIDI FOOD CO LTD

An industrial laser cutting machine

ActiveCN110315217BInfluence of cutting efficiencyImprove cutting efficiencyLaser beam welding apparatusEngineeringLaser cutting

Owner:BENGBU COLLEGE

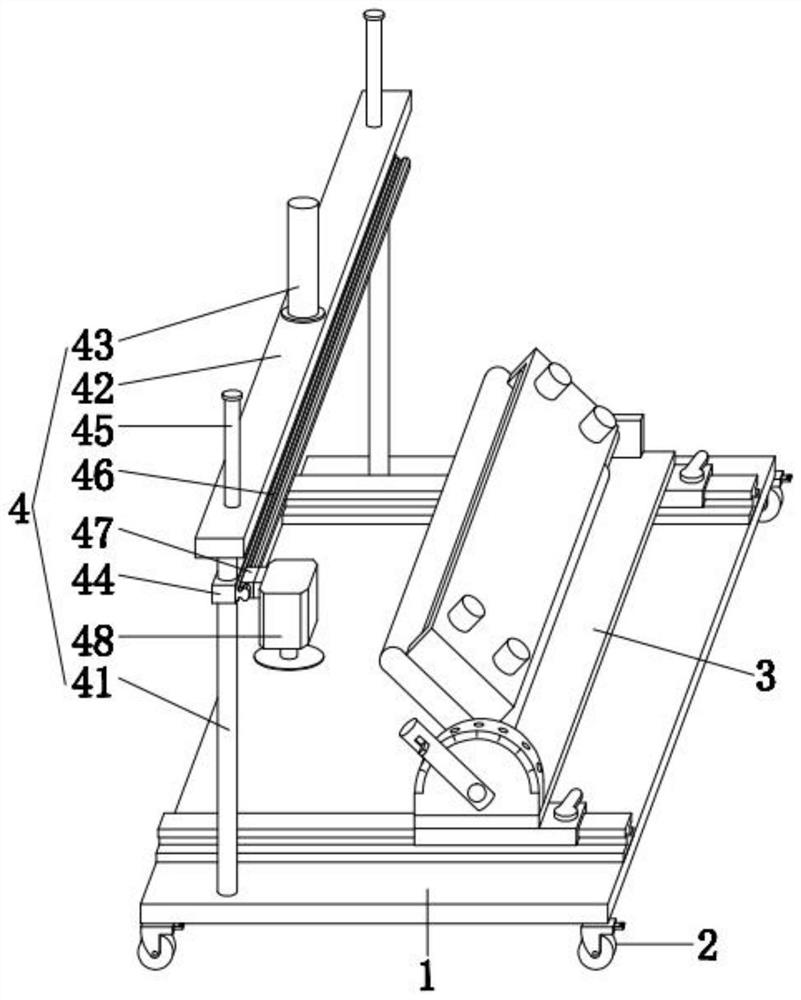

Intelligent cutting equipment for buildings

InactiveCN112060369ARealize multi-angle fixationTo achieve the purpose of positioningWorking accessoriesStone-like material working toolsConstruction engineeringStructural engineering

The invention discloses intelligent cutting equipment for buildings. The intelligent cutting equipment comprises a base and four universal wheels, wherein the four universal wheels are detachably arranged at four corners of the bottom of the base correspondingly, and the intelligent cutting equipment further comprises a positioning mechanism, detachably arranged at the top of the base; and a cutting mechanism, detachably arranged at the left end of the top of the base. When the intelligent cutting equipment is used for cutting, materials can be positioned, the situation that cutting quality isaffected due to shaking is avoided, multi-angle positioning of the materials can be achieved, the accuracy of chamfering and multi-angle cutting of the materials is guaranteed, time and labor are saved, limitation is small, the quality of cut products is guaranteed, and cutting requirements of ceramic tiles, ceramic plates and other materials are greatly met.

Owner:徐云

Leveling device used for fireproof coiled material cutting

InactiveCN110653857AGuaranteed cutting qualityEasy to processMetal working apparatusElectric machineStructural engineering

The invention discloses a leveling device used for fireproof coiled material cutting, and relates to the field of cutting devices. For solving the problem of poor cutting quality due to the fact thatfolded edges of a material cannot be leveled through existing cutting equipment, the leveling device comprises two transverse fixed transverse plates fixed to a base, a material receiving table is arranged between the two fixed transverse plates, a transverse sliding groove is formed in the bottom of the material receiving table, a transverse guiding cross rod is fixed in the transverse sliding groove, two moving sliding blocks are slidably matched on the guiding cross rod, two vertical supporting rods fixed on the base are arranged at the bottom of the fixed transverse plates, forward and reverse rotating motors are fixed to the front sides of the supporting rods, and rockers are fixed to output shafts of the forward and backward rotating motors. According to the leveling device, the device not only can cut the to-be-cut materials, but also can carry out leveling on the folded edges before cutting, the cutting quality is prevented from being influenced by the folded edges, the cuttingeffect is good, the whole device is simple in structure, and the manufacturing cost is low.

Owner:HUZHOU TEACHERS COLLEGE

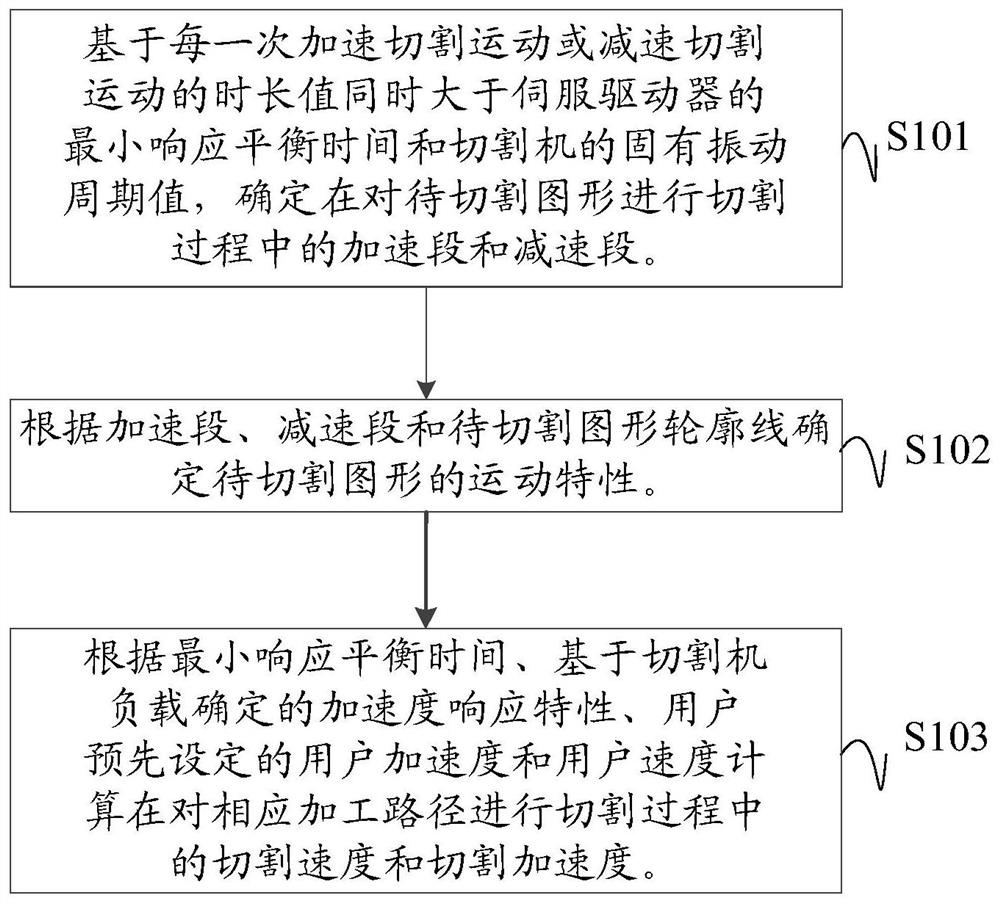

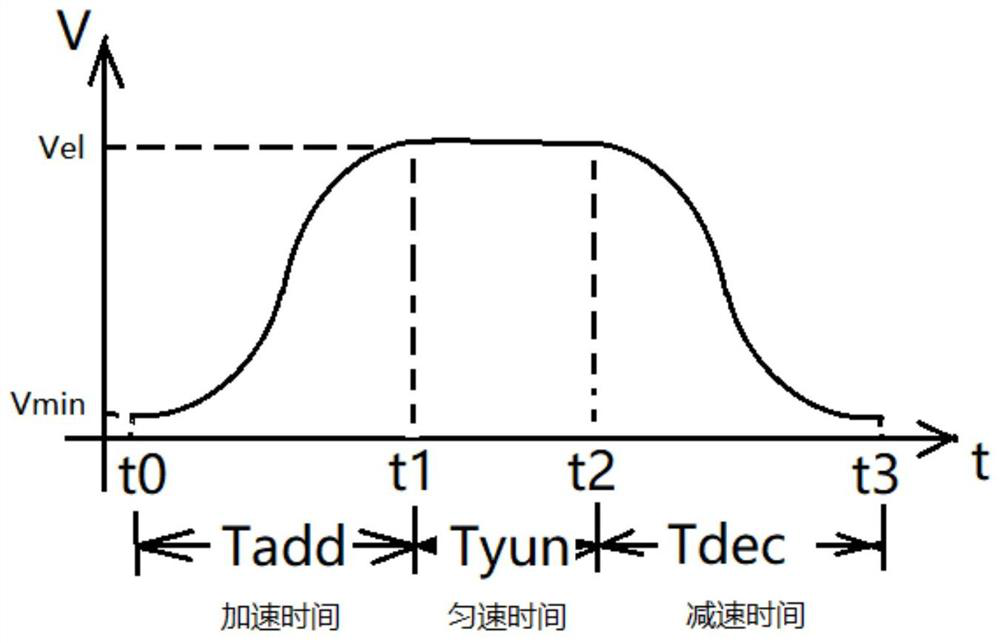

Cutting motion control method and device, and computer readable storage medium

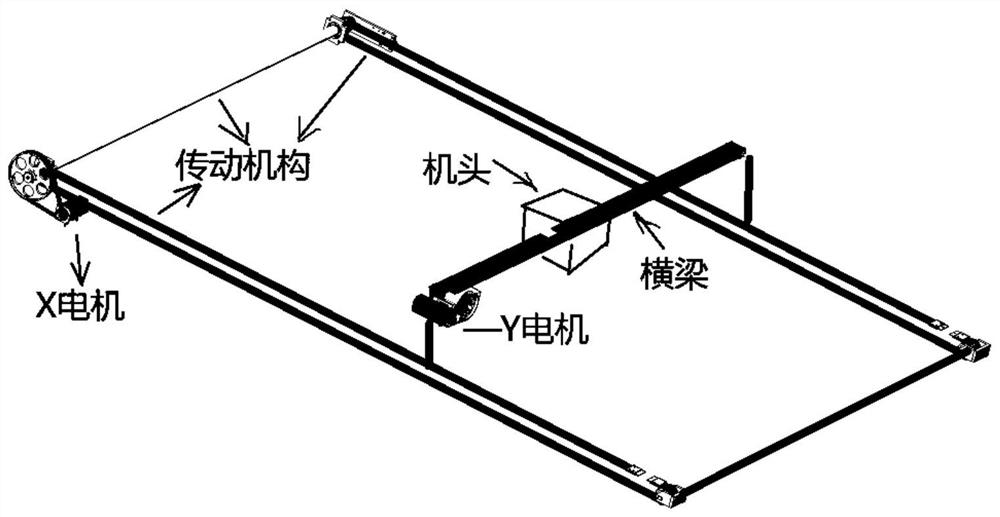

ActiveCN112783096AImprove user experienceAvoid compromising cut qualityProgramme controlComputer controlPhysicsMachining toolpath

The invention discloses a cutting motion control method and device, and a computer readable storage medium. The method comprises the following steps: determining an acceleration section and a deceleration section in the cutting process of a to-be-cut graph on the basis that the duration value of each acceleration cutting motion or deceleration cutting motion is larger than the minimum response balance time of a servo driver and the natural vibration period value of a cutting machine at the same time; determining a processing path of the to-be-cut graph according to the contour line of the to-be-cut graph, and determining an acceleration section and a deceleration section of the corresponding processing path according to the minimum response balance time, an acceleration response characteristic determined based on the rigidity of the cutting machine, and a user acceleration and a user speed preset by a user; and calculating the maximum cutting speed and the maximum cutting acceleration in the cutting process of the corresponding machining path. The machining path with the known length can be stably cut within the shortest time, materials can be cut in a high-acceleration, high-movement-speed and low-vibration mode so that the cutting quality can be guaranteed, and the cutting efficiency and the cutting precision are effectively improved.

Owner:HANGZHOU ECHO SCI TECH

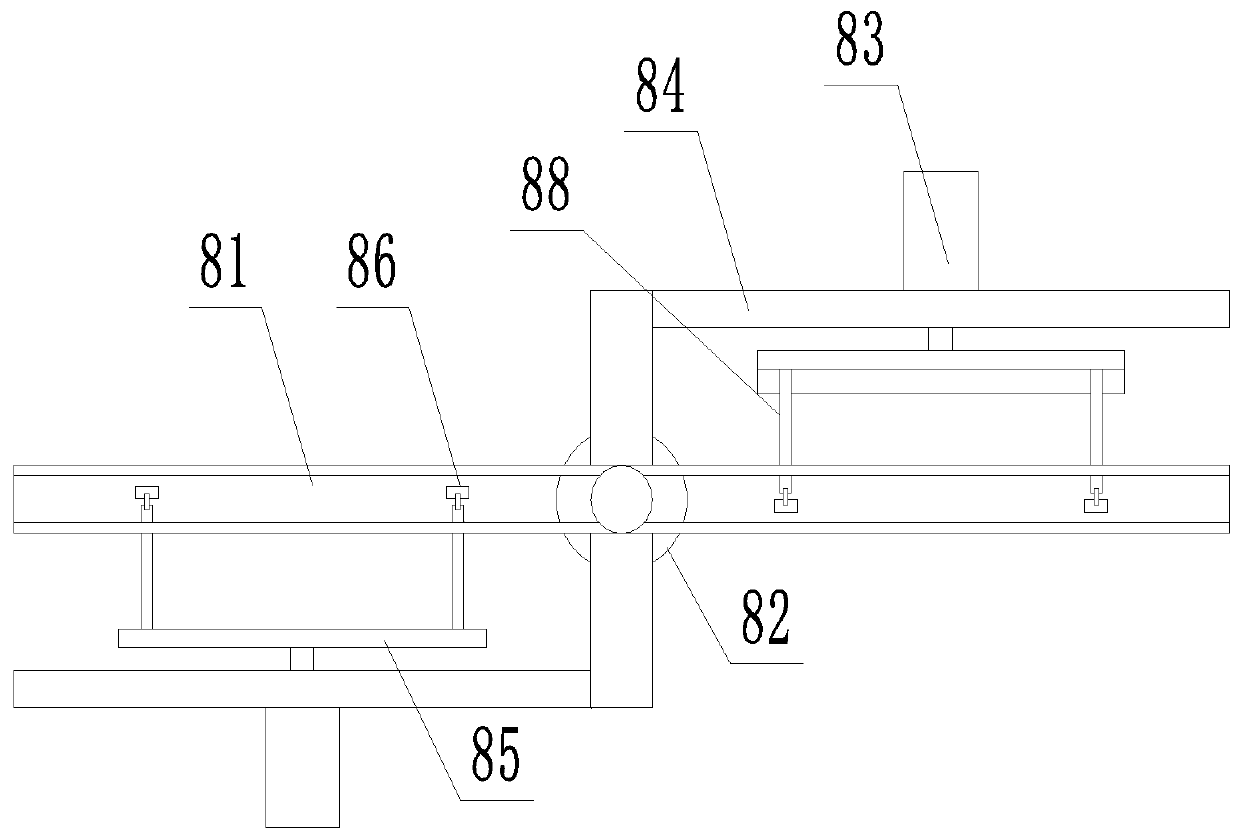

Production method of dried tofu with high-quality mouth feel

ActiveCN111034812AFull and efficient mixingQuality assuranceCheese manufactureFood scienceProcess engineeringIndustrial engineering

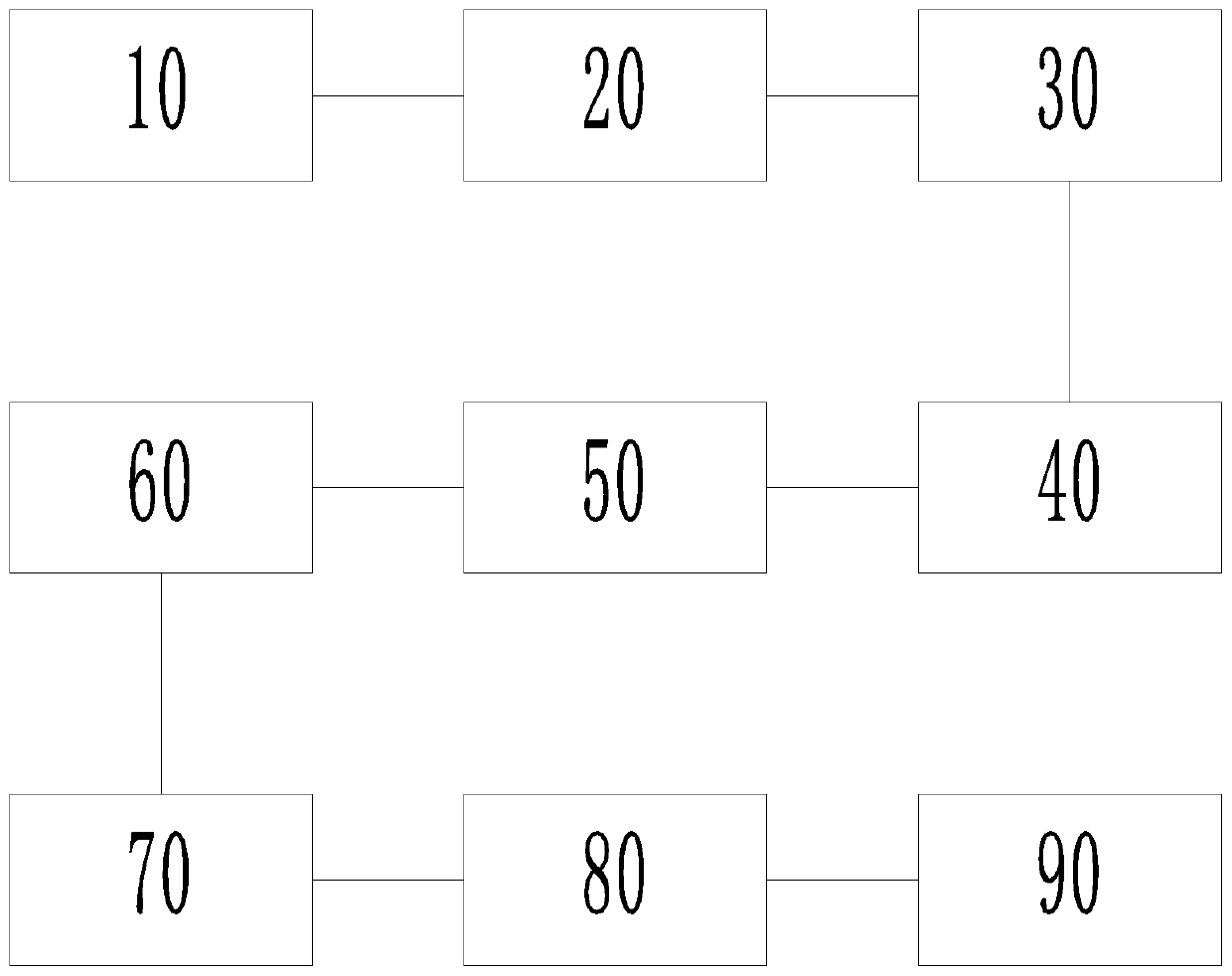

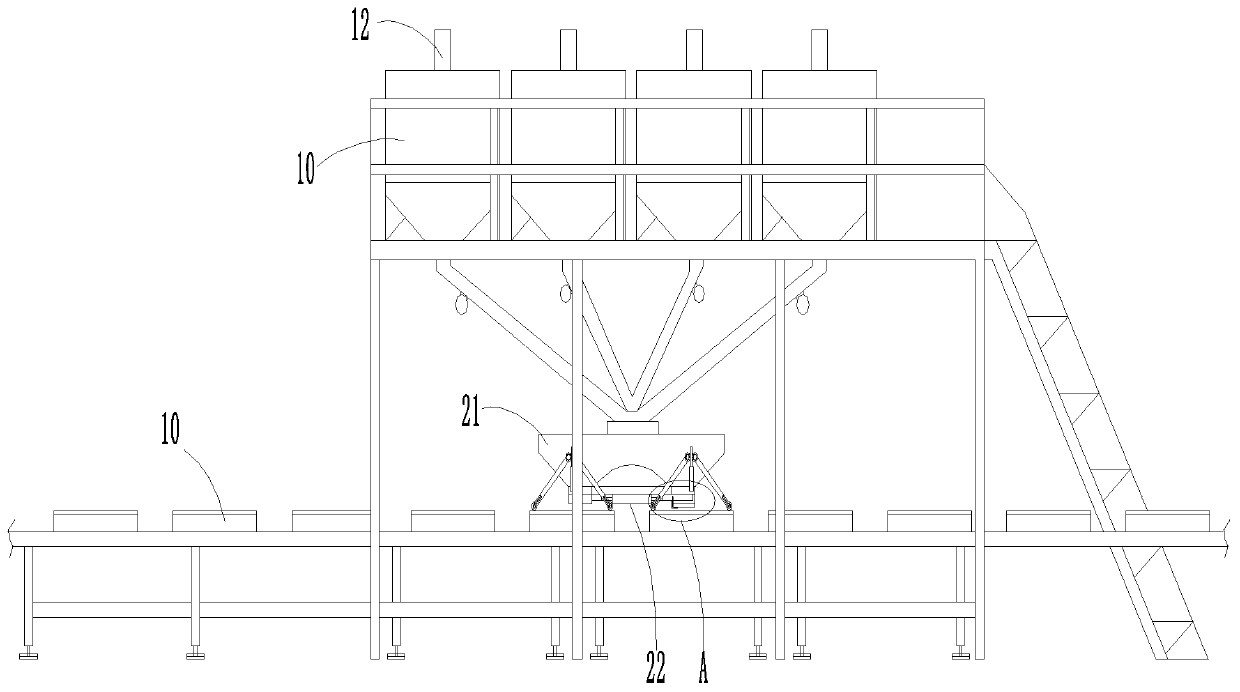

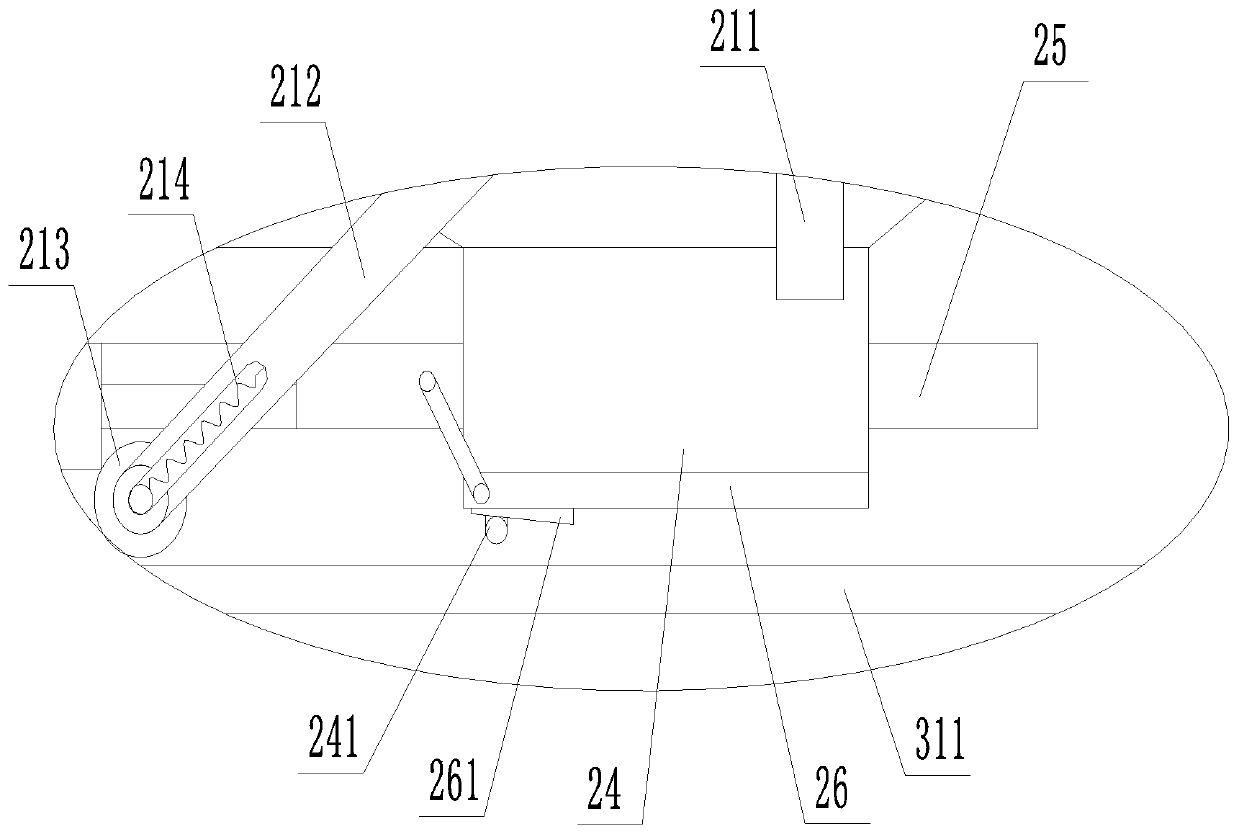

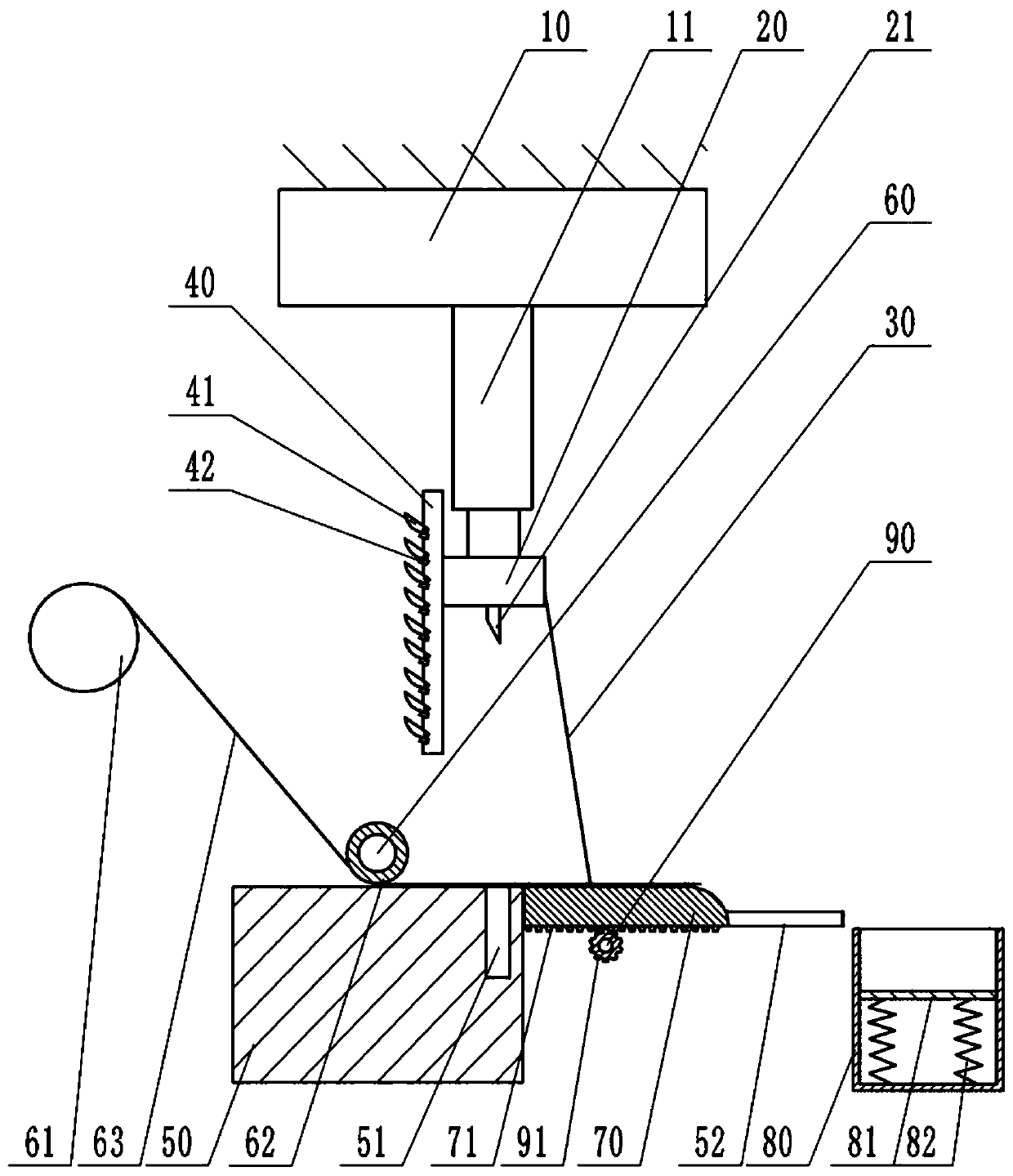

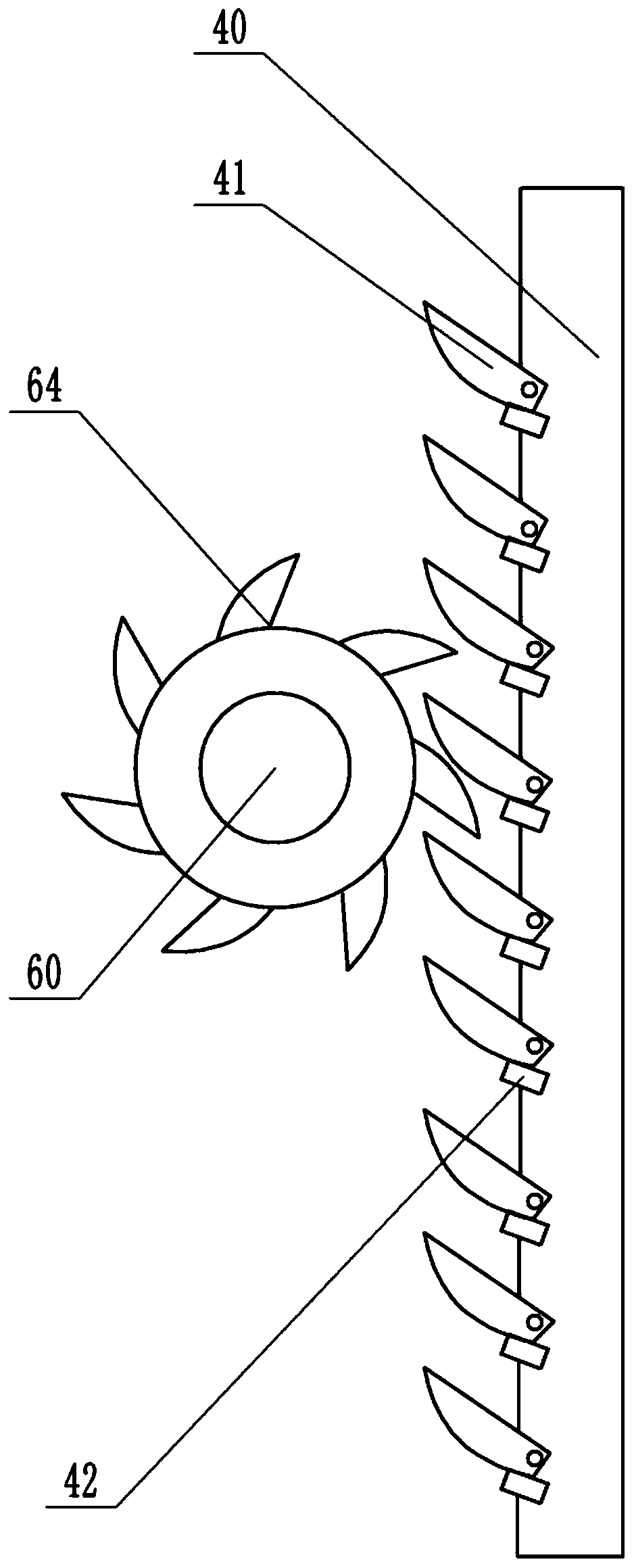

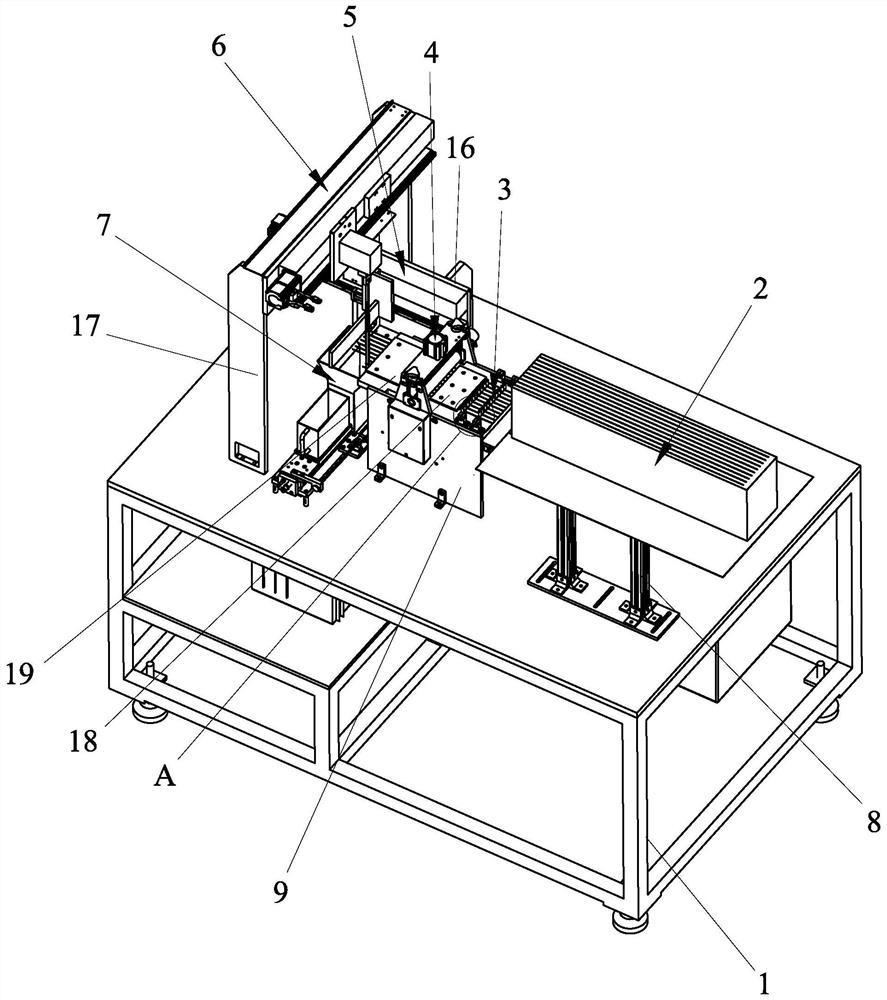

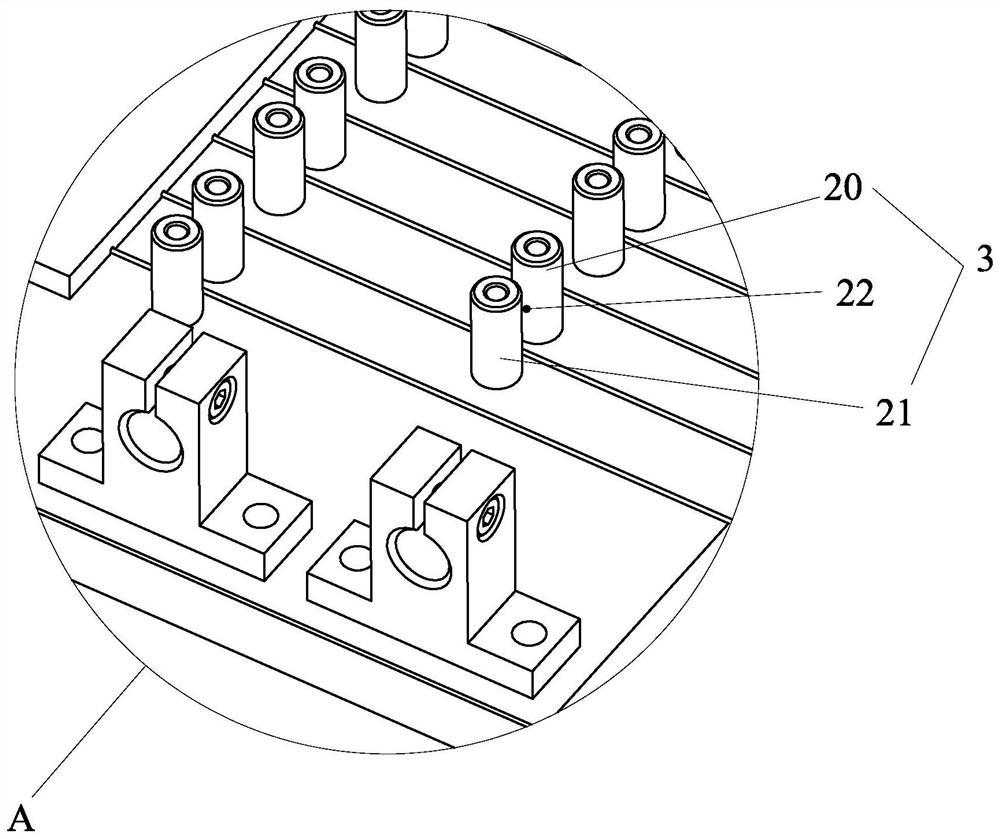

The invention discloses a production method of dried tofu with high-quality mouth feel, and belongs to the technical field of dried tofu production processes. A marinating barrel (10), a distributionmechanism (20), a frame conveying mechanism (30), a cover plate conveying mechanism (40), a stacking mechanism (50), a squeezing mechanism (60), a splitting mechanism (70), a plate overturning mechanism (80) and a dicing mechanism (90) are sequentially arranged from front to back. The production method comprises the steps of sequentially performing soybean milk marinating, mold forming, stacking,primary continuous squeezing, layer-by-layer splitting, plate overturning, dicing and secondary continuous squeezing so as to obtain the dried tofu with high-quality mouth feel. The production methodhas the advantages of high marinating quality, high bean curd jelly forming quality, uniform size of bean curd jelly forming blocks, high degree of automation, high production efficiency, saving of equipment cost, release of limited space, improvement of workshop space utilization rate, great reduction of labor intensity and saving of labor cost.

Owner:JINCAIDI FOOD CO LTD

Device for automatically cutting off fiber nibs

ActiveCN110978072AImprove processing efficiencyImprove machining accuracyMetal working apparatusStructural engineeringFiber

The invention discloses a device for automatically cutting off fiber nibs. The device comprises a cabinet, a discharging mechanism, a guiding mechanism, a feeding mechanism, a size limiting mechanism,a cutting mechanism and a collecting mechanism, wherein a fixing frame is arranged on the cabinet, the discharging mechanism is arranged on the fixing frame and is used for guiding out fiber strips,the portion, located at one side of the fixing frame, of the cabinet is provided with a supporting platform, the guiding mechanism and the feeding mechanism are arranged on the supporting platform, and the feeding mechanism pulls the fiber strips and conducts guiding through the guiding mechanism. When the head ends of the fiber strips are conveyed to the position above the conveying mechanism andabut against the size limiting mechanism, the cutting mechanism cuts the fiber strips, and the fiber strips which are cut off are collected through the collecting mechanism. The device has the advantages of being high in machining efficiency and machining precision, high in safety and capable of guaranteeing life security of employees.

Owner:WENZHOU UNIVERSITY

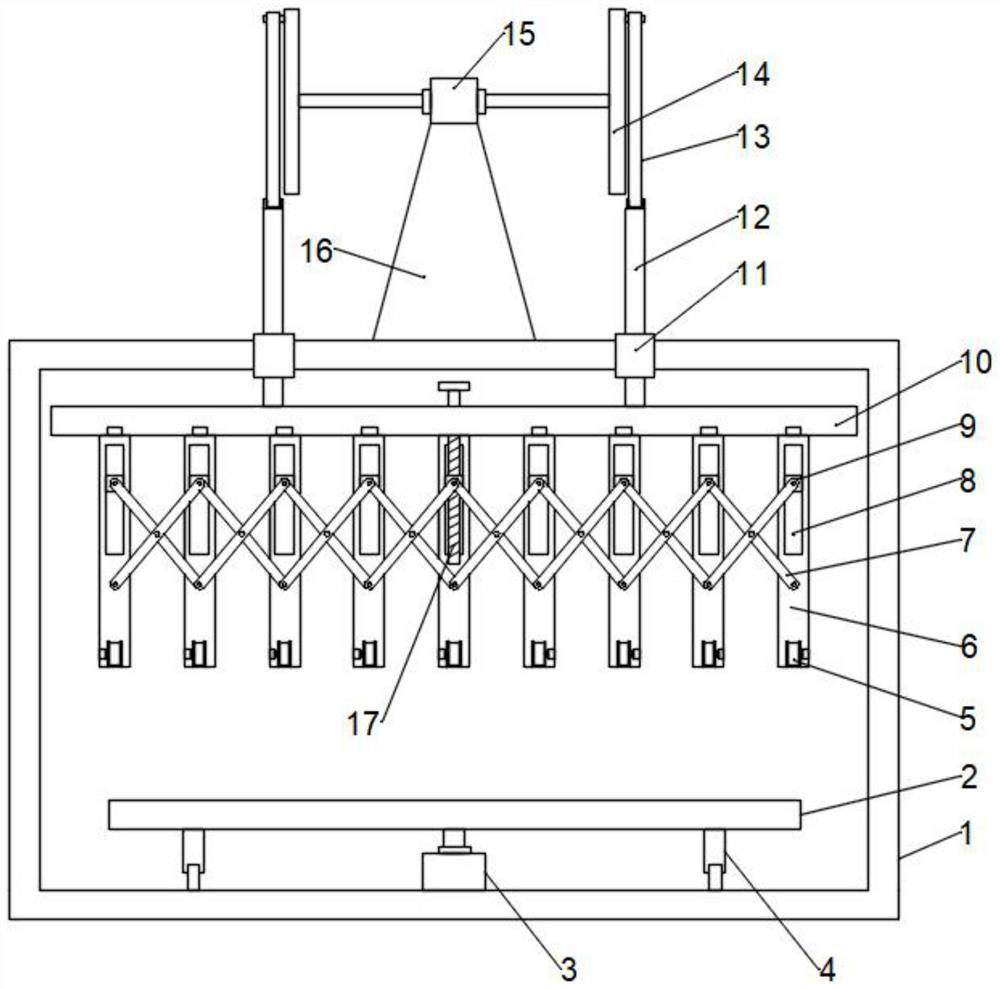

High-precision aerated concrete block production device

PendingCN114211599AImprove work efficiencyImprove adaptabilityCeramic shaping apparatusGear wheelConstruction engineering

The invention is suitable for the technical field of concrete production, and provides a high-precision aerated concrete block production device which comprises a rack; the workbench is mounted on the rack; the cutting assembly is arranged above the workbench and comprises a plurality of steel wires which are arranged in parallel at intervals; the adjusting assembly is used for synchronously adjusting the distance between adjacent steel wires, the transmission part comprises a second connecting rod, a rack, a gear and a third connecting rod, one end of the third connecting rod is eccentrically hinged to the end face of the gear, the other end of the third connecting rod is hinged to a guide sleeve, and the guide sleeve is longitudinally installed on the rack in a sliding mode; according to the aerated concrete cutting device, aerated concrete can be cut at the same time through the multiple steel wires, the working efficiency is improved, the distance between the steel wires is adjusted through the adjusting assembly, the aerated concrete can be cut into blocks of different sizes, and the adaptability is improved; and the transmission part is arranged, the steel wire is driven to gradually descend, meanwhile, longitudinal reciprocating cutting is conducted, aerated concrete cutting is facilitated, and the cutting speed is increased.

Owner:绍兴高新技术产业开发区迪荡新城投资发展有限公司

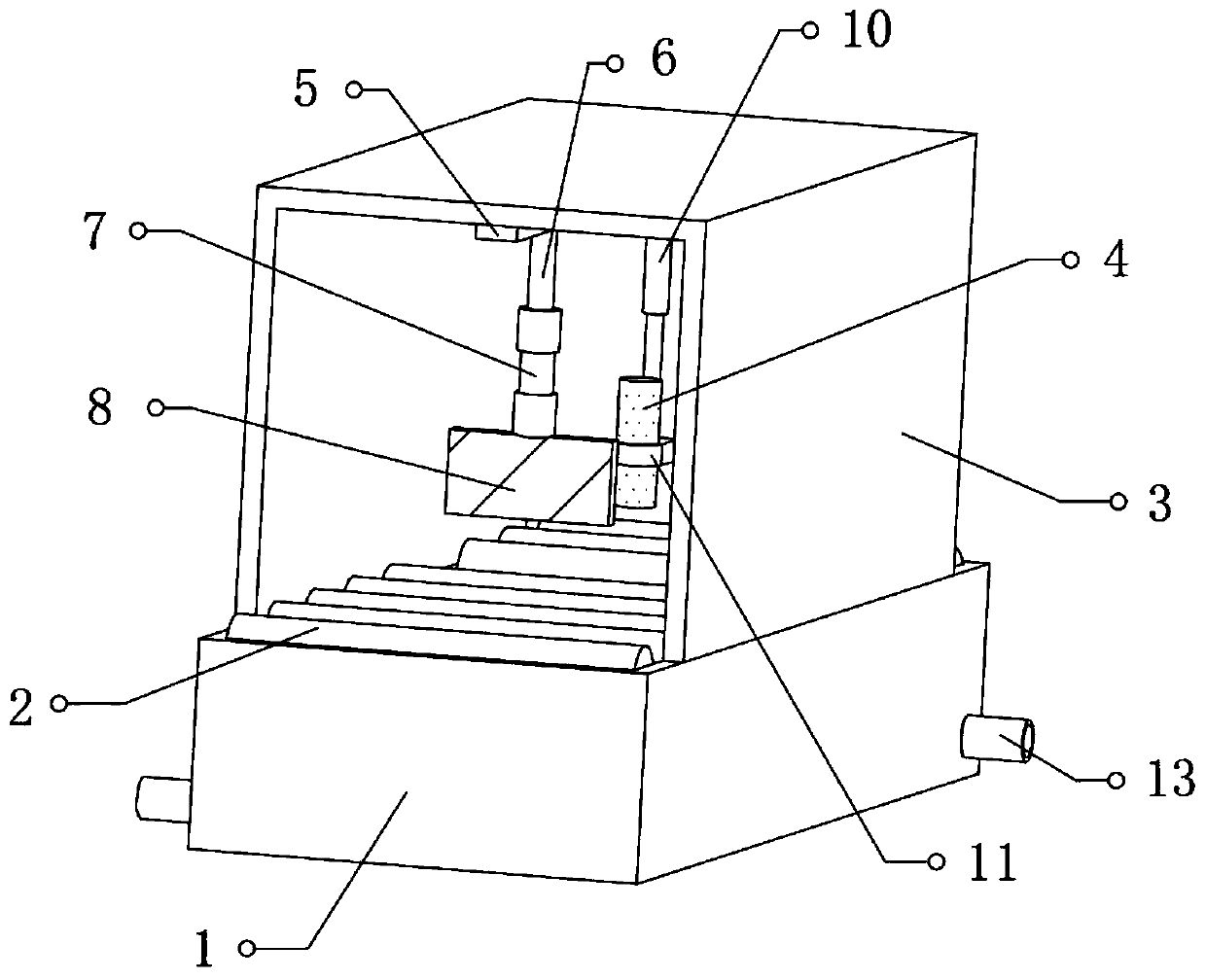

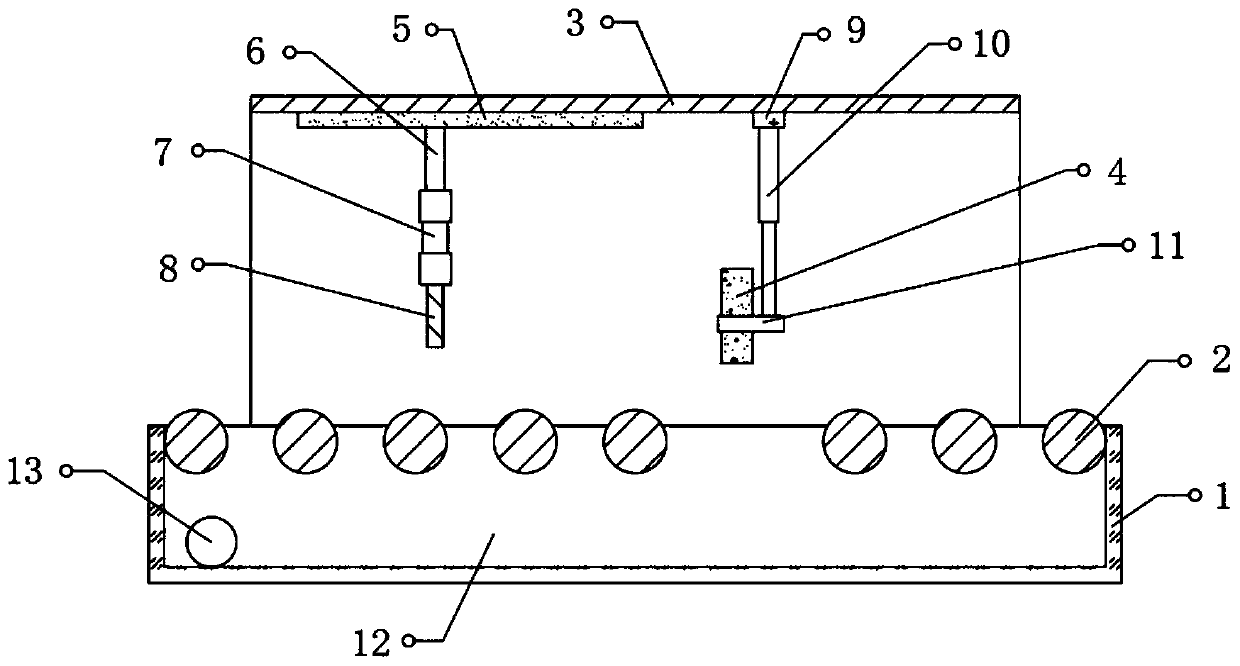

Plate cutting device for automotive frame middle plate machining

InactiveCN110280829AAvoid offsetAccurate massMaintainance and safety accessoriesShearing machine accessoriesMechanical engineeringEngineering

The invention discloses a plate cutting device for automotive frame middle plate machining. The device comprises a base, wherein a plurality of conveying rollers are arranged at the top of the base, a fixing frame is fixed to the top of the base, a cutting mechanism is arranged on one side inside the fixing frame, a first electric guide rail is fixed on the side, far away from the cutting mechanism, of the inner wall of the top of the fixing frame, a fixing piece is connected to the bottom of the first electric guide rail, the bottom end of the fixing piece is fixedly provided with an air cylinder, and the bottom end of the air cylinder is connected with a baffle plate. According to the plate cutting device, a plurality of conveying rollers are arranged on the base for plate conveying operation, the cutting mechanism in the fixing frame is used for carrying out cutting operation, the condition that plates slide forwards to cause the cutting position to be deviated after the plates are conveyed to the position is avoided through limiting of the baffle plate, the distance between the baffle plate and the cutting mechanism can be selected according to requirements through the connection of the first electric guide rail, so that that accurate cutting operation and cutting quality can be ensured.

Owner:十堰市乾德工贸有限公司

Clothing fabric cutting equipment

The invention discloses clothing fabric cutting equipment, and relates to the technical field of clothing. The clothing fabric cutting equipment comprises a fixed seat; two supporting plates are fixedly connected with the right side of the upper surface of the fixed seat; a winding wheel is fixedly hinged between the two supporting plates through a pin shaft; the outer surface of the winding wheelis wound with fabric; two symmetrical electric push rods are fixedly connected with the upper surface of the fixed seat; the telescopic ends of the electric push rods are fixedly connected with a movable plate; a connecting plate is fixedly connected with the middle part of the bottom surface of the movable plate; the bottom end of the connecting plate is fixedly connected with a cutting wheel through a pin shaft; two symmetrical sleeves are fixedly connected with the bottom surface of the movable plate; each sleeve is internally provided with a telescopic spring; a sleeve rod is arranged atthe lower part of each telescopic spring; and the bottom ends of the two sleeve rods correspondingly penetrate through the two sleeves and extend out of the sleeves. With the adoption of the clothingfabric cutting equipment, the fabric can be fixed as a whole, and self-dislocation of the fabric is avoided during cutting so as not to cause cutting deformation which affects the cutting quality.

Owner:广东国色婚纱礼服有限公司

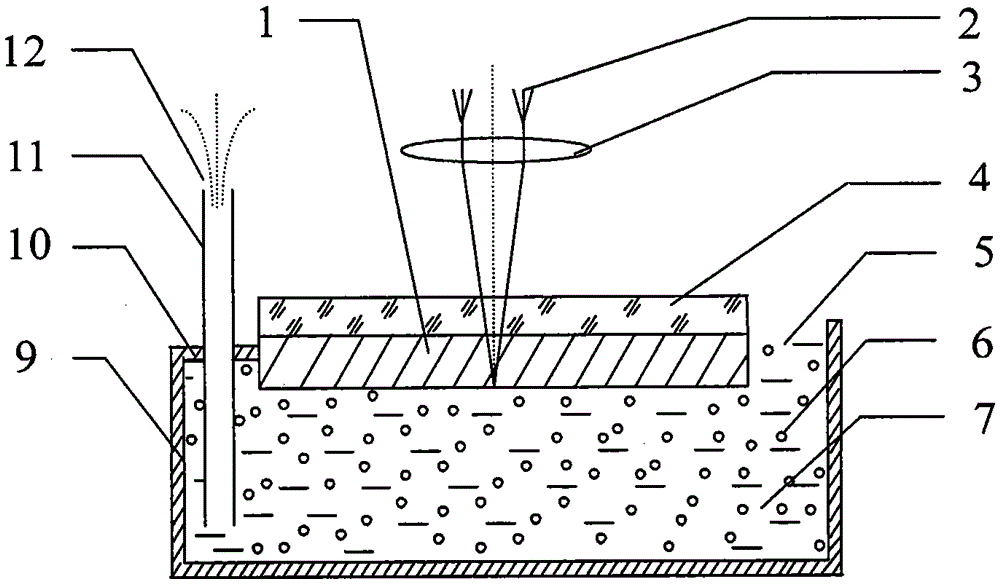

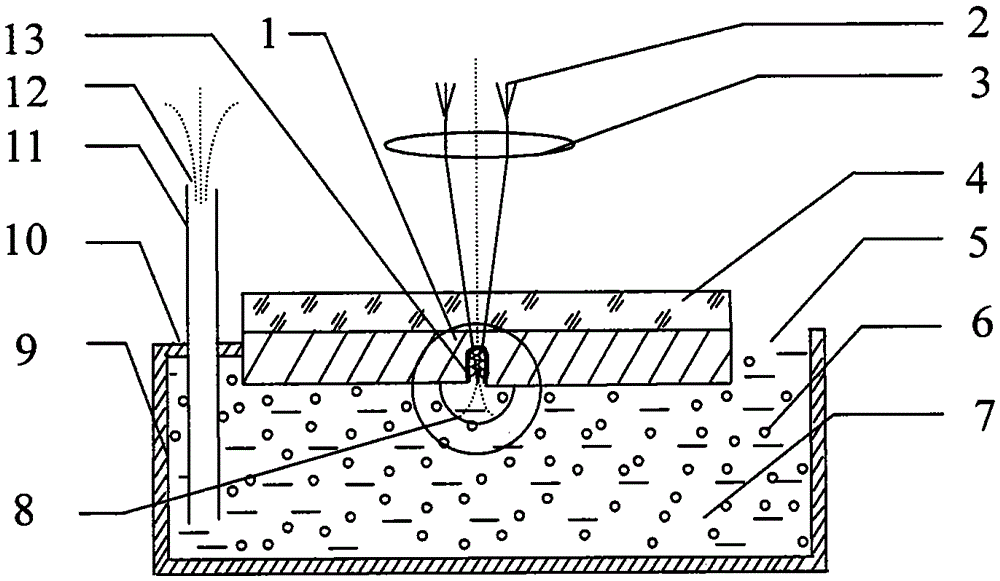

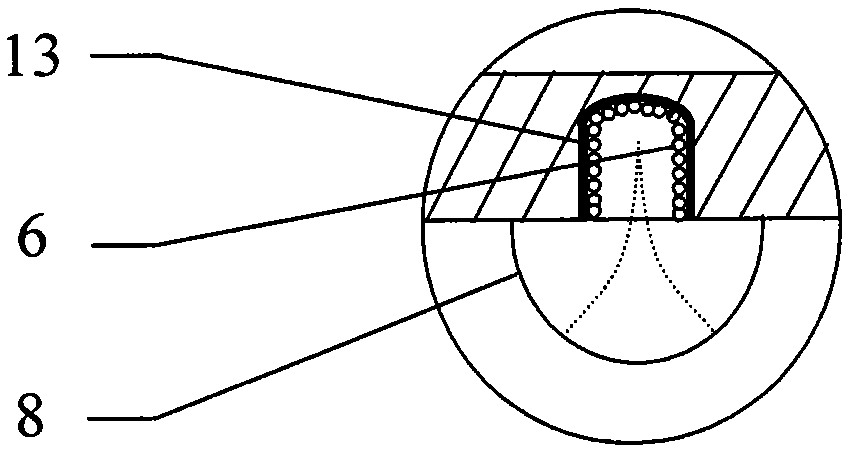

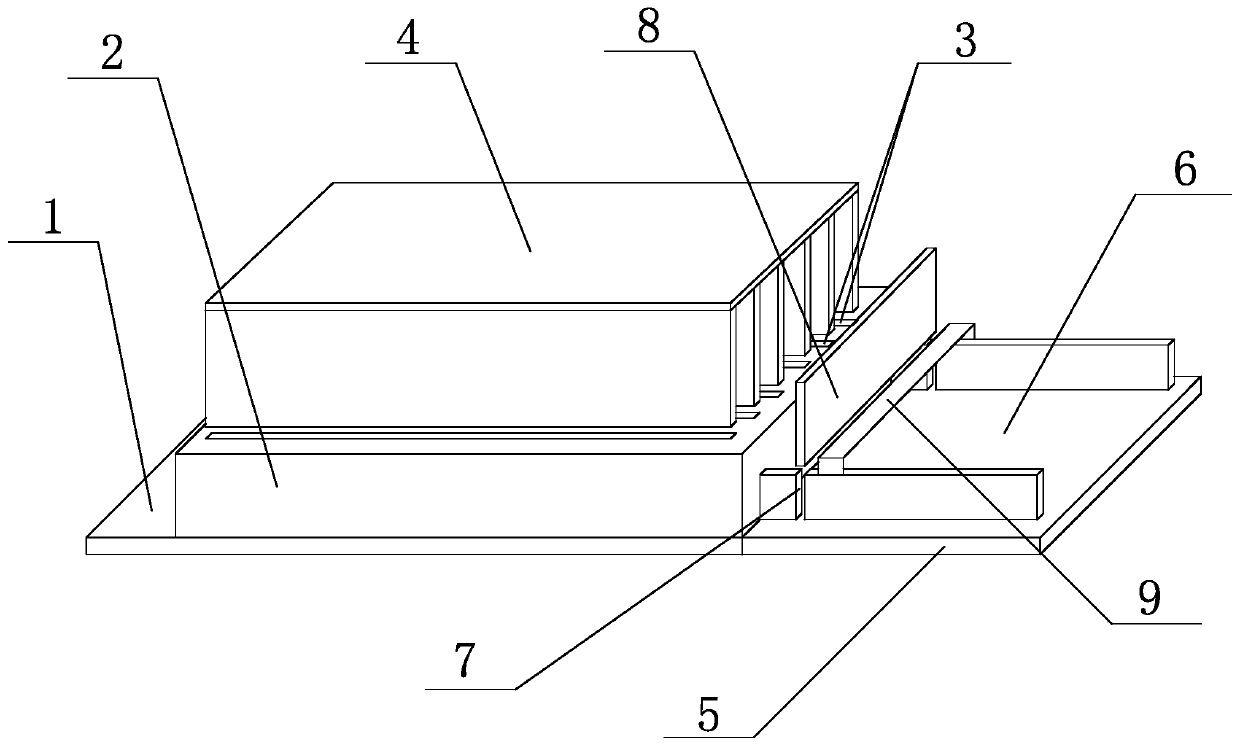

A processing method and device for laser forming and cutting sapphire substrate

ActiveCN104028898BDebris take awayEasy to take awayVacuum evaporation coatingSputtering coatingSuspended particlesRegelation

The invention discloses a machining method and device for laser forming cutting of a sapphire substrate. The machining device mainly comprises a protection device, a laser beam, a lens set, a container, a limiting layer, suspended particles and a gas inlet pipe. Working liquid is arranged in a cavity formed in the container, the working liquid generates a sedimentation layer on the lower surface of a base material through lasers, the suspended particles in the liquid at a solid-liquid contact face and the sedimentation layer are combined to enhance the absorption of laser energy so that the melting temperature and the vaporizing temperature of sapphire materials near a laser focus can be reached, in addition, under laser irradiation, a large amount of small bubbles are generated with the suspended particles as the centers, bubble detonation impact force is used for brushing cut grooves, discharging of chippings is facilitated, and therefore the materials can be removed under the combined action of the laser action and the laser irradiation. According to the machining method, the heat effect of the cut grooves is small, a regelation layer in a machined area is omitted, machining quality is high, and forming cutting can be achieved. The machining method is easy to operate, convenient to conduct, practical, high in machining rate and extremely-low in machining cost.

Owner:GUANGDONG UNIV OF TECH

Meat cutting equipment that can prevent meat from sticking to the knife

The invention discloses meat cutting equipment capable of preventing meat loaf from adhering to a knife. The meat cutting equipment comprises a workbench, the workbench is provided with a meat cutting box, openings are formed in the two end faces of the meat cutting box, the meat cutting box and the workbench form a channel which is opened at the two ends, and multiple parallelly formed knife entering openings are formed in the top face of the meat cutting box; a cutter set is arranged above the knife entering openings; a loaf cutting table is arranged at one opened end of the channel, and is provided with a cutting groove communicated with the channel, the two side walls of the cutting groove are parallel to the channel, a cutting opening is formed in each of the two sides walls of the cutting groove, a meat loaf cutter is arranged above the cutting opening, and a scratch board perpendicular to the side wall of the cutting groove is connected to the upper portion of the cutting groove, the scratch board is located at the side, away from the meat cutting box beside the cutting opening. The meat cutting equipment capable of preventing the meat loaf from adhering to the knife can fast cut the meat loaf, reduce manual operation, prevent the meat loaf from adhering to the knife and cause secondary cutting smashing of the meat loaf, therefore cannot damage the shape of the meat loaf, and enables the prepared pork shashlik to better conform to the requirement.

Owner:德阳市东泽食品有限公司

paper cutter

ActiveCN108145760BAvoid compromising cut qualityEasy to collectMetal working apparatusDrive shaftPulp and paper industry

The invention belongs to the field of paper processing devices, and particularly discloses a paper cutting machine. The paper cutting machine comprises a paper feeding mechanism, a cutting mechanism and a collection mechanism, wherein the cutting mechanism comprises a workbench, a rack, a mounting base, a cutter and a power device; a cutting groove is formed in the upper surface of the workbench;the paper feeding unit comprises an uncoiling roller, a rotary shaft and a paper feeding roller; the paper feeding roller is fixed to the rotary shaft; the rotary shaft is provided with a ratchet wheel; the mounting base is provided with a mounting strip; a plurality of clamping jaws are hinged to the mounting strip and can be clamped to the ratchet wheel; the collection mechanism comprises a slide rail, a torsional spring, a transmission shaft, a conveying board and a collection tank; the conveying board is in sliding connection with the slide rail; a gear is fixed to the transmission shaft;a rack is arranged on the lower surface of the conveying board; one end of the torsional spring is fixed to the workbench; the other end of the torsional spring is fixed to the transmission shaft; thetransmission shaft is wound with a pull rope; and the pull rope is connected to the mounting base. When the paper cutting machine is used, the cutting quality can be ensured, burrs at notches are avoided, cut paper can be effectively collected, and pieces of paper are stacked orderly.

Owner:浙江拉菲草纸制品有限公司

An automatic fiber cutting device

ActiveCN110978072BGuarantee the safety of lifeImprove processing efficiencyMetal working apparatusFiberStructural engineering

The invention discloses a device for automatically cutting off fiber nibs. The device comprises a cabinet, a discharging mechanism, a guiding mechanism, a feeding mechanism, a size limiting mechanism,a cutting mechanism and a collecting mechanism, wherein a fixing frame is arranged on the cabinet, the discharging mechanism is arranged on the fixing frame and is used for guiding out fiber strips,the portion, located at one side of the fixing frame, of the cabinet is provided with a supporting platform, the guiding mechanism and the feeding mechanism are arranged on the supporting platform, and the feeding mechanism pulls the fiber strips and conducts guiding through the guiding mechanism. When the head ends of the fiber strips are conveyed to the position above the conveying mechanism andabut against the size limiting mechanism, the cutting mechanism cuts the fiber strips, and the fiber strips which are cut off are collected through the collecting mechanism. The device has the advantages of being high in machining efficiency and machining precision, high in safety and capable of guaranteeing life security of employees.

Owner:WENZHOU UNIVERSITY

An operating table for cutting hardware pipe fittings

The invention discloses an operation platform for cutting metal pipe fittings, which comprises a support platform, on which a bracket and a lifting frame are respectively provided, on which a mounting plate is provided, on which a rotary cylinder, a turntable and a fixed guide rail are respectively provided, and the rotating The cylinder is connected to the turntable, and the fixed guide rail is distributed around the turntable. The guide block is slidably connected to the fixed guide rail. The transmission rod is connected between the guide block and the turntable. The drive rod is connected to the eccentric position of the turntable. Splint, the center of the turntable is provided with a fixed rod, one end of the fixed rod is provided with a positioning plate, and an elastic seat is distributed around the positioning plate, and an arc-shaped pressure plate is arranged on the elastic seat. The lifting frame is close to the positioning plate, and the top of the lifting frame is provided with an arc shaped pallet. The invention has a novel structure, is suitable for cutting metal pipe fittings with different pipe diameters, has a wide application range, and is stable and reliable to place, thereby improving the cutting quality.

Owner:朱泽鹏

A kind of mold blank cutting equipment and cutting method thereof

ActiveCN111546411BAvoid flying aroundGuaranteed working environmentUsing liquid separation agentMetal working apparatusWater storage tankWorking environment

The invention discloses a mold blank cutting device and a cutting method thereof, belonging to the technical field of mold processing equipment. A mold blank cutting equipment, comprising a frame, the top of the frame is connected with a shell, the outer wall of the shell is dug with an outlet, the inner wall of the shell is connected with a fixed plate, the top of the fixed plate is movably connected with a processing part, and the bottom of the shell is dug There is a through hole, the inner wall of the through hole is connected with a filter screen, the bottom wall of the frame is connected with a water storage tank, the water storage tank and the through hole are connected to each other, the top of the housing is connected with a fixed shaft, and the bottom of the fixed shaft is connected with a fixed frame. A first rotating shaft is rotatably connected in the frame, and a cutting tool is connected to the outer wall of the first rotating shaft. Waste debris and harmful smoke are scattered everywhere, which is conducive to the progress of environmental protection work, thereby ensuring the working environment of the staff and ensuring the health of the staff.

Owner:佛山市顺德区水艺源五金模具有限公司

Cutting equipment for automobile shock absorber spring

The invention discloses cutting equipment for an automobile shock absorber spring in the technical field of automobile shock absorbers, and the cutting equipment comprises a workbench and a moving seat, three groups of positioning assemblies and supporting assemblies are arranged on the workbench, the positioning assemblies are connected with rotating assemblies, cutting assemblies are arranged at the supporting assemblies, and two rotating seats are arranged on the moving seat. According to the shock absorber spring cutting device, feeding is conducted through the positioning assembly in the middle, shock absorber springs are positioned through the positioning assembly and the supporting assembly, the supporting assembly supports the cutting ends of the shock absorber springs, and the problems that when the ends of the shock absorber springs are cut, deformation occurs due to lack of supporting, and the cutting quality is affected are avoided; by arranging the three positioning assemblies and the supporting assemblies and arranging the two rotating seats on the moving seat, the moving seat reciprocates in the first moving groove, so that feeding, feeding and two times of cutting machining are repeatedly conducted, the two rotating seats work at the same time, and the machining efficiency is improved.

Owner:HUANGHE JIAOTONG UNIV

Simple cosmetic bottle cutting device

InactiveCN105729555AAvoid harmReduce the temperatureMetal working apparatusRotational axisNumerical control

The invention discloses a simple cosmetic bottle cutting device, comprising a level gauge, a base, a numerical control motor, a camera, a rotation shaft, a cosmetic bottle fixing table, a cutter, a heat radiation fan, an LED lamp, a dust collector, fixing plates and a water spray tank, wherein the base is provided with the level gauge and the numerical control motor, the rotation shaft is arranged at the central position of the upper surface of the base, the top end of the rotation shaft is provided with the cosmetic bottle fixing table, the cosmetic bottle fixing table is provided with the two rows of fixing plates, the inner walls of the fixing plates are provided with expansion link, the top end of the expansion link is provided with a protection pad, the base is provided with the camera and the water spray tank, the water spray tank is provided with a sprayer, one side of the cosmetic bottle fixing table is provided with the cutter, and the base is provided with the dust collector and the heat radiation fan. The simple cosmetic bottle cutting device can avoid influence to human health, temperature is reduced in time, the service life is prolonged, the structure is simple, the use is convenient, and the popularization is facilitated.

Owner:苏州高新区鼎正精密机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com