High-precision aerated concrete block production device

A technology of aerated concrete and production equipment, which is applied in the direction of ceramic forming machines and manufacturing tools to achieve the effects of accelerating cutting speed, improving adaptability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

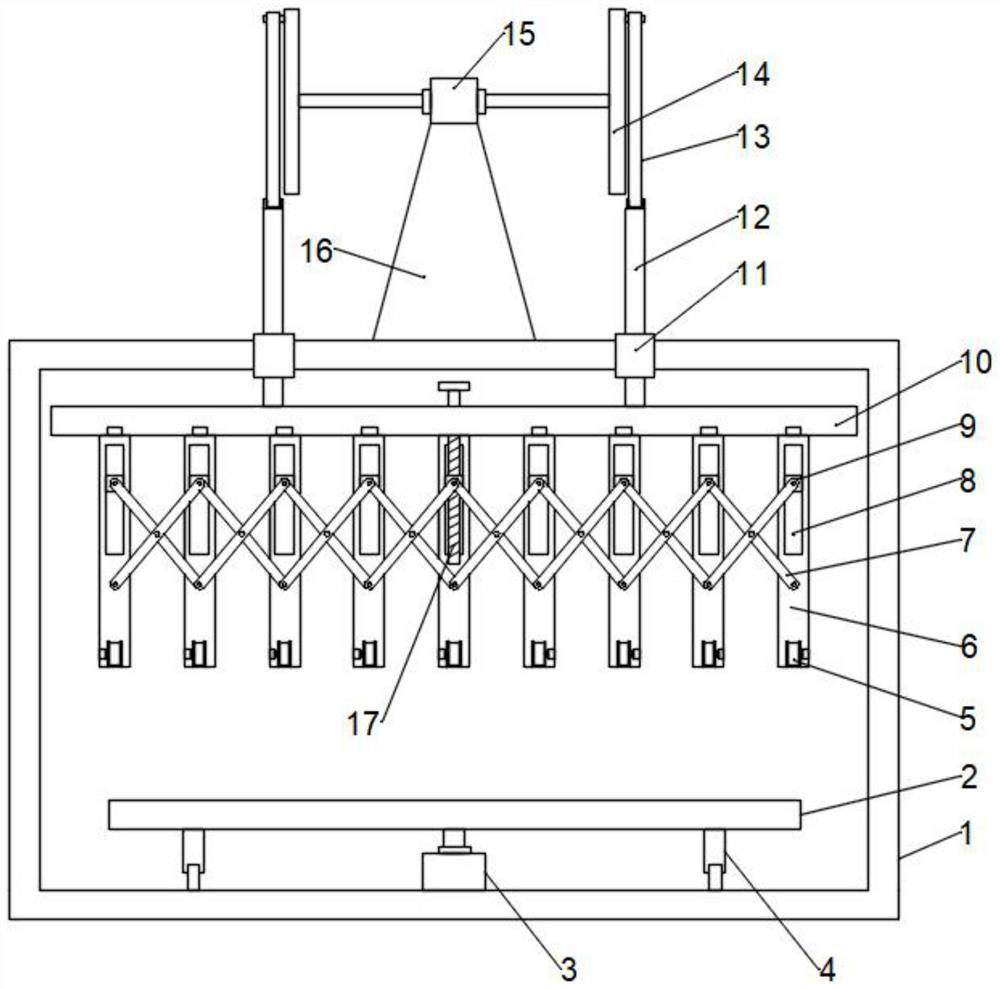

[0054] The embodiment of the present invention provides a high-precision aerated concrete block production device, such as Figure 1-2 shown, including:

[0055] Frame 1 can be a rectangular frame, and moving wheels can also be installed at the bottom of the rectangular frame for easy movement;

[0056] The workbench 2 installed on the frame 1, in this embodiment, the workbench 2 is fixed on the output shaft of the first motor 3, the first motor 3 is fixed on the frame 1, and can be fixed by bolts, the workbench 2 There are multiple support legs 4 fixed at the bottom, and rollers are installed at the bottom of the support legs 4, which can drive the workbench 2 to rotate through the first motor 3, and the workbench 2 drives the aerated concrete on it to rotate to set the angle and adjust the cutting position;

[0057] A cutting assembly arranged above the workbench 2, the cutting assembly includes a plurality of steel wires arranged in parallel at intervals;

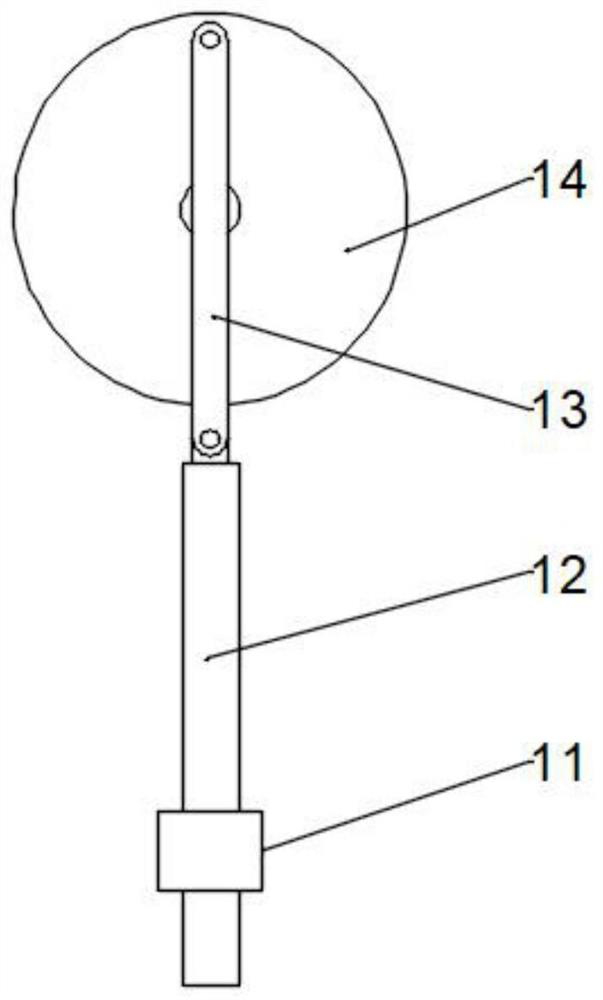

[0058] An adjust...

Embodiment 2

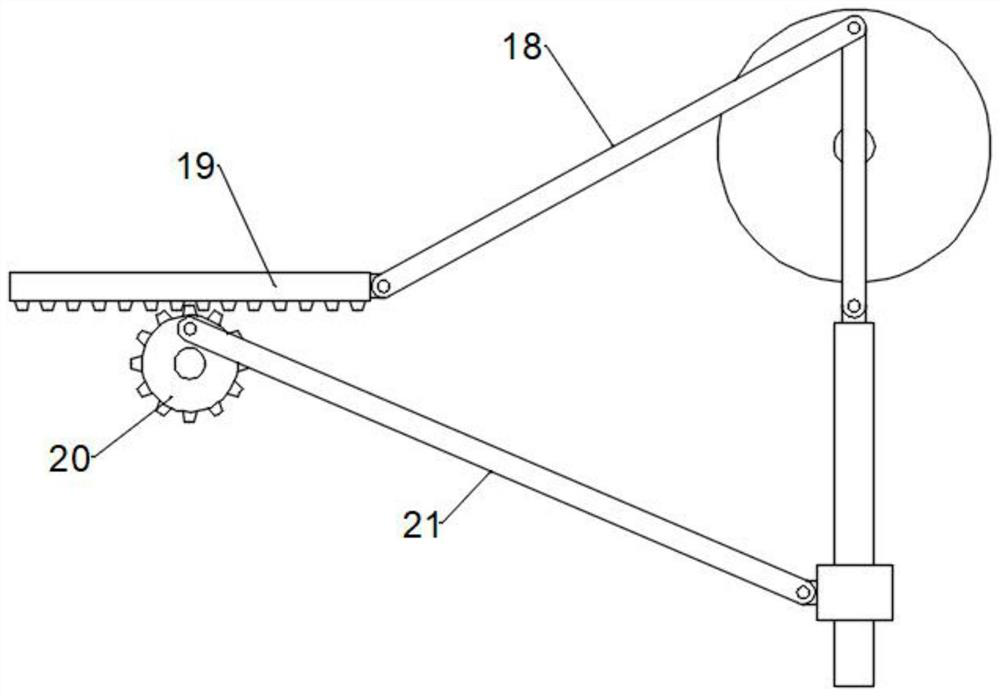

[0075] This embodiment is on the basis of embodiment 1, as image 3 As shown, transmission parts are also included, and the transmission parts include:

[0076] The second connecting rod 18, one end of the second connecting rod 18 is hinged with the first connecting rod 13 and the turntable 14, the other end of the second connecting rod 18 is hinged with a rack 19, and the rack 19 is slidably mounted on the frame 1 On, the sliding seat and the sliding rail can be used to cooperate;

[0077] The gear 20 is used to mesh with the rack 19, and it is rotatably mounted on the frame 1;

[0078] The third connecting rod 21, one end of which is eccentrically hinged to the end face of the gear 20, and the other end is hinged to the guide sleeve 11, and the guide sleeve 11 is longitudinally slidably mounted on the frame 1;

[0079] In this embodiment, when the turntable 14 rotates, the second connecting rod 18 drives the rack 19 to reciprocate, the rack 19 drives the gear 20 to rotate ...

Embodiment 3

[0081] This embodiment is on the basis of embodiment 2, as Figure 4-5 As shown, a cleaning assembly is also included for cleaning the steel wire, and the cleaning assembly includes:

[0082] Sleeve 25 is sleeved on the outside of the steel wire and close to the side wall of the inverted U-shaped plate 6. The inner wall of the sleeve 25 is provided with ribs at intervals in the circumferential direction, and the sides of the ribs are preferably arc-shaped;

[0083] Connected to the fourth connecting rod 24 on the sleeve 25, the fourth connecting rod 24 is eccentrically hinged with the disk 23;

[0084] The third motor 26 fixed on the side wall of the inverted U-shaped plate 6, the third motor 26 is used to drive the disc 23 to rotate;

[0085] Two symmetric cone rollers 22 that are located on the other side wall of the inverted U-shaped plate 6 can be provided with some pulverizing teeth on the surface of the cone roller 22, and the two cone rollers 22 are positioned at both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com