Plate cutting device for automotive frame middle plate machining

A technology for automobile beams and cutting devices, applied in shearing devices, metal processing equipment, accessories of shearing machines, etc., can solve problems such as affecting the quality of plates and offsetting cutting positions, avoid excessive temperature, and ensure accurate cutting. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

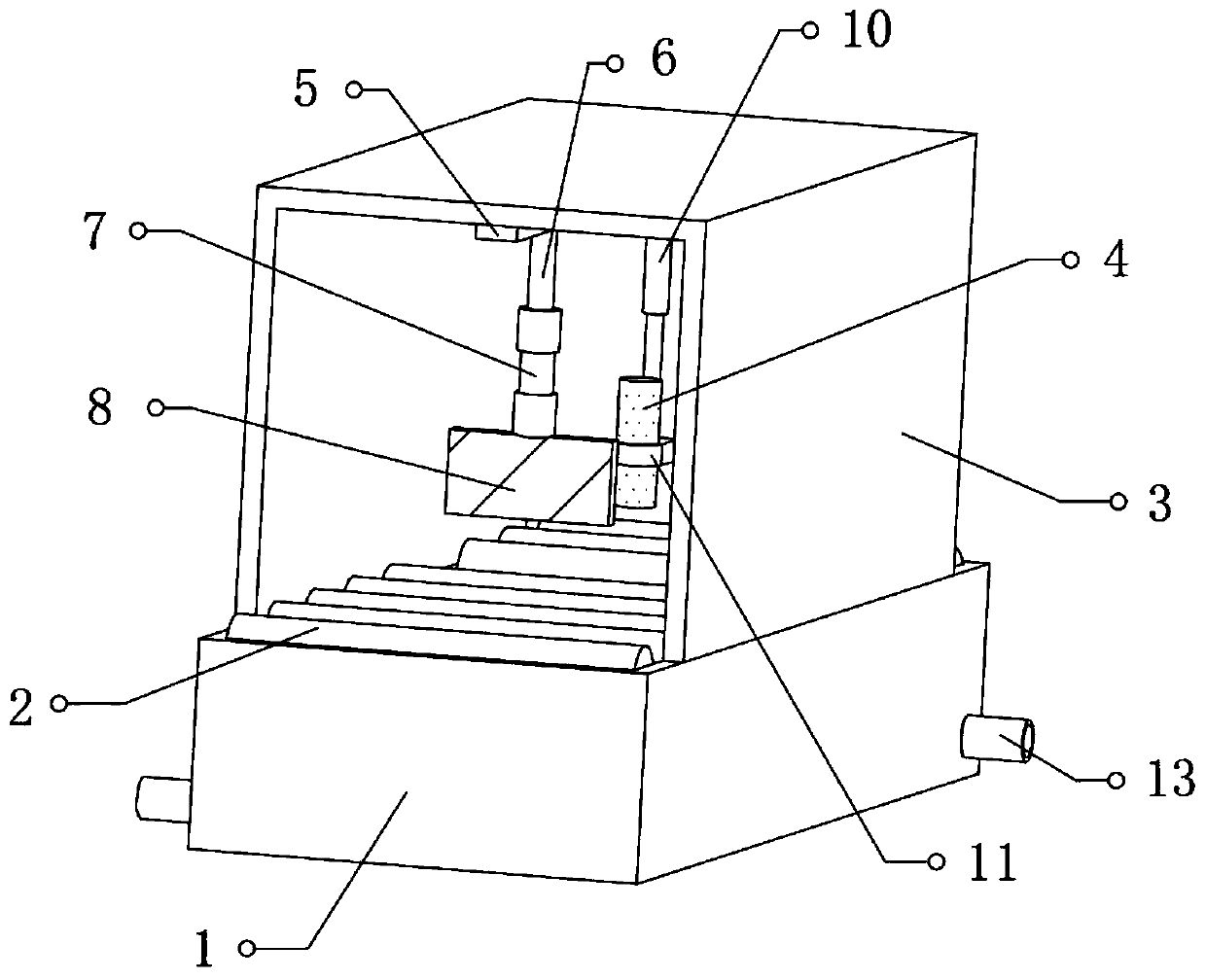

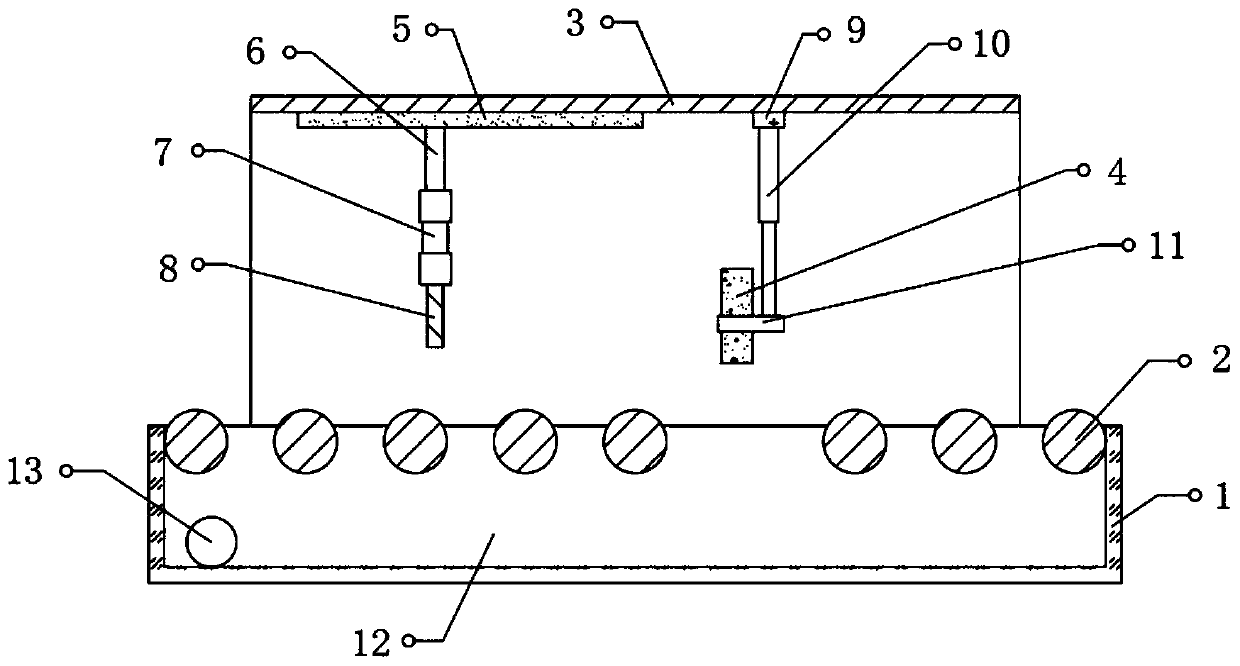

[0023] refer to Figure 1-2 , a plate cutting device for the processing of the middle plate of the automobile girder, comprising a base 1, a plurality of conveying rollers 2 are arranged on the top of the base 1, and the conveying rollers 2 are transmission-connected with a driving mechanism, the top of the base 1 is fixed with a fixed frame 3, and One side inside the fixed frame 3 is provided with a cutting mechanism 4, and the side of the top inner wall of the fixed frame 3 away from the cutting mechanism 4 is fixed with a first electric guide rail 5, and the bottom of the first electric guide rail 5 is connected with a fixing member 6, and the fixing member 6 The bottom end of the cylinder 7 is fixed, and the bottom end of the cylinder 7 is connected with a baffle plate 8 .

[0024] In the present invention, the base 1 is arranged in a box structure, and the bottom end inside the base 1 is provided with a storage cavity 12, and the inner walls of both ends of the storage ca...

Embodiment 2

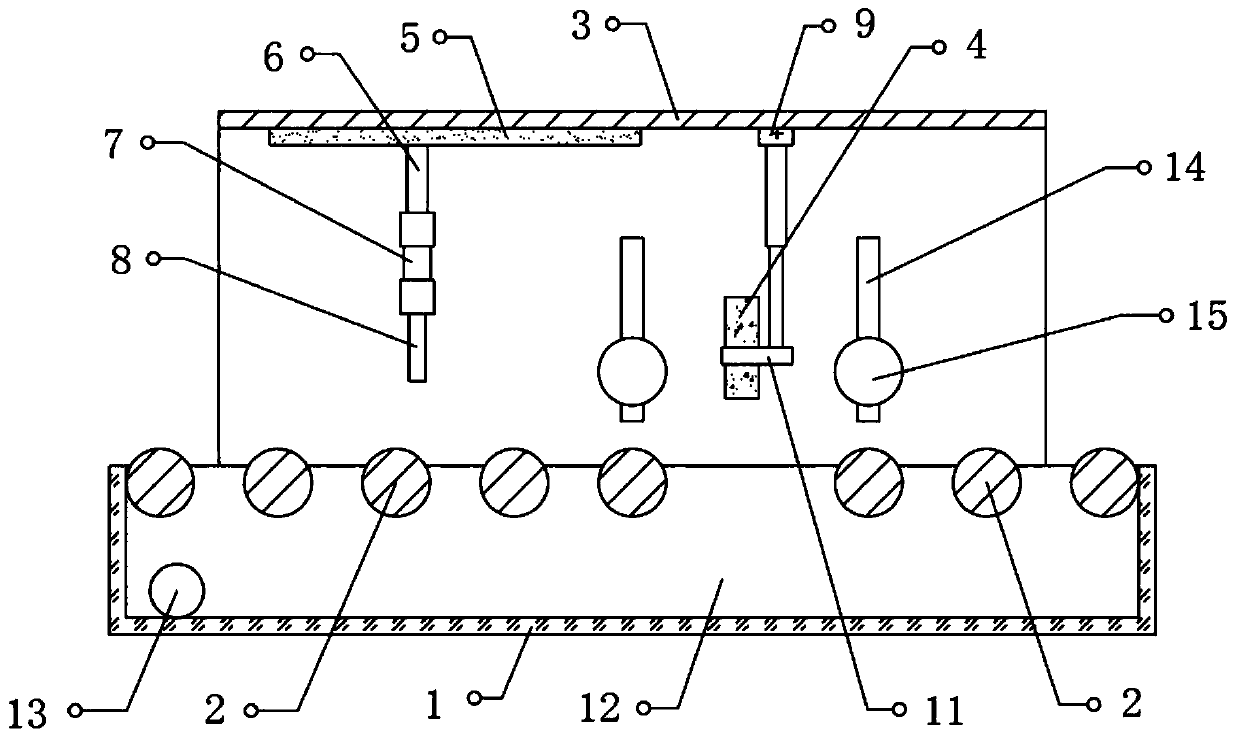

[0026] refer to figure 1 and image 3 , a plate cutting device for the processing of the middle plate of the automobile girder. Further, both sides of the cutting mechanism 4 are provided with limit rollers 15 that are rotatably connected, and the inner walls at both ends of the fixed frame 3 are fixed at the positions corresponding to the limit rollers 15. Three electric guide rails 14, and one end of the third electric guide rail 14 is connected with a connection block, and the two ends of the limit roller 15 are rotationally connected with the two connection blocks.

[0027] Working principle: In the spare part of the device, connect all the above-mentioned driving parts, which refer to the power components, electrical devices and the adapted power supply, through wires. The specific connection means should refer to the following working principle, between the electrical devices The electrical connection is completed in sequence, and the detailed connection method is a wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com