Production method of dried tofu with high-quality mouth feel

A production method and high-quality technology, applied in cheese substitutes, dairy products, applications, etc., can solve problems such as low production efficiency, demand, and unguaranteed product quality, and achieve the effect of improving production efficiency and avoiding unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

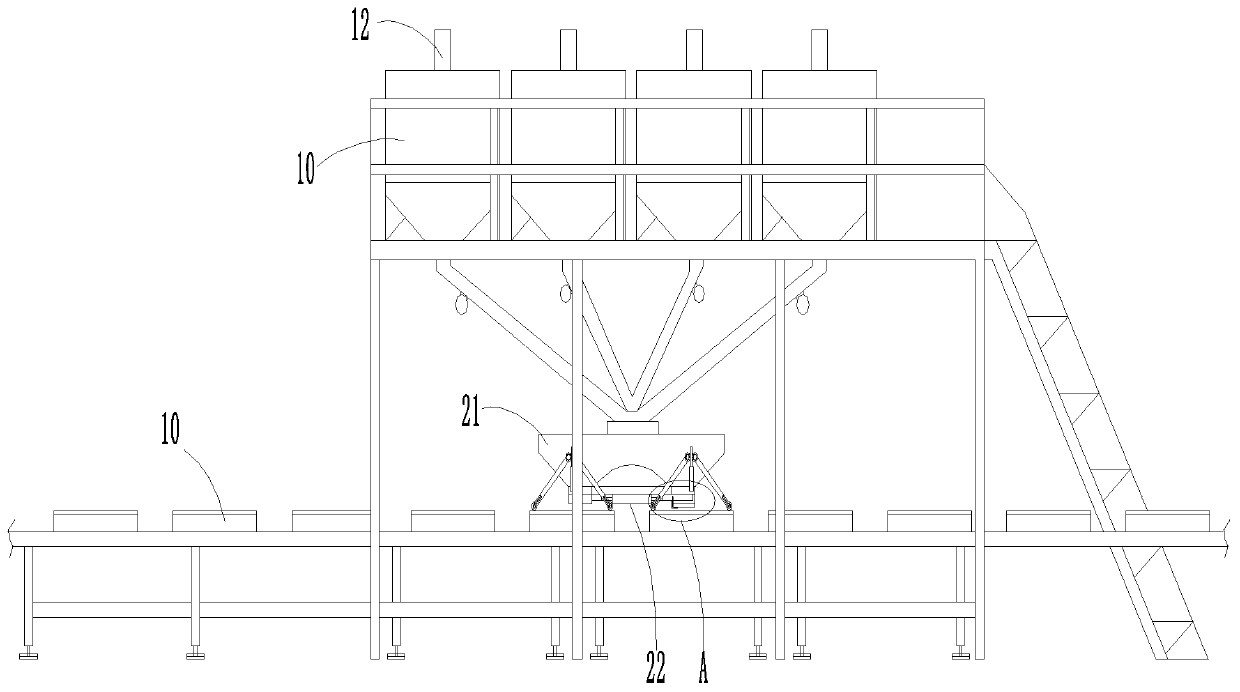

[0040] Such as figure 1 and Figure 4 As shown, a kind of high-quality mouthfeel dry bean curd production equipment comprises a biting barrel 10, and the top of the biting barrel 10 is provided with a driving motor 12 and a transmission mechanism, the output shaft of the driving motor 12 is connected with the transmission mechanism, and the transmission mechanism is connected with Agitator 13, the agitator 13 is a T-shaped structure, the end of the agitator 13 away from the transmission mechanism extends to the inside of the brine bucket 10, and the bottom of the agitator 3 located in the brine bucket 10 is a stirring plate, which realizes efficient stirring. The drive motor 12 makes the agitator 13 move vertically in a circumferential direction through a transmission mechanism. When in use, first import soymilk into the brine point barrel 10, and then when the drive motor 12 drives the transmission unit to make the agitator 13 move vertically and circumferentially, synchrono...

Embodiment 2

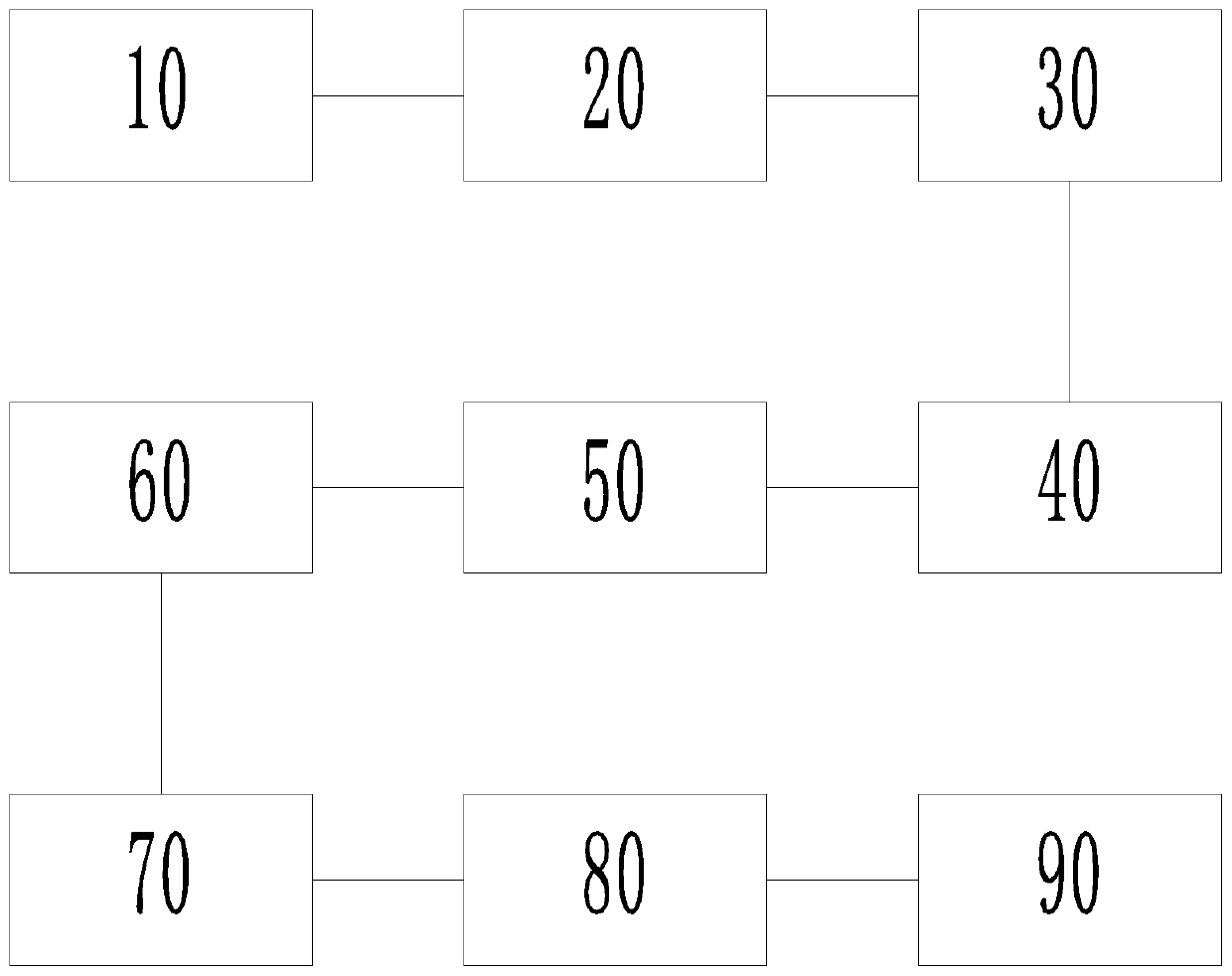

[0043] Such as Figure 1 to Figure 8 As shown, different from Embodiment 1, the bottom of the brine point barrel 10 is provided with a water outlet 11, and the water outlet 11 is provided with a valve, and the water outlet 11 is connected with a distribution mechanism 20 through a pipeline, and the distribution mechanism 20 is connected to the water outlet through the pipeline. 11 connected, the bottom of the distribution mechanism 20 is provided with a frame conveying mechanism 30, and the tail of the frame conveying mechanism 30 is provided with a cover plate conveying mechanism 40, a stacking mechanism 50, a pressing mechanism 60, a splitting mechanism 70, a turnover mechanism 80 and Cutting mechanism 90.

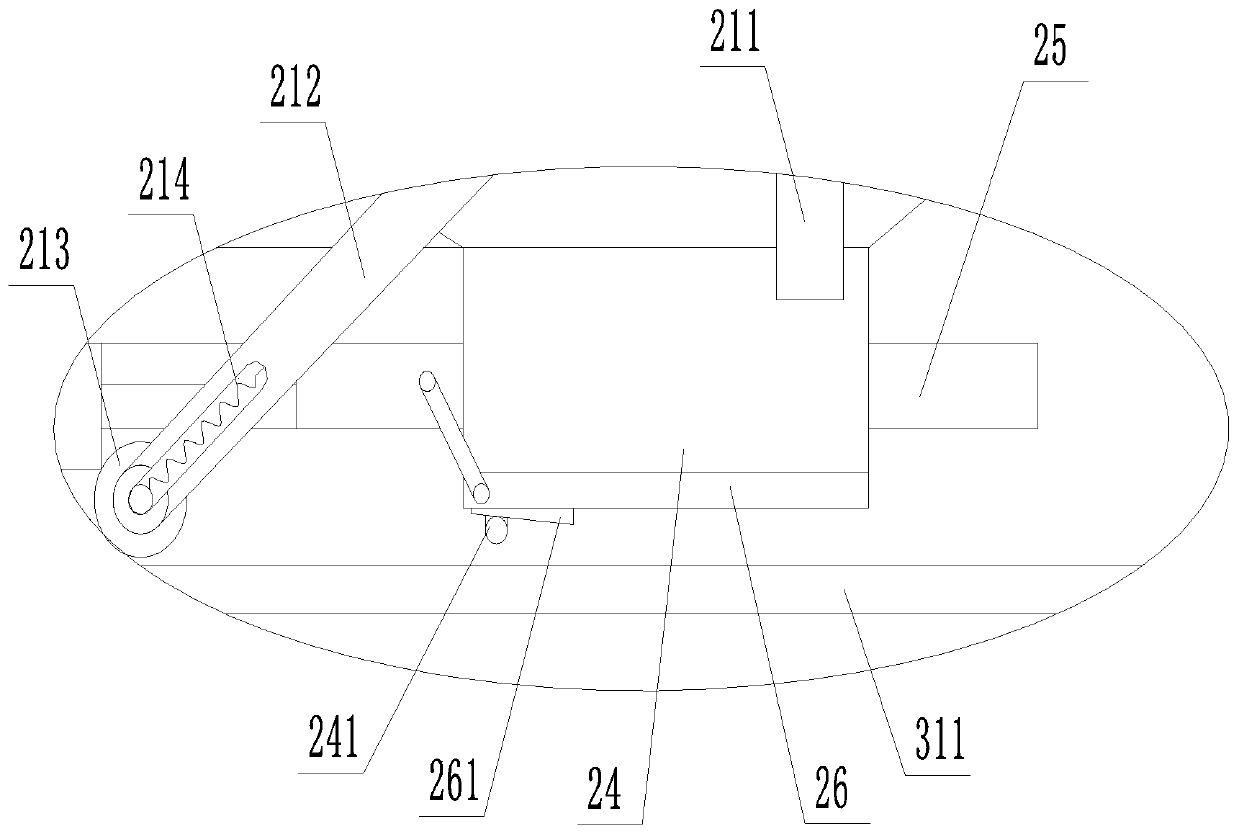

[0044] In a further preferred solution in this embodiment, the distribution mechanism 20 includes a distribution box 21, a distribution driver 22 and an opening and closing unit. The distribution box 21 is provided with a liquid level quantifier and a discharge port 23, ...

Embodiment 3

[0051] Such as figure 2 and image 3 As shown, different from Embodiment 2, in order to ensure the quality of dried bean curds, a leveling structure is provided on the distribution box 21. The leveling structure includes an automatic lifter 211 (cylinder), a rotating rod 212 and a leveling part 213. The lifter 211 is installed on the distribution box 21, and the automatic lifter 211 is fixedly connected with a rack. Gear, rotating bar 212 is provided with reset piece 214 (spring) away from distribution box 21 one end, and leveling piece 213 is a roller structure, and leveling piece 213 is connected on the turning bar 212 by reset piece 214, and leveling piece 213 is used for Level the bean brains discharged by the discharge port 23. In actual production, use the automatic lifter 211 to drive the rack up and down to make the rotating rod 212 rotate through the gear to achieve the leveling part 213 moving laterally on the frame mold 31 so that the internal bean brain is level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com