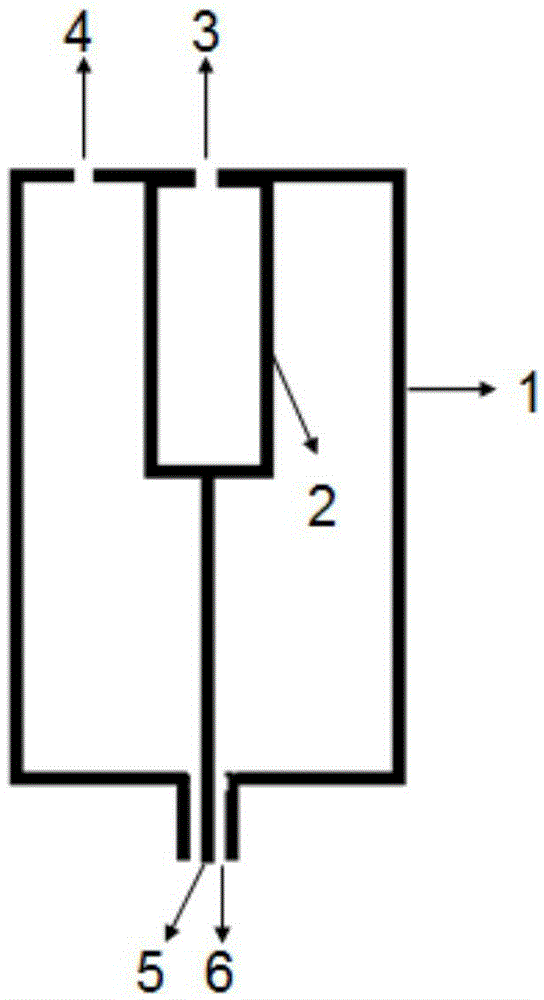

Coaxial parallel flow precipitation device and method for preparing catalyst

A precipitation device and catalyst technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of large particle size, irregular shape, poor monodispersity, etc. Droplet size reduction, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

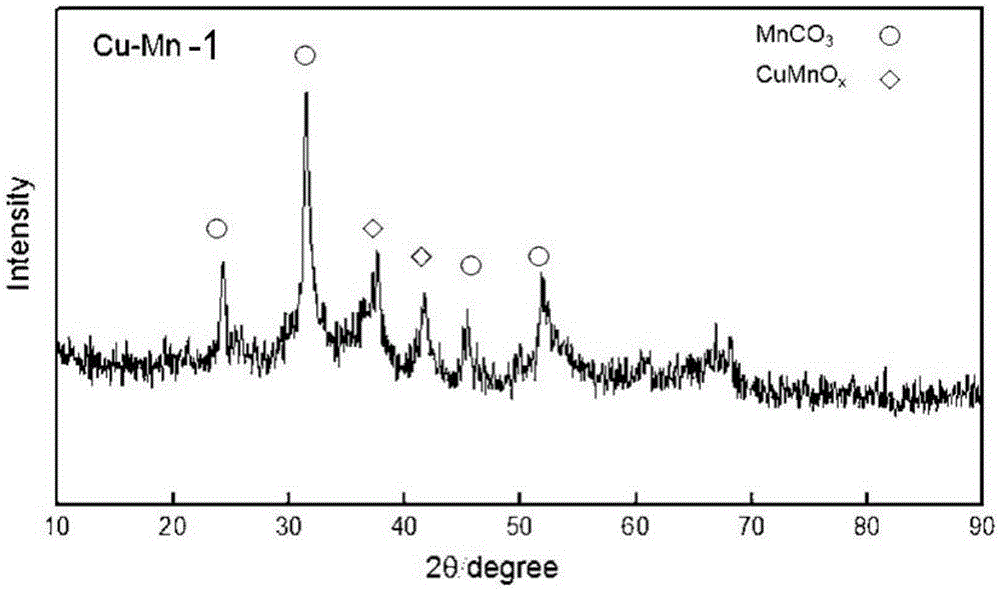

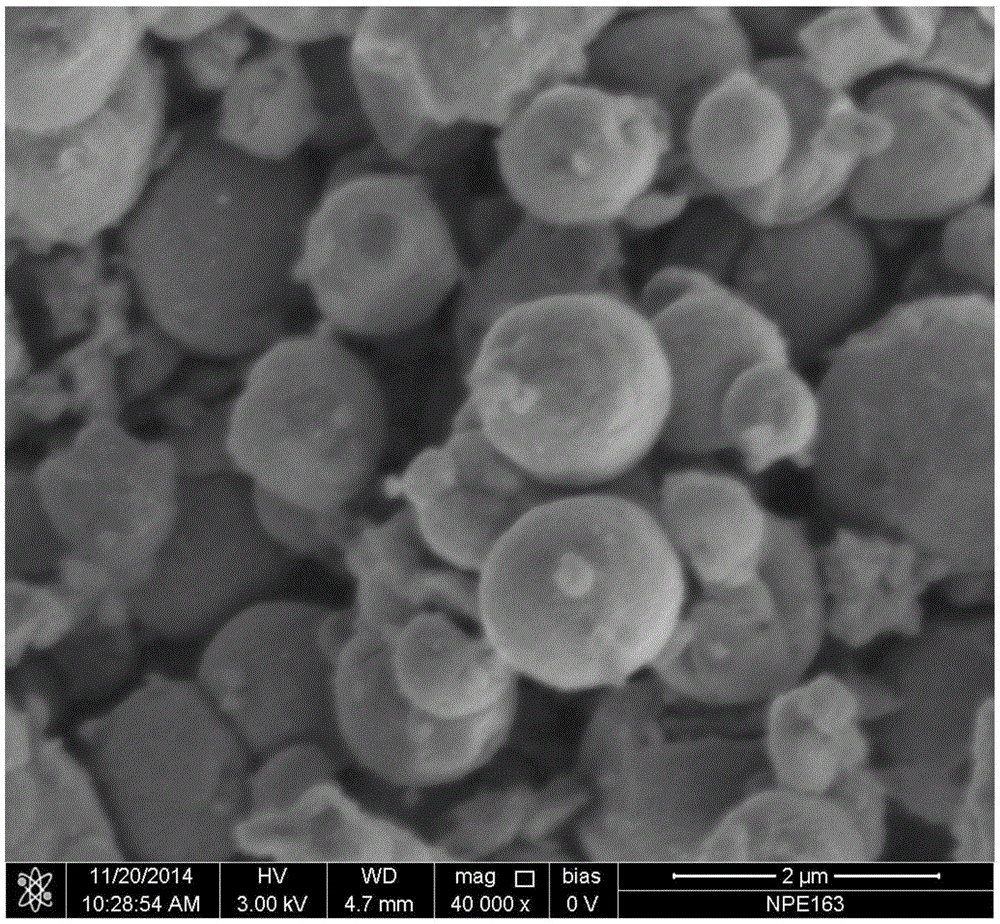

[0034] Preparation of Cu-Mn-1 Catalyst (Coaxial Parallel Flow Precipitator Synthesis)

[0035] 0.5g of Cu(OAc) 2 ·H 2 O and 1.23g of Mn(OAc) 2 4H 2 O was dissolved in 22.5 mL of deionized water as a metal salt solution, and 1.19 g of NH 4 HCO 3 Dissolved in 22.5mL deionized water as a precipitant solution, the ratio of the molar ratio satisfies Cu(OAc) 2 : Mn(OAc) 2 : NH 4 HCO 3 =1:2:6. Heat the metal salt solution and the precipitant solution to 30°C, fill the inner tube with the metal salt solution, and the precipitant solution fills the hollow cavity between the inner and outer tubes; the liquid inlets of the inner and outer tubes respectively pass through the catheter and the salt solution The syringe and the syringe containing the precipitant solution are connected, the syringe is connected to the push pump, and circulating water is passed through the insulation layer to keep the reaction temperature at 30°C.

[0036] Set the inlet flow rate of the pump to 2mL / min...

Embodiment 2

[0040] Preparation of Mg-Al Oxide (Coaxial Parallel Flow Precipitator Synthesis)

[0041] 1.28g of Mg(NO 3 ) 2 ·6H 2 O and 3.75g of Al(NO 3 ) 3 9H 2 O was dissolved in 50mL deionized water as a metal salt solution, the molar ratio Mg / Al=1:2, and 1.59g of Na 2 CO 3 and 2.4 g of NaOH were dissolved in 100 mL of deionized water as a precipitant solution. Fill the inner tube with the metal salt solution, and the precipitant solution fills the cavity between the inner and outer tubes. The liquid inlets of the inner and outer tubes are respectively connected to the syringe with the saline solution and the syringe with the precipitant solution through the catheter. The push pump was connected; the reaction was carried out at room temperature.

[0042] Set the pump inlet flow rate to 0.5mL / min (the flow rate of the metal salt solution is the same as the flow rate of the precipitant solution, both are 0.5mL / min), start the pump, and push the syringe to start the reaction. The ...

Embodiment 3

[0043] The preparation of embodiment 3Cu-Zn-Al catalyst (coaxial parallel current precipitation device is synthesized)

[0044] 5.44g of Cu(NO 3 ) 2 ·3H 2 O, 6.69g of Zn(NO 3 ) 2 ·6H 2 O and 1.88g of Al(NO 3 ) 3 9H 2 O was dissolved in 50 mL deionized water as a metal salt solution, so that Cu 2+ , Zn 2+ 、Al 3+ The total concentration is 1mol / L, the molar ratio Cu / Zn / Al=4.5:4.5:1, the Na of 10.6g 2 CO 3 Dissolve in 100 mL deionized water as a precipitating agent. Fill the inner tube with the metal salt solution, and the precipitant solution fills the hollow cavity between the inner and outer tubes. The liquid inlets of the inner and outer tubes are respectively connected to the syringe with the saline solution and the syringe with the precipitant solution through the catheter. The push pump was connected and the reaction was carried out at room temperature.

[0045] Set the pump inlet flow rate to 1mL / min (the flow rate of the metal salt solution is the same as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com