Low-pressure drop efficient static mixing device beneficial to oil blending and oil blending method

A technology for static mixers and oil products, applied in fluid mixers, mixers, chemical instruments and methods, etc., can solve problems such as insufficient mixing, achieve uniform product quality, and reduce density and stratification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention relates to an oil blending method and a blending device or equipment. The oil products suitable for blending in the method, device or equipment of the present invention include various conventional oil products in this field, such as gasoline, diesel oil, jet fuel, naphtha and light crude oil.

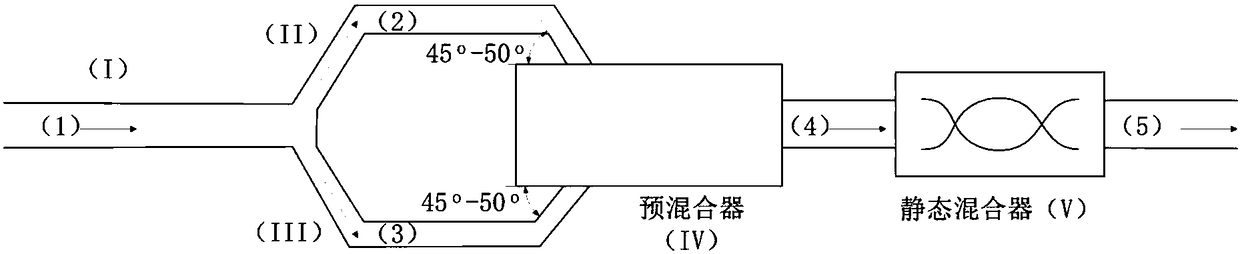

[0035] The oil product blending method of the present invention comprises: throttling and pressurizing the component oil products collected in the blending head and dividing them into 2 or more stocks, passing through 2 or 2 symmetrical pre-mixer container bodies respectively. More than two inlets are connected to the pre-mixer. After the material is fully contacted and pre-mixed in the pre-mixer, it enters the static mixer and mixes to form a qualified oil product.

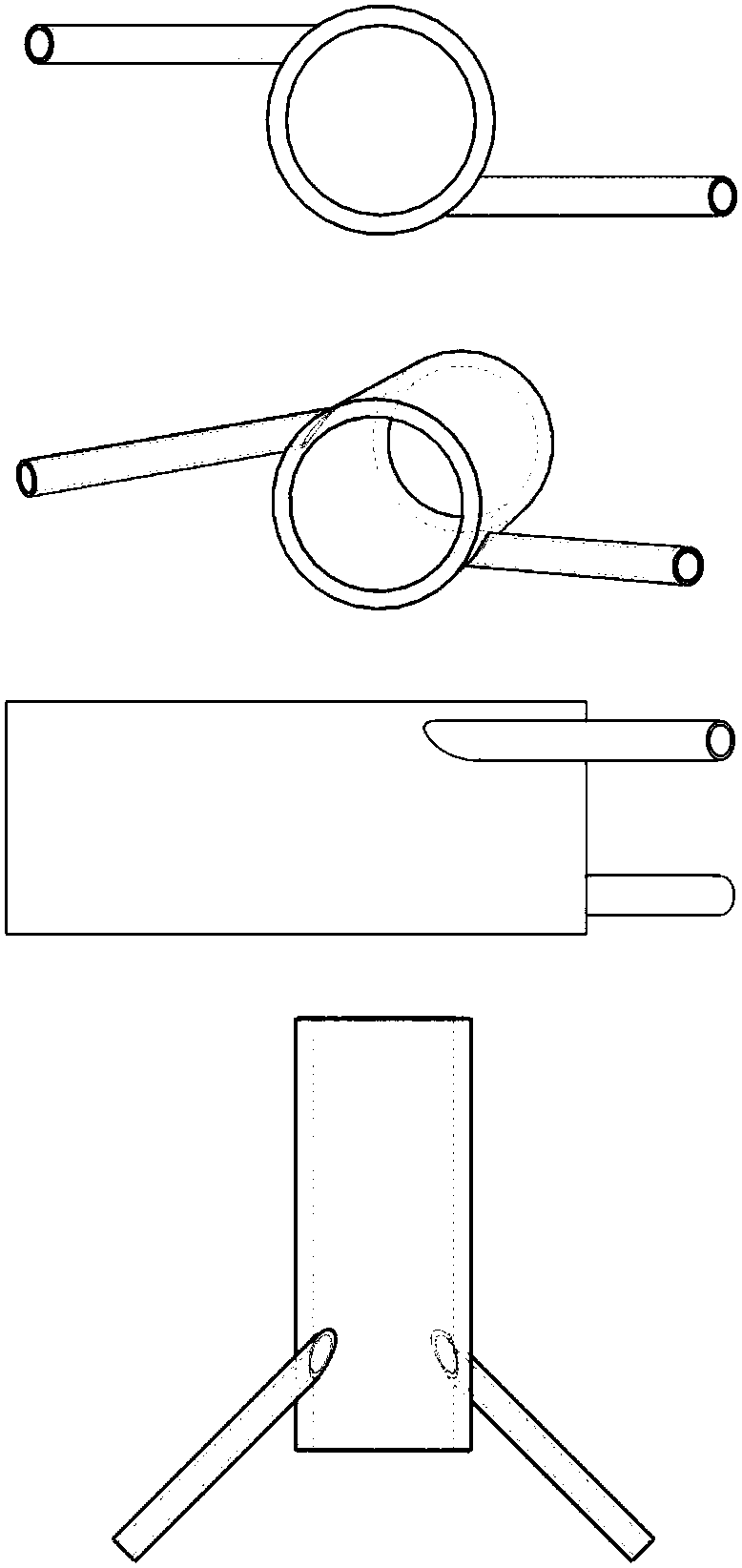

[0036] In the present invention, 2 or more materials (such as 3 stocks, 4 stocks, 5 stocks or 6 stocks) enter the pre-mixer obliquely along the tangent direction of the pipe wall of the respective inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com