Patents

Literature

43results about How to "Full and efficient mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

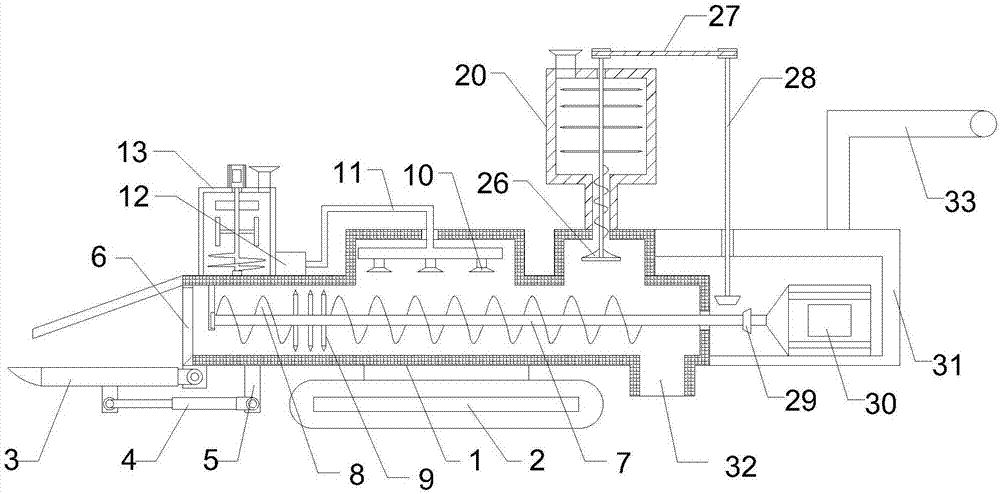

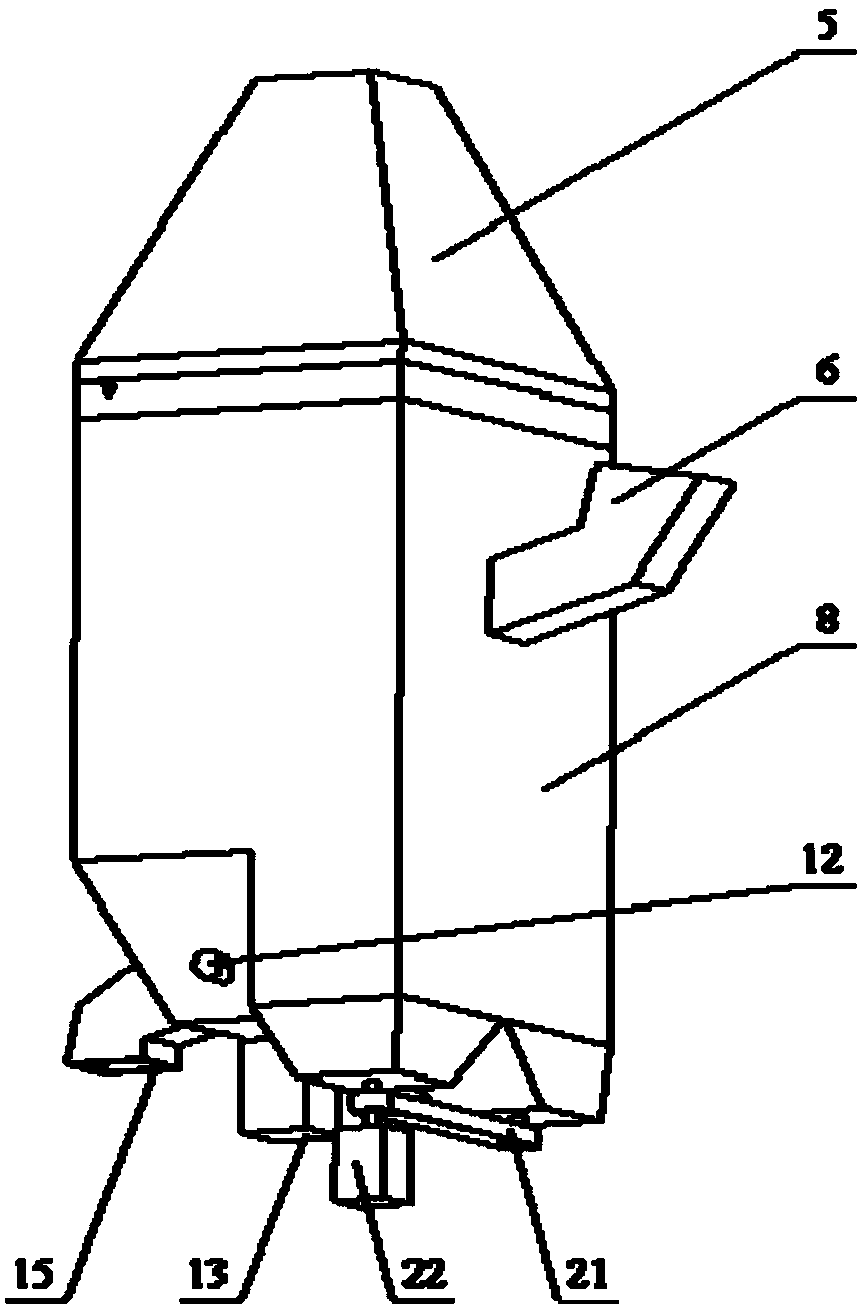

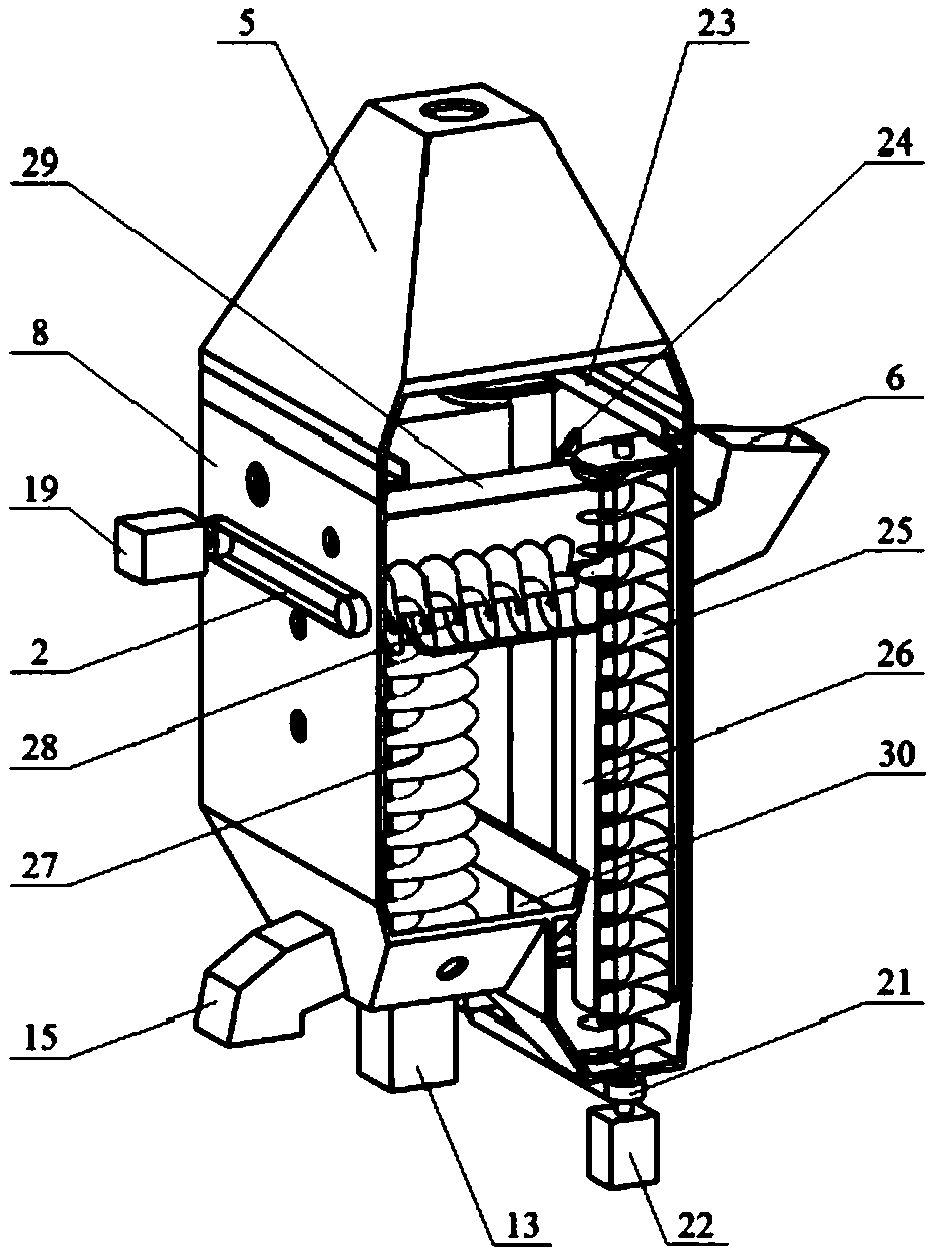

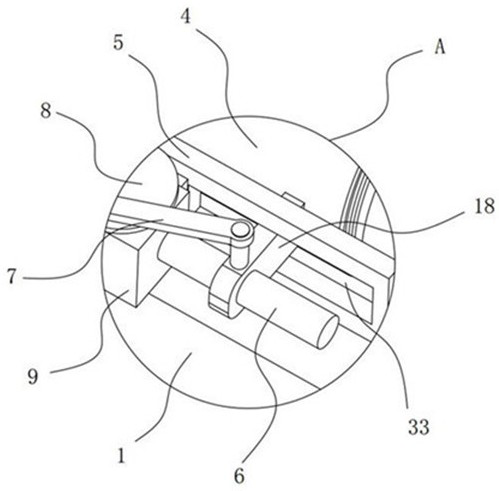

Mini-type hand-push soil governing device

InactiveCN107567733AGood uniformityGuaranteed spraying effectSoil lifting machinesSpadesEngineeringSprayer

The invention discloses a mini-type hand-push soil governing device, which comprises a shell body and a track travelling device; the left side of the shell body is hinged with a shovel plate; one sideof a main rotary shaft closing to a feeding opening is fixedly connected with a vertical smashing cutter blade; a sprayer is arranged at the place where the shell body is located at the upper part ofthe right side of the vertical smashing cutter blade. Through the shovel plate and the vertical smashing cutter blade, soil is efficiently collected and smashed to facilitate the subsequent mixing. The mini-type hand-push soil governing device is provided with a mixing tank, the soil disinfectant raw materials are efficiently mixed and blended, thus the disinfectant homogeneity is better; the spraying effect is guaranteed while the raw materials are saved. The horizontal smashing cutter blade can efficiently smash the solid soil improver so as to mix and contact with soil and improve the mixing effect. A first spiral blade is provided and used for fully and efficiently mixing the soil with the drug; moreover, the soil governing effect is improved, and the operation is continuous and high-efficient.

Owner:李林

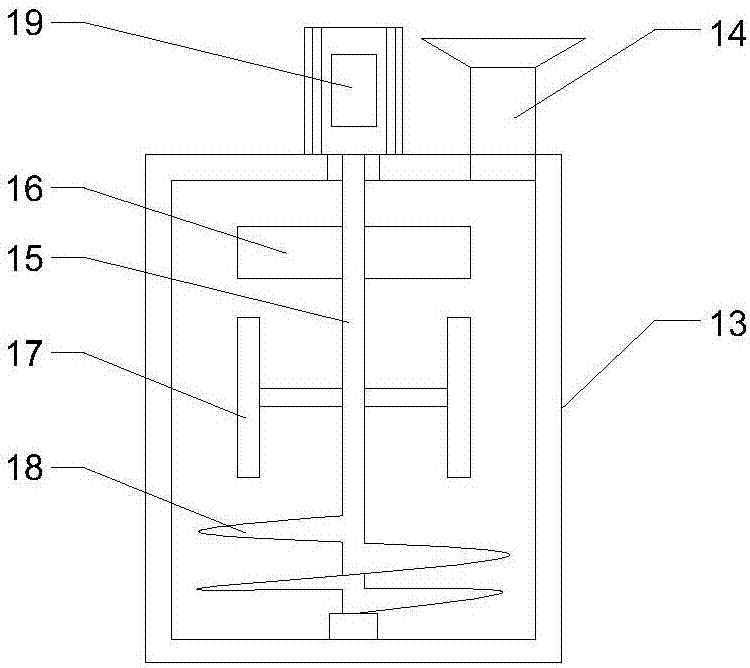

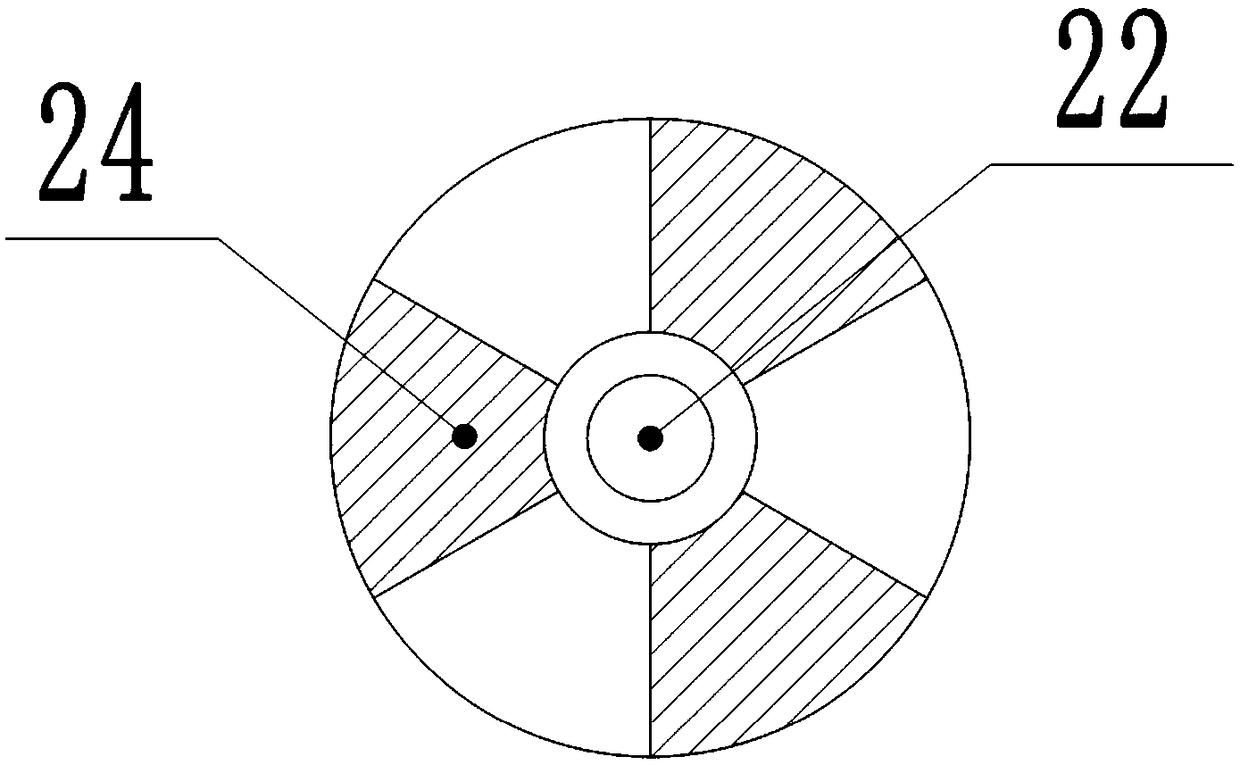

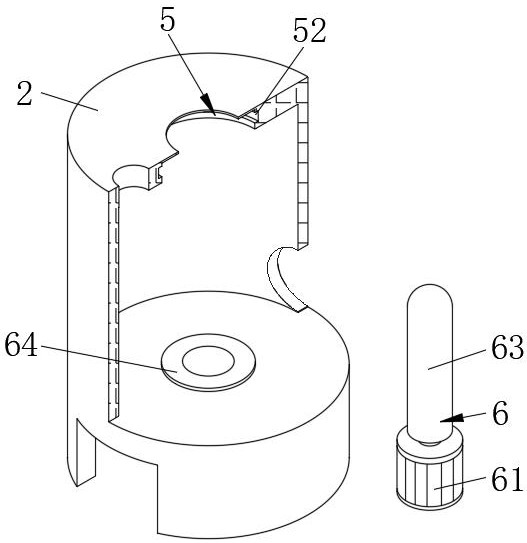

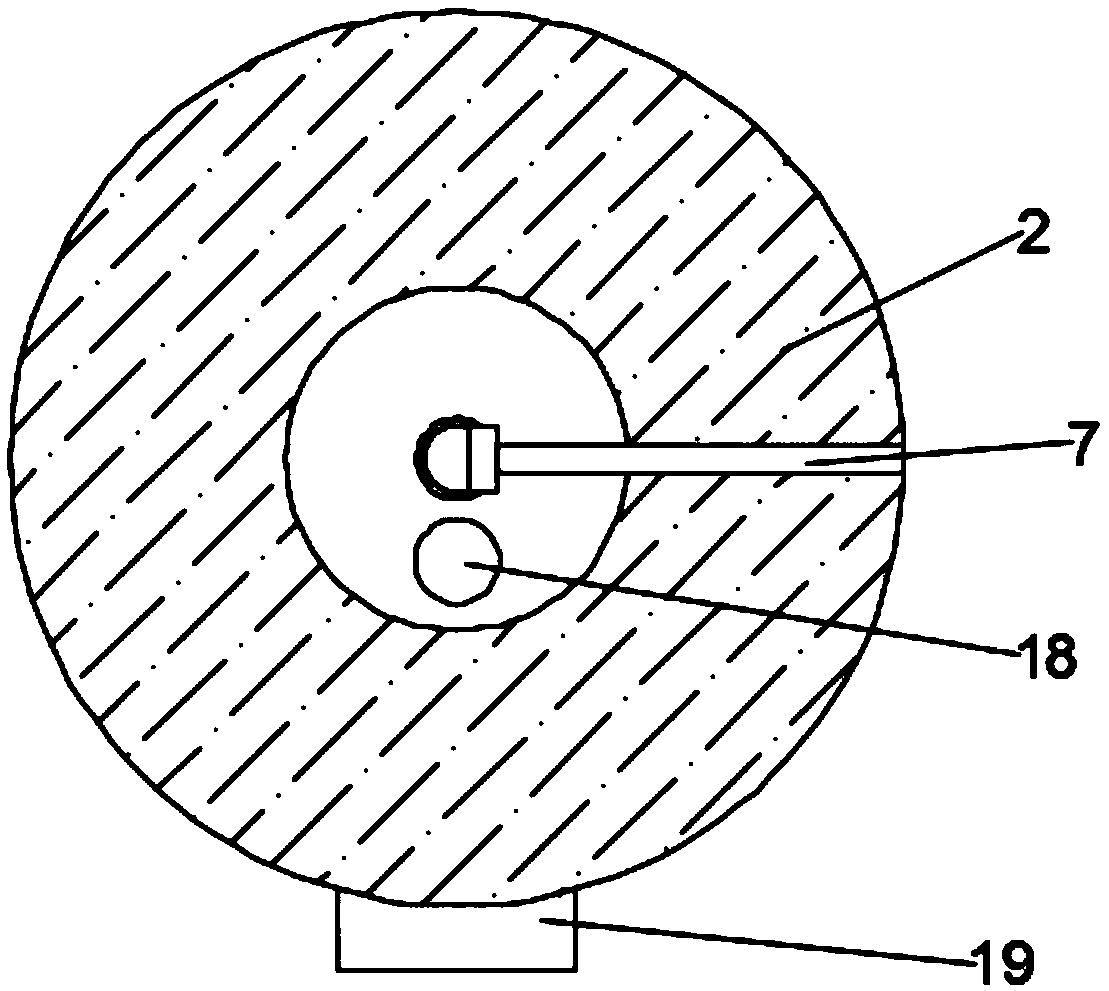

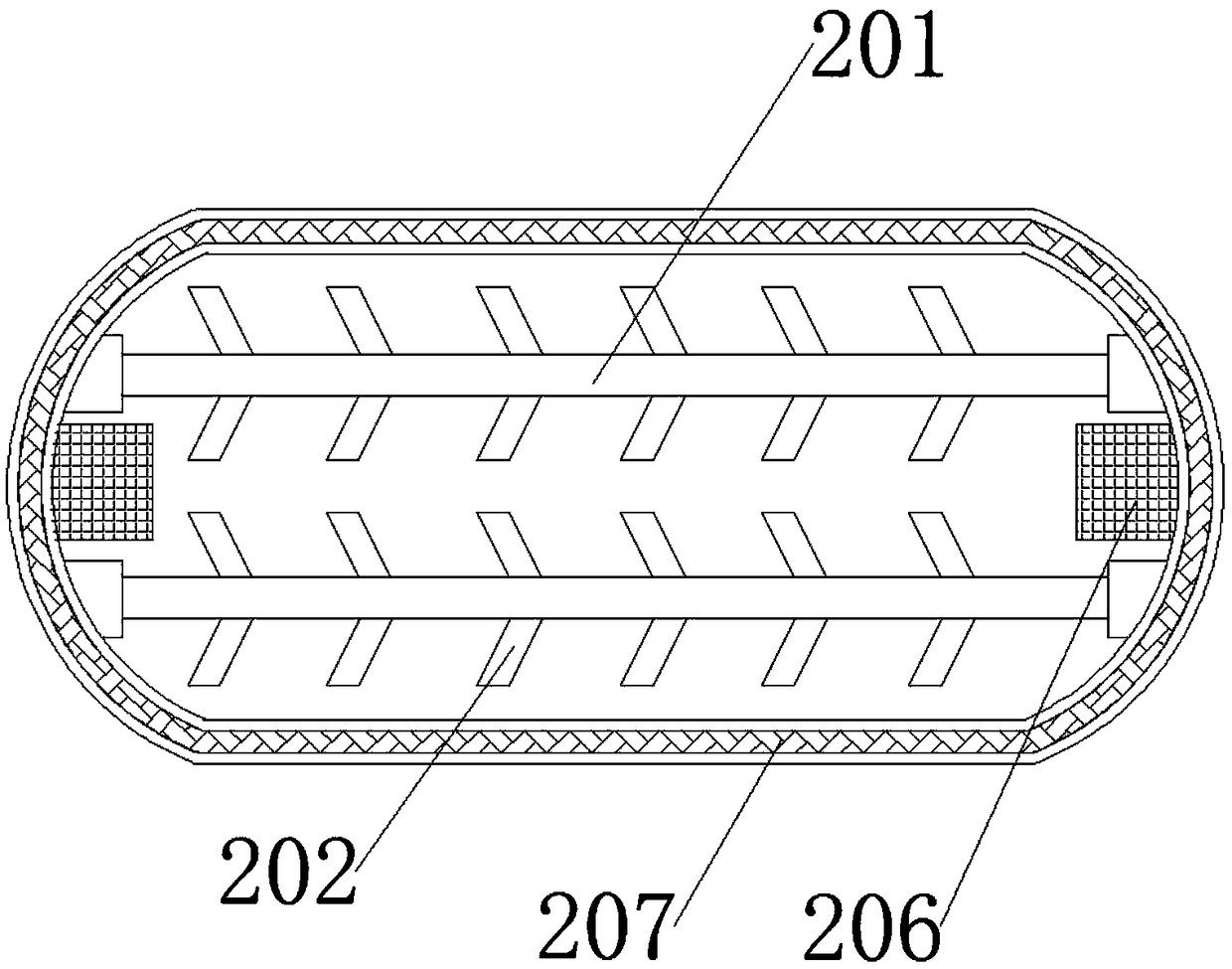

Piezoelectric micro-mixer

InactiveCN103170265AEfficient mixingFull and efficient mixingFlow mixersTransportation and packagingPump chamberEngineering

The invention relates to the field of micro-mechanics for microfluid pumping and mixing, and in particular relates to a piezoelectric valveless micro-mixer, which comprises two inlet channels, an inlet buffer chamber, an inlet vortex tube, pump chambers, a piezoelectric vibrator, an upper substrate, a pump body, an outlet vortex tube, an outlet buffer chamber and an outlet channel. The two inlet channels are intersected at the inlet buffer chamber, the included angle of central lines of the two inlet channels is less than or equal to 90 degrees, and the vortex tubes are produced by adding triangular bodies in diffusion tubes. The piezoelectric micro-mixer provided by the invention has the main advantages that the two inlet channels are intersected at the inlet buffer chamber, so that fluids to be mixed are firstly mixed in the inlet buffer chamber, and then are further mixed in the specially designed vortex tubes effectively, so that the required mixing time is greatly shortened, and the mixing efficiency is improved.

Owner:JIANGSU UNIV

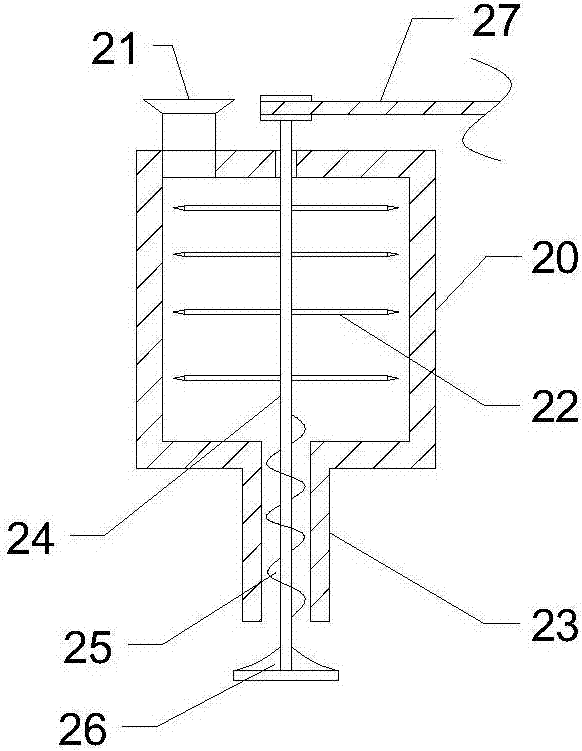

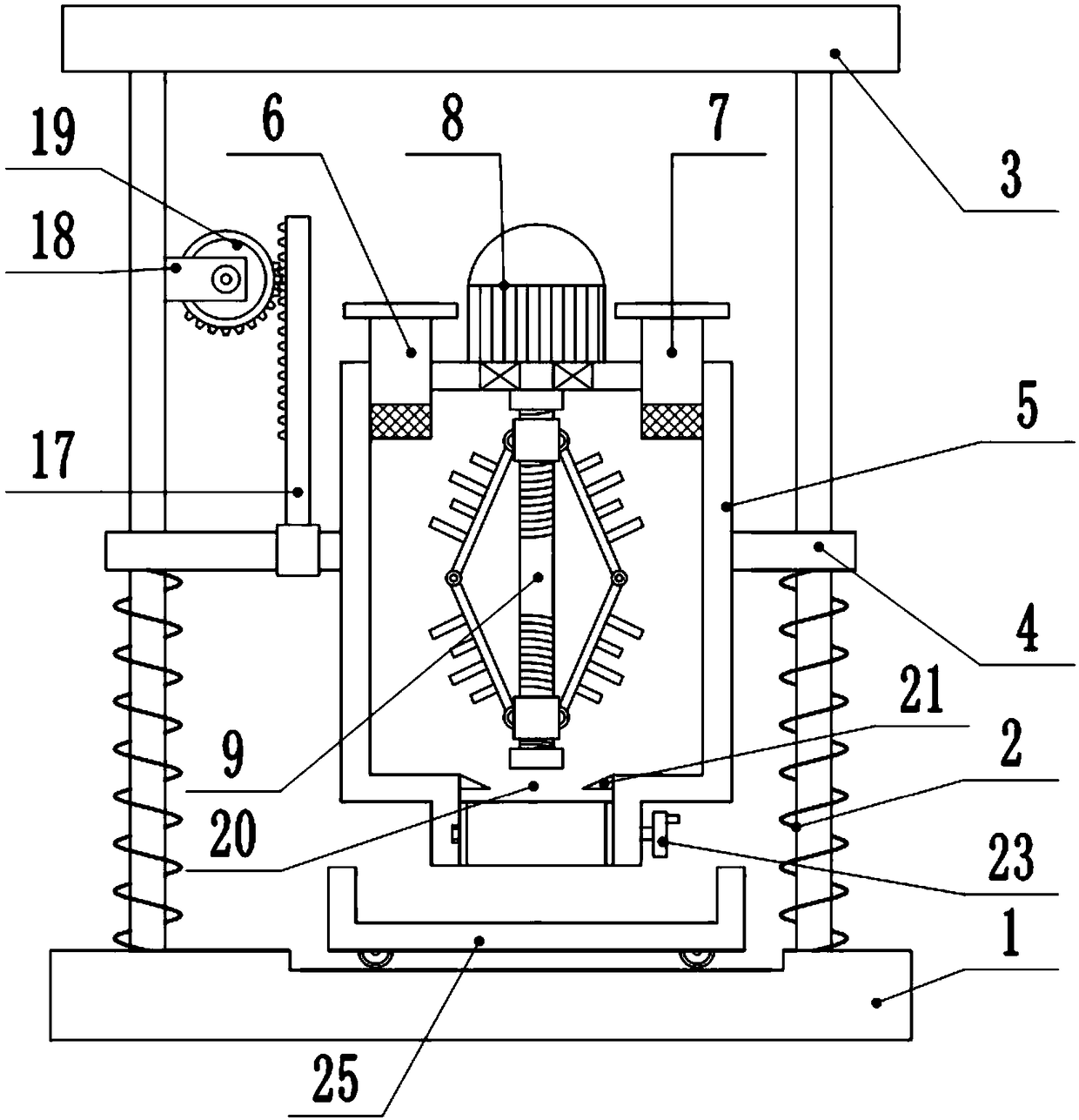

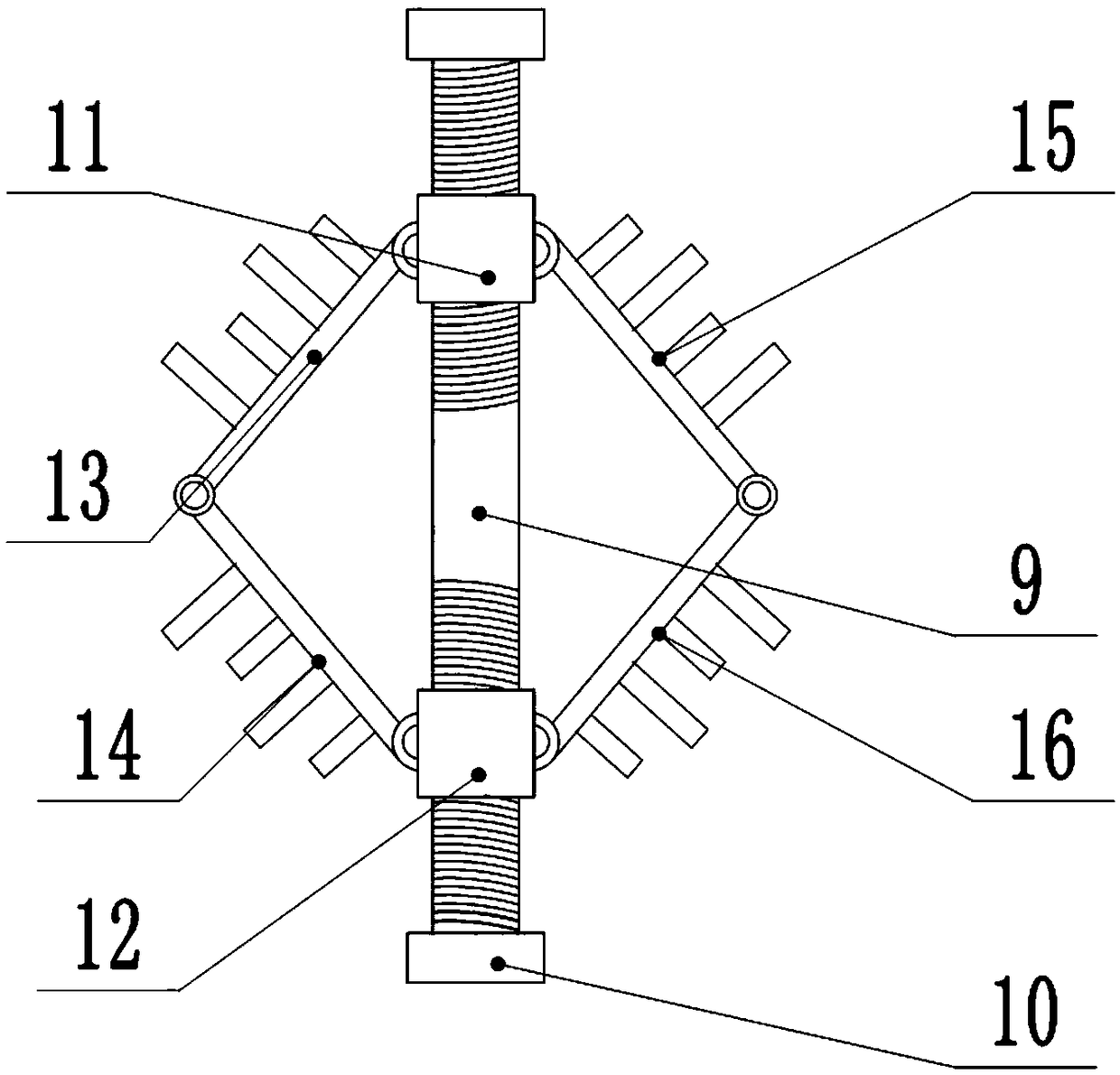

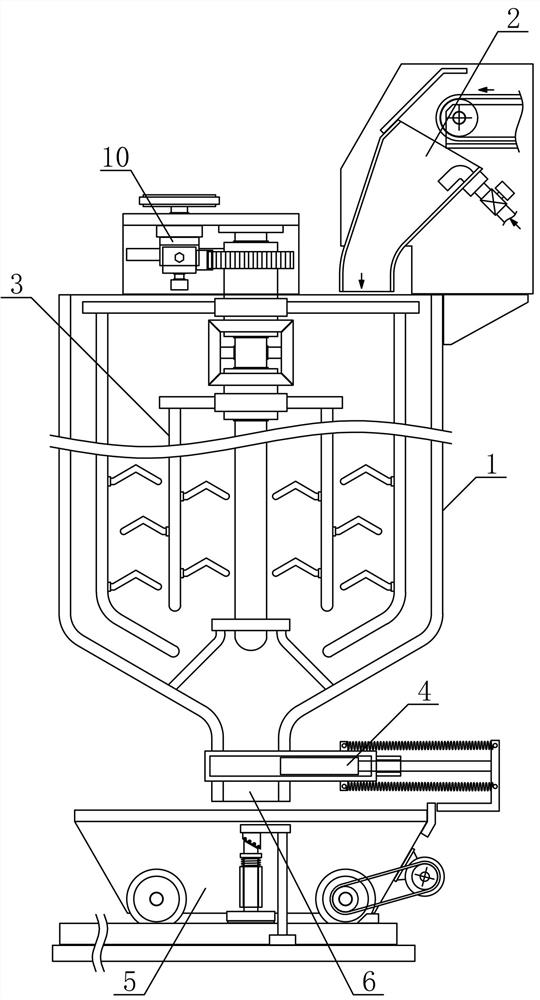

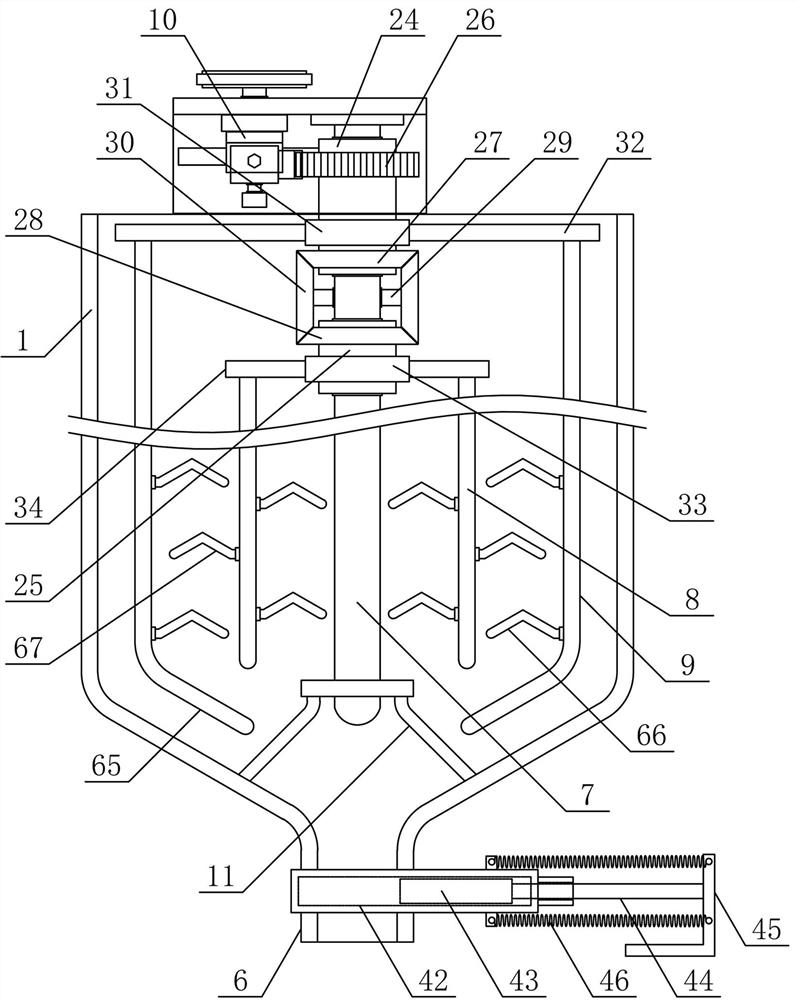

Nutrient solution mixing device for planting herbaceous plants

InactiveCN109046137AHigh purityAffect the blending effectShaking/oscillating/vibrating mixersTransportation and packagingInterference fitDrive motor

The invention discloses a nutrient solution mixing device for planting herbaceous plants. The nutrient solution mixing device comprises a base, guide posts, a mixing tank, a screw rod, a rack, a driving motor and a special-shaped gear, wherein mounting lugs are arranged on the guide posts in a sliding manner; the mixing tank is fixedly connected between the mounting lugs positioned on two sides; material splitting drums are in interference fit with a connecting shaft and are intermittently provided with material storage tanks; a driving motor is fixedly arranged on the guide post positioned onthe left side; an output shaft of the driving motor faces forward and is fixedly connected with the special-shaped gear. A first feeding opening and a second feeding opening are respectively providedwith filter screens, so that the purity of a nutrient solution is improved, and the influence of impurities contained in the nutrient solution on mixing effect is avoided; by controlling positive andnegative rotation of a material mixing motor, stirring range of stirring blades on connecting rods is changed, and stirring is more sufficient and efficient; by rotating the material splitting drums,the dosage of the nutrient solution can be determined according to the sizes of the material storage tanks, and simplicity and convenience are realized.

Owner:徐得强

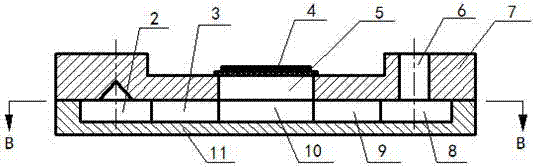

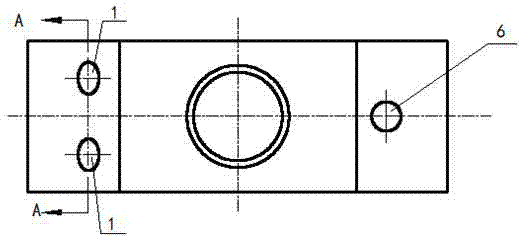

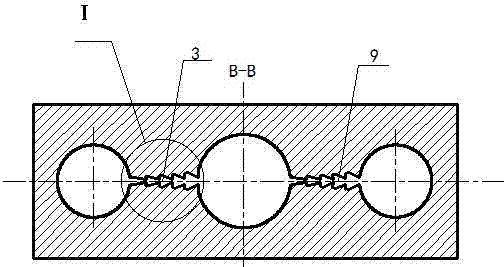

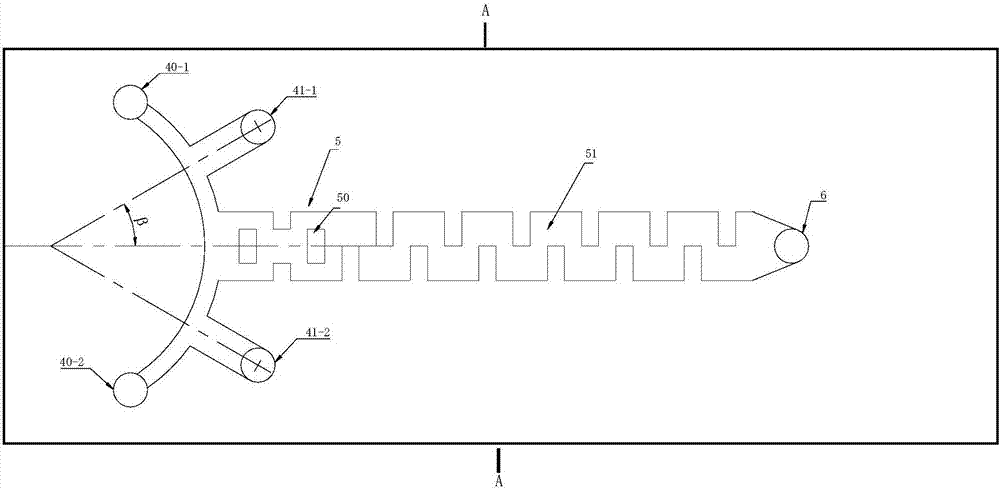

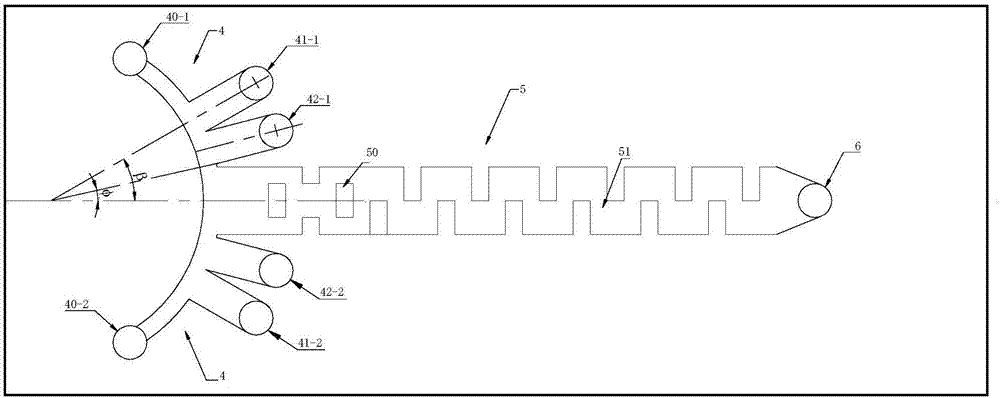

Microfluidic chip capable of realizing high-efficiency mixing

InactiveCN107376750AEfficient mixingEven by forceFlow mixersTransportation and packagingInlet channelGlass chip

The invention discloses a microfluidic chip capable of realizing high-efficiency mixing. The microfluidic chip comprises a substrate as well as an upper glass sheet and a lower glass sheet which are covered on the top and bottom of the substrate, wherein channels with different geometrical structures are arranged on the substrate; the channels comprise an inlet channel, a straight channel and an outlet channel; all the channels are uniformly distributed on the substrate. The microfluidic chip capable of realizing the high-efficiency mixing, disclosed by the invention, has the beneficial effects that uniformity stress of the microfluidic chip is facilitated, the service life of the substrate is prolonged and measurement errors caused by the deformation of the substrate are reduced; high-efficiency and rapid mixing of different components can be realized and a uniformly-mixed solution is obtained.

Owner:QINGDAO UNIV OF SCI & TECH

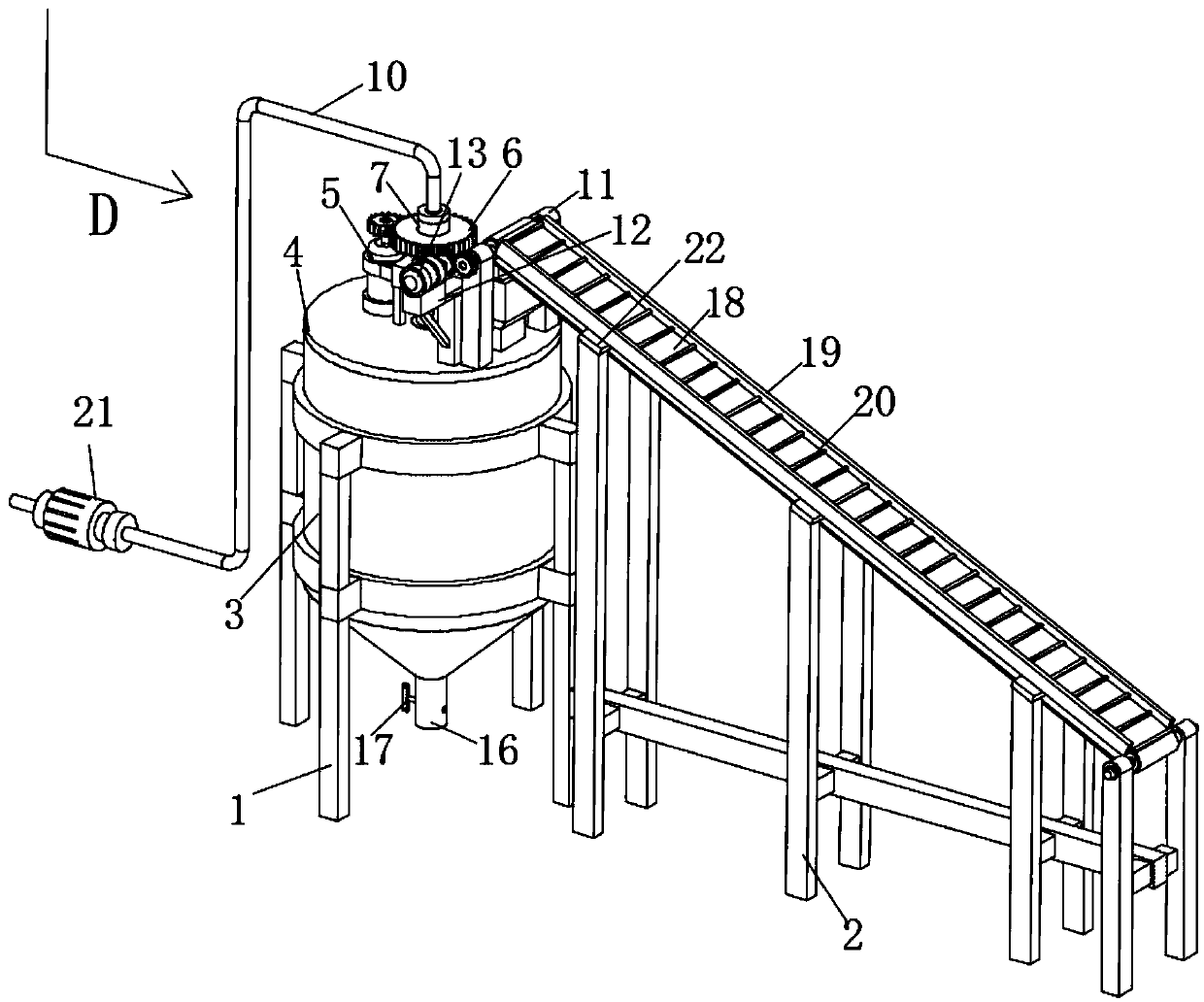

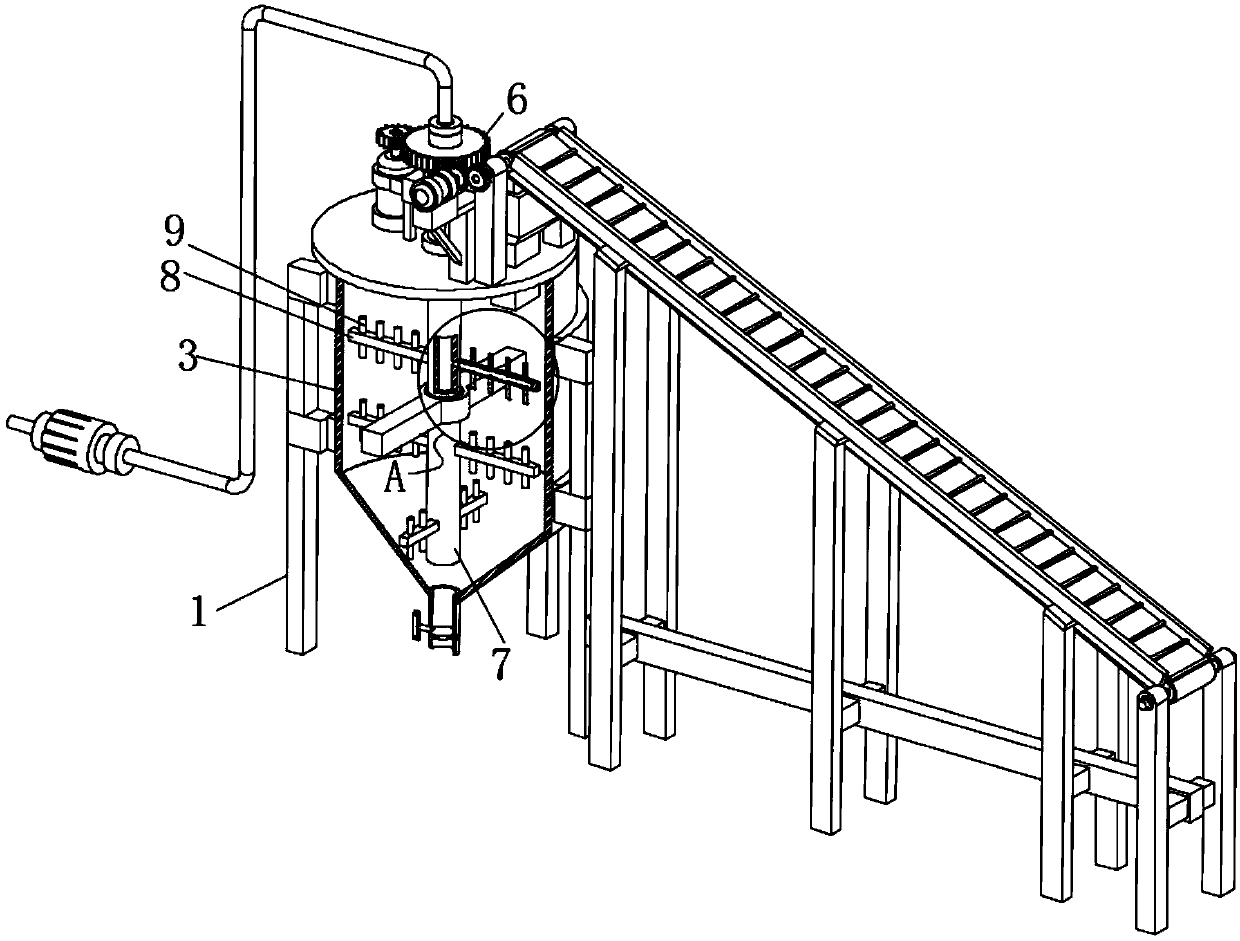

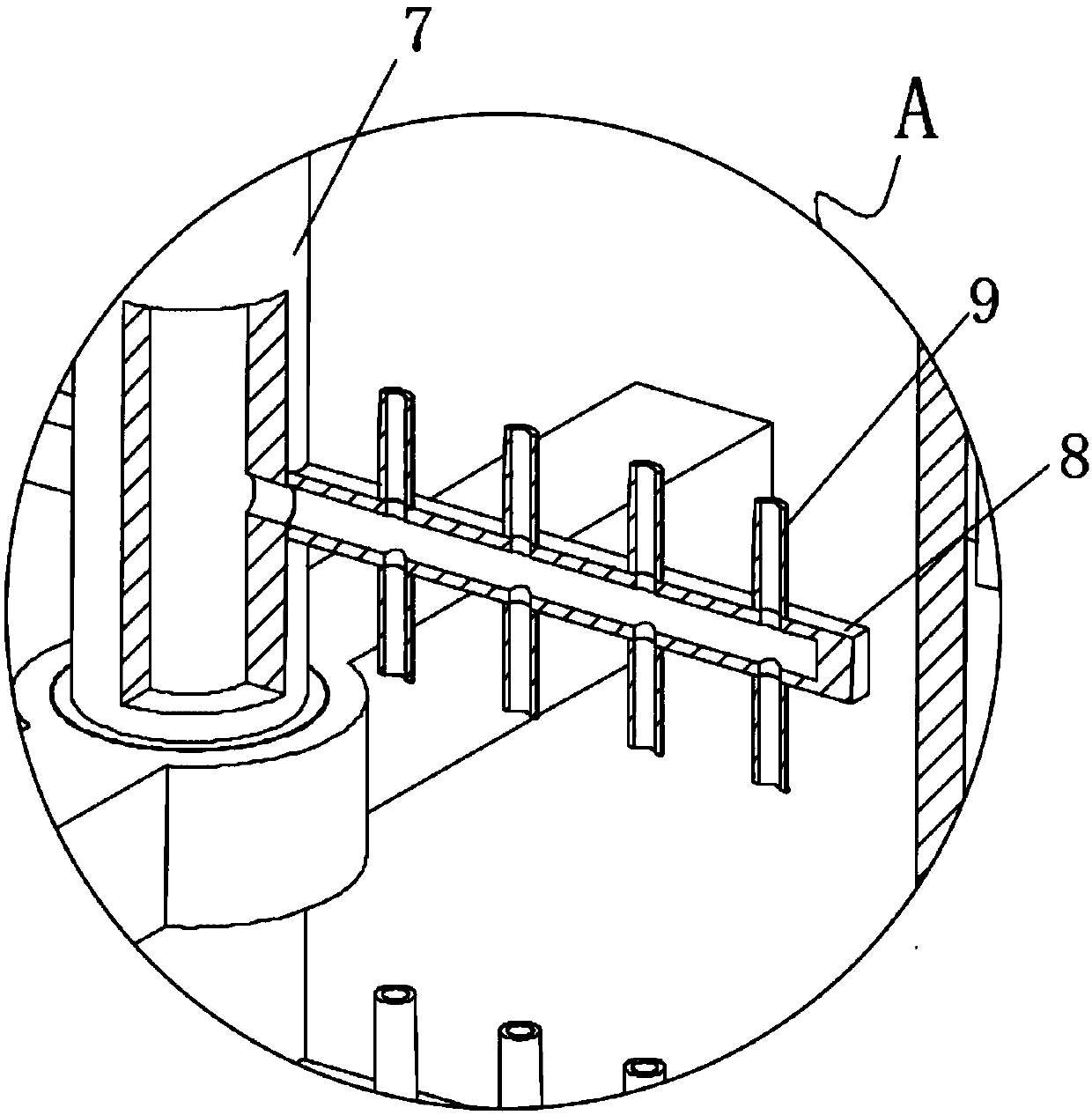

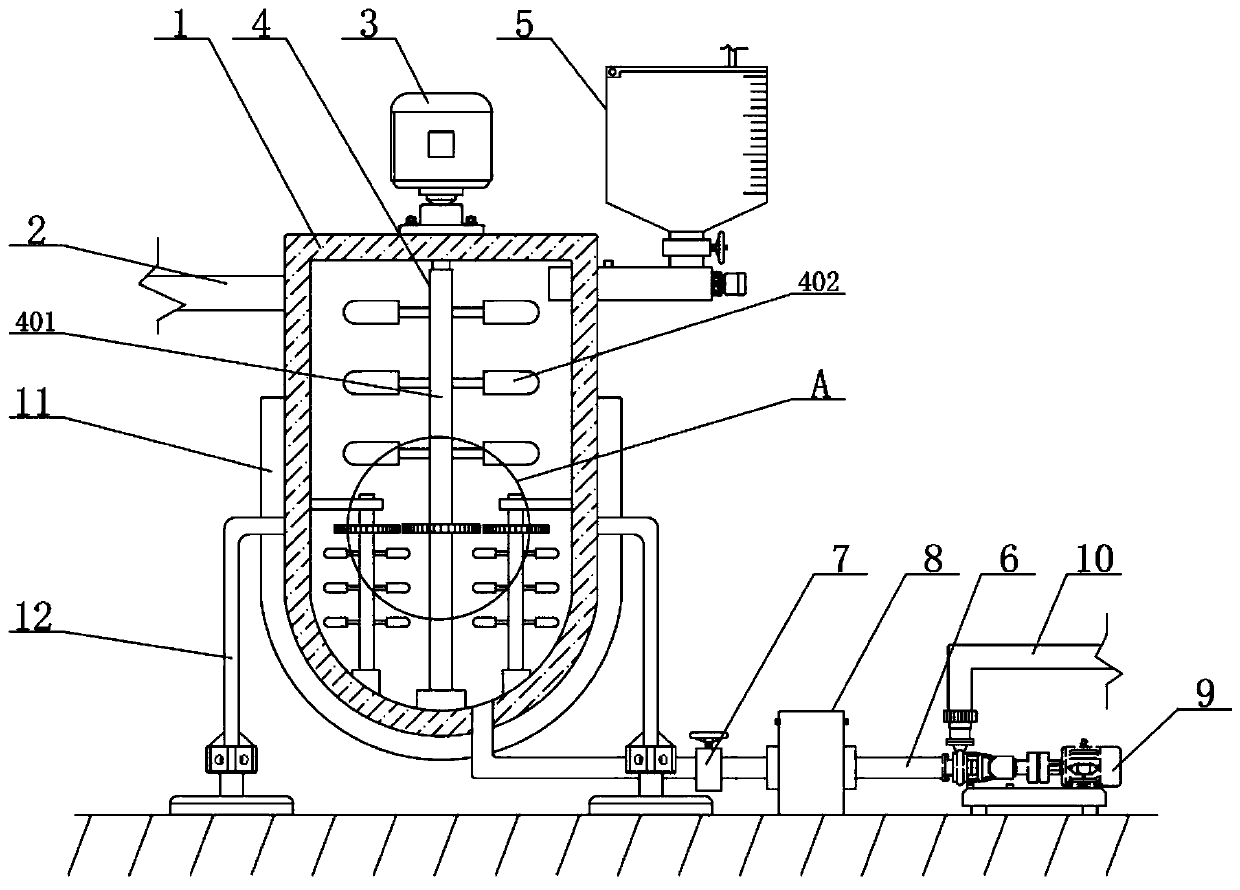

Automatic feeding and discharging stirrer for building

InactiveCN109605574AFull and efficient mixingConvenience fillerDischarging apparatusCement mixing apparatusWater flowEngineering

The invention discloses an automatic feeding and discharging stirrer for building. The automatic feeding and discharging stirrer for building comprises a stirring tank bracket and a conveying mechanism bracket; a stirring tank is fixedly supported on the stirring tank bracket, and a tank cover is arranged on the stirring tank in a sealing and covering mode; a stirring motor is fixedly welded to the upper surface of the tank cover, and a stirring driving gear is fixedly welded to the upper end of an output shaft of the stirring motor; the inner side of the stirring driving gear meshes with a stirring shaft gear, a hollow stirring shaft is fixedly inserted into the middle of the stirring shaft gear in a penetrating mode, and the lower end of the hollow stirring shaft penetrates into the stirring tank; and a plurality of stirring rods are fixedly arranged on the surface of the hollow stirring shaft, and a plurality of stirring branch rods are fixedly connected to the upper surface and thelower surface of the stirring rods. According to the automatic feeding and discharging stirrer for building, the output shaft of the stirring motor rotates to enable the hollow stirring shaft to rotate at high speed, water flows out from water outlets of the stirring branch rods while materials are stirred by the stirring rods at high speed, and therefore concrete is stirred quite efficiently andfully.

Owner:李清华

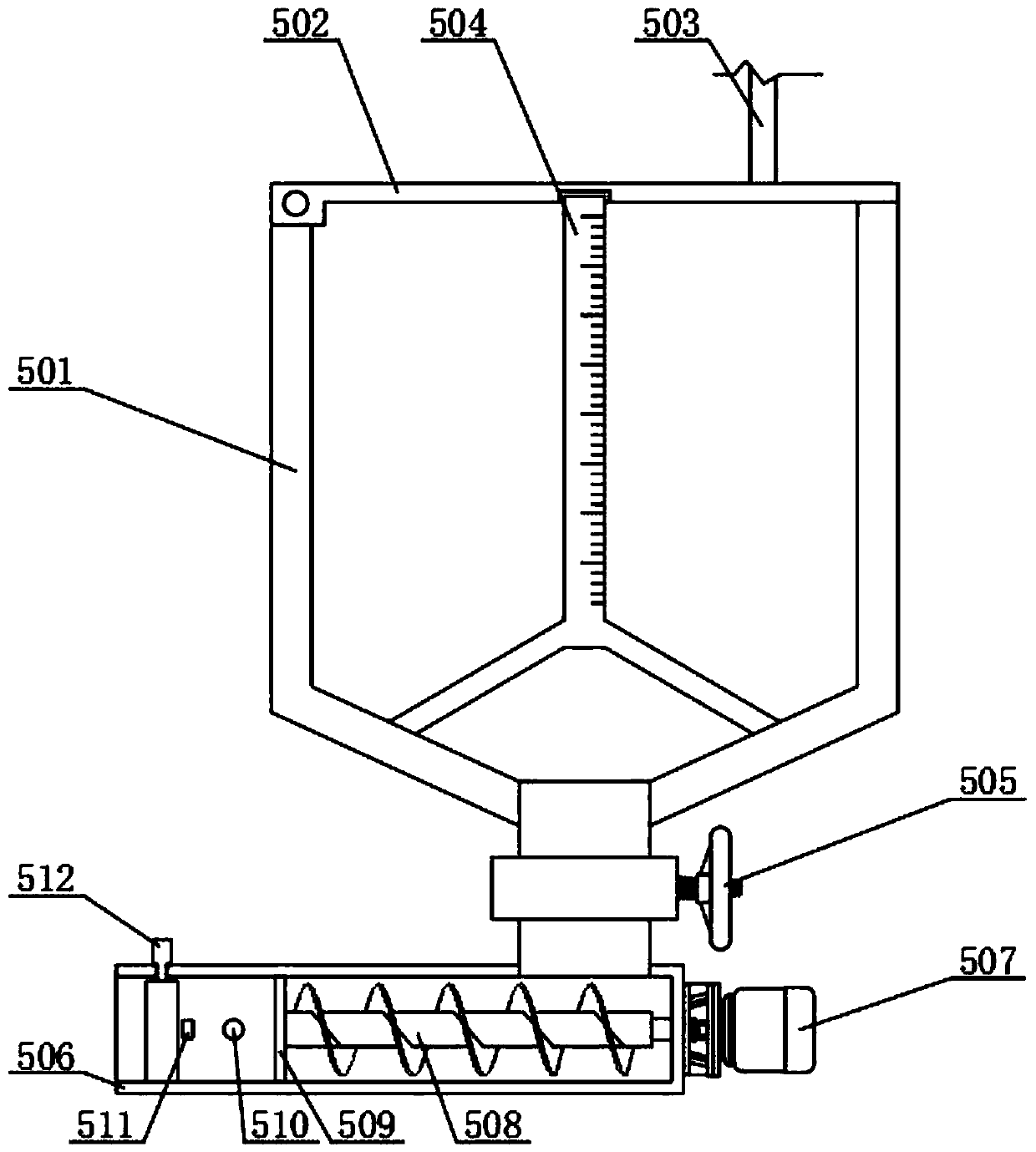

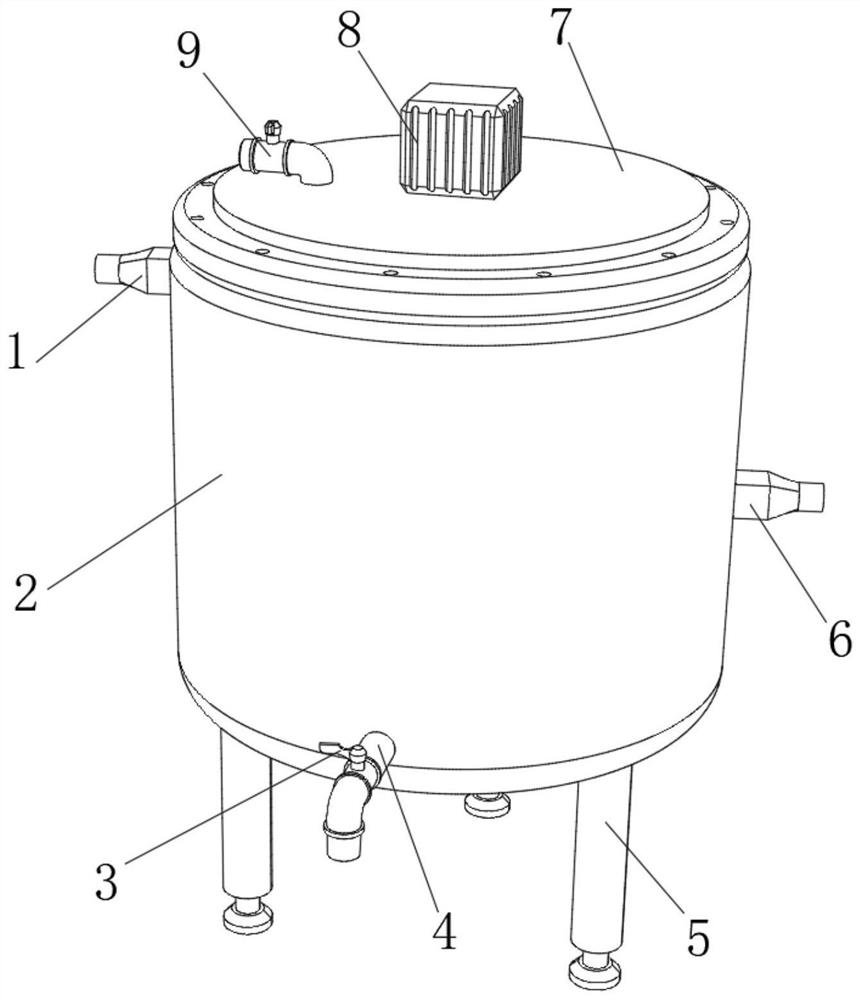

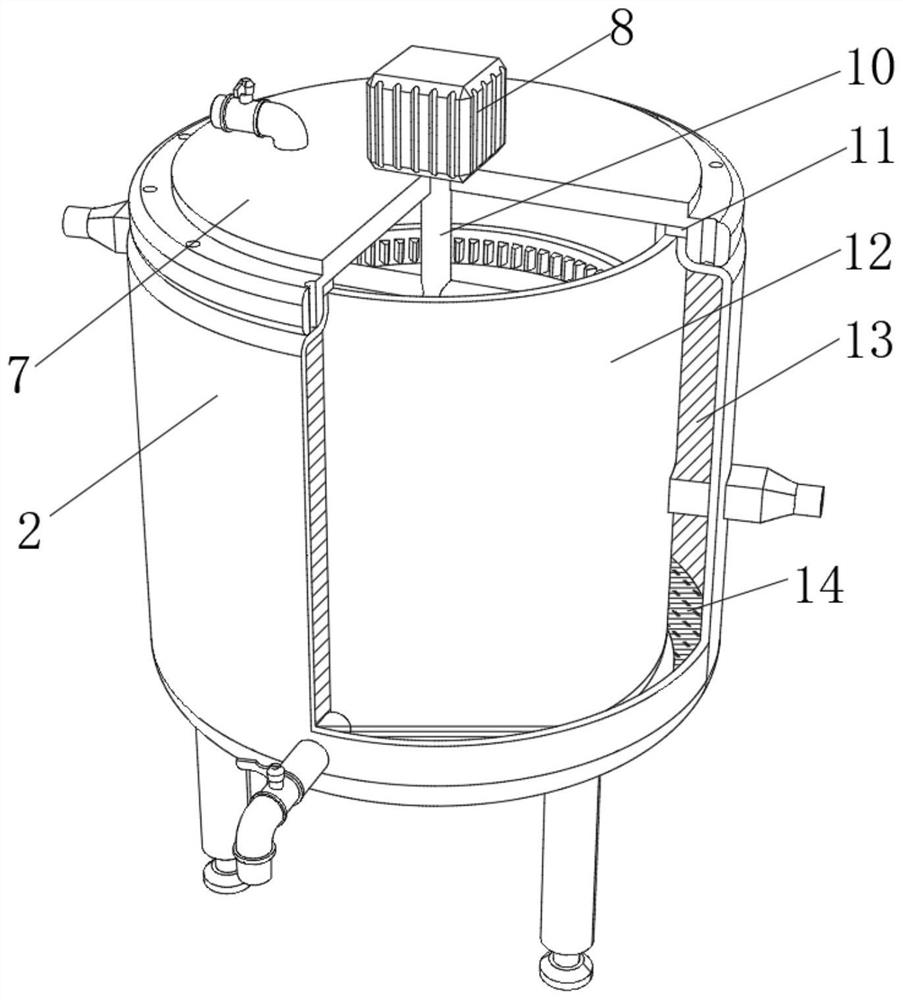

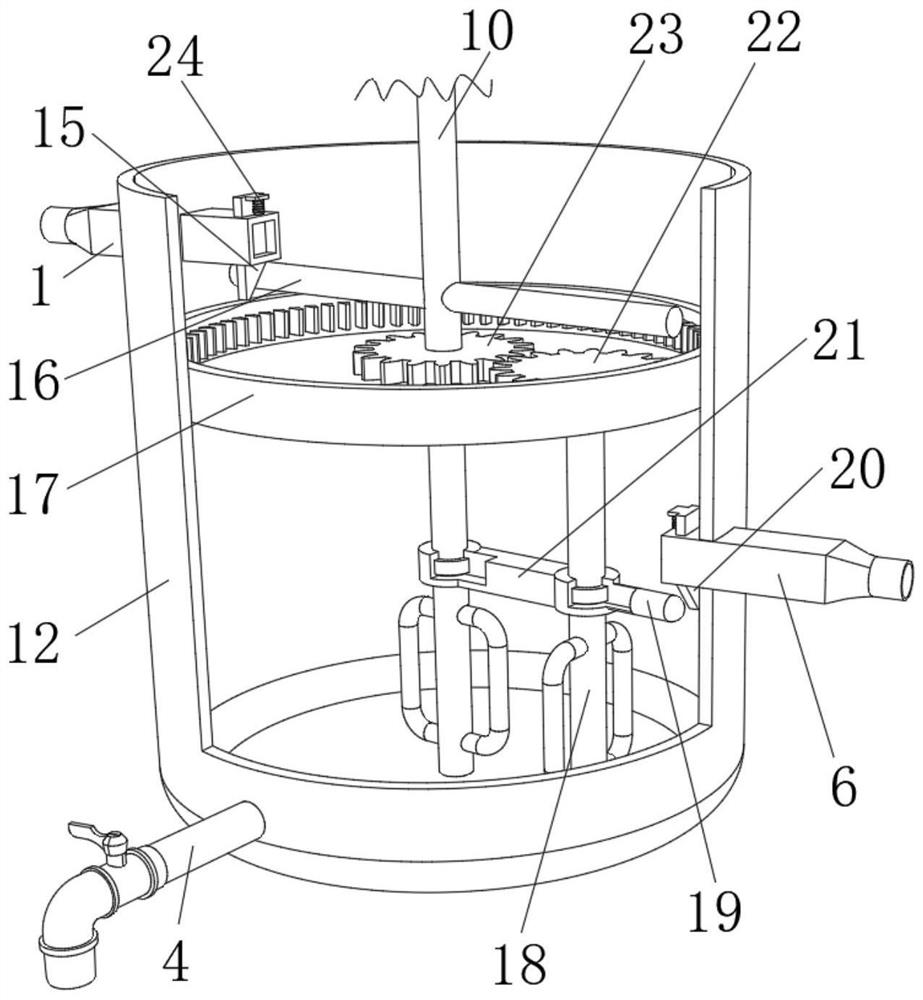

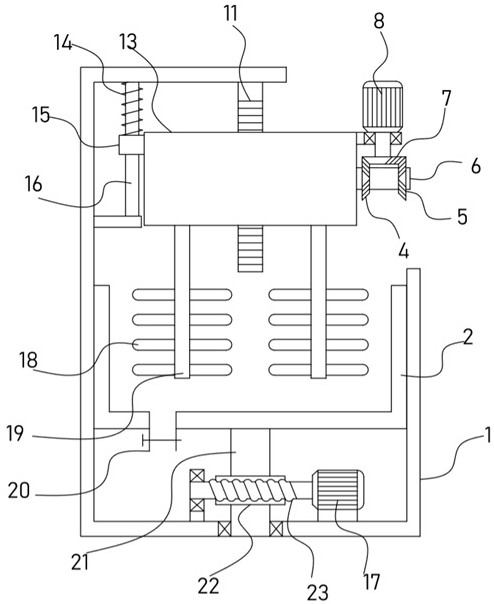

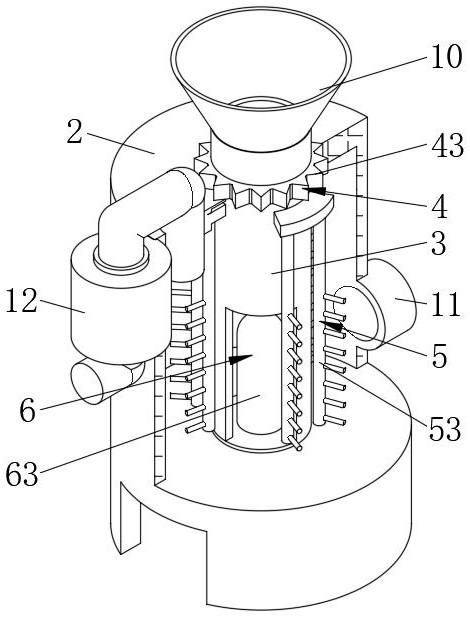

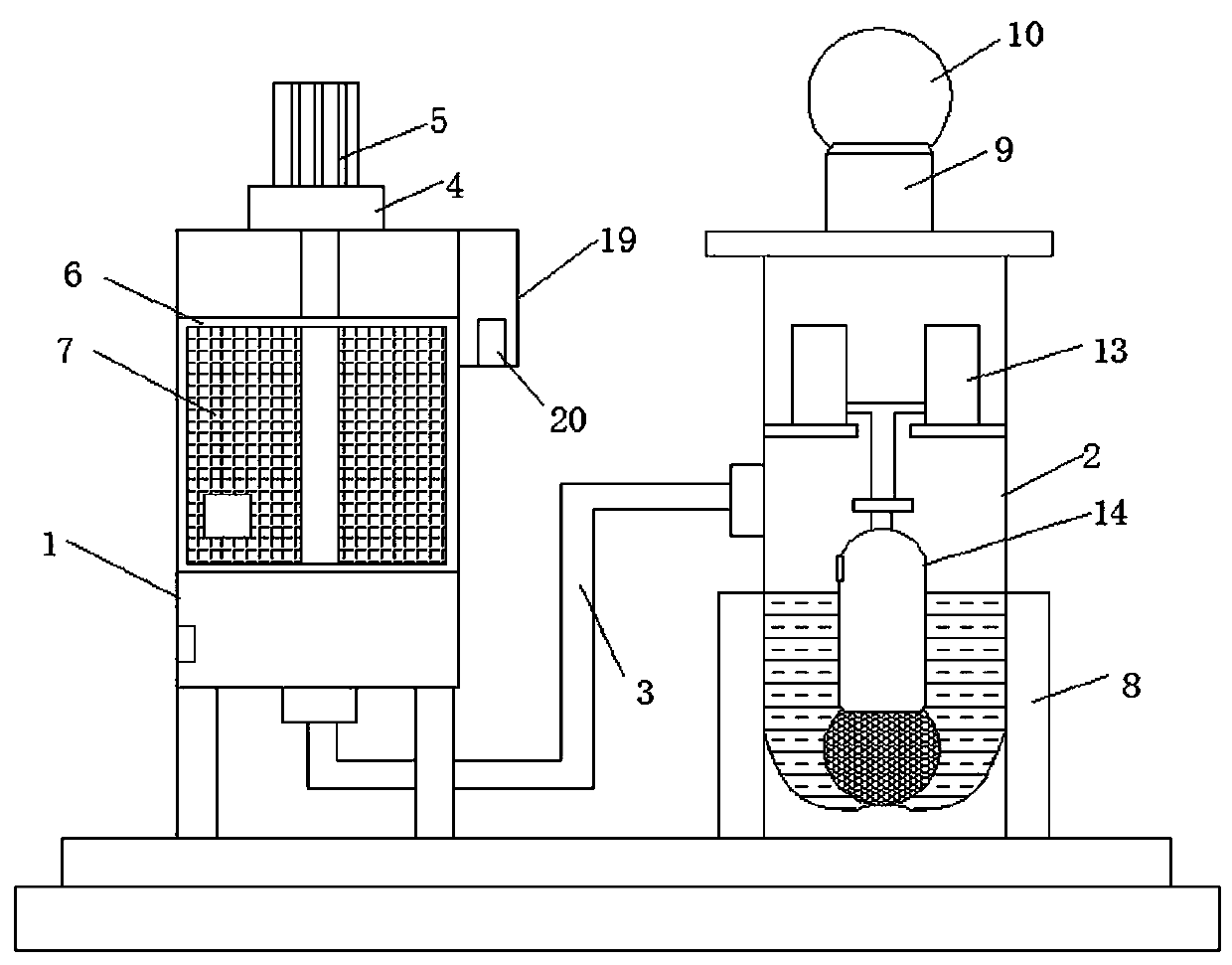

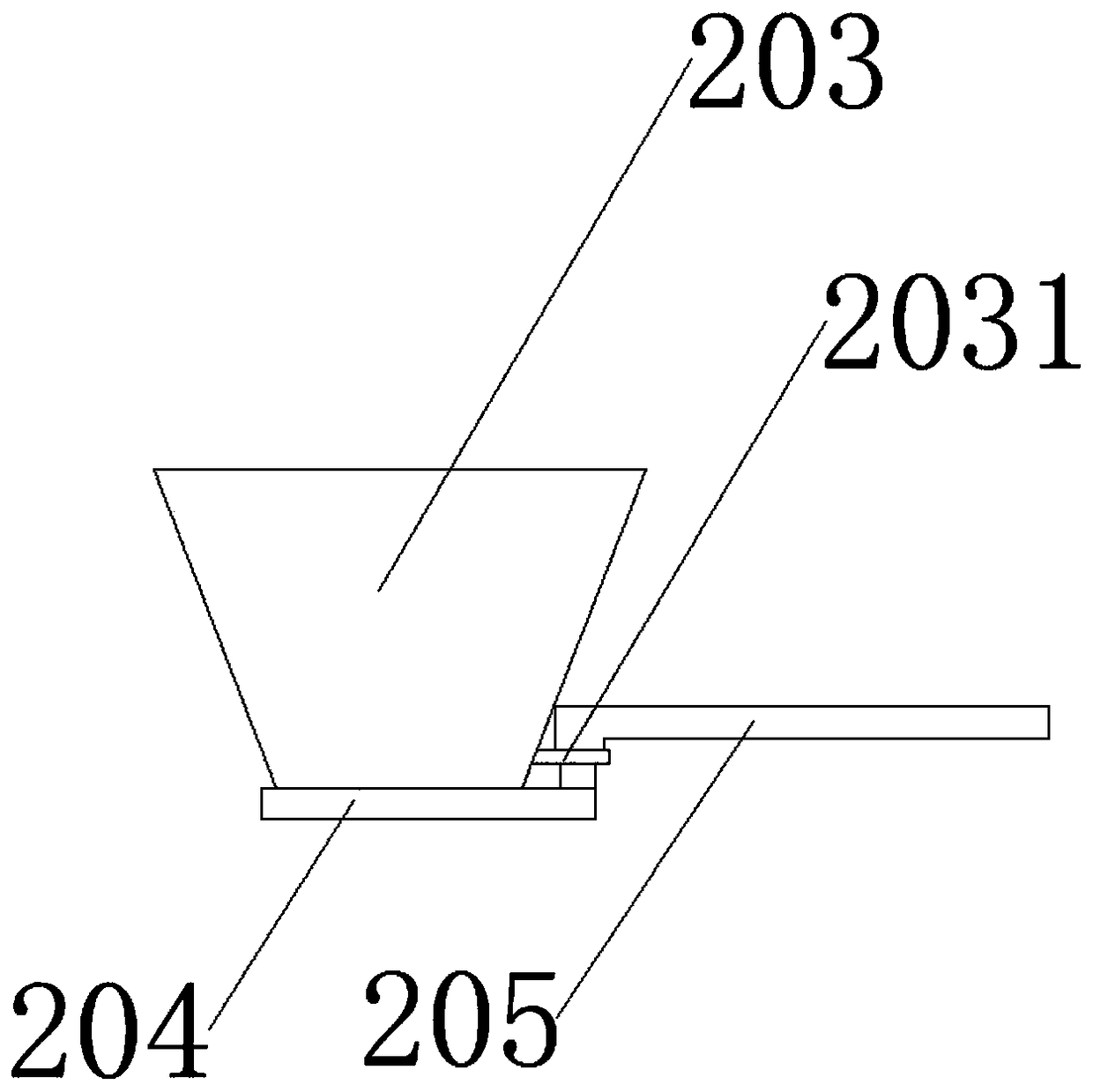

Solution low-temperature extraction device and efficient extraction process thereof

PendingCN110917654AFull and efficient mixingShorten the timeSolid solvent extractionElectric machineGear wheel

The invention relates to the technical field of coffee extraction equipment, and particularly relates to a solution low-temperature extraction device and an efficient extraction process thereof. The solution low-temperature extraction device comprises an extraction tank and a water inlet pipe. A water inlet pipe is communicated above the left end surface of the extraction tank; a stirring motor isfixedly connected on the upper end surface of the extraction tank; an adding device is fixedly connected on the right end surface of the extraction tank; the adding device comprises an adding hopperand a rotating cover, a rotating cover is rotatably connected on the left side of the upper end surface of the adding hopper, an air inlet pipe is communicated on the upper end surface of the rotatingcover, a first valve is fixedly connected on the outer side of the lower part of the adding hopper, and a quantitative rod is fixedly connected in the adding hopper. With the arrangement of the mainstirring shaft, the driven gear and the auxiliary stirring shaft, the stirring motor drives the main stirring shaft to rotate and the main stirring shaft drives the auxiliary stirring shaft to rotateso that irregular rotation of liquid in the extraction tank in forward and reverse directions is realized, sufficient and efficient mixing of the materials and the solution is guaranteed and normal operation of subsequent work is guaranteed.

Owner:昆明弘承食品科技有限公司

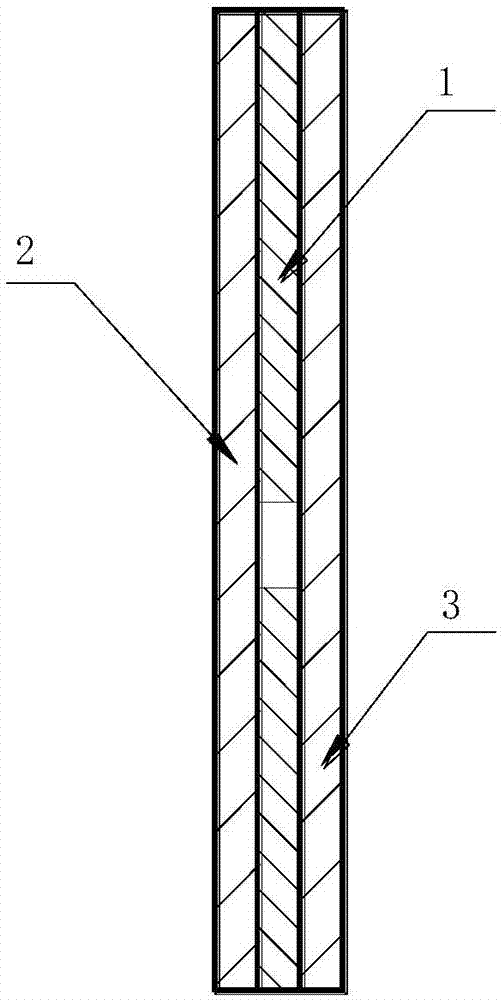

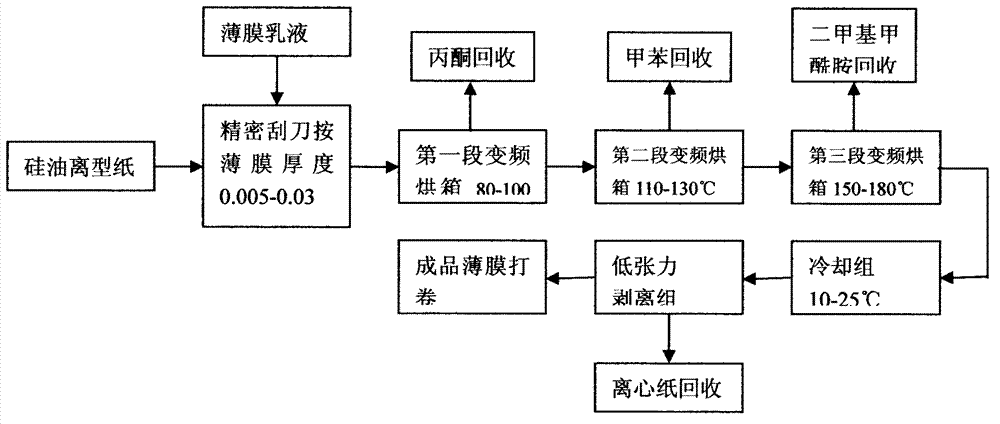

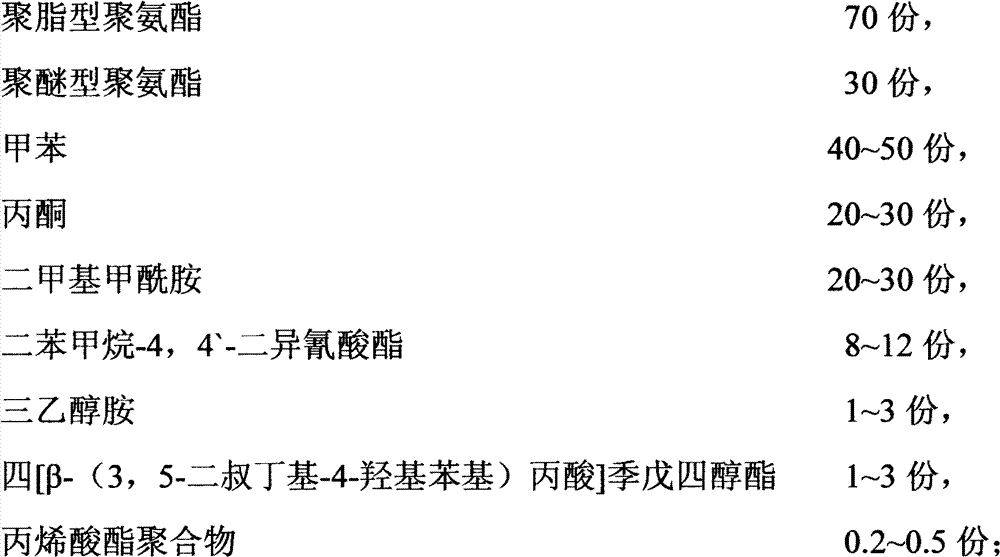

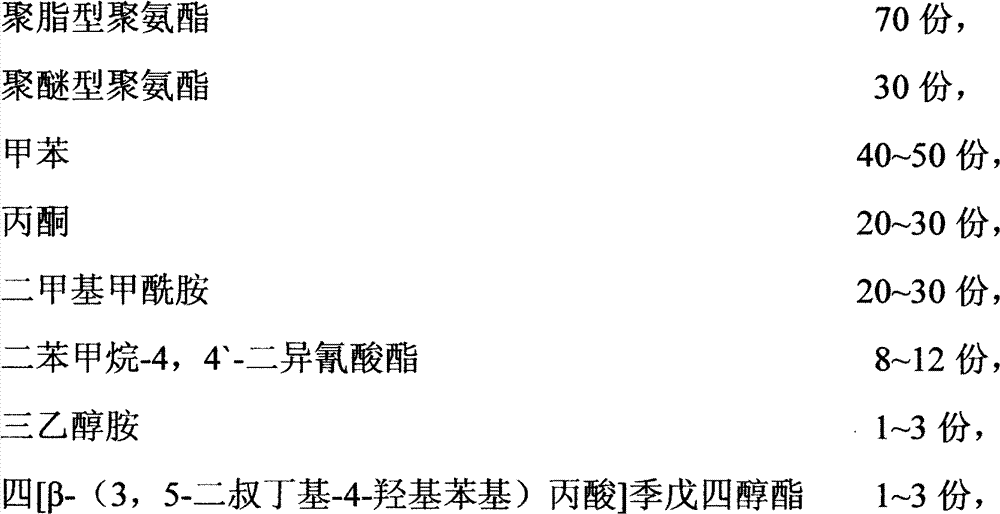

Degradable thin film with waterproof and moisture permeable function

The invention discloses a degradable thin film with a waterproof and moisture permeable function. The degradable thin film is obtained by drying a slurry emulsion, and the slurry emulsion is formed by the following components by weight parts: 70 parts of polyester type polyurethane, 30 parts of polyether polyurethane, 40-50 parts of toluene, 20-30 parts of acetone, 20-30 parts of dimethylformamide, 8-12 parts of diphenylmethane-4,4'-diisocyanate, 1-3 parts of triethanolamine, 1-3 parts of tetra-[beta-(3,5-ditertiary butyl-4-hydroxy phenyl) propionic acid] pentaerythritol ester and 0.2-0.5 part of acrylate polymer; the slurry emulsion is processed by using the following process to form the degradable thin film; and the process comprises the following steps of: coating the slurry emulsion on the surface of silicone oil release paper; and sequentially drying under a low-speed flowing air atmosphere under the conditions of 80-100 DEG C, 110-130 DEG C and 150-180 DEG C to obtain the degradable thin film. The degradable thin film disclosed by the invention guarantees the flexibility and the malleability, and also accelerates the forming of the thin film to improve the moisture permeable performance of the thin film.

Owner:KUNSHAN HUAYANG NEW MATERIAL

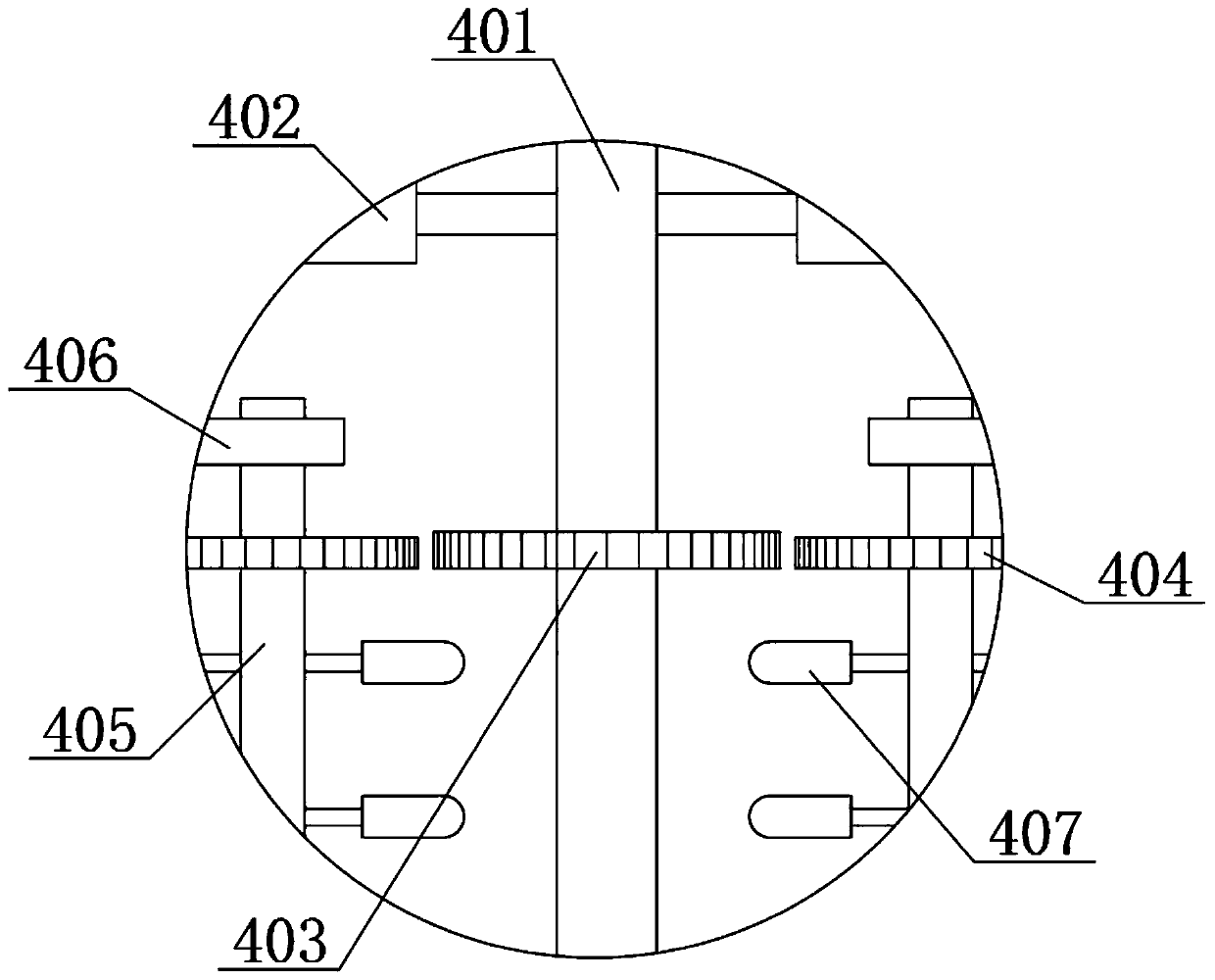

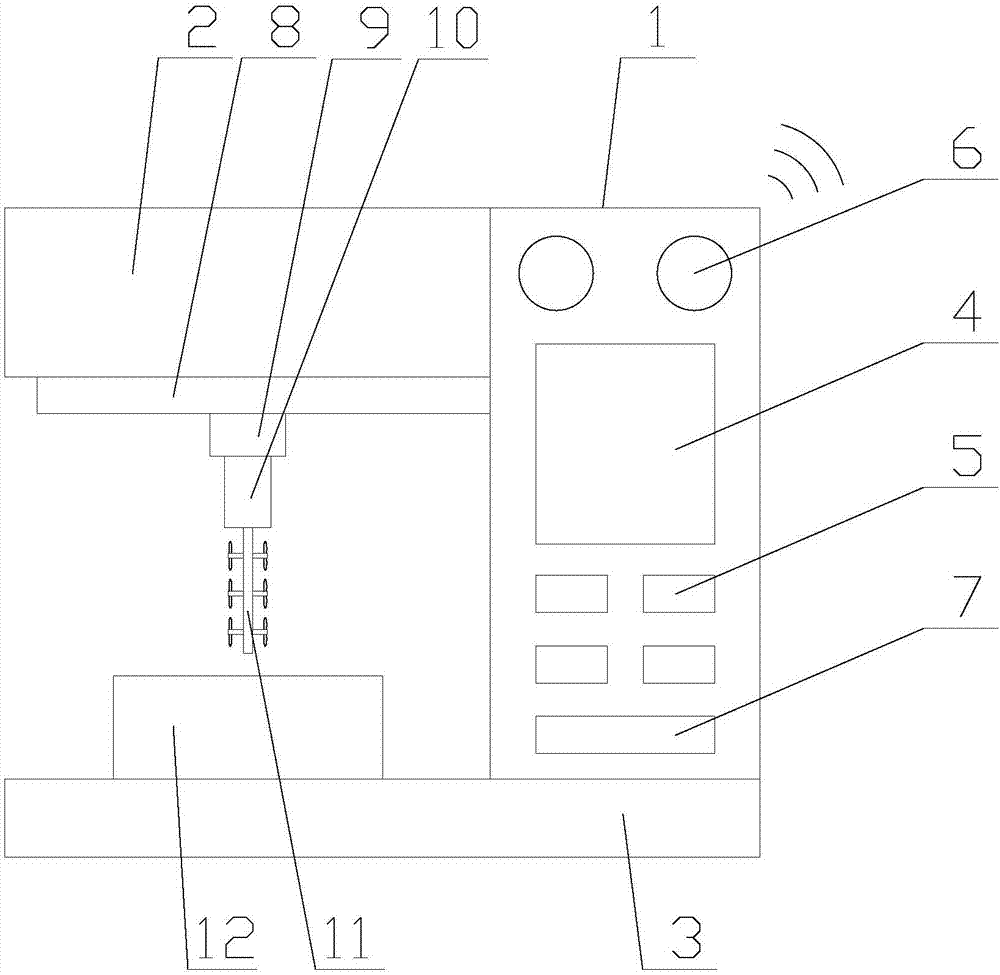

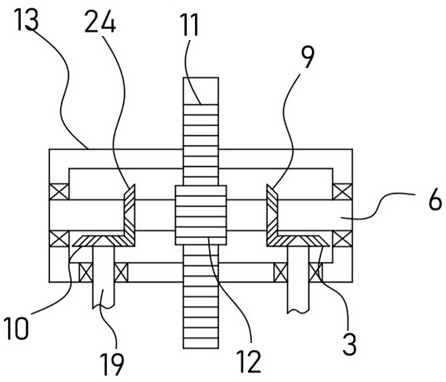

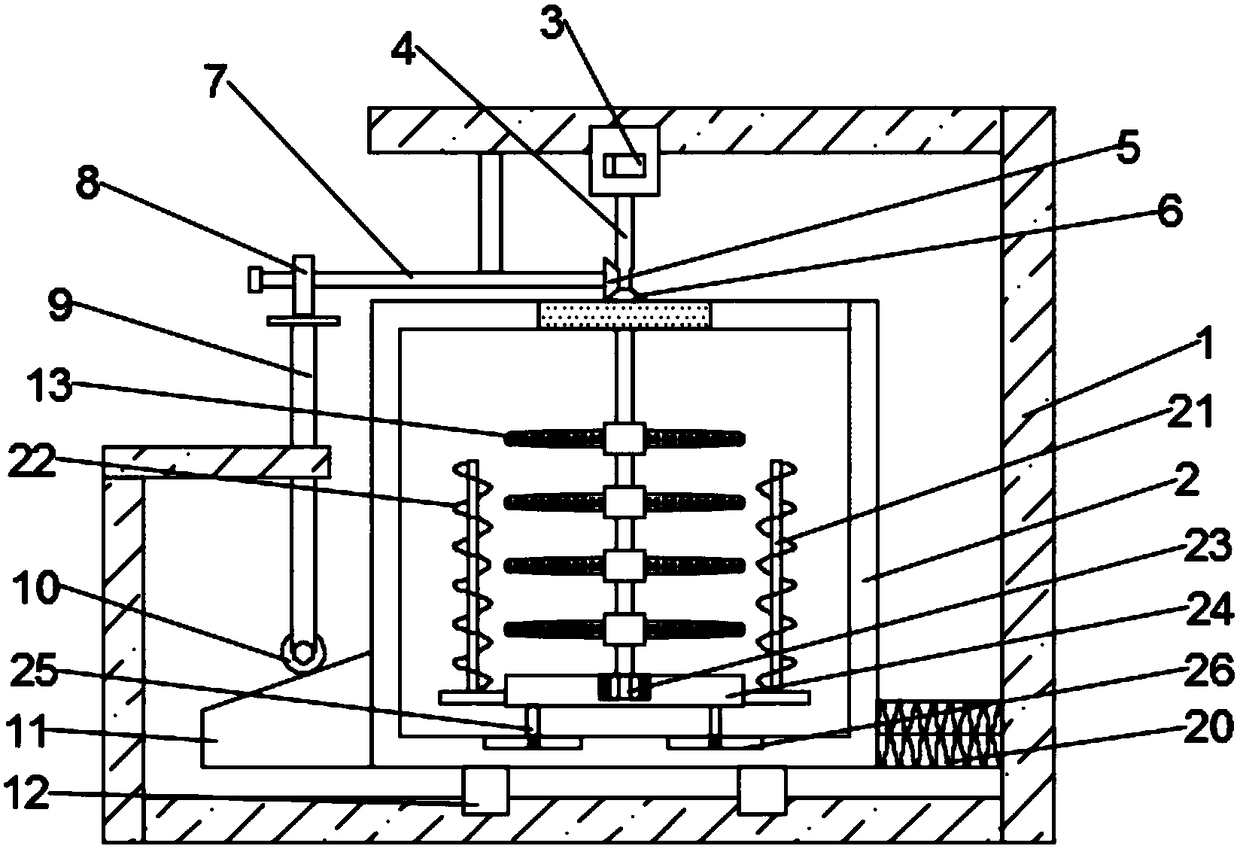

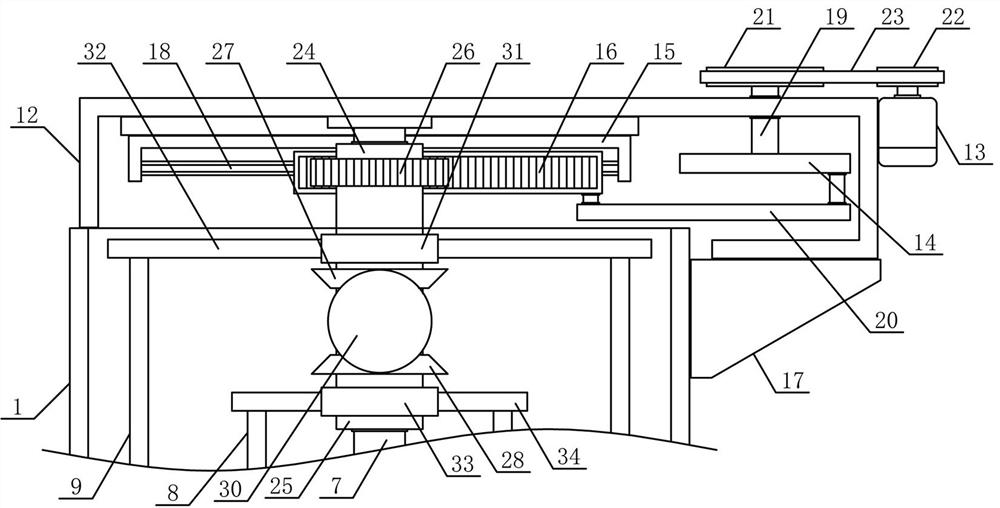

Stirring device used for biological medicine development

InactiveCN107126862AImprove the effectImprove practicalityRotary stirring mixersTransportation and packagingPower circuitsMechanical engineering

The invention relates to a stirring device used for biological medicine development. The stirring device comprises a shell, a cross beam, a base, a center control mechanism and a stirring mechanism, wherein the stirring mechanism comprises a displacement assembly, a driving assembly and a stirring assembly; the displacement assembly comprises a second motor, a second driving shaft, a driving gear and a displacement frame; the driving assembly comprises a first motor and a first driving shaft; the stirring assembly comprises a stirring shaft and a plurality of stirring units; each stirring unit comprises a fixed sleeve pipe, a rotating shaft, a plurality of stirring blades and a spring; and a working power module comprises a working power circuit. The stirring device used for biological medicine development has the following advantages: the stirring mechanism can realize complete and highly-efficient stirring of a medicine in the interior of a stirring cup, so practicability of the device is improved; moreover, the working power circuit can realize soft starting of a power voltage, so reliability of the device is improved.

Owner:SHENZHEN BEIYOUTONG NEW ENERGY TECH DEV CO LTD

Production method and device of swelling and pain relieving solution

PendingCN113680233AWell mixedAvoid reducing the efficacy of the drugHydroxy compound active ingredientsAntipyreticPharmaceutical drugElectric machinery

The invention relates to the technical field of medicine processing, and discloses a production device of a swelling and pain relieving solution. The production device comprises an outer shell; an inner shell is arranged in the outer shell; a plurality of supporting columns are fixedly connected to the bottom of the outer shell; an upper cover is fixedly connected to the top of the outer shell; and a motor is fixedly connected to the upper surface of the upper cover. The invention further discloses a production method of the swelling and pain relieving solution. The production method comprises the following steps of: S1, preparing raw materials; S2, cleaning and crushing the raw materials; and S3, soaking the raw materials. Medicines can be stirred and mixed well, and the mixing effect of the device is improved. Meanwhile, the medicines in the inner shell can be heated through a heating pad, and the heating effect of the device is improved. The proportion is reasonable, and the raw material cost is low. The swelling and pain relieving solution has good swelling and pain relieving effects, and can expel wind and remove cold, eliminate dampness and relieve swelling, and relax tendons and activate collaterals. Qualified crushed raw materials can be screened out, then unqualified raw materials are crushed together, and the crushing efficiency is improved.

Owner:国创时珍湖北大健康有限公司

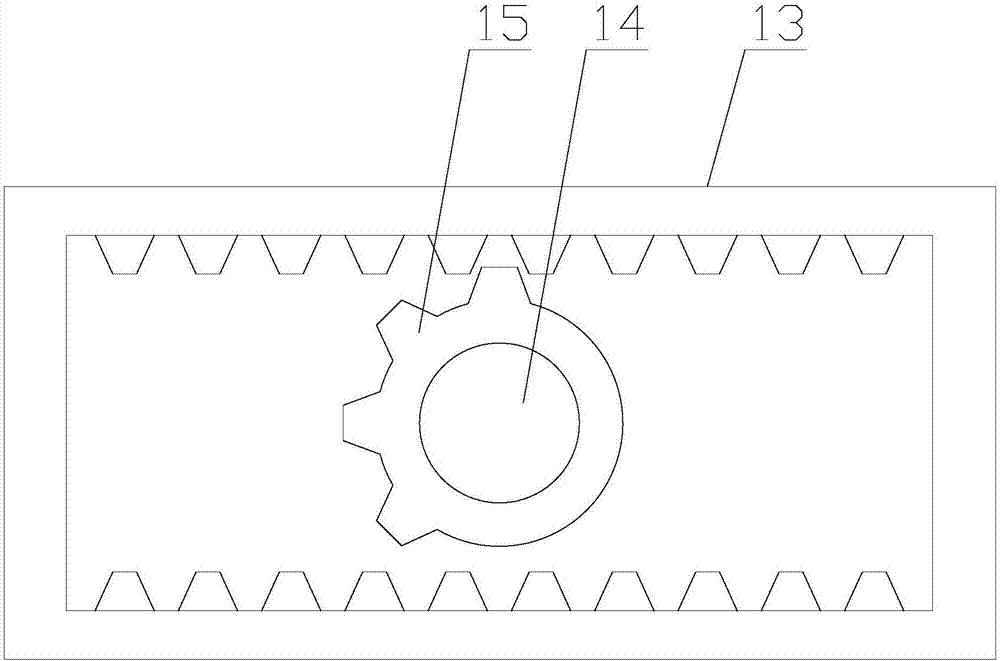

Gravel mixing device for constructional engineering

InactiveCN111974284ARealize the effect of rotating and stirringRealize the rotating stirring effectShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionClassical mechanics

The invention discloses a gravel material mixing device for constructional engineering, and relates to the technical field of building construction. The device comprises a fixing frame, the fixing frame is provided with a mixing tank used for storing sand and stone materials, a driving motor is fixed to a transmission box, the driving motor is in driving connection with a transmission mechanism located in the transmission box, the transmission mechanism is in driving connection with two stirring shafts vertically extending into the mixing tank, and a plurality of pairs of stirring rods are fixed to the stirring shafts at equal intervals. The transmission mechanism can drive the two stirring shafts to drive the respective stirring rods to rotate in opposite directions, the rotary stirring effect on sand and stone materials in the mixing tank is realized, the arranged stirring rod can vertically reciprocate while rotating along with the stirring shaft, the rotary stirring effect on the sand and stone materials at different vertical positions in the mixing tank is achieved, and the sufficient stirring degree of the sand and stone materials is remarkably improved. Meanwhile, the sand and stone materials in the mixing tank can be driven to rotate relative to the stirring rod, and sufficient and efficient stirring and mixing of the sand and stone materials are achieved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

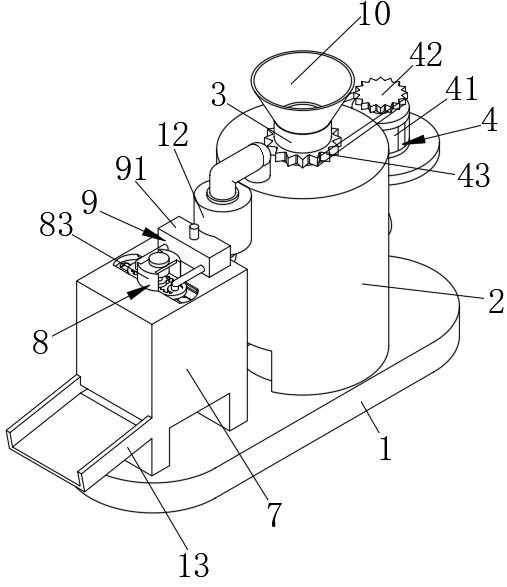

Rapid glue stirring device for footwear industry

InactiveCN112007551AFull and efficient mixingAvoid inhalationShaking/oscillating/vibrating mixersRotary stirring mixersAdhesive glueProcess engineering

The invention discloses a rapid glue stirring device for the footwear industry. The device includes a base; the right side of the top of the base is fixedly connected with a stirring tank; the bottomof the inner cavity of the stirring tank is fixedly connected with a material guide pipe; the top of the material guide pipe penetrates through the top of the stirring tank and is communicated with aconical feeding cylinder; a driving mechanism is arranged at the top of the right side of the stirring tank; a stirring mechanism is arranged in the inner cavity of the stirring tank; a vibrating mechanism is arranged at the bottom of the stirring tank; the left side of the top of the base is fixedly connected with a degradation box; and a reciprocating swing mechanism is arranged at the top of the degradation box. According to the invention, the driving mechanism, the stirring mechanism and the vibrating mechanism are used cooperatively to fully and efficiently stir glue in the inner cavity of the stirring tank; and through cooperative use of an exhaust fan, a reciprocating swing mechanism and a spraying mechanism, raised toxic chemical substances are extracted and purified, and the purposes of efficient and sufficient stirring, sealing, drifting prevention and toxic substance suction prevention can be achieved.

Owner:温州宇岚科技有限公司

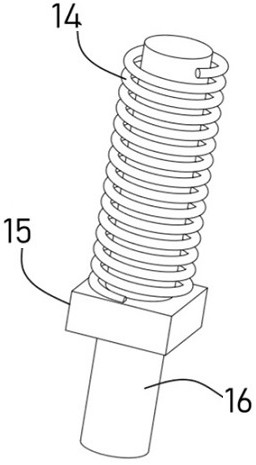

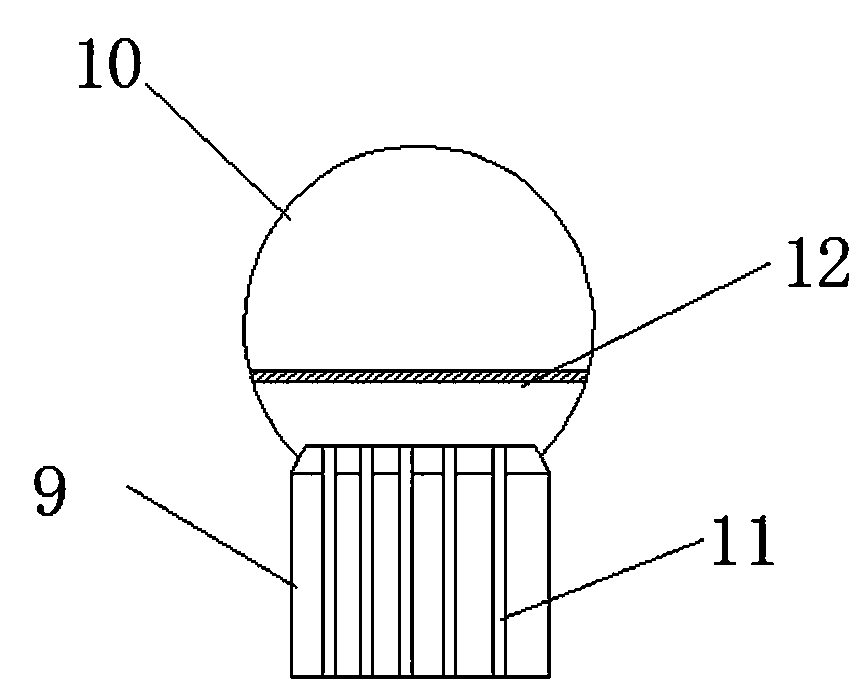

Egg beater

InactiveCN102613917AFull and efficient mixingEasy to process in mass productionKitchen equipmentGear wheelBevel gear

The invention relates to an egg beater, comprising a first gear and a second gear which are meshed mutually. A gear shaft of the first gear is connected with a jiggle bar, a gear shaft of the second gear is connected with a stirrer, the stirrer is deviated from the axis of the gear shaft of the second gear, and the head of the stirrer locally or completely extends into an egg liquid container. The egg beater sufficiently and efficiently stirs egg liquid by the aid of transmission of a group of bevel gears meshed mutually, and is favorable for realizing batch production and processing of food and dish which utilize eggs as raw materials.

Owner:SHANGHAI MINHANG HIGH SCHOOL

Novel environment-friendly reaction kettle for processing detergent

InactiveCN109603712AFunctionalFull and efficient mixingProcess control/regulationDispersed particle separationExhaust gasChemistry

The invention discloses a novel environment-friendly reaction kettle for processing a detergent, comprising a mixing reaction kettle and a catalytic reaction kettle, wherein the bottom of the mixing reaction kettle is provided with a liquid-passing column tube, and the right side of the liquid-passing column tube is connected to the catalytic reaction kettle; the top of the mixing reaction kettleis provided with a fixed bearing, the fixed bearing is fixedly connected with the mixing reaction kettle, the top of the fixed bearing is connected with a rotating electrical machine, and the bottom of the fixed bearing is connected with a rotating pole; the exterior of the rotating pole is connected to a filter protective frame, and the inner side of the filter protective frame is provided with afilter screen; and the left and right sides of the bottom of the catalytic reaction kettle are symmetrically provided with support poles, and the bottoms of the support poles are fixedly connected with stabilization pads. The device can efficiently process the detergent and collect exhaust gas, and is friendly to environment, simple in structure and strong in function.

Owner:温州宜科洁清洁剂有限公司

Tank body efficient uniform-shaking equipment

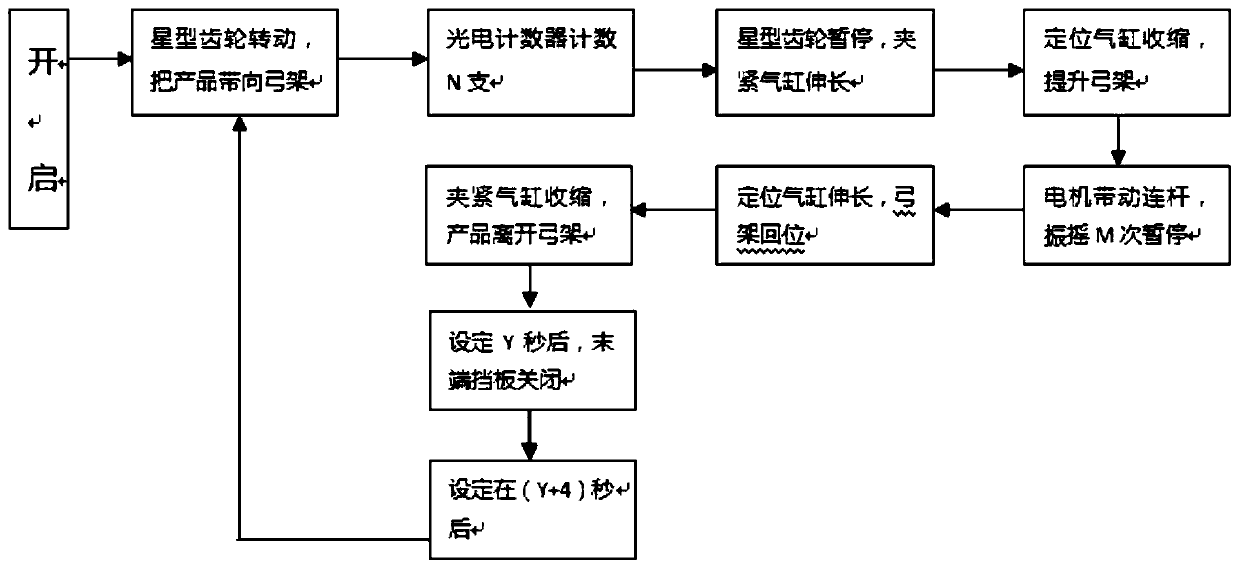

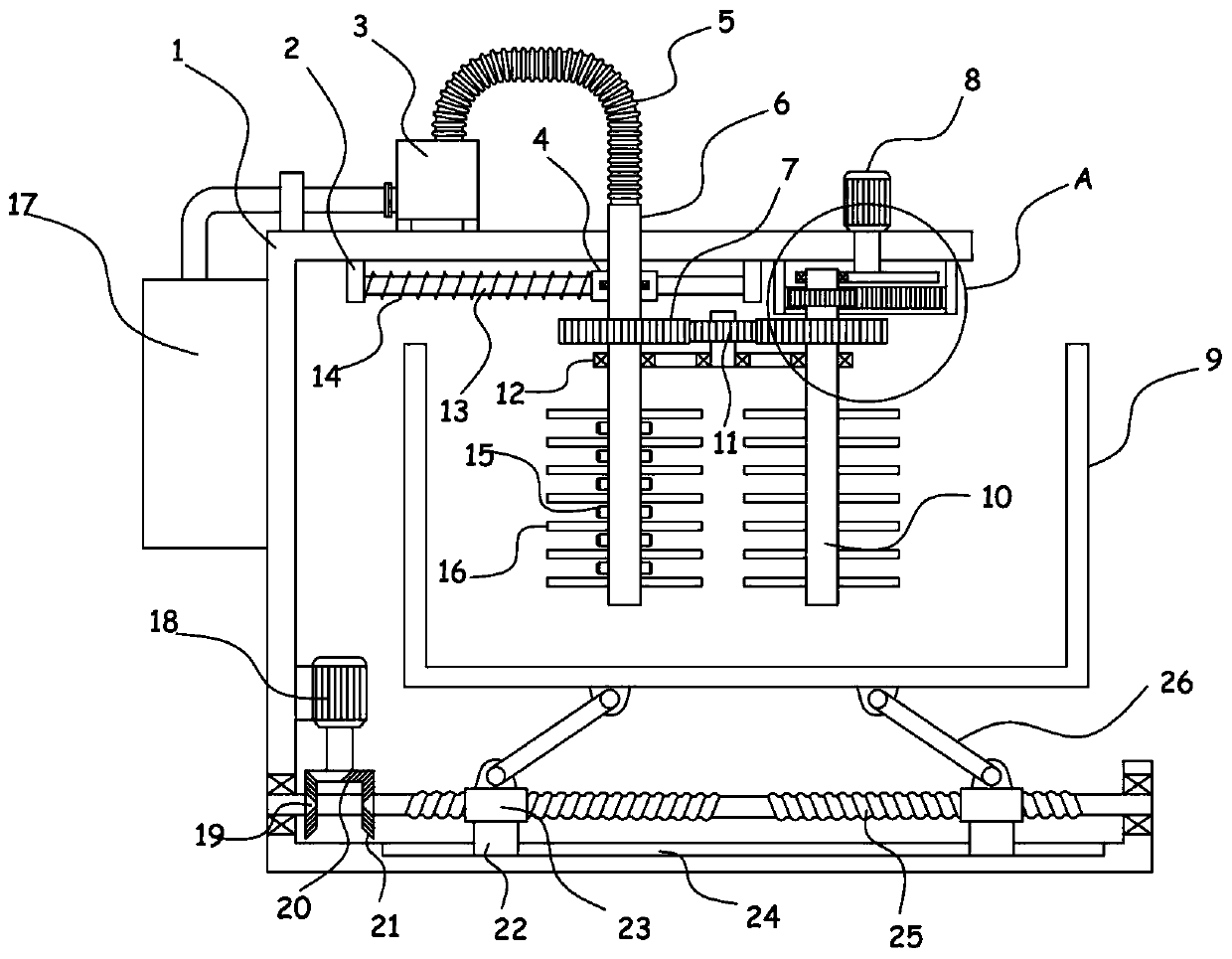

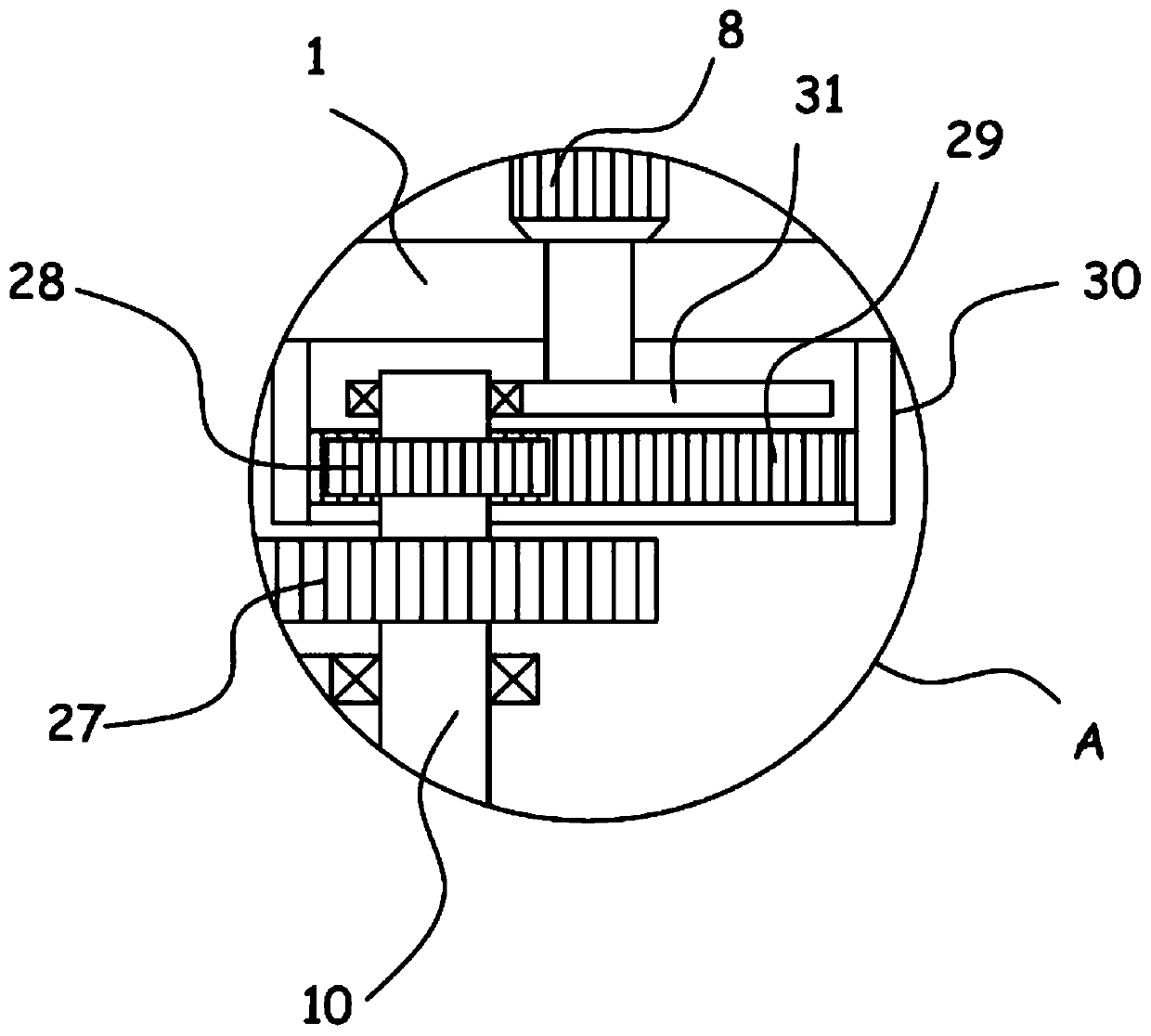

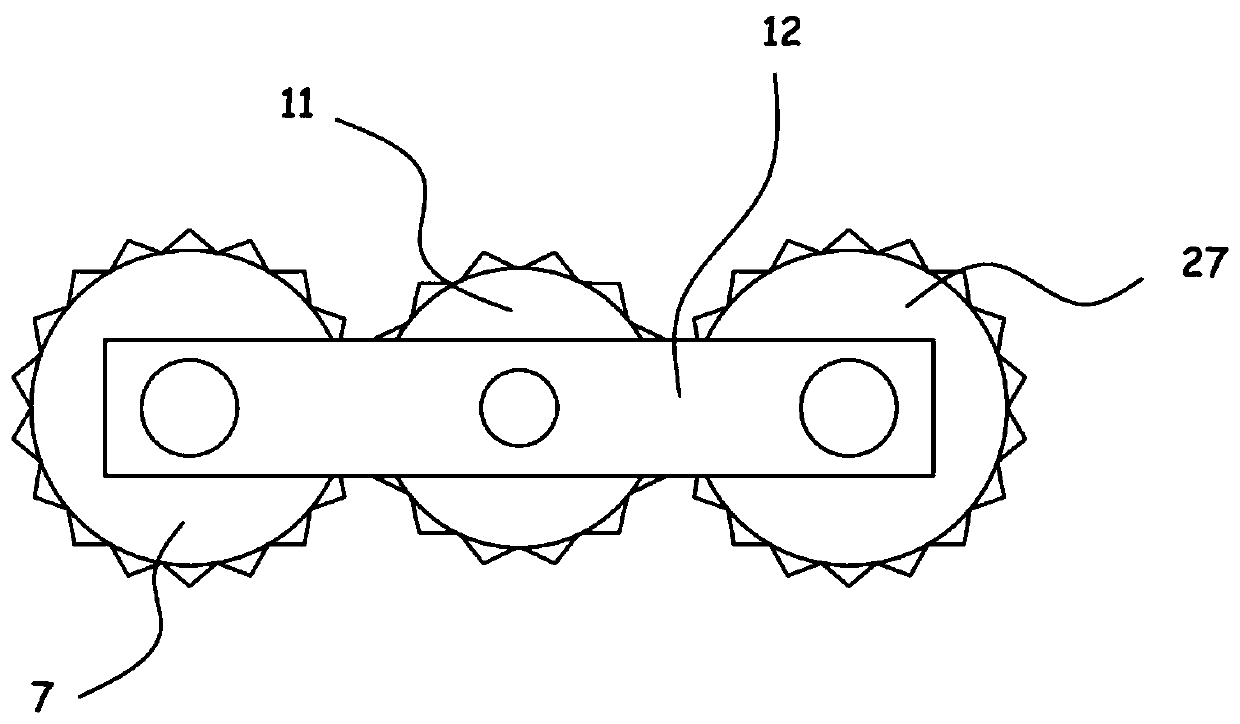

InactiveCN111468015AFull and efficient mixingShaking/oscillating/vibrating mixersTransportation and packagingElectric machineryDrive motor

The invention discloses tank body efficient uniform-shaking equipment which comprises a driving motor, eccentric wheels, a front end star gear, a tail end baffle, a photoelectric counter, a bow rack,a pneumatic clamp, an elastic cylinder, a rocker arm, a rocker arm base, a connecting rod, a positioning cylinder and a bearing support, the front end star gear and the tail end baffle are fixed to the front end and the rear end of the bow rack in the feeding direction respectively. The photoelectric counter is fixed on the rear side of the star gear; two groups of eccentric wheels are arranged; the eccentric wheels are arranged on the bearing support and connected with the two power output ends of the driving motor respectively, the eccentric wheels are connected with the connecting rod, theconnecting rod is connected with the bow rack through the rocker arm, the pneumatic clamp is fixed to the inner side of the bow rack, the elastic cylinder is fixed to one side of the pneumatic clamp,one end of the elastic cylinder is hinged to the bow rack, and the other end is connected with the rocker arm base. Compared with the prior art, the equipment has the advantage that the full mixing and shaking-up effects of various products can be effectively improved.

Owner:山东誉中新材料股份有限公司

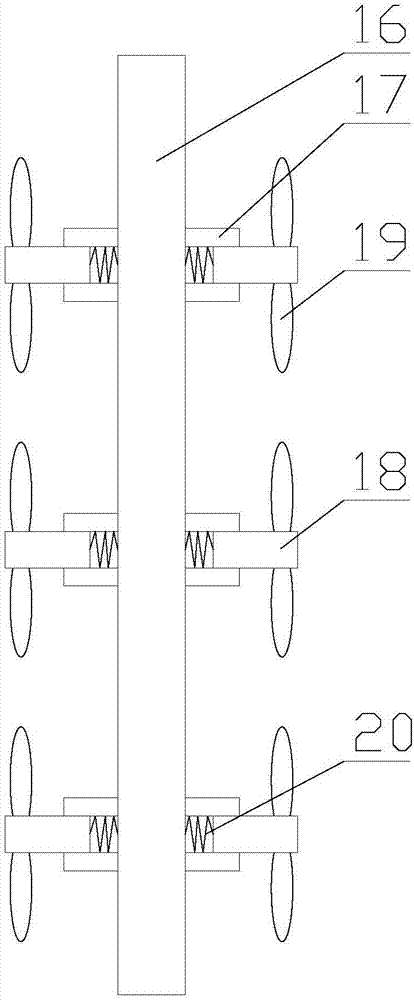

Minced meat stirring and mixing device for fish ball production and processing

InactiveCN111437755AFull and efficient mixingExpand the mixing rangeShaking/oscillating/vibrating mixersTransportation and packagingMeat pasteRotational axis

The invention discloses a minced meat stirring and mixing device for fish ball production and processing, and relates to the technical field of fish ball processing. The device comprises a supportingframe, a hollow shaft and a rotating shaft which are vertically arranged are rotatably installed in a mixing tank, a plurality of pairs of stirring rods are fixed to the hollow shaft and the rotatingshaft, a rotating mechanism used for driving the hollow shaft and the rotating shaft to rotate is arranged on the supporting frame, and a swing mechanism used for driving the hollow shaft and the rotating shaft to swing is arranged on the supporting frame; the rotating mechanism drives the hollow shaft and the rotating shaft to rotate, and then the stirring rod is driven to rotate to realize the rotary stirring of the minced fish and the seasonings in the mixing tank and the adequate mixing effects can be realized. The arranged swinging mechanism can drive the hollow shaft and the rotating shaft to continuously swing so that the stirring range of the meat paste in the mixing tank is widened, the arranged lifting mechanism can drive the mixing tank to vertically reciprocate up and down, itis guaranteed that the fish meat paste at different vertical positions in the mixing tank is stirred and stirring is sufficient and efficient.

Owner:常敏

Rotary mixing device for glass raw materials

PendingCN111921406ASimple structureAvoid single stirring directionRotary stirring mixersTransportation and packagingPhysicsElectric machinery

The invention discloses a rotary mixing device for glass raw materials. The device comprises a cylindrical mixing bin, a control bin is fixedly mounted at the top of the mixing bin, a motor is fixedlymounted at the top of the control bin, a rotating disc is fixedly connected to the bottom of the motor and located in the control bin, and a wavy rail is formed in the side wall of the rotating disc.A plurality of sets of pulleys are movably clamped to the side wall of the rotary disc through rails, and a connecting rod is fixedly installed at the bottom of each set of pulleys. A ring plate is fixedly mounted at the lower part of the inner cavity of the mixing bin, a plurality of groups of internal thread rotary drums are rotatably connected to the ring plate, and a plurality of blades are fixedly connected to the side walls of two groups of limiting rings of each group of internal thread rotary drums; the lower part of each set of connecting rods is provided with threads, and the lowerpart of each set of connecting rods is connected to corresponding internal thread rotary drums through threads. The materials in the mixing bin can clockwise rotate along with the blades, and can anticlockwise rotate along with the blades, such that the raw materials in the mixing bin can be completely and efficiently mixed, and the mixing efficiency is improved.

Owner:ANHUI FENGYANG HUAIHE GLASS

Dual-rotation coating production stirring equipment

InactiveCN108993223AAchieve tumblingStir wellTransportation and packagingRotary stirring mixersPulp and paper industryMixing effect

The invention discloses dual-rotation coating production stirring equipment. The equipment comprises a support frame, a stirring tank, a working motor, an inclined abut-against plate and a horizontalstirring module; the stirring tank is slidingly arranged in the support frame, welding sliding blocks are symmetrically arranged on two sides of the lower surface of the stirring tank, the sliding block is slidingly connected with the lower surface of the support frame, and the inclined abut-against plate is welded at the bottom of the left sidewall of the stirring tank. The stirring equipment ischaracterized in that the upper surface of the inclined abut-against plate is obliquely arranged with low left side and high right side, a reset spring is arranged between the bottom of the right sidewall of a first bevel gear and the support frame; and the horizontal stirring module is arranged in the stirring tank, and the working motor is arranged at the lower part of the middle location of theupper wall of the support frame. The stirring equipment disclosed by the invention is reasonable in design, and capable of guaranteeing the sufficient and efficient mixing of the coating, and guaranteeing the good mixing effect of the coating, thereby guaranteeing the quality of the produced coating.

Owner:YANCHENG BILLION CONNAUGHT MACHINERY CO LTD

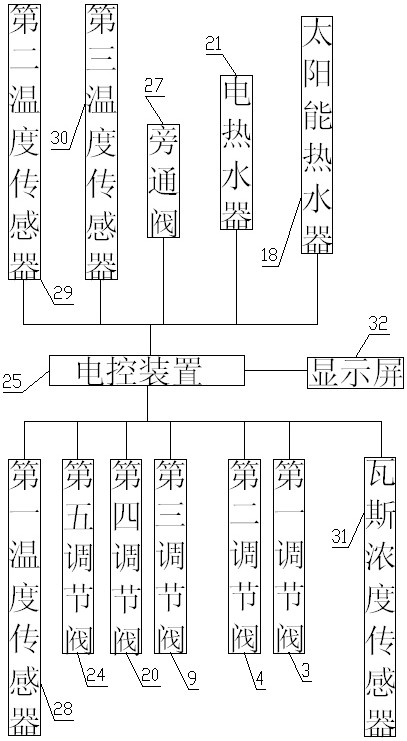

Mixing device for high-concentration gas and low-concentration gas, and using method thereof

ActiveCN112604597AIntense flow mixingSpeed up the mixingTransportation and packagingMixer accessoriesWater jacketThermal water

The invention discloses a mixing device for high-concentration gas and low-concentration gas. The mixing device comprises a high-concentration gas pipeline, a low-concentration gas pipeline and a gas mixing tank, wherein the mounting position of the high-concentration gas pipeline is lower than the mounting position of the low-concentration gas pipeline; the high-concentration gas pipeline is connected with a first inlet of the gas mixing tank; the low-concentration gas pipeline is connected with a second inlet of the gas mixing tank; an outlet of the gas mixing tank is connected with a first pipeline; the high-concentration gas pipeline is sleeved with a water jacket; the water jacket is connected with a hot water supply mechanism; and the hot water supply mechanism is used for heating gas in the high-concentration gas pipeline to 80 + / - 3 DEG C through a water jacket. The invention further discloses a corresponding using method. According to the invention, uniform gas mixing is achieved through temperature convergence and density convergence, low-concentration gas can also be utilized, resource waste and environmental pollution caused by direct emptying of the low-concentration gas are avoided, energy is fully utilized, and the explosion problem of the low-concentration gas is effectively prevented.

Owner:HENAN POLYTECHNIC UNIV

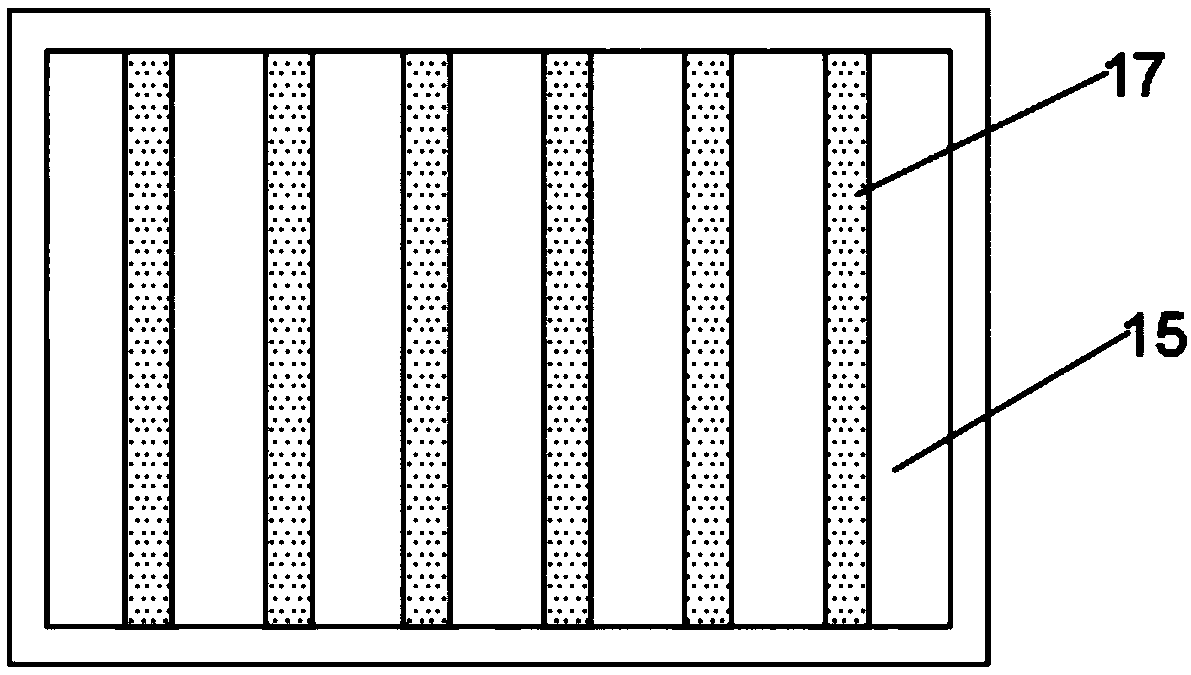

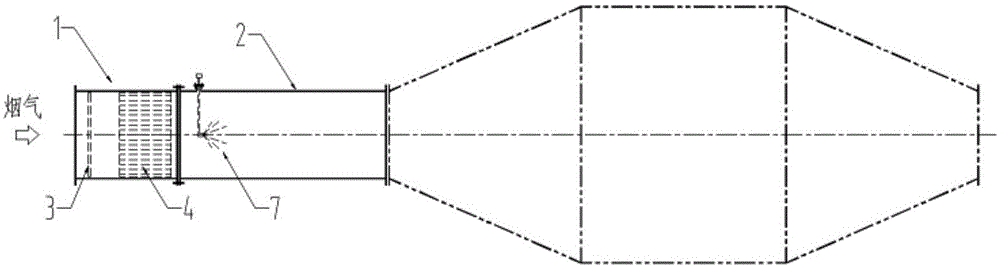

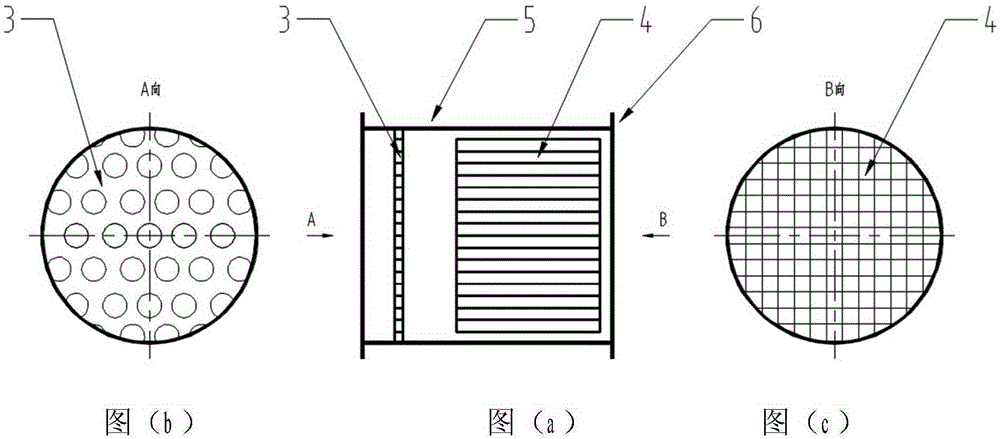

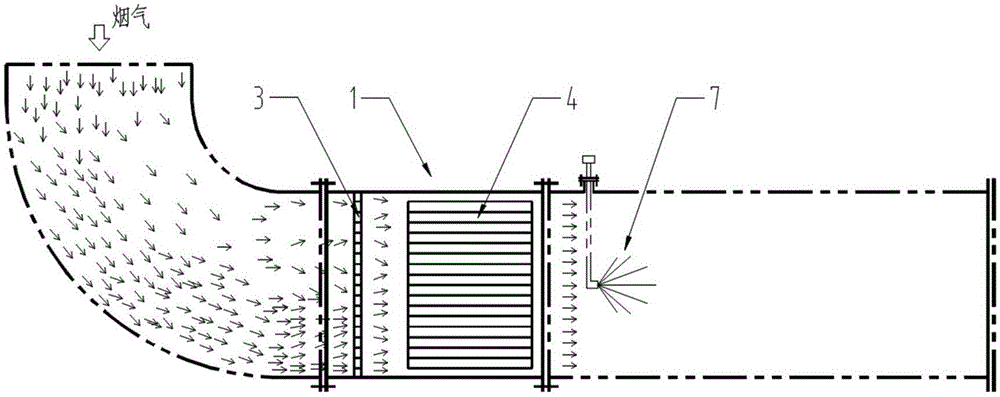

Gas flow uniform-distributing device for selective catalytic reduction (SCR) denitration

InactiveCN105148726AFull and efficient mixingEfficient mixingDispersed particle separationSheet steelFlue gas

The invention relates to a gas flow uniform-distributing device for selective catalytic reduction (SCR) denitration. The gas flow uniformly-distributing device comprises a mixer in an SCR denitration device, is connected to the front part of the mixer in the SCR denitration device, and comprises a shell, wherein flanges are arranged at the two ends of the shell; the flanges at the two ends are respectively connected with a flue at the front part and the mixer in the SCR denitration device at the rear part; a front-stage porous uniform-distributing plate and a rear-stage multitube uniform distributor are fixed inside the shell along the axial direction; the front-stage porous uniform-distributing plate is a steel plate, in which a plurality of circular holes or square holes are formed; and the rear-stage multitube uniform distributor is a tubular passage which is formed through arranging and combining a plurality of steel tubes. Biased gas flow introduced from the flue at the front part firstly passes through the front-stage porous uniform-distributing plate; the flow velocity of gas flow of the cross section is uniformly distributed; after the gas flow passes through the rear-stage multitube uniform distributor, the direction of vector of the flow direction is adjusted to be parallel to the geometric axial direction of the mixer; and flue gas is fully and efficiently mixed with a reactant sprayed from a spray nozzle arranged in the mixer in the SCR denitration device, and thus the efficiency of subsequent catalytic reaction is increased.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

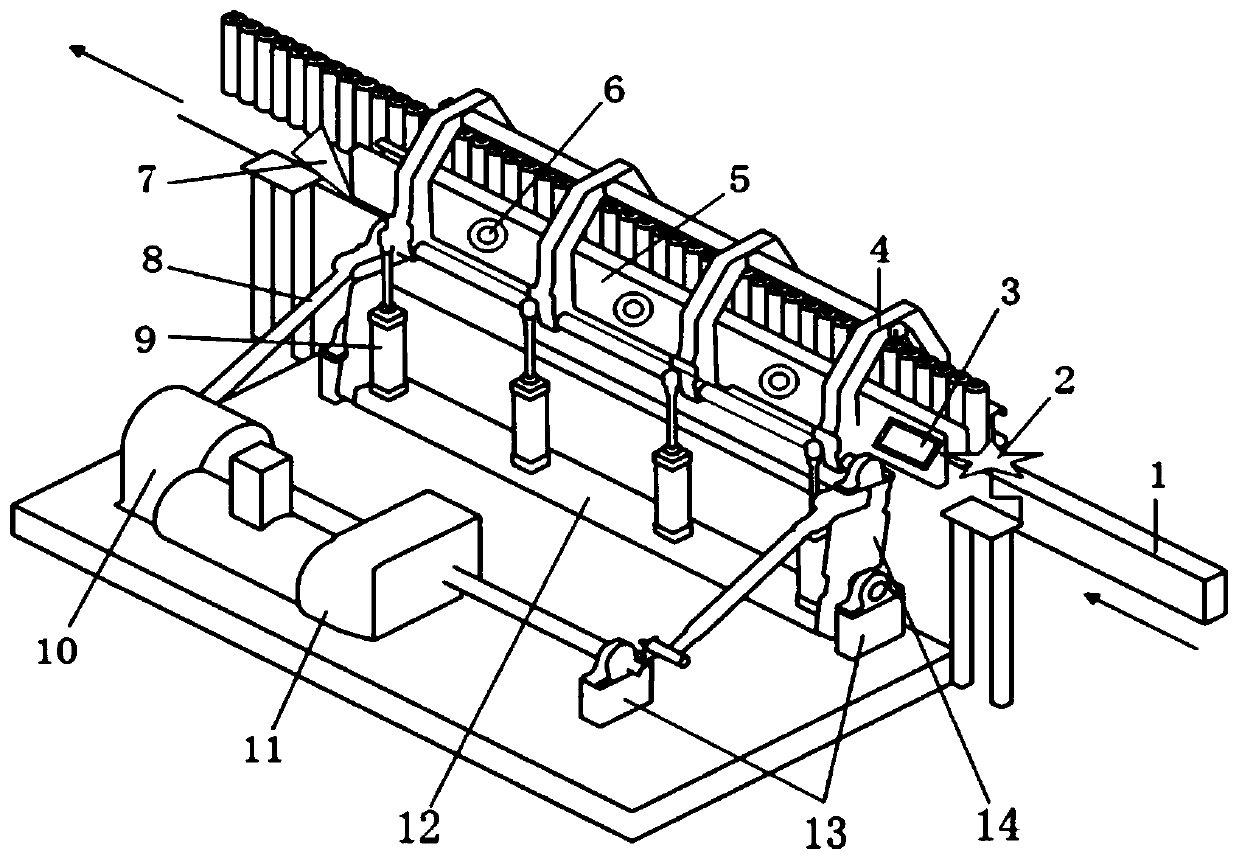

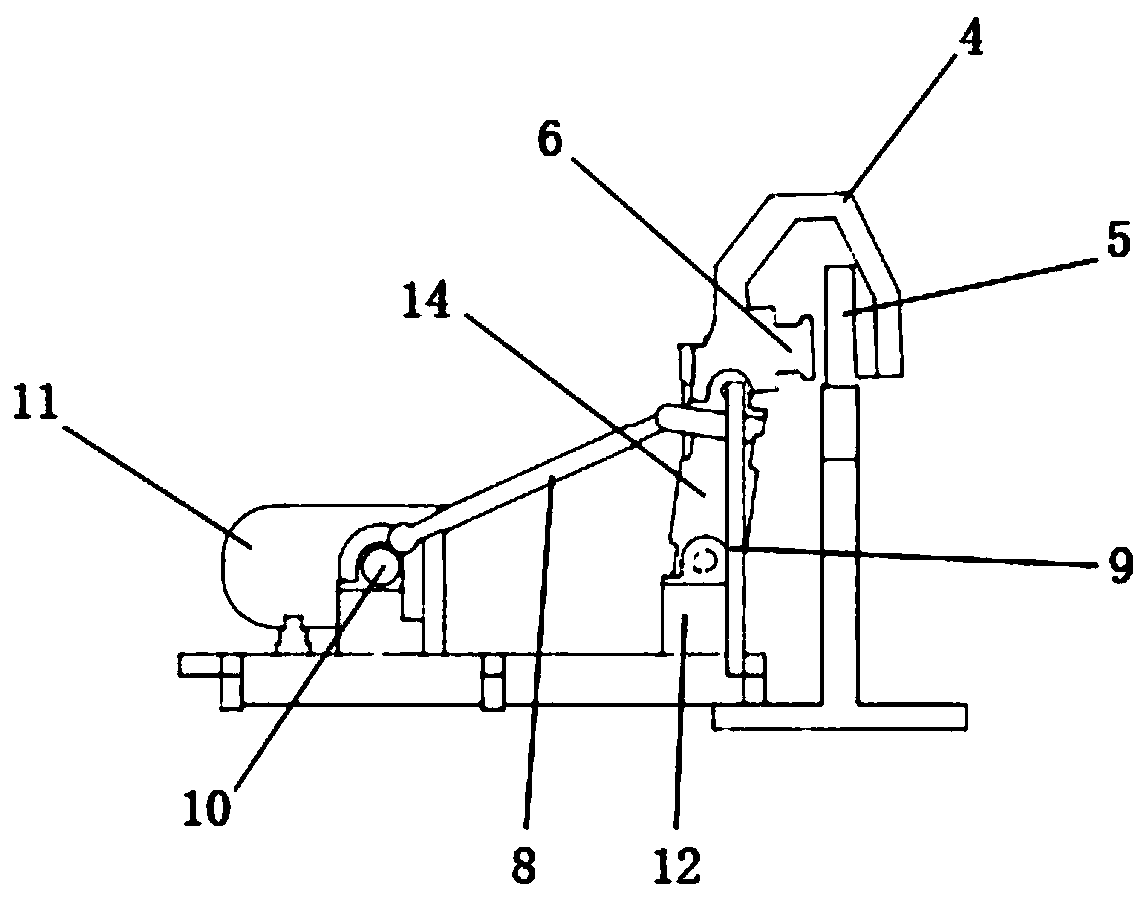

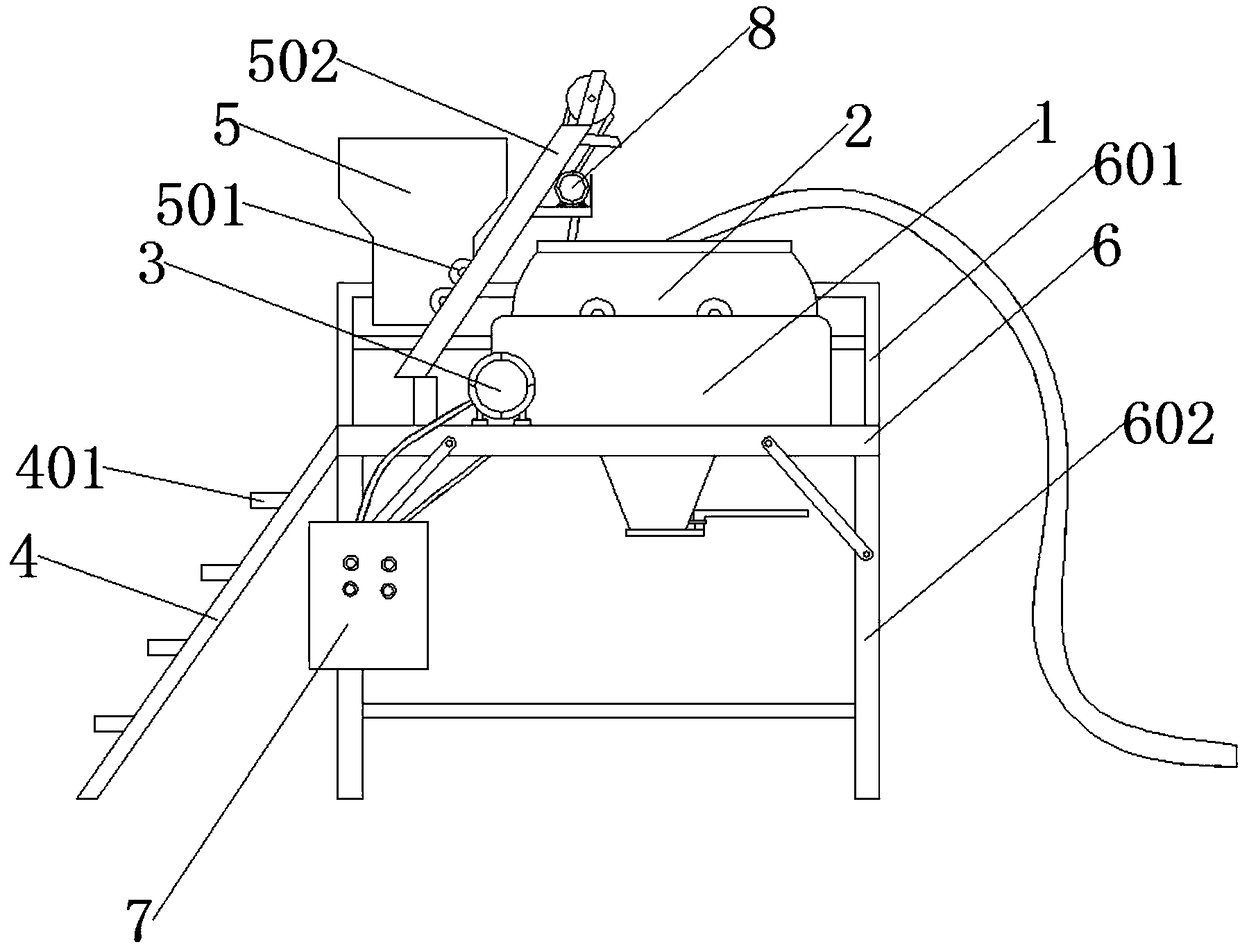

Production method of dried tofu with high-quality mouth feel

ActiveCN111034812AFull and efficient mixingQuality assuranceCheese manufactureFood scienceProcess engineeringIndustrial engineering

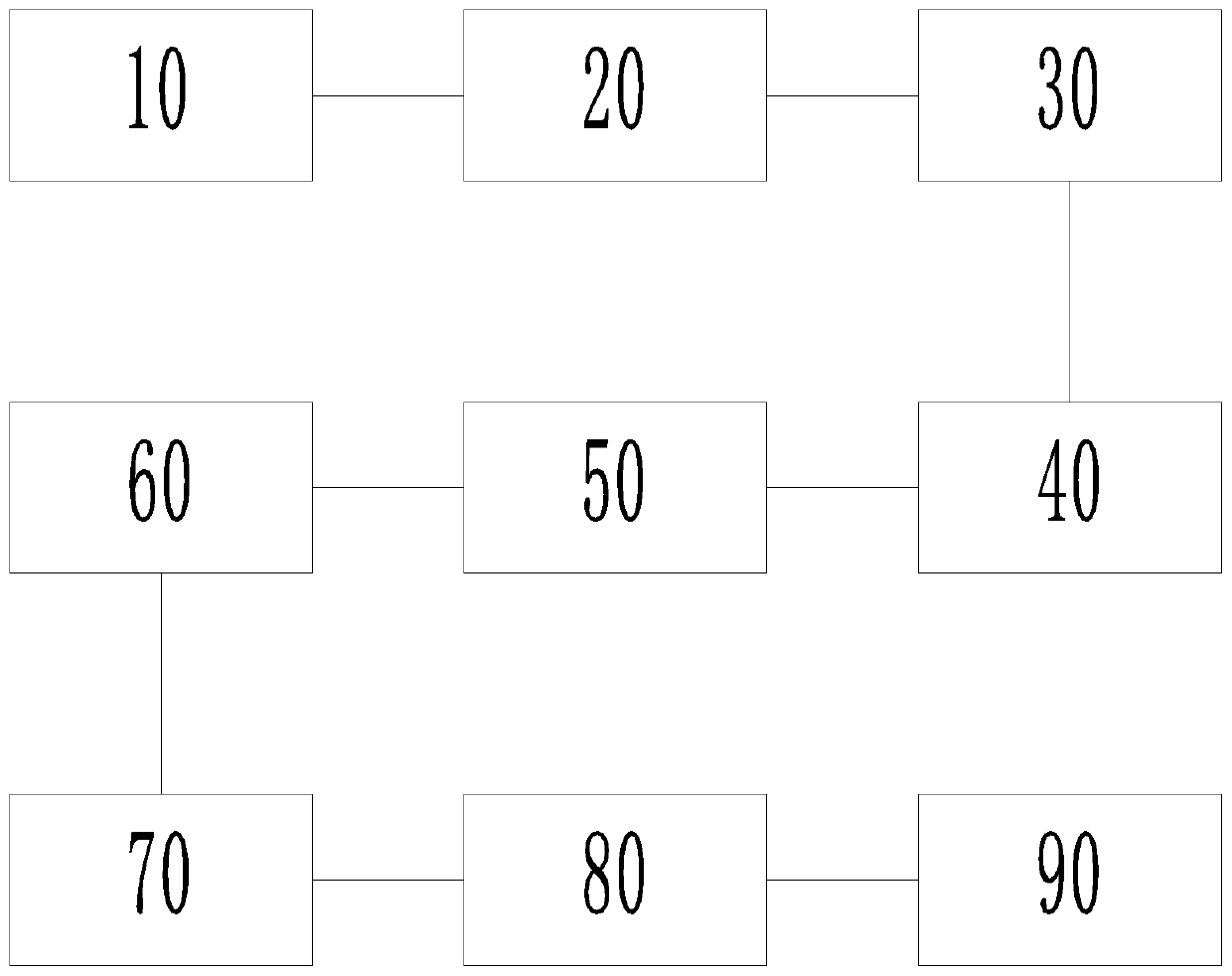

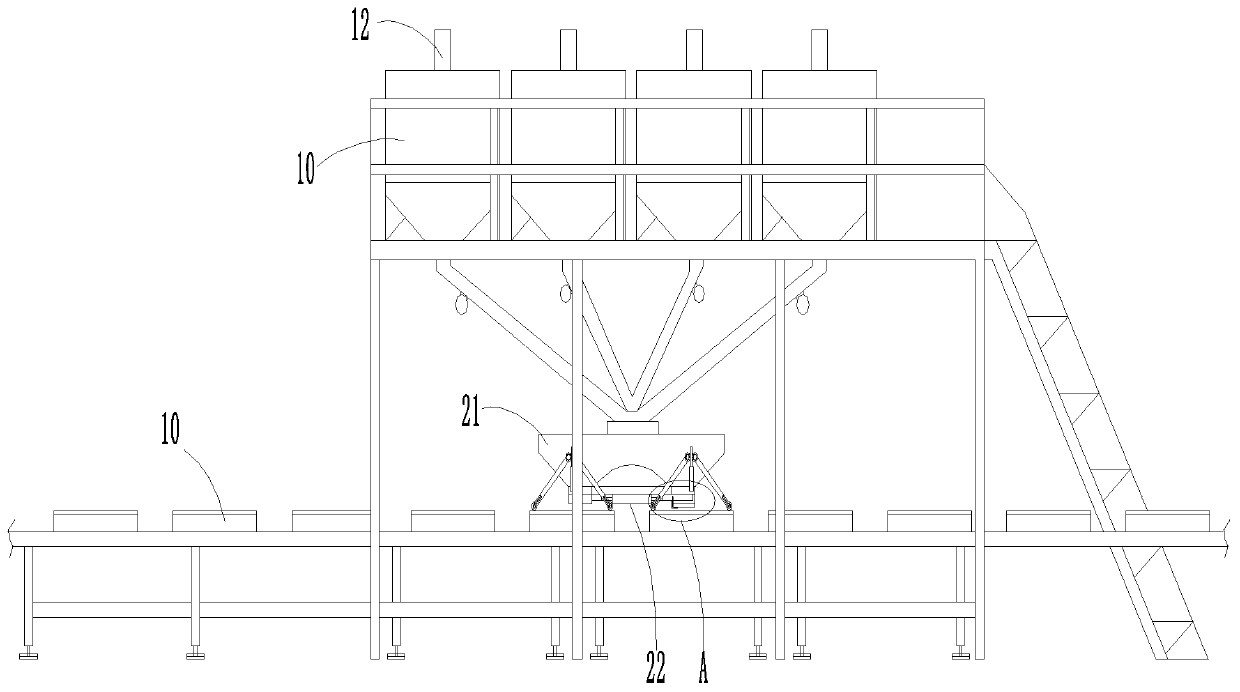

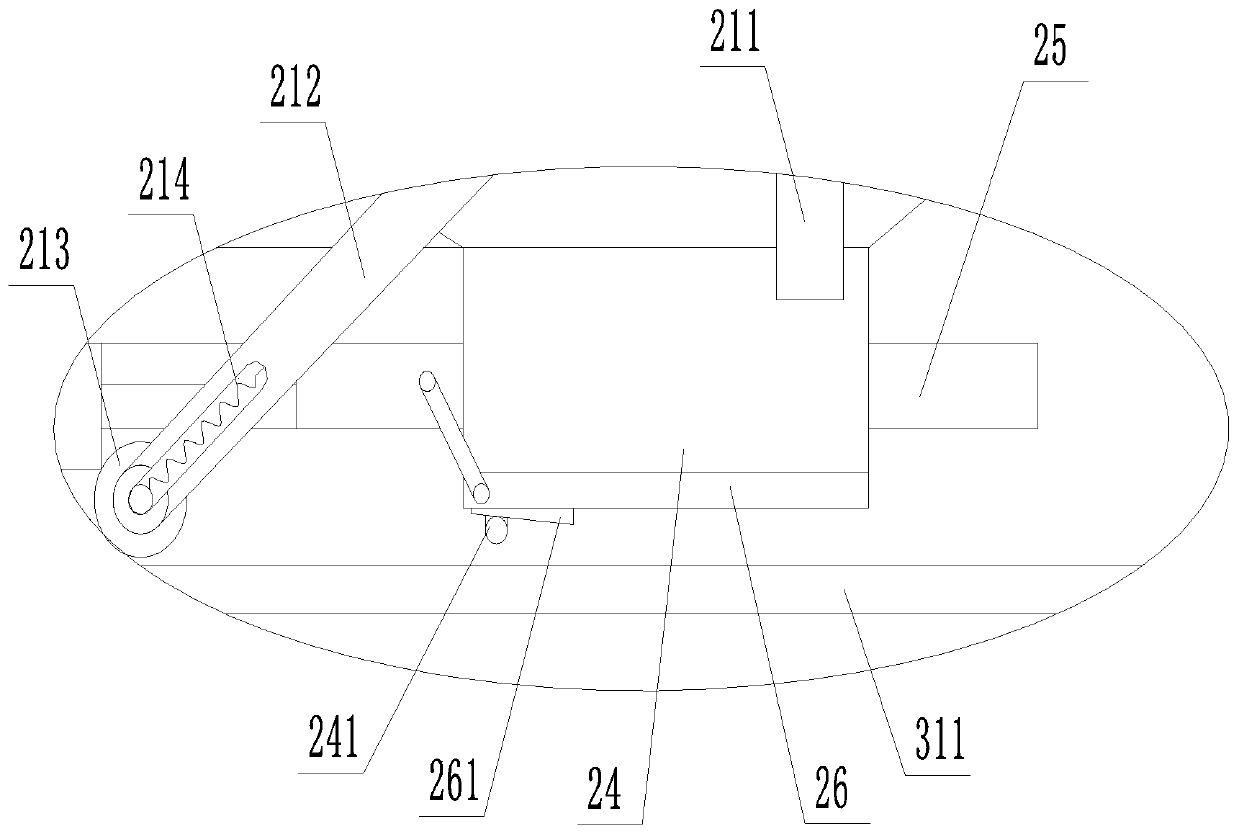

The invention discloses a production method of dried tofu with high-quality mouth feel, and belongs to the technical field of dried tofu production processes. A marinating barrel (10), a distributionmechanism (20), a frame conveying mechanism (30), a cover plate conveying mechanism (40), a stacking mechanism (50), a squeezing mechanism (60), a splitting mechanism (70), a plate overturning mechanism (80) and a dicing mechanism (90) are sequentially arranged from front to back. The production method comprises the steps of sequentially performing soybean milk marinating, mold forming, stacking,primary continuous squeezing, layer-by-layer splitting, plate overturning, dicing and secondary continuous squeezing so as to obtain the dried tofu with high-quality mouth feel. The production methodhas the advantages of high marinating quality, high bean curd jelly forming quality, uniform size of bean curd jelly forming blocks, high degree of automation, high production efficiency, saving of equipment cost, release of limited space, improvement of workshop space utilization rate, great reduction of labor intensity and saving of labor cost.

Owner:JINCAIDI FOOD CO LTD

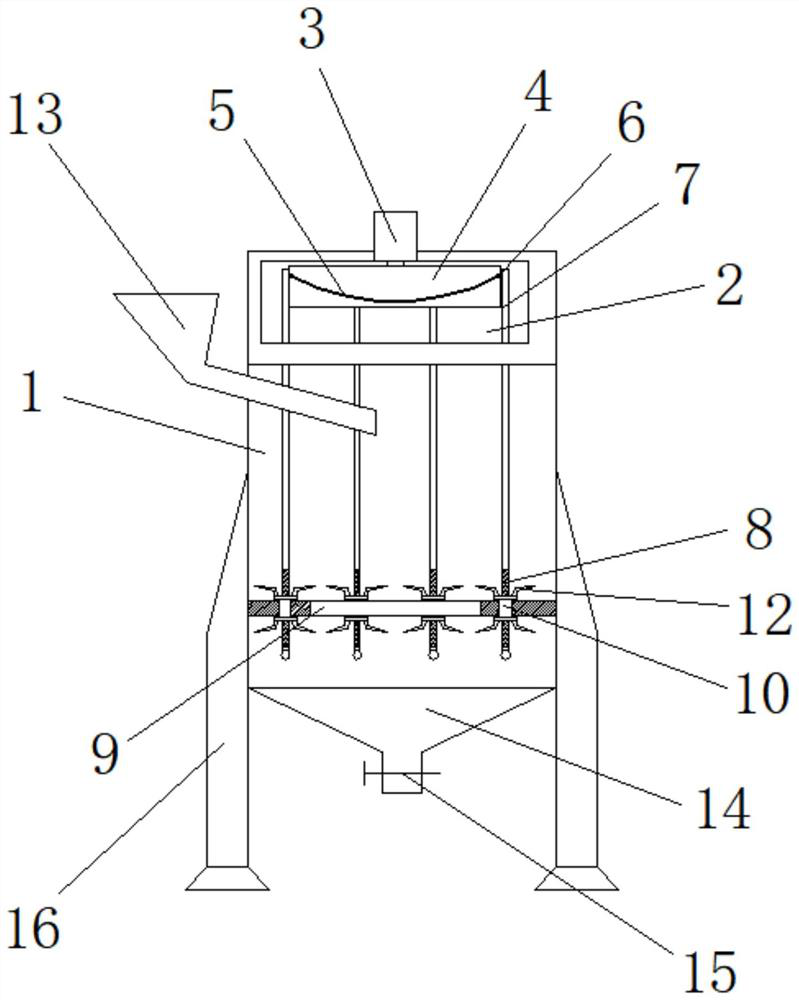

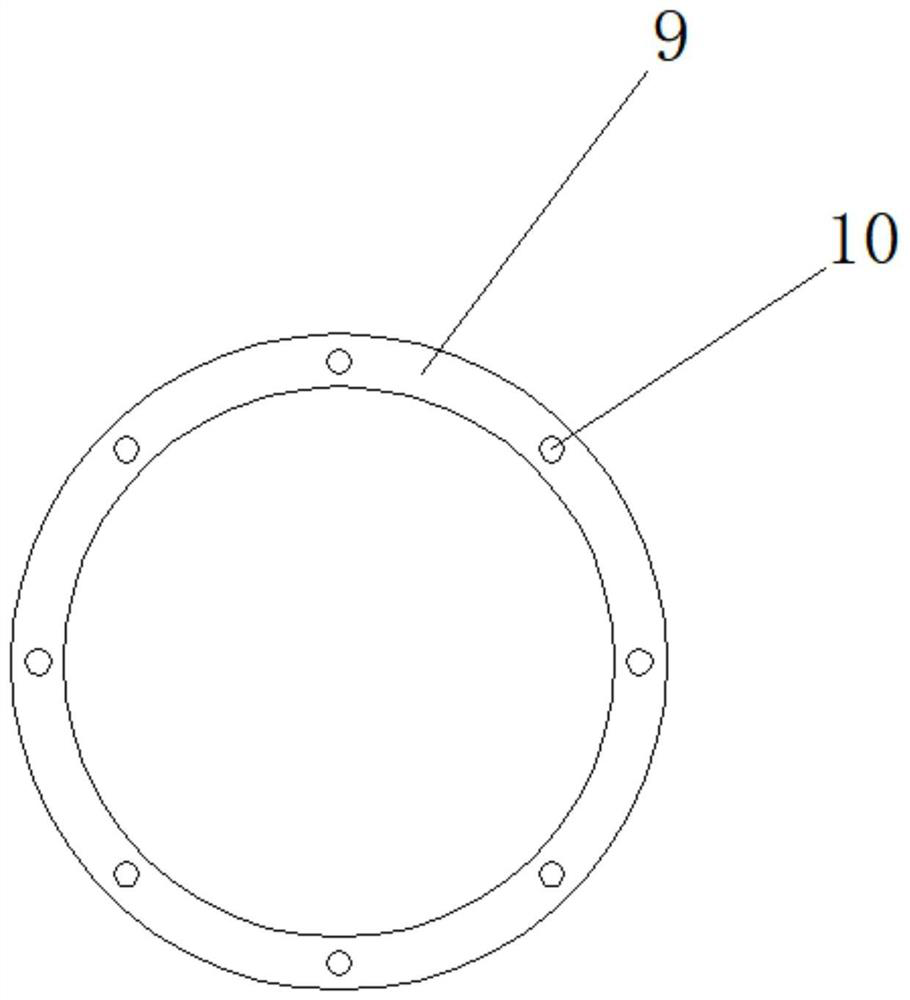

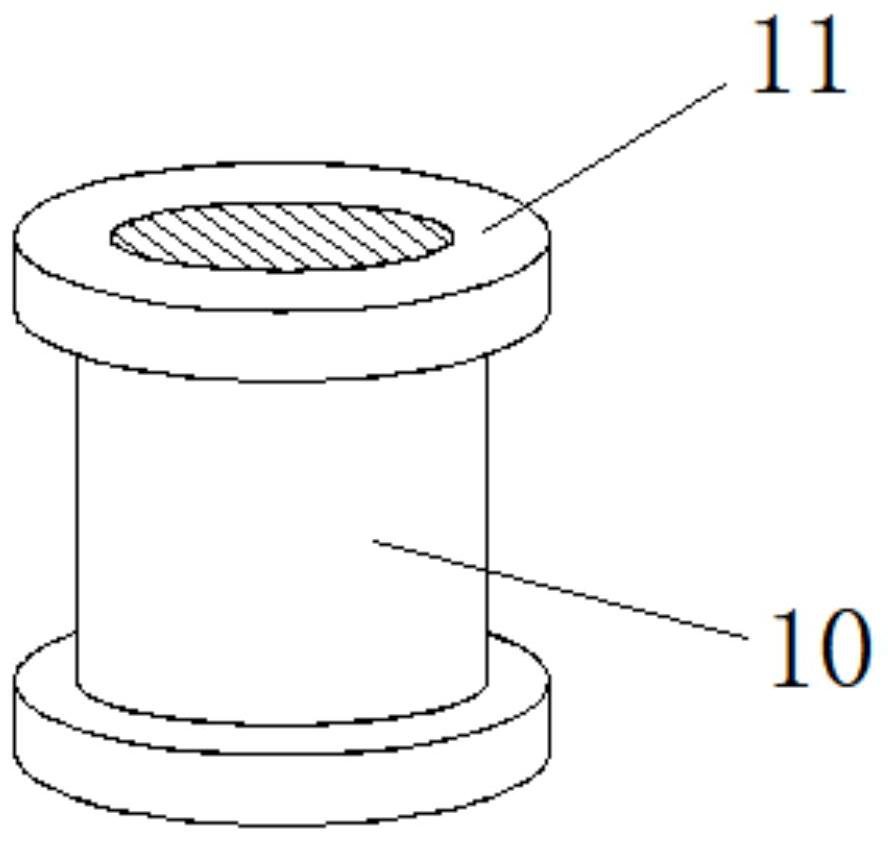

High-efficiency vertical domestic garbage treatment device

PendingCN109201712AIncrease temperatureMeet clean emission standardsRotary stirring mixersSolid waste disposalVoid ratioClosed loop

The invention discloses a high-efficiency vertical domestic garbage treatment device, comprising a reactor, wherein the reactor comprises an upper cover and a shell, the shell is internally provided with a screw conveying mechanism I, a screw conveying mechanism II and an auger conveying mechanism, the screw conveying mechanism I and the auger conveying mechanism are vertically arranged on two sides in the shell, the auger conveying mechanism is located at the lower side in the shell, and the screw conveying mechanism I and the screw conveying mechanism II are vertical to each other. The high-efficiency vertical domestic garbage disposal device carries out closed-loop circulating conveying and mixing on materials, so that the materials are mixed and stirred more uniformly, material accumulation is avoided, a certain void ratio exists between the materials, the materials are in sufficient contact with oxygen, and the reaction efficiency is high; the whole biological reaction process iscompleted in a sealed reactor, so that heat loss and odor escape can be avoided during the stirring reaction process; the conversion rate of resources is increased, and treated domestic garbage reaches a standard of clean discharge.

Owner:绿水青山环保科技(大连)有限公司

Concrete processing and conveying device

InactiveCN112357614ASmooth and accurate translational movementImprove efficiencyCement mixing apparatusLoading/unloadingConstruction engineeringStructural engineering

The invention discloses a concrete processing and conveying device, and belongs to the field of building material processing mechanical equipment. A raw material guiding and conveying mechanism is arranged on one side of the upper portion of a concrete preparation tank, a processing and stirring mechanism is arranged on the inner side of the concrete preparation tank, a discharging guiding and conveying pipe is vertically arranged in the middle of the lower side of the concrete preparation tank in a communicating mode, a falling control mechanism is fixedly arranged on the discharging guidingand conveying pipe, a concrete conveying mechanism is arranged on the lower side of the concrete preparation tank, a stirring driving mechanism is fixedly arranged on the upper side of the concrete preparation tank, a stirring supporting column is vertically arranged in the middle of the inner side of the concrete preparation tank, a flashboard reset tension spring is arranged between a translation pushing bearing plate at the end of a translation supporting guide rod and a falling valve support, and a translation conveying vehicle is arranged on the upper side of a concrete conveying base. The device is reasonable in structural design, concrete can be rapidly and efficiently produced and prepared, the concrete can be stably and conveniently translated and conveyed, the production and conveying automation degree is high, and the production and use requirements are met.

Owner:桐乡市钟大建材有限公司

Steam heating type stirrer used for concrete stirring

InactiveCN108943392AEfficient mixingSolve the relatively low stirring efficiencyDischarging apparatusCement mixing apparatusHeating powerSteam heating

The invention provides a steam heating type stirrer used for concrete stirring. The steam heating type stirrer comprises a supporting table, a stirring barrel and a main motor. A top plate is seamlessly welded to the bottom end of the supporting table. The main motor is arranged at the front end of the left side of the supporting table. Supporting rods are seamlessly welded to the four corners ofthe bottom end of the top plate. An operation box is fixedly connected to the front ends of the left sides of the supporting rods through bolts. Two long strips are seamlessly welded to the left sideof the top plate. A pedal is fixed between the two long strips. The stirring barrel is arranged between the positions of the supporting table in an embedded manner. Heating power supply boxes are arranged on the left side and the right side in the stirring barrel. A steam heating layer is arranged on the inner wall of the stirring barrel in an embedded manner. The steam heating type stirrer used for concrete stirring has wide practicality, is high in stirring efficiency, sufficient in stirring and convenient to use and has high promotional value.

Owner:天津市裕昇建筑工程有限公司

Low-pressure drop high-efficiency static mixing device and oil blending method beneficial to oil blending

ActiveCN108273403BFull and efficient mixingFlow mixersTransportation and packagingStatic mixerOil generation

Owner:EAST CHINA UNIV OF SCI & TECH

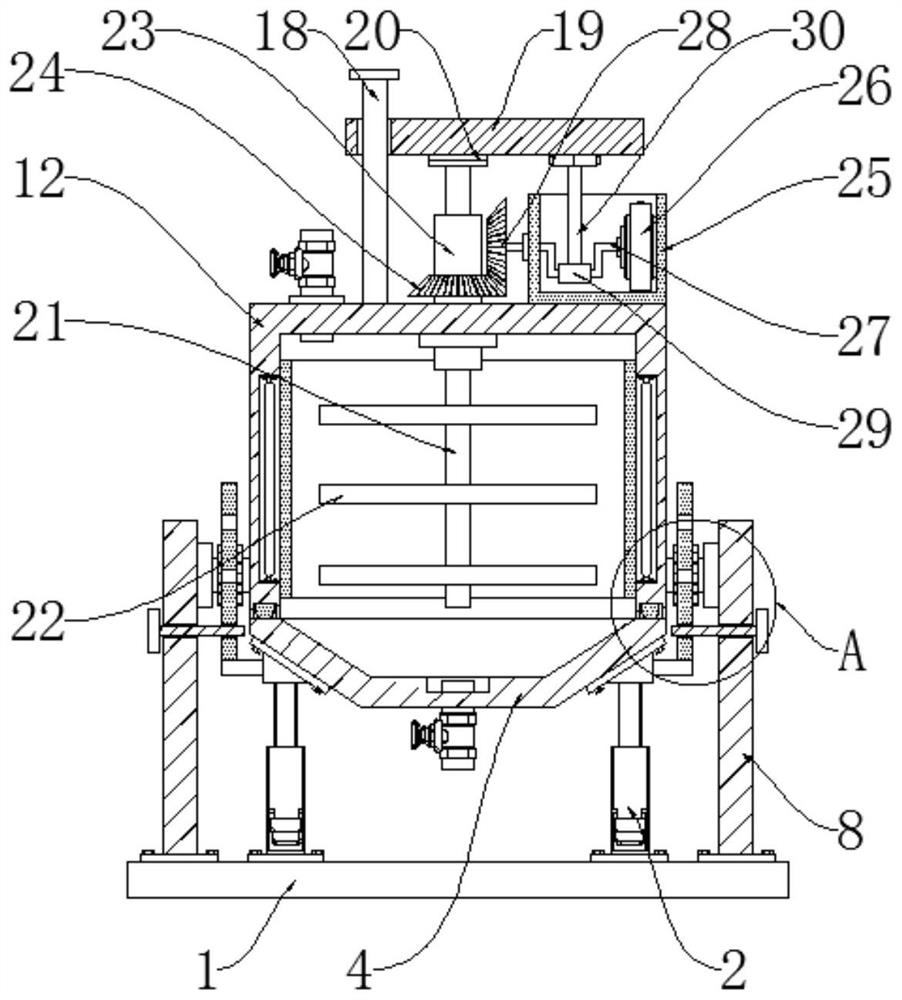

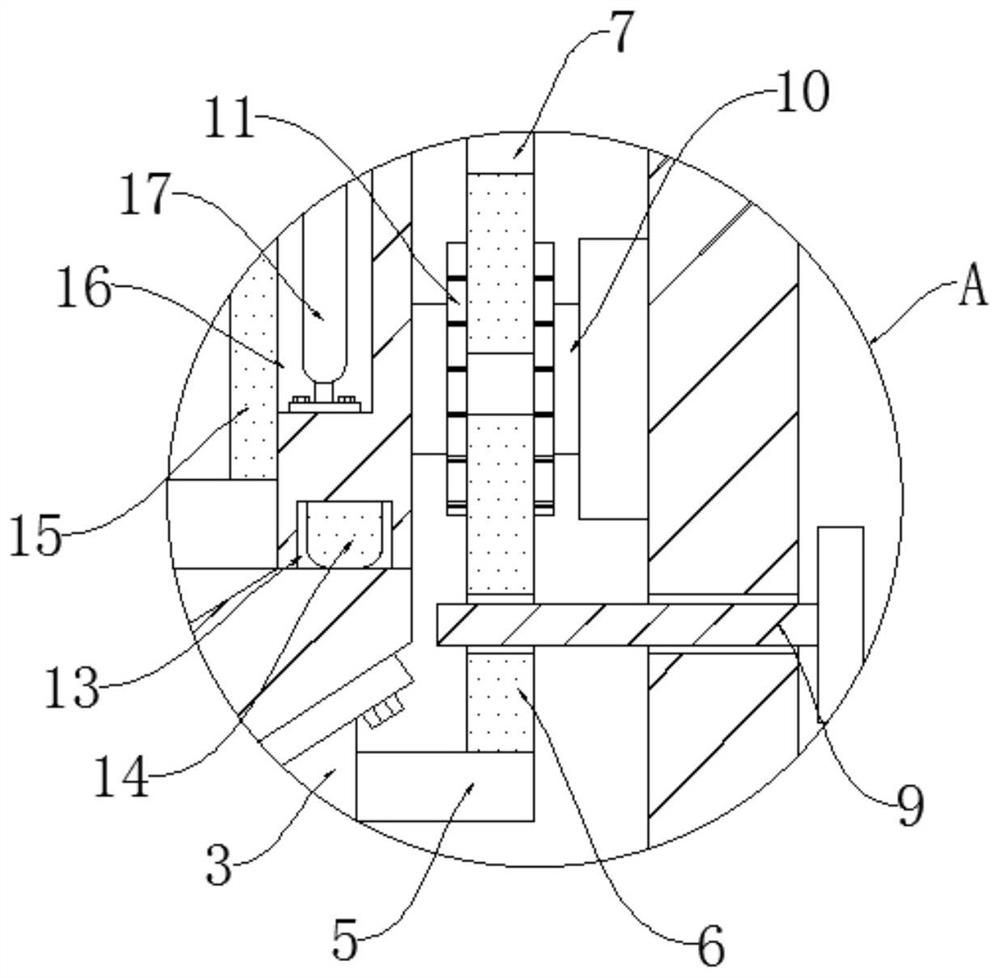

High-stability automobile brake fluid preparation equipment

PendingCN114307773AFull and efficient mixingQuick and full cleaningShaking/oscillating/vibrating mixersTransportation and packagingHydraulic cylinderElectric machinery

The high-stability automobile brake fluid preparation equipment comprises a base, hydraulic cylinders are mounted on the two sides of the top of the base, the output ends of the hydraulic cylinders are connected with a fixed mounting base, and a first combined tank body is mounted on the top of the fixed mounting base; a mounting plate is fixed to the side, away from the first combined tank body, of the fixed mounting base, a rack is mounted at one end of the top of the mounting plate, and limiting holes are evenly formed in one side of the rack. A second bevel gear is in meshed connection with a first bevel gear, a sleeve is arranged on a crankshaft, and a connecting rod hinged to a movable plate is arranged on the sleeve, so that when a motor drives the crankshaft to rotate, a mounting cylinder can rotate along with the crankshaft, and the movable plate can drive a square stirring rod main body to slide up and down in a reciprocating manner; and therefore, raw materials in the second combined tank body can be stirred and mixed more sufficiently and efficiently, a sufficient cleaning task can be conveniently carried out, and meanwhile the stability during use and cleaning can be guaranteed.

Owner:苏州众宝行汽车有限公司

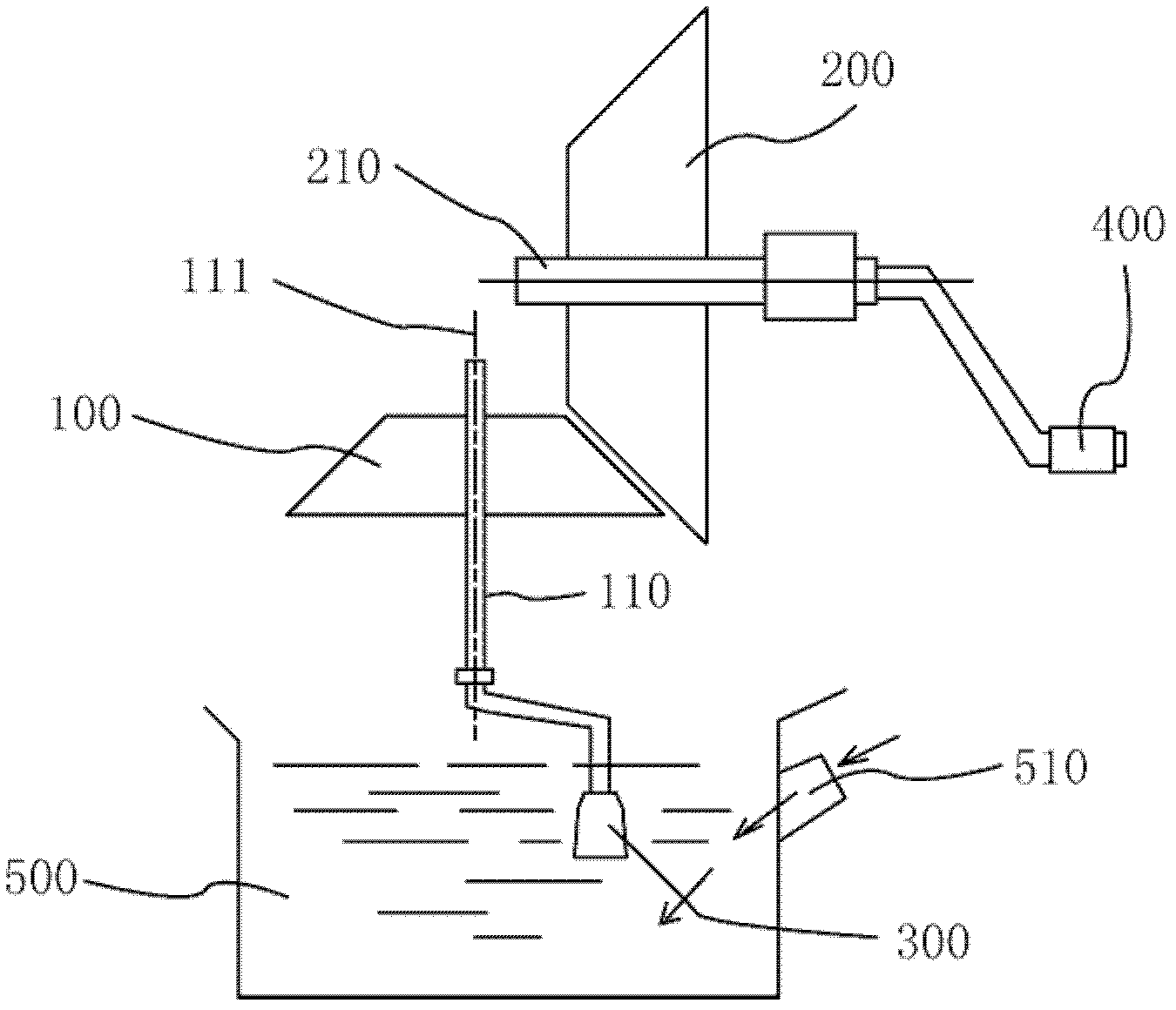

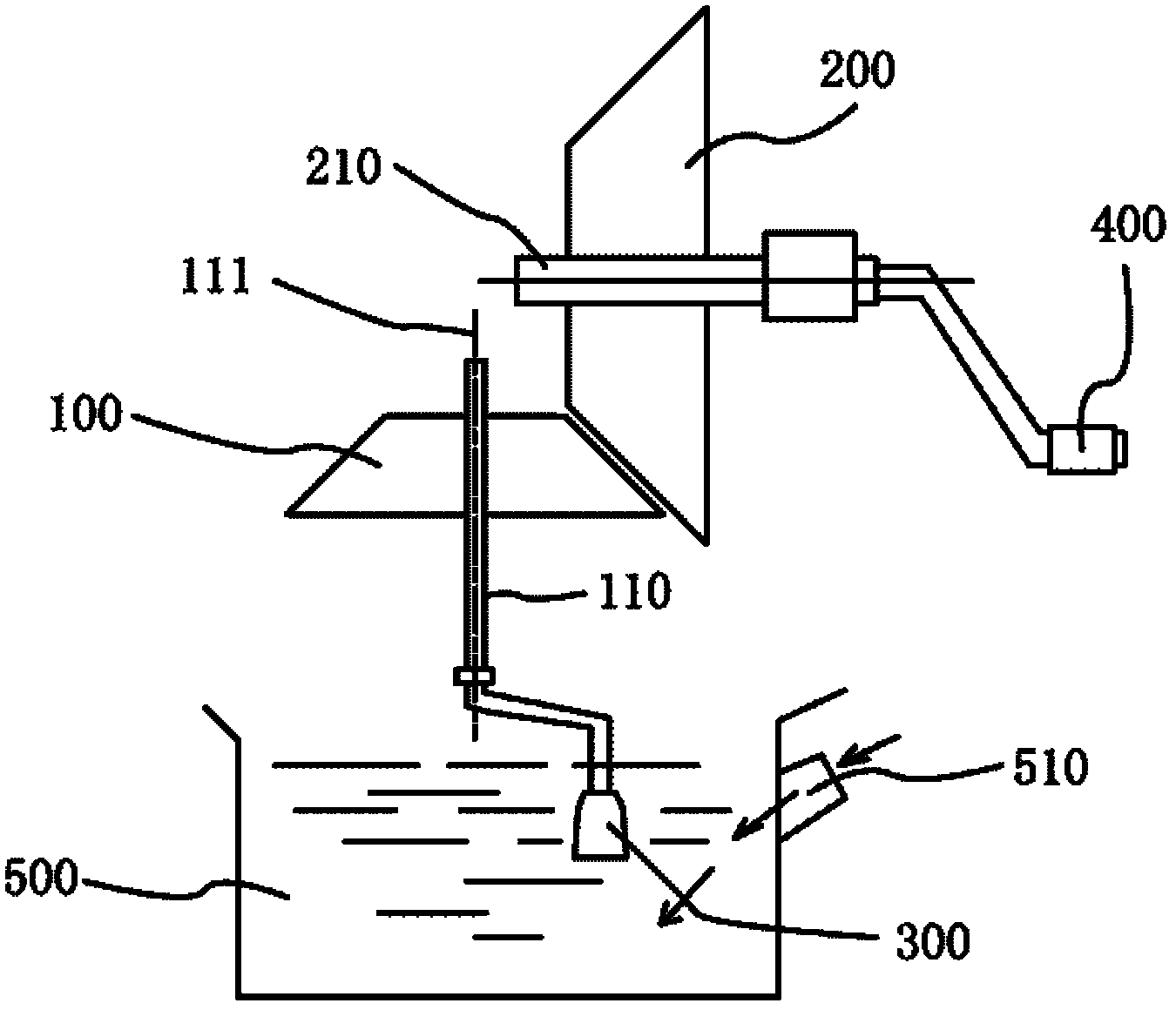

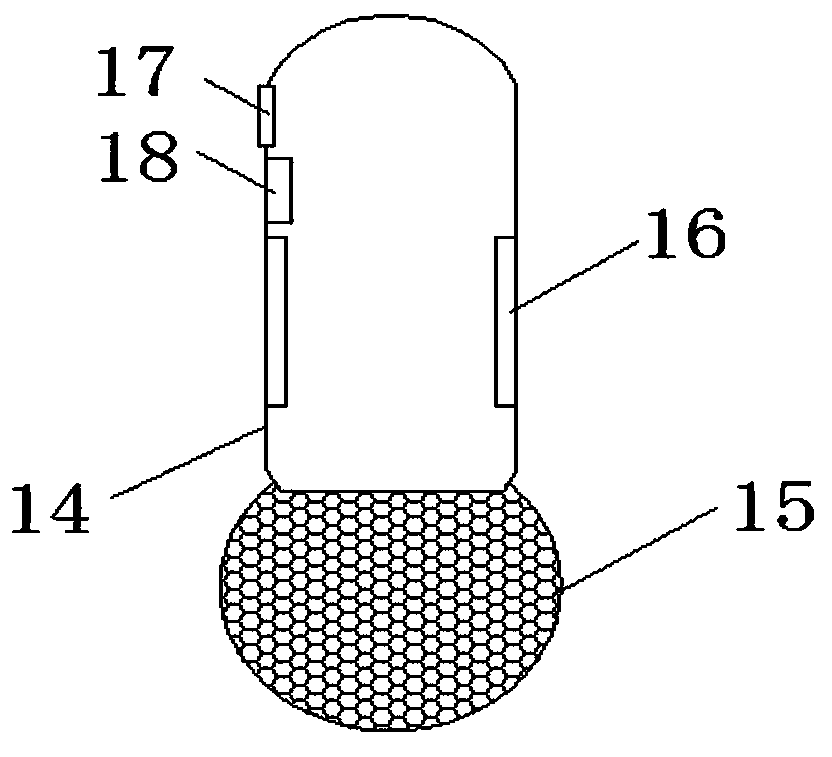

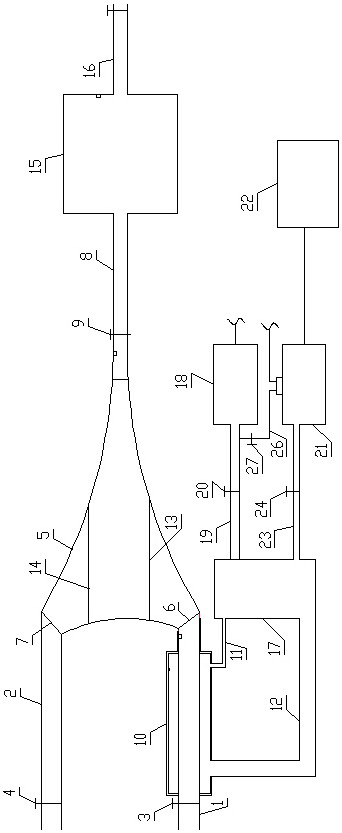

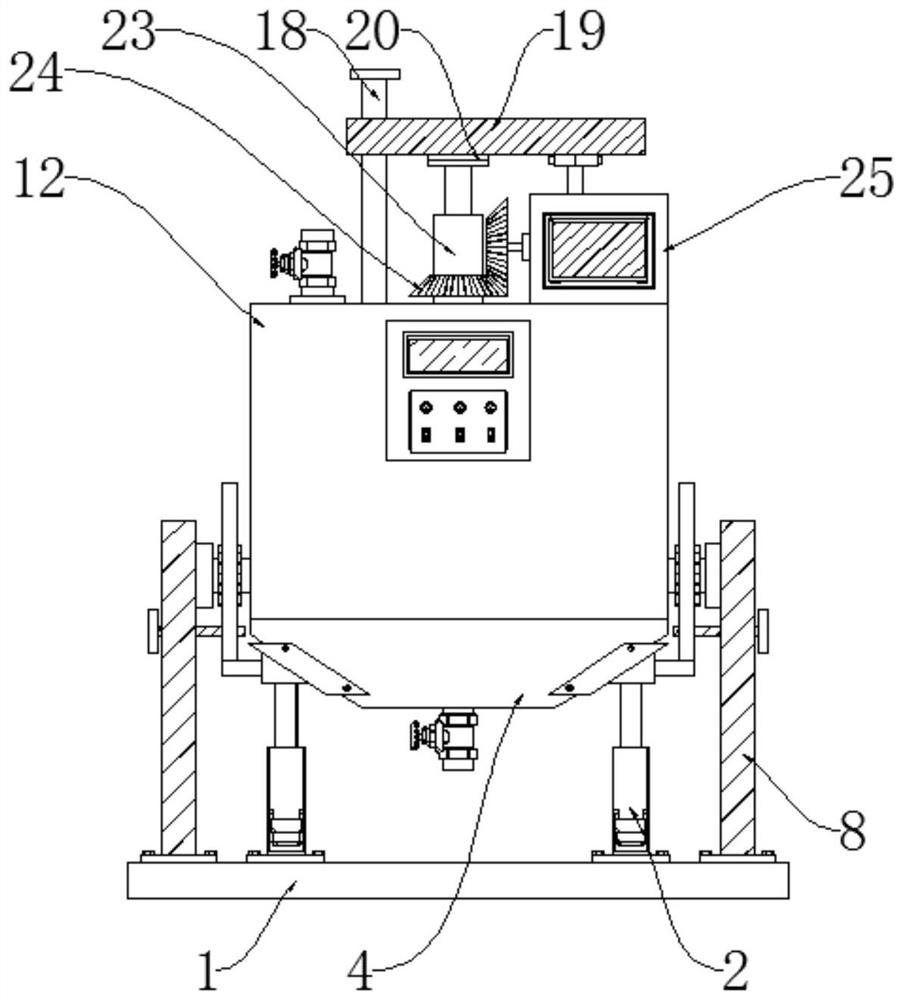

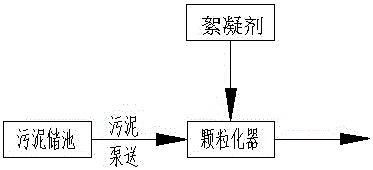

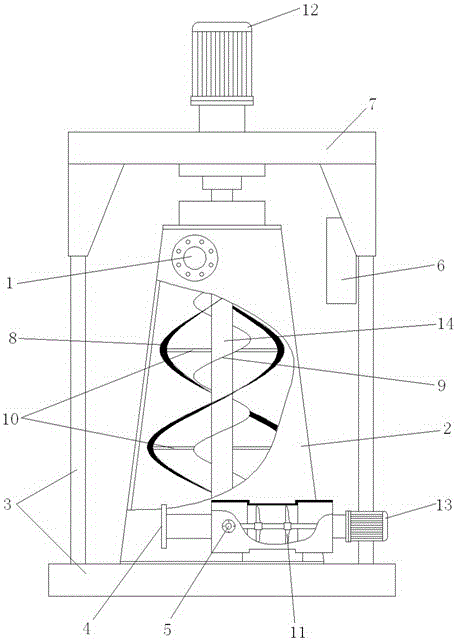

A method and special equipment for enhancing the mixing effect of sludge and chemicals

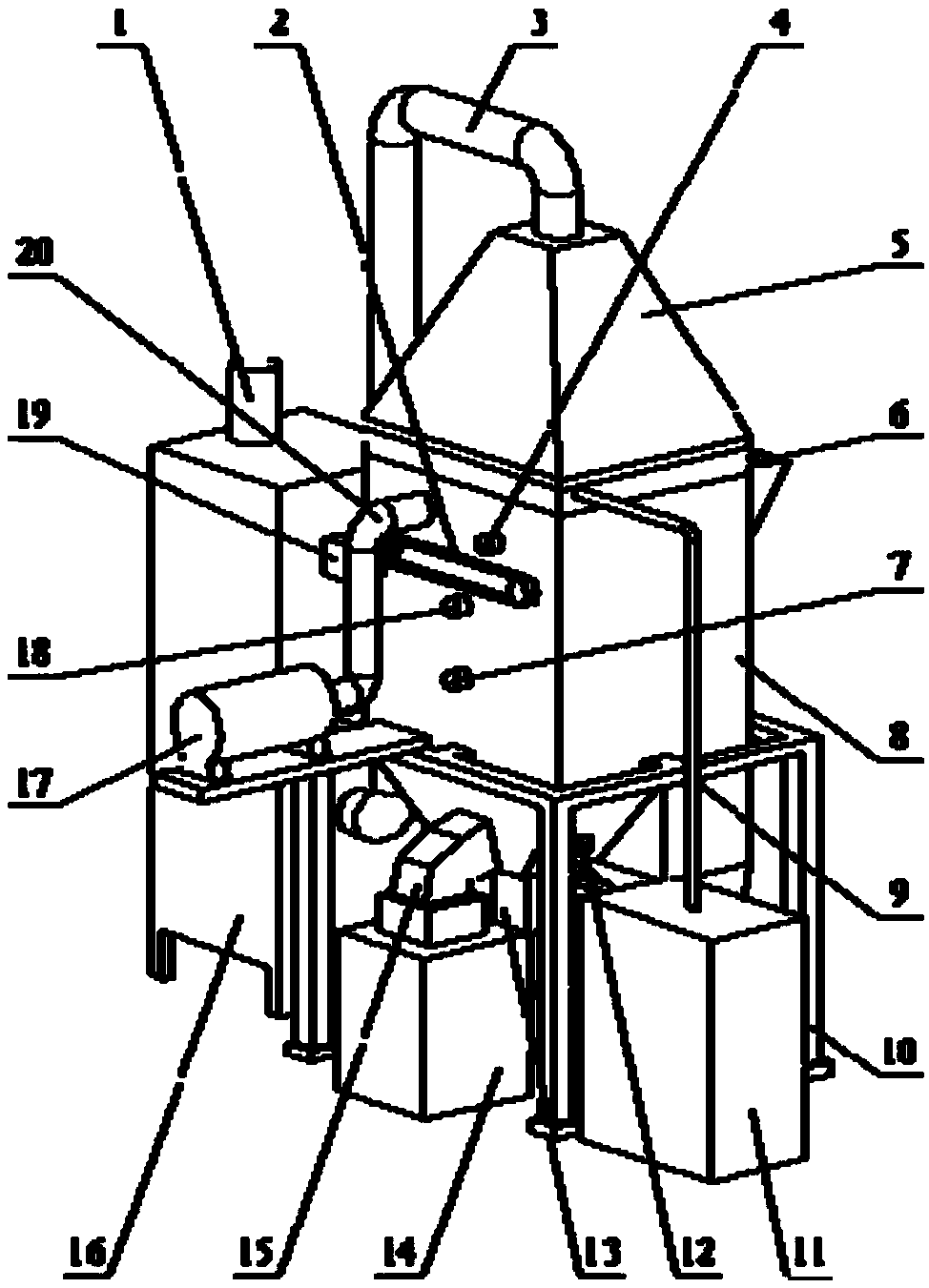

ActiveCN104788006BEfficient Mixing EffectsGood floc effectSludge treatment by de-watering/drying/thickeningRotary stirring mixersZoogloeaPre treatment

A method for intensifying the mixing effect of sludge and medicament comprises the steps of conducting quick stirring on the sludge, and then conducting slow stirring on the sludge, wherein according to the quick stirring, activated sludge and a flocculating agent are quickly injected into a quick stirring mechanism, the residence time is less than 1 s, the average speed gradient and the mixing strength are controllable, a mixing function is achieved, and low shear force stability of high-volume floc is formed; according to the slow stirring, the activated sludge subjected to the quick stirring enters into a slow stirring mechanism, and granule sludge can be formed by the tapered slow stirring mechanism. The method aims at the zoogloea formed by hydrophilic negative bio-particles contained in excess sludge produced in urban sewage treatment, the zoogloea enables the sludge to achieve a better dehydration property, coagulation of the activated sludge and the flocculating agent is finished through the quick stirring mechanism, granule sludge with better hydrophobic property can be formed through the tapered slow stirring mechanism, and sludge granulation pretreatment is realized. Through the sludge granulation pretreatment, the dehydration effect of follow-up mechanical dehydration systems is intensified, the dehydration efficiency is improved, and the consumption of the flocculating agent is reduced.

Owner:大连迈克环境科技工程有限公司

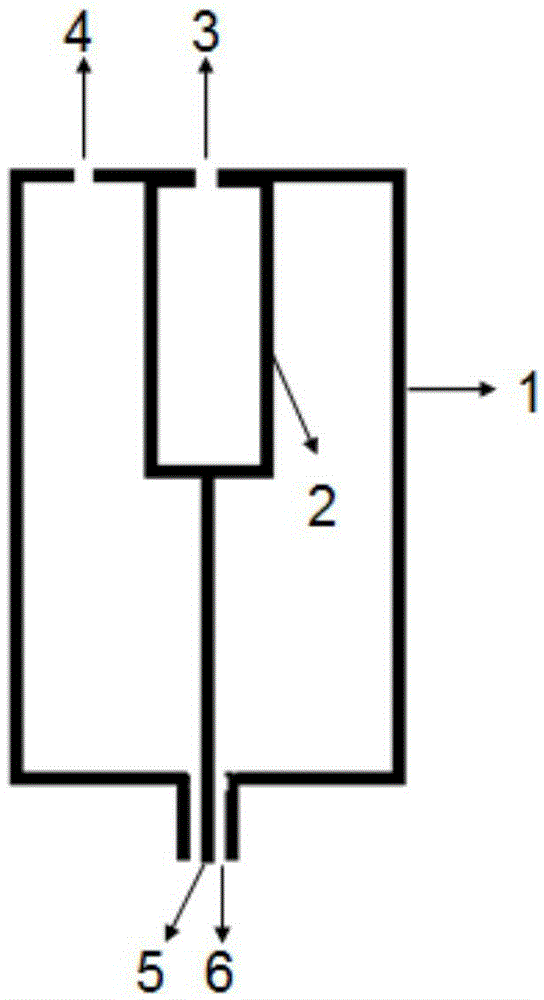

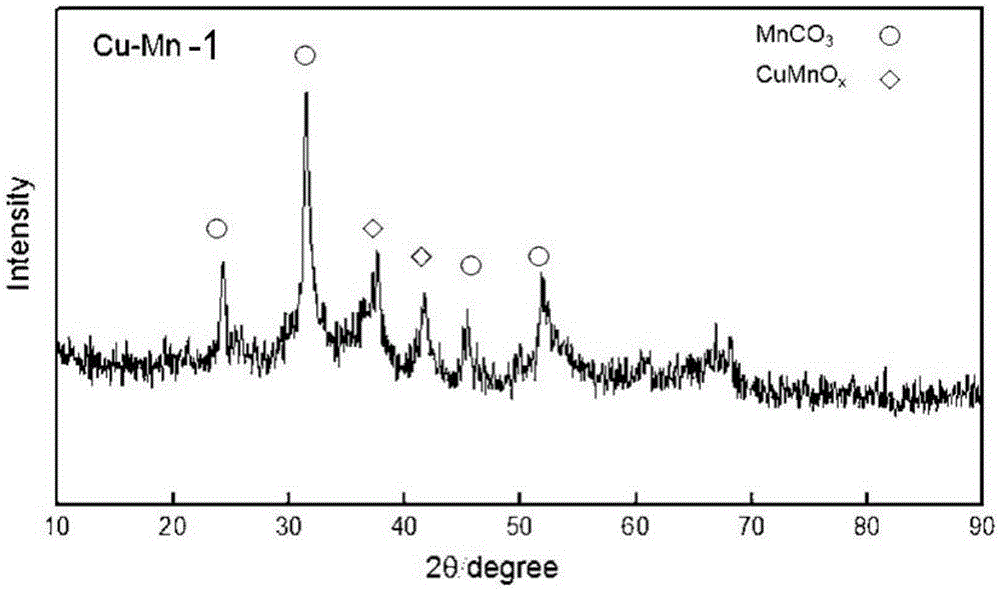

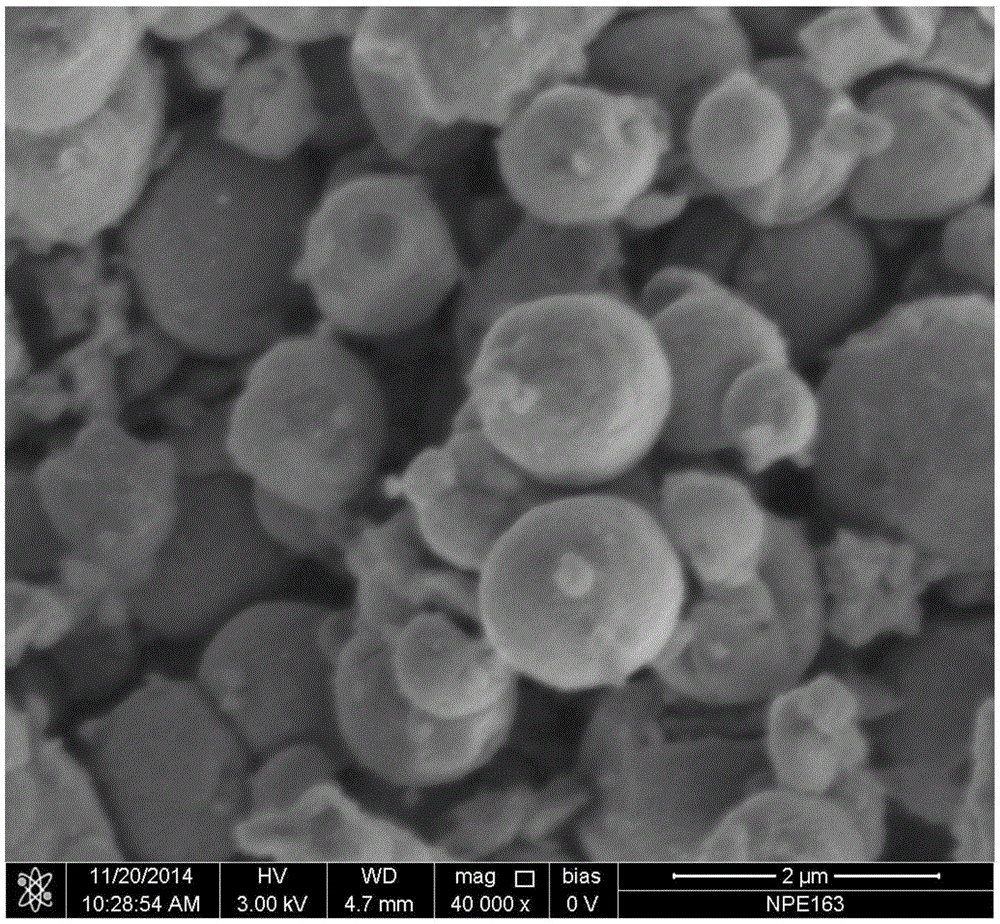

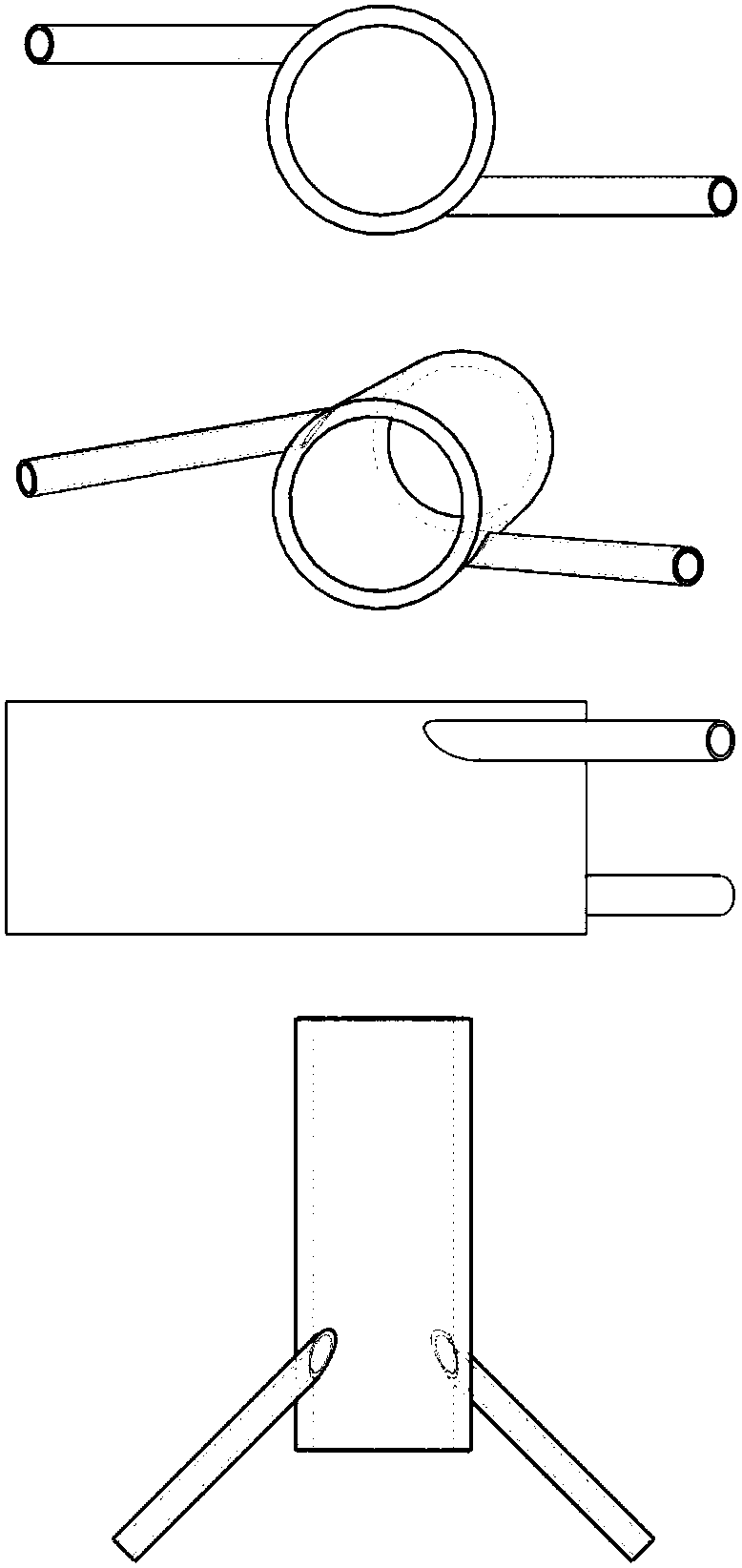

Coaxial parallel flow precipitation device and method for preparing catalyst

InactiveCN105327664AInlet flow constantFull and efficient mixingCatalyst activation/preparationChemical/physical/physico-chemical processesEngineeringGuide tube

The invention relates to a coaxial parallel flow precipitation device and a method for preparing a catalyst. The coaxial parallel flow precipitation device comprises a casing pipe formed by an outer pipe and an inner pipe, wherein an inner pipe liquid inlet and an outer pipe liquid inlet are respectively formed in the upper ends of the inner pipe and the outer pipe; the inner diameter of an inner pipe liquid outlet is 0.3 to 1mm; the inner diameter of an outer pipe liquid outlet is 1 to 2mm; the inner pipe liquid outlet is located in a lower part with a distance from 0.5 to 1.5mm from the outer pipe liquid outlet; the inner pipe liquid inlet and the outer pipe liquid inlet are respectively connected with an injector filled with a metal salt solution and an injector filled with a precipitant solution by a guide pipe; the injectors are connected with a pushing pump; the metal salt solution is injected into the inner pipe from the inner pipe liquid inlet; the precipitant solution is injected into a hollow cavity formed between the inner pipe and the outer pipe from the outer pipe liquid inlet; the metal salt solution is mixed with the precipitant solution in the inner pipe liquid outlet to form precipitate; the precipitate is dripped, filtered, washed, dried and roasted to obtain the catalyst. The method is controllable in preparation process and is capable of quickly and efficiently mixing liquid droplets to obtain the uniform and small-particle-size catalyst.

Owner:DALIAN UNIV OF TECH

A feed mixing device for animal husbandry

ActiveCN114377583BAchieving rotational agitationSmooth rotationRotating receptacle mixersShaking/oscillating/vibrating mixersAnimal scienceGear drive

The invention discloses a feed mixing device for animal husbandry, which relates to the technical field of mixing devices, and comprises a frame on which a drive shaft is rotatably mounted, and the drive shaft is connected to a bevel gear through a transmission assembly. There is an agitating assembly in the mixing inner cylinder, a gear box is installed on the turret, and a gear transmission assembly is arranged in the gear box, and a translation assembly is connected to the gear transmission assembly, and the translation assembly is used to drive the mixer. The material inner cylinder moves axially relative to the material mixing outer cylinder; the invention can drive the turret to rotate through the rotation of the set driving shaft, so as to realize the rotation of the mixing outer cylinder and the mixing inner cylinder, and promote the rotation of the internal feed around the turret, while at the same time , through the transmission of the transmission component, the mixing component drives the mixing outer cylinder and the mixing inner cylinder to rotate and stir the internal feed, which greatly improves the dispersion of the feed and the feed is fully mixed.

Owner:诸城市中裕机电设备有限公司

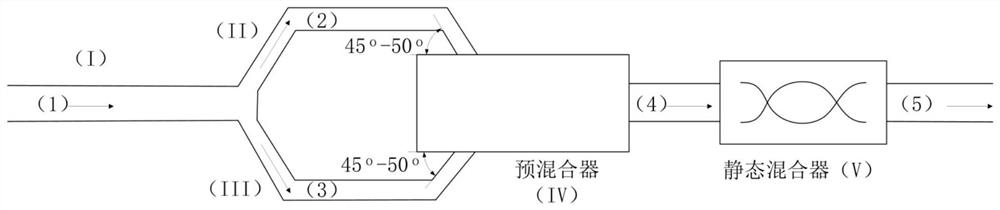

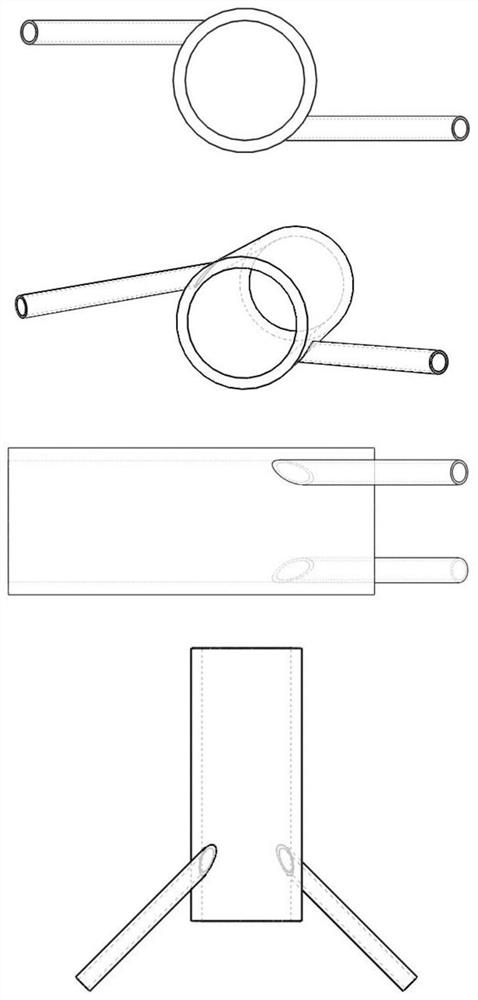

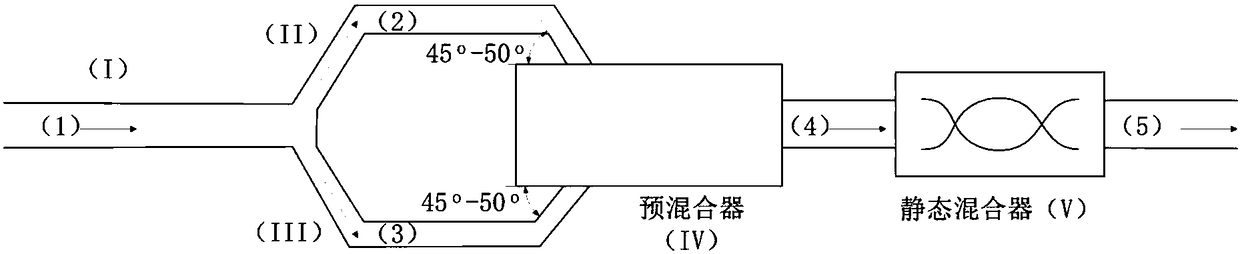

Low-pressure drop efficient static mixing device beneficial to oil blending and oil blending method

ActiveCN108273403AWell mixedReduce Density StratificationFlow mixersTransportation and packagingVolumetric Mass DensityEngineering

The invention relates to a low-pressure drop efficient static mixing device beneficial to oil blending and an oil blending method. The static mixing device comprises a premixer; the premixer comprisesa vessel body and two or more inlet joint pipes which are symmetrically arranged on the vessel body, wherein the two or more inlet joint pipes form included angles of 45-50 degrees with the axis direction of the premixer respectively, and the two or more inlet joint pipes are in liquid communication with the inside of the vessel body through inlets on the corresponding positions of the vessel body of the premixer. By adopting the method provided by the invention, component oil which gathers at a blending head is throttled and pressurized to form multiple strands of materials, and the materials enter the premixer through inlet joint pipes of the premixer respectively, are symmetrically sprayed into the premixer slantingly tangentially in a tangential direction of a pipe wall in a mode of ahigh-speed swirl and enter the static mixing device for further mixing after being fully contacted and premixed. The static mixing device provided by the invention can ensure that various component oils are efficiently and fully mixed, lowers the density layering and enables mixing of products to be more uniform.

Owner:EAST CHINA UNIV OF SCI & TECH

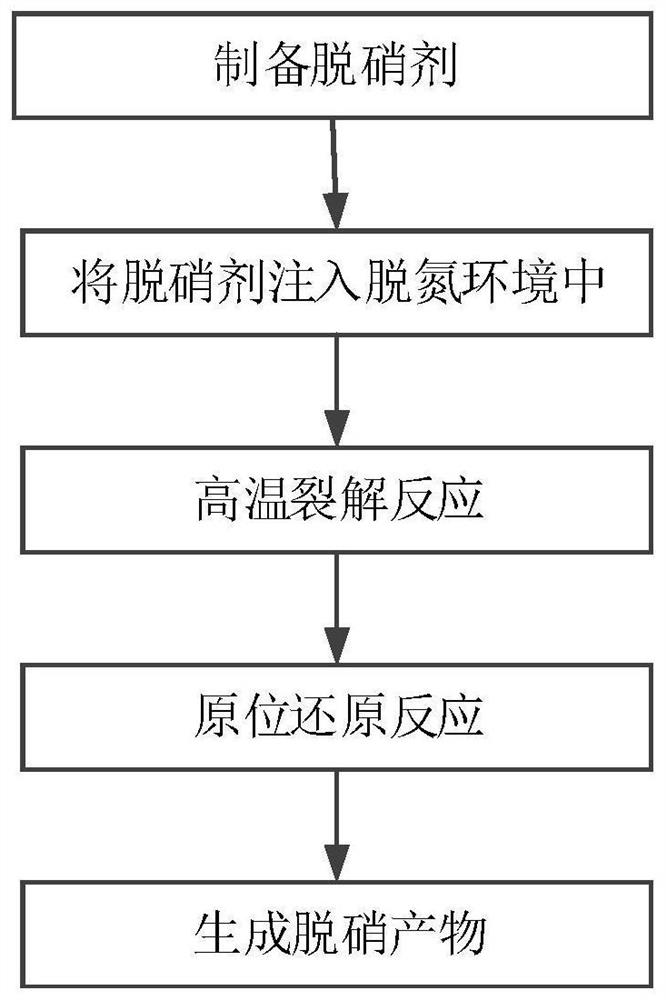

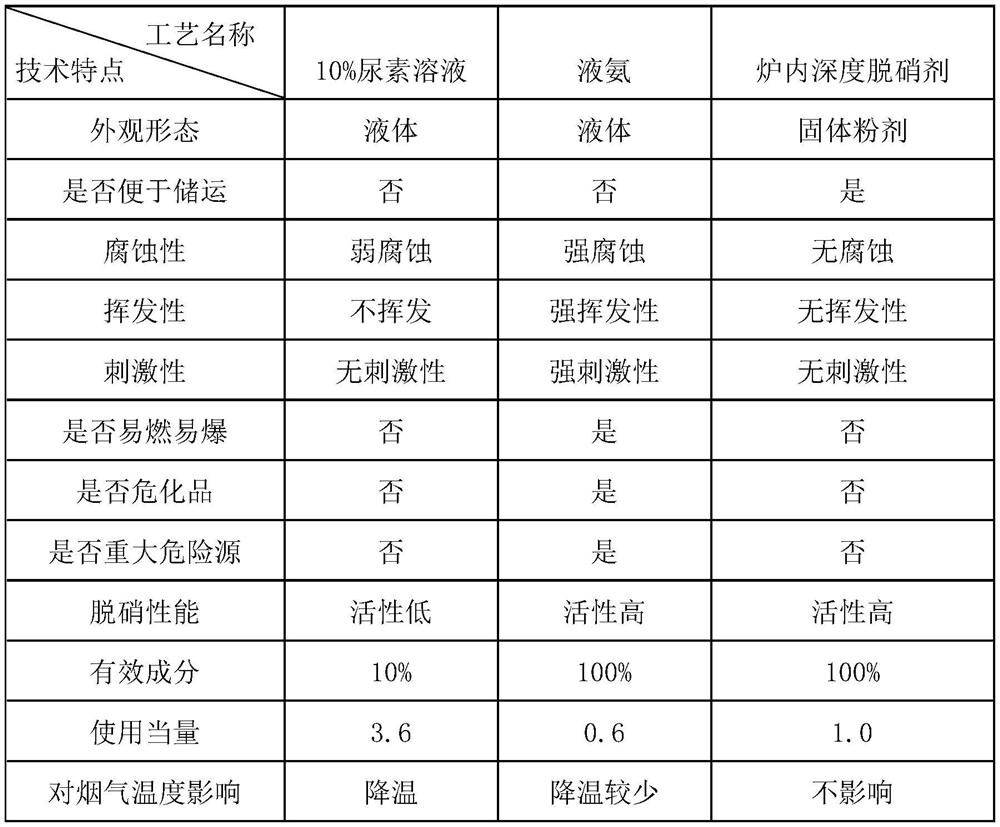

In-furnace deep denitration process, denitration agent and preparation method of denitration agent

PendingCN111672291AIncrease productivityFull and efficient mixingGas treatmentDispersed particle separationNitric oxideNitrogen oxides

The invention belongs to the technical field of denitration, and particularly relates to an in-furnace deep denitration process, a denitration agent and a preparation method of the denitration agent.The in-furnace deep denitration process comprises the following steps that a denitration agent is added into a heated hearth, so that the denitration agent is subjected to high-temperature cracking reaction to generate a gaseous denitration reducing agent; and the gaseous denitration reducing agent and nitrogen oxide in the hearth are subjected to in-situ reduction reaction so as to carry out deepdenitration. By utilizing the good diffusivity of the gaseous denitration reducing agent in a denitrification environment, the gaseous denitration reducing agent can be fully and efficiently mixed with gaseous nitric oxide, so that an in-situ reduction reaction is facilitated, and the effect of deep denitrification is achieved; and meanwhile, the concentration of nitric oxide in the hearth does not need to be limited, and the production efficiency is improved.

Owner:常州和艺翔环境工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com