Rapid glue stirring device for footwear industry

A technology of mixing device and glue, which is applied to mixers with rotating mixing devices, accessories of mixers, transportation and packaging, etc., can solve the problems of low work efficiency, general mixing effect, rising glue raw materials, etc., and achieve efficient mixing and full sealing. The effect of preventing the inhalation of scattered toxic substances and preventing the inhalation of toxic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

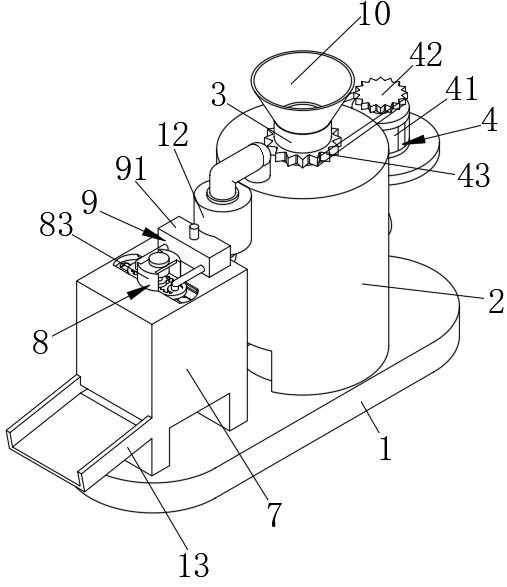

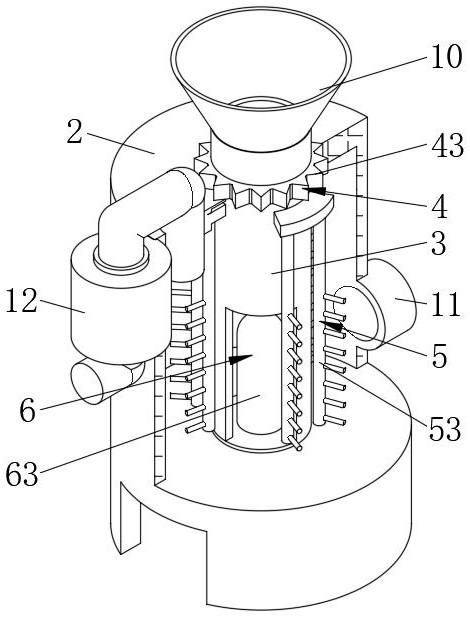

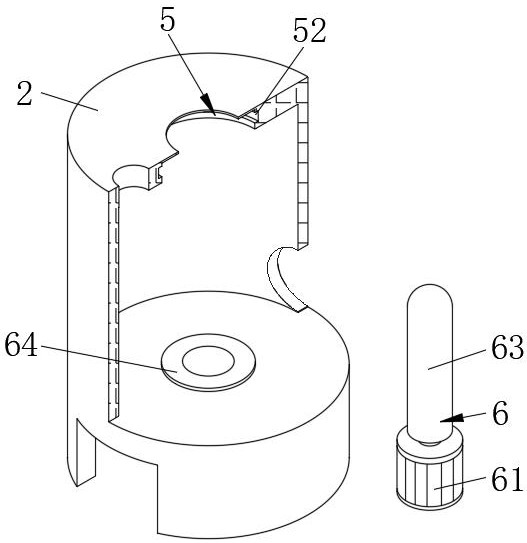

[0036] see Figure 1-8 , the present invention provides a technical solution: a fast glue mixing device for the shoe industry, comprising a base 1, a stirring tank 2 is fixedly connected to the right side of the top of the base 1, and a material guide pipe 3 is fixedly connected to the bottom of the inner cavity of the mixing tank 2 , the top of the feed pipe 3 runs through to the top of the stirring tank 2 and is connected with a conical feeding cylinder 10, the top of the stirring tank 2 right side is provided with a driving mechanism 4, and the inner cavity of the stirring tank 2 is provided with a stirring mechanism 5, and the stirring The bottom of the tank 2 is provided with a vibration mechanism 6, the left side of the top of the base 1 is fixedly connected with a degradation box 7, the top of the degradation box 7 is provided with a reciprocating swing mechanism 8, and the right side of the top of the degradation box 7 is provided with a spraying mechanism 9, and the st...

Embodiment 2

[0041] see Figure 1-8 , the present invention provides a technical solution: a fast glue mixing device for the shoe industry, comprising a base 1, a stirring tank 2 is fixedly connected to the right side of the top of the base 1, and a material guide pipe 3 is fixedly connected to the bottom of the inner cavity of the mixing tank 2 , the top of the feed pipe 3 runs through to the top of the stirring tank 2 and is connected with a conical feeding cylinder 10, the top of the stirring tank 2 right side is provided with a driving mechanism 4, and the inner cavity of the stirring tank 2 is provided with a stirring mechanism 5, and the stirring The bottom of the tank 2 is provided with a vibration mechanism 6, the left side of the top of the base 1 is fixedly connected with a degradation box 7, the top of the degradation box 7 is provided with a reciprocating swing mechanism 8, and the right side of the top of the degradation box 7 is provided with a spraying mechanism 9, and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com