Patents

Literature

181results about "Liquid degasification by vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Removing solids from a fluid

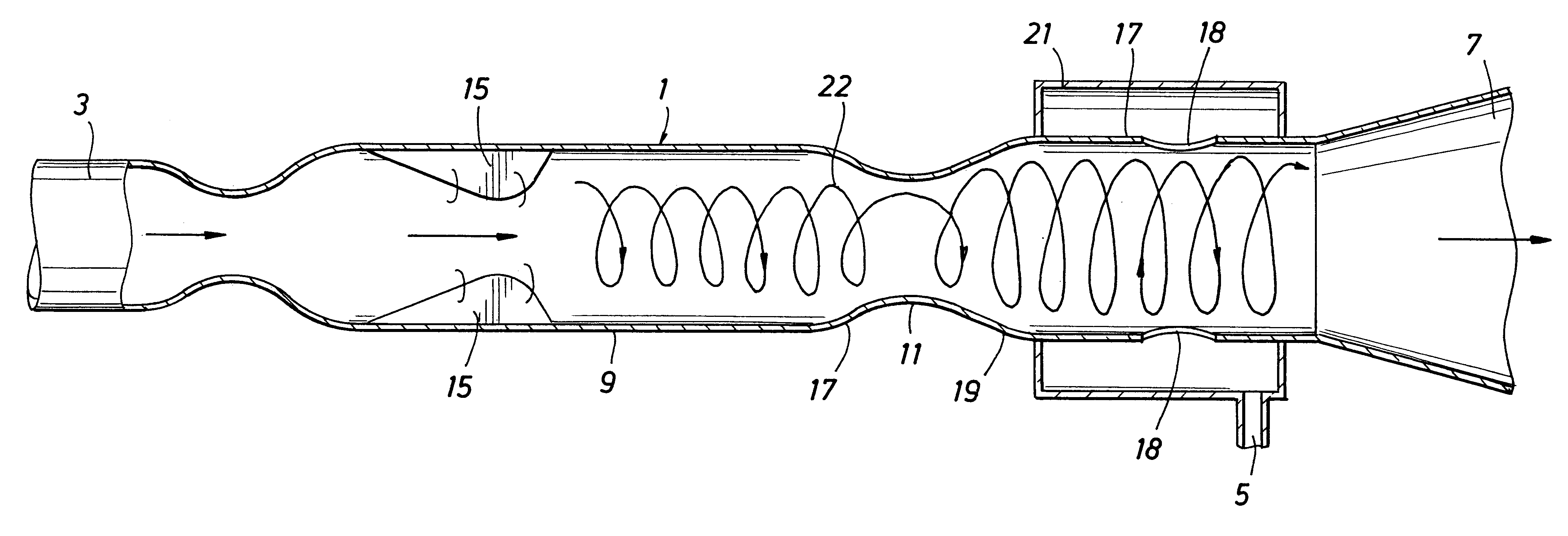

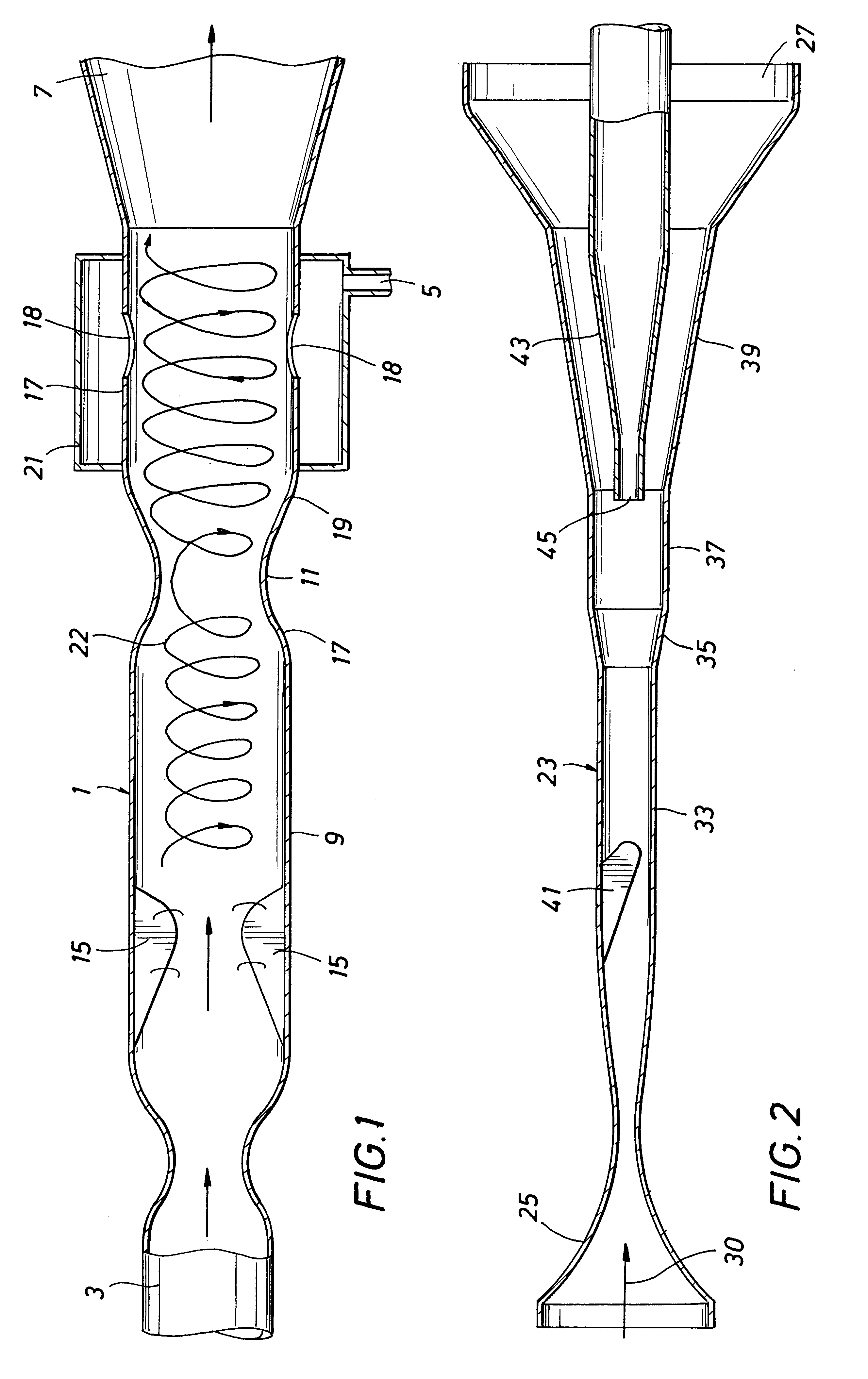

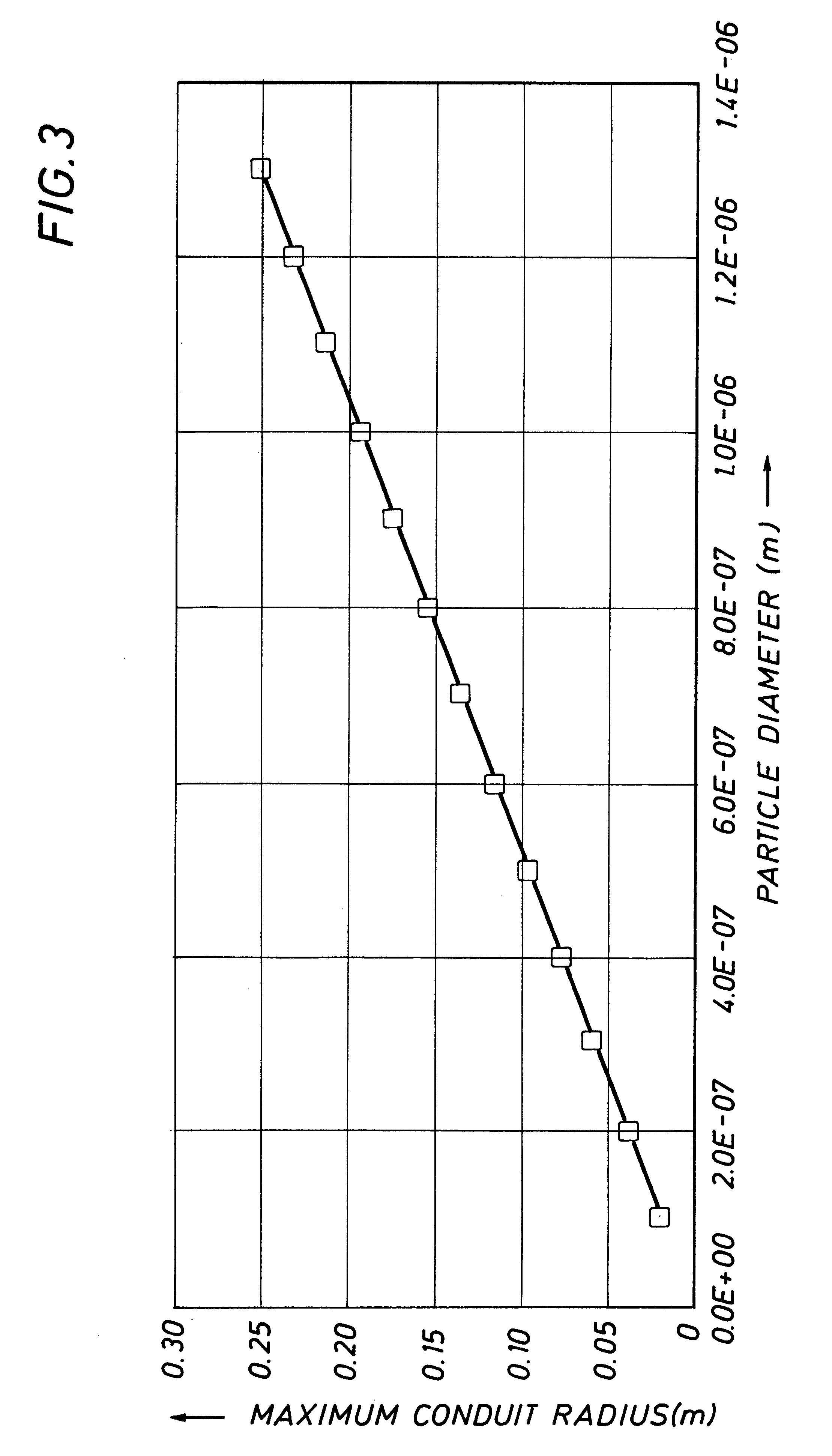

InactiveUS6280502B1Large kinetic energyEasy to separateCombination devicesAuxillary pretreatmentEngineeringSolid particle

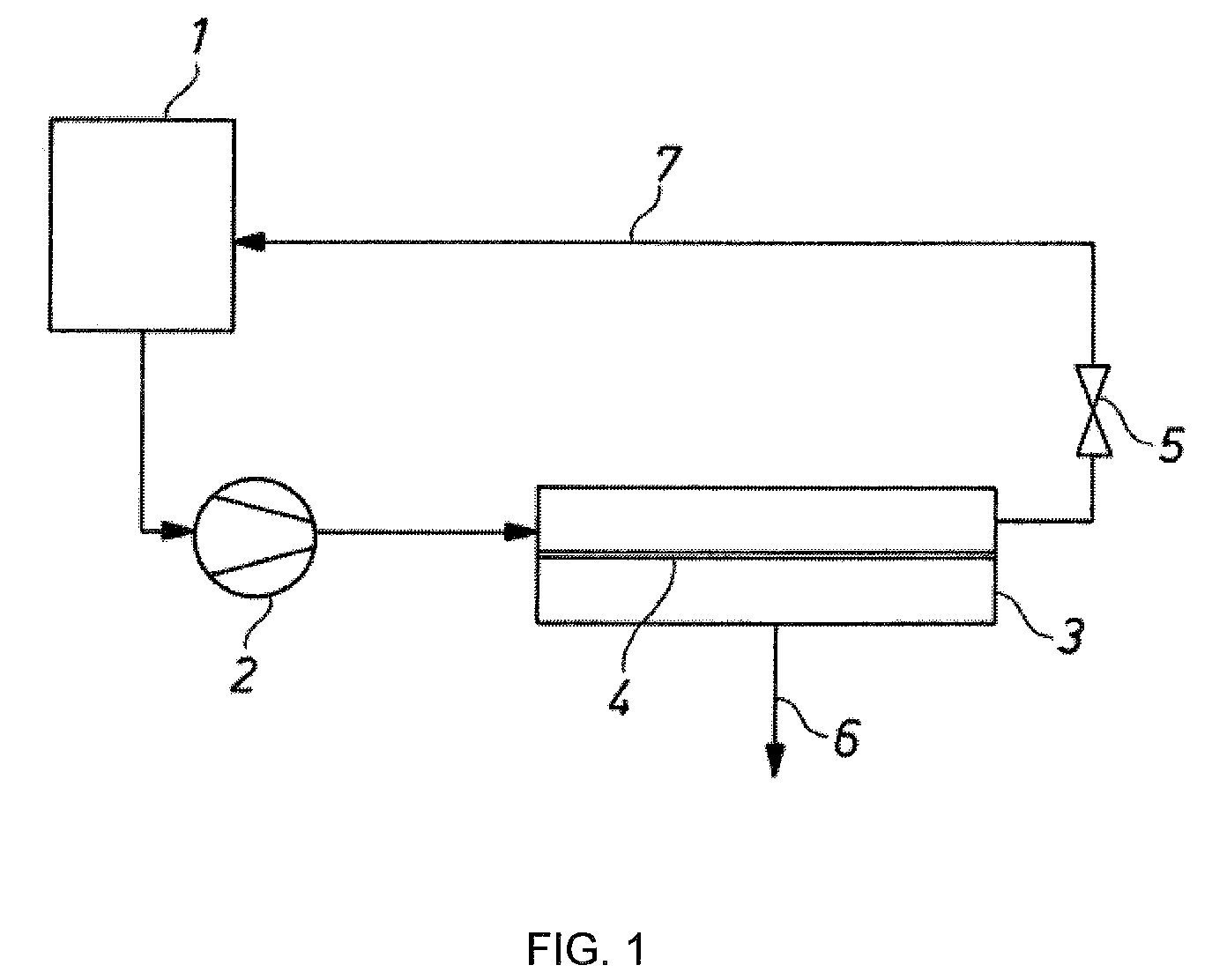

A method and apparatus are provided for removing solid particles from a particle containing stream of fluid, the method including the steps of: inducing the stream to flow at supersonic velocity through a conduit; inducing a swirling motion to the supersonic stream of fluid thereby causing the particles to flow to a radially outer section of a collecting zone in the stream; and extracting the solid particles into an outlet stream from the radially outer section of the collecting zone. The apparatus is an apparatus effective for performance of this method.

Owner:TWISTER BV

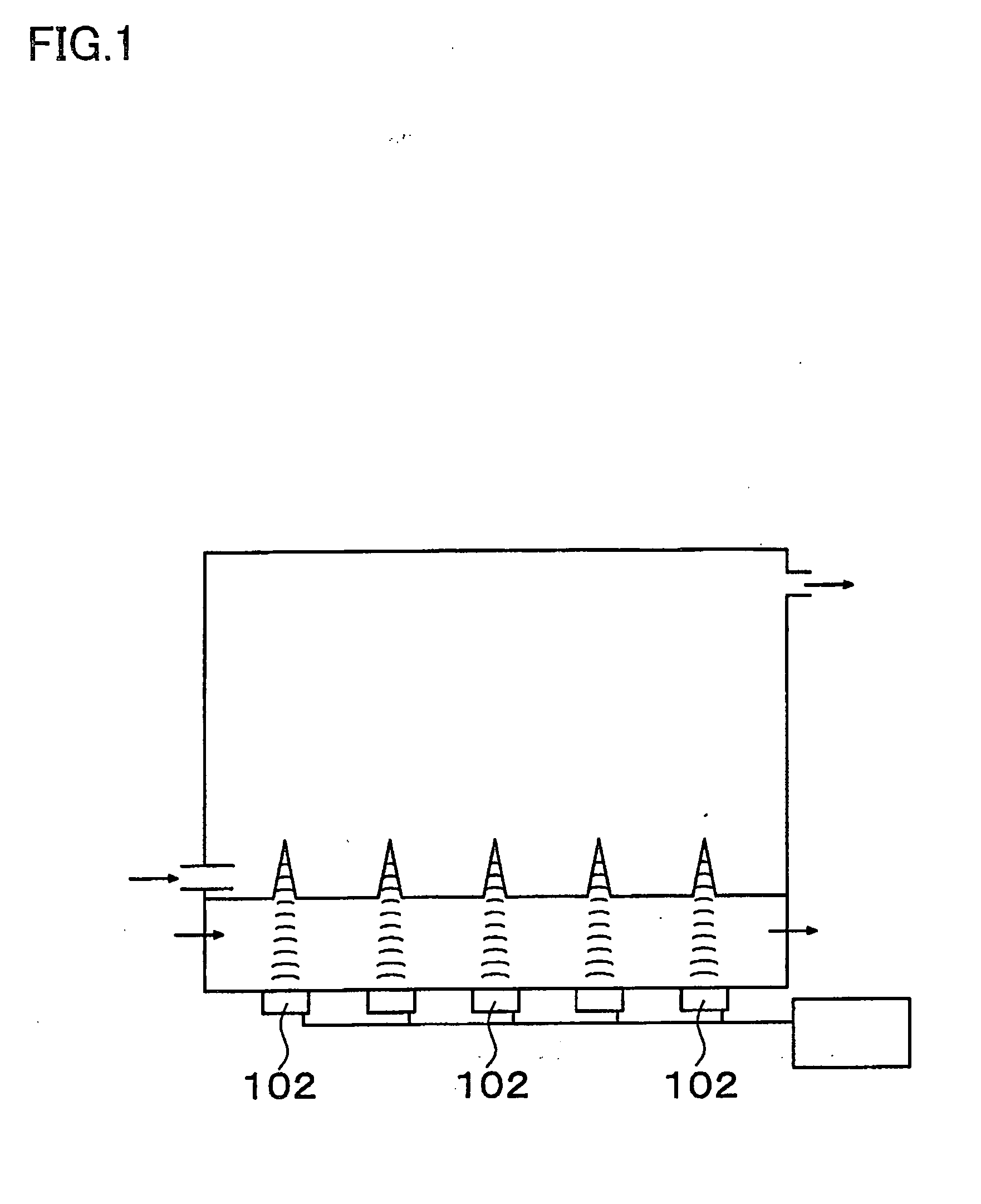

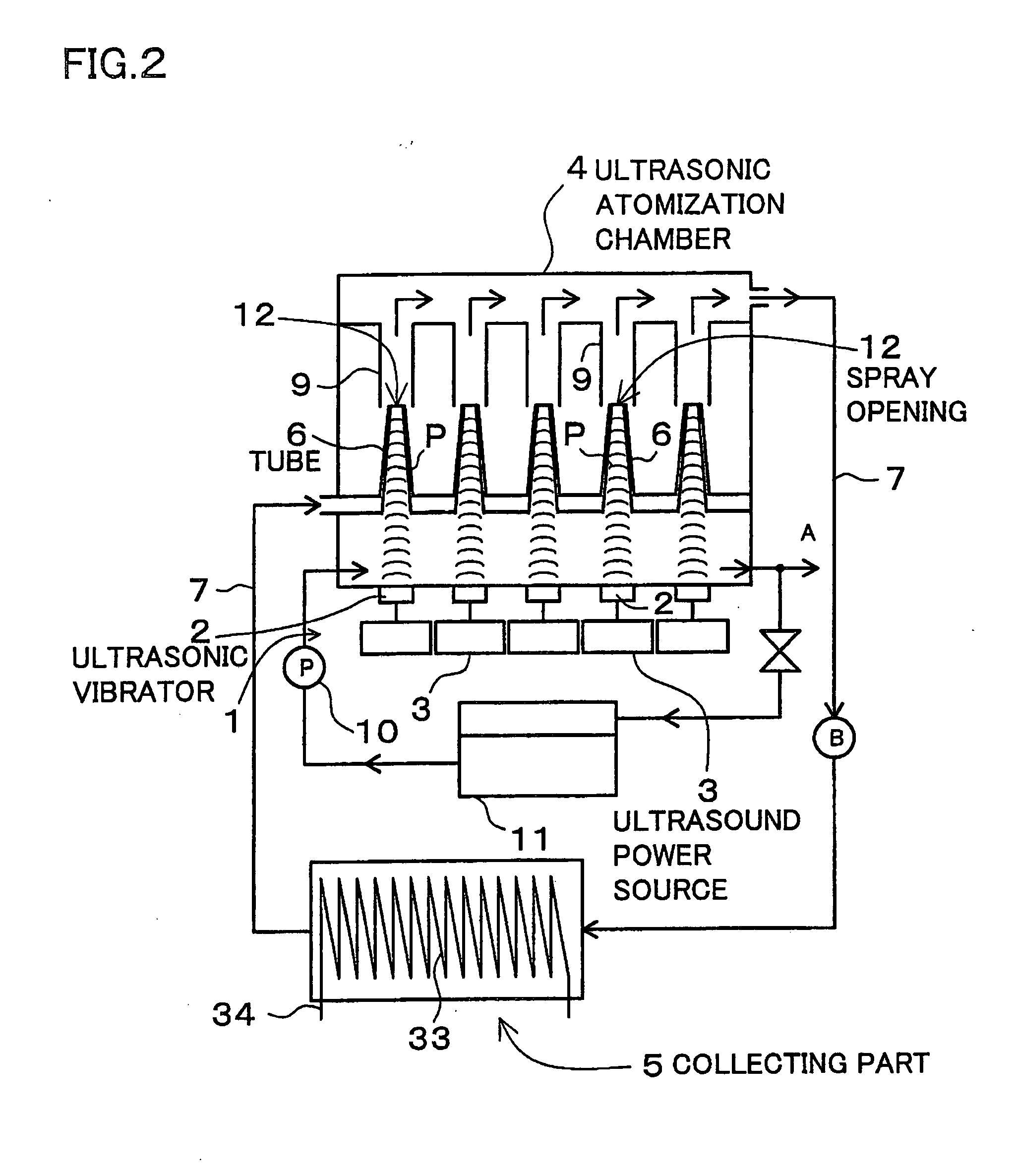

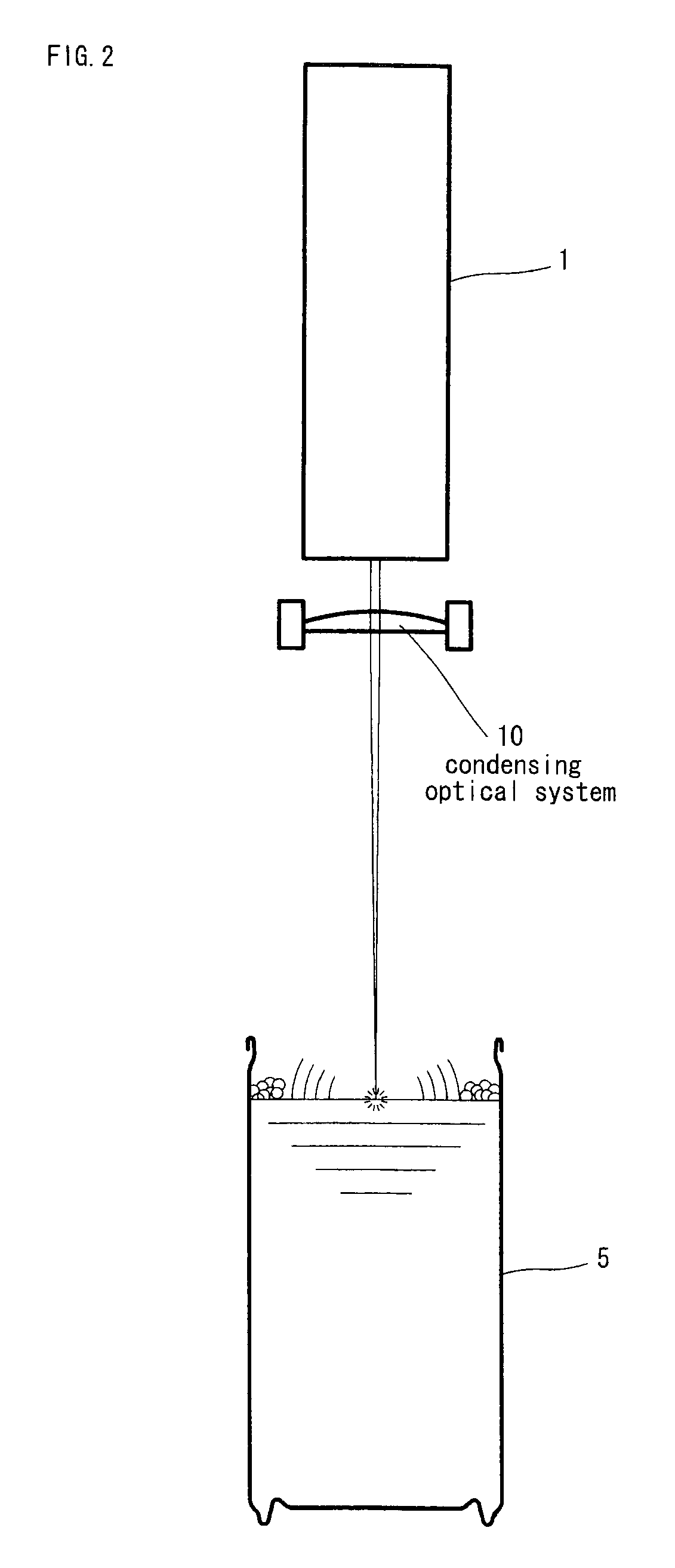

Ultrasonic Solution Separating Method and Ultrasonic Separating Apparatus Used In Such Method

InactiveUS20080000842A1Reduce the amount requiredInhibit deteriorationDistillation by vibrationOther chemical processesPresent methodEngineering

An ultrasonic solution separating method and apparatus separates a solution by ultrasonically vibrating the solution by using an ultrasonic vibrator to atomize the solution into mists, and such atomized mists are condensed and collected for separation from the solution. In the present method and apparatus, a tube 6, defining a spray opening 12 at an upper end of the tube, is filled with the solution; an ultrasonic vibration is applied to the solution inside the tube 6, toward the spray opening 12; the atomized mists are dispersed from the spray opening 12; and a carrier gas is supplied to the mists dispersed from the spray opening 12 so that the mists are atomized in the carrier gas.

Owner:ULTRASOUND BREWERY

Acoustic degassing heat exchanger

InactiveUS20080098894A1Increase heating capacityImproves overall fuel deoxygenationIsotope separationLiquid degasification by filtrationPlate heat exchangerNuclear engineering

Owner:UNITED TECH CORP

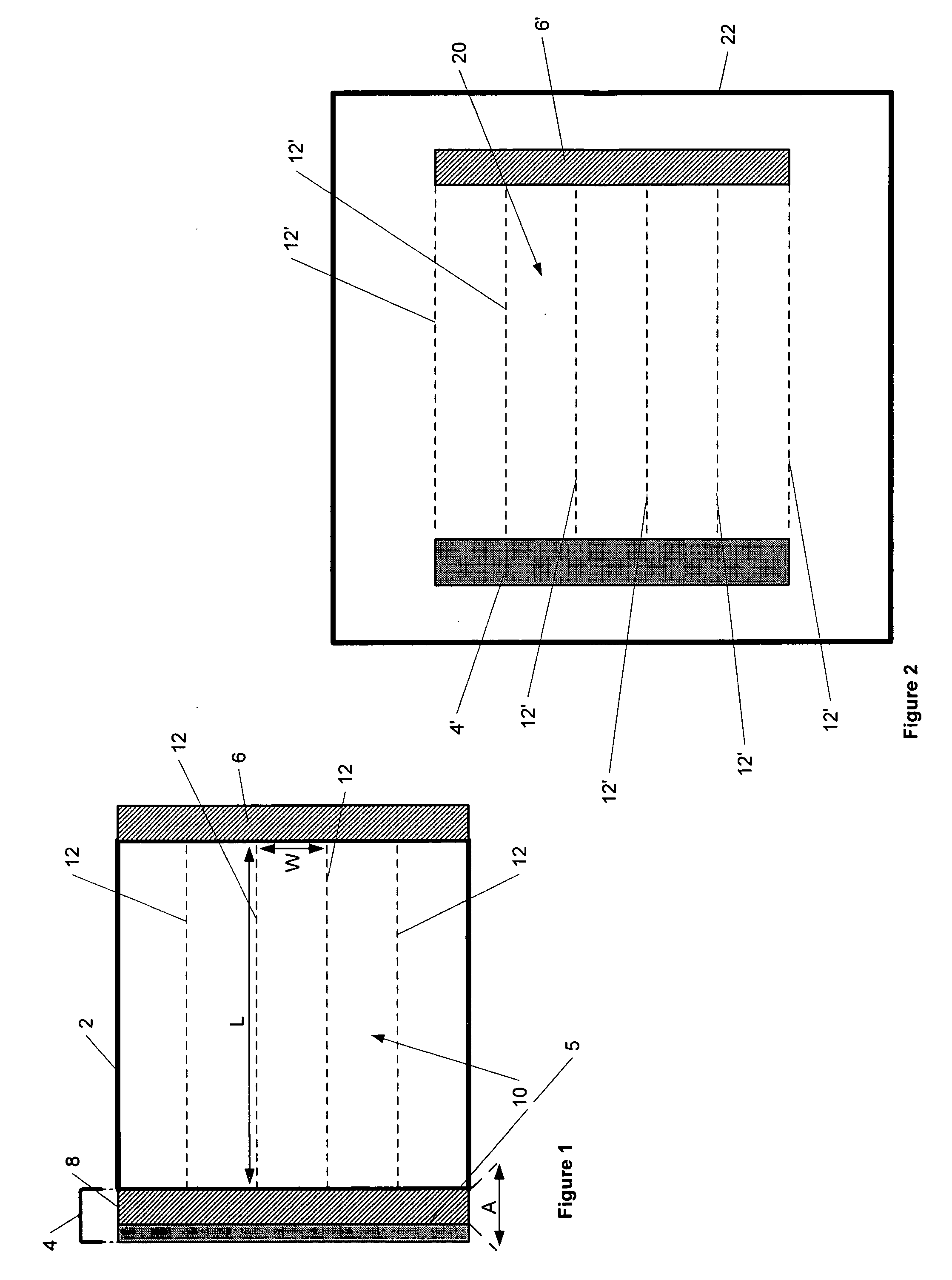

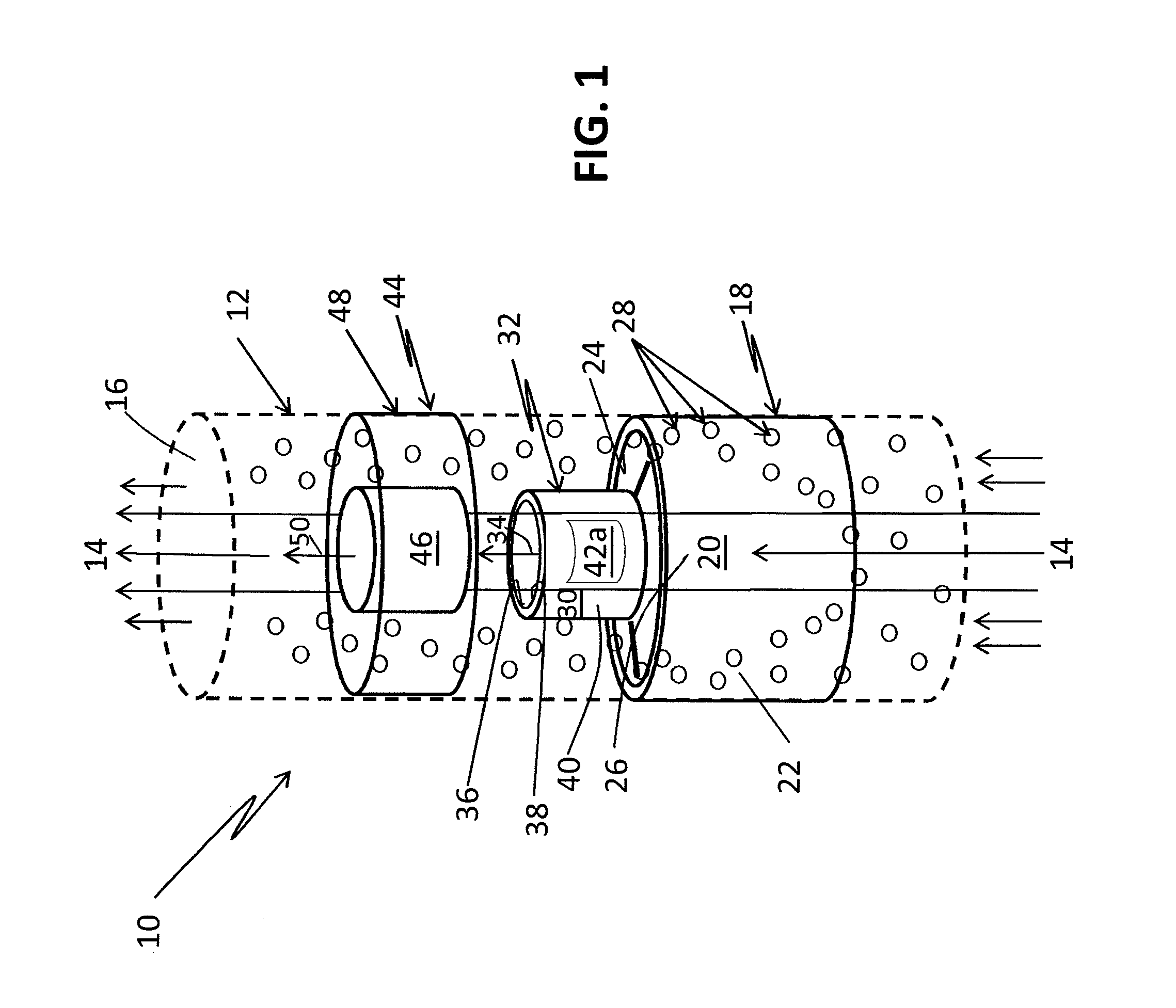

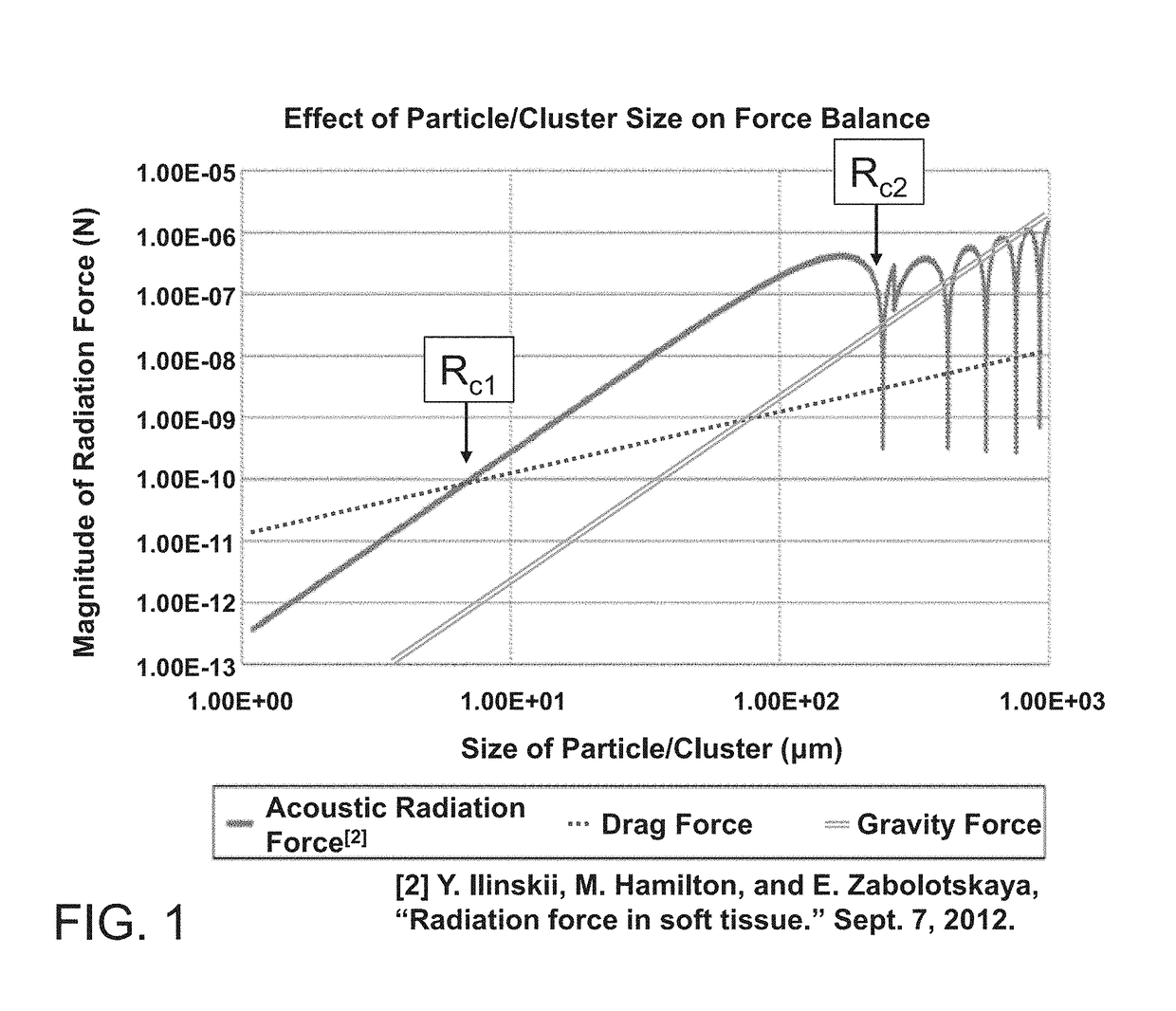

Integrated acoustic phase separator and multiphase fluid composition monitoring apparatus and method

InactiveUS20120055262A1Avoid large pressure differencesMaterial analysis using sonic/ultrasonic/infrasonic wavesConstructionsCapacitanceAcoustic radiation force

An apparatus and method for down hole gas separation from the multiphase fluid flowing in a wellbore or a pipe, for determining the quantities of the individual components of the liquid and the flow rate of the liquid, and for remixing the component parts of the fluid after which the gas volume may be measured, without affecting the flow stream, are described. Acoustic radiation force is employed to separate gas from the liquid, thereby permitting measurements to be separately made for these two components; the liquid (oil / water) composition is determined from ultrasonic resonances; and the gas volume is determined from capacitance measurements. Since the fluid flows around and through the component parts of the apparatus, there is little pressure difference, and no protection is required from high pressure differentials.

Owner:TRIAD NAT SECURITY LLC

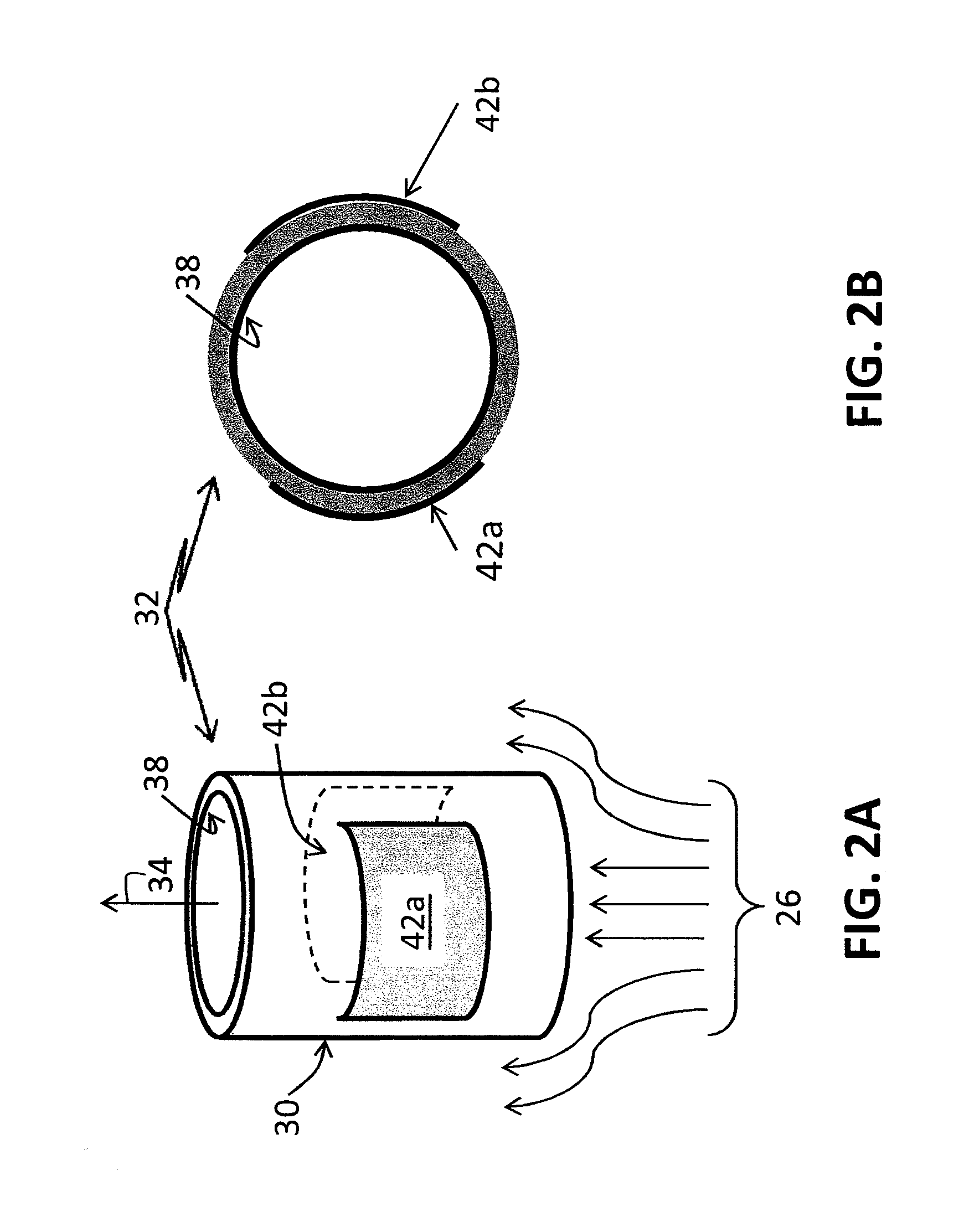

Ultrasonic treatment chamber for increasing the shelf life of formulations

An ultrasonic treatment system having a treatment chamber for treating a formulation to increase the shelf life thereof. In one embodiment, the shelf life is produced by degassing the formulation using the treatment chamber. Specifically, the treatment chamber has an elongate housing through which a formulation flows longitudinally from an inlet port to a first outlet port and a second outlet port thereof. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency to ultrasonically energize the formulation within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other. The horn and agitating members are constructed and arranged for dynamic motion of the agitating members relative to the horn at the predetermined frequency and to operate in an ultrasonic cavitation mode of the agitating members corresponding to the predetermined frequency and the formulation being treated in the chamber.

Owner:KIMBERLY-CLARK WORLDWIDE INC

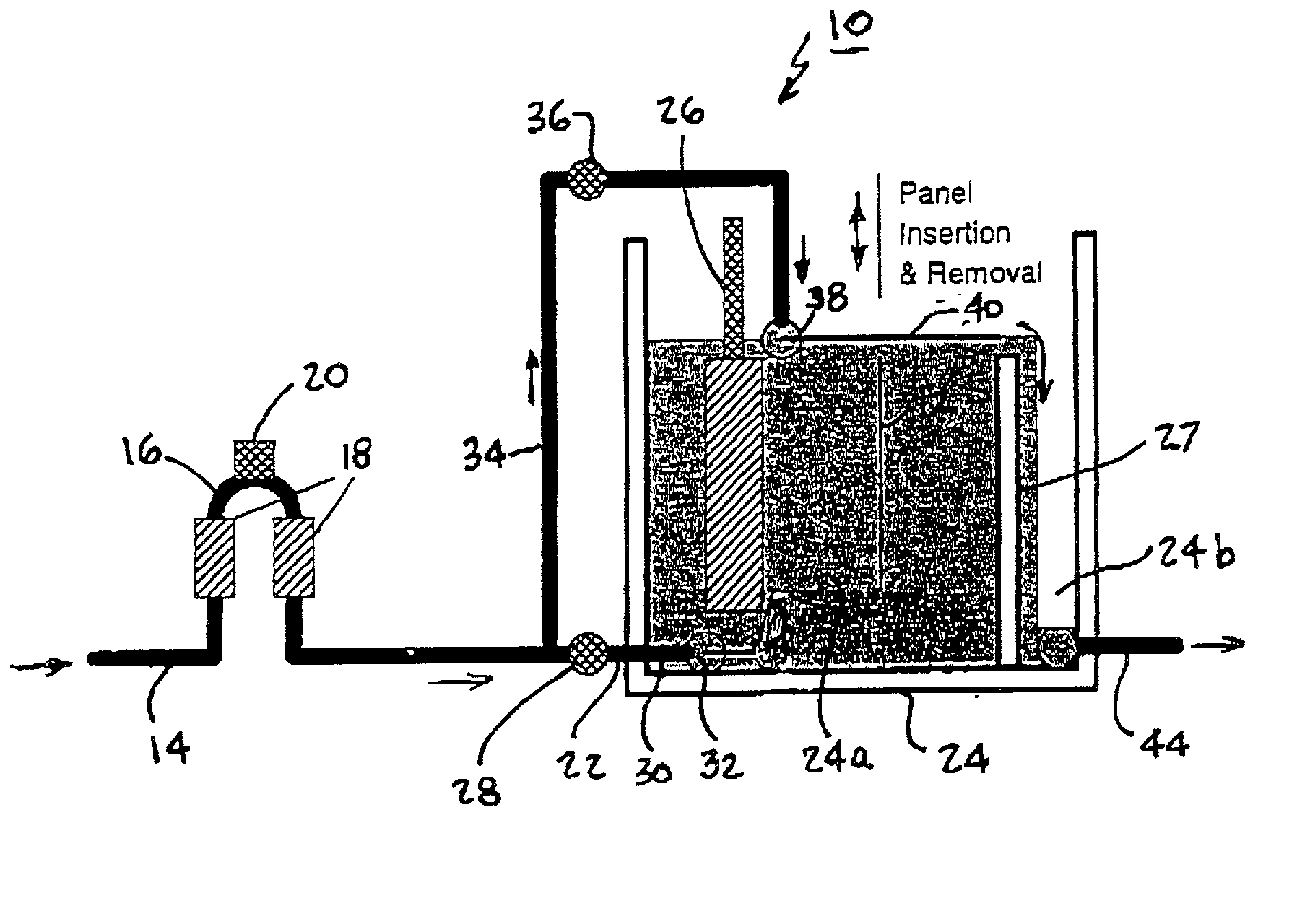

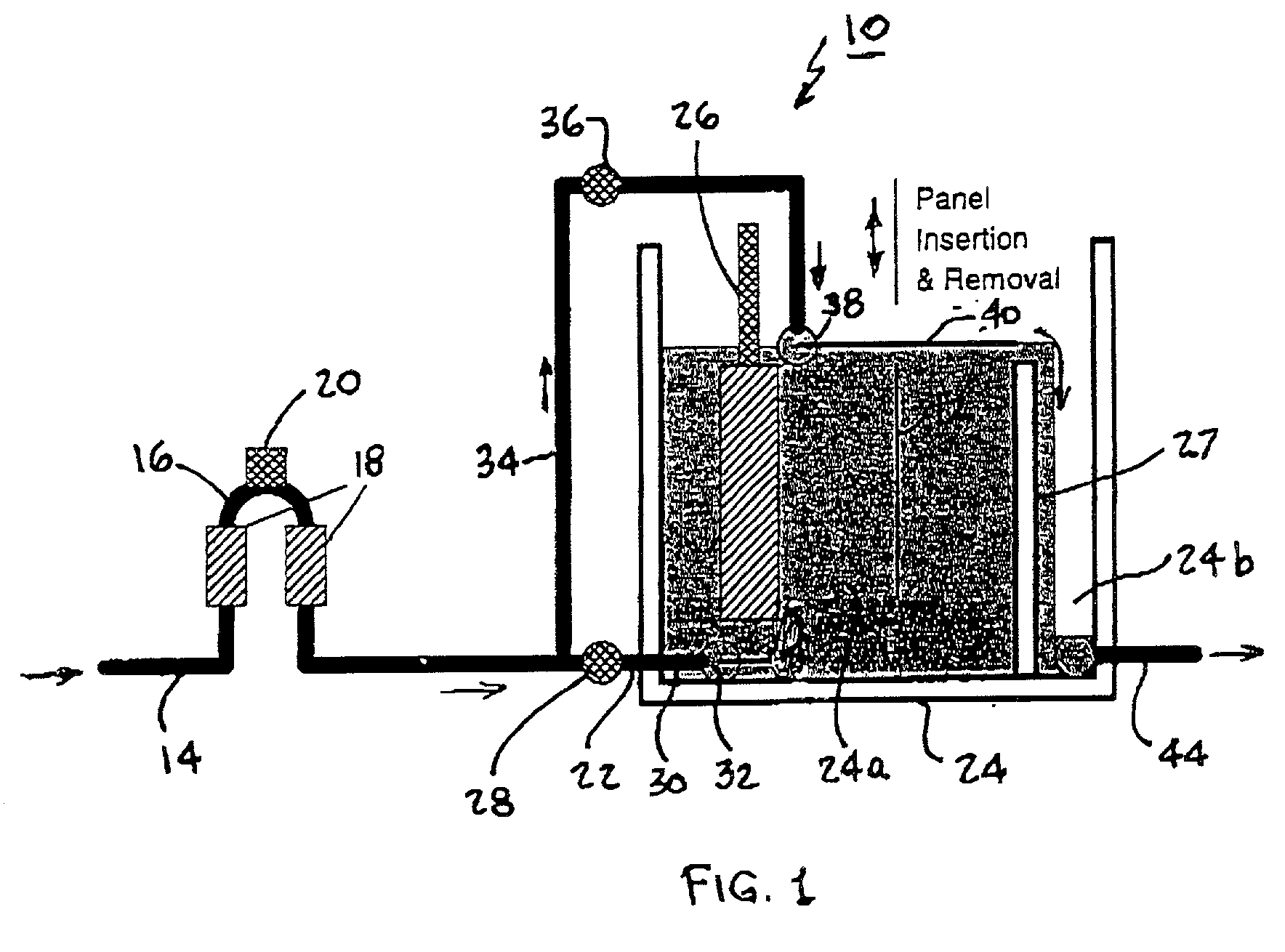

Arrangement and method for degassing small-high aspect ratio drilled holes prior to wet chemical processing

InactiveUS6626196B2Electrostatic cleaningLiquid/solution decomposition chemical coatingCopper platingEngineering

An arrangement and method for the degassing small high-aspect ratio drilled holes or vias which are present in panels such as printed circuit boards prior to wet chemical processing, including copper plating of the vias, in order to remove any air or gas bubbles from the vias tending to inhibit the reliable plating thereof. This is carried out through the utilization of an ultrasonic prewetting in a liquid bath preceding cleaning for the electroless plating process, thereby enabling all of the vias or holes to be degassed; in effect, having air removed and the vias or holes filled with liquid; thereby allowing subsequent process cleansing solutions to easily flow into the respective holes or vias in order to facilitate the electroless copper plating process.

Owner:GOOGLE LLC

Methods and apparatus for conditioning and degassing liquids and gases in suspension

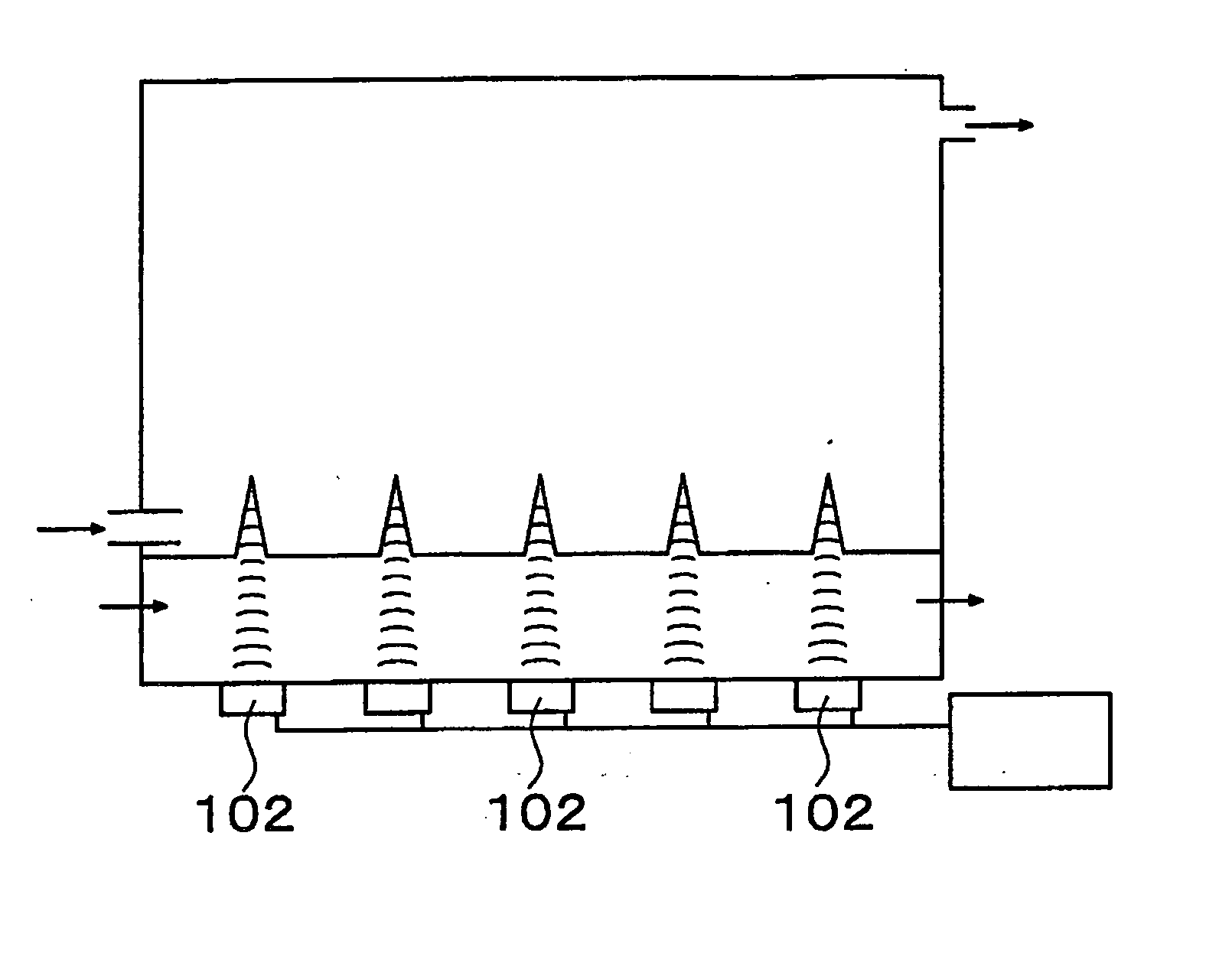

ActiveUS20070138108A1Increase droplet sizeIncrease chanceShaking/oscillating/vibrating mixersWater/sewage treatment by irradiationUltrasonic sensorEngineering

A method and apparatus are provided for the controlled application of ultrasonic energy for conditioning of mixtures of gas and liquids by evolving and / or agglomerating gas bubbles existing with or in a liquid or for coalescing droplets of liquid dispersed in another liquid. The invention in preferred embodiments thereof comprises a coalescing apparatus for Increasing the droplet size of a mixture formed as a liquid dispersed in another liquid, and a de-gassing apparatus arranged to evolve and / or agglomerate gaseous bubbles in a gas / liquid mixture. In the apparatuses, ultrasonic transducers are used to impart vibrational energy to the mixtures.

Owner:SCHLUMBERGER TECH CORP

Defoaming method

InactiveUS8026288B2Short timeReliable generationTea extractionPackaging under special atmospheric conditionsShock waveSound sources

Owner:TOYO SEIKAN KAISHA LTD

Integrated acoustic phase separator and multiphase fluid composition monitoring apparatus and method

InactiveUS8640529B2Material analysis using sonic/ultrasonic/infrasonic wavesConstructionsCapacitanceAcoustic radiation force

An apparatus and method for down hole gas separation from the multiphase fluid flowing in a wellbore or a pipe, for determining the quantities of the individual components of the liquid and the flow rate of the liquid, and for remixing the component parts of the fluid after which the gas volume may be measured, without affecting the flow stream, are described. Acoustic radiation force is employed to separate gas from the liquid, thereby permitting measurements to be separately made for these two components; the liquid (oil / water) composition is determined from ultrasonic resonances; and the gas volume is determined from capacitance measurements. Since the fluid flows around and through the component parts of the apparatus, there is little pressure difference, and no protection is required from high pressure differentials.

Owner:TRIAD NAT SECURITY LLC

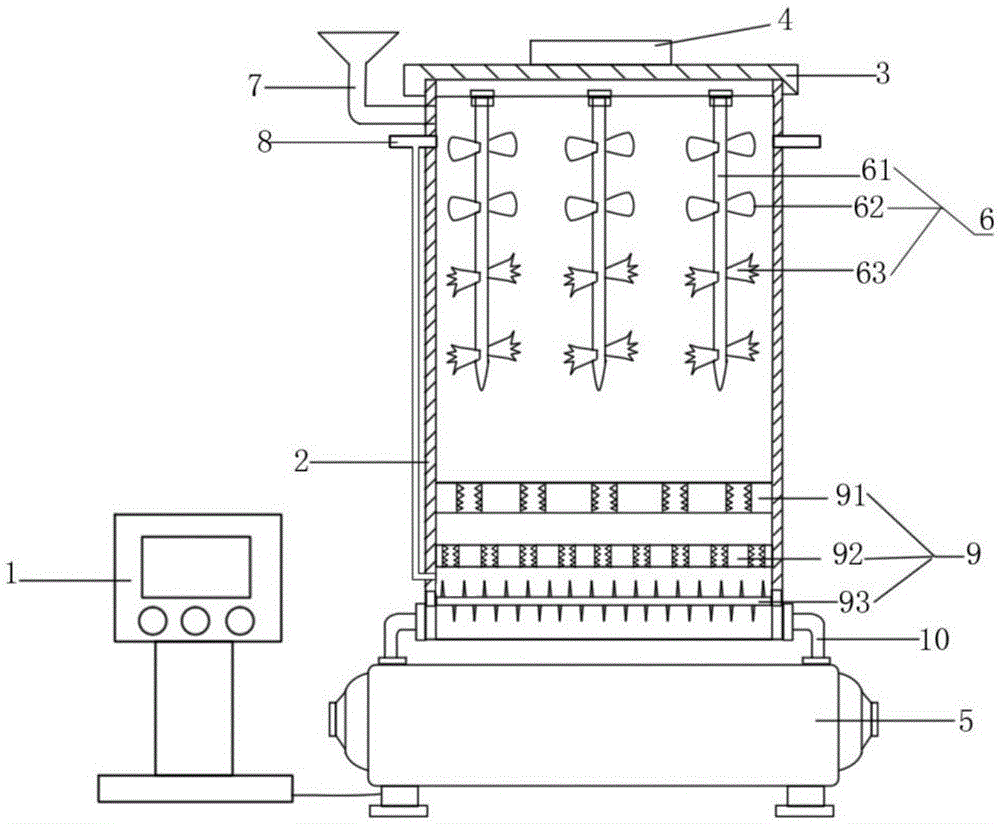

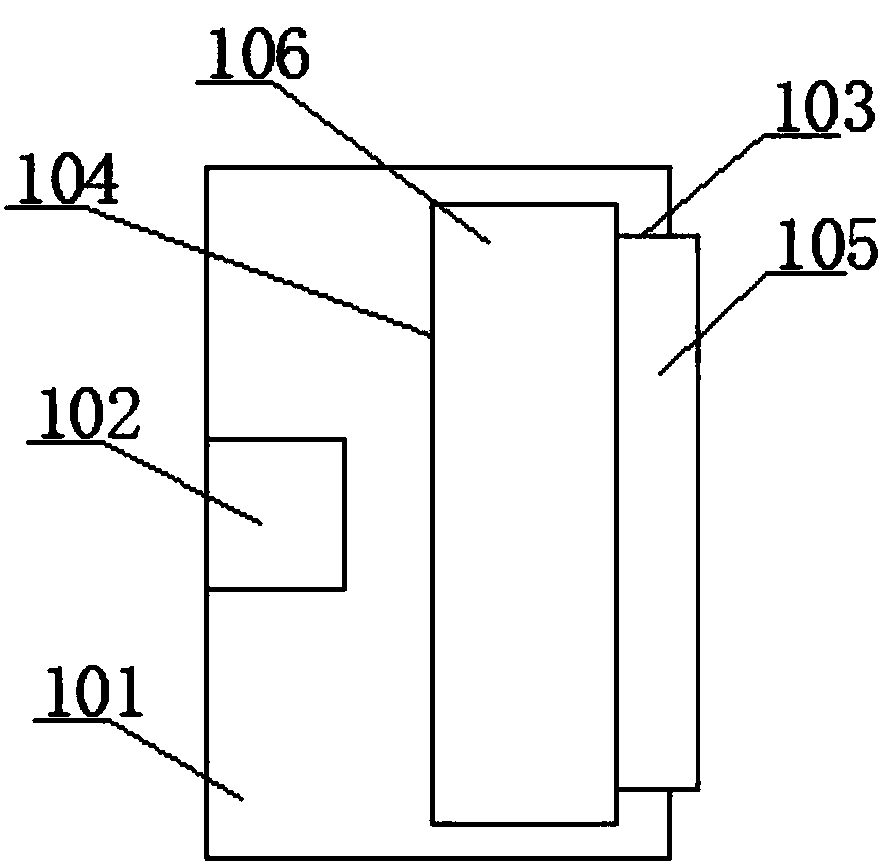

Water-based paint defoaming equipment

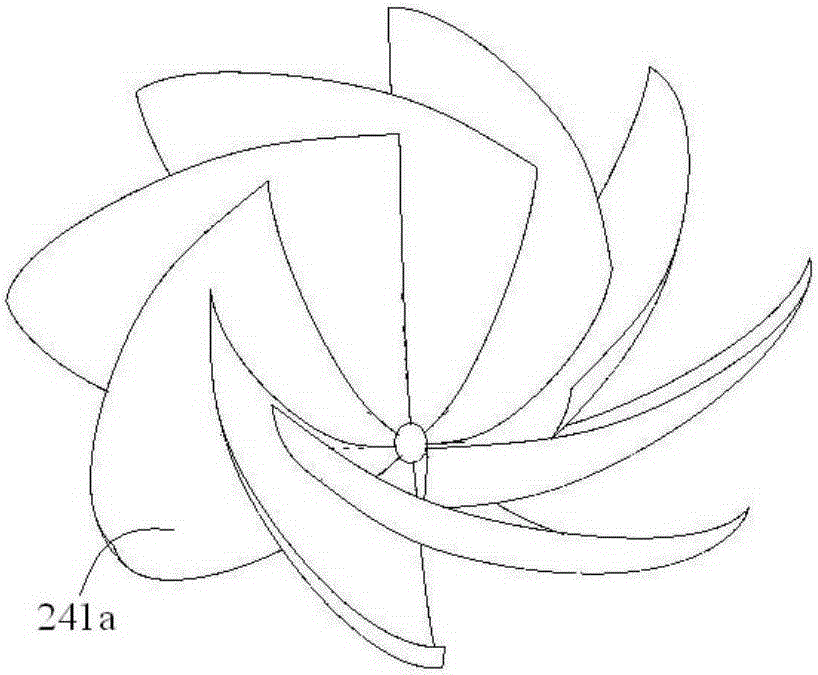

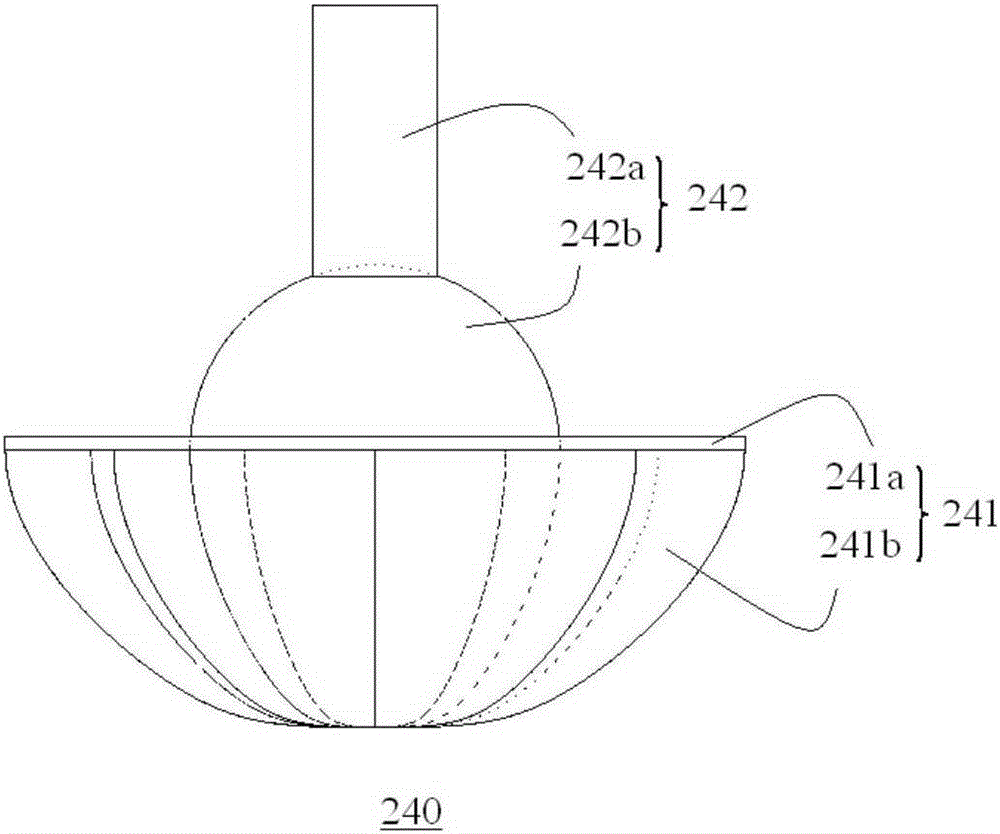

InactiveCN106823478AStir wellPromote ruptureLiquid degasification by filtrationLiquid degasification by vibrationWater basedLacquer

The invention provides water-based paint defoaming equipment, including a control device, a liquid storage tank, a sealing cover, a motor, and a discharge tank. It is characterized in that: the control device is connected to the motor through a power supply, and the sealing cover is installed on the liquid storage tank At the top, the motor is installed above the outside of the sealing cover; at the top of the liquid storage tank, a variable speed stirring device, a feed inlet and an exhaust hole are installed, and the variable speed stirring device is composed of a stirring shaft, a stirring blade and a gear stirring blade ; A multi-stage filter defoaming layer is installed at the bottom of the liquid storage tank, and the multi-stage filter defoaming layer is composed of a first-stage variable-diameter defoaming layer, a secondary variable-diameter defoaming layer and a vibrating crushing layer, wherein the The vibrating crushing layer includes multiple transverse shafts and metal needles connected on the surface of the transverse shafts; the discharge tank is arranged under the liquid storage tank and connected by a liquid discharge pipe. The beneficial effects of the invention are: the water-based paint can be fully stirred, and the bubbles can be broken through multi-stage filtration and vibration to achieve the purpose of elimination.

Owner:TIANJIN DONGDING TECH CO LTD

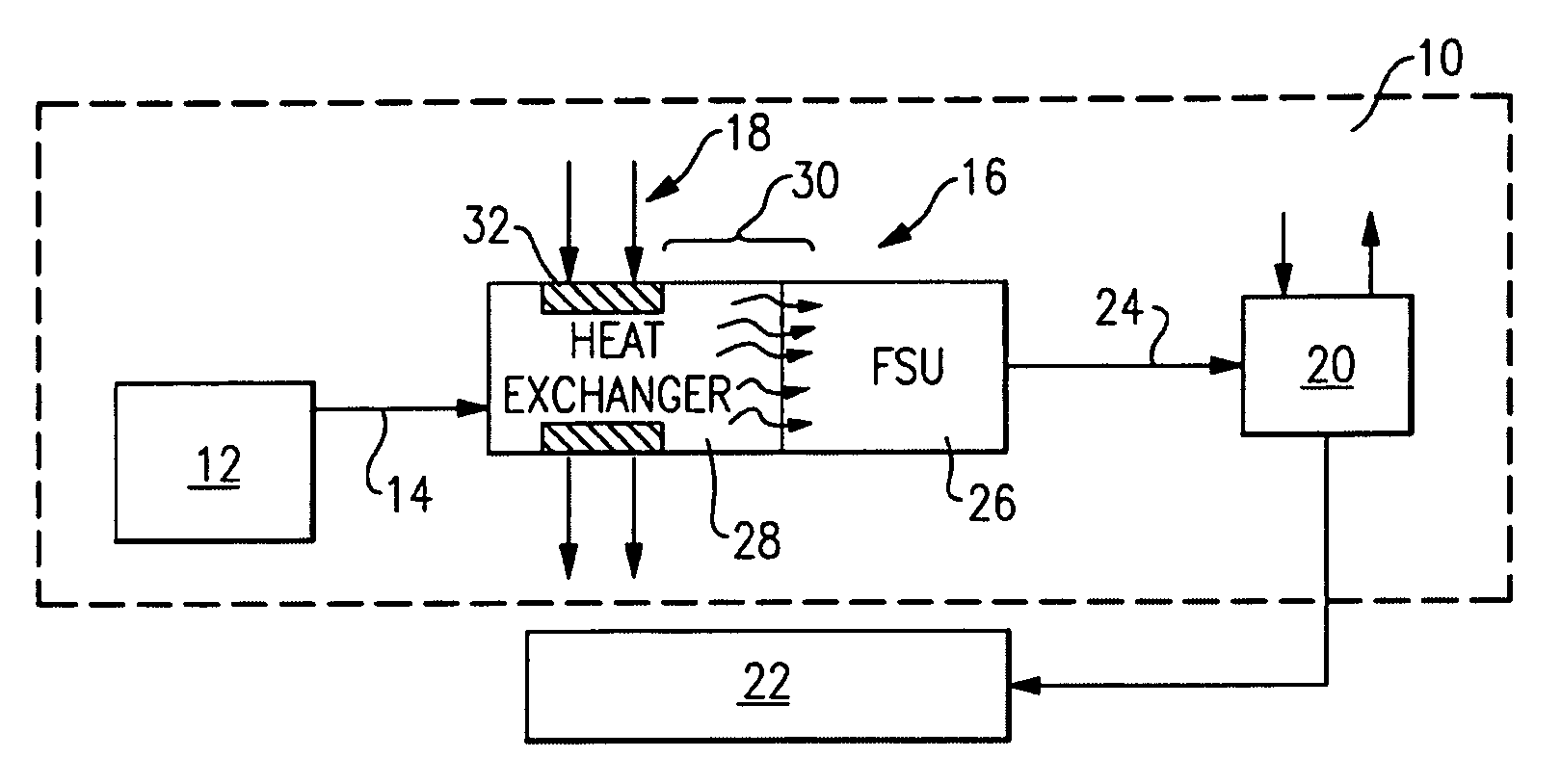

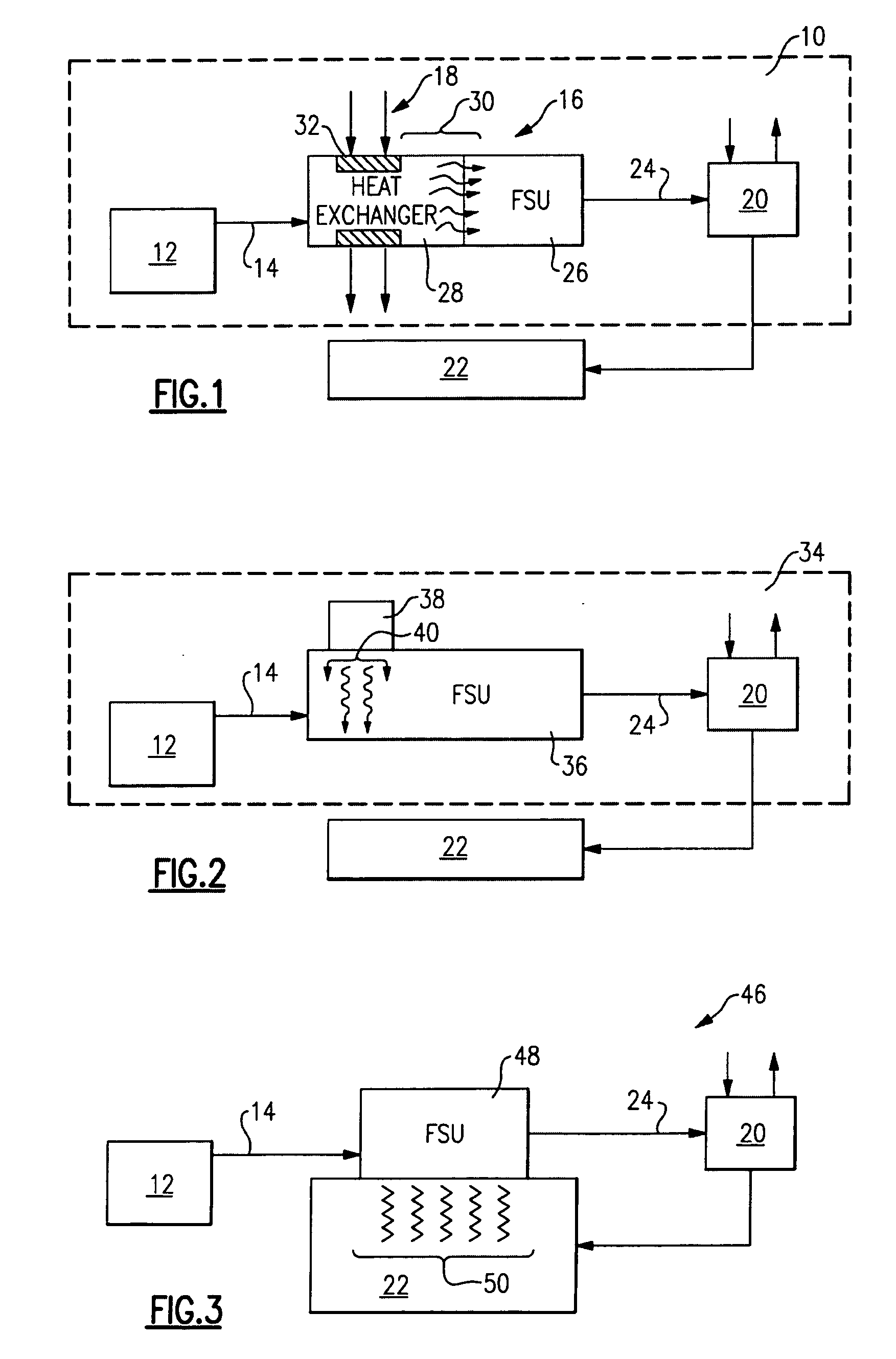

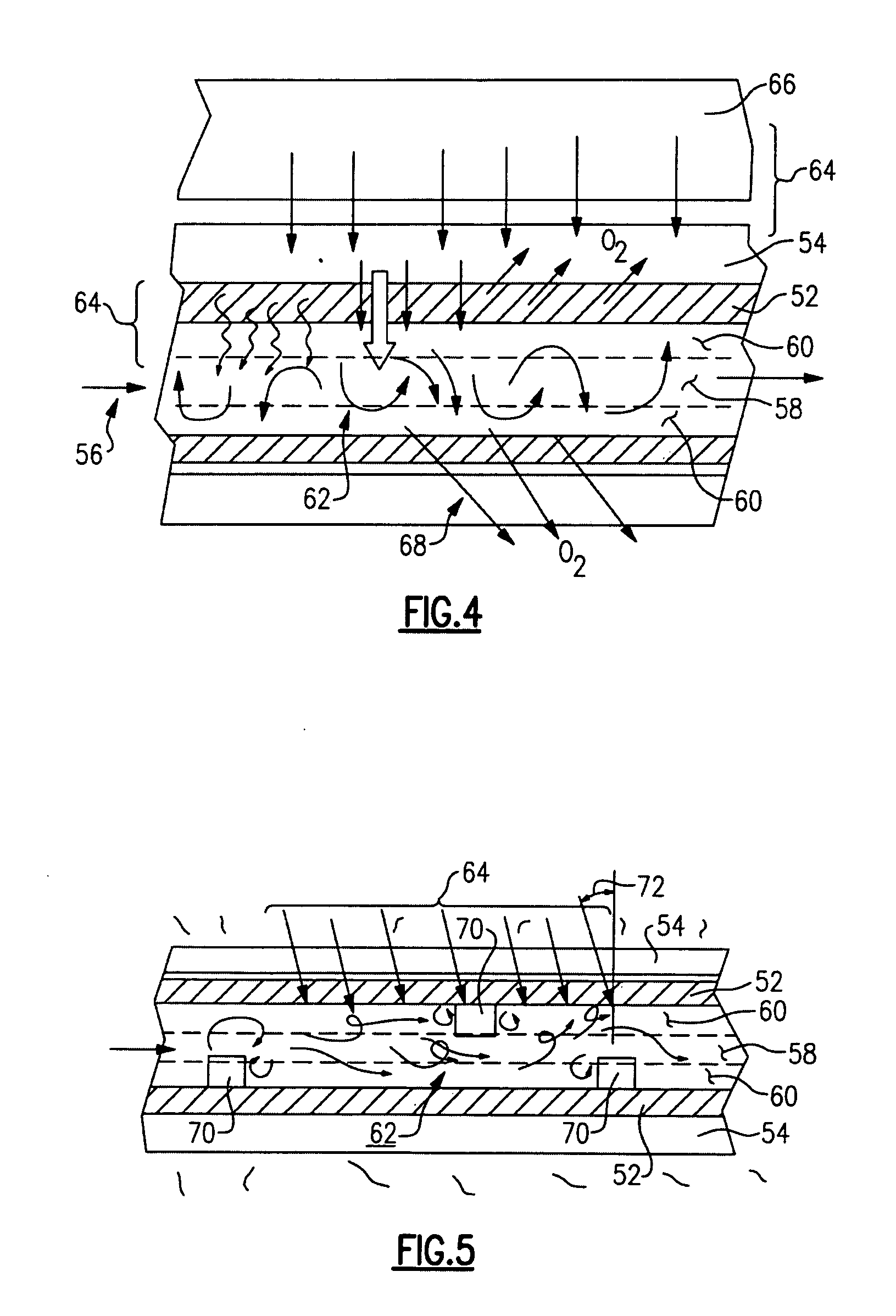

Process and Apparatus for In-line Degassing of a Heterogeneous Fluid using Acoustic Energy

InactiveUS20160199756A1Increase surface areaPerformance maximizationLiquid degasification with auxillary substancesLiquid degasification regulation/controlAcoustic energyEngineering

Owner:SAINT VINCENT STEPHEN

Arrangement and method for degassing small-high aspect ratio drilled holes prior to wet chemical processing

InactiveUS20020189637A1Electrostatic cleaningLiquid/solution decomposition chemical coatingChemical treatmentCopper plating

An arrangement and method for the degassing small high-aspect ratio drilled holes or vias which are present in panels such as printed circuit boards prior to wet chemical processing, including copper plating of the vias, in order to remove any air or gas bubbles from the vias tending to inhibit the reliable plating thereof This is carried out through the utilization of an ultrasonic prewetting in a liquid bath preceding cleaning for the electroless plating process, thereby enabling all of the vias or holes to be degassed; in effect, having air removed and the vias or holes filled with liquid; thereby allowing subsequent process cleansing solutions to easily flow into the respective holes or vias in order to facilitate the electroless copper plating process.

Owner:GOOGLE LLC

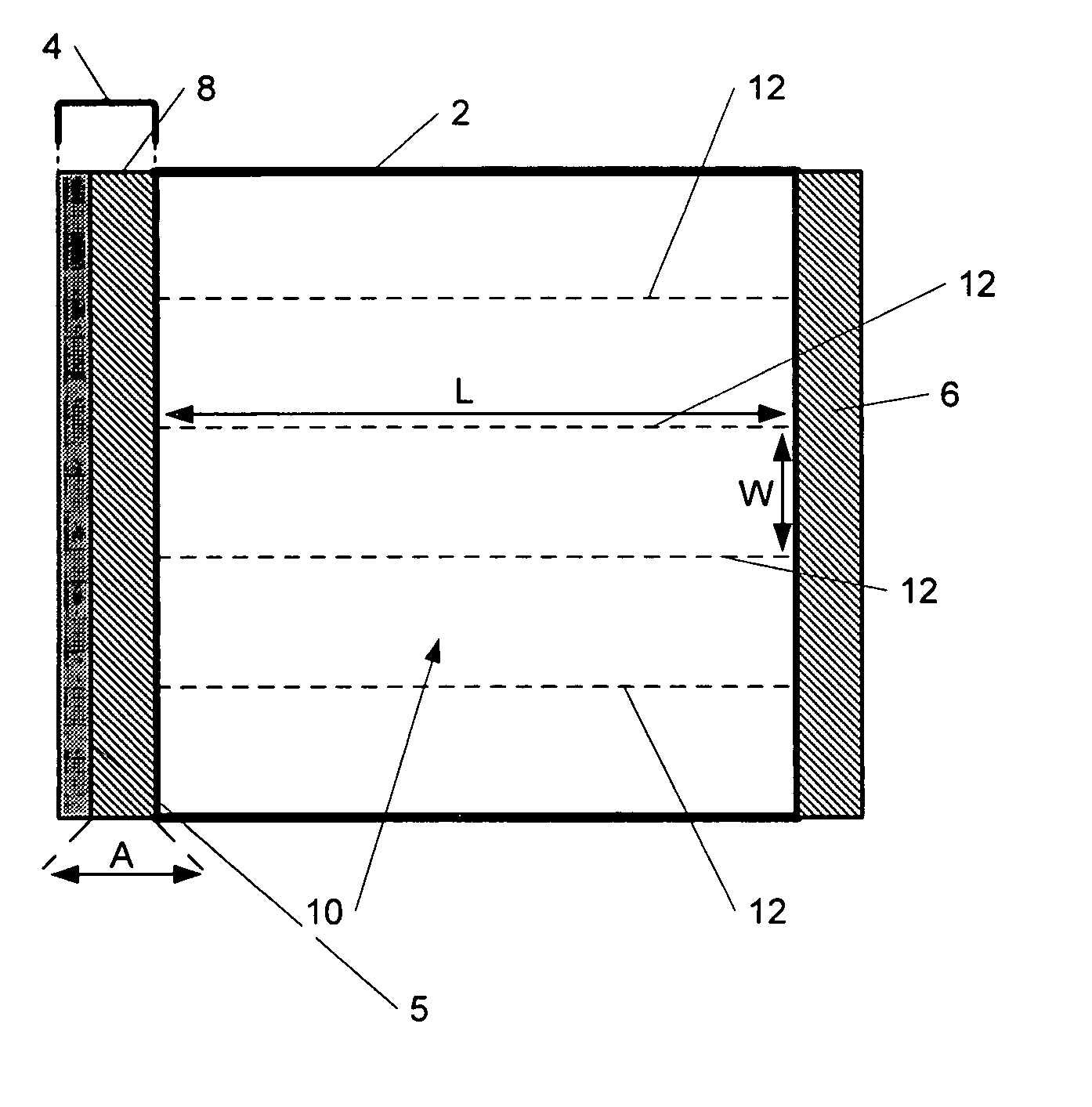

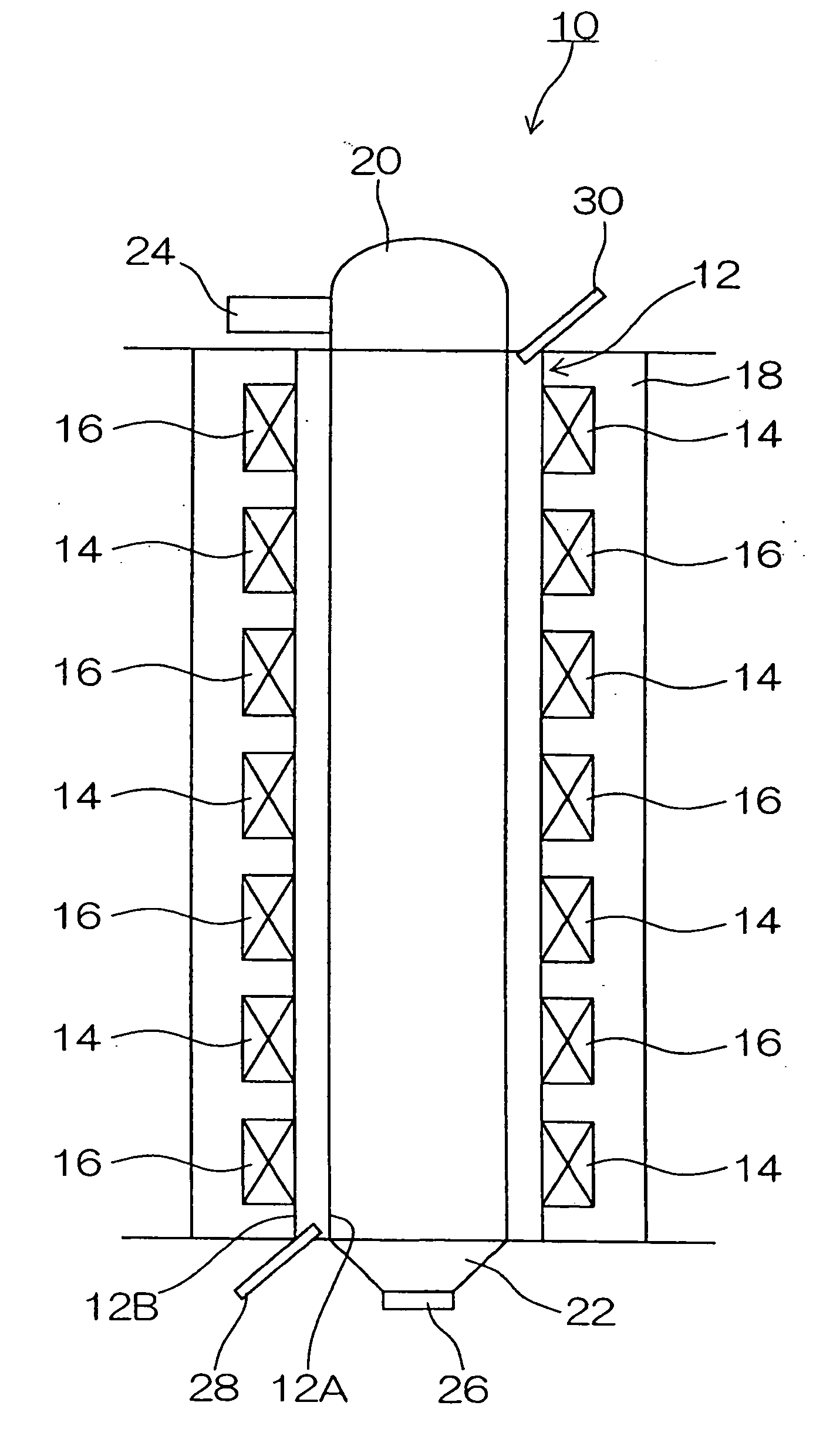

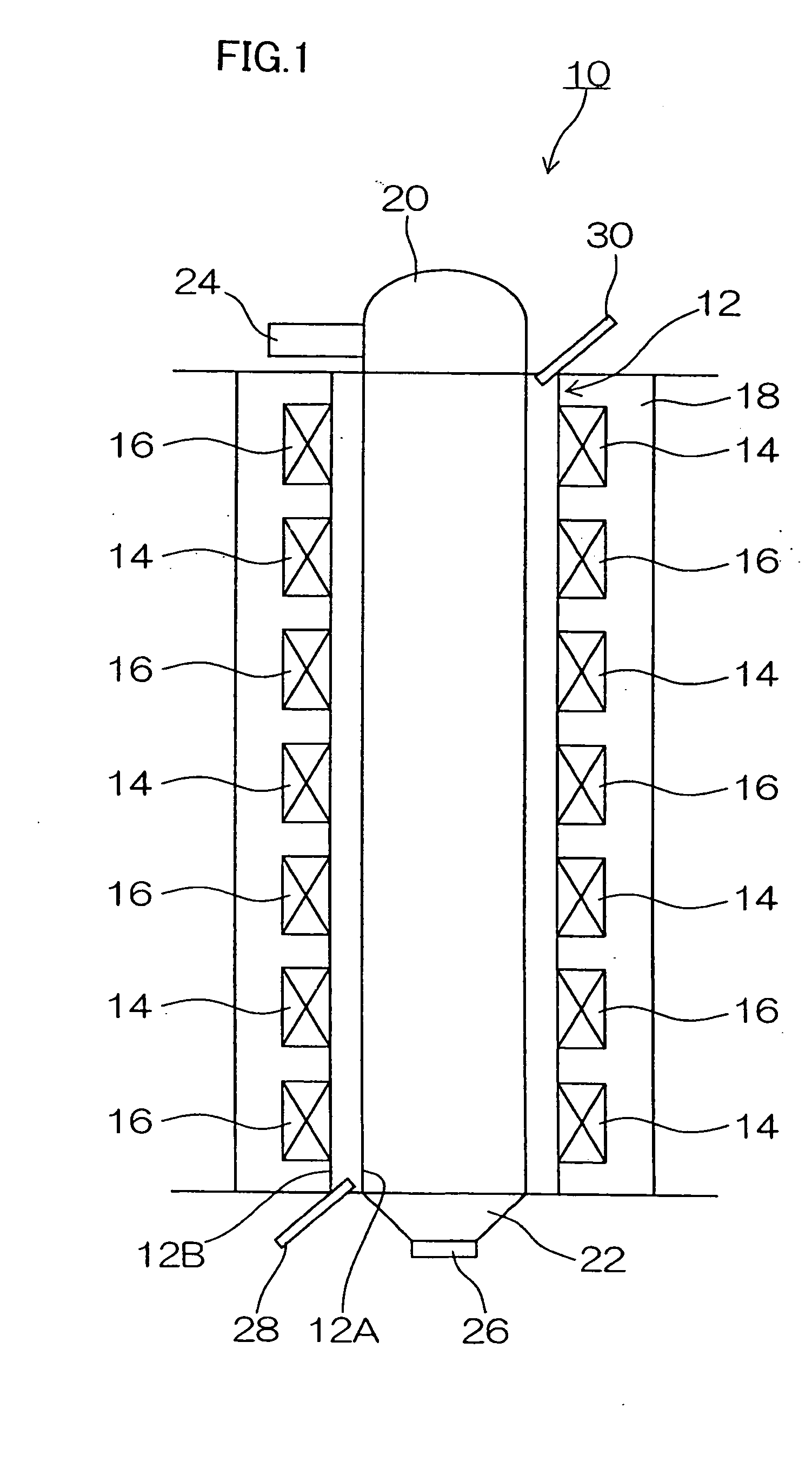

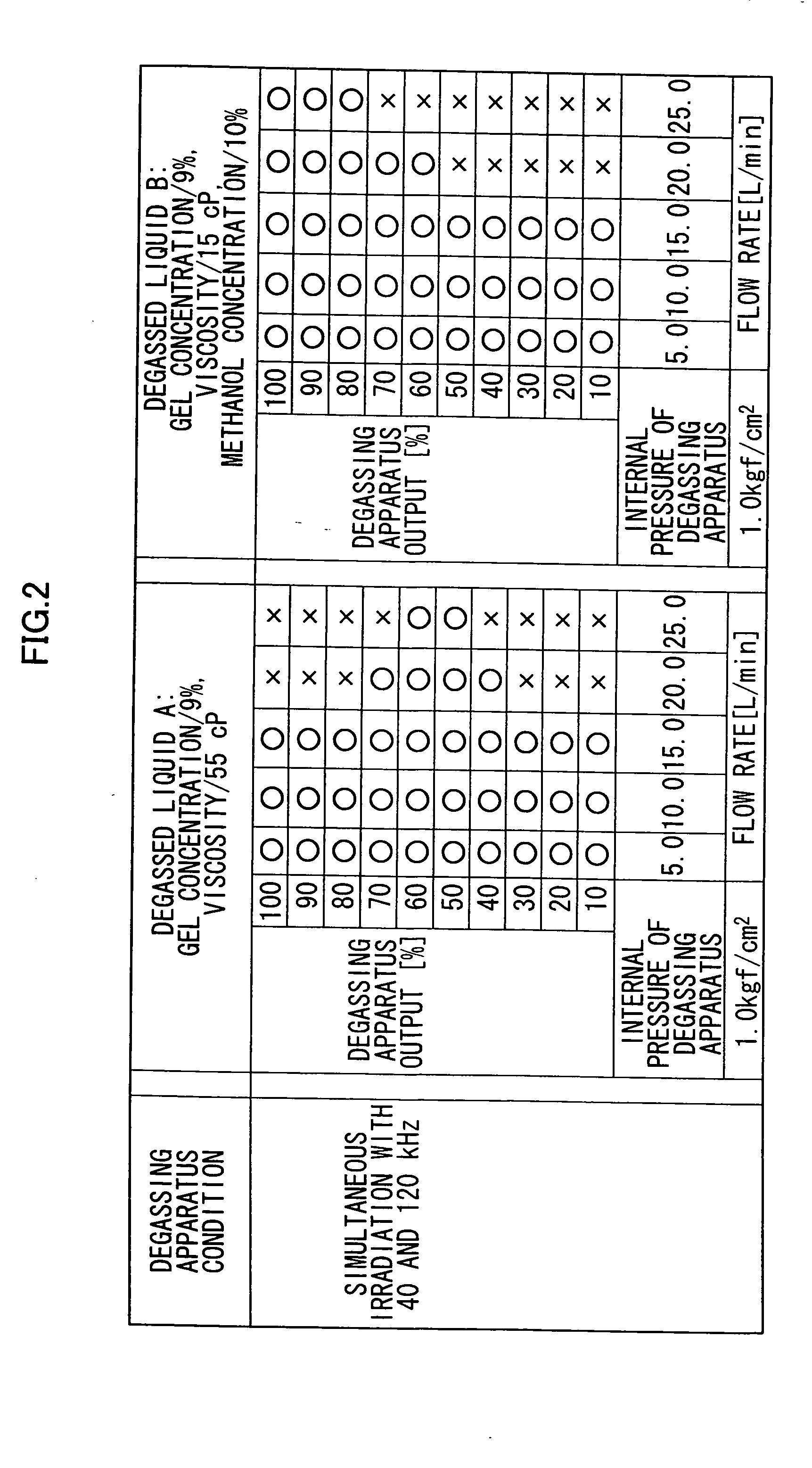

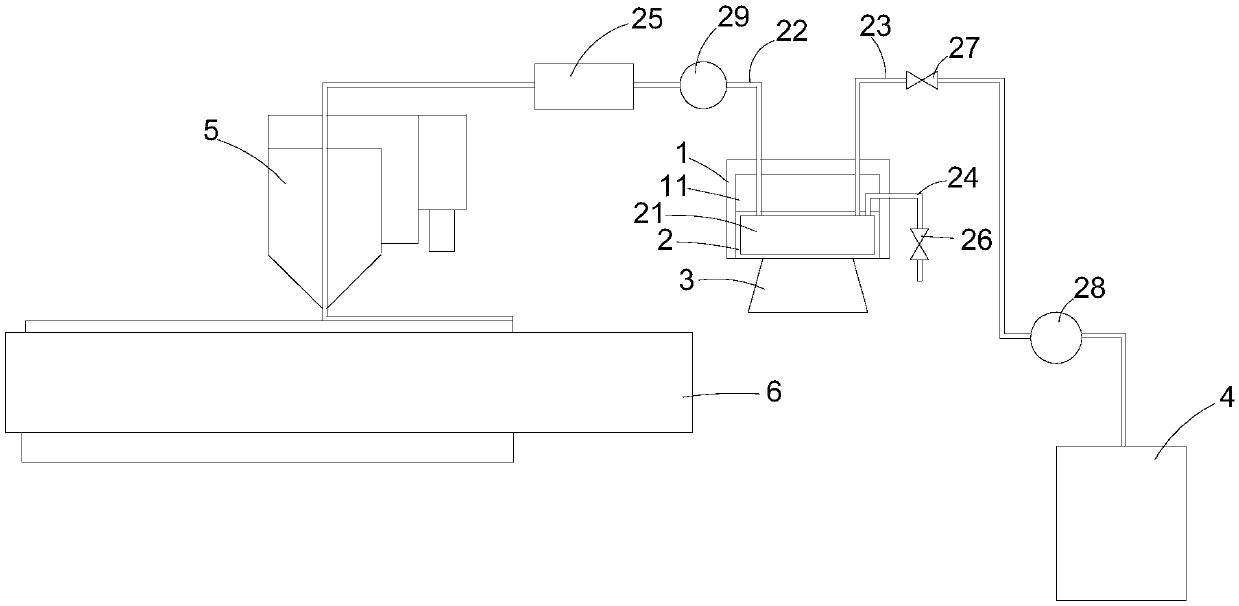

Method and apparatus for degassing coating liquid

ActiveUS20050115405A1Preventing bubble defectsEfficient removalPretreated surfacesPhotothermographic systemsMaterials scienceFrequency band

Owner:FUJIFILM CORP +1

Solution bubble removal device and coating machine

InactiveCN107754381AImprove efficiencyStable ratioLiquid surface applicatorsLiquid degasification regulation/controlEngineeringExhaust pipe

The invention provides a bubble removal device for a polyimide solution. The device comprises a first tank, a second tank and an ultrasonic generator, wherein the second tank is arranged in the firsttank; the ultrasonic generator is arranged on the first tank; the volume of the second tank is smaller than that of the first tank; a first containing chamber and a second containing chamber which arenot connected with each other are respectively formed in the first tank and the second tank; the first containing chamber is filled with water; the second containing chamber is filled with a solution; and a liquid outlet pipe, a liquid inlet pipe and an exhaust pipe communicated with the second containing chamber are respectively arranged on the second tank. The invention further provides a coating machine. The coating machine comprises the bubble removal device for the polyimide solution, wherein the liquid outlet pipe is connected with a solution pipeline of a coating nozzle; and the liquidinlet pipe is connected with a storage tank. Compared with the prior art, the bubble removal device for the polyimide solution is capable of removing bubbles in the polyimide solution, so that the bubble removal time can be shortened, and time needed by the process is greatly reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

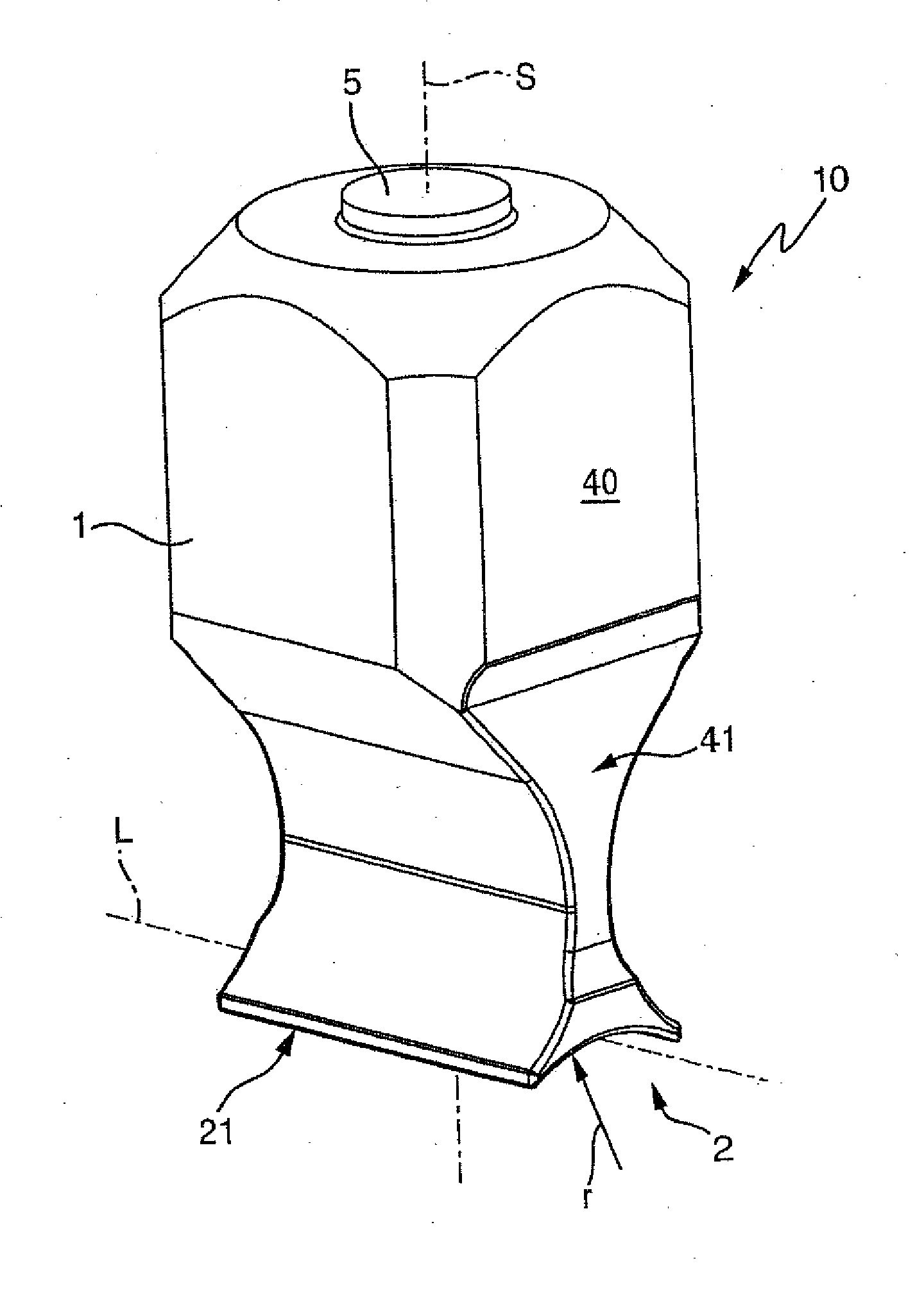

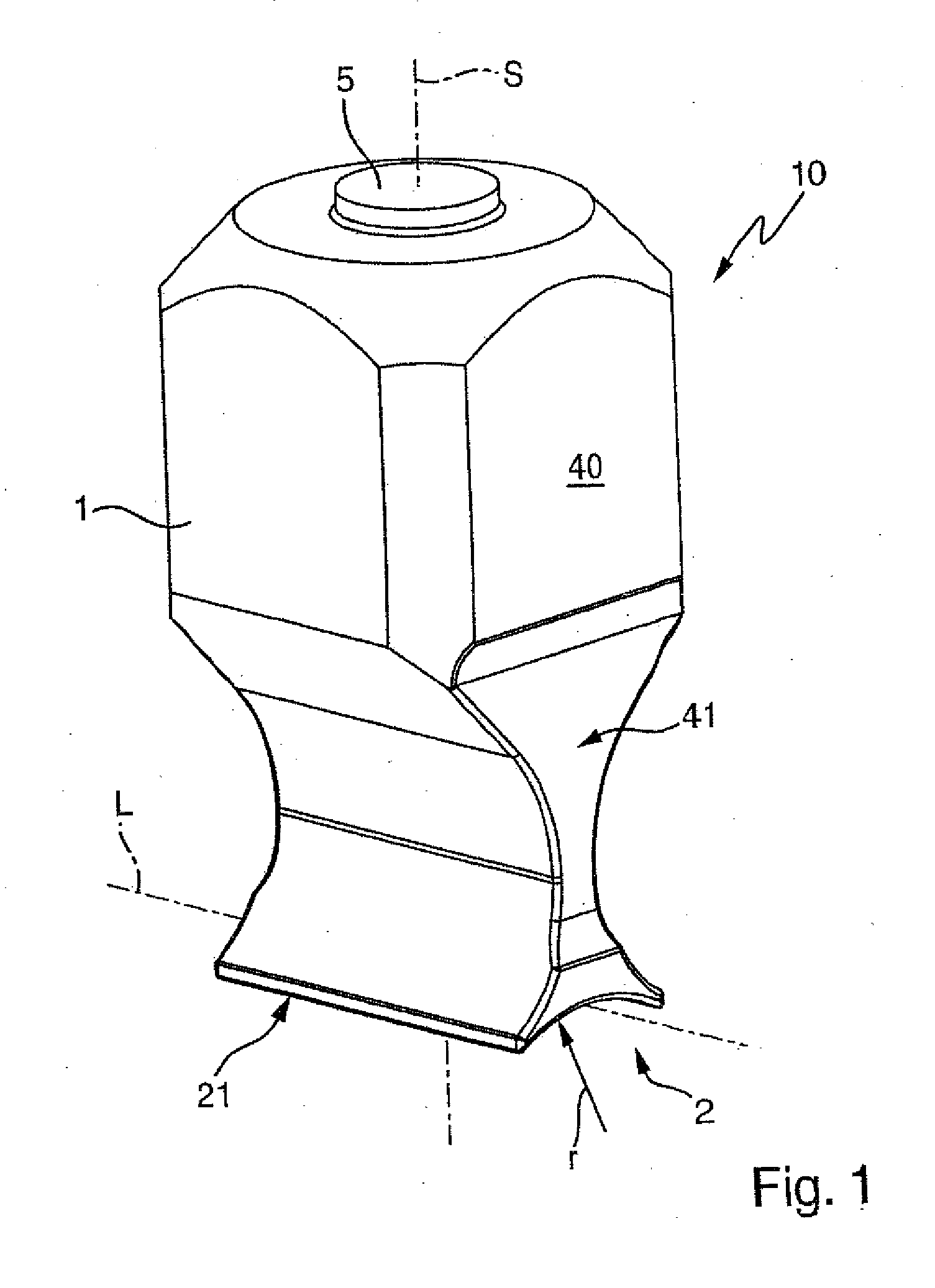

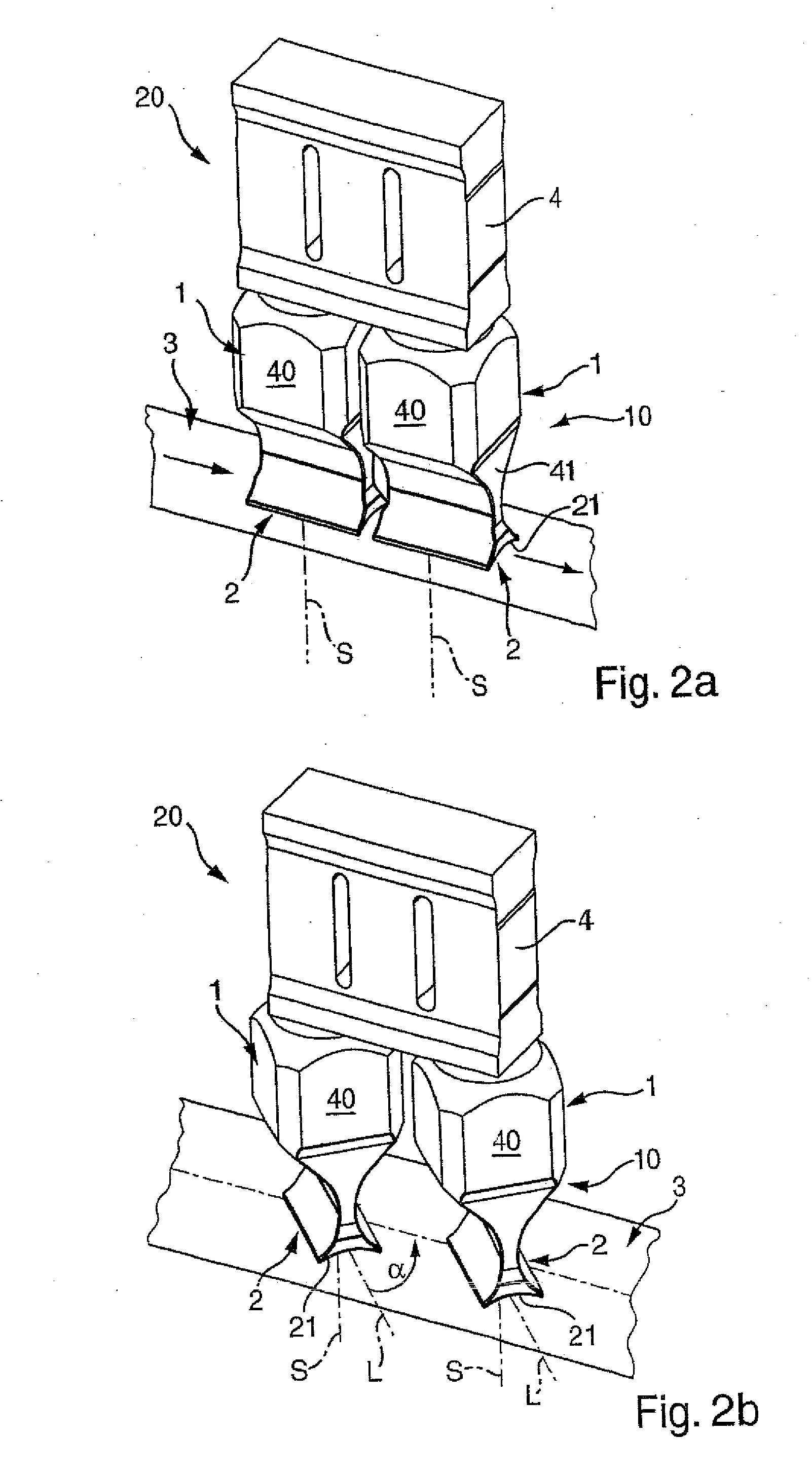

Sonotrode and device for reducing and eliminating foaming of liquid products

ActiveUS20140000460A1Good effectIncrease the curvatureMechanical vibrations separationLiquid degasification by vibrationLiquid productWave field

A Sonotrode for generating an ultrasonic field in industrial production processes such as chemical, food, petroleum, pharmaceutical, beverage or mining-related processes for reducing and eliminating foaming of liquid products has a compact one-piece form, wherein the sonotrode is provided with a main body part having a connector for connection with a high frequency generator and having a front face from which the ultrasonic field is directed to the desired spot or area of the product to be de-foamed, wherein the main body part has the shape of a compact block element and in that the front face is concave in shape in relation to a product surface such that the ultrasonic field is focused and directed to a specific area of a product foam to be treated in a concentrated form compared to a non-focused ultrasound.

Owner:CAVITUS SOLUTIONS +1

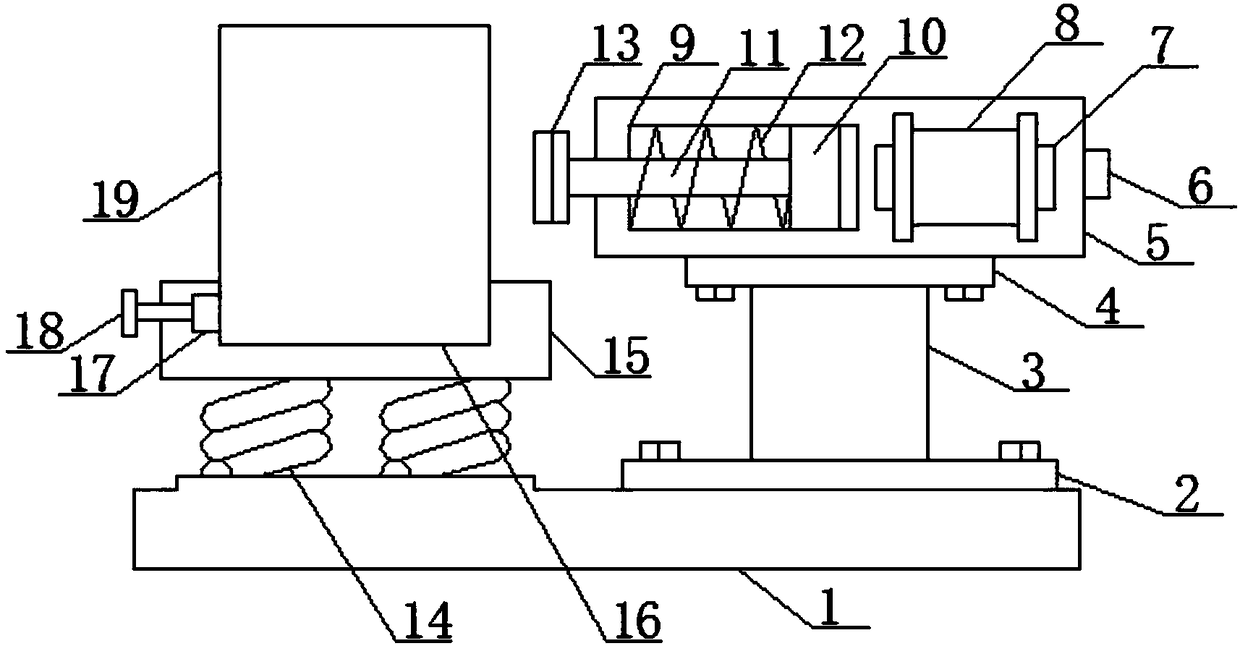

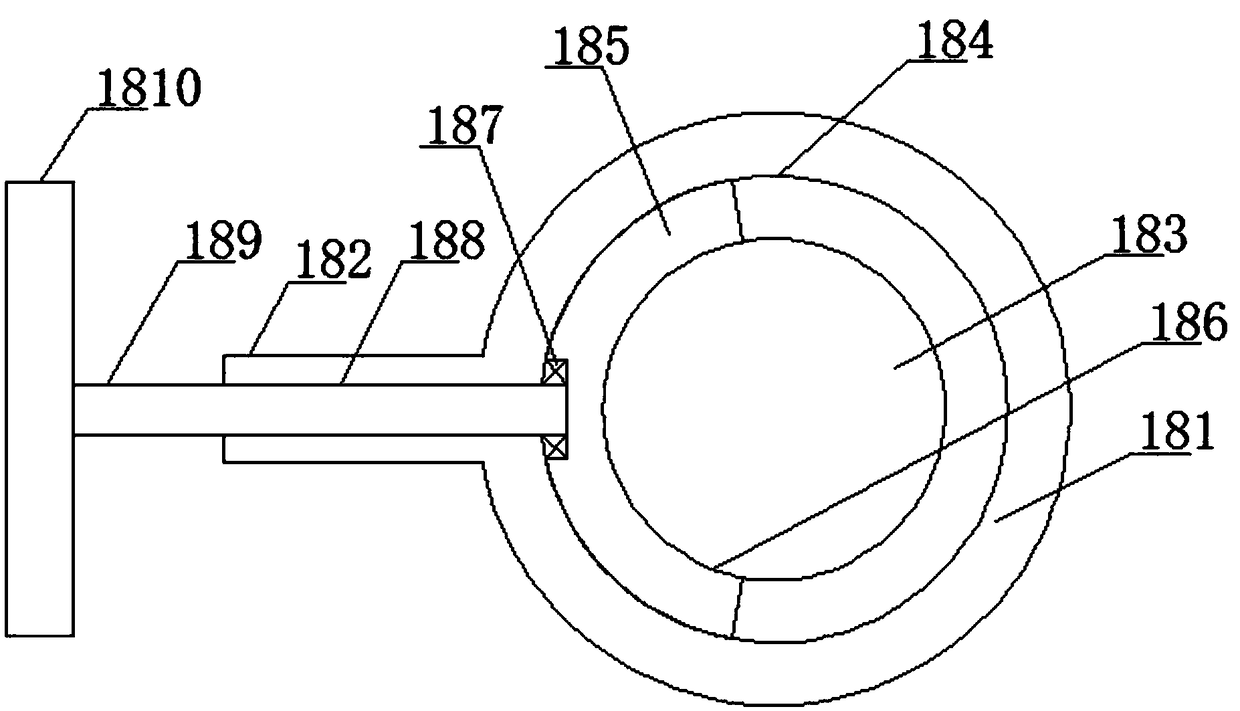

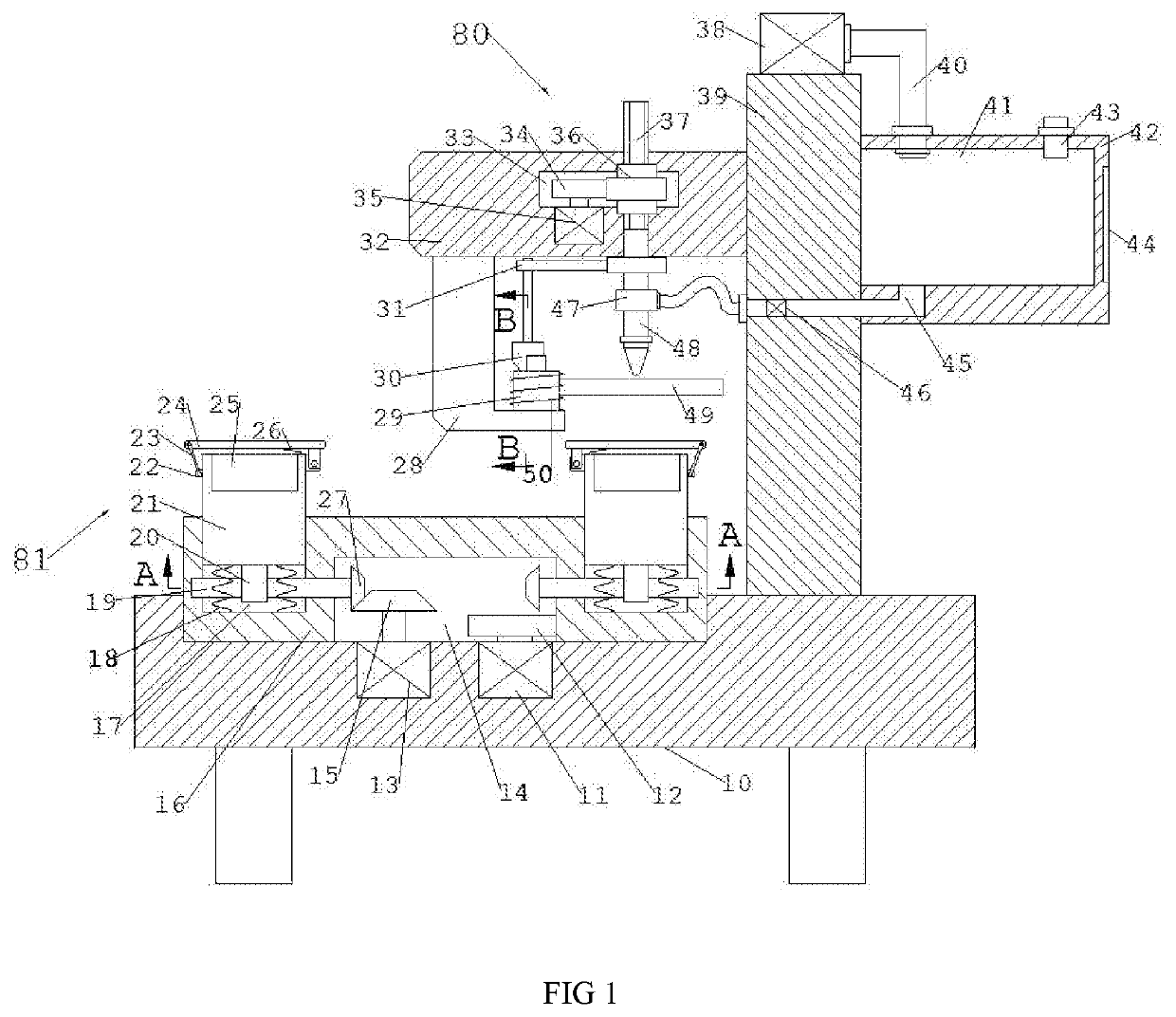

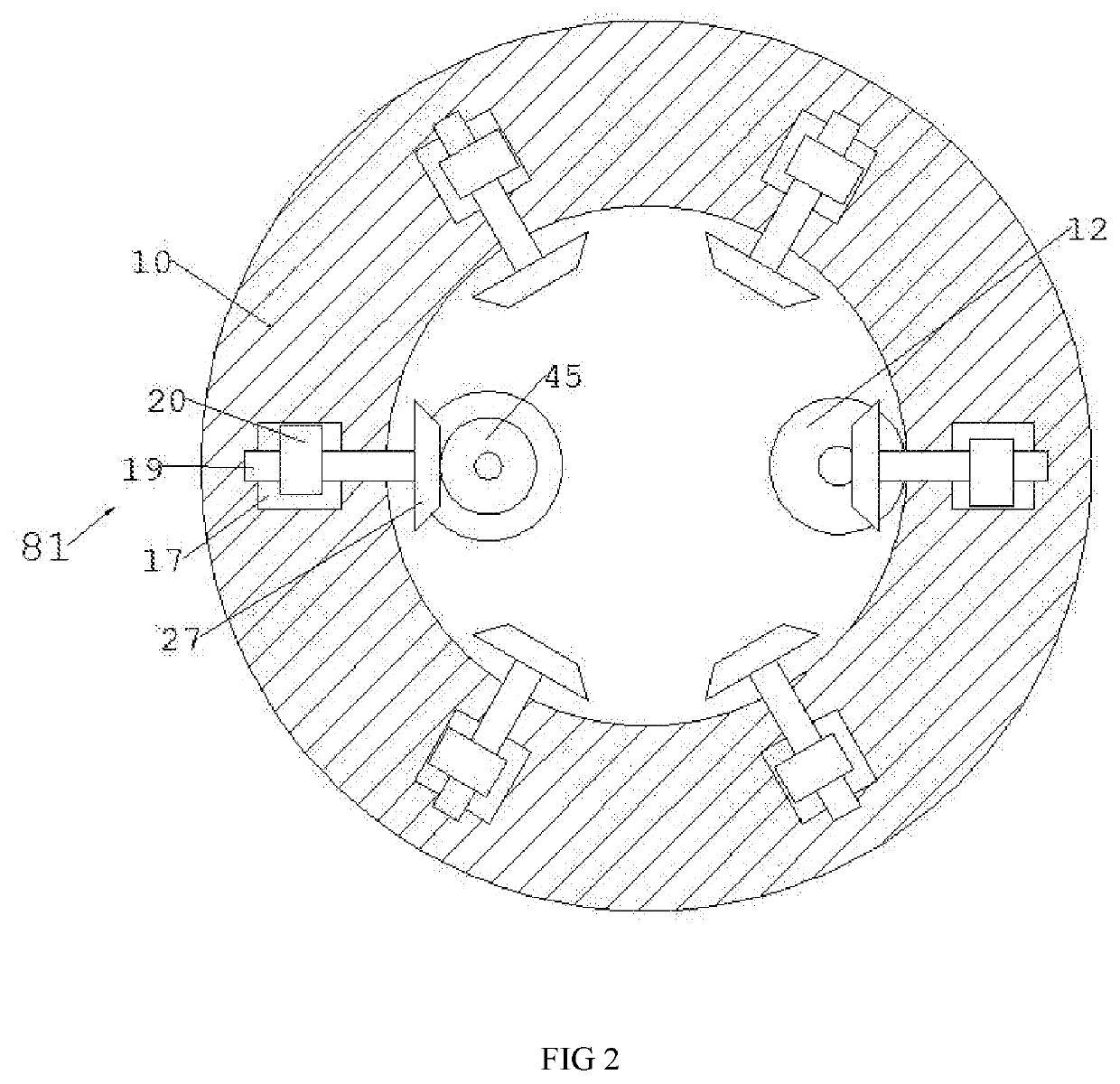

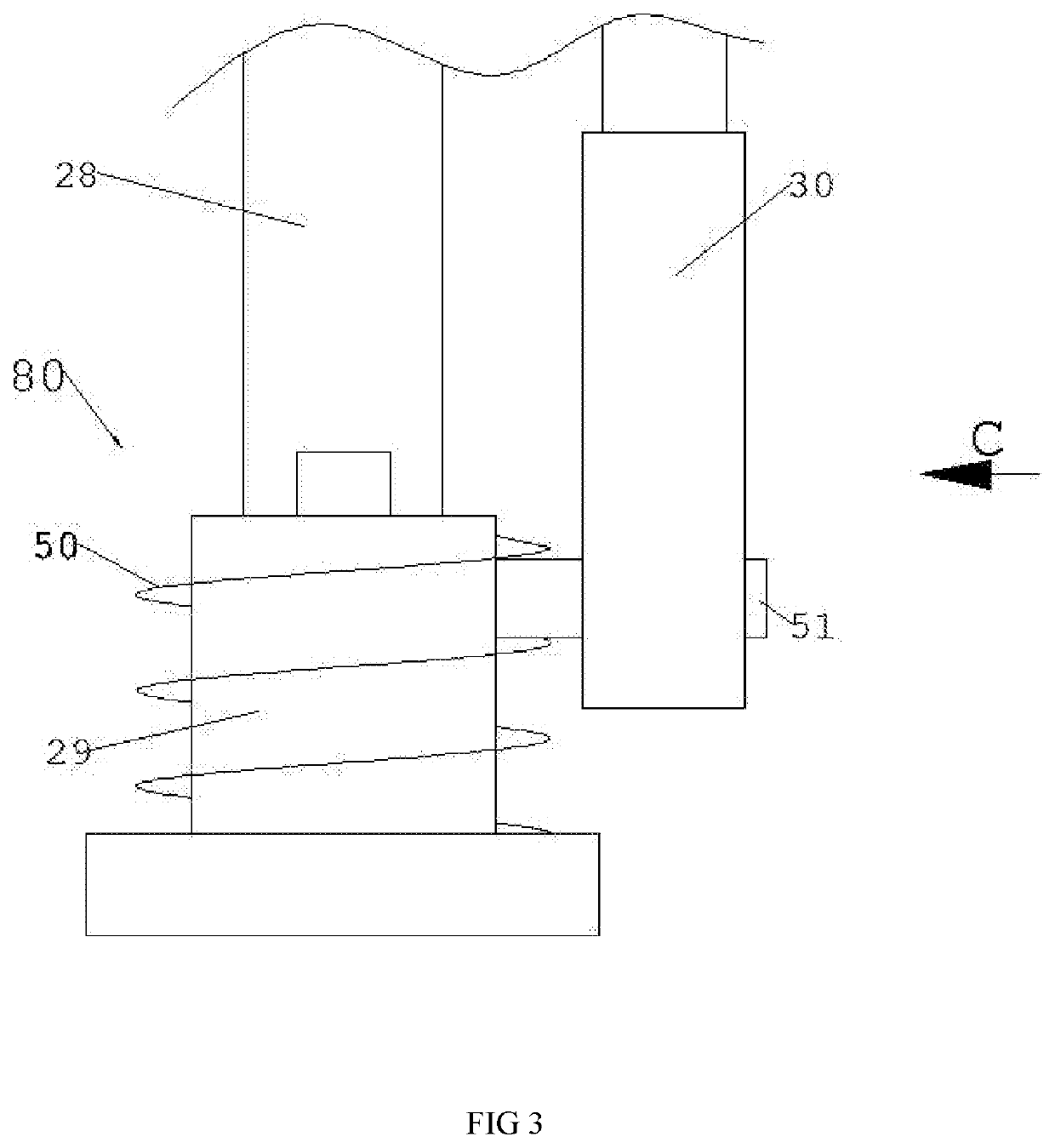

Bubble-removing device for strong adhesive liquid

InactiveCN108579136AHarm reductionQuality improvementLiquid degasification by vibrationMagnetic polesCoil spring

The invention discloses a bubble-removing device for a strong adhesive liquid. The device comprises a bottom supporting substrate; and a bottom connecting plate is fixed on one side of the upper surface of the bottom supporting substrate by bolts. By utilizing the vibration principle, the device effectively reduces the harm caused by bubbles to raw materials, enhances the quality of finished products after the orientation of the raw materials, and is strong in vibration effect; in addition, the device is equipped with an electromagnetic driven driving mechanism which utilizes the acting forcebetween electromagnetic magnetic poles to realize the driving action of an instantaneous power source, and has the characteristics of strong instantaneity and obvious driving effect; moreover, the device is equipped with an annular bottom thread control positioning mechanism which can fix the installation of equipment for storing liquid raw materials, thereby preventing the occurrence of the tilting of components caused by impact; in addition, the device is equipped with a liquid raw material storage shocking vibration mechanism which can convert the impact from the outside into a vibration effect under the action of a plurality of coil springs, thereby realizing the effect of vibration and bubble removal.

Owner:郭三婷

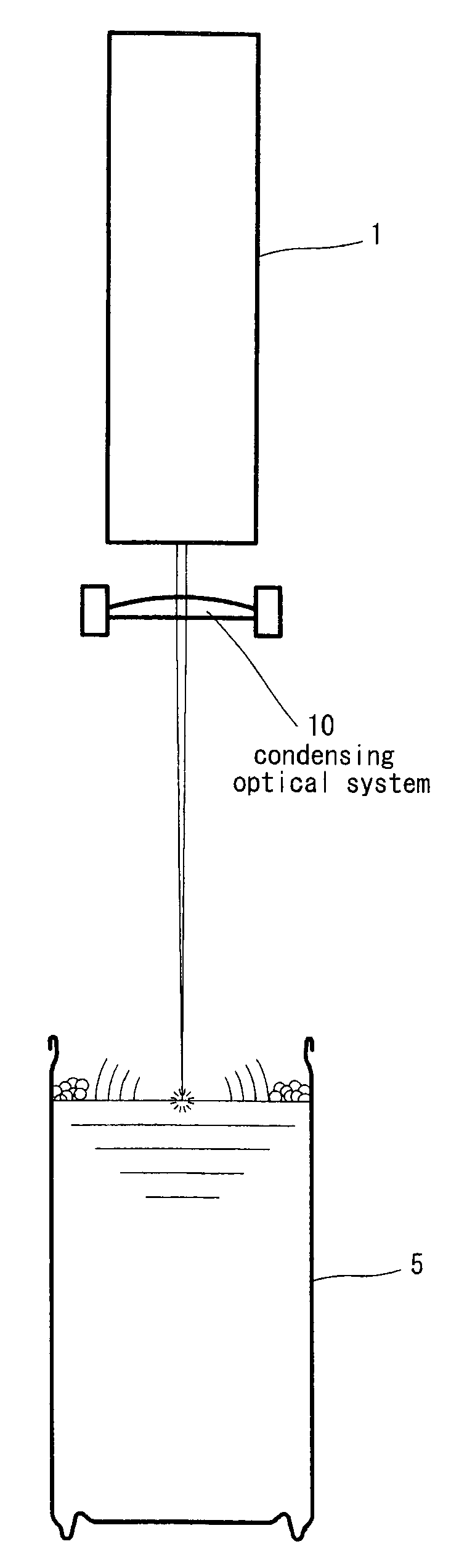

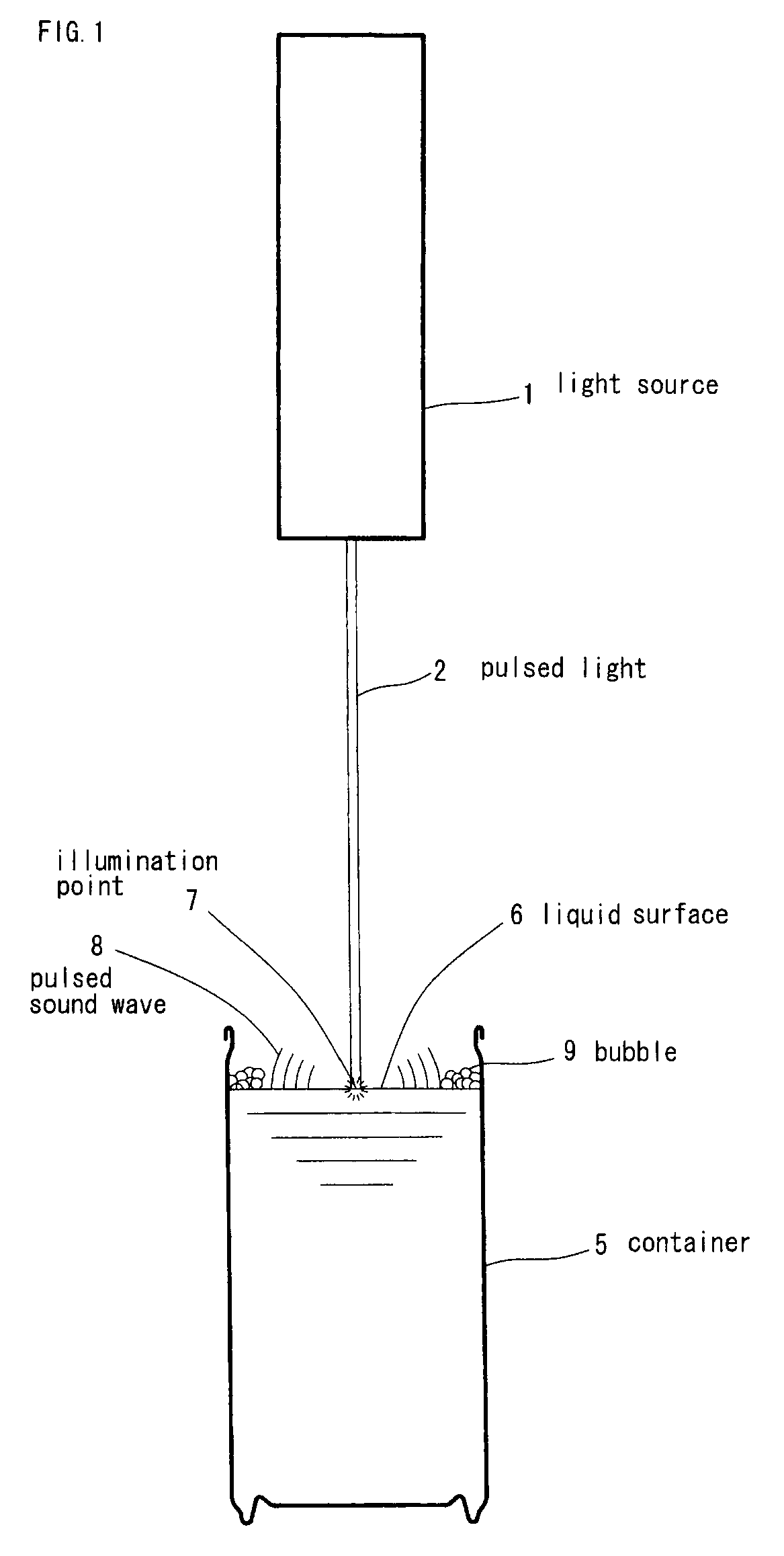

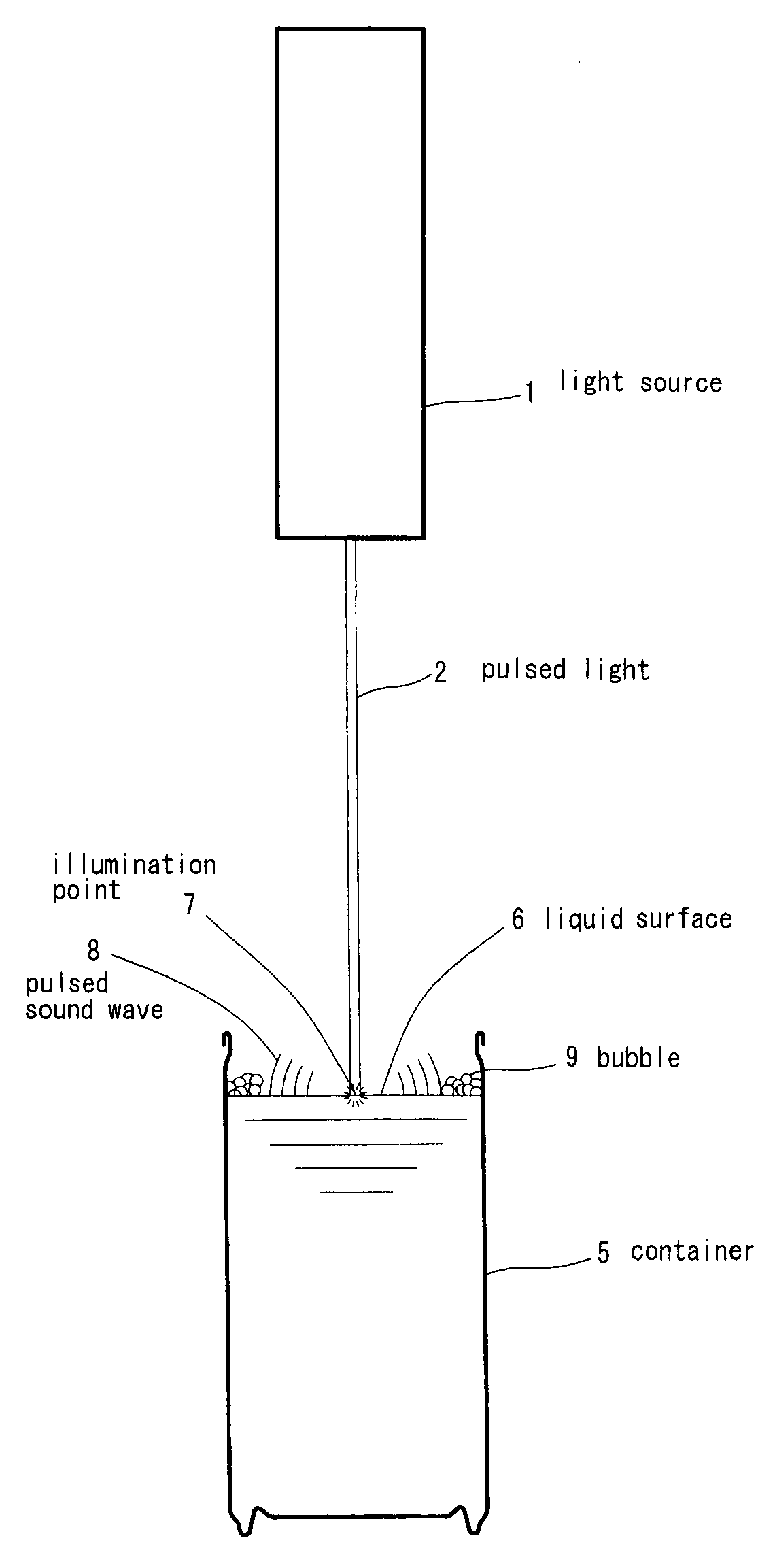

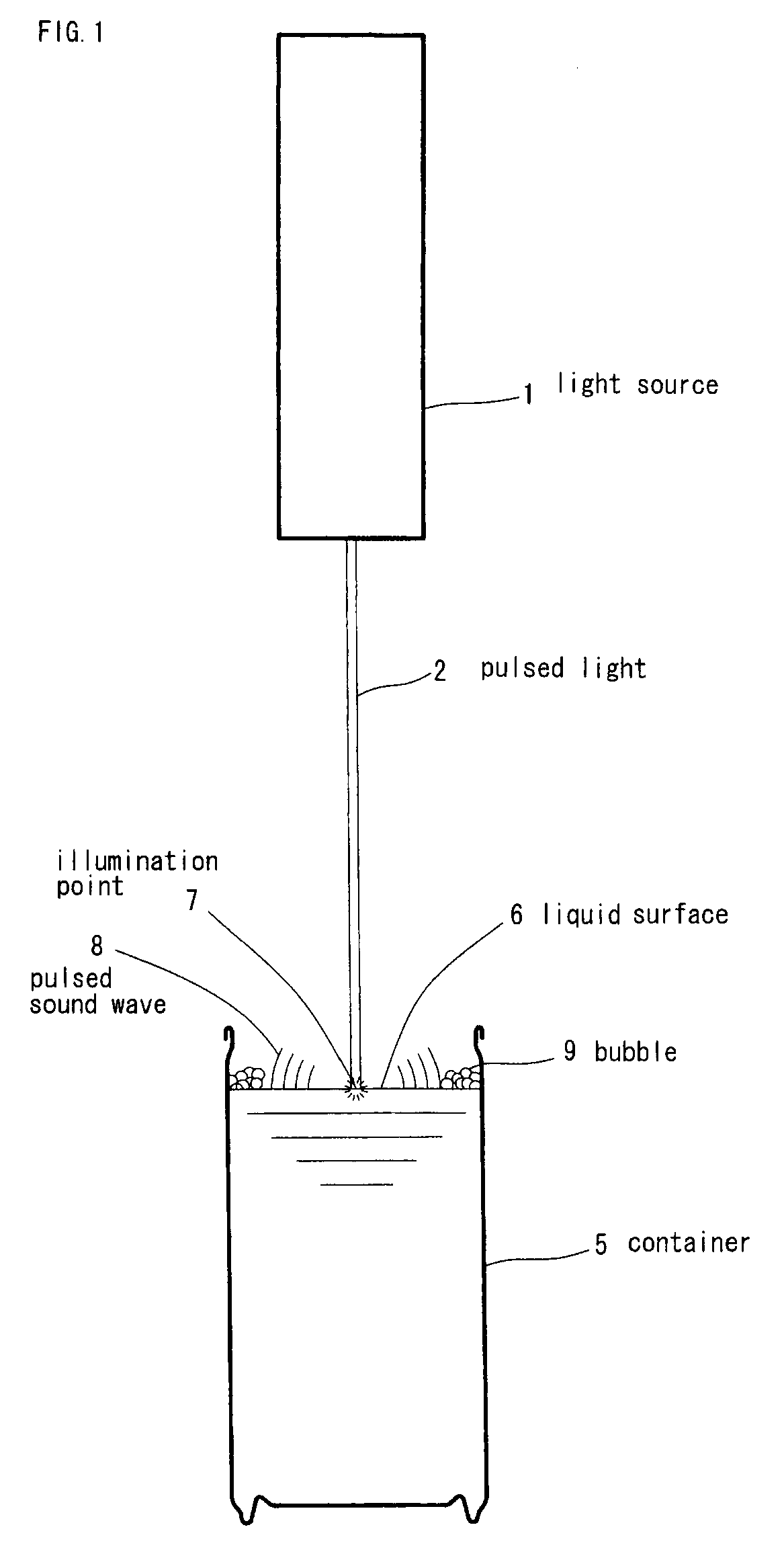

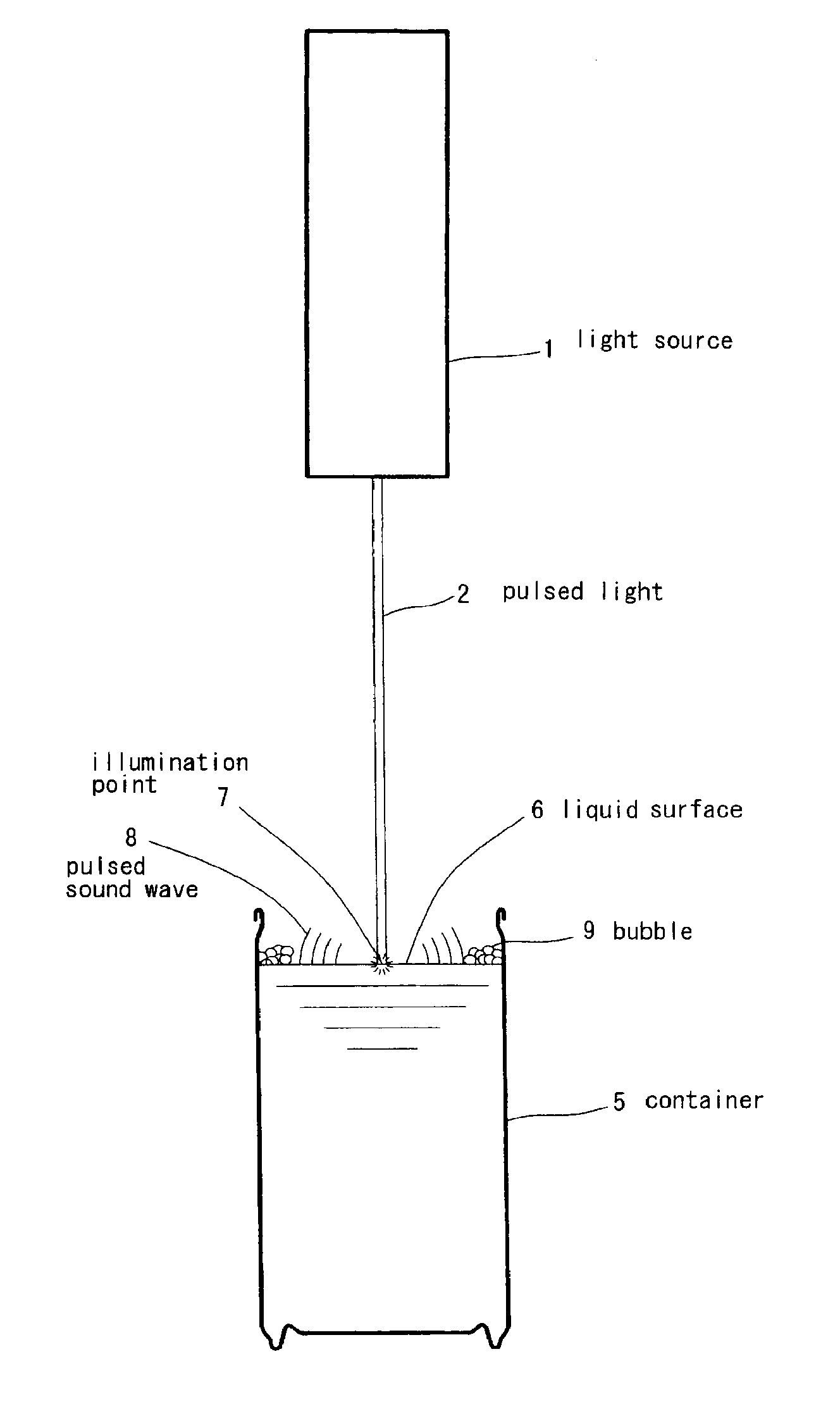

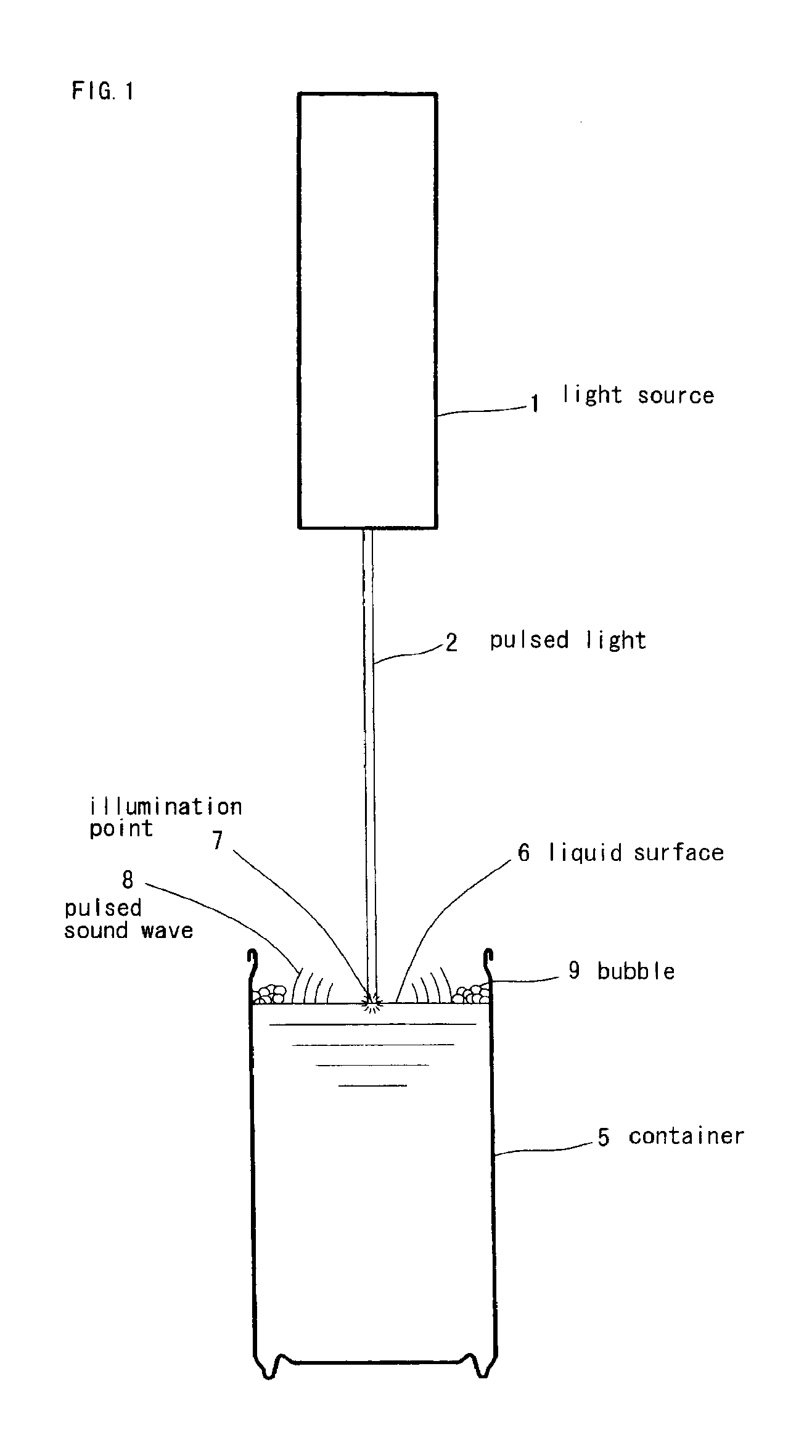

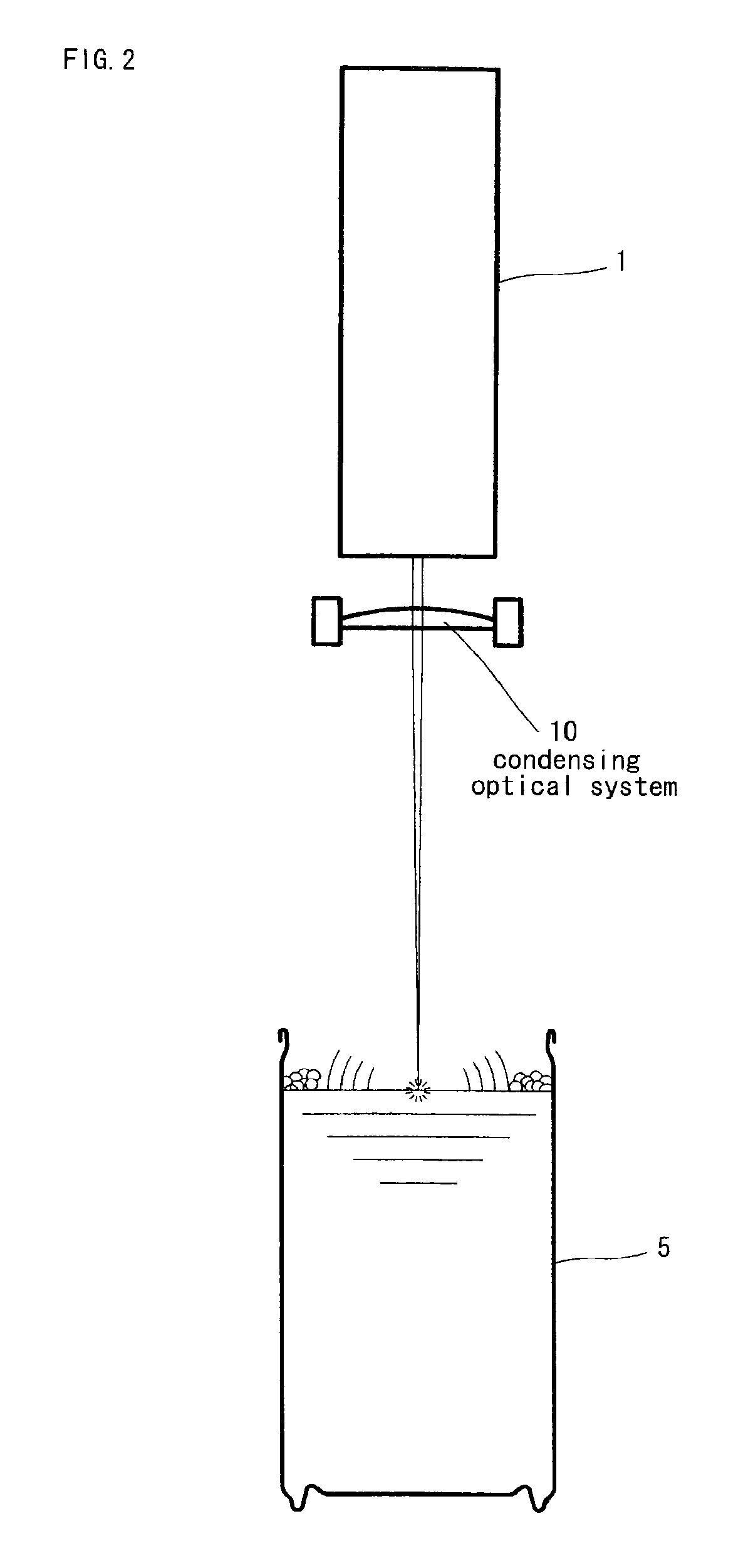

Defoaming method

ActiveUS20090020412A1Short timeDestroy bubbleTea extractionPackaging under special atmospheric conditionsShock waveSound sources

A defoaming method capable of destroying foams generated when a container is filled with drink, or the like, efficiently at a high speed and destroying foams effectively even in the case of a container having a narrow mouth. Liquid surface (6) in a container (1) is irradiated with pulse-like light (2) and a pulse-like sound wave (8) is generated from an irradiated point (7) as a sound source. The pulse-like sound wave thus generated propagates from the sound source as a strong spherical wave to reach a bubble (9) and to destroy the bubble. It can also destroy a bubble located at a place remote from the optical path quickly, thus destroying bubbles efficiently at a high speed. Alternatively, pulse-like light is condensed at a gas portion above the liquid surface and the bubbles can be destroyed with a shock wave generated by breakdown phenomenon.

Owner:TOYO SEIKAN KAISHA LTD

Electromagnetic coil dispenser for improving waterproof performance

InactiveUS20200179975A1Improve dispensing efficiencyImprove coiling qualityLiquid surface applicatorsSpraying apparatusGear wheelElectric machine

The present invention discloses a method for improving the solenoid dispensing water resistance, comprising a base, said base top surface of the fixed mounting support column slidably mounted threaded rod of the boom, the bottom of the threaded rod fixedly mounted may coil for dispensing of the dispensing head, when the dispensing start lifting the motor, the lifting motor drives a first gear, a first gear rotatably drives the second gear, the second gear rotates the threaded rod may be down to the coil dispensing improved dispensing manner, increasing the efficiency of dispensing can be generated after a significant reduction dispensing bubbles, to improve the quality of the coil, glue extrusion by pressurizing the way, bubbles in the glue are deposited After the dispensing is completed, use the vibration method to shake the air bubbles in the coil to make the coil have better quality.

Owner:LIAN JINWEI

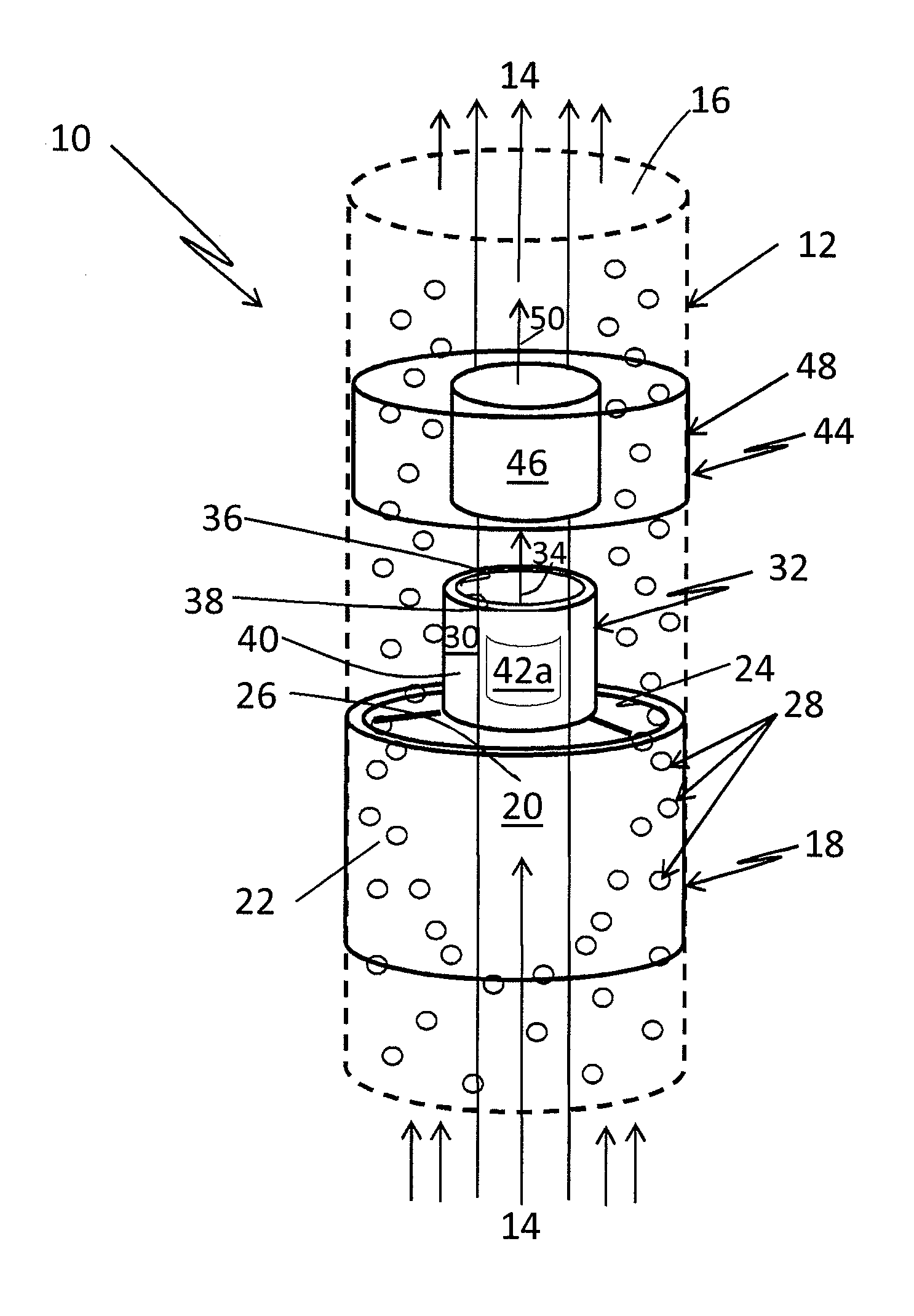

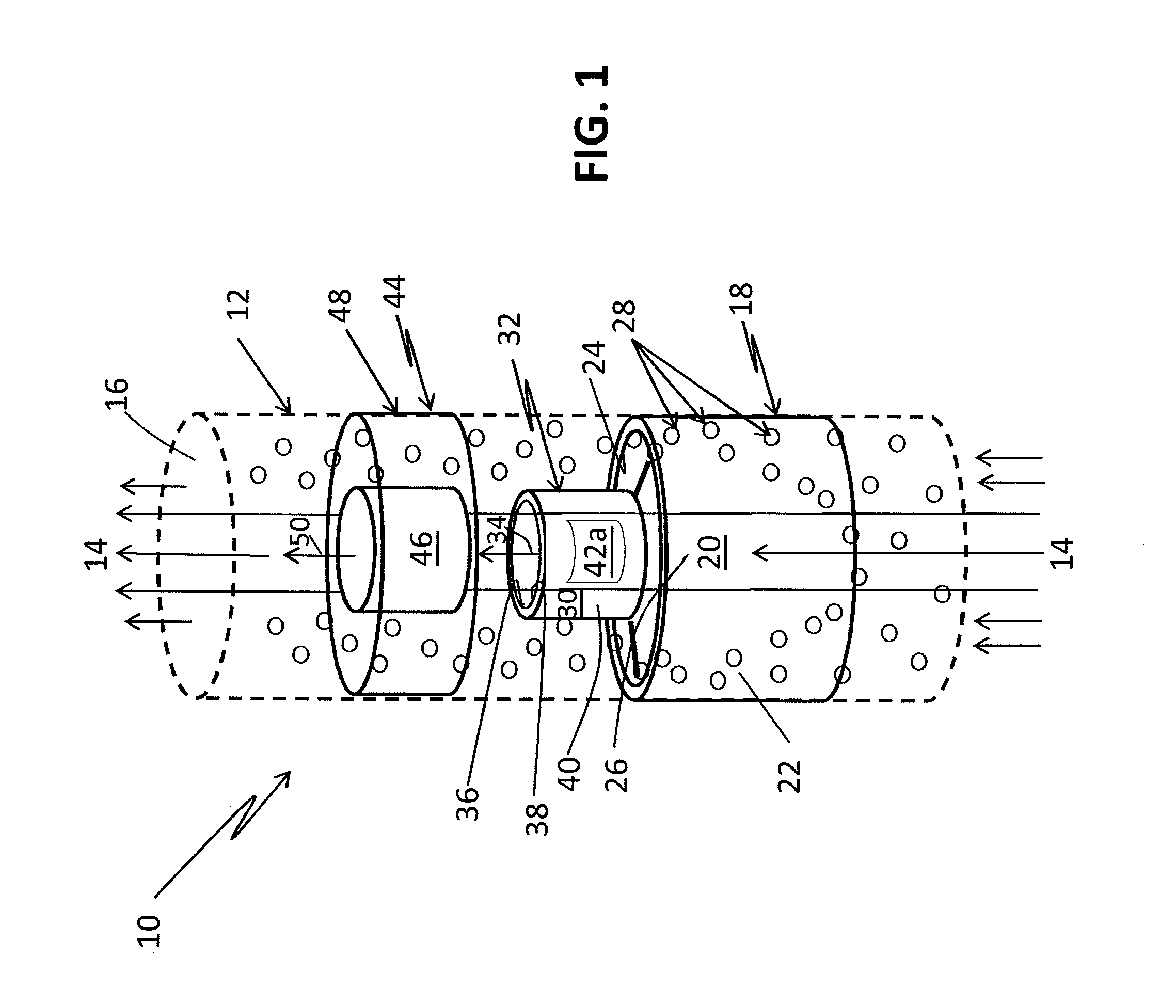

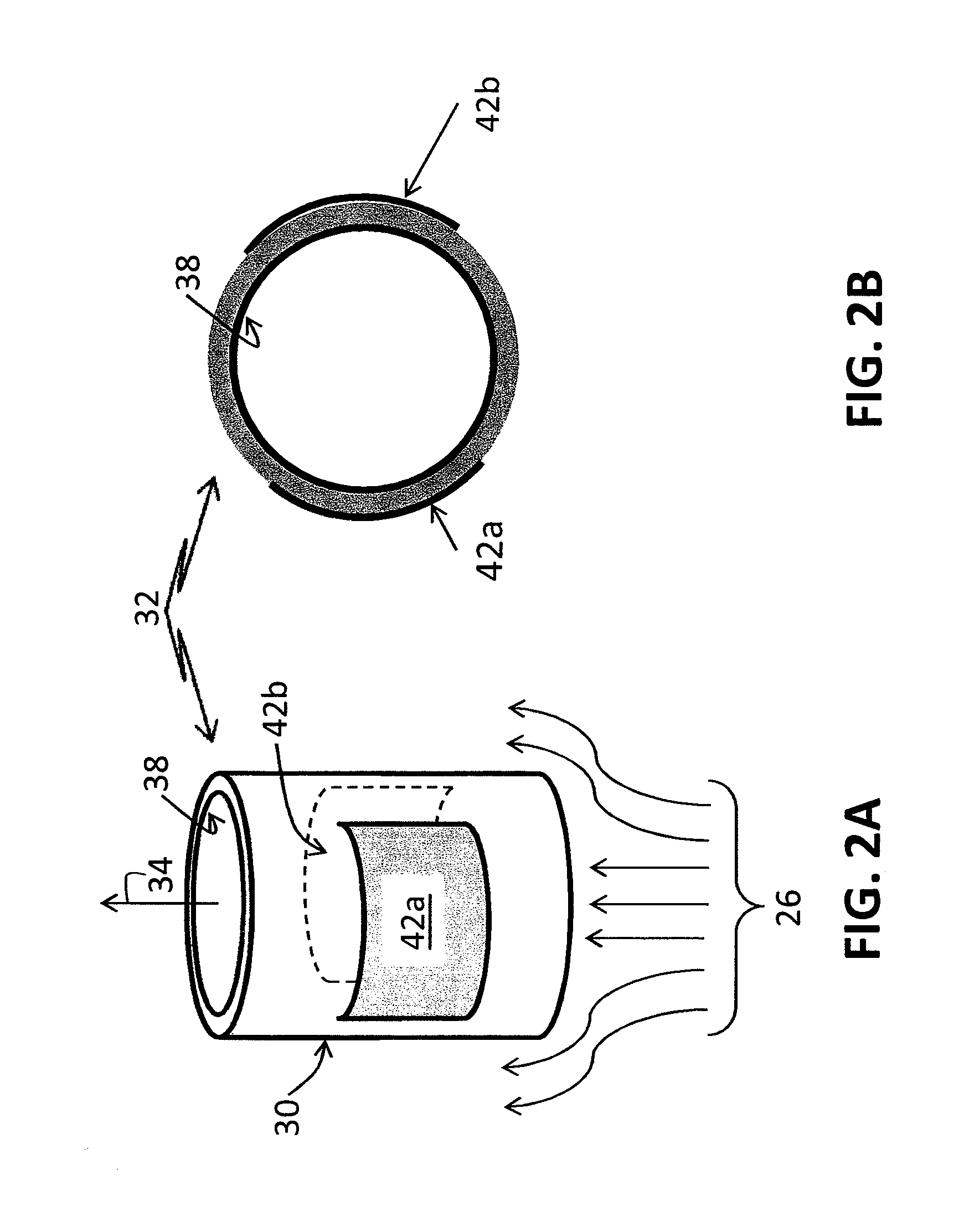

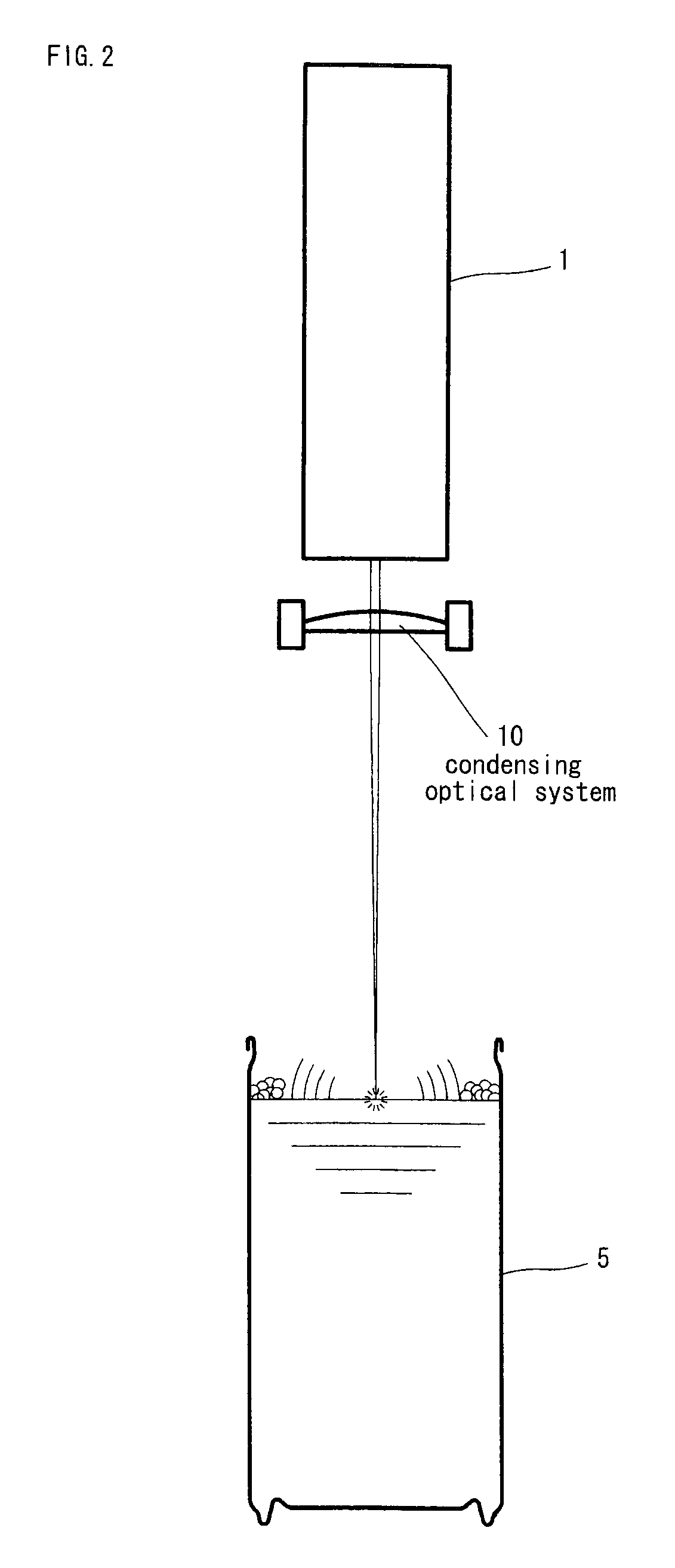

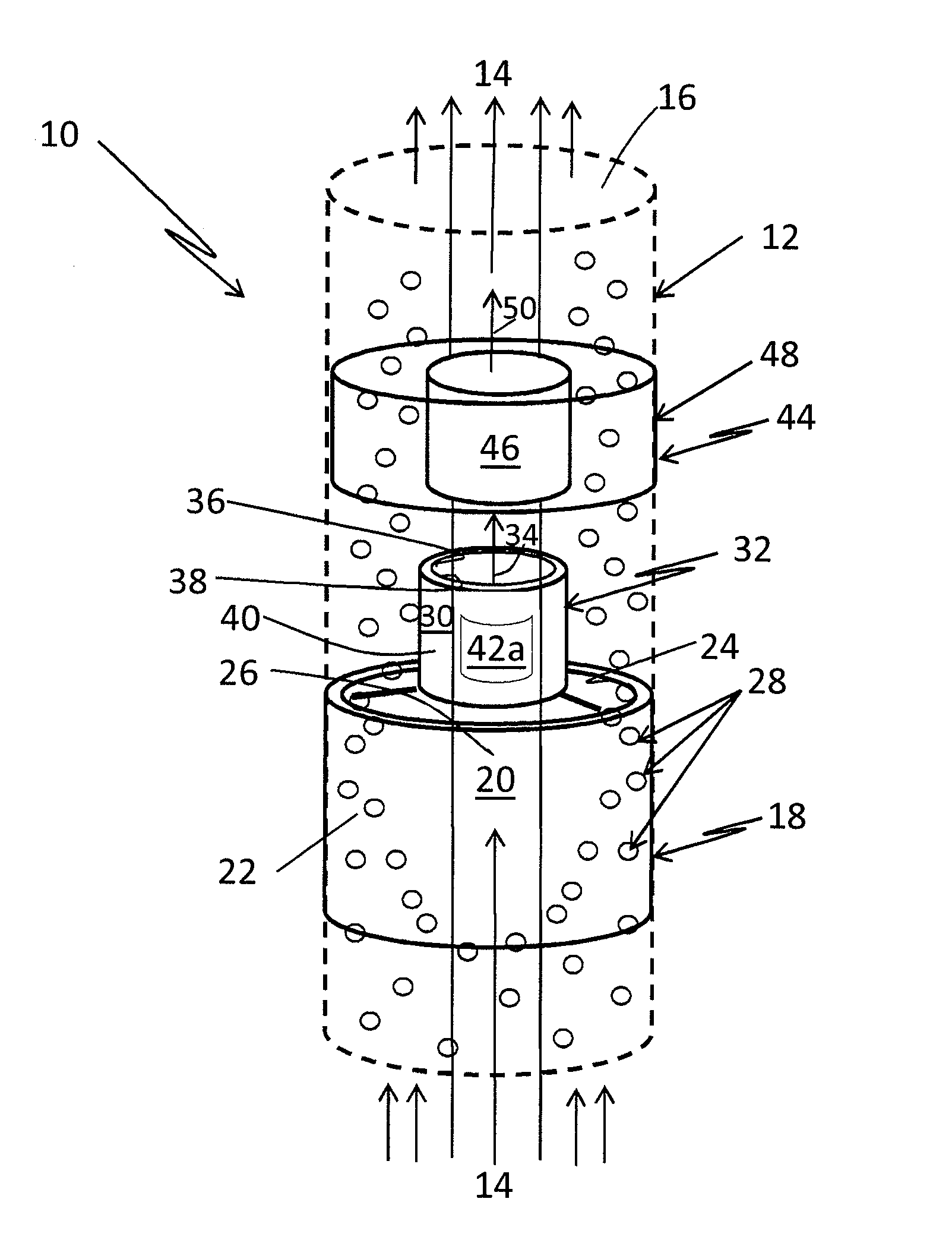

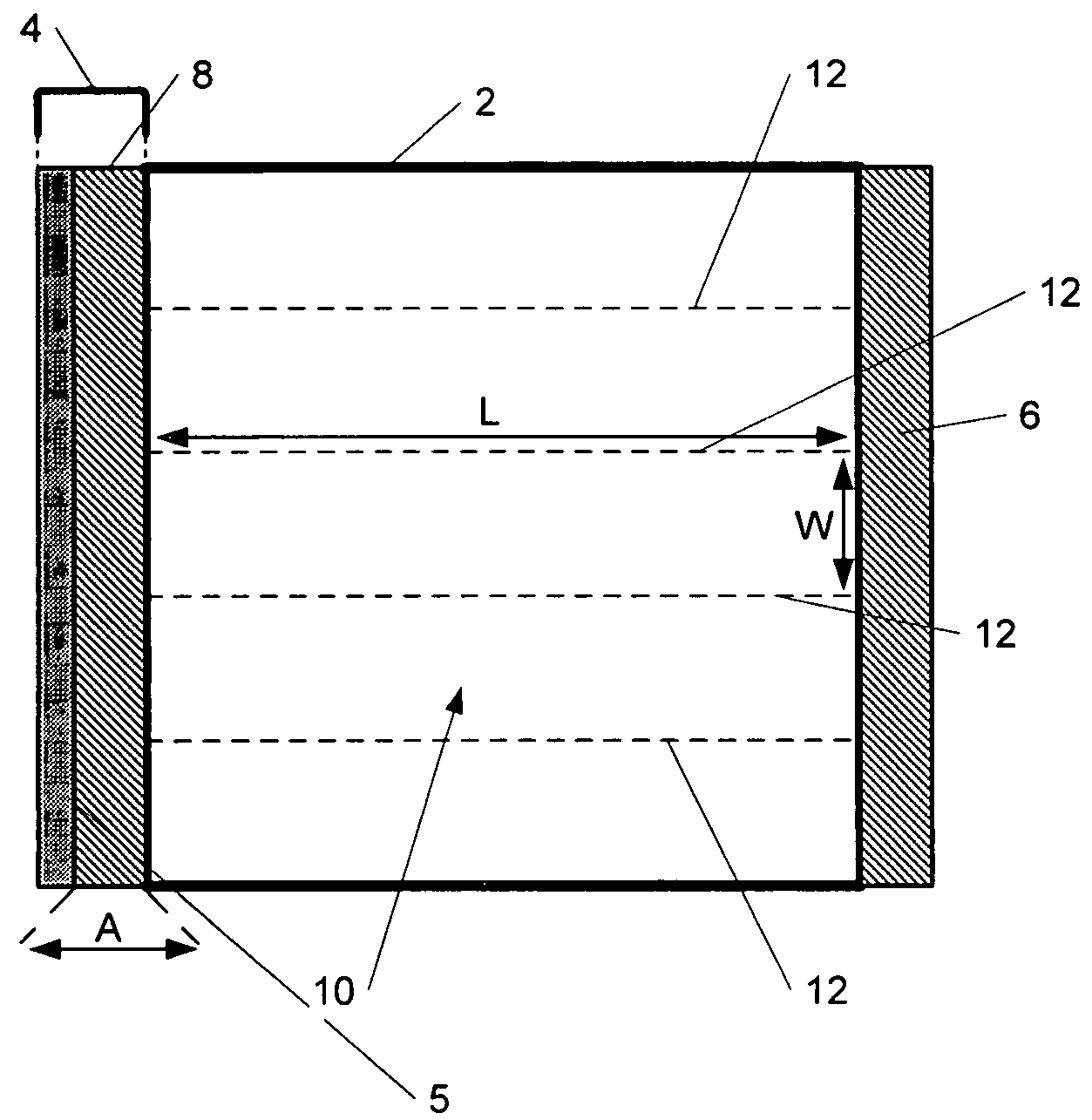

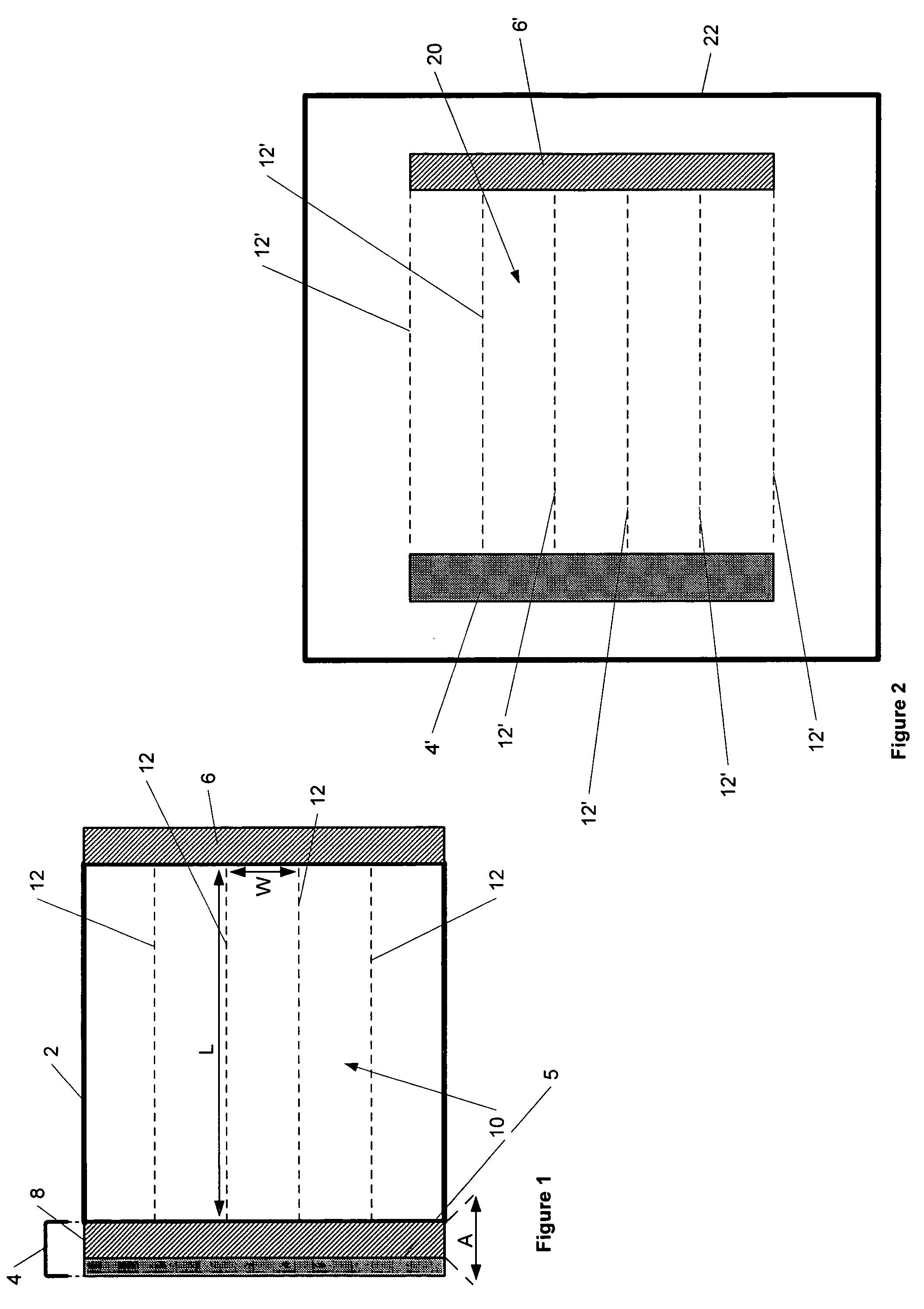

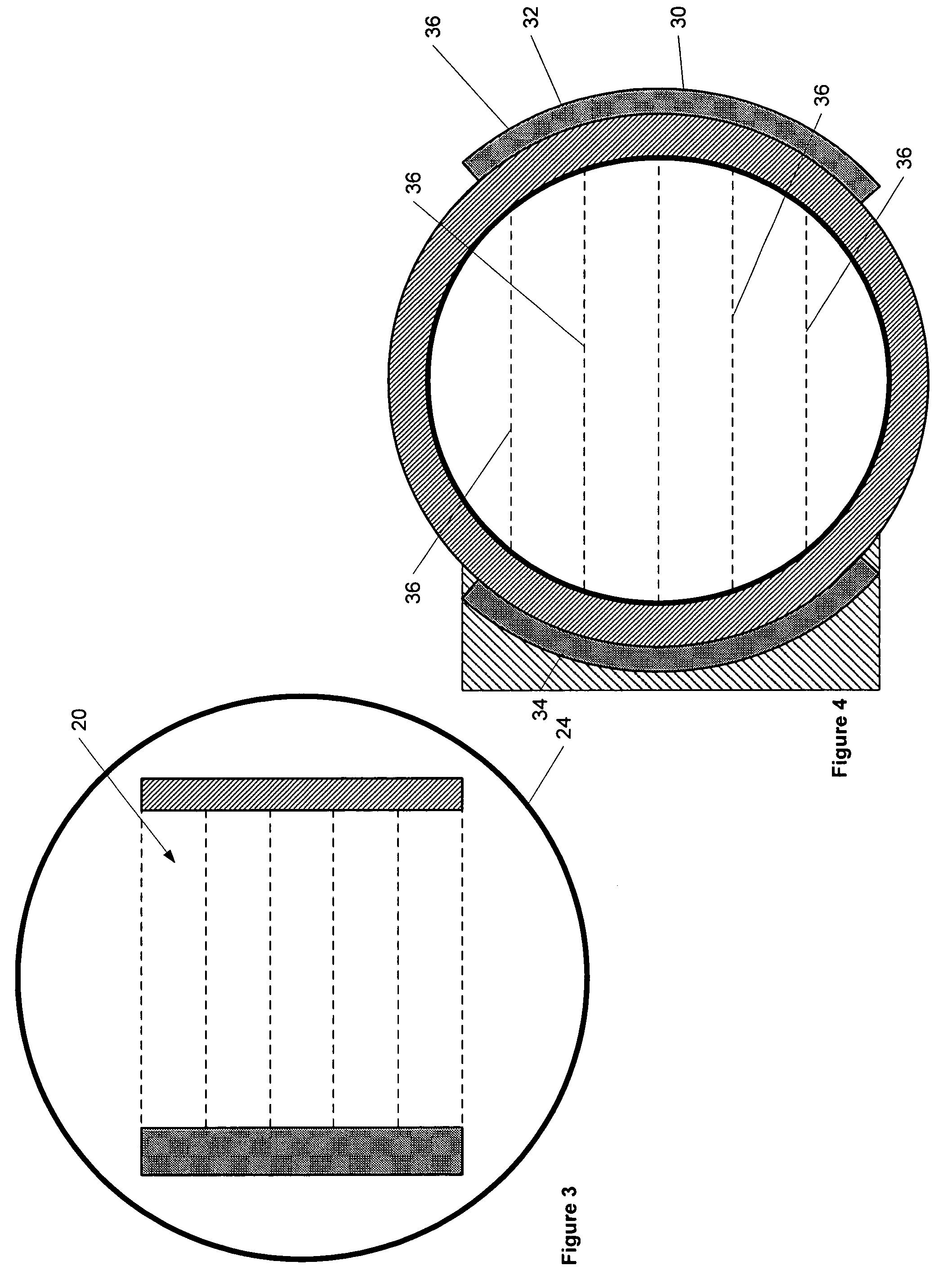

Methods and apparatus for conditioning and degassing liquids and gases in suspension

ActiveUS7766121B2Increase in sizeIncrease chanceShaking/oscillating/vibrating mixersWater/sewage treatment by irradiationUltrasonic sensorEngineering

A method and apparatus are provided for the controlled application of ultrasonic energy for conditioning of mixtures of gas and liquids by evolving and / or agglomerating gas bubbles existing with or in a liquid or for coalescing droplets of liquid dispersed in another liquid. The invention in preferred embodiments thereof comprises a coalescing apparatus for increasing the droplet size of a mixture formed as a liquid dispersed in another liquid, and a de-gassing apparatus arranged to evolve and / or agglomerate gaseous bubbles in a gas / liquid mixture. In the apparatuses, ultrasonic transducers are used to impart vibrational energy to the mixtures.

Owner:SCHLUMBERGER TECH CORP

Method for separating an organic phase from an electrolyte-containing aqueous and organic phase

InactiveUS20080185343A1Easy to separateHigh rateEther separation/purificationSolid sorbent liquid separationPermeationElectrolyte

Owner:COVESTRO DEUTSCHLAND AG

Defoaming method

ActiveUS20110306681A1Short timeReliable generationTea extractionPressure pumpsShock waveSound sources

A defoaming method capable of destroying foams generated when a container is filled with drink, or the like, efficiently at a high speed and destroying foams effectively even in the case of a container having a narrow mouth. Liquid surface (6) in a container (1) is irradiated with pulse-like light (2) and a pulse-like sound wave (8) is generated from an irradiated point (7) as a sound source. The pulse-like sound wave thus generated propagates from the sound source as a strong spherical wave to reach a bubble (9) and to destroy the bubble. It can also destroy a bubble located at a place remote from the optical path quickly, thus destroying bubbles efficiently at a high speed. Alternatively, pulse-like light is condensed at a gas portion above the liquid surface and the bubbles can be destroyed with a shock wave generated by breakdown phenomenon.

Owner:TOYO SEIKAN KAISHA LTD

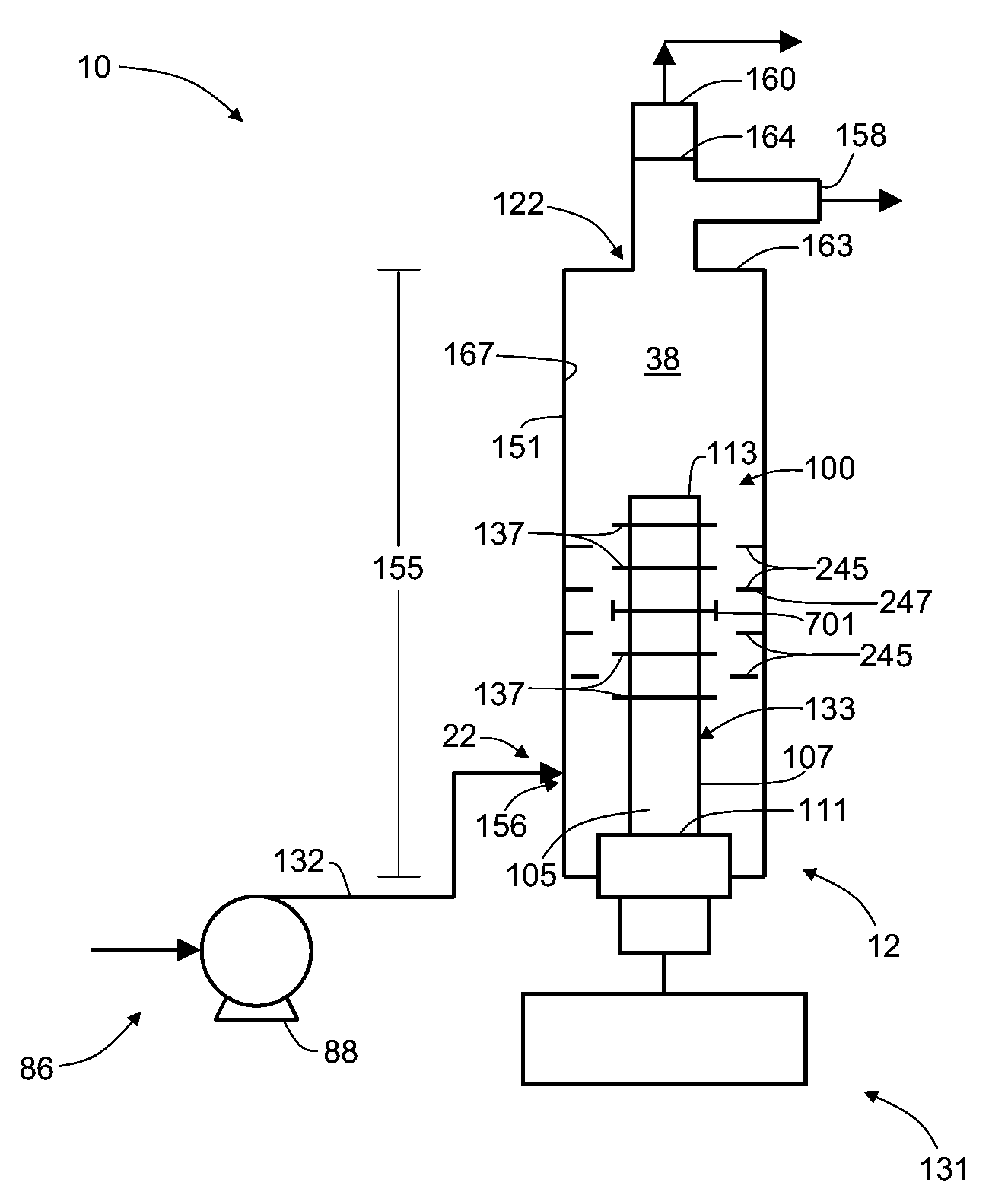

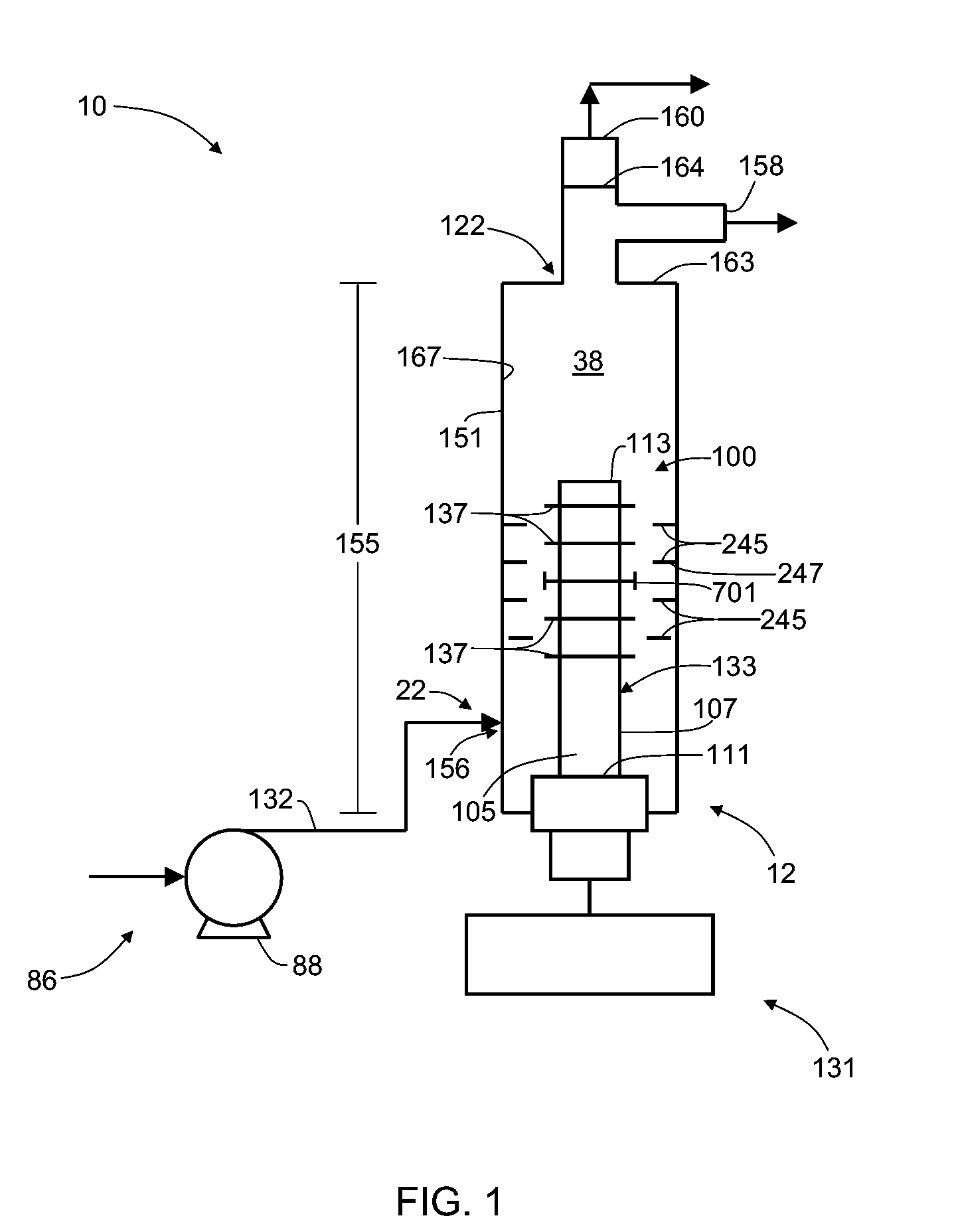

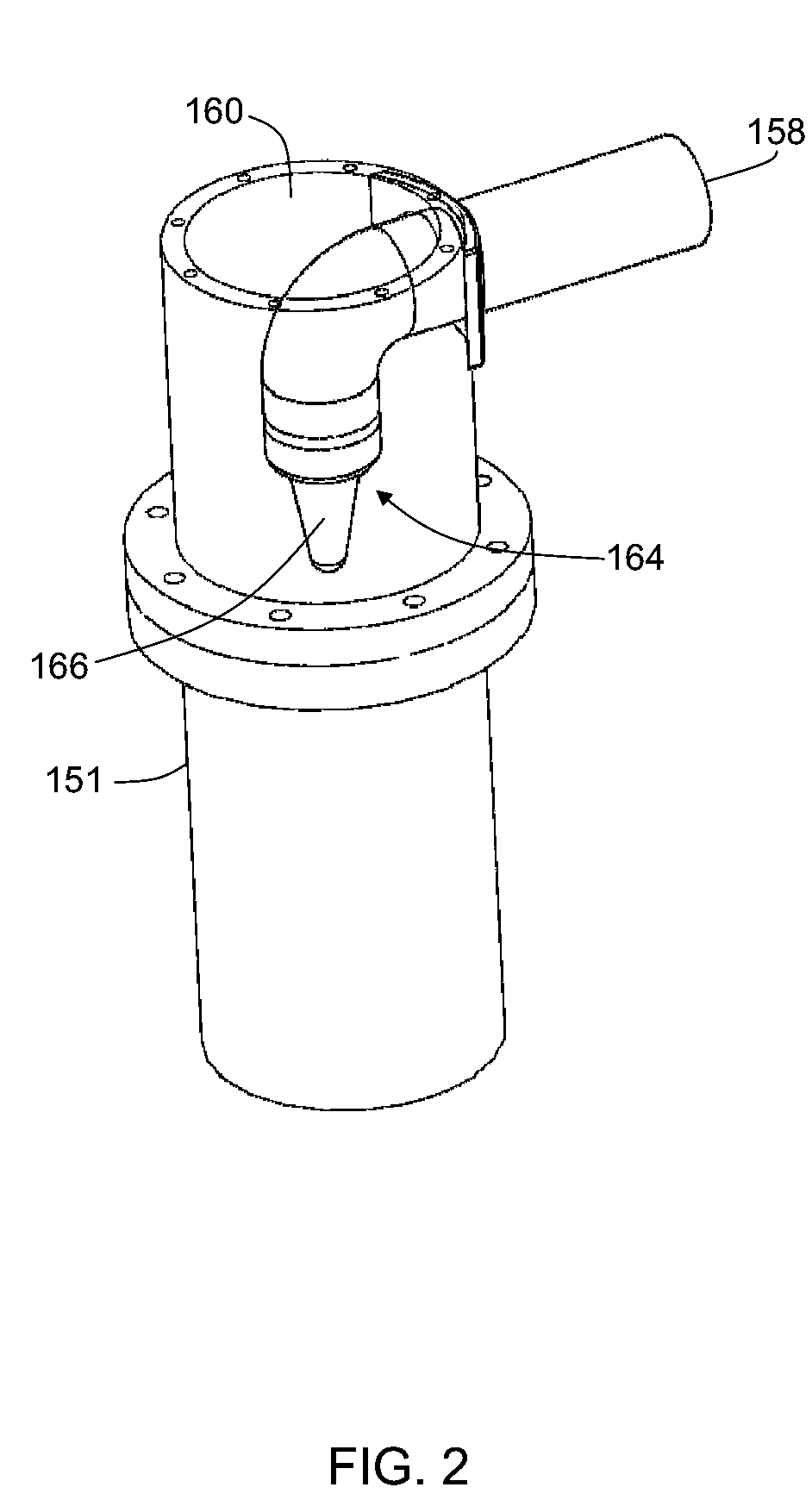

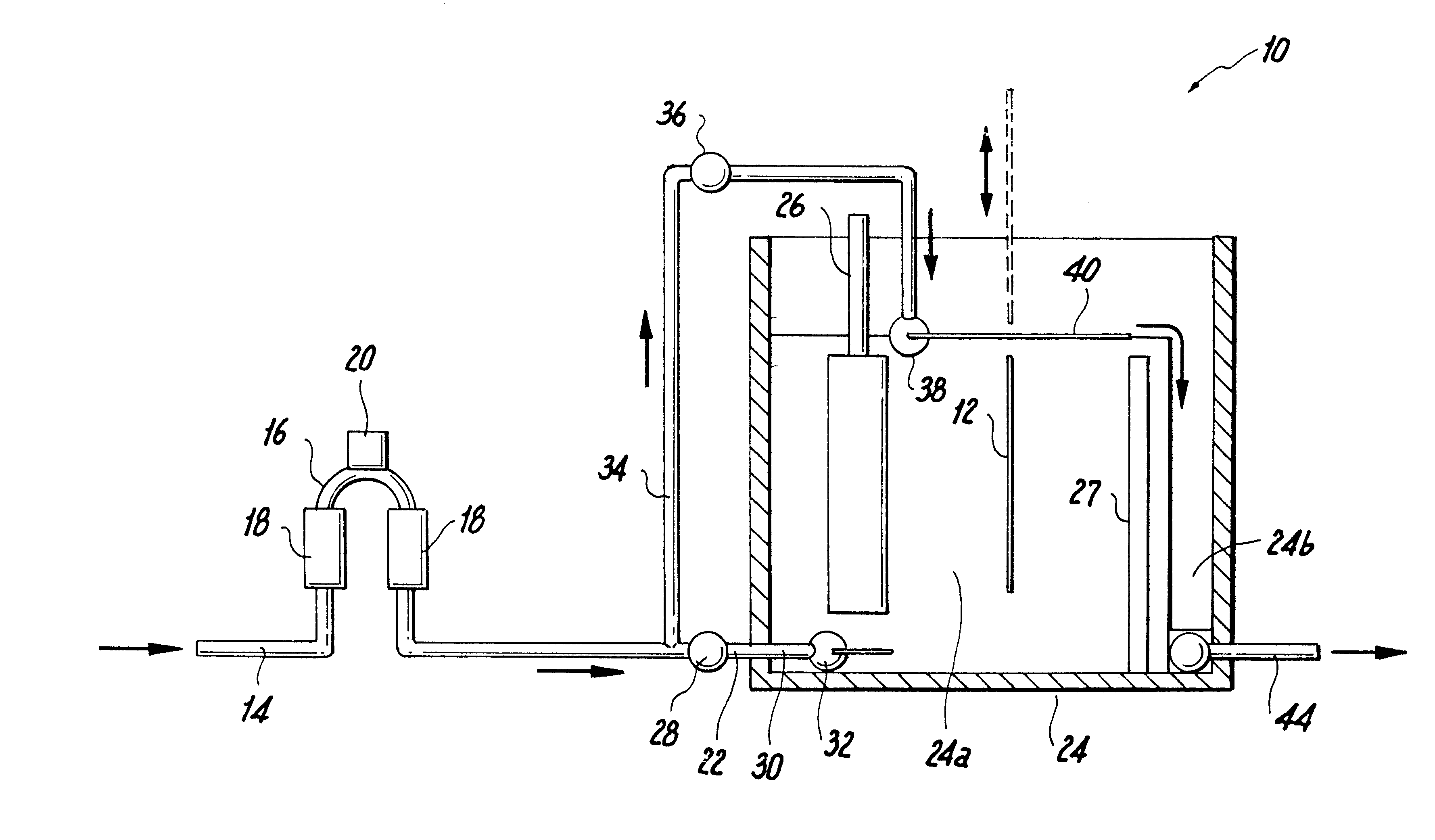

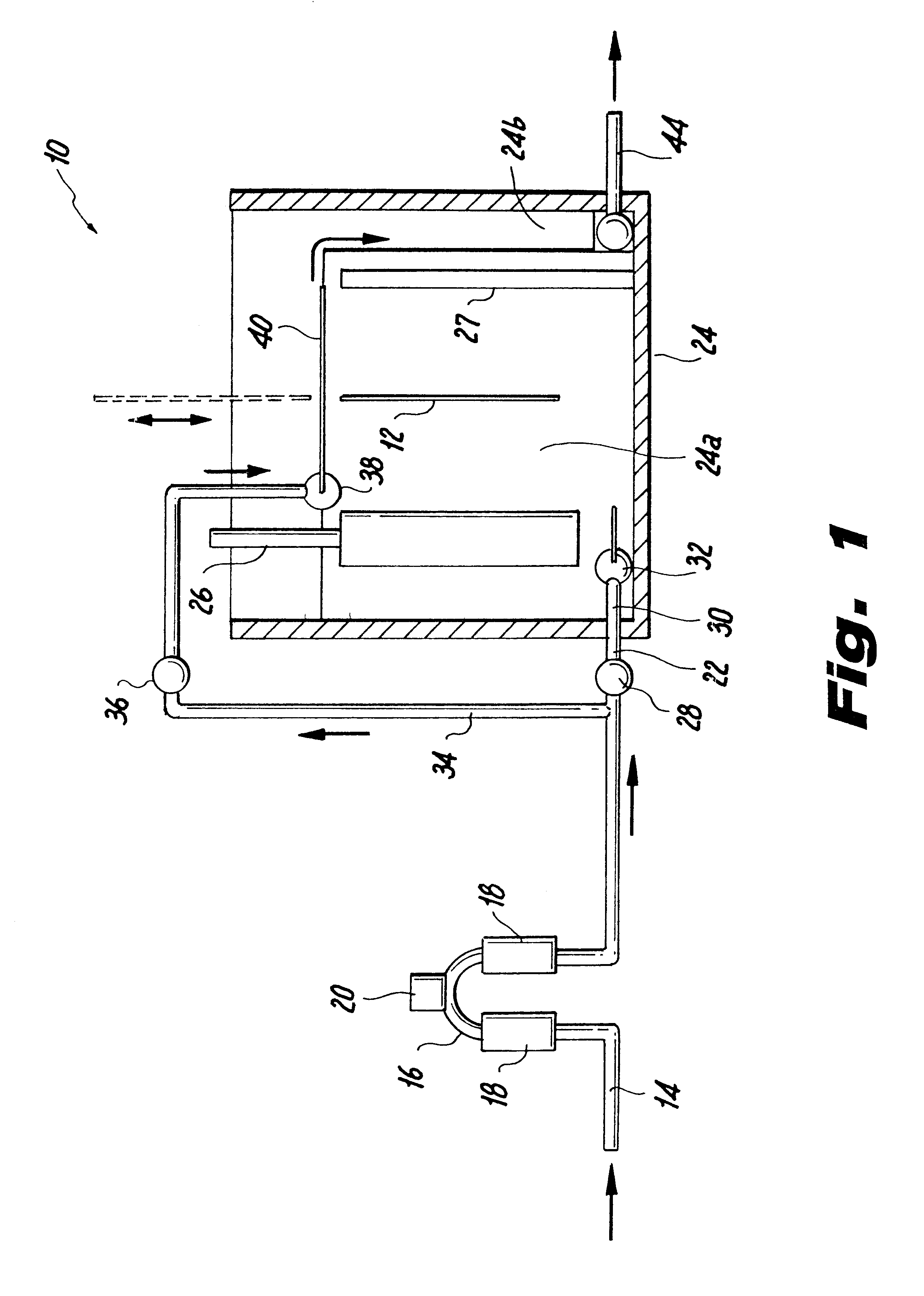

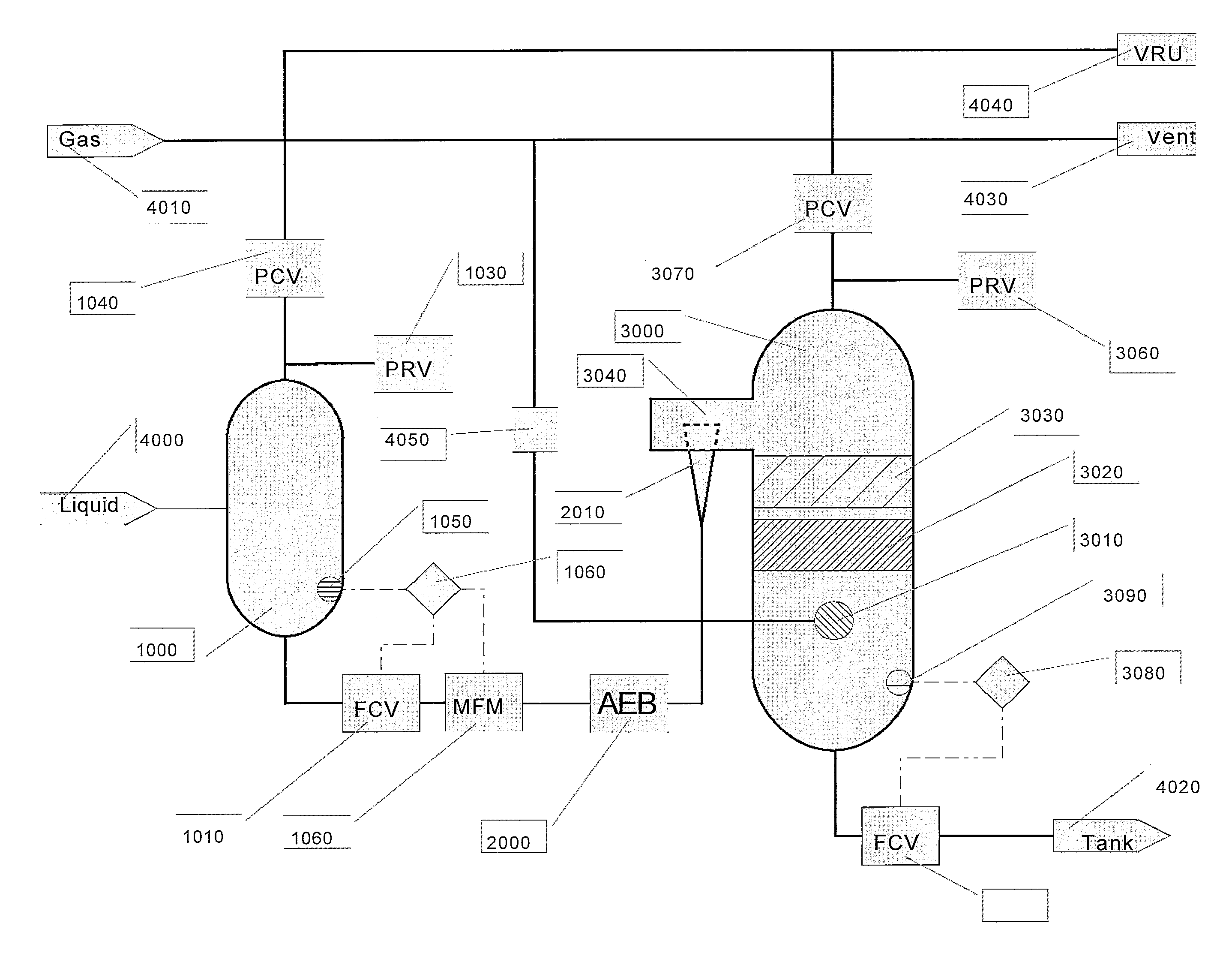

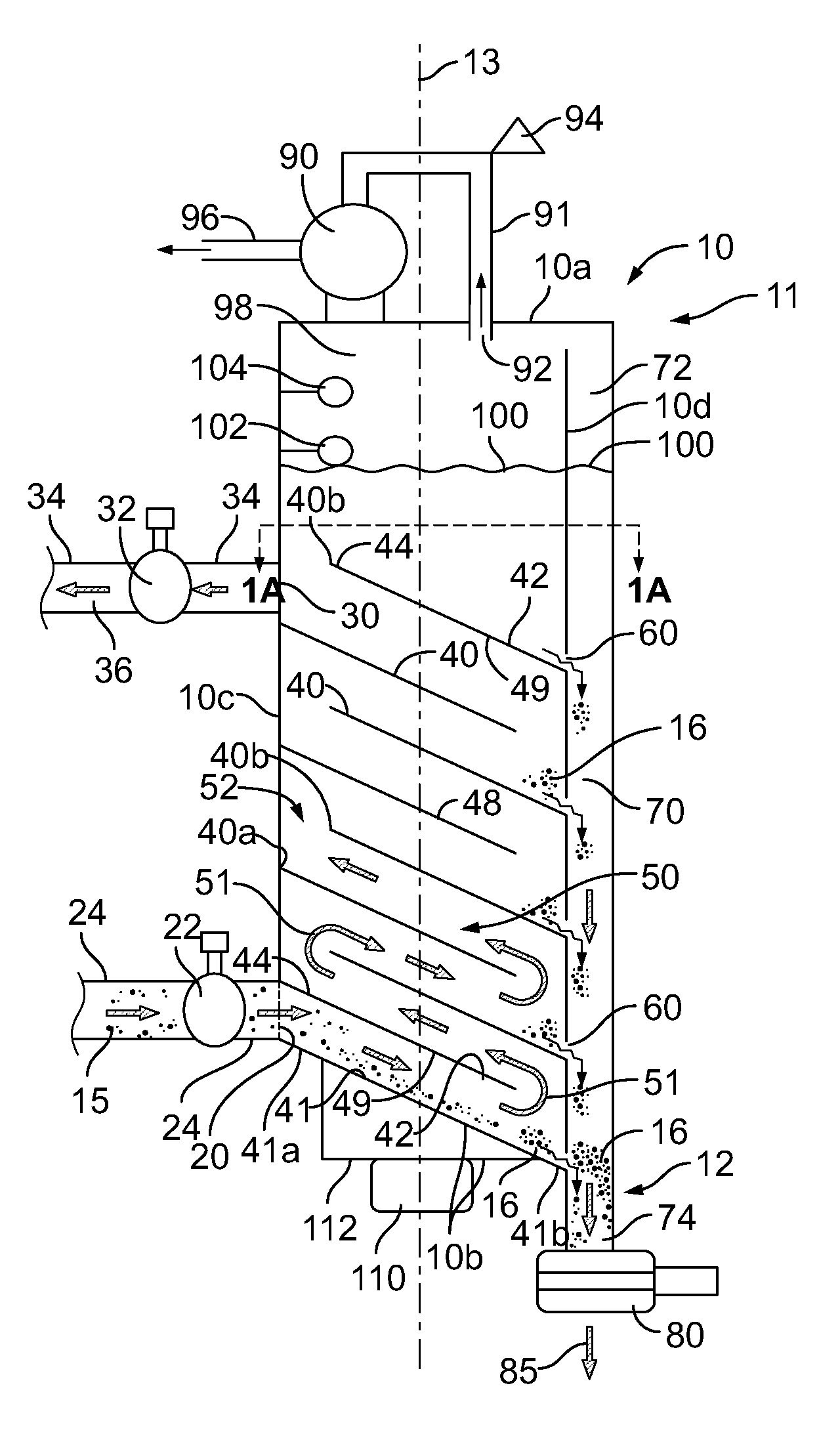

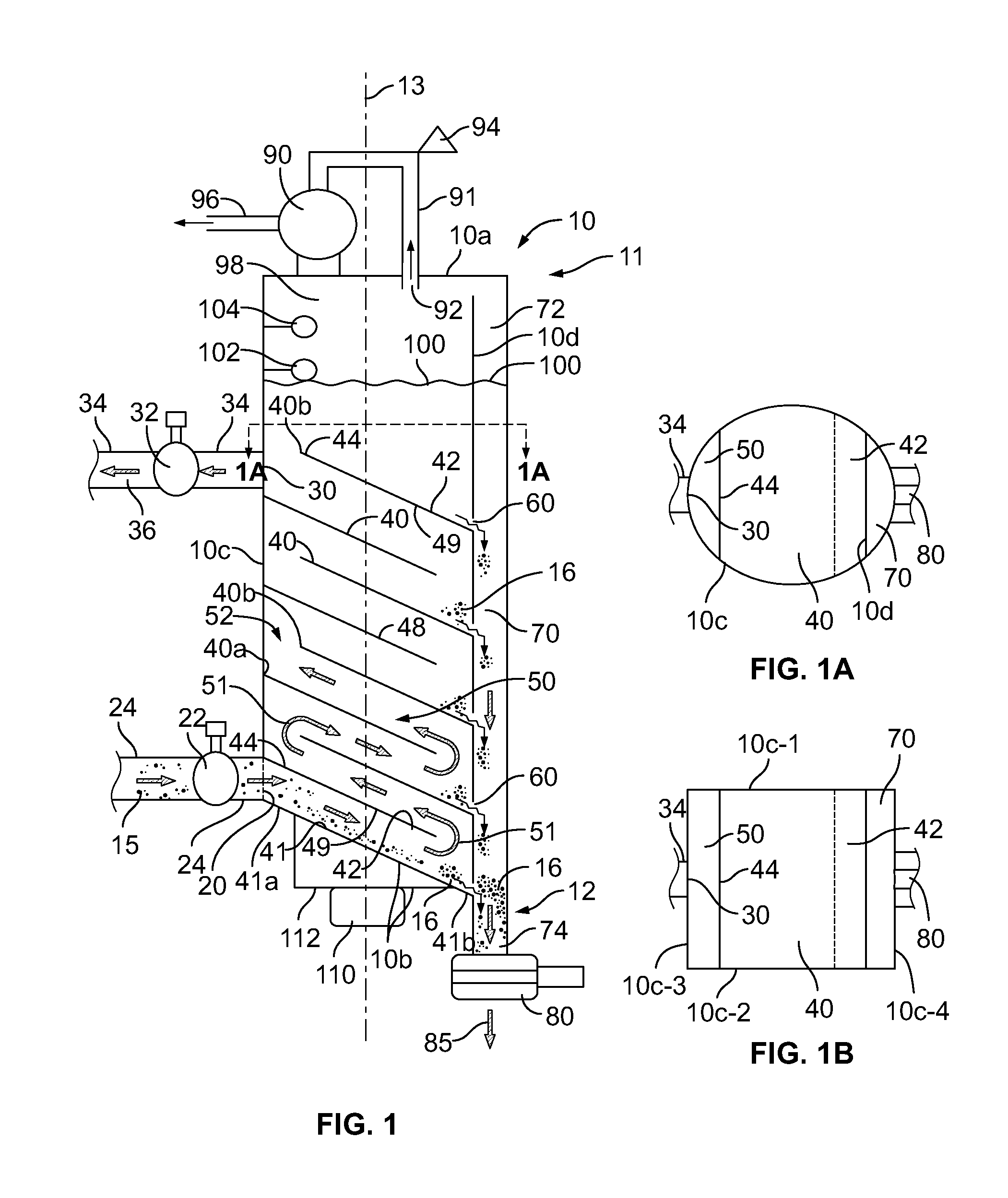

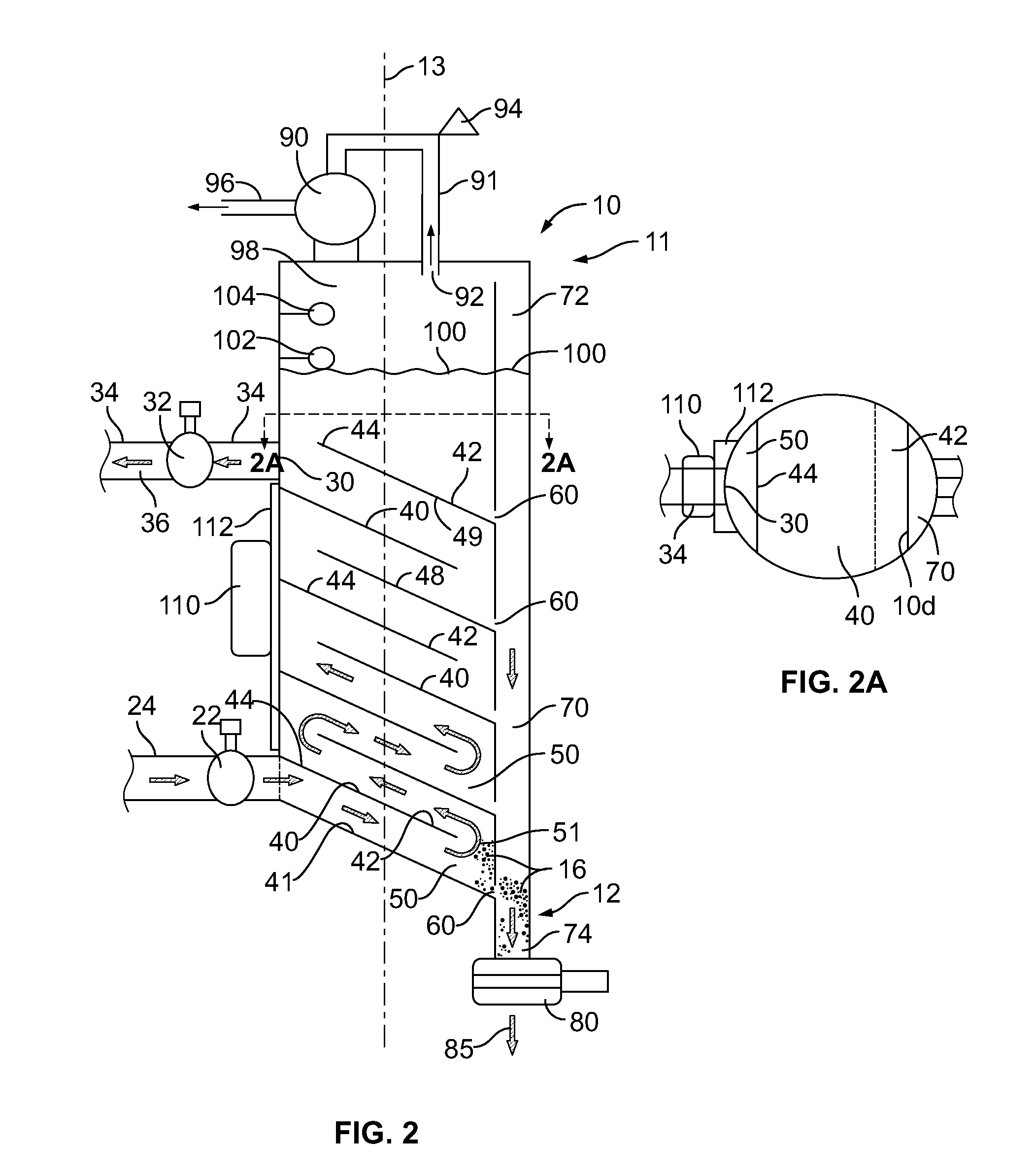

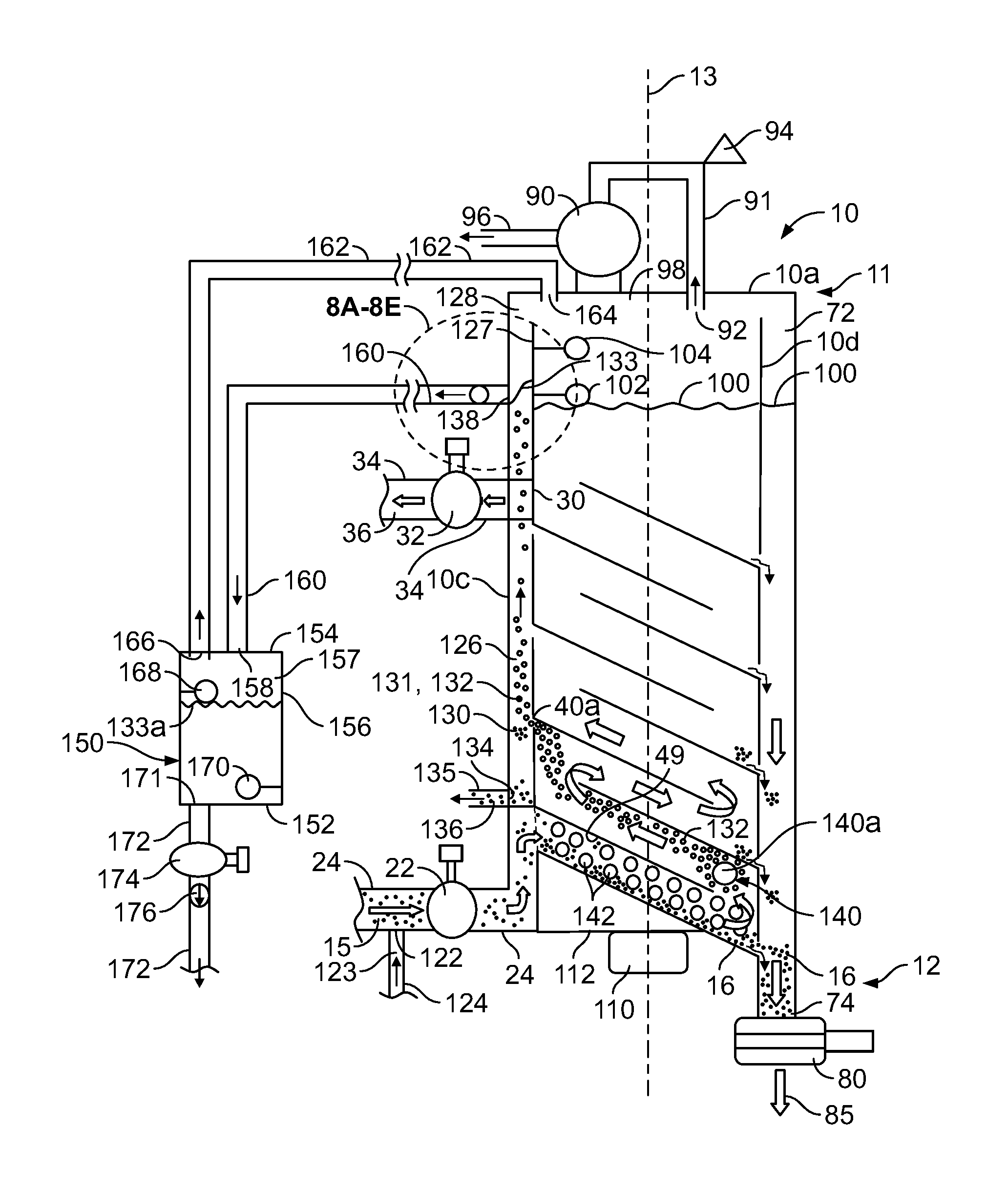

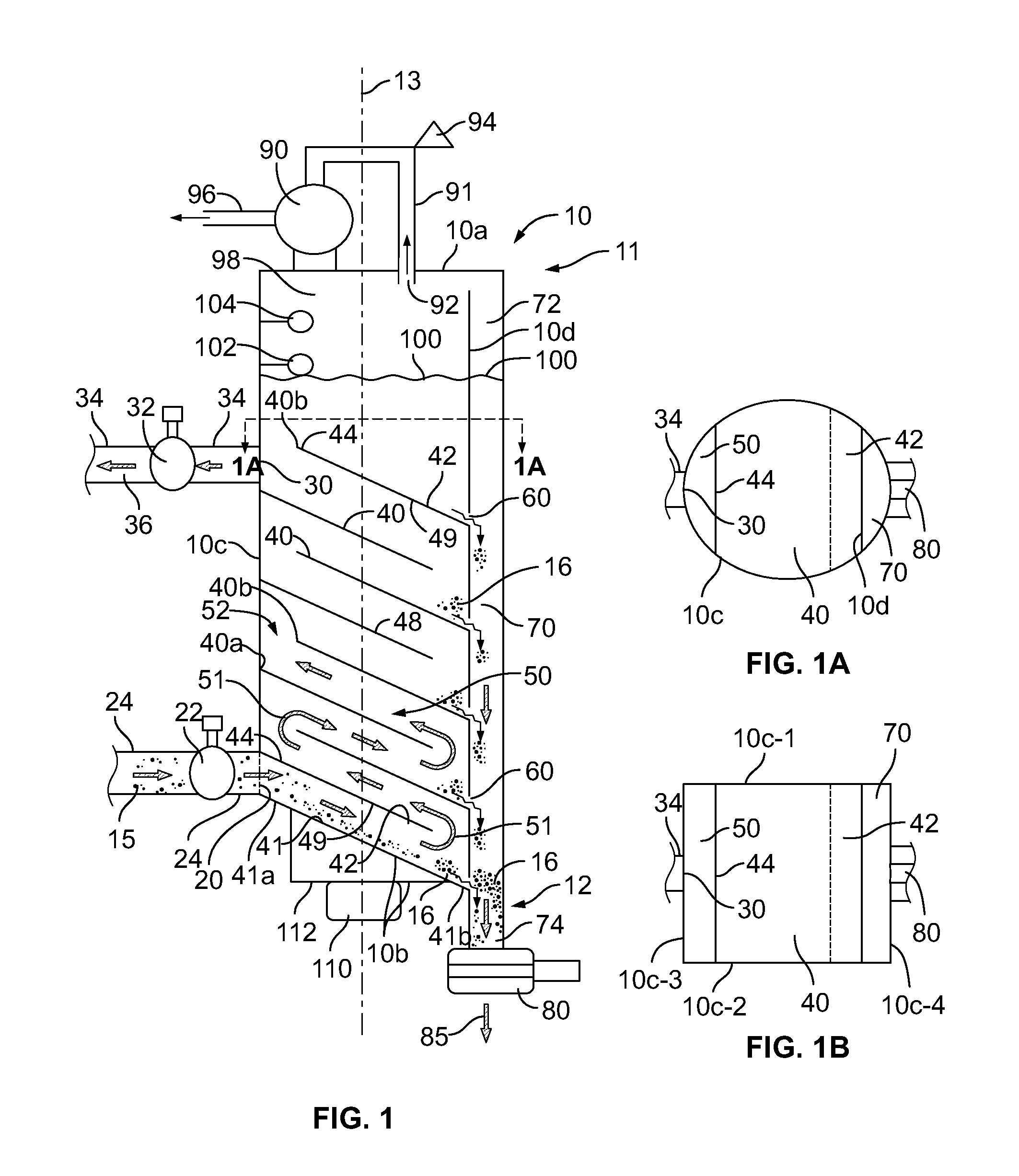

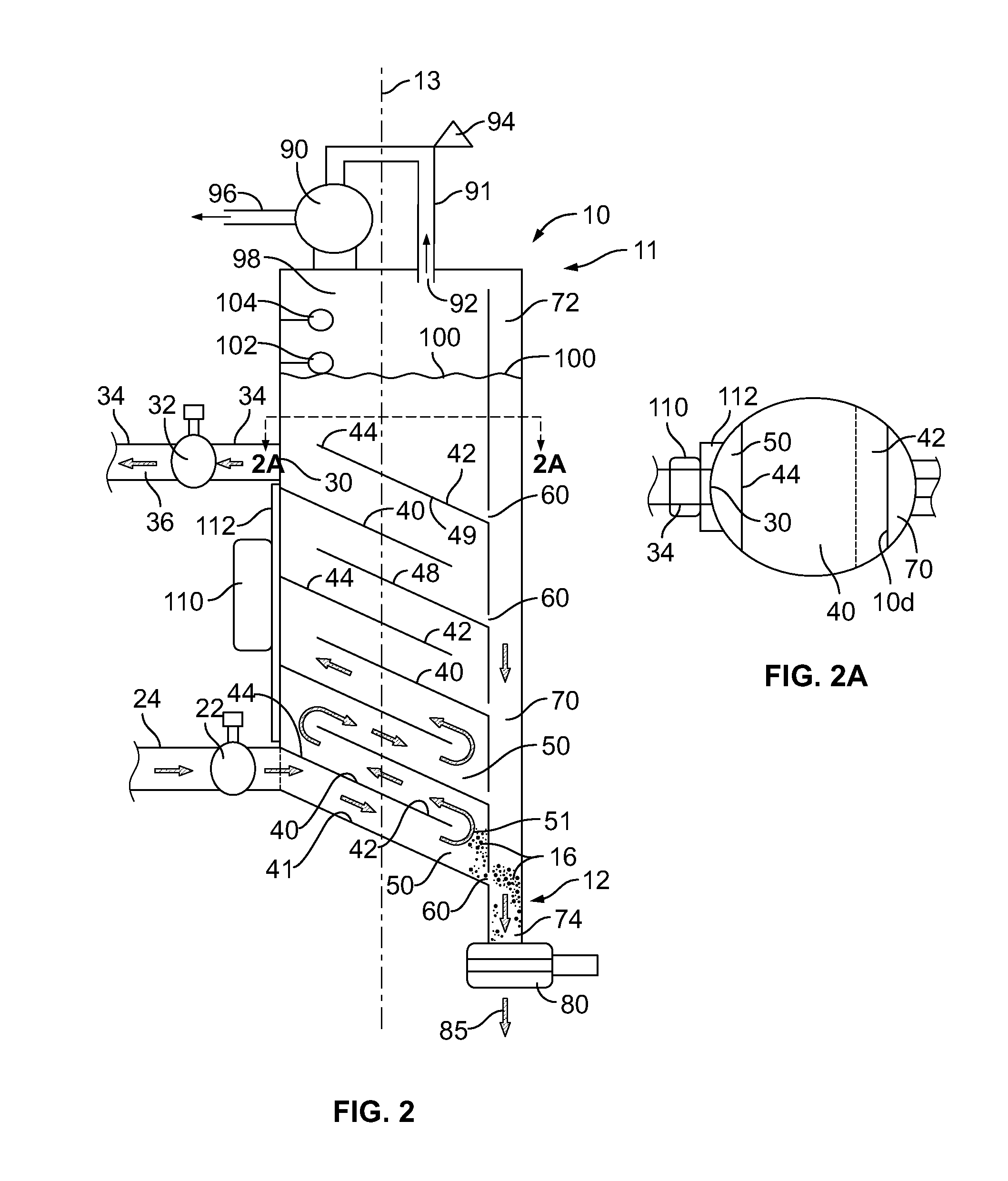

Solids removal system and method

The system and method is directed to improved separation or clarification of solids from a solids-laden liquid, including the removal of low gravity solids. A liquid to be treated is introduced into the inlet of a solid-liquid separator modified to include one or more sources of vibrational energy. The liquid is directed through a conduit within the separator. This conduit can be configured into a tortuous flow path to assist in the separation of solids from the liquid, the tortuous path being interconnected between two separation towers. Vibrational energy and gas sparging is applied to the flow path. As solids fall out of solution, they are collected. The clarified liquid is also collected. A vacuum can be applied to the system to assist in moving the solid-liquid mixture through the system and to provide vacuum clarification. Electrocoagulation electrodes can also be employed.

Owner:1612017 ALBERTA LTD

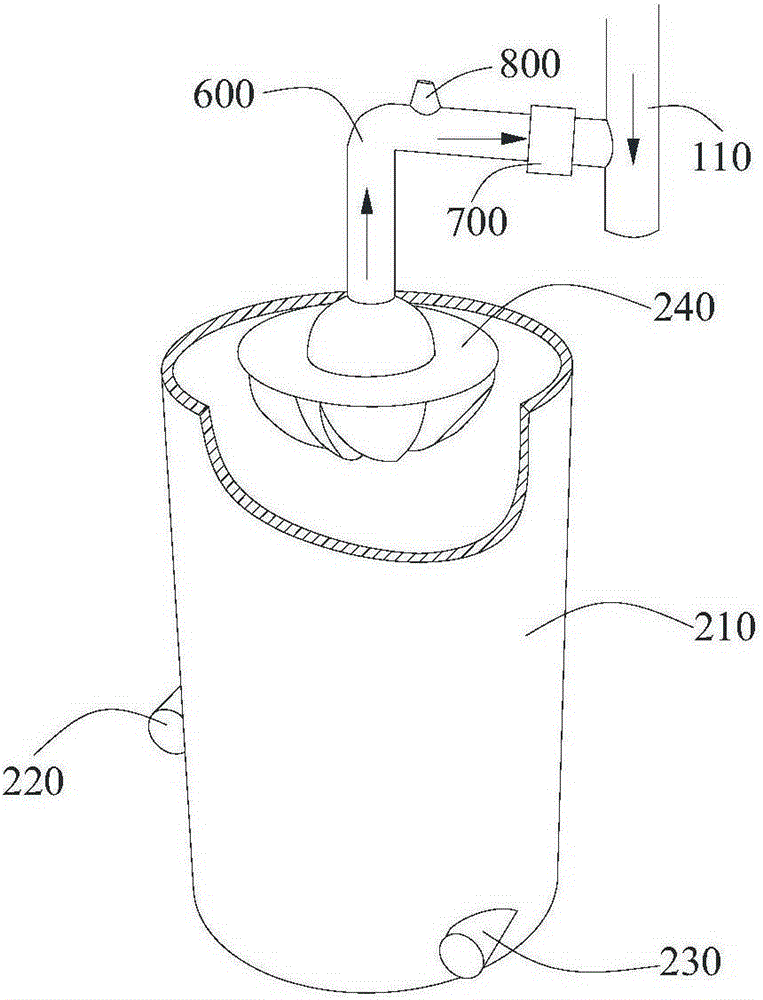

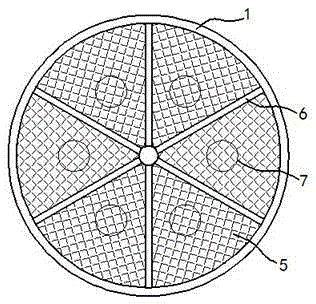

Bubble removing system

ActiveCN105251241ABig spaceSimple structureWater/sewage treatment with mechanical oscillationsLiquid degasification by filtrationEngineeringCavity wall

The invention provides a bubble removing system. The bubble removing system comprises a main bubble removing apparatus; the main bubble removing apparatus comprises a first enclosed container, a main gelatin inlet pipe, a main gelatin outlet pipe and a bubble colleting member; the cross section of the inner cavity of the first enclosed container is circular, and the first enclosed container is used for accommodating gelatinoids; the main gelatin inlet pipe penetrates the sidewall of the first enclosed container and is tangent to the inner cavity wall of the first enclosed container and arranged on the upper part of the first enclosed container; the main gelatin outlet pipe penetrates the sidewall of the first enclosed container and is arranged on the lower part of the first enclosed container; and the bubble colleting member comprises a hollow bubble collecting part and a communicating part, the bubble collecting part is arranged at the central part of the top of the inner cavity of the first enclosed container to collect gelatinoids located at the top of the first enclosed container and rich in bubbles, and the communicating part is arranged out of the first enclosed container and communicated with a hollow part of the bubble collecting part. The bubble removing system can highly efficiently remove bubbles in the gelatinoids.

Owner:BOE TECH GRP CO LTD +1

Influence of acoustic energy on coke morphology and foaming in delayed coking

InactiveUS20060196811A1Reduce the amount requiredThermal non-catalytic crackingCoking carbonaceous materialsThermodynamicsAcoustic energy

This invention relates to a process for controlling coke morphology and. foaming in delayed coking. More particularly, acoustic energy is used to control coke morphology and foaming in a delayed coking process.

Owner:EXXON RES & ENG CO

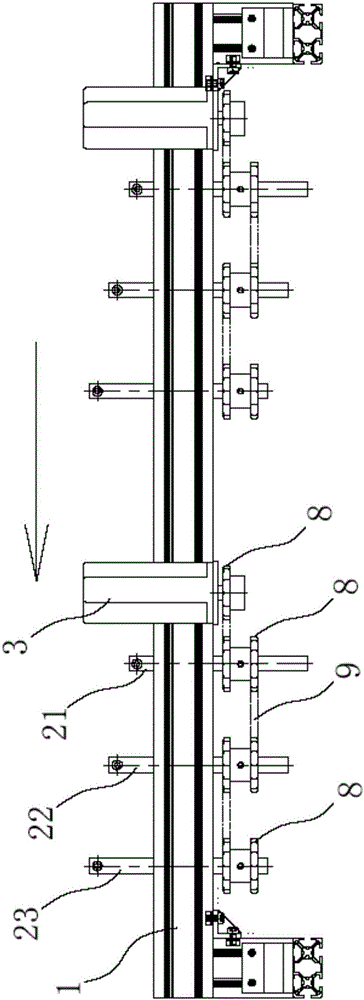

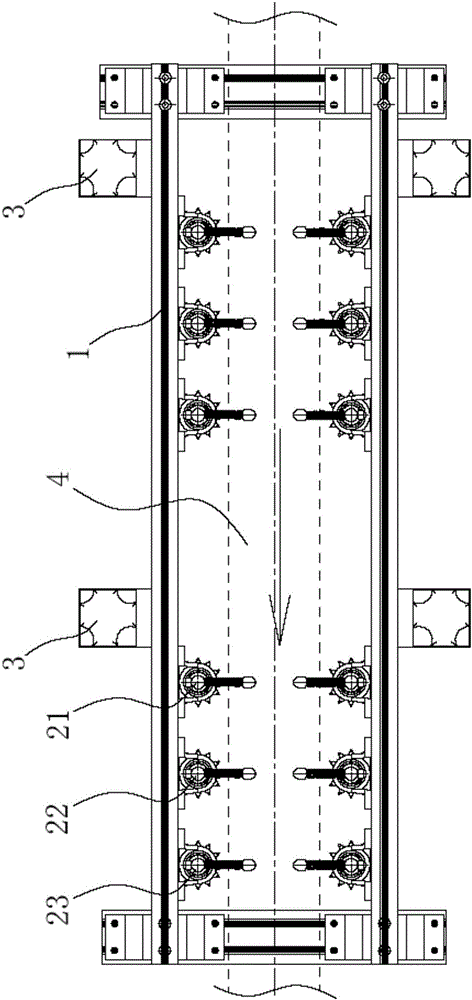

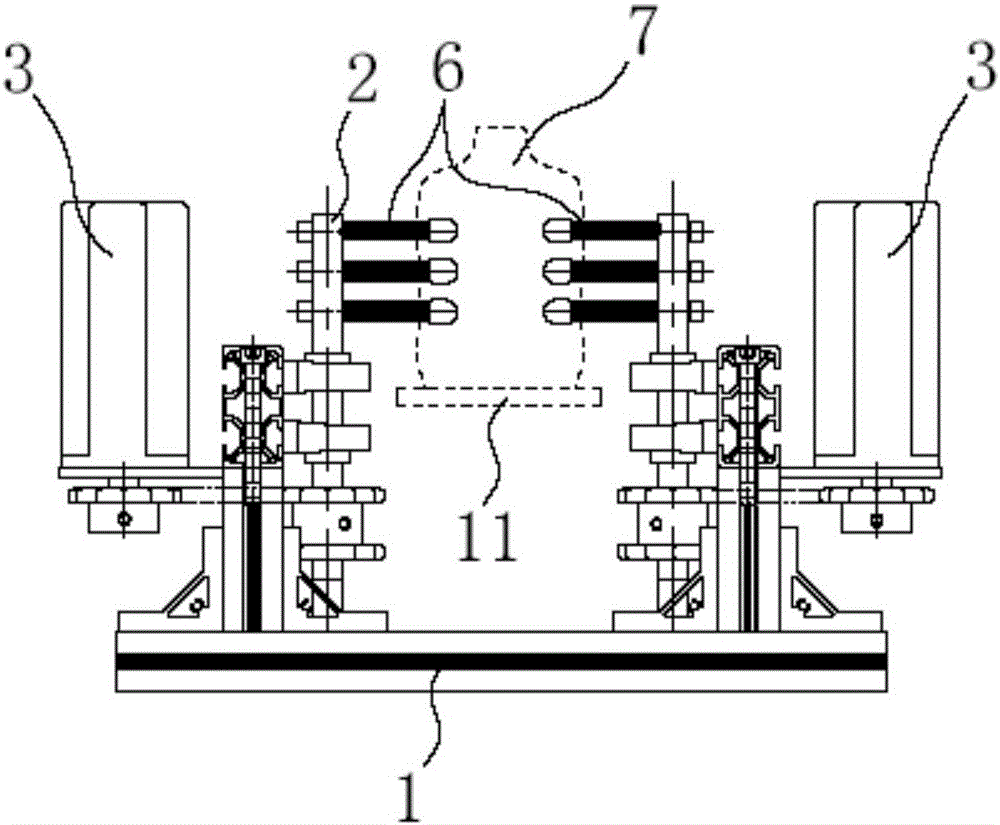

Knocking defoaming device applied to online bottle body conveyance

ActiveCN105999772ARealize tapping defoamingRealize defoaming treatmentLiquid degasification by vibrationFoam dispersion/preventionEngineeringBottle

The invention discloses a knocking defoaming device applied to online bottle body conveyance, and belongs to the field of defoaming equipment. The knocking defoaming device applied to the online bottle body conveyance eliminates foams attached onto the wall of a bottle body in order to improve a defoaming effect and can be applied to the online bottle body conveyance. The knocking defoaming device comprises a mounting rack, a knocking mechanism and a driving mechanism, wherein the knocking mechanism is mounted on the mounting frame, and the driving mechanism drives the knocking mechanism to conduct knocking; and a conveyance channel is arranged on the mounting frame, and the knocking mechanism corresponds to the conveyance channel. According to the knocking defoaming device applied to the online bottle body conveyance, the knocking mechanism is provided to knock the wall of the bottle body to eliminate the foams; knocking rods directly knock the bottle body, thereby achieving a defoaming effect, and in particular improving an effect of eliminating the foams attached on the wall of the bottle body; furthermore, the knocking defoaming device can be applied to the existing flow line production equipment and can implement a defoamting treatment of the bottle body in an online conveyance process.

Owner:CHENGDU HONGRUI TECH

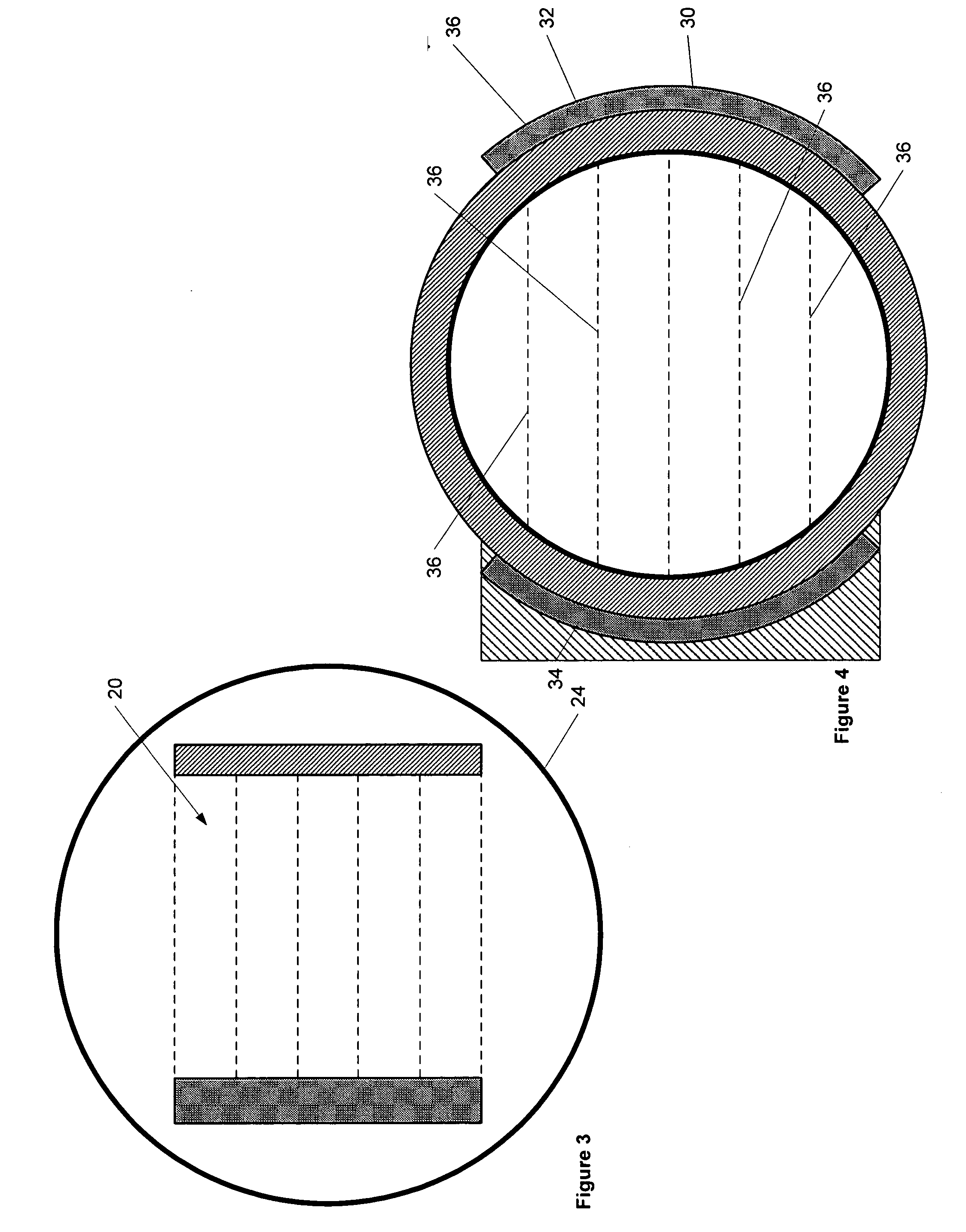

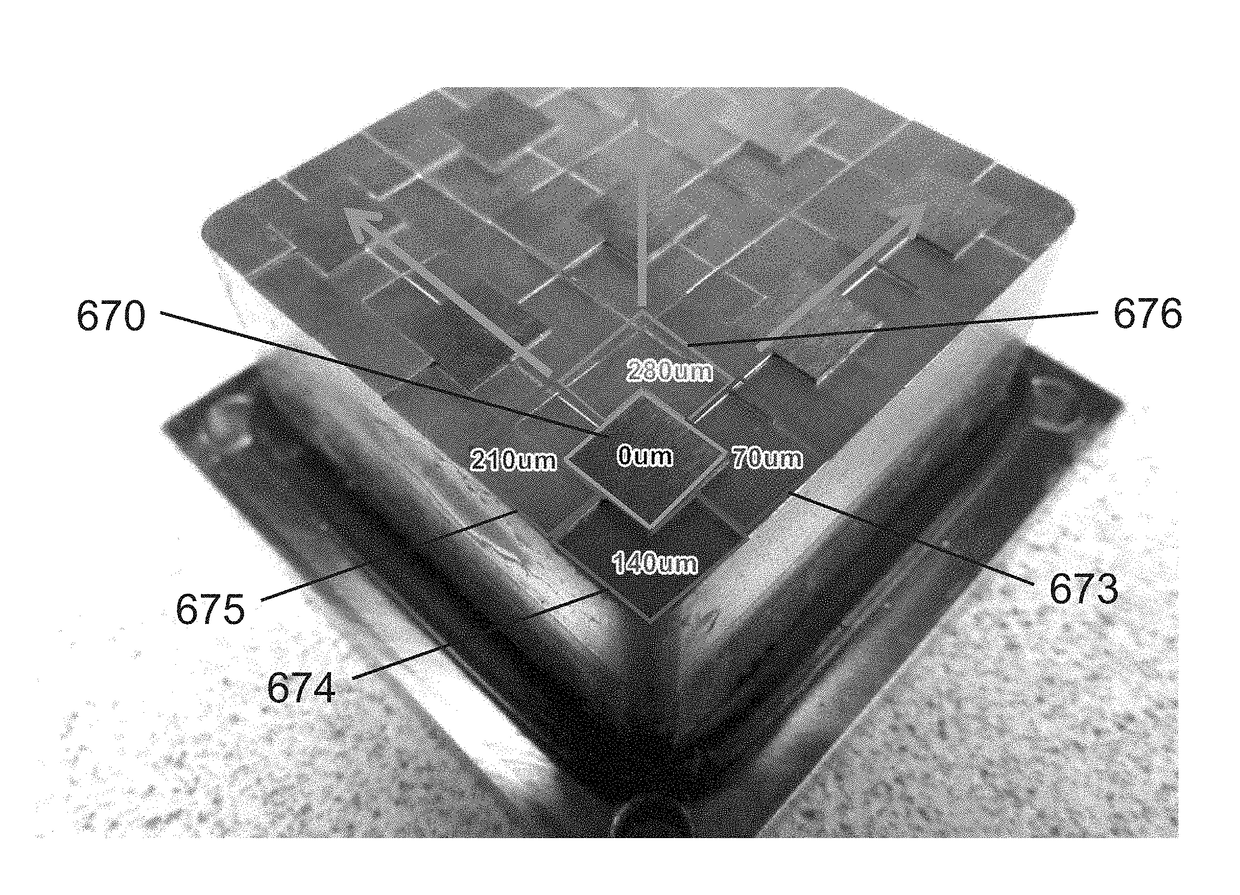

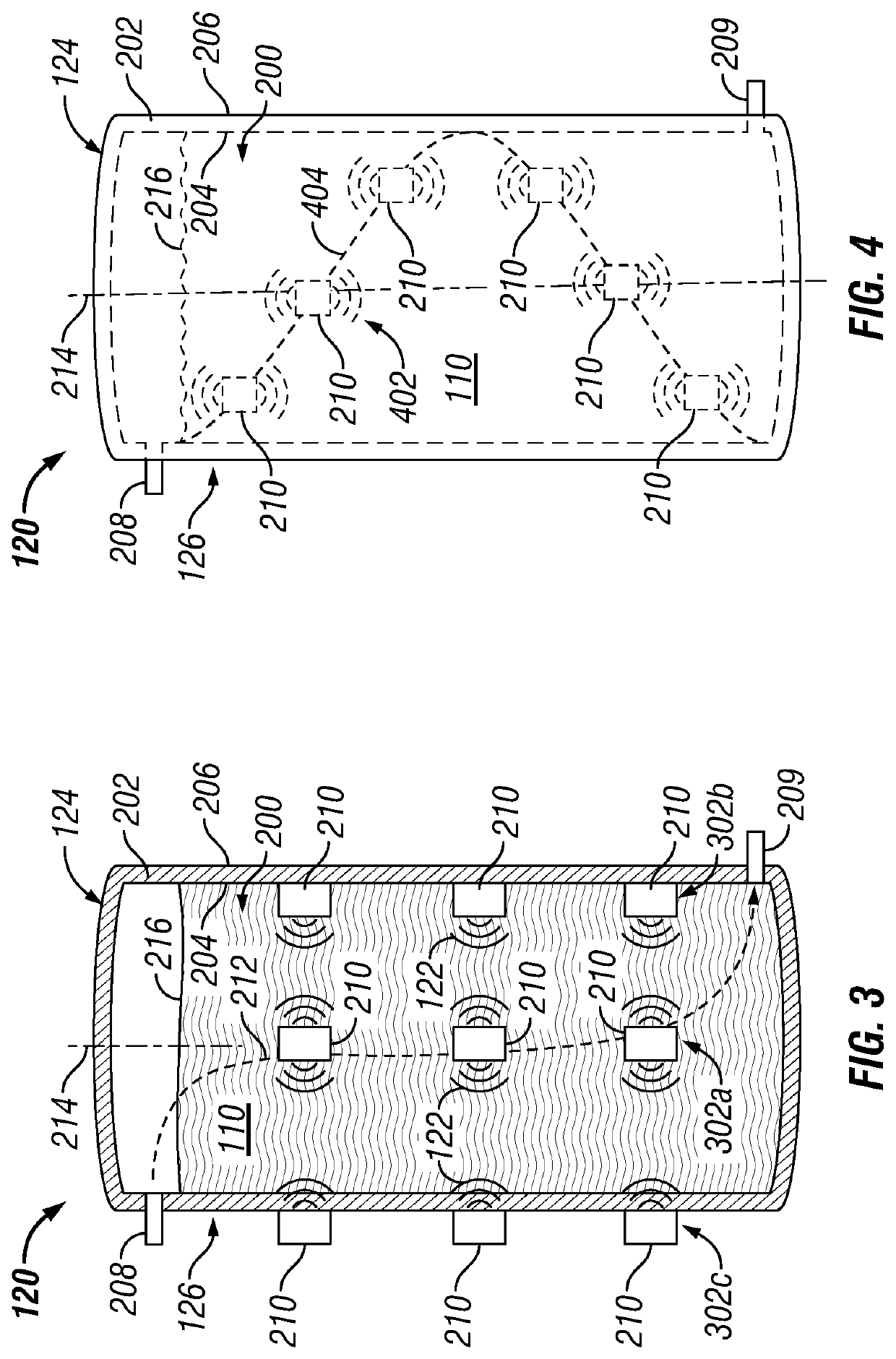

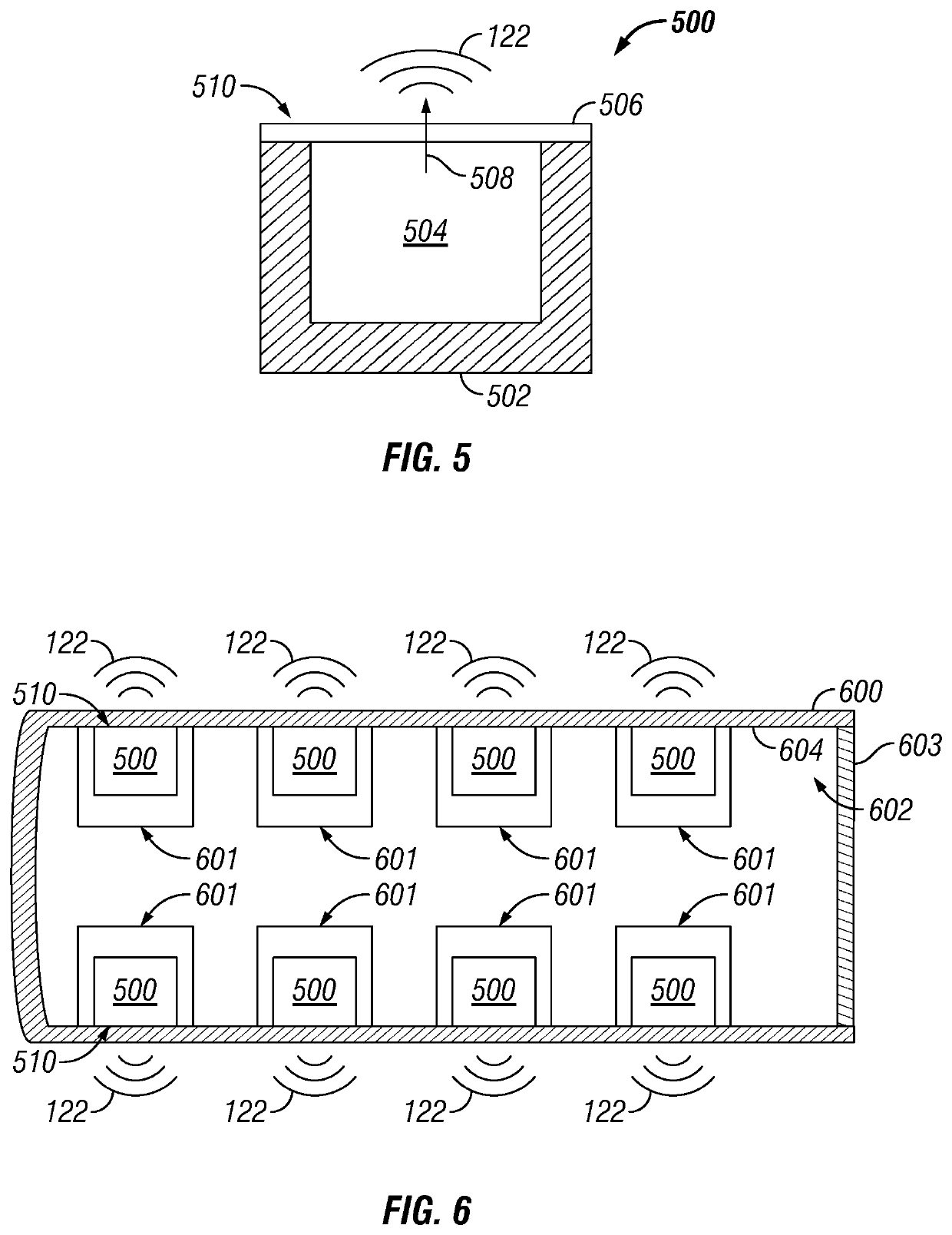

Transducer and reflector configurations for an acoustophoretic device

ActiveUS20170217794A1High strengthFatty/oily/floating substances removal devicesWater/sewage treatment with mechanical oscillationsTransducerPlastic film

Separation of particles or droplets from a host fluid may be achieved using a transducer and / or reflector that is a thin, non-planar structure. The thin non-planar structure improves operation of an acoustic standing wave generated by an acoustic transducer. The structure may operate as a pressure release boundary and may be constructed as plastic film.

Owner:FLODESIGN SONICS

Methods for providing oxidatively stable ophthalmic compositions

InactiveUS20070077303A1Improve stabilityPowder deliverySenses disorderOphthalmologyCompound (substance)

Owner:ALLERGAN INC

Solids removal system and method

ActiveUS9192879B2Liquid degasification regulation/controlFlash degasificationElectricityElectrocoagulation

The system and method is directed to improved separation or clarification of solids from a solids-laden liquid, including the removal of low gravity solids. A liquid to be treated is introduced into the inlet of a solid-liquid separator modified to include one or more sources of vibrational energy. The liquid is directed through a conduit within the separator. This conduit can be configured into a tortuous flow path to assist in the separation of solids from the liquid, the tortuous path being interconnected between two separation towers. Vibrational energy and gas sparging is applied to the flow path. As solids fall out of solution, they are collected. The clarified liquid is also collected. A vacuum can be applied to the system to assist in moving the solid-liquid mixture through the system and to provide vacuum clarification. Electrocoagulation electrodes can also be employed.

Owner:SOLIDS REMOVAL SERVICES LLC

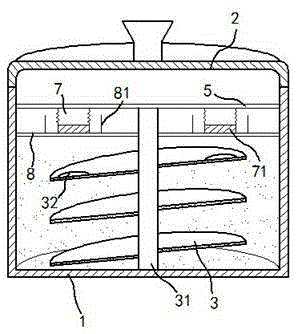

Defoaming reaction vessel

InactiveCN105413620ADoes not affect purityEliminate effectiveChemical/physical/physico-chemical stationary reactorsLiquid degasification by vibrationSurface mountingMarine engineering

The invention relates to a defoaming reaction vessel. The defoaming reaction vessel comprises a vessel body, a vessel cover and a rotating shaft. Thread paddles used for stirring are installed on the rotating shaft. A permanent magnetism block is installed on the upper surface of each thread paddle. A defoaming device is installed in the vessel body. The defoaming device comprises a spacing screen plate and a support. The support is fixed under the spacing screen plate. Elastic air bags are distributed on the lower surface of the spacing screen plate. A blowhole is arranged in the side wall of each elastic air bag. A ferromagnetic plate is installed at the bottom of each elastic air bag. A defoaming screen plate is fixedly installed on each ferromagnetic plate. Each defoaming screen plate can slide up and down along the side wall of the support. The reaction vessel is delicate in structure, is low in cost and can achieve high-efficiency defoaming on the premise of constant voltage, new impurities cannot be introduced, and high-efficiency and stable operation of the reaction is ensured.

Owner:盐城盛大肠衣食品有限公司

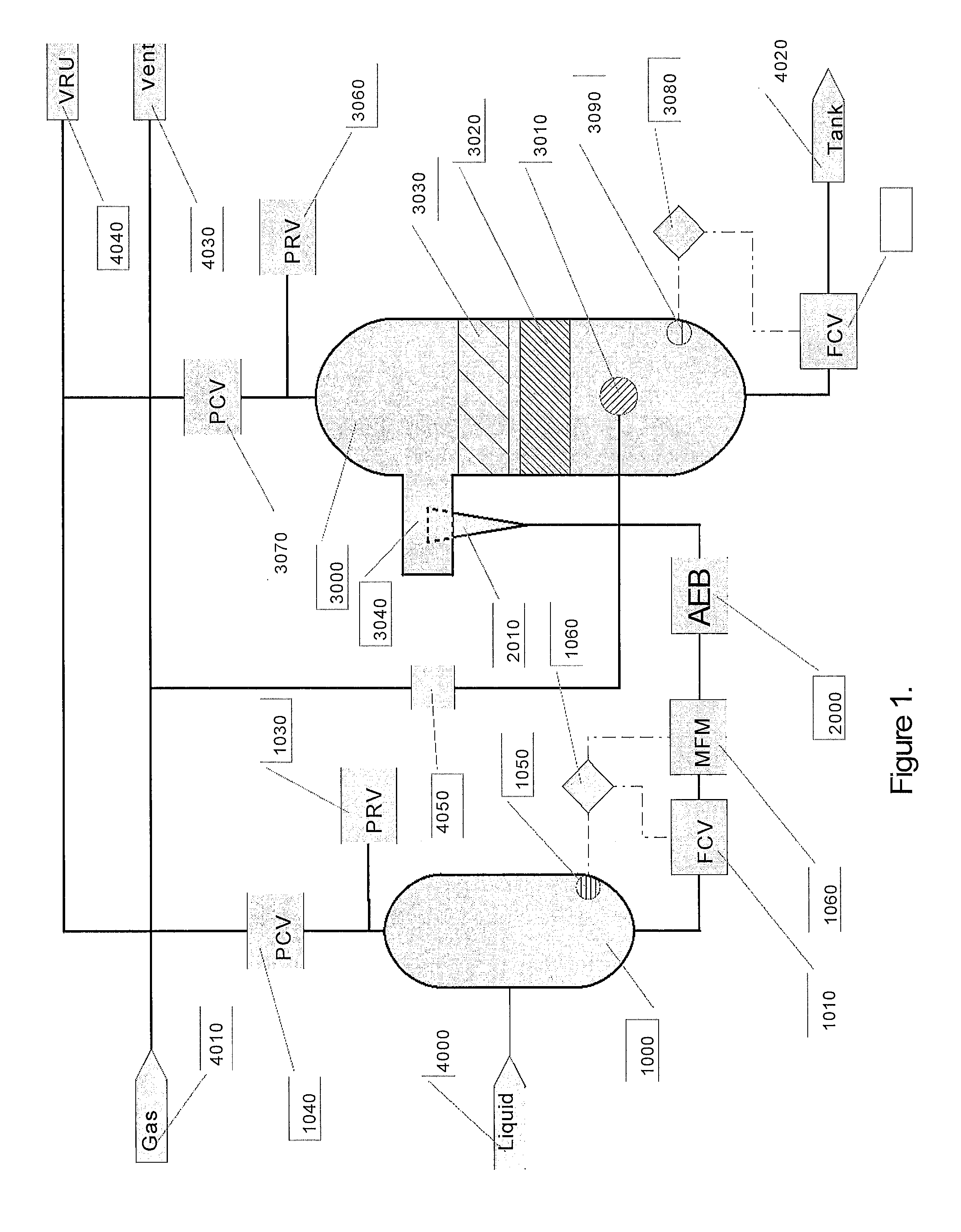

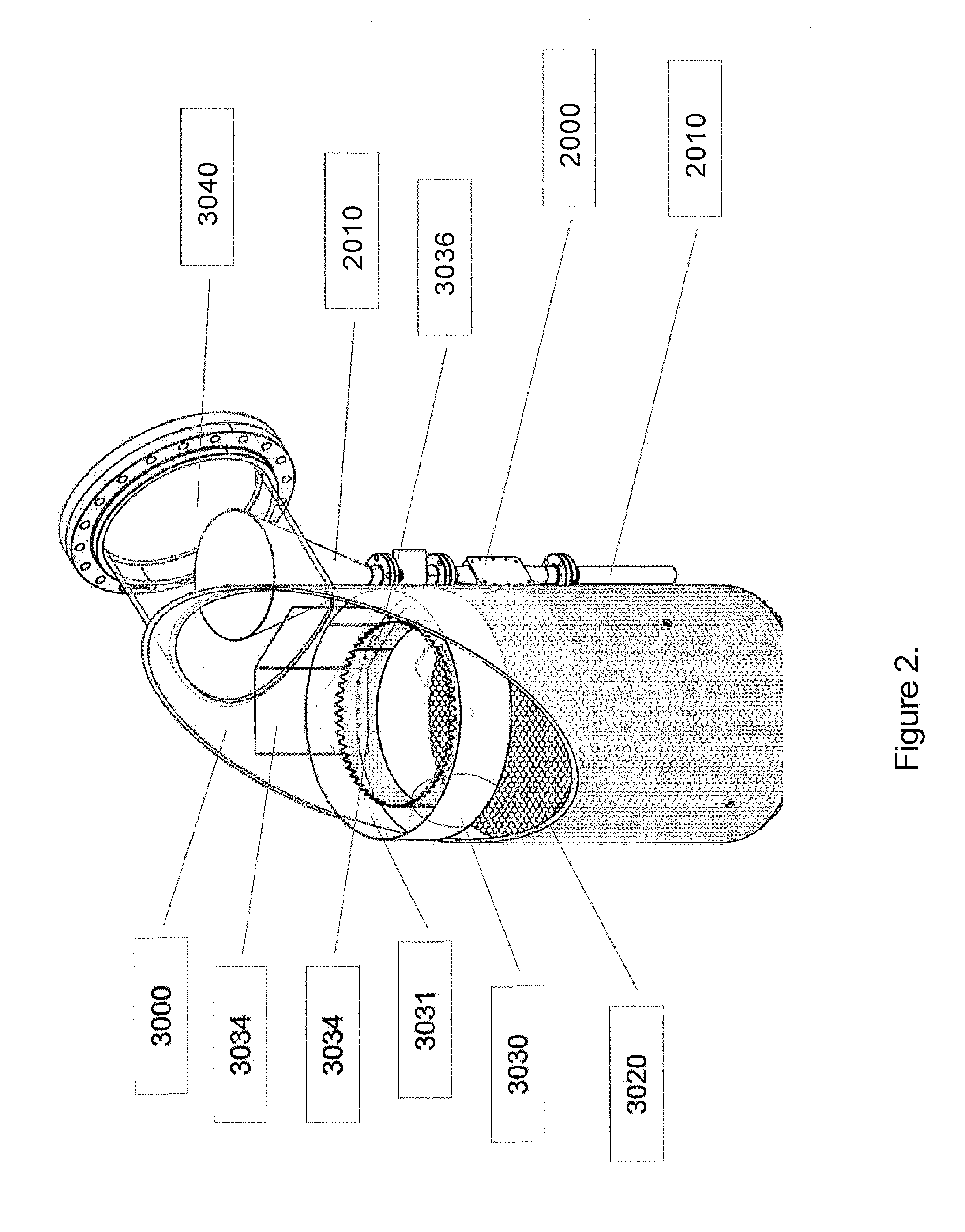

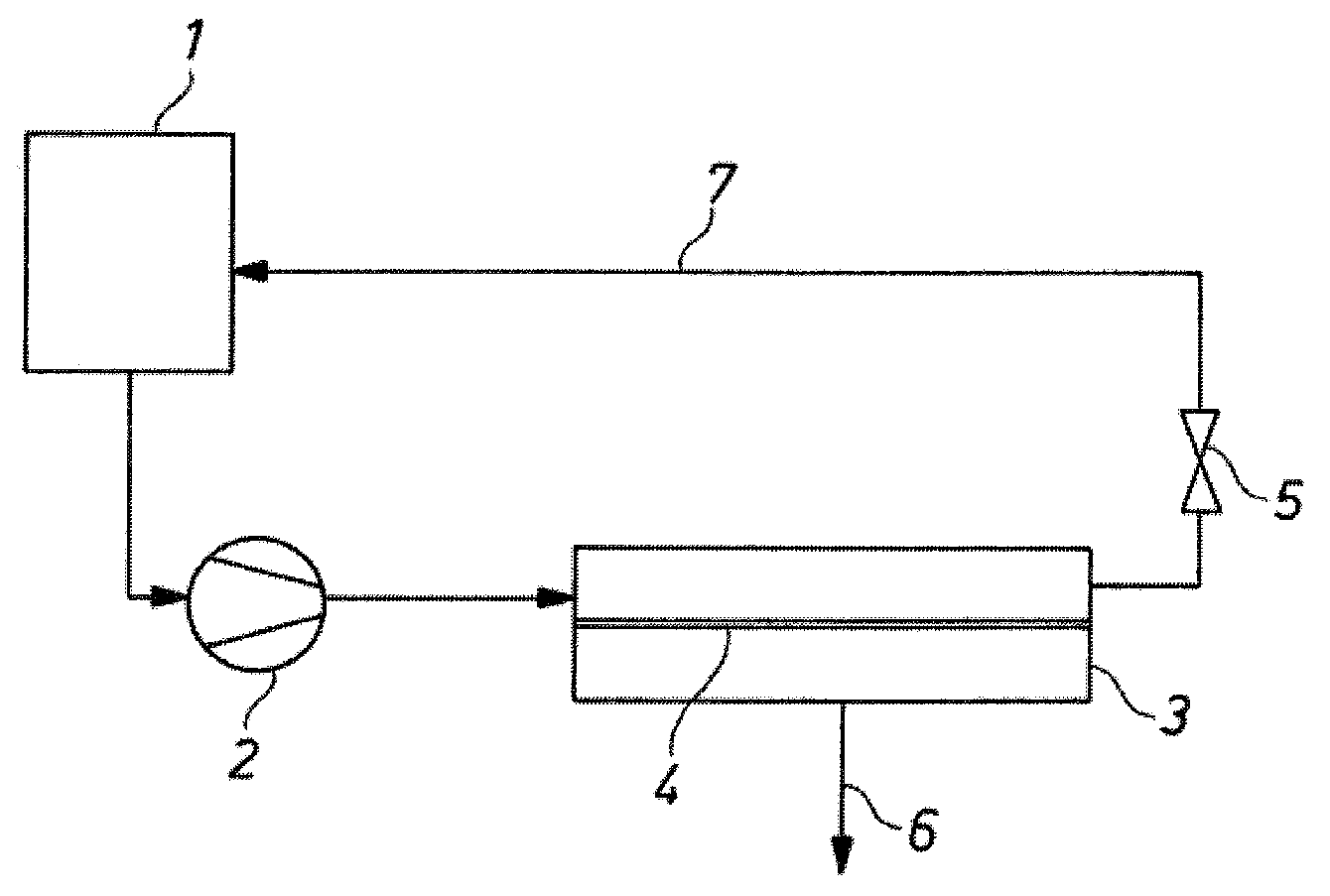

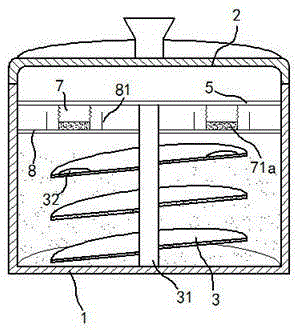

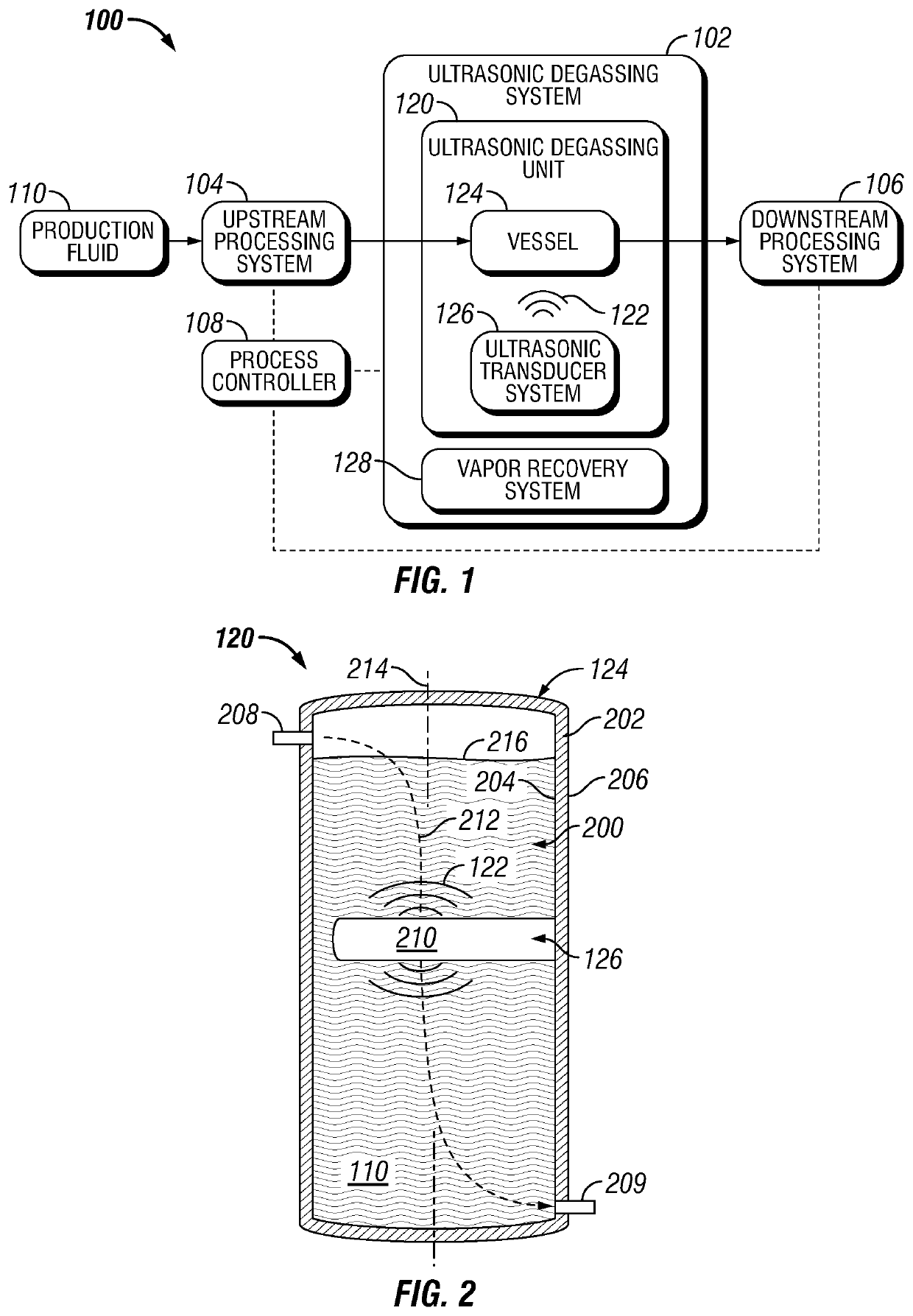

Ultrasonic degassing of hydrocarbon production fluid

ActiveUS20190345396A1Low vapor pressureReduce gas contentTreatment with plural serial refining stagesHydrocarbon oils refiningUltrasonic sensorHandling system

Provided are embodiments that include a hydrocarbon fluid processing system including an ultrasonic hydrocarbon degassing unit including a vapor recovery vessel adapted to direct flow of a hydrocarbon fluid mixture along a flowpath extending through an interior of the vapor recovery vessel, and an ultrasonic transducer system disposed inside the vapor recovery vessel and in the flowpath of the hydrocarbon fluid mixture. The hydrocarbon fluid mixture including a hydrocarbon liquid and a gas entrained in the hydrocarbon liquid, the ultrasonic transducer system adapted to transmit ultrasonic signals into the hydrocarbon fluid mixture along the flowpath, and the ultrasonic signals adapted to separate the gas from the hydrocarbon liquid.

Owner:CONOCOPHILLIPS CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com