Defoaming reaction vessel

A reaction kettle and kettle body technology, applied in chemical/physical/physical-chemical stationary reactors, foam dispersion/prevention, degassing by vibrating liquid, etc., can solve the problems of air pressure change, reduced foam removal effect, and high cost, To achieve the effect of reasonable stroke, exquisite structure and elimination of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

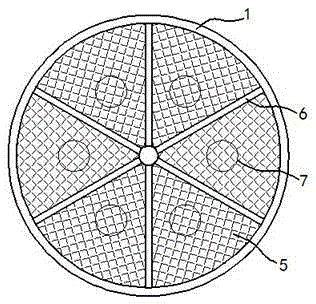

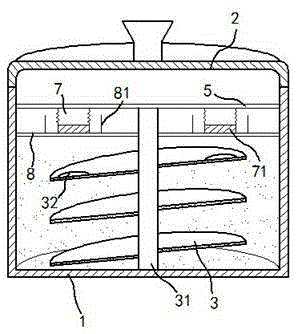

[0018] exist figure 1 , figure 2 In the shown embodiment one, this defoaming reaction kettle includes a kettle body 1, a kettle cover 2 and a rotating shaft 31, and a threaded paddle 3 for stirring is also installed on the rotating shaft 31; Permanent magnet blocks 32 are installed on the surface; each of the permanent magnet blocks 32 is evenly distributed on the horizontal plane relative to the rotating shaft 31 circumferentially; The bottom surface of the body 1 is parallel; the defoaming device includes a limit screen 5 and a support 6, and the limit screen 5 is installed on the rotating shaft 31; the support 6 is fixed on the limit screen 5 Below; the support 6 divides the limiting screen 5 into 6 fan-shaped areas; in each of the fan-shaped areas, elastic airbags 7 are also distributed on the lower surface of the limiting screen 5, and each The side wall of the elastic airbag 7 is provided with an air injection hole, the air injection hole is simple in structure and sm...

Embodiment 2

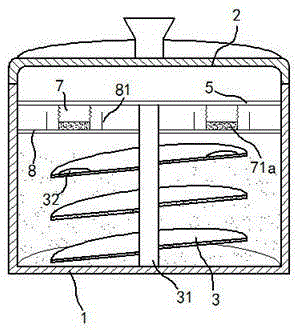

[0025] exist image 3 In the shown embodiment two, different from embodiment one, the ferromagnetic plate 71 in this embodiment is replaced by magnetic powder 71a, and the particle size of the magnetic powder 71a is larger than the size of the gas injection hole; when the permanent magnet block When 32 is close to the magnetic powder 71a and absorbs the magnetic powder 71a, the elastic airbag 7 stretches and sucks the surrounding gas and air bubbles. At this time, the magnetic powder 71a is concentrated at the bottom of the elastic airbag 7; Return to the original shape and bounce back, the internal gas is sprayed out along each of the gas injection holes, and the magnetic powder 71a at the bottom is bounced and scattered in the elastic airbag 7 at the same time, and the bubbles in the elastic airbag 7 are quickly broken; compared with Embodiment 1 , the present embodiment strengthens the defoaming effect inside the elastic airbag 7, and further improves the defoaming effect; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com