Back extraction solution prepared by extraction separation of washing organic matter of saponification wastewater by recycling rare earth and solution washing method

A technology for extracting, separating and saponifying waste water of rare earth, applied in the direction of improving process efficiency, can solve the problems of increasing waste water discharge, large equipment investment, large new water volume, etc., to reduce organic consumption, improve rare earth yield, and reduce resource waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

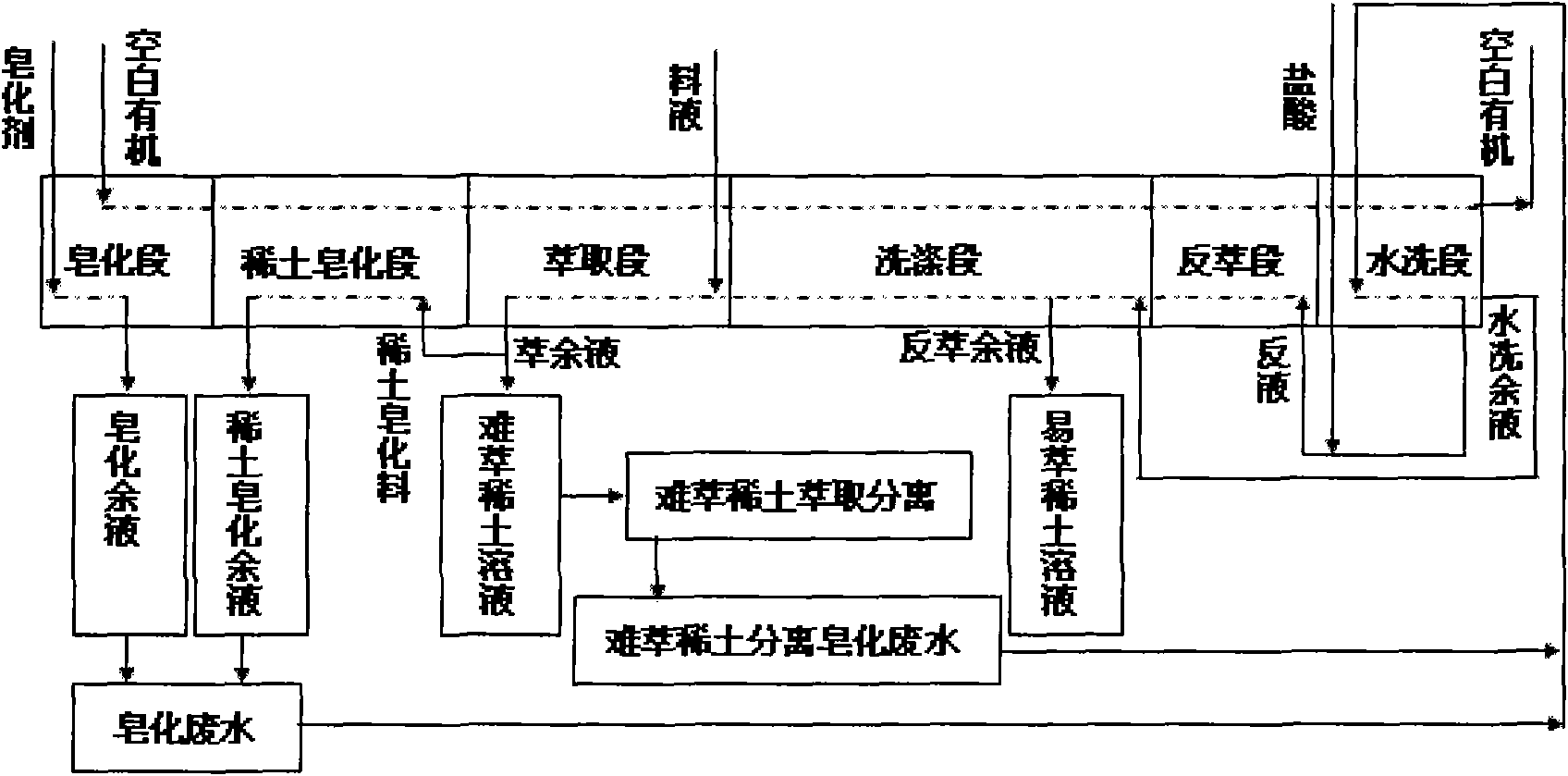

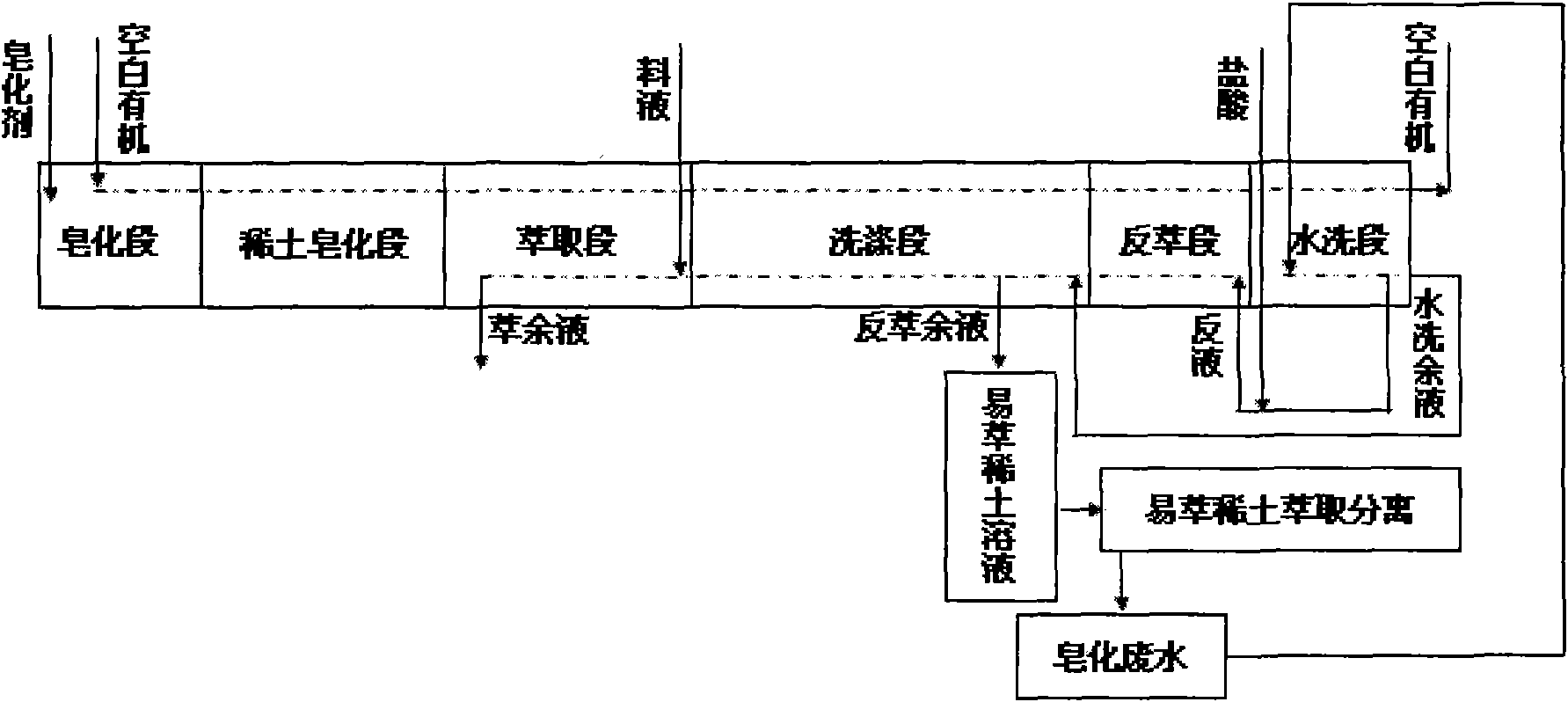

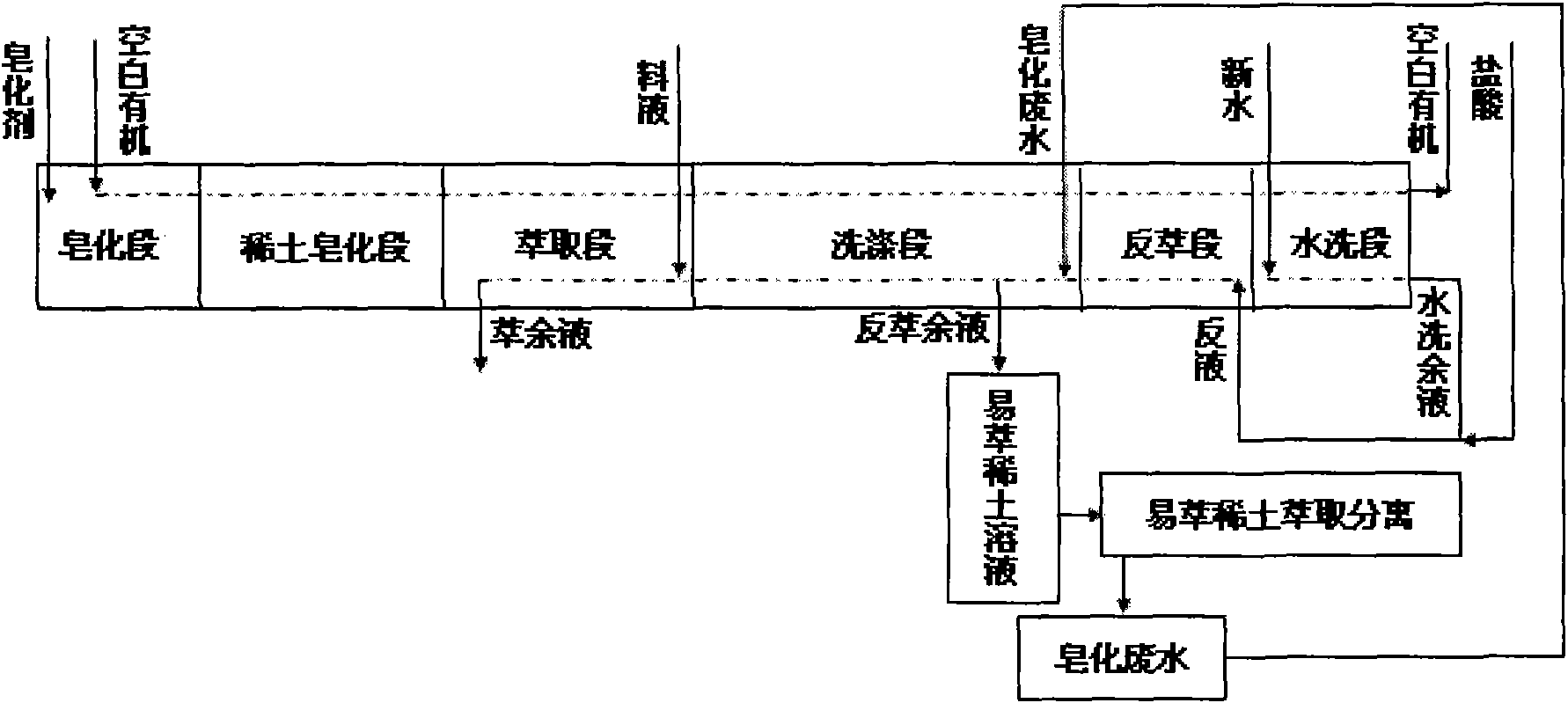

Method used

Image

Examples

Embodiment 1

[0018] The raw material is the raffinate after the separation of neodymium and samarium from the mixed rare earth chloride solution, the rare earth concentration is 1.5mol / L, pH=2, and its composition includes La 2 o 3 Content is 28.61%, CeO 2 The content is 50.46%, Pr 6 o 11 The content is 5.31%, Nd 2 o 3 The content is 15.63%; the separation scale is 12250 tons / year (calculated by rare earth oxide);

[0019] The organic phase is P 507 (diluted with kerosene), its concentration is 1.5mol / L;

[0020] La 3+ and Ce 3+ For refractory rare earth elements, Pr 3+ and Nd 3+ Easy to extract rare earth elements;

[0021] Ammonia is used as the saponification agent for the extraction and separation of cerium and praseodymium and the saponification agent for the extraction and separation of praseodymium and neodymium;

[0022] The saponification wastewater produced by the extraction and separation of praseodymium and neodymium is 174M 3 / day, the concentration of ammonium ch...

Embodiment 2

[0026] The raw material is the back-extraction solution after the mixed rare earth chloride solution is separated by gadolinium and terbium, the rare earth concentration is 1.2mol / L, pH=2, and its composition includes Tb by weight ratio 4 o 7 The content is 6.72%, Dy 2 o 3 The content is 22.52%, (Ho-Lu, Y) 2 o 3 The content is 70.76%; the separation scale is 464 tons / year (calculated by rare earth oxide);

[0027] The organic phase is P 507 (diluted with kerosene), its concentration is 1.5mol / L;

[0028] Tb 3+ and Dy 3+ Refractory rare earth elements, (Ho-Lu, Y) 3+ Easy to extract rare earth elements;

[0029] Sodium hydroxide is used as the saponification agent for the extraction and separation of dysprosium and holmium and the saponification agent for the extraction and separation of erbium and thulium;

[0030] Erbium and thulium extraction and separation to produce saponification wastewater is 9.25M 3 / day, the sodium chloride concentration in the waste water is...

Embodiment 3

[0034] The raw material is a mixed rare earth chloride solution, the rare earth concentration is 1.5mol / L, pH=2, and its composition is by weight ratio La 2 o 3 -Nd 2 o 3 Content is 98%, Sm 2 o 3 -Lu 2 o 3 and Y 2 o 3 The content is 2%; the separation scale is 12,500 tons / year (calculated as rare earth oxides)

[0035] The organic phase is P 507 (diluted with kerosene), its concentration is 1.5mol / L;

[0036] La 3+ -Nd 3+ For refractory rare earth elements, Sm 3+ -Lu 3+ and Y 3+ Easy to extract rare earth elements;

[0037] Ammonium bicarbonate solution is used as the saponification agent for the extraction and separation of neodymium and samarium, and ammonia water is used as the saponification agent for the extraction and separation of praseodymium and neodymium;

[0038] The saponification wastewater produced by the extraction and separation of praseodymium and neodymium is 174M 3 / day, the concentration of ammonium chloride in the waste water is 2.6mol / L; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com