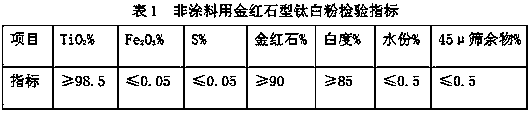

Production method of non-coating rutile type titanium dioxide

A technology of rutile-type titanium dioxide and a production method, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve problems such as low quality of primary rutile products, low rutile conversion rate of seed crystals, and complicated process flow, and achieve transformation High efficiency, low calcination temperature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A production method of rutile titanium dioxide for non-coating, including the following steps:

[0032] (1) Selected raw materials: control P in titanium ore 2 0 5 The mass percentage content is less than 0.05%;

[0033] (2) Titanium liquid preparation: add sulfuric acid to titanium ore according to the conventional process, and obtain the titanium liquid after acidolysis, sedimentation, freezing, crystallization and separation of ferrous iron. The titanium liquid is not concentrated, and the obtained titanium liquid The relevant indicators are as follows: TiO 2 Concentration: 140±10g / L, F value: 1.85~2.05; Fe-titanium ratio: 0.30~0.45; Clarity: first-grade Shenqing; trivalent titanium content: 0.5~1.5g / L; stability: ≥300;

[0034] (3) Titanium liquid preheating: the titanium liquid prepared and measured according to the process indicators is poured into the hydrolysis preheating pot, and steamed for heating; at the same time, the seed titanium is measured at 2.2% of the volum...

Embodiment 2

[0042] A production method of rutile titanium dioxide for non-coating, including the following steps:

[0043] (1) Selected raw materials: control P in titanium ore 2 0 5 The mass percentage content is less than 0.05%;

[0044] (2) Titanium liquid preparation: add sulfuric acid to titanium ore according to the conventional process, and obtain the titanium liquid after acidolysis, sedimentation, freezing, crystallization and separation of ferrous iron. The titanium liquid is not concentrated, and the obtained titanium liquid The relevant indicators are as follows: TiO 2 Concentration: 140±10g / L, F value: 1.85~2.05; Fe-titanium ratio: 0.30~0.45; Clarity: first-grade Shenqing; trivalent titanium content: 0.5~1.5g / L; stability: ≥300;

[0045] (3) Titanium liquid preheating: the titanium liquid prepared and measured according to the process indicators is poured into the hydrolysis preheating pot, and steamed for heating; at the same time, it is measured to the seed titanium at 2.2% of the...

Embodiment 3

[0053] A production method of rutile titanium dioxide for non-coating, including the following steps:

[0054] (1) Selected raw materials: control P in titanium ore 2 0 5 The mass percentage content is less than 0.05%;

[0055] (2) Titanium liquid preparation: add sulfuric acid to titanium ore according to the conventional process, and obtain the titanium liquid after acidolysis, sedimentation, freezing, crystallization and separation of ferrous iron. The titanium liquid is not concentrated, and the obtained titanium liquid The relevant indicators are as follows: TiO 2 Concentration: 140±10g / L, F value: 1.85~2.05; Fe-titanium ratio: 0.30~0.45; Clarity: first-grade Shenqing; trivalent titanium content: 0.5~1.5g / L; stability: ≥300;

[0056] (3) Titanium liquid preheating: the titanium liquid prepared and measured according to the process indicators is poured into the hydrolysis preheating pot, and steamed for heating; at the same time, the seed titanium is measured at 2.2% of the volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com