Patents

Literature

38results about How to "Raise the yield of rare earth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering rare earth from rare earth fluoride fused salt electrolysis waste with effects of environmental protection and low cost

InactiveCN104843761ARaise the yield of rare earthResponse equipment requirements are lowRare earth metal compoundsElectrolysisRare earth

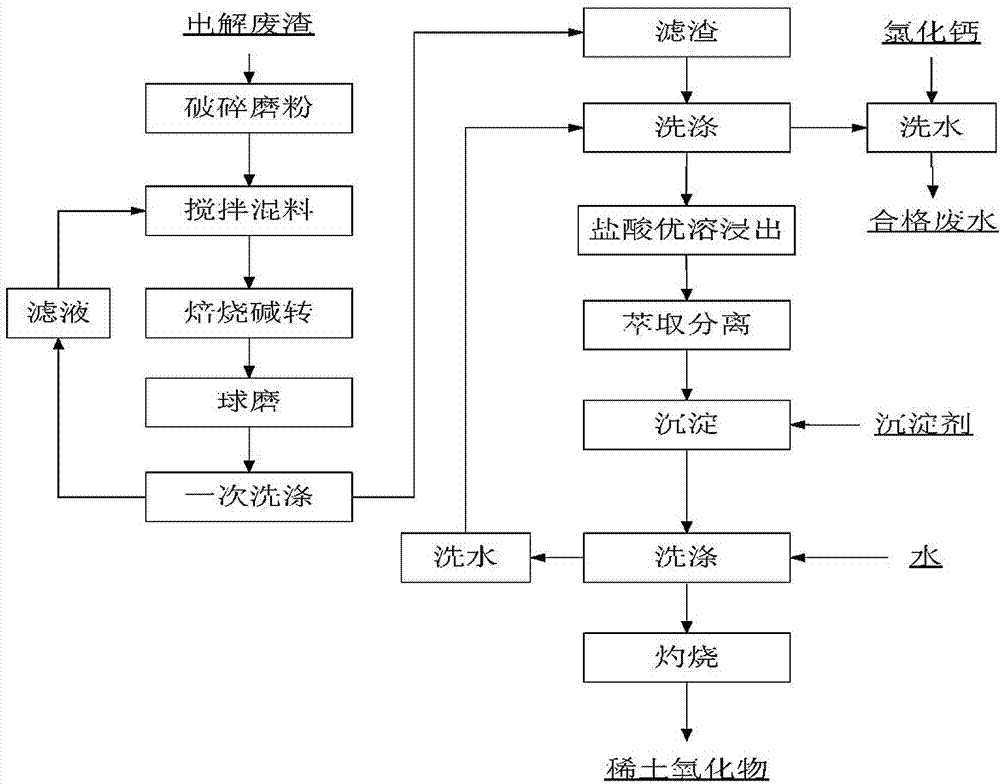

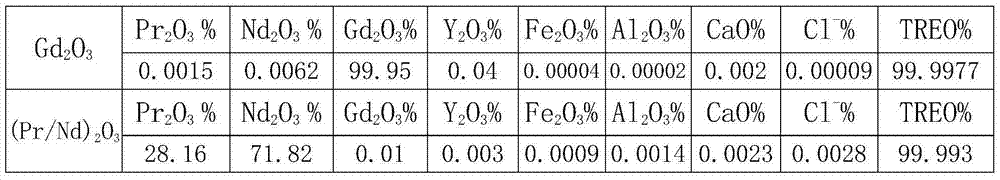

The invention discloses a method for recovering rare earth from rare earth fluoride fused salt electrolysis waste with effects of environmental protection and low cost. Rare earth fluoride fused salt electrolysis waste is taken as a raw material, and is subjected to breaking, grinding, agitation, mixing, calcining alkali conversion, ball milling, washing, optimal solution leaching, extraction separation, depositing, washing and burning to prepare a single or mixed rare earth oxide. The method has the advantages of high recovery rate of rare earth, low requirement on reaction equipment, repeated use of production sewage, low production cost, energy saving, environmental protection, good working environment, good economic benefit and the like.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

Method for adding rare earth into RH refining furnace

The invention relates to a method for adding rare earth into RH refining furnace. The method is characterized in that rare earth lanthanum ferroalloy is added into a RH refining station vacuum feeding bin; molten steel, which satisfies the condition that total oxygen content T.O is less than or equal to 0.002 wt%, active oxygen content a [O] is less than or equal to 0.0005 wt% and [S] content is less than or equal to 0.005 wt% in steel, undergoes vacuum treatment at the RH refining station for 10 min or more than 10 min; and according to the calculated addition of rare earth, rare earth lanthanum ferroalloy is added into a vacuum chamber from the vacuum feeding bin, wherein the addition of the rare earth is controlled within the range of 0.005-0.015 wt%. The invention has the following advantages: by the adoption of the method, the yielding rate of rare earth is high and stable; continuous casting production is smooth; rare earth in steel is uniformly distributed; by the adoption of the rare earth lanthanum ferroalloy, performance of steel is substantially improved; the method requires low cost and is simple to operate; metallurgical effects of rare earth microalloyed steel are obvious; and the method has an extensive popularization and application prospect.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

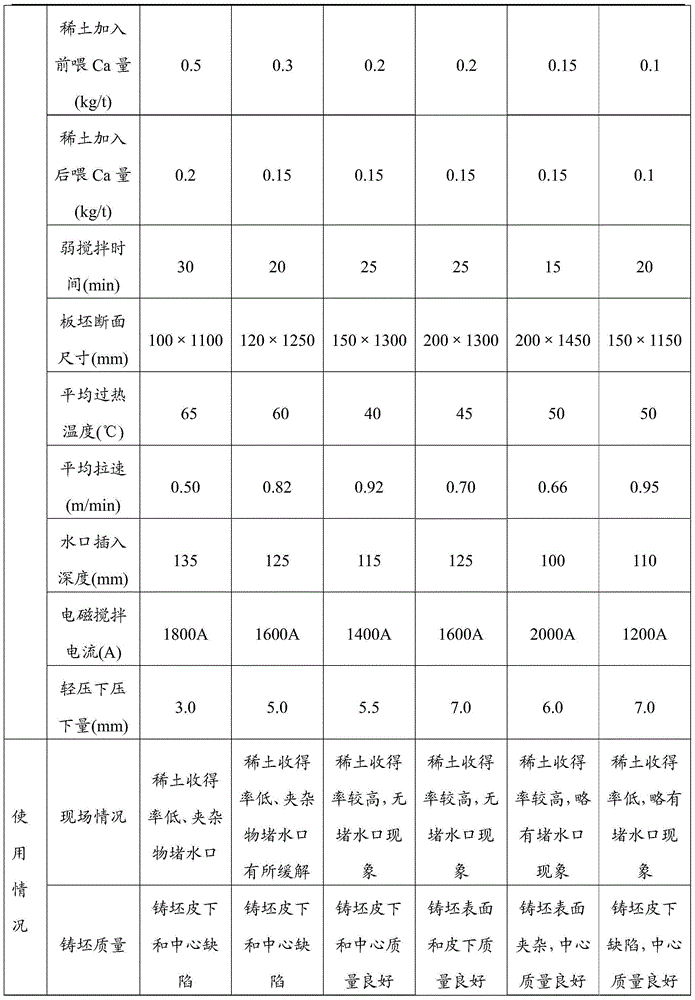

Steel containing rare earth element and producing method of slab continuous casting

ActiveCN105821339AEfficient removalRaise the yield of rare earthGas emission reductionRare-earth elementSlag

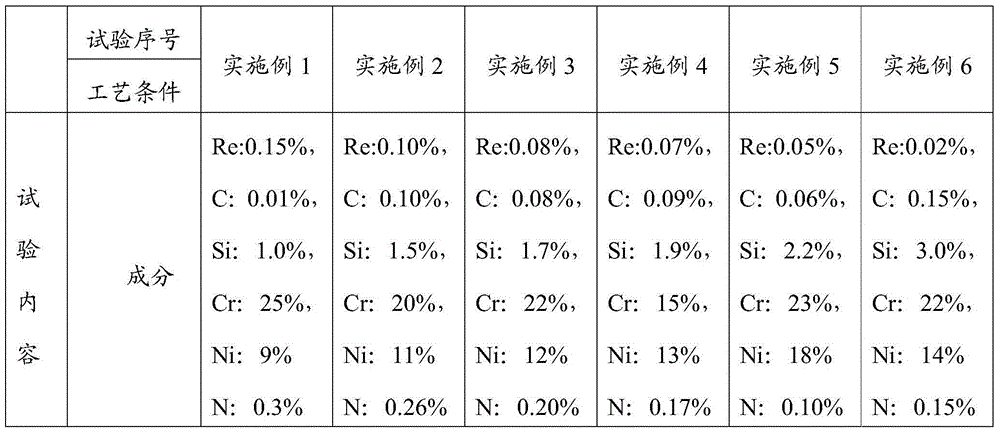

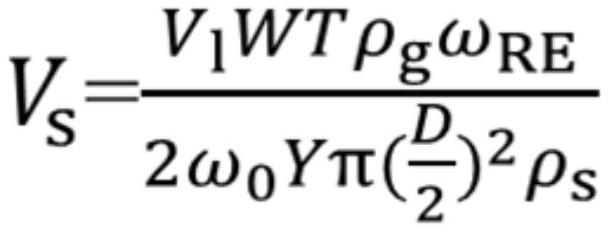

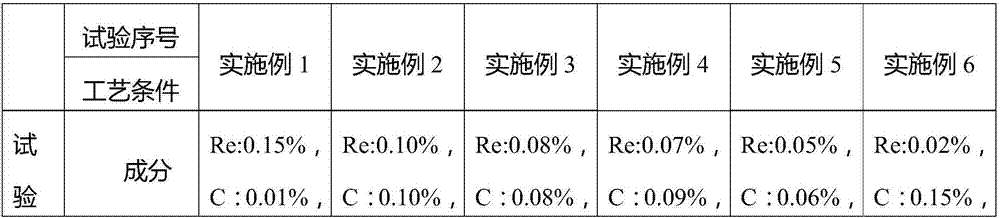

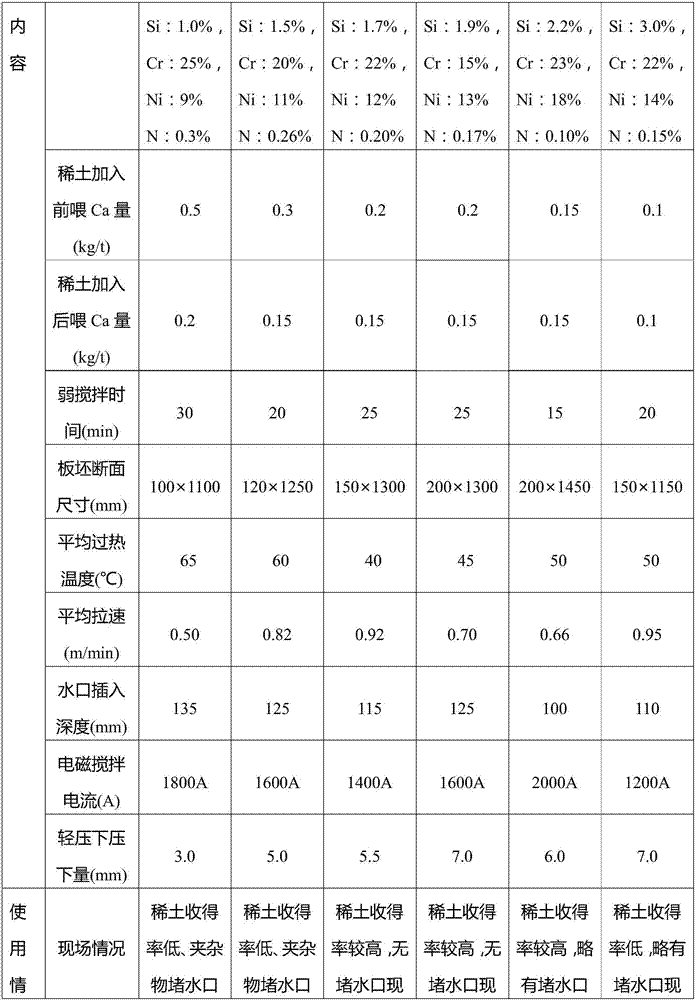

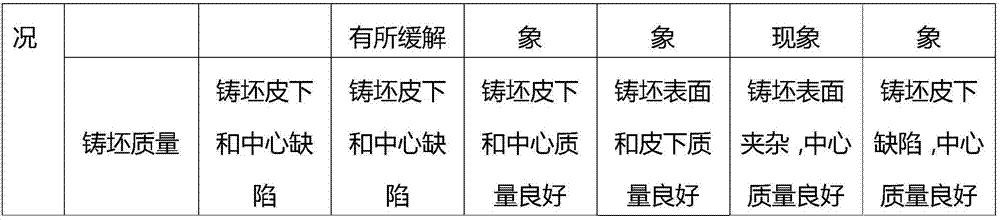

The invention discloses a steel containing rare earth element and a producing method of slab continuous casting. The steel comprises the elements of Re, C, Si, Cr, Ni, and N according to a certain ratio, and the balance of iron and inevitable impurity; the production method comprises a ladle furnace refining process and a continuous casting operation; wherein, in the ladle furnace refining process, feeding metal Ca wire before rare earth is added in molten steel, then feeding rare earth metal wires, simultaneously passing the rare earth metal wires through the surface of slag, feeding the metal Ca wires again, controlling the weak stirring time of ladle furnace refining and slag interfacial fluctuation area; and in the continuous casting process, controlling the super-heated rate of molten steel in a tundish at 35-65 DEG C, and controlling the inserting depth of an port of a continuous casting crystallizer at 100-135 mm. Compared with the prior art, the method has the advantages of high rare earth yielding rate, and good continuous casting surface and center quality, impurity in the steel is effectively removed, and rare earth yielding rate is stable.

Owner:宝武特种冶金有限公司

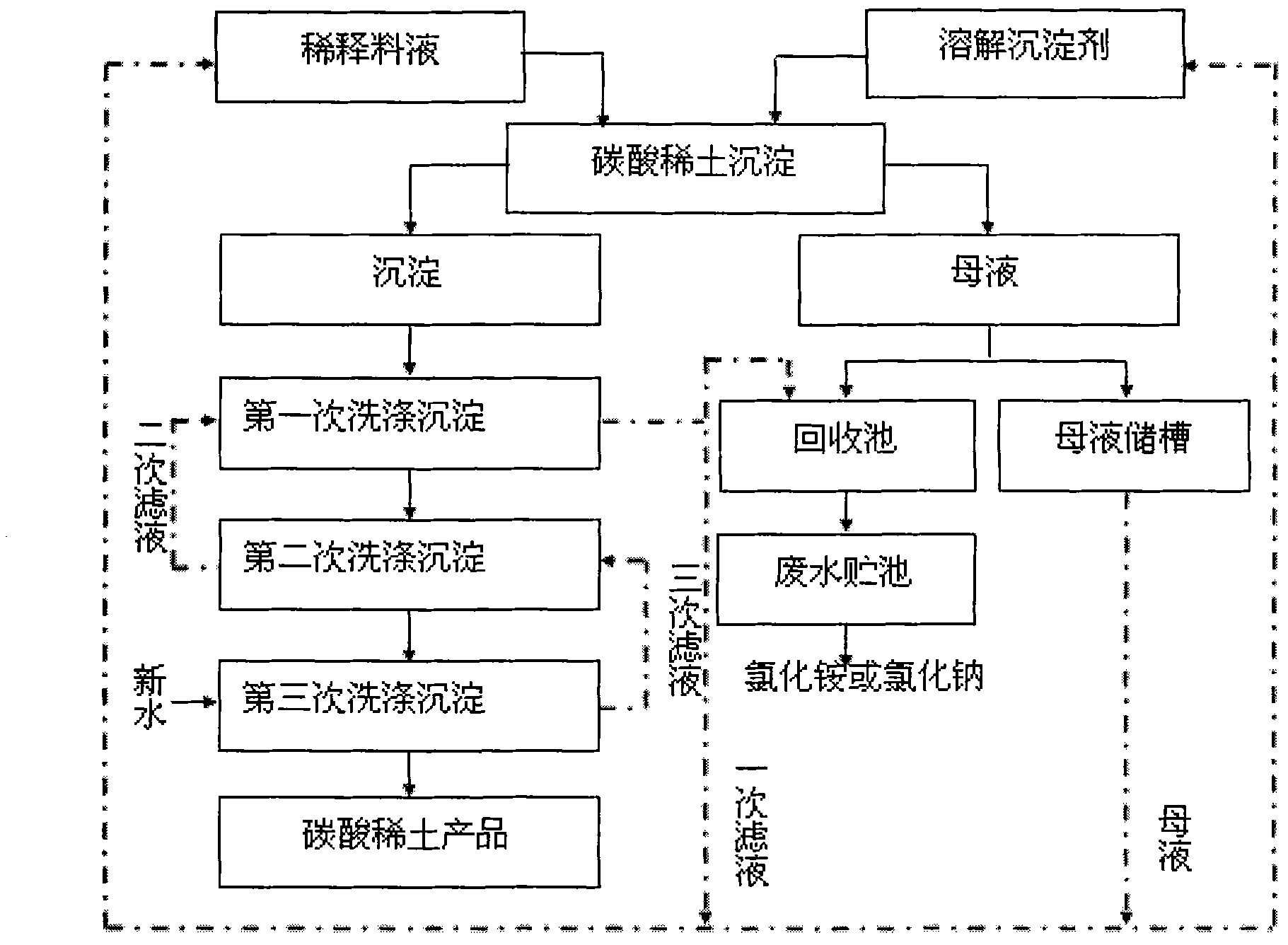

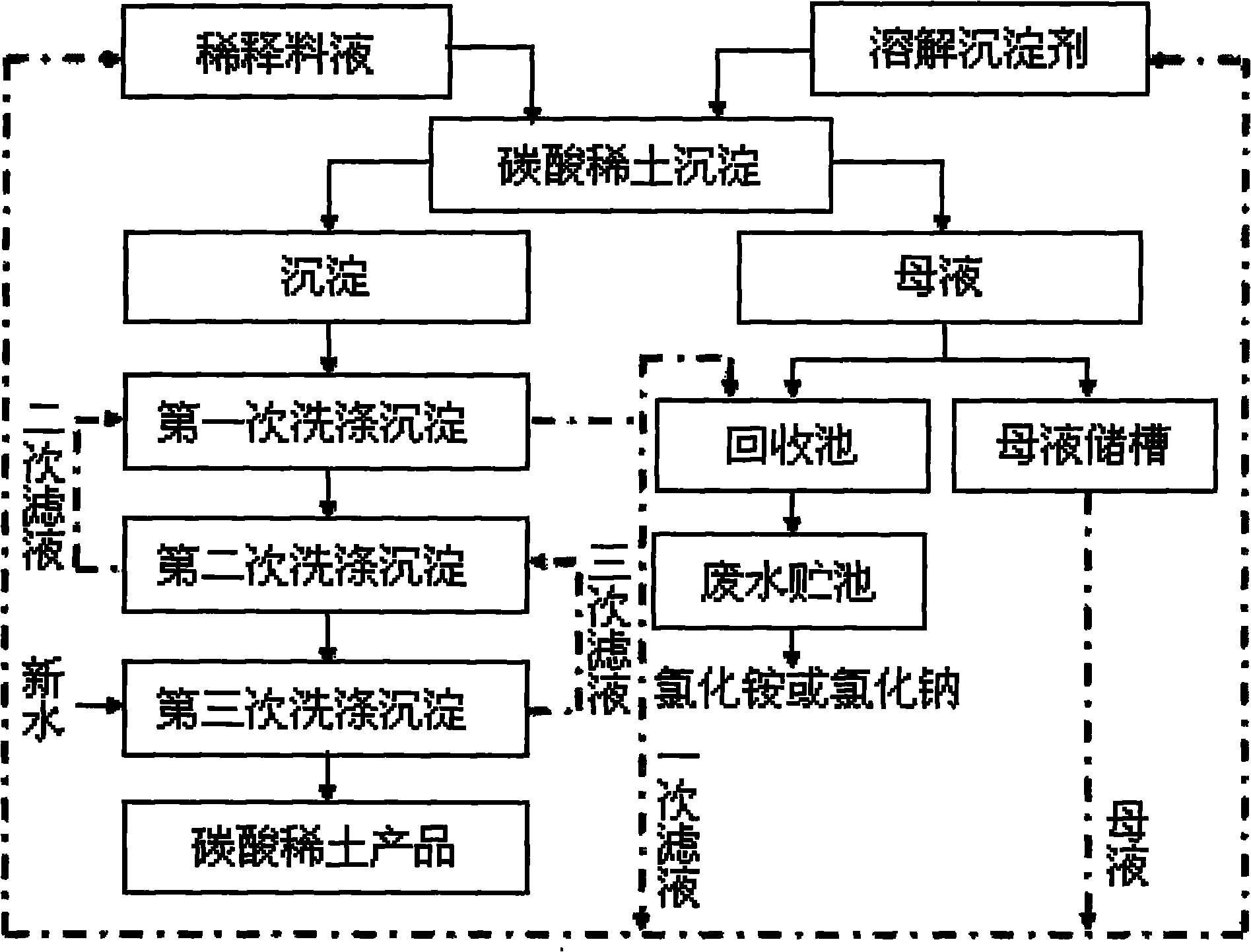

Self recycling method of waste water in rare earth carbonate precipitation

InactiveCN101967559AReduce wasteDoes not affect purityRare earth metal compoundsProcess efficiency improvementWater dischargeRare earth

The invention relates to a self recycling method of waste water in rare earth carbonate precipitation, which belongs to the field of rare earth hydrometallurgy. The method comprises the following steps: part of mother liquor, which is generated in the rare earth carbonate precipitation production process, is directly transmitted into a rare earth carbonate recycling pool to be clarified, and concentrating and crystallization equipment is used for recyling ammonium chloride or sodium chloride; the rest of the mother liquor is transmitted into a mother liquor storage tank, and is used for adjusting the concentration of carbonate precipitation liquor and dissolving the precipitant; the rare earth carbonate precipitate is washed in a reverse flow mode to obtain a first filtrate; the first filtrate and the mother liquor are recycled to the rare earth carbonate precipitation technique to dissolve the precipitant and dilute the liquor; and the residual waste water after recycling is concentrated and crystallized to recycle ammonium chloride or sodium chloride. The precipitation waste water is recycled, thereby reducing waste water discharge amount and the consumption of new water, increasing the concentration of ammonium chloride or sodium chloride in waste water and lowering the energy consumption for concentration and crystallization.

Owner:BAOTOU JINGRUI NEW MATERIAL

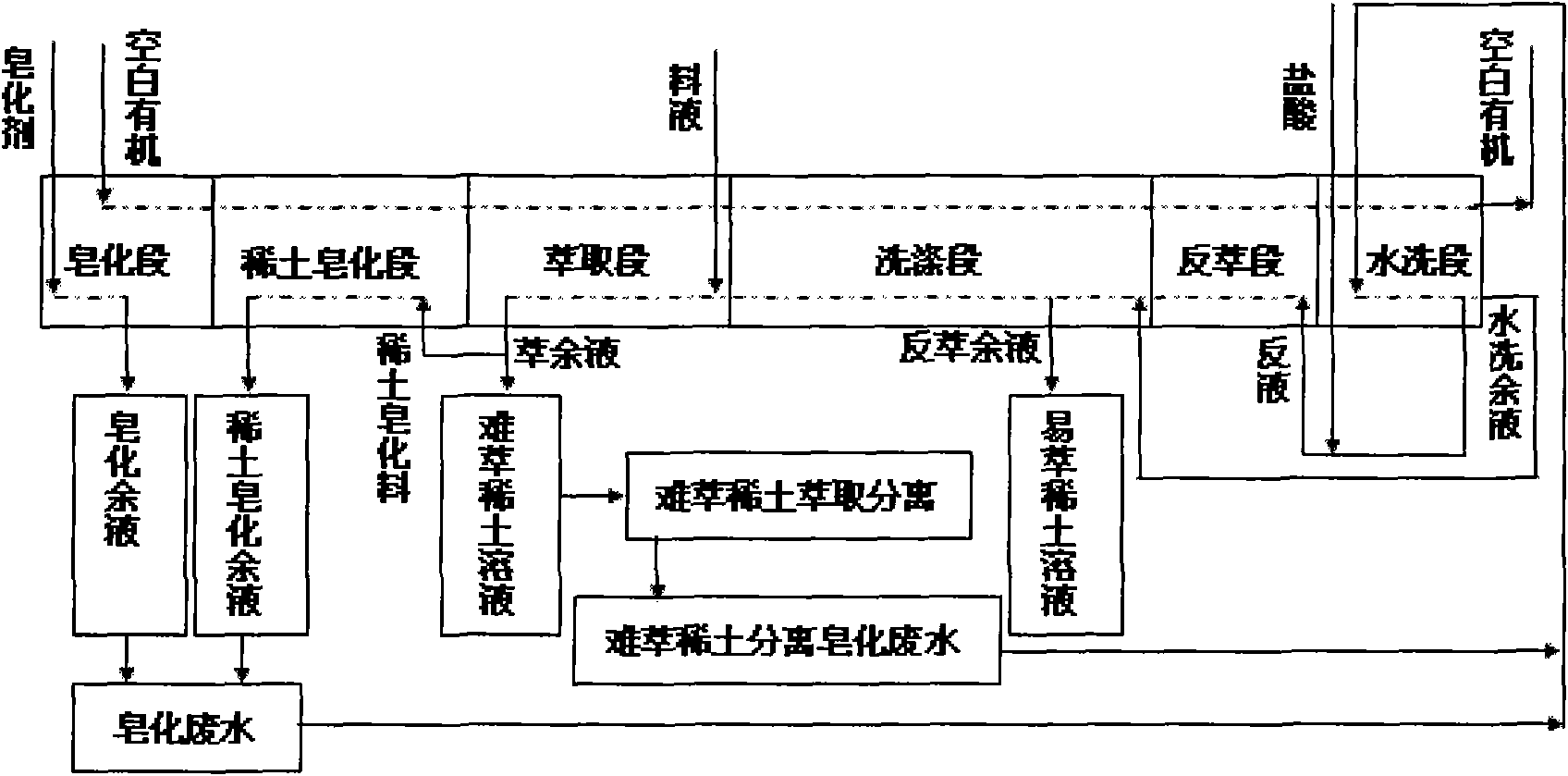

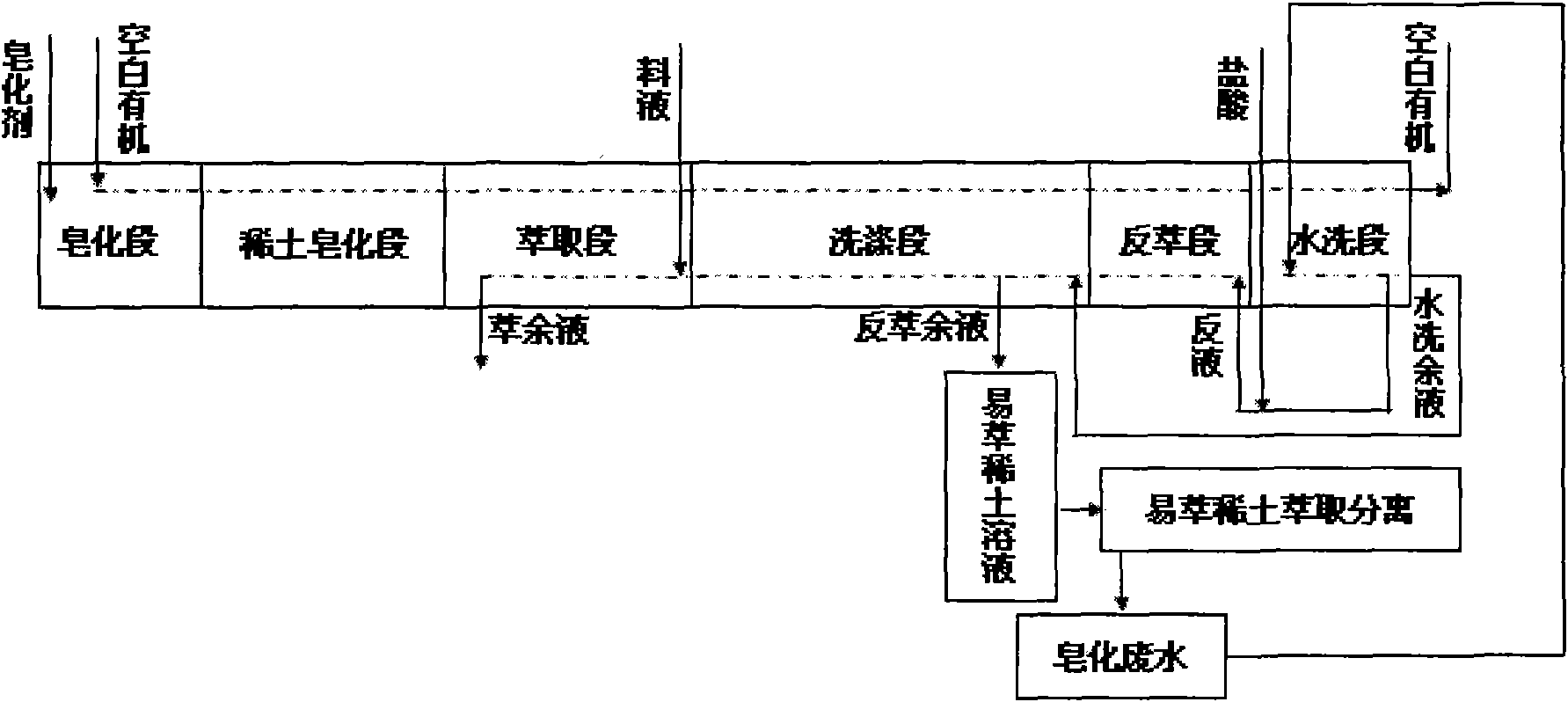

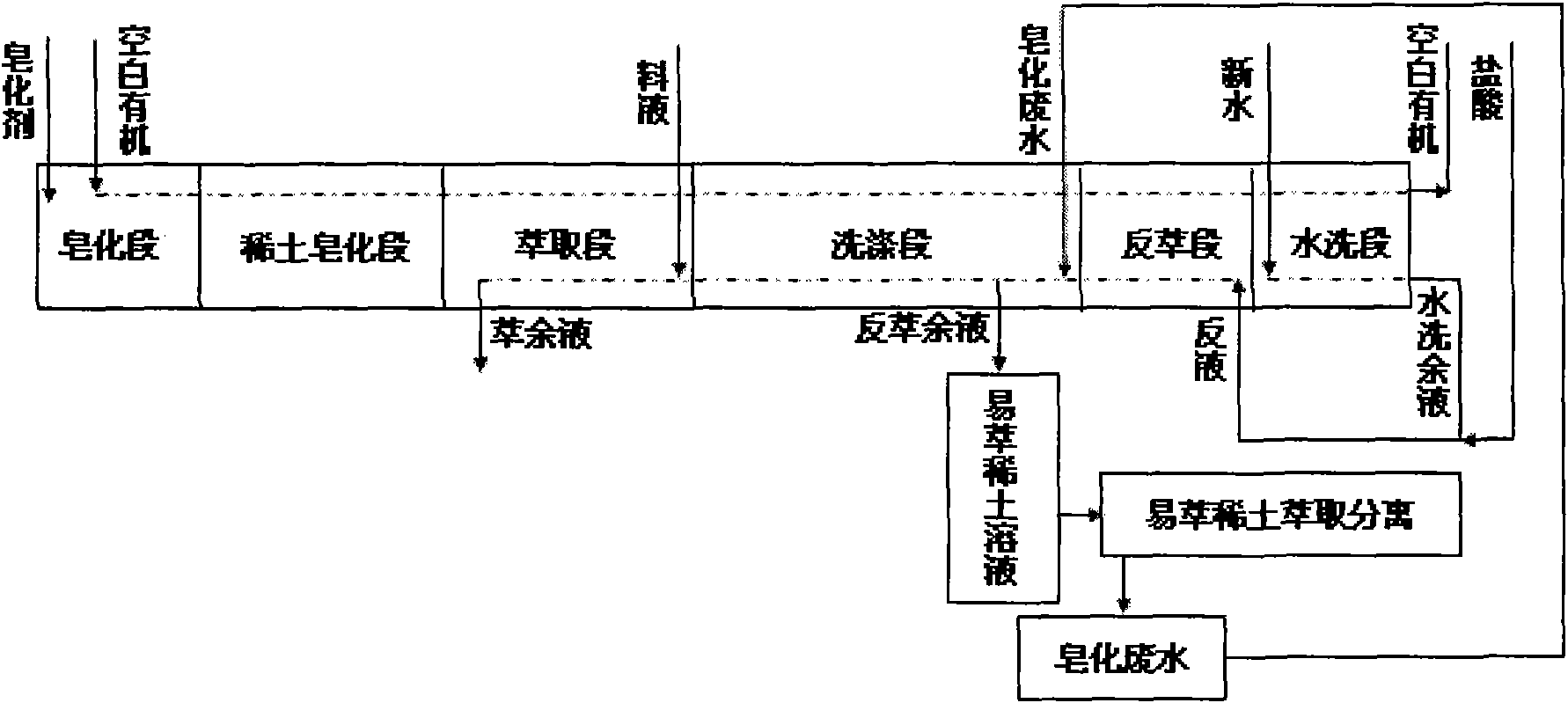

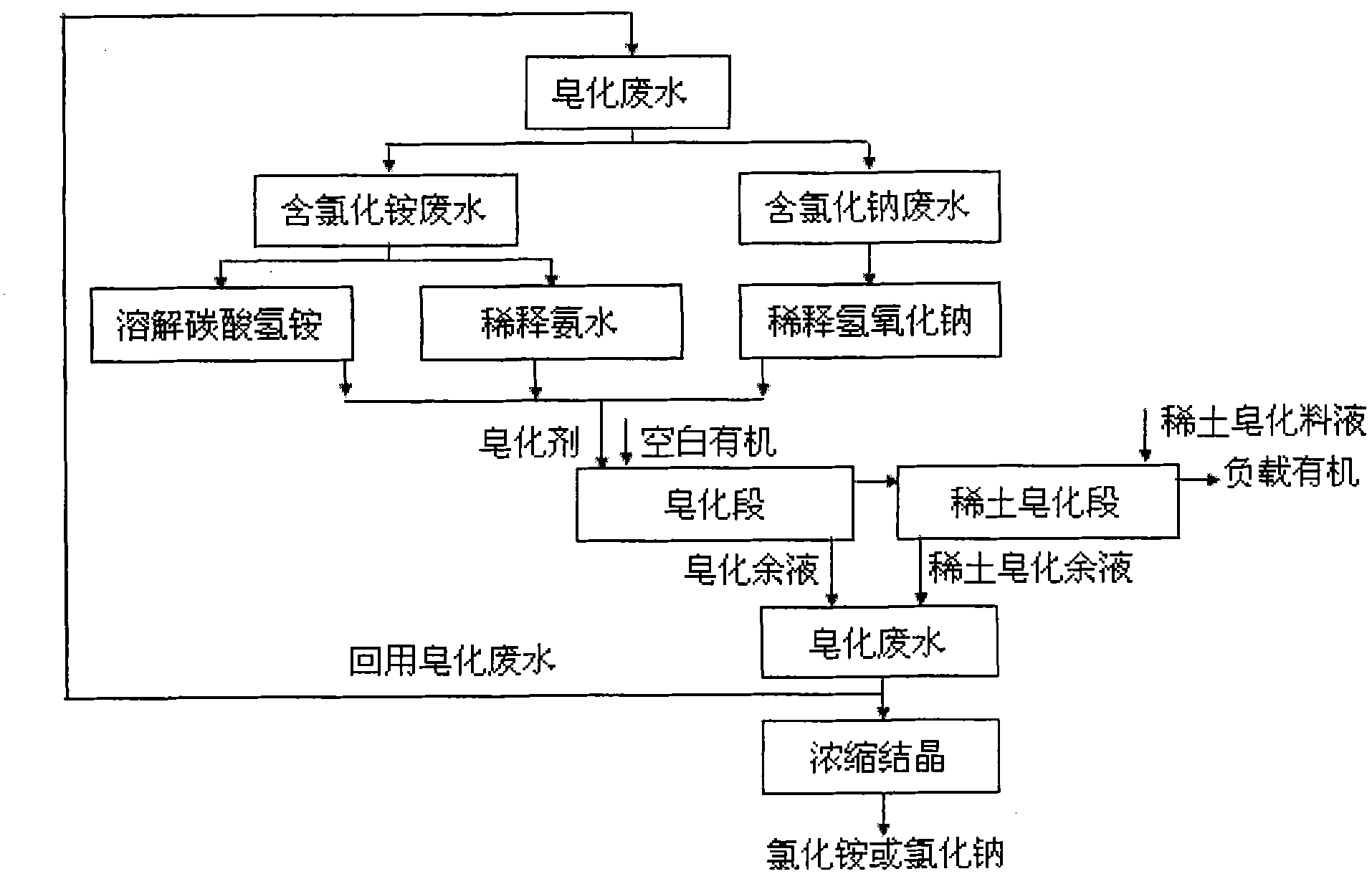

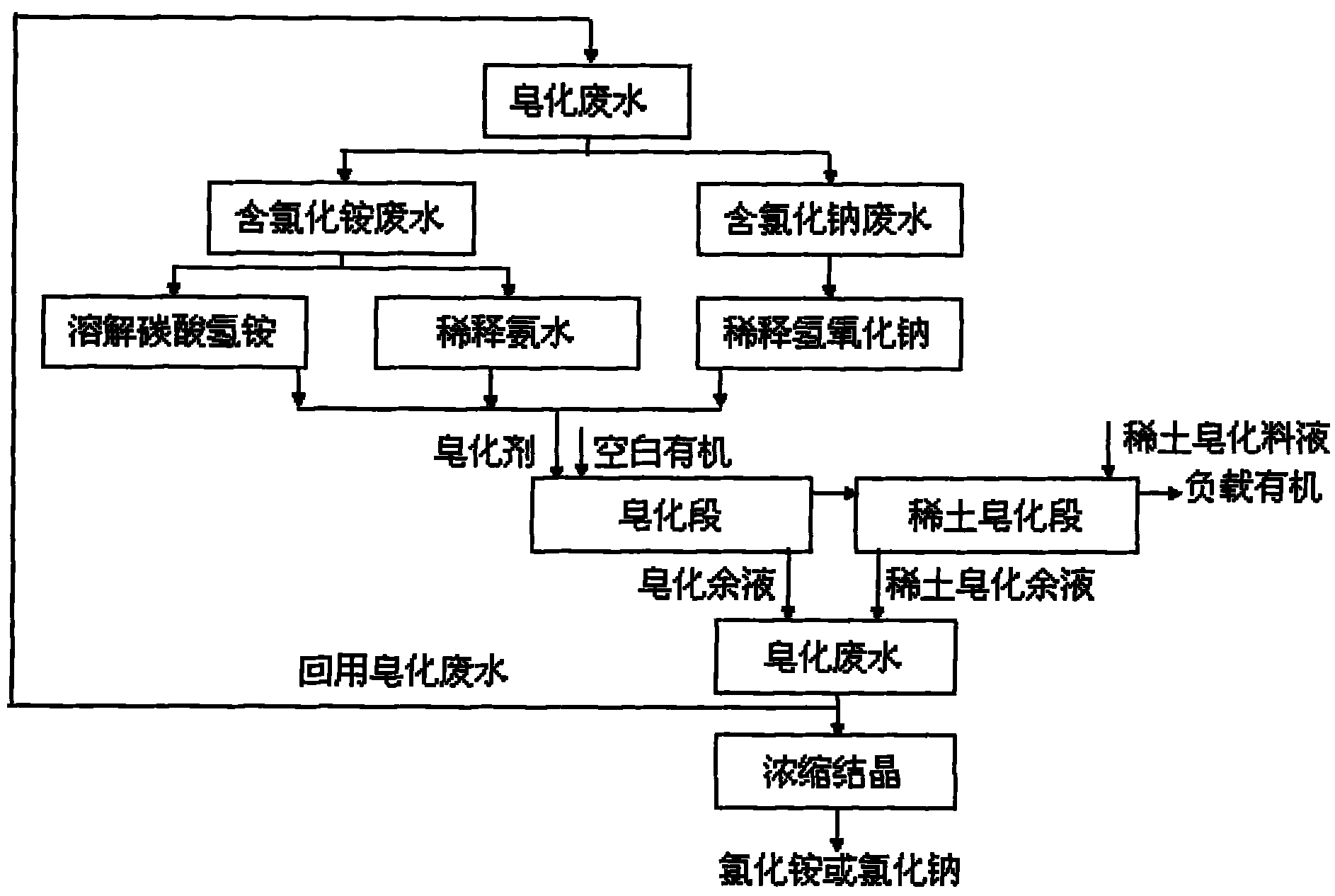

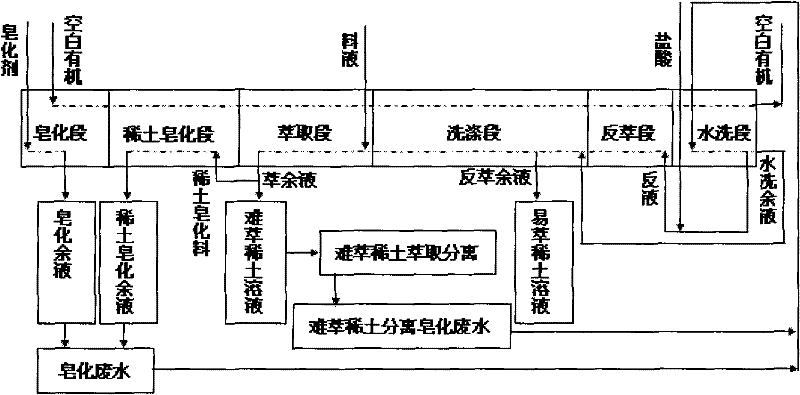

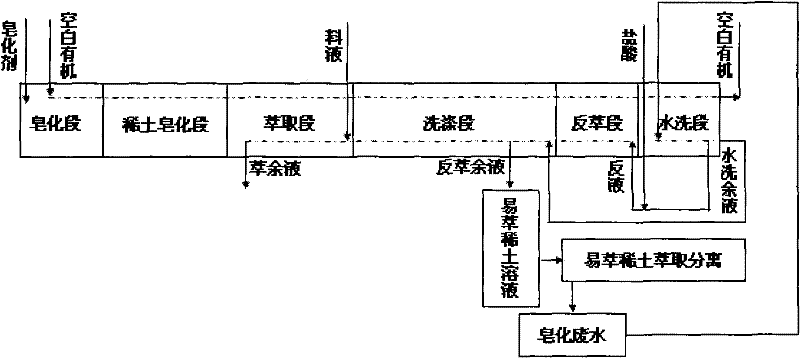

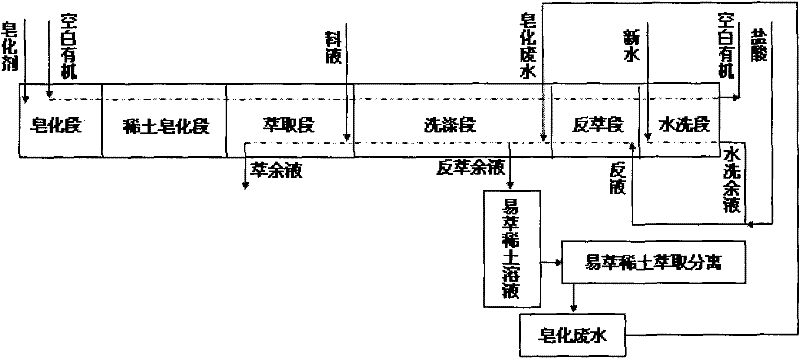

Back extraction solution prepared by extraction separation of washing organic matter of saponification wastewater by recycling rare earth and solution washing method

InactiveCN101974686ADoes not affect purityReduce wasteProcess efficiency improvementRare earthWastewater

The invention relates to a back extraction solution prepared by extraction separation of a washing organic matter of saponification wastewater by recycling rare earth and a solution washing method, belonging to the field of rare earth wet method hydrometallurgy. According to the requirement on purity of difficultly-extracted and easily-extracted elements by a rare earth extraction separation process and different ammonium chloride or sodium chloride media in a water phase in the process, the saponification wastewater is recycled and used as a washing organic matter water solution for preparing a back extraction solution and a washing solution, thus the wastewater discharge is lowered, the consumption of fresh water is reduced, the concentration of ammonium chloride or sodium chloride in the wastewater is improved, the energy consumption of concentrating and crystallizing as well as recycling the ammonium chloride or sodium chloride is decreased, the rare earth yield is improved and the organic matter loss is lowered.

Owner:BAOTOU JINGRUI NEW MATERIAL

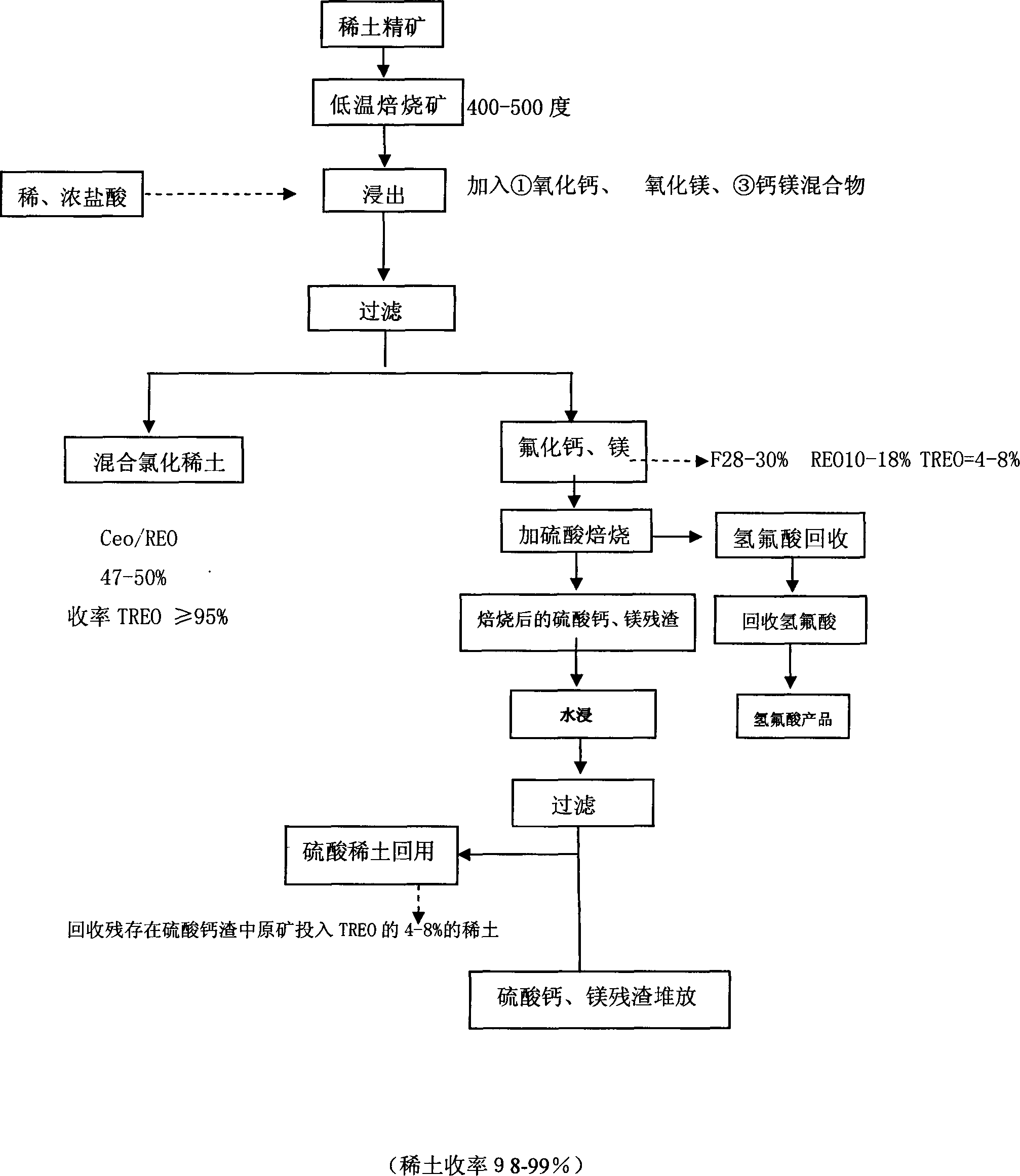

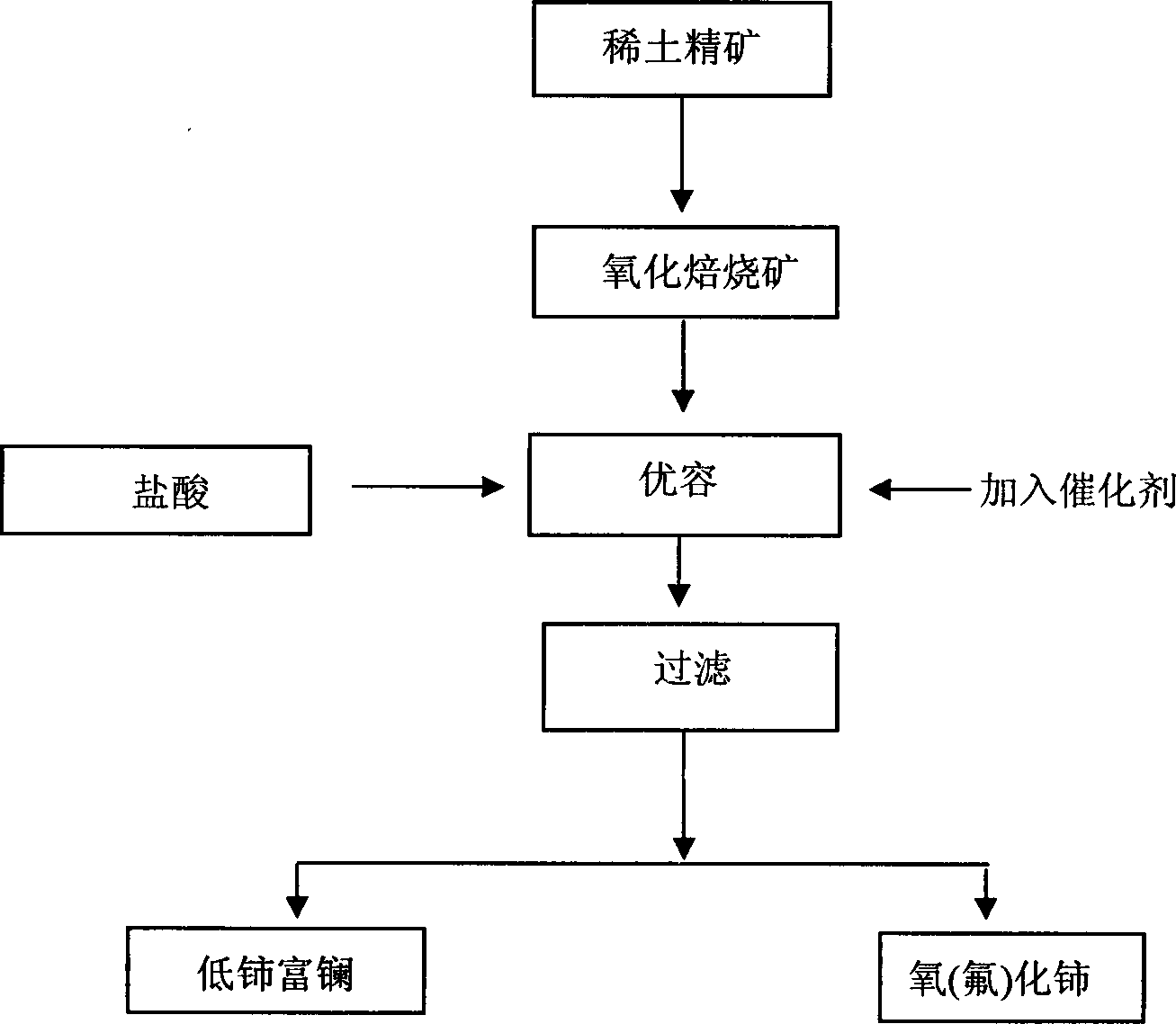

Method for replacement dissolution of bastnaesite (bastnasite)

InactiveCN103014334ALow costDoes not affect product qualityProcess efficiency improvementRare-earth elementWater immersion

The invention belongs to separation of nonferrous metals and rare earth, and particularly relates to a method for replacement dissolution of rare earth bastnaesite and bastnasite. The technical scheme is that the method comprises the following steps of: performing low-temperature roasting on the bastnaesite and bastnasite at 400 to 500 DEG C; adding chlorhydric acid into the materials after the low-temperature roasting to dissolve out rare earth, and adding non-rare-earth substances which can be combined with fluorine (F) into the mixtures to combine with the F so as to obtain a rare earth chloride solution and solid fluoride, and performing solid-liquid separation; adding sulfuric acid into the obtained solid fluoride to roast and recover hydrofluoric acid; and performing water immersion on rare earth sulfate contained in dry residues after the recovery of the hydrofluoric acid to obtain a rare earth sulfate solution. According to the method, the fluorine ions which are dissolved out when the bastnaesite is dissolved with the chlorhydric acid are not combined with the rare earth, but are combined with other non-rare-earth substances, so that the fluorine cannot be formed into rare earth fluoride to influence the dissolution rate of the rare earth. By adopting the method, a process for defluorination and a process for directed complexation of cerium are not required, the aim of completely dissolving the bastnaesite as much as possible through one step by using the chlorhydric acid is fulfilled, the fluorine is changed into other high-added-value chemical raw materials and the rare earth can be recovered through one step, so that the rare earth recovery rate and the value of rare earth elements are high.

Owner:周毅

Method for applying baotite mixed carbonate-rare earth precipitation wastewater in precipitation of europium (II) sulfate

InactiveCN102337405AWill not affect the preparation process of reduced europium sulfateWill not affect the preparation processProcess efficiency improvementRare earthHydrometallurgy

The invention relates to a method for applying baotite mixed carbonate-rare earth precipitation wastewater in precipitation of europium (II) sulfate, belonging to the field of rare earth hydrometallurgy. The method comprises the step of concentrating precipitation wastewater from production of mixed carbonate-rare earth by baking and decomposing rare earth baotite concentrate with concentrated sulfuric acid to obtain a concentrated mixed solution of ammonium sulfate and magnesium sulfate. The obtained concentrated mixed solution is used as a rich europium preparation reagent in europium oxide extraction process from Sm-Eu-Gd enrichment mineral to replace single magnesium sulfate heptahydrate to be used as europium (II) sulfate precipitant, thereby broadening the recycling ranges of precipitation wastewater from production of mixed carbonate-rare earth from rare earth baotite concentrate, lowering the energy consumption in concentration and crystallization of recovered wastewater, saving the production cost, and reducing the resource waste and environmental pollution.

Owner:BAOTOU JINGRUI NEW MATERIAL

Method for preparing saponifier by directly recycling saponification wastewater produced by extraction and separation of rare earth

InactiveCN101967558ADoes not affect purityReduce wasteProcess efficiency improvementRare-earth elementWastewater

The invention relates to a method for preparing saponifier by directly recycling saponification wastewater produced by the extraction and separation of rare earth, which belongs to the field of rare earth hydrometallurgy. In the invention, the saponification wastewater produced by the extraction and separation of the rare earth is directly recycled to prepare the saponifier; the saponification wastewater is recycled according to different ammonium chloride or sodium chloride contents of the wastewater and the characteristics of contained trace rare earth elements as well as the requirements for extraction and separation purity of the rare earth; the saponification wastewater is recycled, which reduces the discharge of wastewater, reduces the using amount of pure water, improves the ammonium chloride or sodium chloride contents of the wastewater, reduces the energy consumption on concentrating, crystallizing and recycling ammonium chloride or sodium chloride, improves the rare earth yield, and lowers the organic consumption.

Owner:BAOTOU JINGRUI NEW MATERIAL

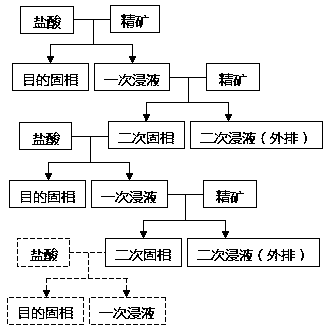

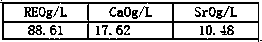

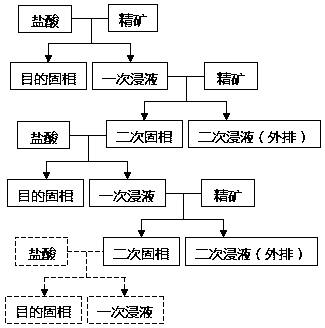

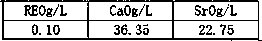

Method for leaching calcium and strontium by using low concentration hydrochloric acid to chemically separate Weishan Lake rare earth concentrate

ActiveCN108559842ARealize efficient chemical selectionReduce loss rateProcess efficiency improvementPregnant leach solutionStrontium carbonate

The invention provides a method for leaching calcium and strontium by using low concentration hydrochloric acid to chemically separate Weishan Lake rare earth concentrate. The method comprises the following steps: immersing the Weishan Lake rare earth concentrate in the low concentration hydrochloric acid, and heating the obtained solution to perform a reaction; adding the Weishan Lake rare earthconcentrate to a filtered leachate, heating the obtained solution to perform a reaction, carrying out solid-liquid separation, discharging the obtained liquid, and reusing the obtained solid phase. The grade of the Weishan Lake rare earth concentrate is improved to 50% from 40%, 90% of calcium carbonate and 85% of strontium carbonate in the Weishan Lake rare earth concentrate are efficiently leached out, the rare earth loss rate of below 1% is ensured, a discharged acid leaching waste liquid only contains calcium chloride, strontium chloride and a small amount of iron chloride, and wastewatertreatment is easy.

Owner:中稀(寿光)资源科技有限公司

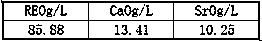

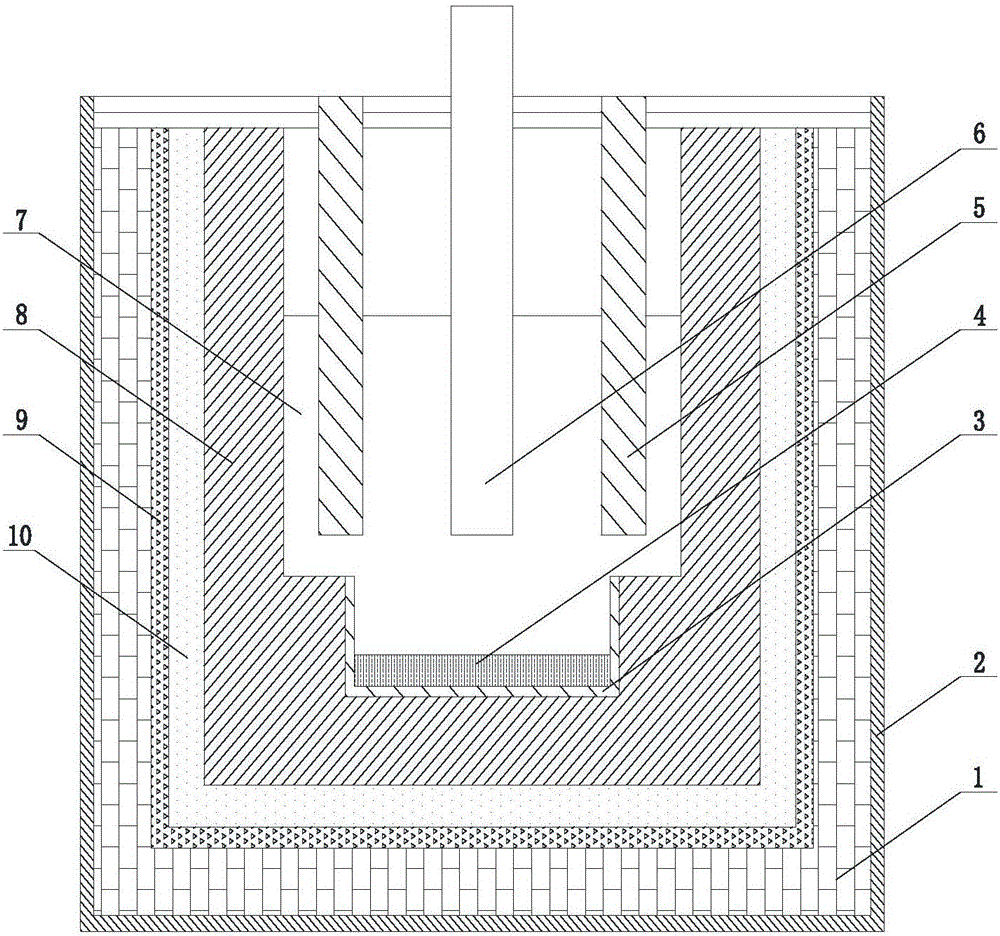

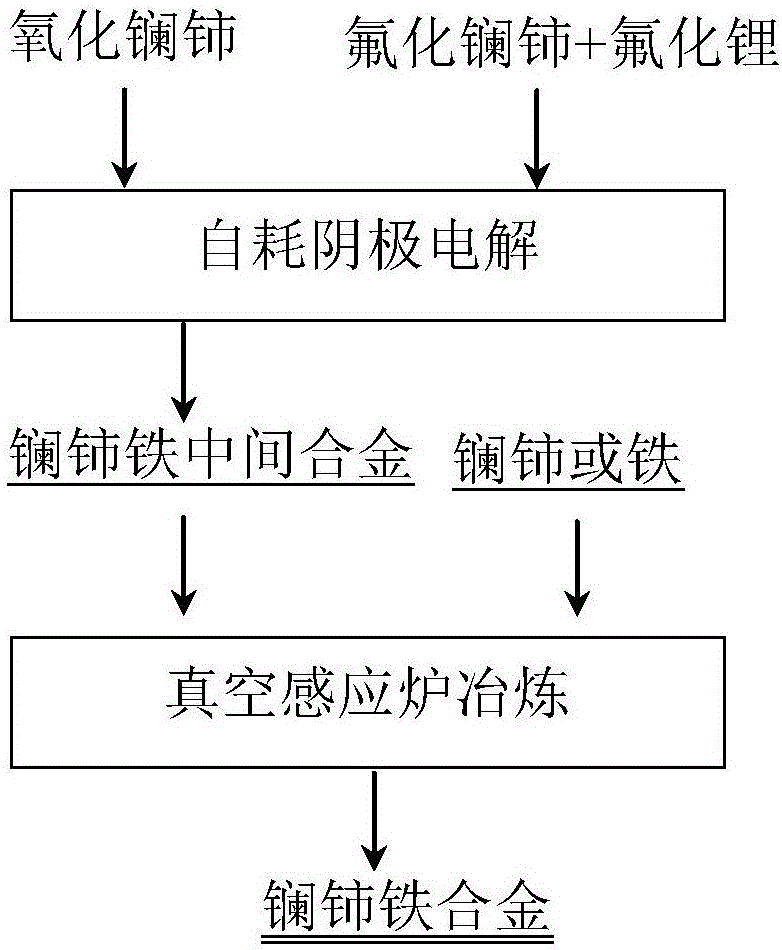

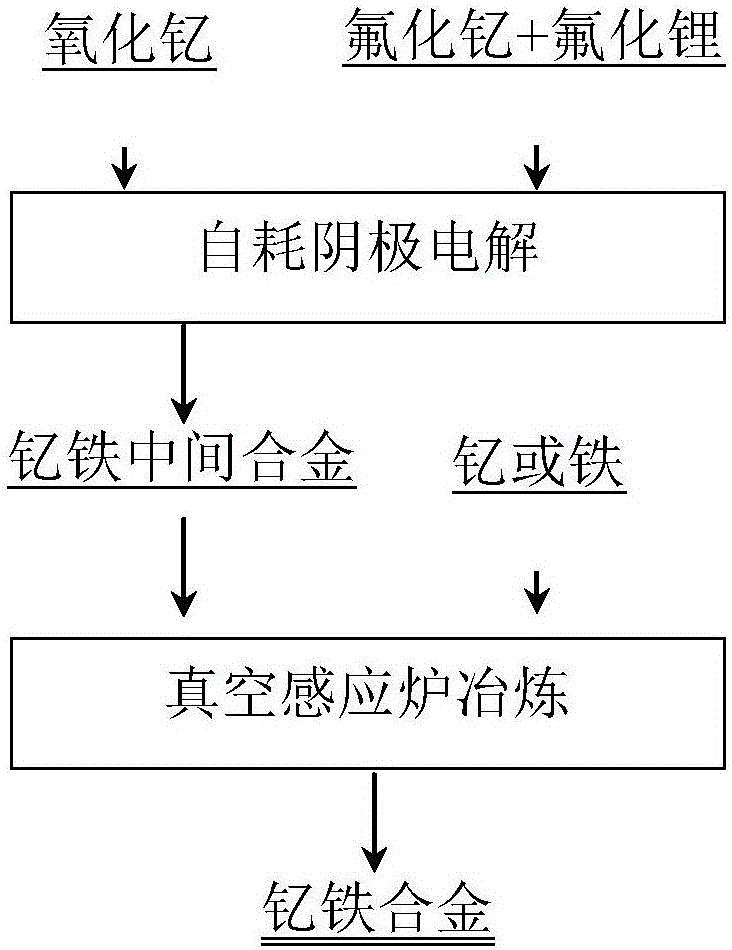

Praseodymium-neodymium-iron alloy and preparation method thereof

The invention discloses a praseodymium-neodymium-iron alloy. The praseodymium-neodymium-iron alloy comprises 0-95wt% of praseodymium and neodymium and the balance iron and inevitable impurities of which the total content is less than 0.5wt%, wherein the content of oxygen is less than or equal to 0.01wt%, the content of carbon is less than or equal to 0.01wt%, the content of phosphorus is less than or equal to 0.01wt%, and the content of sulfur is less than or equal to 0.005wt%. The invention further discloses a preparation method of the praseodymium-neodymium-iron alloy. The praseodymium-neodymium-iron alloy prepared through the method is uniform in composition, small in segregation, low in impurity content, high in rare-earth yield, low in cost, and free of pollution; and the praseodymium-neodymium-iron alloy is high in rare-earth yield and remarkable in effect when applied to rare-earth steel, and is suitable for large-scale industrial production.

Owner:BAOTOU RES INST OF RARE EARTHS +1

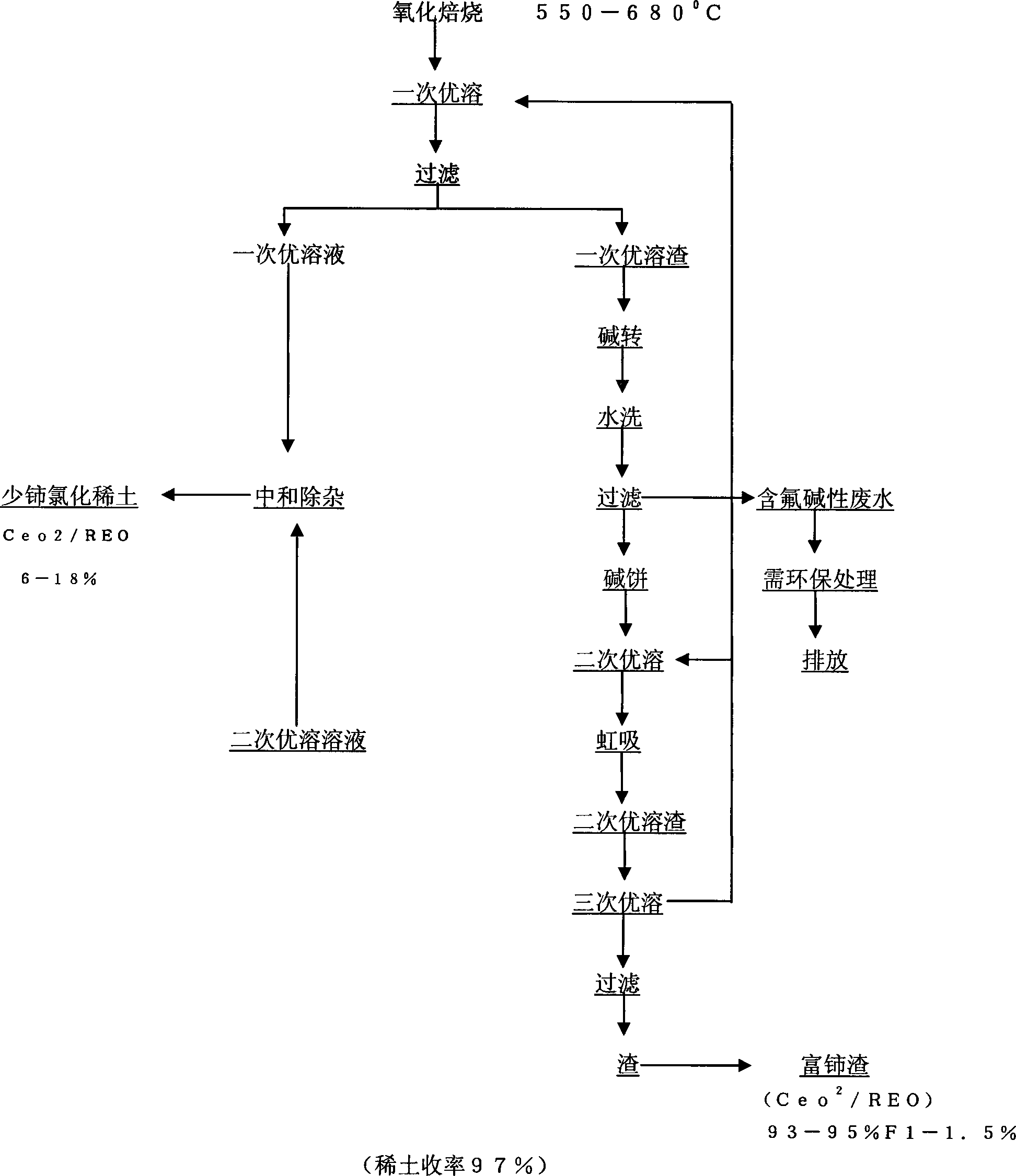

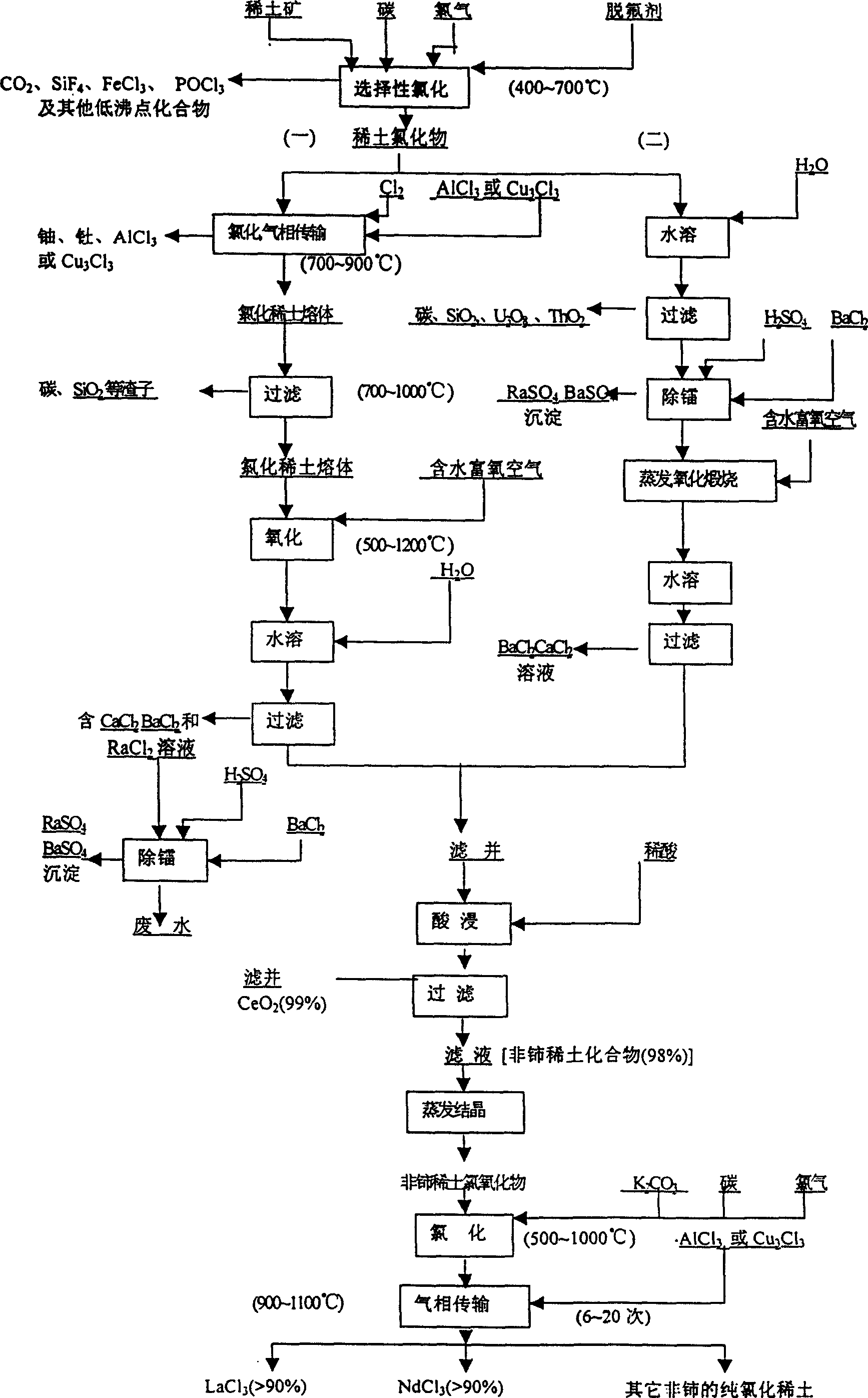

Carburizing chlorination process for extracting and separating cerium and non-Ce rare earth from rare-earth ore

InactiveCN1200123CReduce consumptionRaise the yield of rare earthRare-earth elementAlkaline earth metal

Owner:NORTHEASTERN UNIV LIAONING

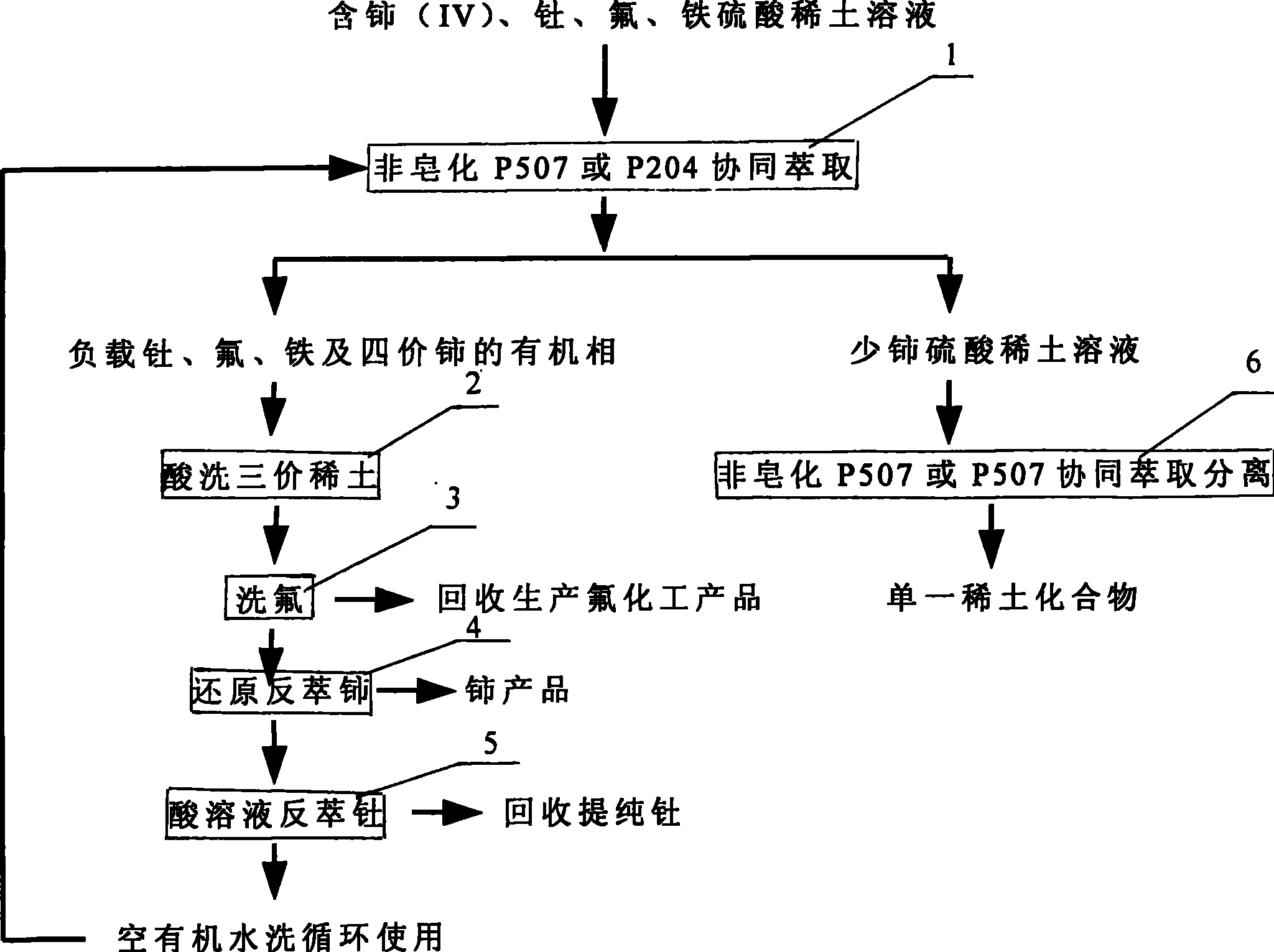

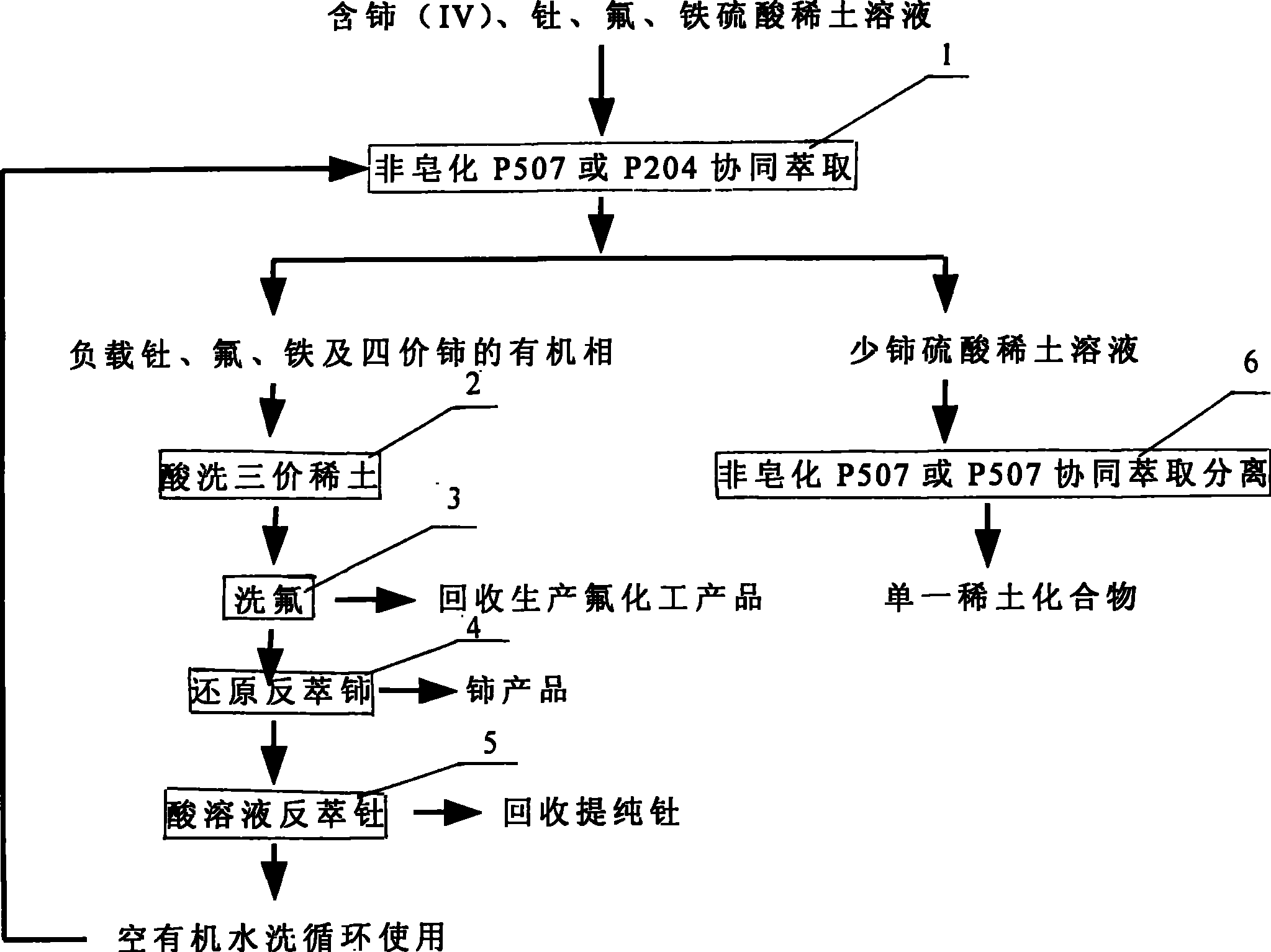

Technique for extraction separation of quadravalence cerium, thorium, fluorine and cerium less tervalence rare earth from sulphuric acid rare earth solution

ActiveCN101294244BNo pollution in the processReduce consumptionProcess efficiency improvementRare-earth elementAmmoniacal nitrogen

The invention relates to a technological method for extracting and separating quadrivalent cerium, thorium, fluorine and less-cerium trivalent rare-earth from rare earth sulfate solution. The rare earth sulfate solution, which is obtained through processing the rare-earth ores and contains high-valence cerium, the fluorine, the thorium and ferrum, is used as raw material; synergistic extraction agent basing on P507 and P204 is adopted for extracting and separating; the cerium (1V), the thorium, the fluorine, and the ferrum are extracted into an organic phase, then selective washing and back extraction are performed step by step to obtain three products that are the cerium, the fluorine, and the thorium, the trivalent rare-earth is left in a water phase, and then unsaponifiable P507 or thesynergistic extraction agent basing on P507 is adopted to perform multistage fractional extraction to separate single rare earth elements. The technological method has the characteristics that the synergistic extraction agent basing on P507 and P204 is adopted, the thorium is easy to perform the back extraction, and extraction capacity is large, and the emulsification is not generated during the extraction process; the cerium (1V), the thorium, the fluorine, the ferrum and the trivalent rare-earth are extracted and separated in the same extraction system; both extraction and the separation adopt unsaponifiable extraction agent, and ammonia-nitrogen wastewater is not generated; in addition, the thorium and the fluorine are recovered as products, and the pollutions caused by thorium-containing waste residue, fluoride-containing wastewater and the ammonia-nitrogen wastewater are eliminated from headstream. Therefore, the technological method has the advantages of simple procedures, greenenvironmental protection, and low manufacturing cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

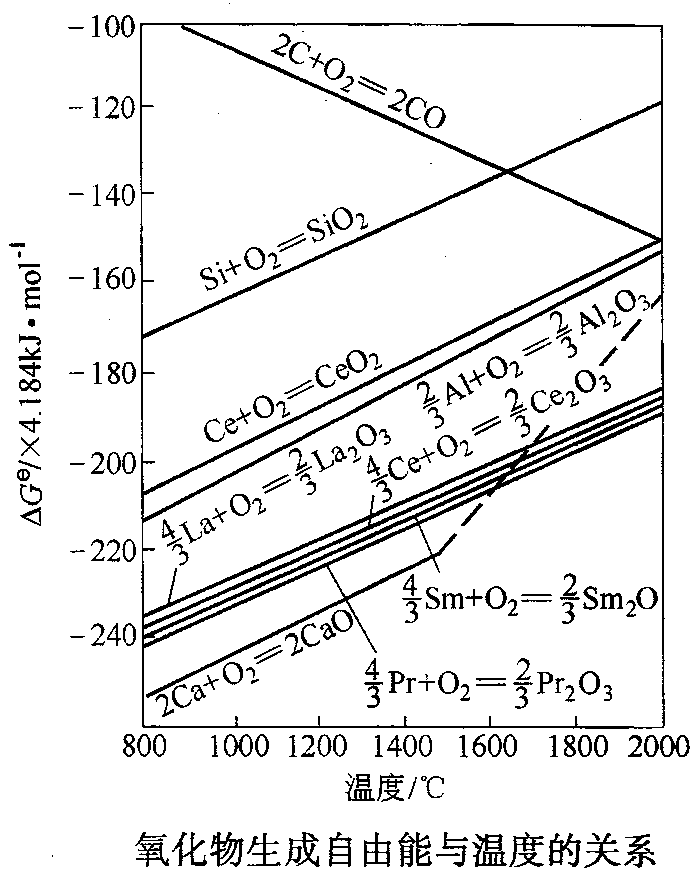

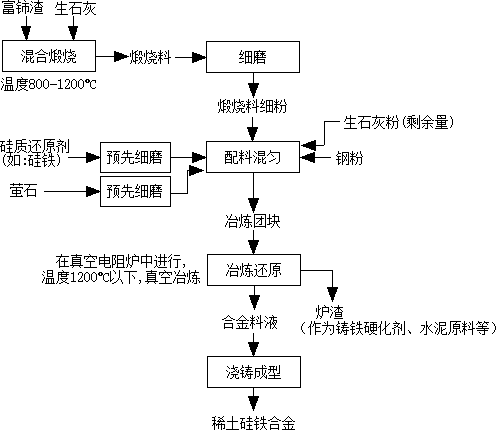

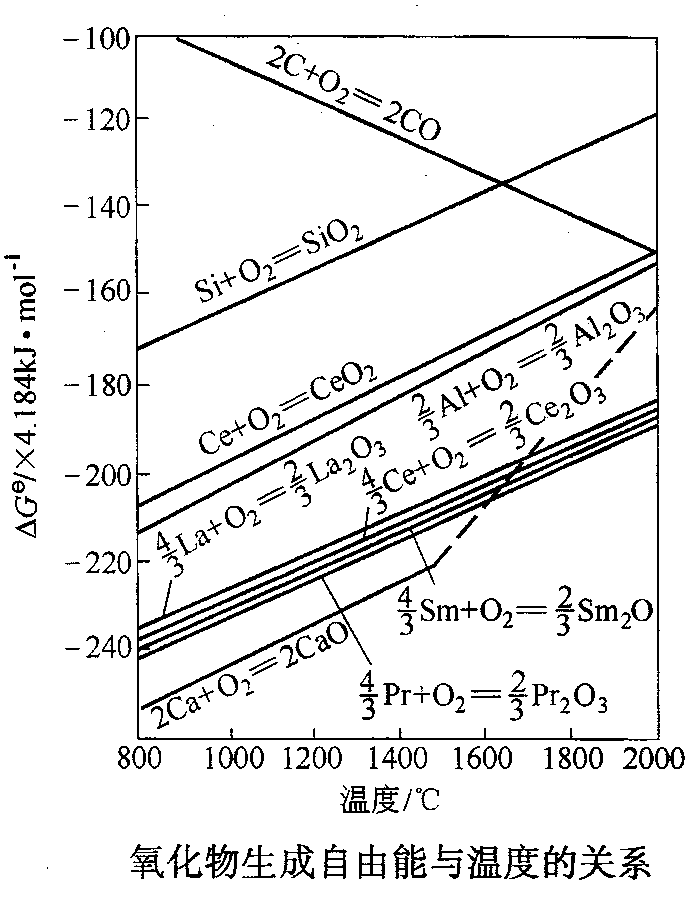

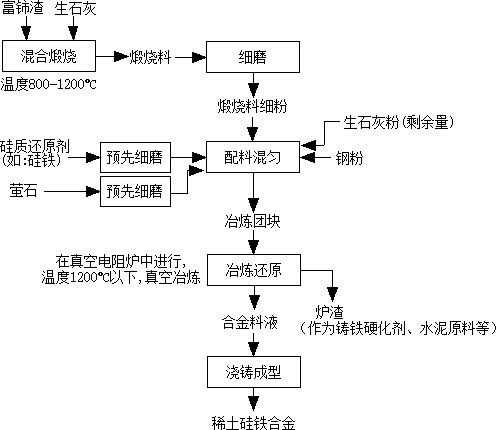

Method for producing rare earth ferrosilicon alloy

ActiveCN108456773AIncrease Si contentImprove conversion utilizationProcess efficiency improvementSmelting processCerium

The invention discloses a method for producing rare earth ferrosilicon alloy. The technical purpose is to provide a method which can increase the yield of rare earth in the alloy, increase the conversion and utilization rate of silicon in a silicon reducing agent, increase the content of Si in the alloy by reducing burning loss of silicon, lower the power consumption for reduction, and reduce thetechnological slag yield based on cerium-enriched slag raw materials aiming at the many insufficiencies of an existing silicothermic method of producing the rare earth ferrosilicon alloy. According tothe method, based on the cerium-enriched slag raw materials, the rare earth ferrosilicon alloy is produced, in the process of smelting the alloy under the temperature of 1,200 DEG C or below, the method can be smoothly implemented, the yield of the rare earth in the process of producing the rare earth ferrosilicon alloy by using the silicothermic process is greatly increased, and the technical purposes of increasing the conversion and utilization rate of the silicon element, and increasing the content of Si in the alloy by reducing the burning loss of silicon are achieved. In the meanwhile, the technology requirement for the smelting reduction temperature is lowered, the production period of the smelting processes is obviously shortened, and therefore, power consumption in the smelting process is obviously lowered.

Owner:包头市华商稀土合金有限公司 +1

Lanthanum cerium iron alloy for producing rare earth steel and preparation method thereof

The invention discloses a lanthanum-cerium ferroalloy for producing rare earth steel. The content of lanthanum-cerium is 0 to 95wt%, and the balance is iron and unavoidable impurities with a total amount less than 0.5wt%, in which oxygen ≤ 0.01wt%. Carbon ≤ 0.01wt%, phosphorus ≤ 0.01wt%, sulfur ≤ 0.005wt%. The invention also discloses a preparation method of lanthanum-ferrocerium alloy for producing rare earth steel. The lanthanum-ferrocerium alloy prepared by the invention has uniform composition, small segregation, low impurity content, high rare earth yield, low cost and no pollution. It can be applied to rare earth steel with high rare earth yield and significant effect, and is suitable for large-scale industrial production.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Yttrium-ferrous alloy and preparation method thereof

The invention discloses a yttrium-ferrous alloy, which is prepared from the following components in percent by weight: 0 to 95 percent of yttrium, and the balance ferrous and inevitable impurities with the total amount being less than 0.5 percent, wherein oxygen is less than or equal to 0.01 percent by weight, carbon is less than or equal to 0.01 percent by weight, phosphorus is less than or equal to 0.01 percent by weight, and sulfur is less than or equal to 0.005 percent by weight. The invention further discloses a preparation method of the yttrium-ferrous alloy. The yttrium-ferrous alloy prepared through the invention is uniform in component, small in segregation, low in impurity content, high in rare earth yield, low in cost and free of pollution, is high in rare earth yield and remarkable in effect when being applied in rare earth steel, and is suitable for large-scale industrial production.

Owner:BAOTOU RES INST OF RARE EARTHS +1

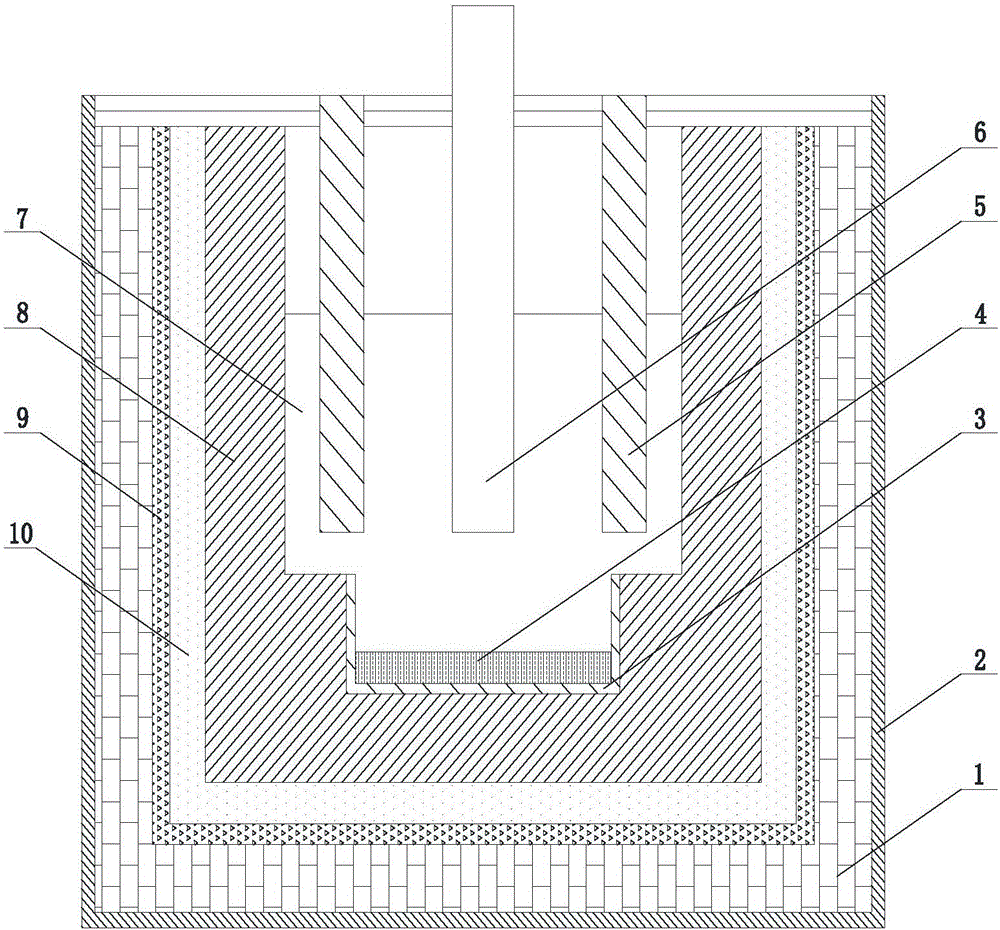

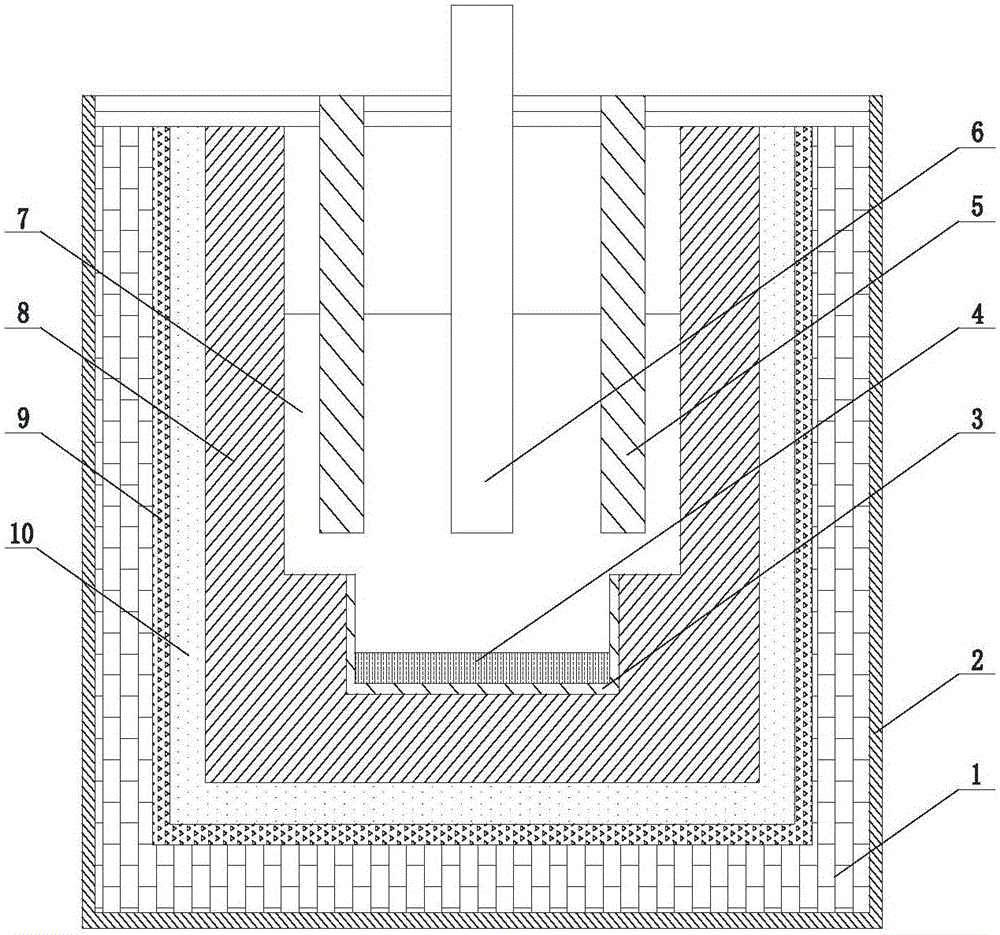

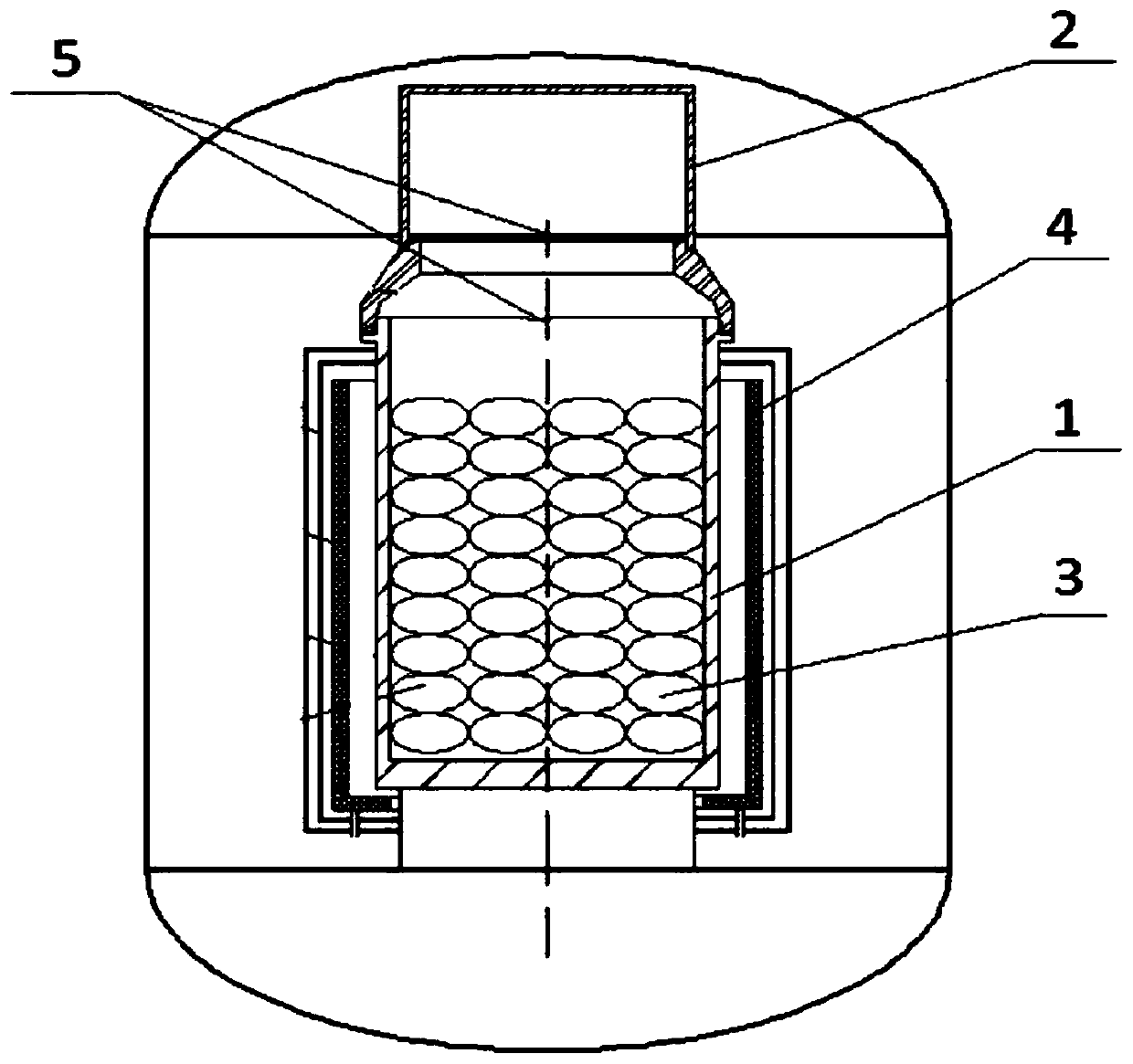

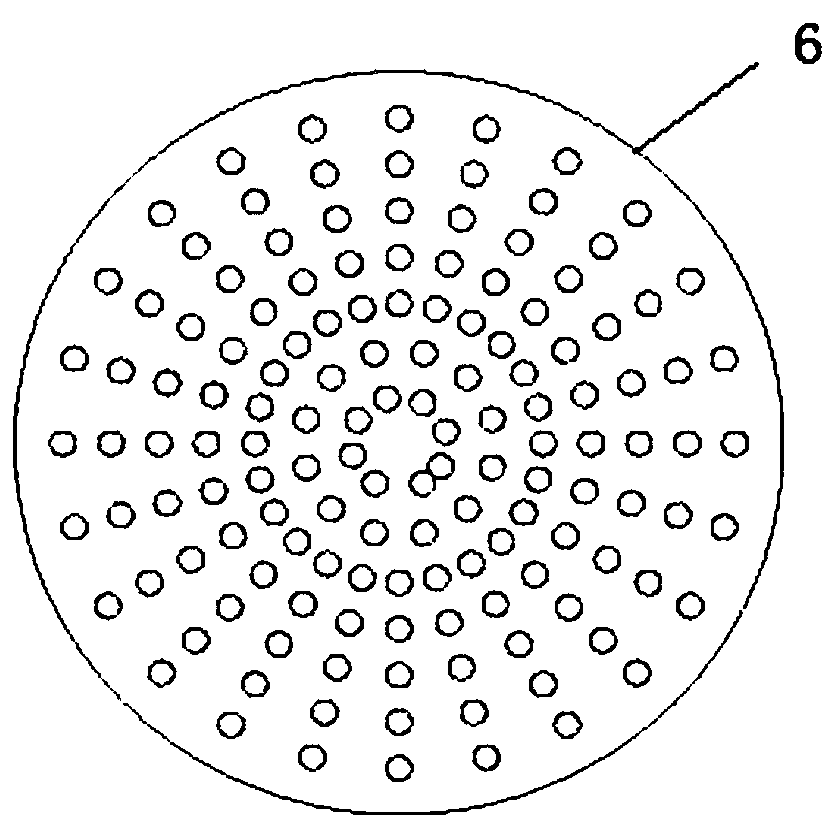

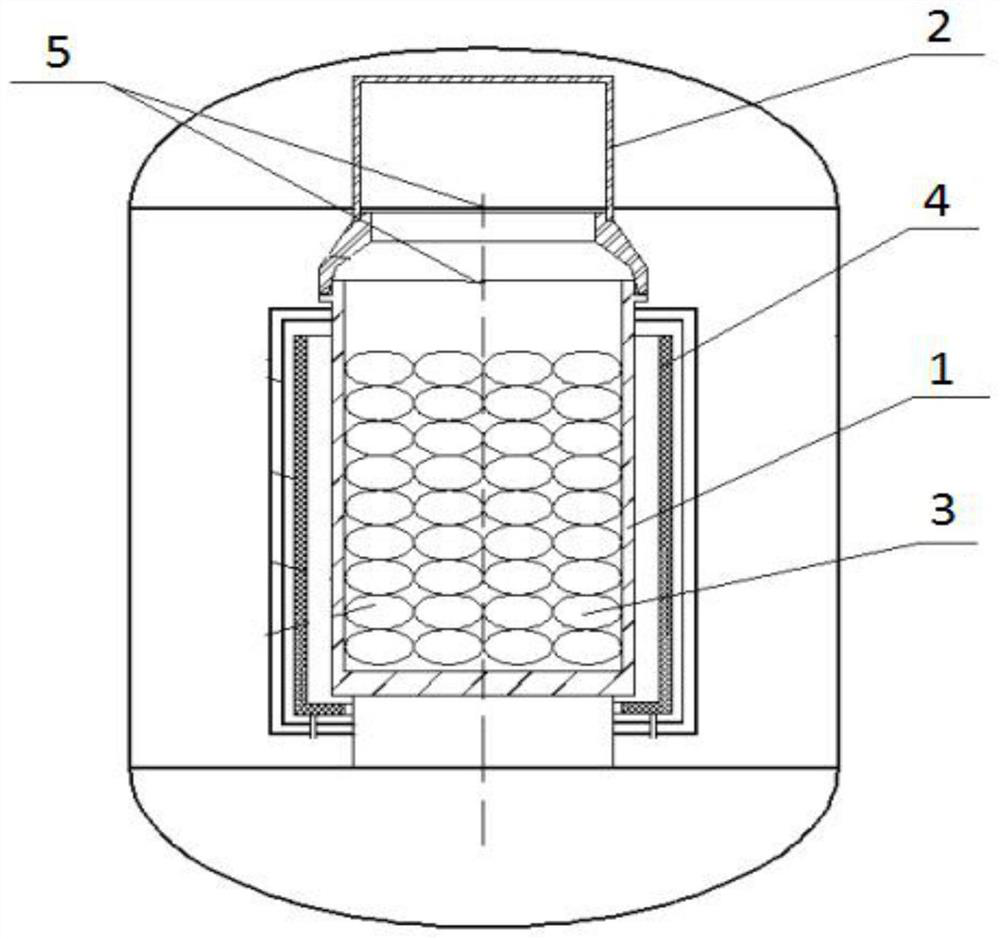

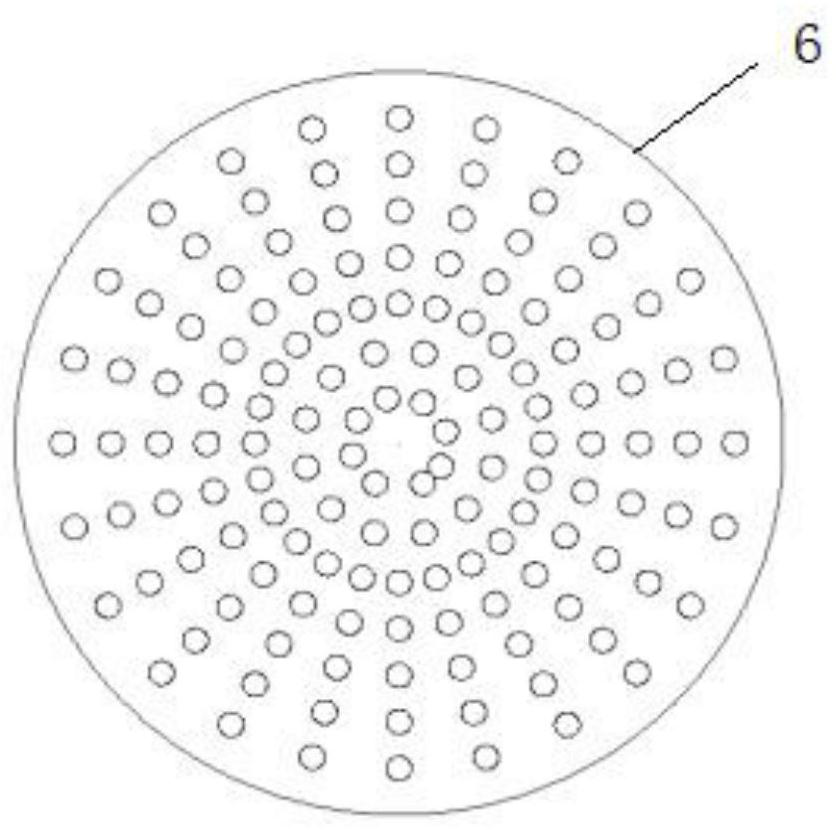

Vacuum smelting furnace and method for preparing high-purity metal ytterbium through one-time continuous reduction distillation

ActiveCN111424184ARaise the yield of rare earthReduce overflow rateYTTERBIUM OXIDECombustion chamber

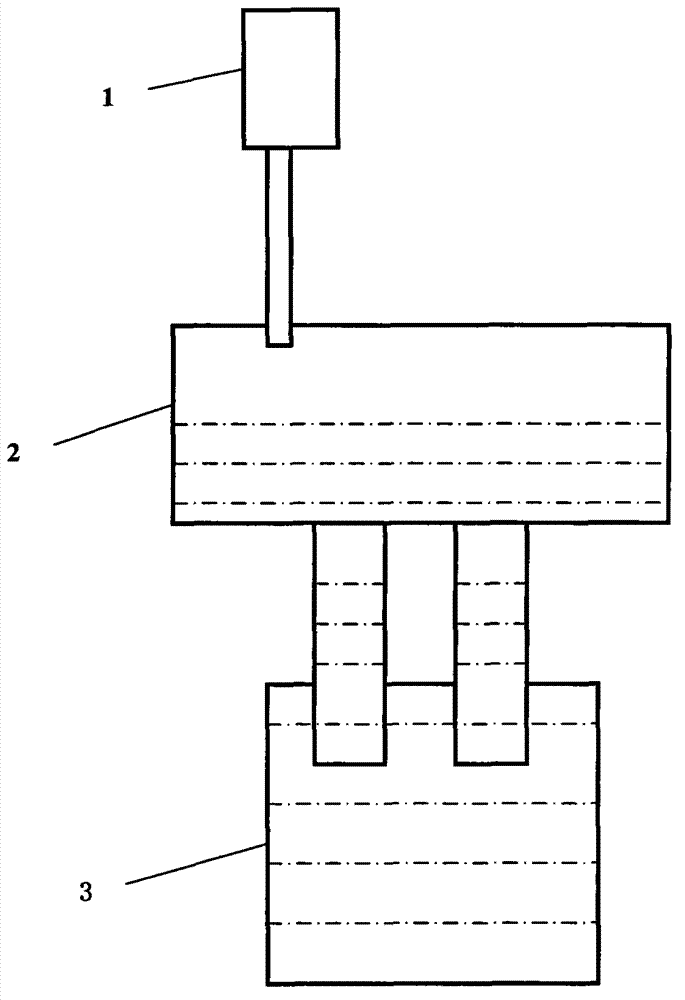

The invention discloses a method for preparing high-purity metal ytterbium through one-time continuous reduction distillation. The method comprises the steps that a vacuum smelting furnace is adopted,a basic raw material pressing block is placed in a metal crucible, and titanium and molybdenum-manufactured double-plug plates are arranged at different temperature transition sections of a distillation system; a combustion chamber of the vacuum smelting furnace is vacuumized to be 10 Pa or below, current delivery and heating are carried out, the heating rate, and thermal insulation time are controlled for heating, metal lanthanum is used for thermal reduction on high-purity ytterbium oxide, a generated metal ytterbium is condensed in a receiver after being distilled by the double-plug plates, a diffusion pump is closed after distillation is completed, argon is filled, and cooling is conducted to a normal temperature according to the set cooling speed and time. The invention further discloses the vacuum smelting furnace. According to the method, stable operation of a distillation process is ensured, the metal ytterbium is low in overflow rate, the rare earth yield is high, impurity entrainment is effectively removed, and lanthanum impurities in the metal ytterbium are greatly reduced.

Owner:BAOTOU RES INST OF RARE EARTHS +1

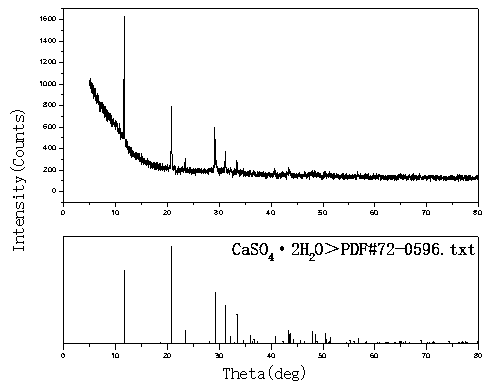

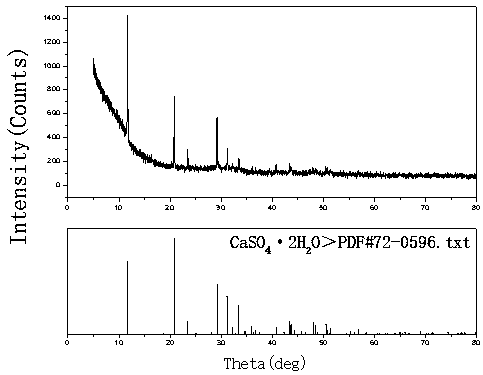

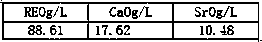

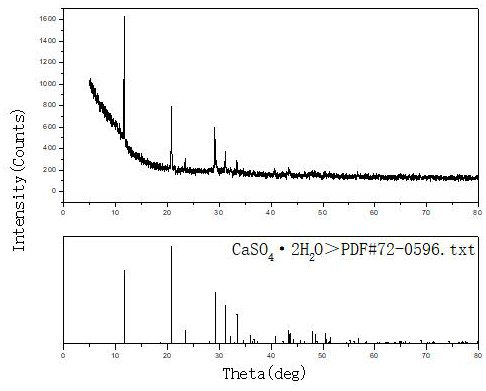

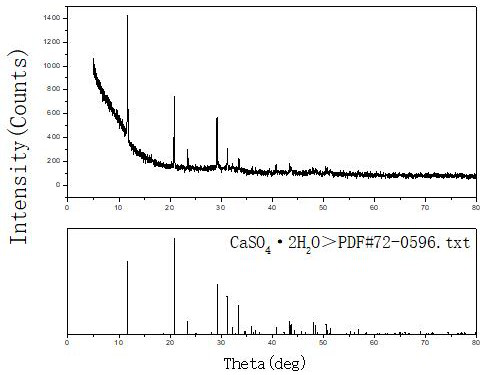

Method for preparing low magnesium calcium sulfate dihydrate byproduct from sulfuric acid rare earth solution

ActiveCN110106373AReduce manufacturing costHas economic valueCalcium/strontium/barium sulfatesProcess efficiency improvementRare earthReaction temperature

The invention relates to a method for preparing a low magnesium calcium sulfate dihydrate byproduct from a sulfuric acid rare earth solution. The method includes steps: using the sulfuric acid rare earth solution generated during the sulfuric acid smelting rare earth ore concentrate separation process as raw material, using calcium hydroxide as a neutralizing agent, and by controlling conditions such as concentration of calcium hydroxide grouting liquid, REO (rare earth oxide) concentration in the sulfuric acid rare earth solution, reaction time, reaction temperature, neutralization of PH (potential of hydrogen) value and aging mode, preparing the byproduct of CaSO4.2H2O which meets use requirements in industry of cement, building material, chemical engineering and the like under the condition that the yield of rear earth is not reduced and supply of qualified sulfuric acid rare earth feed liquid for extraction separation of downstream rear earth smelting is guaranteed. Additionally, the quality of the CaSO4.2H2O meets following formulas: m(CaO)>=30.9%, and m(MgO)<=0.05%. The whole process of the method achieves low cost of industrial production, and builds a firm foundation for green environment-friendly production and circular economy usage.

Owner:甘肃稀土新材料股份有限公司

A kind of modified 4cr5mosiv1 hot work die steel and preparation method thereof

Owner:INNER MONGOLIA UNIV OF SCI & TECH

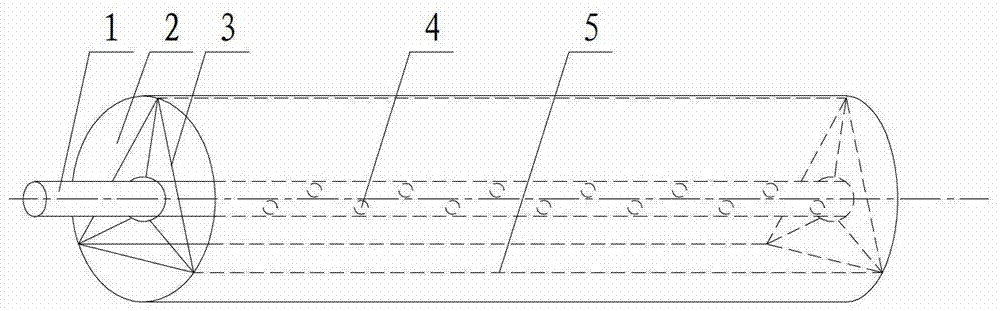

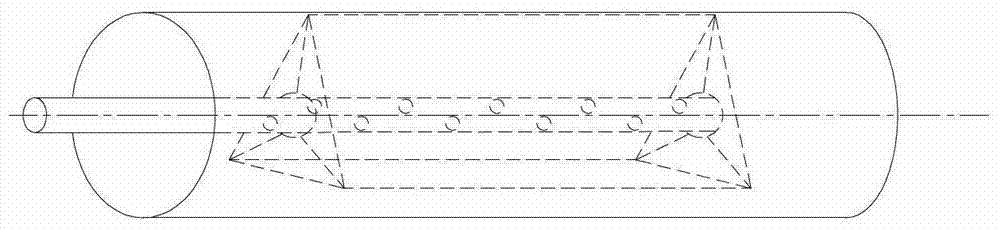

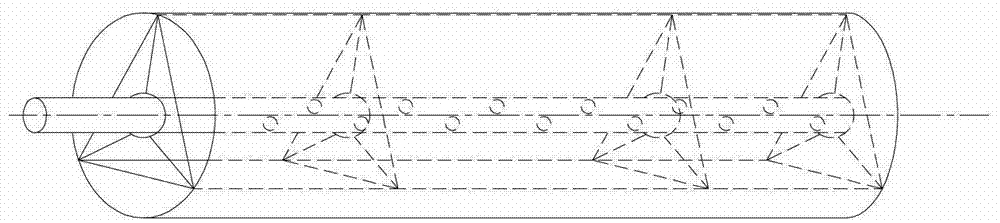

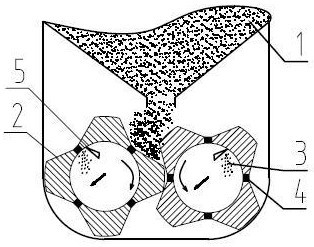

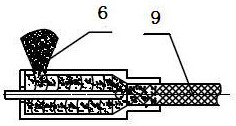

A device for improving the oxidation rate of NdFeB oxide material

The invention relates to a device for increasing the oxidation rate of neodymium-iron-boron oxide materials, which comprises a rotary kiln, in which a stirrer and a ventilation pipe are placed through a mounting frame, and a plurality of air holes are formed on the ventilation pipe. The invention is a rotary kiln with simple structure, ingenious design, convenient disassembly and assembly, and safe use. The rotary kiln achieves the purpose of increasing the oxidation rate of the oxidizing material by increasing the stirring and oxygen content of the oxidizing material in the kiln body, thereby improving the oxidation rate. Rare earth yield of raw materials, saving auxiliary raw materials and energy, reducing production costs of enterprises and improving production efficiency.

Owner:中稀天马新材料科技股份有限公司

Rare earth calcium core-spun yarn

ActiveCN114317889AQuality improvementImprove utilization efficiencyProcess efficiency improvementYarnMischmetal

The invention provides a rare earth calcium core-spun yarn. The rare earth calcium core-spun yarn comprises a rare earth calcium core-spun material, a trapping agent and a metal shell protection tube. According to the method, the effect and the purpose that the molten steel is subjected to rare earth alloying by directly using the rare earth oxide without a special reduction smelting link by utilizing the excess (or surplus) temperature of the molten steel are achieved; the metal silicon is adopted as a reducing agent to convert rare earth oxide into rare earth metal for alloying, and the metal aluminum is adopted as a reducing agent to reduce calcium oxide into metal calcium (steam), so that the effects of deoxidizing the molten steel, removing inclusions and changing the morphology of the inclusions are achieved. The method has the characteristics of high rare earth yield, low cost, economy, practicability and convenience in large-scale production. The method has great positive significance in reducing the alloying cost of the molten steel, improving the quality of the molten steel, improving the utilization efficiency of the rare earth and saving rare earth resources.

Owner:包头市艾瑞达新材料科技有限责任公司

A kind of method of producing rare earth ferrosilicon alloy

ActiveCN108456773BIncrease Si contentImprove conversion utilizationProcess efficiency improvementSmelting processCerium

The invention discloses a method for producing rare earth ferrosilicon alloy. The technical purpose is to provide a method which can increase the yield of rare earth in the alloy, increase the conversion and utilization rate of silicon in a silicon reducing agent, increase the content of Si in the alloy by reducing burning loss of silicon, lower the power consumption for reduction, and reduce thetechnological slag yield based on cerium-enriched slag raw materials aiming at the many insufficiencies of an existing silicothermic method of producing the rare earth ferrosilicon alloy. According tothe method, based on the cerium-enriched slag raw materials, the rare earth ferrosilicon alloy is produced, in the process of smelting the alloy under the temperature of 1,200 DEG C or below, the method can be smoothly implemented, the yield of the rare earth in the process of producing the rare earth ferrosilicon alloy by using the silicothermic process is greatly increased, and the technical purposes of increasing the conversion and utilization rate of the silicon element, and increasing the content of Si in the alloy by reducing the burning loss of silicon are achieved. In the meanwhile, the technology requirement for the smelting reduction temperature is lowered, the production period of the smelting processes is obviously shortened, and therefore, power consumption in the smelting process is obviously lowered.

Owner:包头市华商稀土合金有限公司 +1

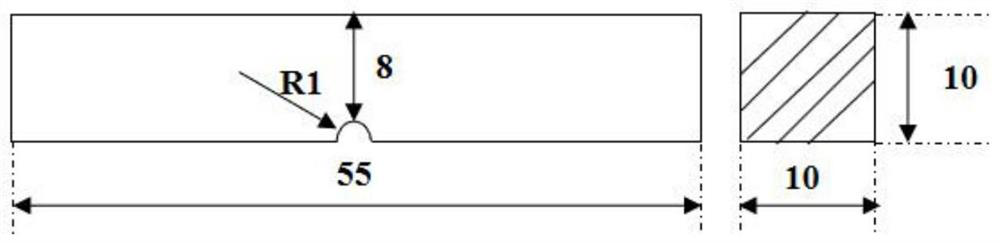

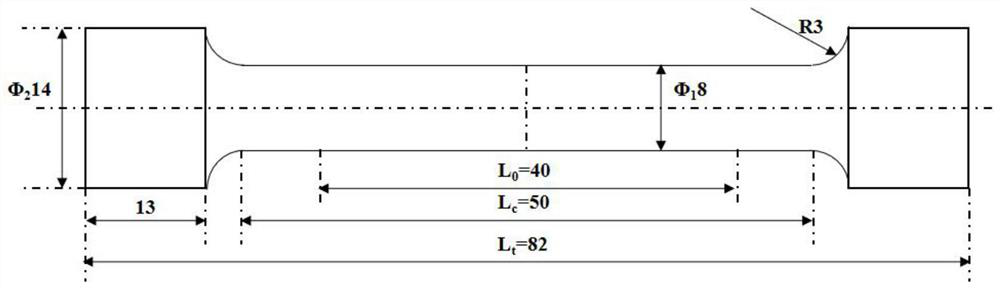

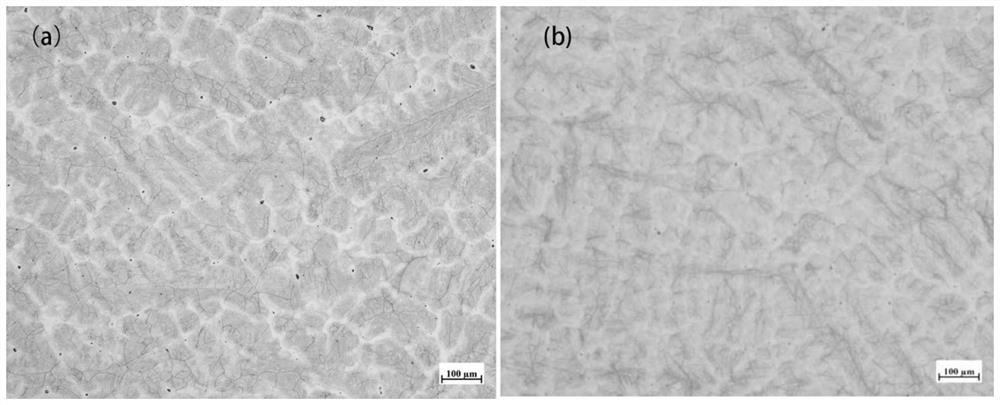

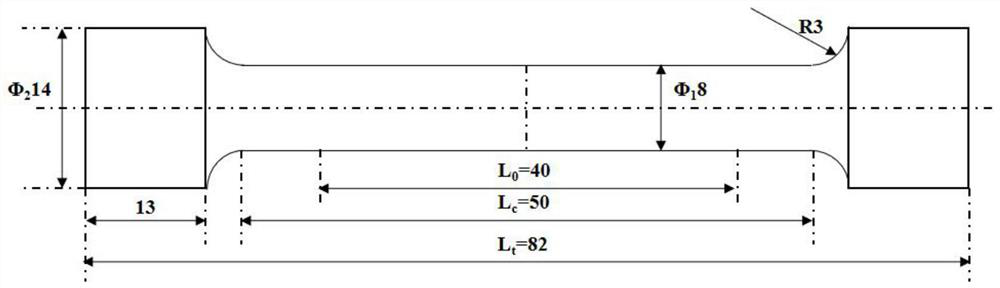

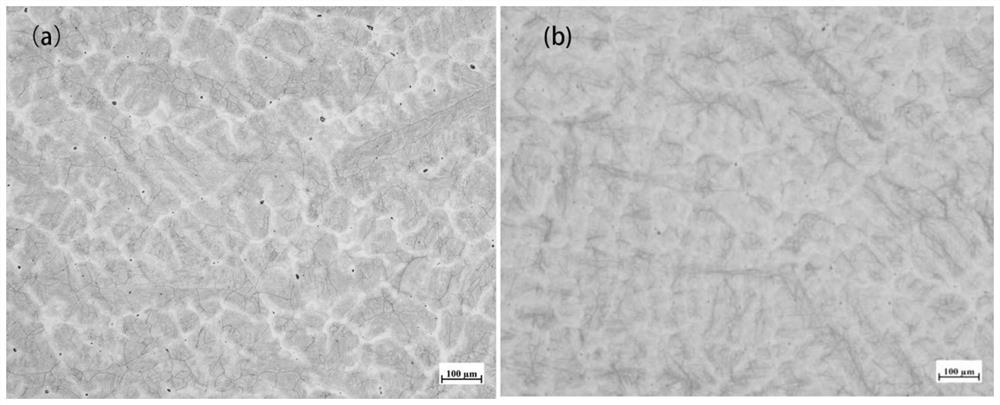

Modified 4Cr5MoSiV1 hot work die steel and preparation method thereof

ActiveCN114000038ARaise the yield of rare earthMitigating dendrite segregationMetal-working apparatusAlloy elementVacuum furnace

The invention belongs to the technical field of hot work die steel, and discloses modified 4Cr5MoSiV1 hot work die steel and a preparation method thereof.The preparation method comprises the following steps: putting weighed raw materials into vacuum furnace, smelting to molten state, adding reducing agent, smelting at 1450-1550 DEG C, casting under argon protection, and naturally cooling after casting to obtain steel ingot; remelting the steel ingot by using a protective atmosphere electroslag remelting technology, preserving heat at 1250 DEG C, forging and cooling; and carrying out heat preservation at 850 DEG C, and then carrying out segmented furnace cooling to room temperature, so as to obtain the modified 4Cr5MoSiV1 hot work die steel. By adding the rare earth intermediate alloy and utilizing the interaction of all the components, the yield of rare earth in the steel is increased; segregation of alloy elements such as Cr, Mo and V at the grain boundary is reduced, and the purpose of reducing dendritic segregation is achieved; and the as-cast structure of the steel is improved, and the fatigue life and other mechanical properties of the steel are improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for preparing metal ytterbium by reducing and distilling ytterbium oxide raw material with high chlorine content

The invention discloses a method for preparing metal ytterbium by reducing and distilling an ytterbium oxide raw material with high chlorine content. The method comprises the following steps: puttingthe high-purity ytterbium oxide raw material with chlorine content greater than 100 PPM into a metal crucible, transferring the metal crucible into a vacuum heating furnace, gradually heating up the metal crucible to a temperature of 1100-1200 DEG C to perform vacuum roasting in a staged heating-up and heat-preserving way under a sealing environment with vacuum degree lower than 10 Pa; switching off a mechanical pump after completing vacuum roasting, and cooling the metal crucible to the normal temperature; moving the metal crucible out of the vacuum heating furnace, and putting vacuum-roastedhigh-purity ytterbium oxide and lanthanum chip pressure blocks into a vacuum carbon tube furnace to reduce and distill; reducing ytterbium oxide into metal ytterbium by metal lanthanum in a staged heating-up, heat-preserving and cooling way for reducing and distilling under the sealing environment with the vacuum degree lower than 10 Pa, and distilling and condensing the metal ytterbium in a receiver. Cl content in the metal ytterbium obtained by the method is less than 100 PPM, and the rare-earth yield is greatly increased.

Owner:BAOTOU RES INST OF RARE EARTHS +1

A method for preparing high-purity metal ytterbium by continuous reduction distillation

The invention discloses a method for preparing high-purity metal ytterbium by one-time continuous reduction distillation, which comprises: adopting a vacuum smelting furnace, putting basic raw material briquettes into a metal crucible, and setting double plugs made of titanium and molybdenum at different temperature transition sections of the distillation system Plate; the hearth of the vacuum smelting furnace is evacuated to below 10Pa, the temperature is raised by power transmission, and the temperature is raised by controlling the heating rate and holding time, and the metal lanthanum is thermally reduced to high-purity ytterbium oxide by lanthanum to generate metal ytterbium, which is distilled by a double plug plate and condensed in the receiver In the process, after the distillation is completed, the diffusion pump is turned off, argon is filled, and the temperature is lowered to room temperature according to the set cooling rate and time. The invention ensures stable operation of the distillation process, low metal ytterbium overflow rate, high rare earth yield, and effectively removes impurity entrainment, so that the lanthanum impurity in the metal ytterbium is greatly reduced.

Owner:BAOTOU RES INST OF RARE EARTHS +1

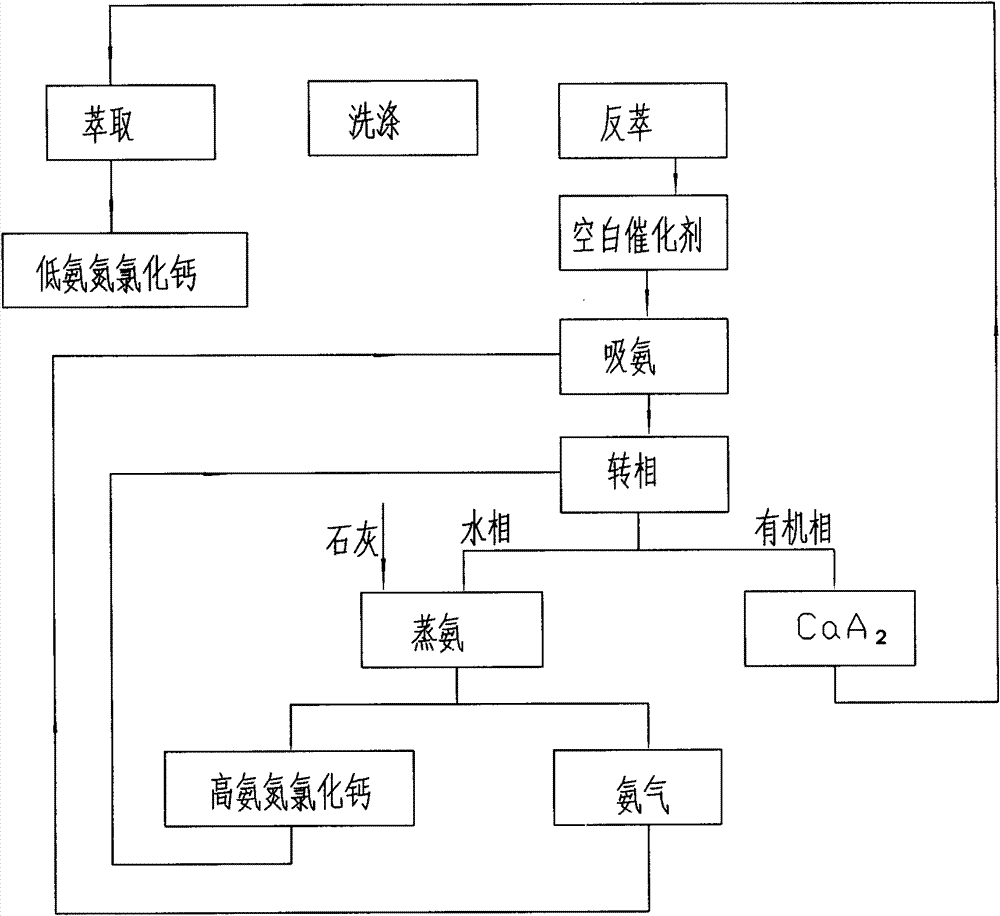

Method for preparing calcium soap by utilizing quick lime and method for processing produced emulsified compound

InactiveCN101948483BReduce ammonia nitrogen contentRare earth separation factor has no effectGroup 5/15 element organic compoundsFiltration separationHigh concentrationRare earth

The invention relates to a method for preparing calcium soap by utilizing quick lime or lime milk and a method for processing produced emulsified compound, in particular to a technical method for preparing calcium soap in a rare earth extraction section by utilizing quick lime or lime milk. The method comprises the following steps: carrying out ammonia steaming-ammonia absorbing: carrying out dual firing and ammonia steaming on the quick lime or lime milk and ammonium chloride solution according to the molar ratio that n Ca+: n ammonium chloride =1: 1.5-2.2; absorbing the steamed ammonia gas by blank extracting agent to form ammonium soap; filtering or clarifying the reacted solution to obtain high concentration ammonia nitrogen calcium chloride solution; and carrying out phase inversion: mixing and stirring the ammonium soap with the high concentration ammonia nitrogen calcium chloride solution prepared by ammonia steaming-ammonia absorbing for 5-15 min, wherein the ammonium enters the aqueous phase to form ammonium chloride, the calcium enters the organic phase to form the calcium soap. In the invention, as the quick lime is adopted, the economic benefits are high, no three wastes is discharged and nopollution to the environment is generated; and meanwhile, consumption of the extracting agent can be reduced by more than 2 / 3 and the yield of the rare earth is improved.

Owner:王德兴

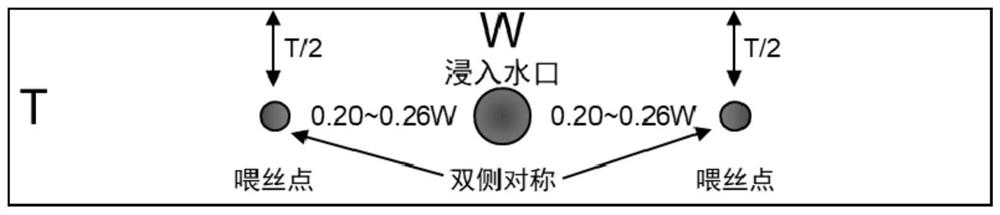

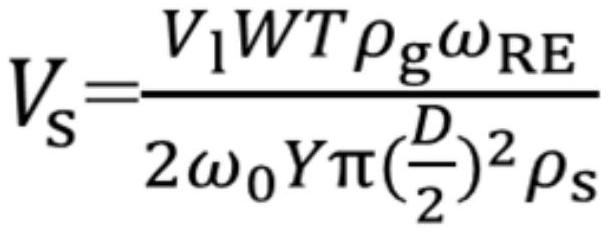

Production method for rare earth alloying of wide steel strip iron-chromium-aluminum continuous casting slab

The invention discloses a production method for rare earth alloying of a wide steel strip iron-chromium-aluminum continuous casting slab. The production method comprises the steps of (1) preparing rare earth wires; (2) sequentially treating iron-chromium-aluminum molten steel through a K-OBM-S furnace, a VOD furnace and an LF furnace; (3) conveying the molten steel treated in the step (2) to a continuous casting machine through a tundish protected in a sealed mode and pouring the molten steel into a crystallizer; and (4) feeding the rare earth wires through a single-machine double-flow method, and preparing the continuous casting slab. According to the production method, by reducing the oxygen and sulfur content of the molten steel and adopting the measures of carrying out protective pouring, selecting the proper wire feeding position and speed, optimizing the components of protective slag and the like, rare earth alloying of the iron-chromium-aluminum continuous casting slab is achieved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

A production method for continuous casting of steel slabs containing rare earth elements

ActiveCN105821339BEfficient removalRaise the yield of rare earthGas emission reductionRare-earth elementSlag

The invention discloses a steel containing rare earth element and a producing method of slab continuous casting. The steel comprises the elements of Re, C, Si, Cr, Ni, and N according to a certain ratio, and the balance of iron and inevitable impurity; the production method comprises a ladle furnace refining process and a continuous casting operation; wherein, in the ladle furnace refining process, feeding metal Ca wire before rare earth is added in molten steel, then feeding rare earth metal wires, simultaneously passing the rare earth metal wires through the surface of slag, feeding the metal Ca wires again, controlling the weak stirring time of ladle furnace refining and slag interfacial fluctuation area; and in the continuous casting process, controlling the super-heated rate of molten steel in a tundish at 35-65 DEG C, and controlling the inserting depth of an port of a continuous casting crystallizer at 100-135 mm. Compared with the prior art, the method has the advantages of high rare earth yielding rate, and good continuous casting surface and center quality, impurity in the steel is effectively removed, and rare earth yielding rate is stable.

Owner:宝武特种冶金有限公司

Back extraction solution prepared by extraction separation of washing organic matter of saponification wastewater by recycling rare earth and solution washing method

InactiveCN101974686BDoes not affect purityReduce wasteProcess efficiency improvementSoil organic matterRare earth

Owner:BAOTOU JINGRUI NEW MATERIAL

A method for low-concentration hydrochloric acid leaching of calcium and strontium chemical separation of Weishan Lake rare earth concentrate

ActiveCN108559842BReduce loss rateEasy to handleProcess efficiency improvementStrontium carbonateWater chlorination

The invention provides a method for selecting Weishan Lake rare earth concentrate by leaching calcium strontium with low concentration hydrochloric acid, which is characterized in that: the Weishan Lake rare earth concentrate is soaked in low concentration hydrochloric acid and heated to react. After the reaction is completed, it is filtered, and the Weishan Lake rare earth concentrate is added again to the filtered leachate, and heated to react. The liquid obtained after solid-liquid separation is discharged, and the solid phase is reused. The invention can increase the grade of the Weishan Lake rare earth concentrate from 40% to 50%, efficiently leaching 90% calcium carbonate and 85% strontium carbonate in the Weishan Lake rare earth concentrate, and ensures that the rare earth loss rate is less than 1%. The discharged acid leaching waste liquid only contains calcium chloride, strontium chloride and a small amount of ferric chloride, which is easy for wastewater treatment.

Owner:中稀(寿光)资源科技有限公司

A method for preparing low-magnesium calcium sulfate dihydrate by-product from rare earth sulfate solution

ActiveCN110106373BReduce manufacturing costHas economic valueCalcium/strontium/barium sulfatesProcess efficiency improvementChemical industryHydration reaction

The invention relates to a method for preparing low-magnesium calcium sulfate dihydrate by-product from a rare earth sulfate solution. The method uses the rare earth sulfate solution produced in the process of sulfuric acid smelting and separating rare earth concentrate as a raw material, and uses calcium hydroxide as a neutralizing agent. By controlling the concentration of calcium hydroxide slurry, REO concentration in rare earth sulfate solution, reaction time, reaction temperature, neutralization pH value, aging method and other conditions, the yield of rare earth will not be lost, and the supply for downstream rare earth smelting, that is, extraction and separation, will be qualified. Under the condition of rare earth sulfuric acid feed solution, CaSO can be prepared to meet the requirements of cement, building materials, chemical industry and other industries. 4 2H 2 O by-products. And its CaSO 4 2H 2 O quality achieved: m (CaO) ≥30.9%, m (MgO) ≤0.05%. The overall process realizes the lower cost of industrialized production, and lays a solid foundation for green production and circular economic utilization.

Owner:甘肃稀土新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com