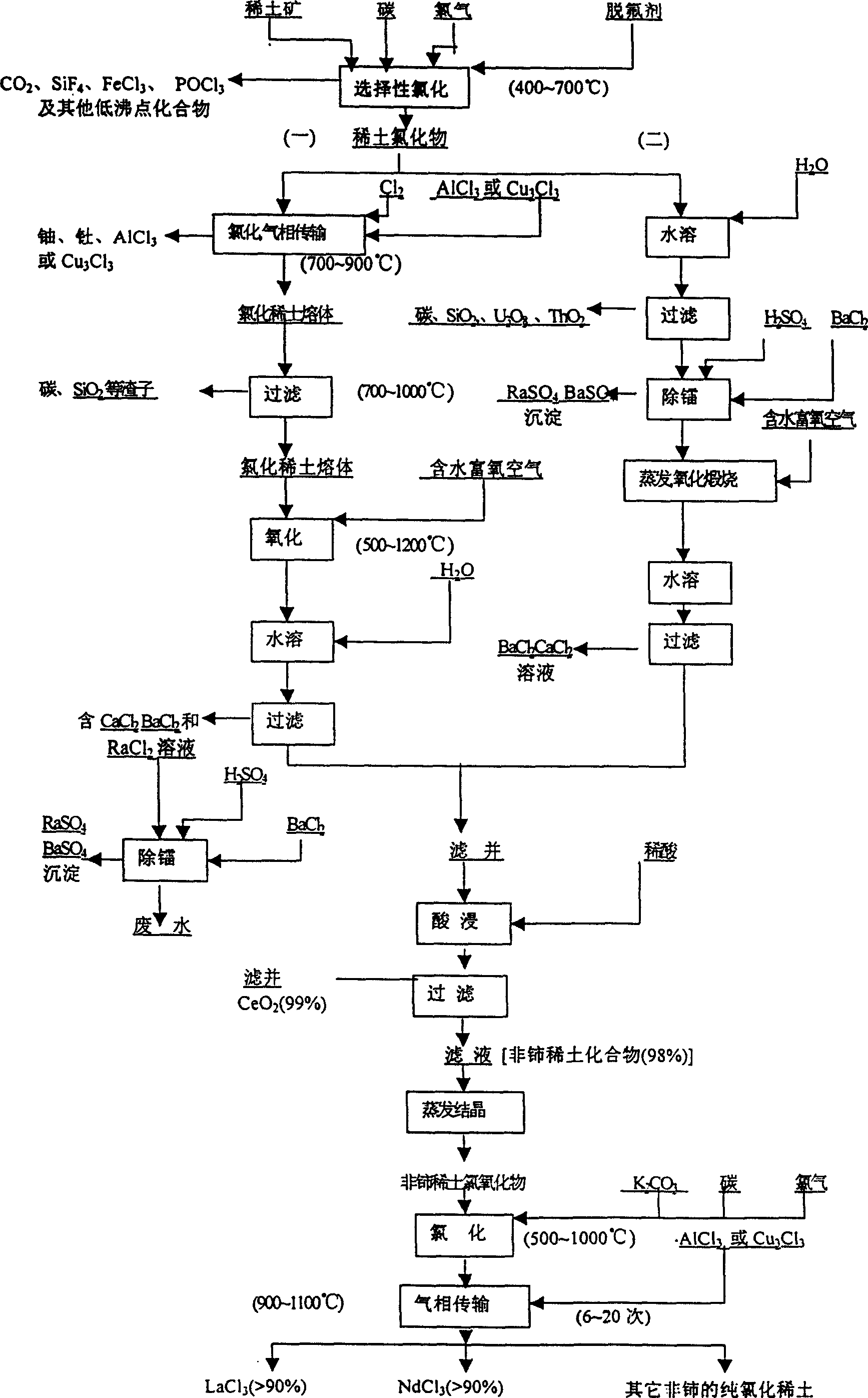

Carburizing chlorination process for extracting and separating cerium and non-Ce rare earth from rare-earth ore

A technology of rare earth compounds and rare earths, which is applied in the field of carbochlorination to extract and separate cerium and non-cerium rare earths from rare earth minerals. Problems such as inability to be effectively separated out, to achieve the effect of being beneficial to operation, realizing large-scale industrial production, and being easy to large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Bastnaesite - monazite mixed concentrate, main chemical composition (%): REO (65.2), TFe (1.7), CaO (3.3), BaO (1.1), ThO 2 (0.2), Nb 2 o 5 (0.1), F(5.4), P(3.1), S(0.4), SiO 2 (0.6), the atomic ratio of cerium and non-cerium rare earth elements in the rare earth elements is 1.0.

[0023] After mixing 10 grams of concentrate with a particle size of 19 microns and 1.0 grams of activated carbon, react with chlorine and silicon tetrachloride at 550 ° C for 2 hours at an input rate of 0.15 grams and 1.5 milligrams per minute, respectively, fluorine, sulfur, phosphorus , iron and niobium are discharged in the form of gas or low-boiling volatiles.

[0024] The solid product was dissolved in water and then filtered, and sulfuric acid and barium chloride were added to the filtrate to co-precipitate and radium was filtered off. After the solution was evaporated to dryness, it was reacted with industrial oxygen at 700°C for half an hour. After condensation, it was dissolved in...

Embodiment 2

[0027] Bastnaesite concentrate, main chemical composition (%): REO(64.3), TFe(0.3), CaO(0.4), BaO(0.2), Al 2 o 3 (0.2), ThO 2 (0.3), F(10), SiO 2 (0.9); the atomic ratio of cerium and non-cerium elements in rare earth elements is 0.85.

[0028] This is an example of high fluorine content in the raw material, therefore, the gas flow with high silicon tetrachloride content is used when the concentrate is chlorinated. After mixing 10 grams of concentrated ore with a particle size of 22 microns and 1.0 gram of activated carbon, at 550 ° C, react with chlorine gas and silicon tetrachloride with input speeds of 0.15 grams and 2.5 milligrams per minute respectively for 2 hours. Exhaust as gas or low-boiling volatiles.

[0029] After replacing the collector, the chlorinated product is heated up to 800°C in a chlorine atmosphere, and at this temperature, the input rate is 0.1 grams of aluminum chloride per minute to react for half an hour, thorium and aluminum are transported in th...

Embodiment 3

[0034] Bastnaesite medium ore, main chemical composition (%): REO (16.8), TFe (2.6), MgO (1.7), CaO (6.4), BaO (11.2), Al 2 o 3 (10.7), PbO(0.6), ThO 2 (0.2), F(2.8), P(0.4), SiO 2 (41.6) The atomic ratio of cerium and non-cerium elements in the rare earth elements is the same as in Example 2.

[0035] This is an example where the rare earth content in the raw material is low and the content of elements such as silicon and alkaline earth metals is high.

[0036] For medium ore with a particle size of 35 microns, after dolomite and other carbonate minerals are dissolved out with dilute acid, 10 grams of dry mineral powder and 1.5 grams of activated carbon are mixed, and at 550 ° C, the input speed is 0.15 grams per minute. React with 1.5 mg of chlorine and silicon tetrachloride for 2 hours, filter the reaction product after soaking in water, and filter out a large amount of unreacted substances. Add sulfuric acid to the aqueous solution to remove radium.

[0037] After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com