Method for preparing saponifier by directly recycling saponification wastewater produced by extraction and separation of rare earth

A rare earth extraction and separation and saponification wastewater technology, which is applied in the direction of improving process efficiency, etc., can solve the problems of large energy consumption in evaporation and concentration, large wastewater volume, and low salt content, so as to improve the stratification effect, reduce organic consumption, and improve Effect of Rare Earth Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

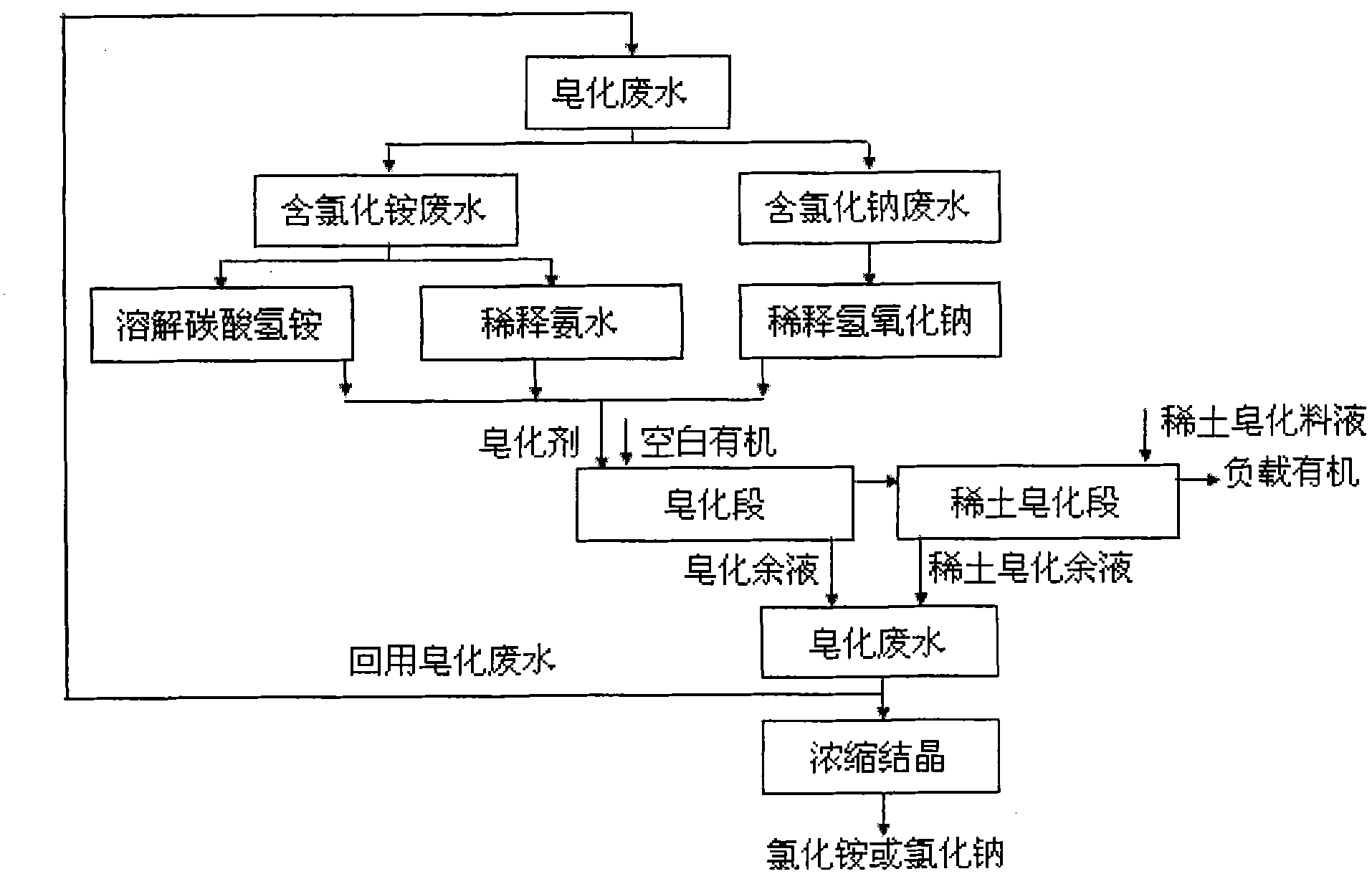

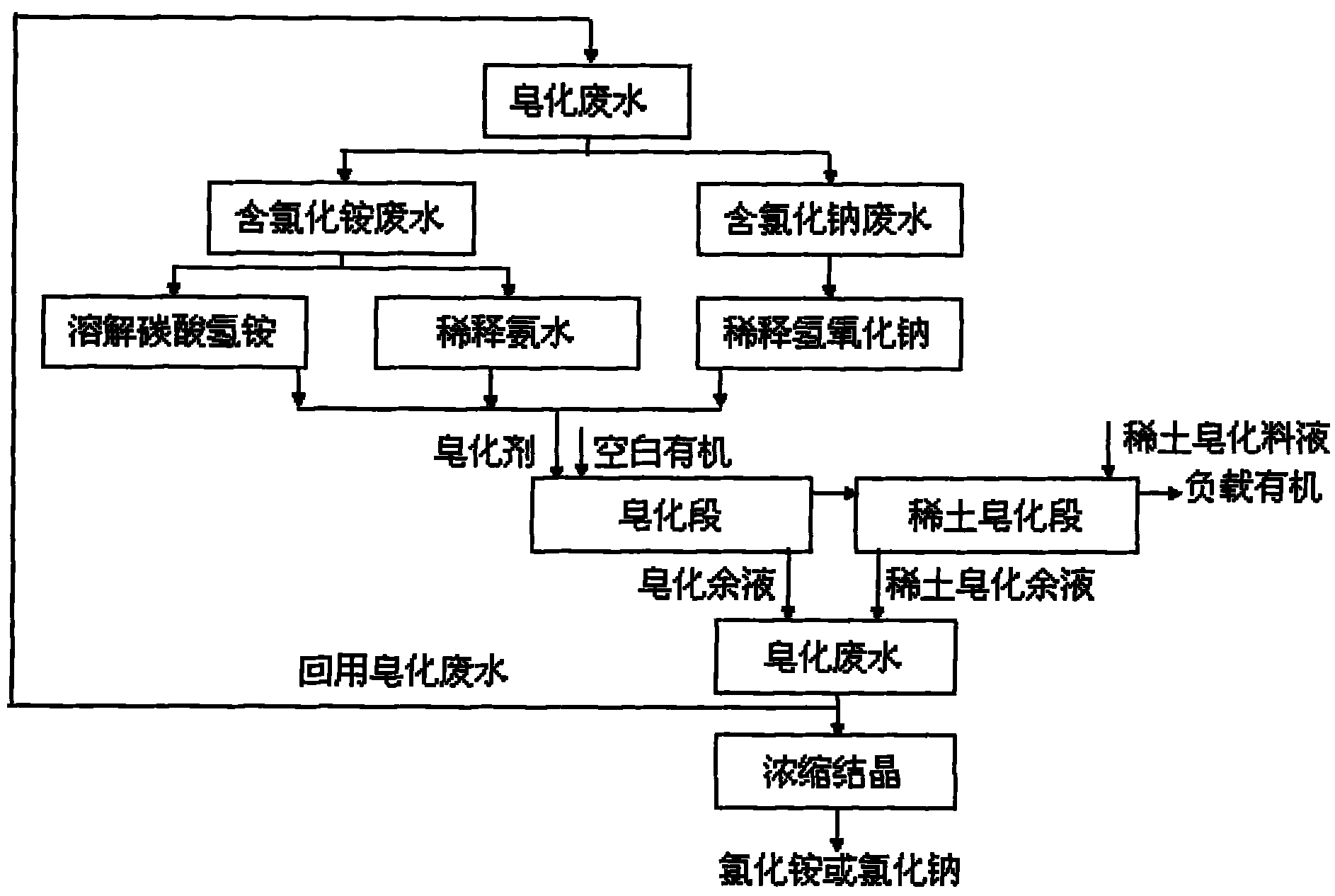

Method used

Image

Examples

Embodiment 1

[0015] The raw material is the raffinate after the mixed rare earth chloride solution is divided into groups of neodymium and samarium, the rare earth concentration is 1.5mol / L, pH=2, and its composition includes La 2 o 3 and CeO 2 The content is 79%, Pr 6 o 11 and Nd 2 o 3 The content is 21%; the separation scale is 12250 tons / year (according to rare earth oxides);

[0016] The organic phase is P 507 (diluted with kerosene), its concentration is 1.5mol / L;

[0017] La 3+ and Ce 3+ For refractory rare earth elements, Pr 3+ and Nd 3+ Easy to extract rare earth elements;

[0018] Adopt ammonia water as saponification agent;

[0019] The mixed clarification extraction tank is used for the extraction and separation of cerium and praseodymium. The raffinate is the high-purity material liquid obtained by extraction and separation of lanthanum and cerium. Saponification agent is prepared from the saponified waste water generated in the stage.

[0020] In order to make th...

Embodiment 2

[0022] The raw material is mixed rare earth chloride solution, the rare earth concentration is 1.5mol / L, pH=2, and its composition includes La 2 o 3 -Nd 2 o 3 Content is 98%, Sm 2 o 3 -Lu 2 o 3 and Y 2 o 3 The content is 2%; the separation scale is 12,500 tons / year (according to rare earth oxides);

[0023] The organic phase is P 507 (diluted with kerosene), its concentration is 1.5mol / L;

[0024] La 3+ -Nd 3+ For refractory rare earth elements, Sm 3+ -Lu 3+ and Y 3+ Easy to extract rare earth elements;

[0025] Adopt ammonium bicarbonate solution as saponification agent;

[0026] A mixed clarification extraction tank is used for the extraction and separation of neodymium and samarium. The raffinate is a high-purity feed solution obtained by extraction and separation of cerium and praseodymium. , the product does not require high content of refractory rare earth elements. The saponification wastewater produced by extraction and separation of cerium and praseo...

Embodiment 3

[0029] The raw material is mixed rare earth chloride solution, the rare earth concentration is 1.2mol / L, pH=2, and its composition includes Sm 2 o 3 and Eu 2 o 3 Content is 38%, Gd 2 o 3 The content is 62%; the separation scale is 220 tons / year (according to rare earth oxides);

[0030] The organic phase is P 507 (diluted with kerosene), its concentration is 1.5mol / L;

[0031] SM 3+ and Eu 3+ For refractory rare earth elements, Gd 3+ Easy to extract rare earth elements;

[0032] Adopt sodium hydroxide as saponification agent;

[0033] A mixed clarification extraction tank is used for the extraction and separation of europium and gadolinium. The raffinate is a europium-rich solution, which is used as a feed solution for the separation of europium. The solution contains very low refractory rare earth elements, and gadolinium chloride is the raw material solution for preparing gadolinium carbonate products; the saponification wastewater produced in this section is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com