Patents

Literature

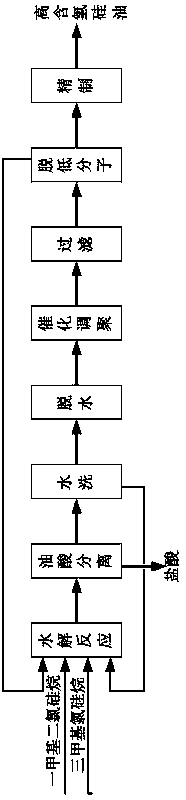

371results about How to "Avoid emulsification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

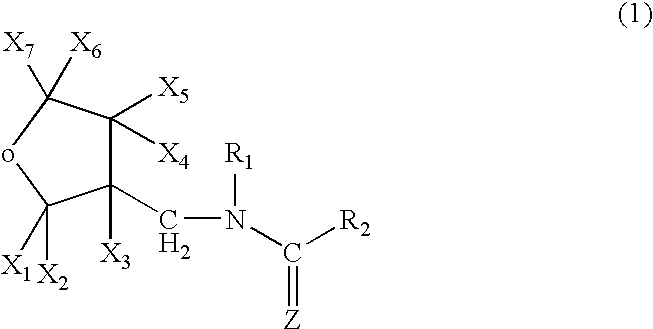

High concentration topical insecticide containing insect growth regulator

InactiveUS20050009880A1Easy to useOvercomes drawbackBiocideDead animal preservationHigh concentrationSide effect

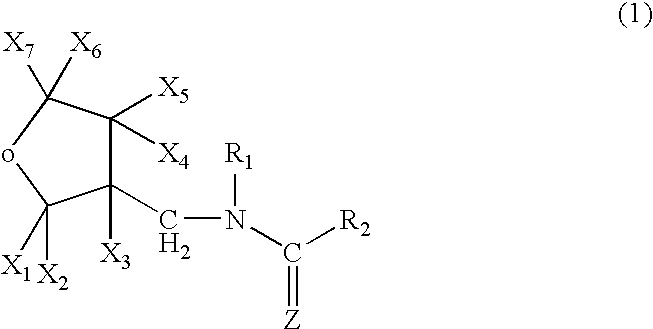

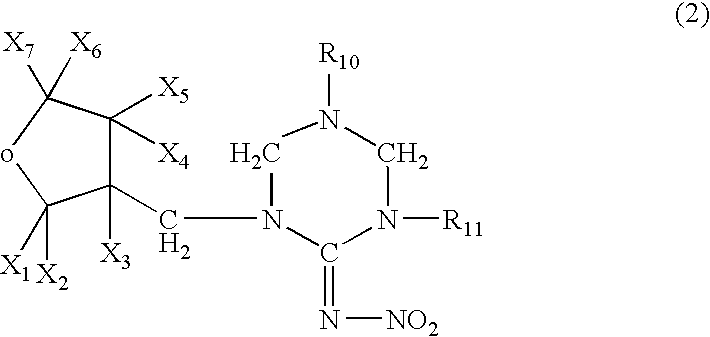

A topical insecticide is provided which can be safe to use and avoids many common deleterious side effects of conventional topical insecticides. The insecticide contains an insecticide and an insect growth regulator effective for killing fleas, flea larvae and flea eggs. The insecticide is formulated by dissolving an insecticidal (tetrahydro-3-furanyl) methylamine derivative or a chloronicotinyl insecticide and an insect growth regulator (IGR) in a solvent containing a quaternary ammonium salt to increase the solvency of the IGR component, thereby providing an insecticide having high insecticidal activity.

Owner:CEVA ANIMAL HEALTH

Method for non-saponification extraction and separation of light rare earth elements

ActiveCN104120258ALow viscosityImprove liquidityProcess efficiency improvementRare-earth elementPhosphate

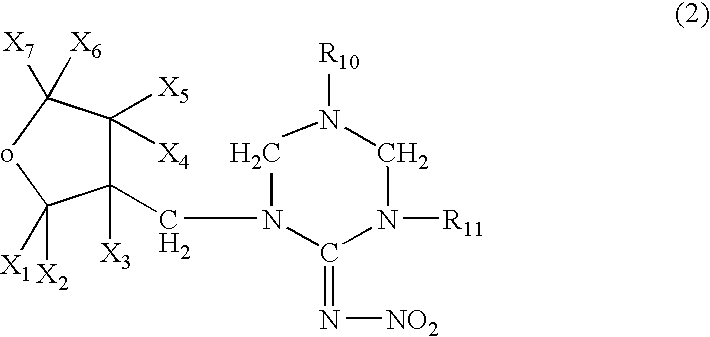

The invention discloses a method for non-saponification extraction and separation of light rare earth elements. After a compound extraction agent consisting of acid phosphorus type extraction agent, alkaline amine type extraction agent and solvent oil is mixed with phosphate solvent or organic alcohol solvent at 30-70 DEG C, chlorinated light rare earth liquid is extracted and separated; and the water washing and the hydrochloric acid reverse extraction are performed to finally realize the separation of La, Ce, Pr and Nd; and a mixed organic phase after the reverse extraction is returned to an extraction tank for recycling. The method pretreats the mixed organic phase consisting of the compound extraction agent and the solvent, so that such defects as high viscosity, weak mobility, easy emulsification and long phase splitting time are overcome; the method has no need to saponify the acid phosphorus type extraction agent, so that no alkali liquor consumption and no waste water emission in the extraction process are realized, but the separation capacity of a saponification extracting agent system is achieved, and the extraction grade is reduced compared with that needed by the saponification extracting agent system; and the method is a rare earth element separation process with economy and high efficiency.

Owner:GUANGXI NORMAL UNIV

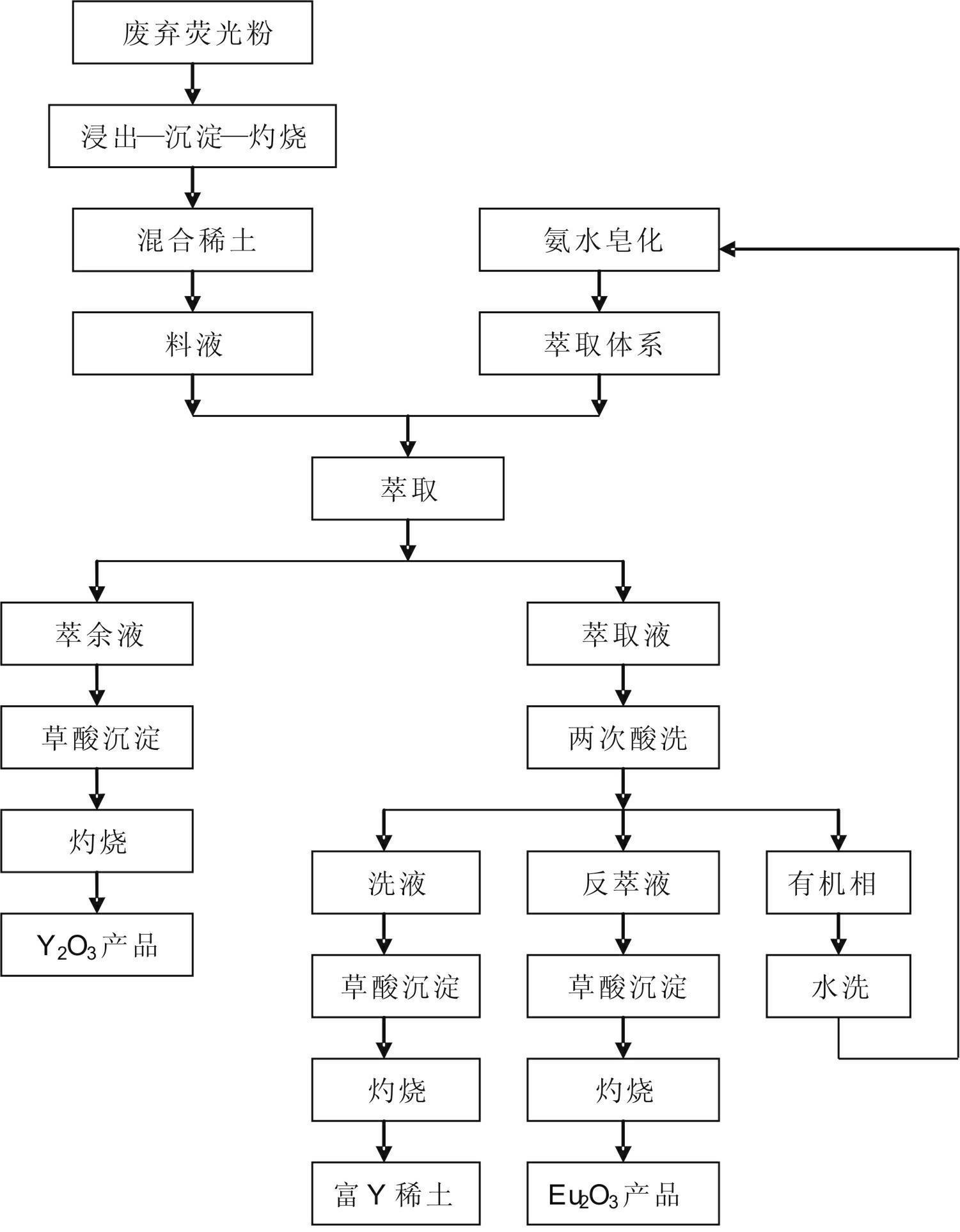

Method for separation and purification of fluorescent grade yttrium oxide and europium oxide from waste phosphor powder

InactiveCN102312098AWide variety of sourcesLow priceProcess efficiency improvementFiltrationRare earth

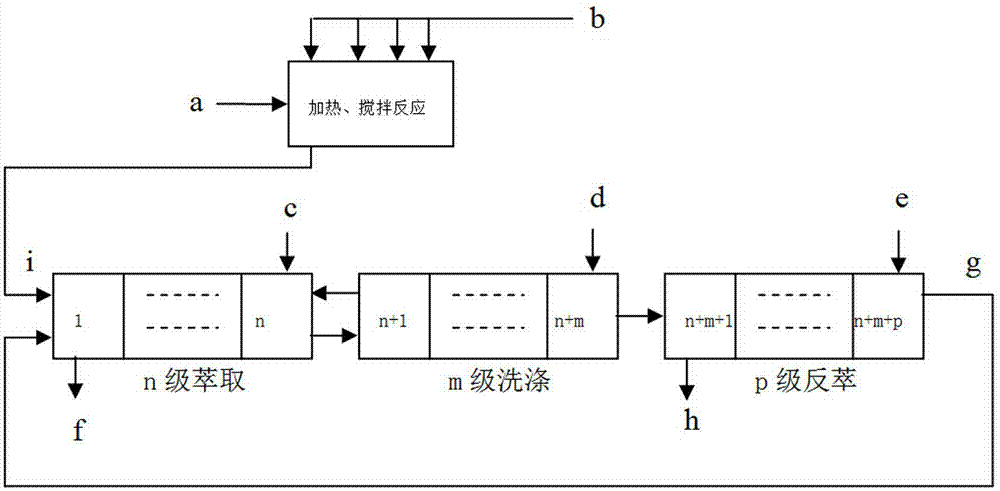

The invention relates to a method for separation and purification of fluorescent grade yttrium oxide and europium oxide from waste phosphor powder, comprising the steps of: first conducting impurity removal so as to obtain mischmetal containing Y2O3 and Eu2O3, then dissolving the mischmetal with an acid solution for preparing a rare earth feed liquid, and carrying out extraction with an extraction system after alkaline solvent saponification, thus obtaining the raffinate, washing liquid and strip liquor; adding an oxalic acid solution and conducting filtration, then subjecting the obtained filter residue to calcination, thus obtaining the fluorescent grade yttrium oxide, and yttrium-rich rare earth and europium oxide. The invention has the advantages that, reagents are of wide source, lowprice and easy availability, and the simple process of the method can greatly shorten the extraction process of naphthenic acid. In the invention, three deposition impurity-removal treatments before extraction can remove most impurities and leave only a small amount of aluminium and silicon, so that an emulsification phenomenon in the naphthenic acid extraction system cannot be caused, thus providing a good solution to the problem that naphthenic acid extraction is susceptible to high valent metal ions and results in emulsification.

Owner:WUHAN UNIV OF TECH

Novel extraction process of coenzyme Q10

ActiveCN104694613AIncrease productionReduce extraction costsQuinone separation/purificationMicroorganism based processesOrganic solventAlcohol

The invention belongs to the technical field of biology and discloses a novel extraction process of coenzyme Q10. The novel extraction process of the coenzyme Q10 takes coenzyme Q10 fermentation liquid as a raw material and comprises the following steps: extracting through an organic solvent, carrying out base-alcohol saponification, carrying out chromatography through a silica gel column, crystallizing through absolute ethyl alcohol, and carrying out suction filtration and vacuum drying to prepare the coenzyme Q10 product. The process is simple to operate, low in pollution, low in requirements on instruments and equipment and low in cost.

Owner:XINJIANG FUFENG BIOTECH

Method for enriching rare-earth elements from red mud

InactiveCN102127642AAvoid emulsificationIncrease contentProcess efficiency improvementRare-earth elementRed mud

The invention relates to a method for enriching rare-earth elements from red mud, belonging to the technical field of enriching rare-earth elements and aiming to provide a method for removing silicon and aluminum in red mud and enriching rare-earth elements in the red mud to solve the technical problem. The invention adopts the technical scheme that the method for enriching rare-earth elements from red mud comprises the following steps of: (1) obtaining a red mud hydrochloric acid leaching solution; (2) carrying out desilication treatment to the red mud hydrochloric acid leaching solution obtained in the step (1); (3) adding a NaOH solution at a room temperature to the desilicated red mud hydrochloric acid leaching solution obtained in the step (2), finishing precipitating and separating solid and liquid to obtain a solid containing rare-earth elements; and (4) carrying out dealuminzation treatment to the solid containing rare-earth elements obtained in the step (3). The invention effectively solves an emulsification phenomenon when extracting the rare-earth elements by using a wet method and improves the extraction rate of the rare-earth elements and the purity of the product.

Owner:TAIYUAN UNIV OF TECH +1

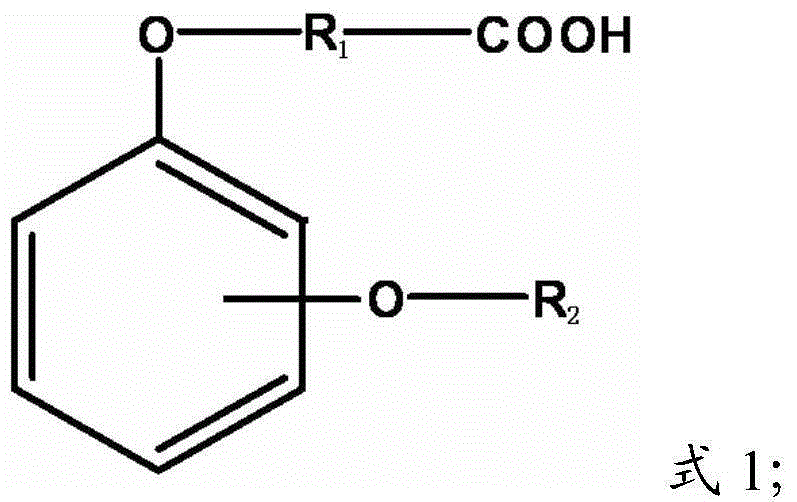

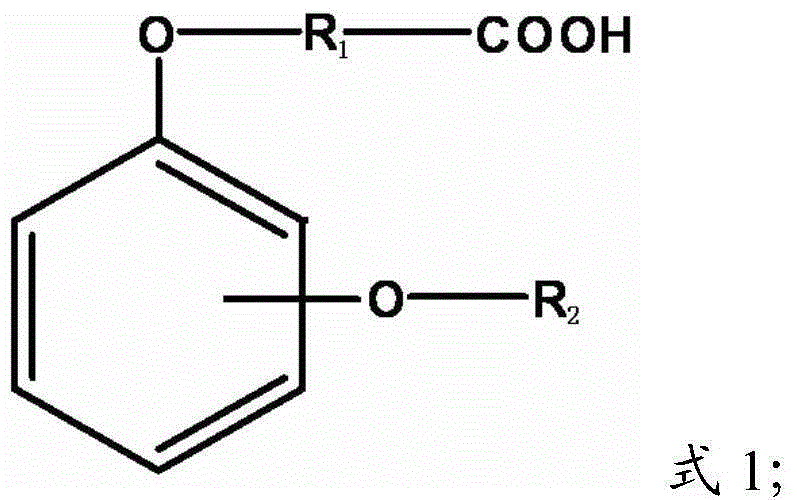

Scandium element extraction method

ActiveCN106702180AReduce concentrationHigh separation selectivityProcess efficiency improvementRare-earth elementEmulsion

Theinvention provides a scandium element extraction method. The scandium element extraction method comprises the following steps of: (A) mixing alkoxy phenoxy carboxylic acid, tributyl phosphate and a diluting agent to obtain an organic phase; and (B) extracting a scandium-containing mischmetal solution by using the organic phase to obtain a scandium ion-containing solution. The scandium element extraction method has the beneficial effects that the separation selectivity between the scandium element and other rare earth elements can be effectively improved by adopting the alkoxy phenoxy carboxylic acid as the extraction agent on the basis of ensuring the purity of a scandium product and relatively high yield; the concentration of the organic phase is effectively prevented from decreasing after extraction by adopting the tributyl phosphate as an additive, so that the organic phase can be recycled; meanwhile, an emulsion phenomenon in an extraction process can be avoided; and experimental results show that the separation coefficients of the scandium element and a lanthanide element are 526 due to adoption of the scandium element extraction method.

Owner:王艳良

Process for producing high-grade pentadiene petroleum resin

The present invention is production process of high grade piperyene petroleum resin. The piperyene petroleum resin is produced with separated and purified C5 cracking fraction rich in diolefin and coarse pentene to form the copolymerization material liquid in C5 olefin content of 80-92 wt%, AlCl3, main solvent and cosolvent mixed to react to produce cationic complex polymerization catalyst, and recovered C5 fraction as polymerization solvent, and through polymerization at 10-80 deg.c and 0.03-0.40 MPa for 2-5 hr, and neutralization and water washing after polymerization. The piperyene petroleum resin has high softening point, low color hue, high transparency, low melt viscosity, high heat resistance and high weather resistance. The production process has reaction yield up to 92-96 % and low production cost.

Owner:上海奔骅化工有限公司

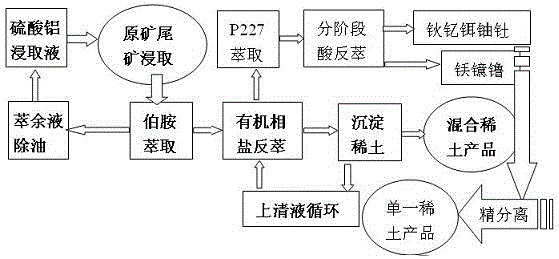

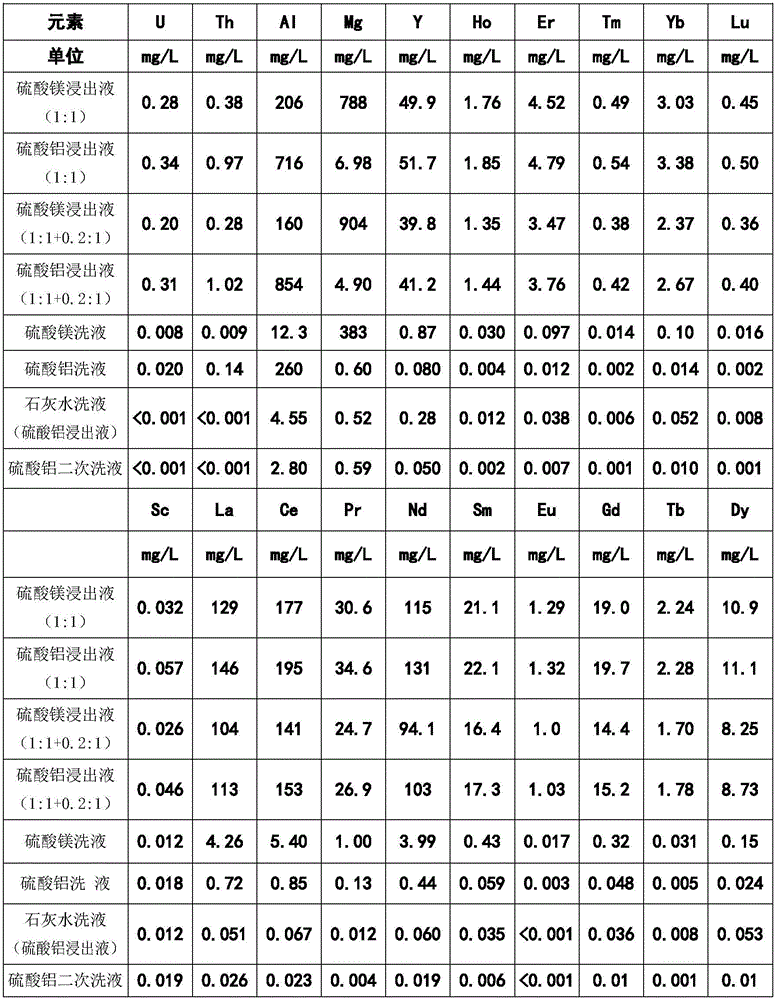

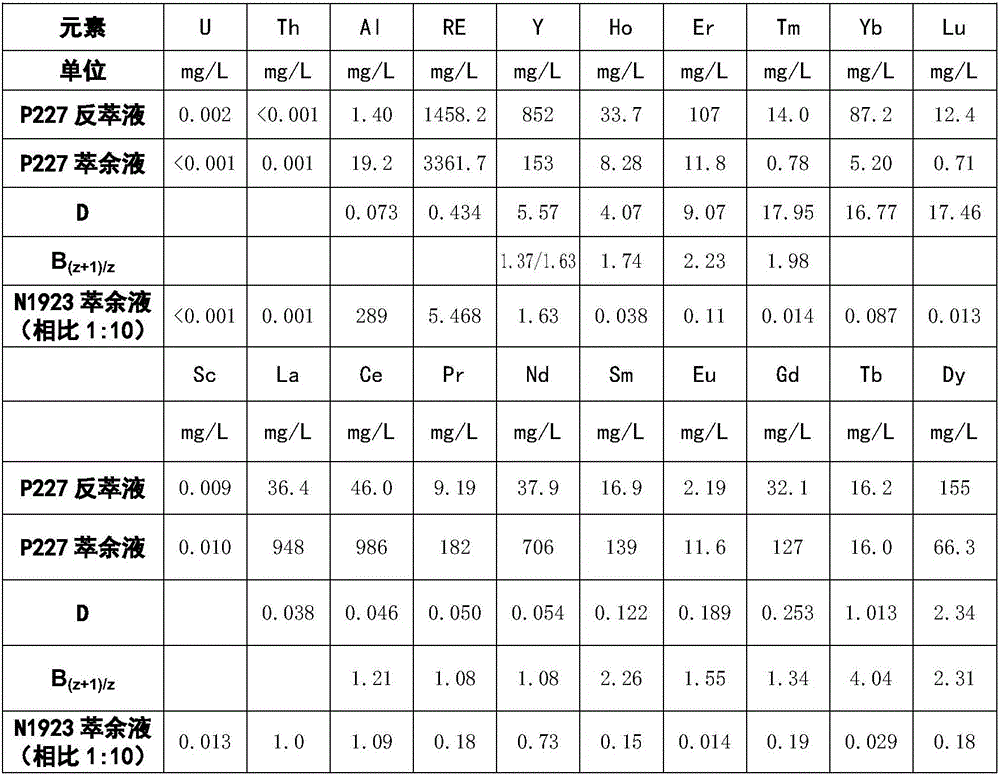

High-efficient and green ion-absorbed-type rear earth extraction method by adopting aluminum sulfate as leaching agent

ActiveCN106367622ASimple extraction and separationAvoid emulsification and three-phase problemsIonAluminium salts

The invention relates to a high-efficient and green ion-absorbed-type rear earth extraction method by adopting aluminum sulfate as a leaching agent. The method comprises the steps of preparing a leaching agent solution; leaching ion-absorbed-type rear earth, using primary amine for extracting rare earth, uranium, thorium and ferrum from the leaching solution and reverse extracting the rare earth, the uranium, the thorium and the ferrum from an extraction organic phase; using p227 for extracting heavy rare earth, the uranium and the thorium from a reverse extraction liquid; using hydrochloric acid for reverse extracting and separating the rare earth from the uranium and the thorium; using hydroxide and basic oxide for precipitating residual aluminium-ferrum-thorium from the reverse extraction liquid; preparing rare earth products with different specifications through a precipitation method; unoiling and recycling a raffinate; recycling precipitated wastewater; protonizing an extracted organic phase; and the like. According to the method, the leaching efficiency of the current ion-absorbed-type rear earth can be remarkably improved, the emission of harmful elements is greatly reduced, radioactive elements such as the uranium and the thorium are reasonably treated and recovered, the pollutant load in a tail water immersion liquid is ensured to meet the emission requirement, the security and the stability of tailings are improved, and the method is a key technology for realizing high-efficient and green ion-absorbed-type rear earth extraction.

Owner:NANCHANG UNIV

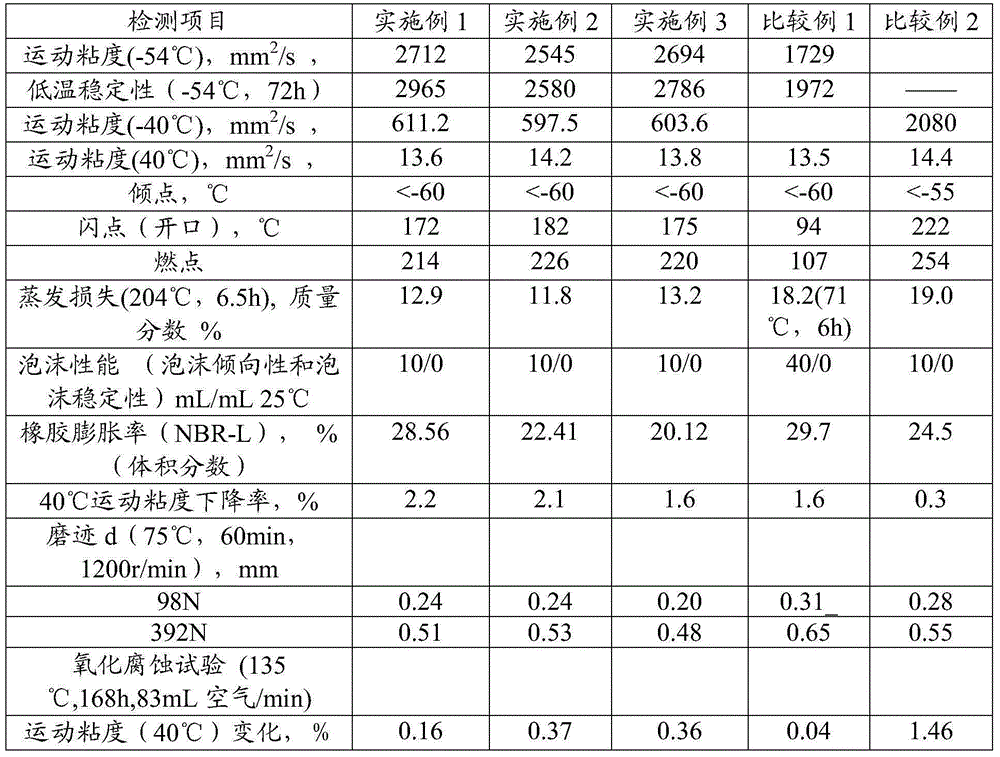

Hydraulic oil

ActiveCN104987942AGood low temperature performanceGood viscosity and film thicknessLubricant compositionOxidation stabilityAntioxidant

The invention provides a hydraulic oil. The hydraulic oil comprises, by weight, 70-90 parts of poly-alpha-olefin, 10-30 parts of a diester compound, 0.1-3 parts of an antioxidant, 0.1-0.5 parts of an antirust agent, 0.1-5 parts of an extreme pressure anti-wear agent, 0.0005-0.05 parts of an antifoaming agent, 0.001-0.1 parts of a coloring agent and 5-20 parts of a viscosity improver. The use amounts of all components and the comprehensive effects of all the components are controlled to make the hydraulic oil have good low-temperature performances and high flash point. Experiment results that the hydraulic oil can be used at -50DEG C, and the flash point of the hydraulic oil is 172-182DEG C. The hydraulic oil provided by the invention has the advantages of good viscosity-temperature properties, high burning point, good anti-foaming performance and good oxidation stability.

Owner:CHINA PETROLEUM & CHEM CORP

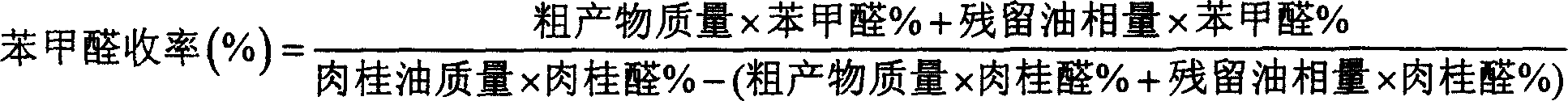

Process for preparing natural benzaldehyde

InactiveCN1634837AAvoid polymerization and disproportionation reactionsAvoid emulsificationCarbonyl compound preparation by hydrolysisCinnamon OilBenzaldehyde

The preparation method of natural benzaldehyde relates to a kind of benzaldehyde, and provides a new method for preparing natural benzaldehyde by hydrolyzing cinnamon oil under alkaline conditions. Add water to organic base, Na2CO3, and cationic surfactant; heat the mixed aqueous solution, drop in cinnamon oil; condense and collect the product; when the amount of the collected oil phase is only 8% to 12% of the initial amount, stop adding water, when the benzaldehyde When the content is reduced to less than 10% and the cinnamaldehyde content is greater than 60%, the reaction is stopped. Avoid the polymerization and disproportionation reaction of products under strong alkaline conditions, and reduce the amount of benzene and toluene generated due to the existence of small molecule OH-. The use of cationic surfactant instead of nonionic surfactant avoids saponification and emulsification of the product, and the reaction rate is greatly improved. The side reactions such as polymerization and disproportionation of the product are directly reduced. The reaction time of the process is shortened; the yield of the main product of the reaction is increased.

Owner:XIAMEN UNIV +1

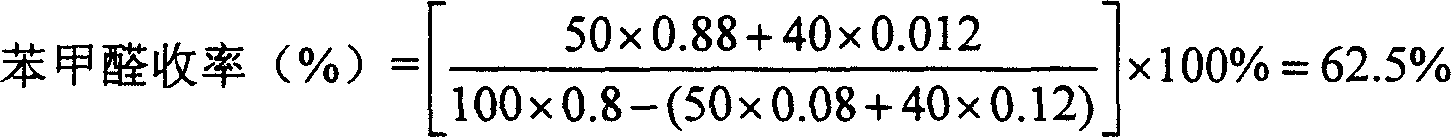

a diesel fuel additive

ActiveCN102277212AAvoid emulsificationObvious anti-emulsification effectLiquid carbonaceous fuelsFuel additivesEmulsionOil additive

The invention relates to a diesel fuel additive for improving diesel fuel performances. The diesel fuel additive is a dual-purpose additive mixture which can be utilized as a diesel fuel anti-wear agent and a diesel fuel emulsion inhibitor. The diesel fuel additive for improving diesel oil performances comprises components of A) tall oil fatty acid, B) oleamide, and C) naphthenic acid imidazoline, wherein a weight ratio of the component A to the component B to the component C is 100: (5 to 100): (5 to 50) and the component A, the component B and the component C can be respectively added directly into diesel fuel for use. The component A, the component B and the component C also can be mixed into a lubricant additive and then the lubricant additive is added into diesel fuel, wherein an additive amount is in a range of 50 to 300 mg / kg. The diesel fuel additive for improving diesel fuel performances has prominent substantive characteristics and remarkable improvements that 1, the diesel fuel additive can improve lubricity of diesel fuel and thus can be utilized as a diesel fuel anti-wear agent; and 2, the diesel fuel additive has obvious anti-emulsification effects on diesel fuel, can inhibit emulsification of diesel fuel and can be utilized as a diesel fuel emulsion inhibitor for use.

Owner:CHINA PETROLEUM & CHEM CORP

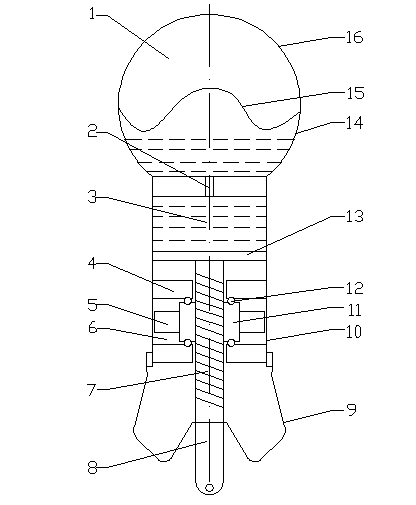

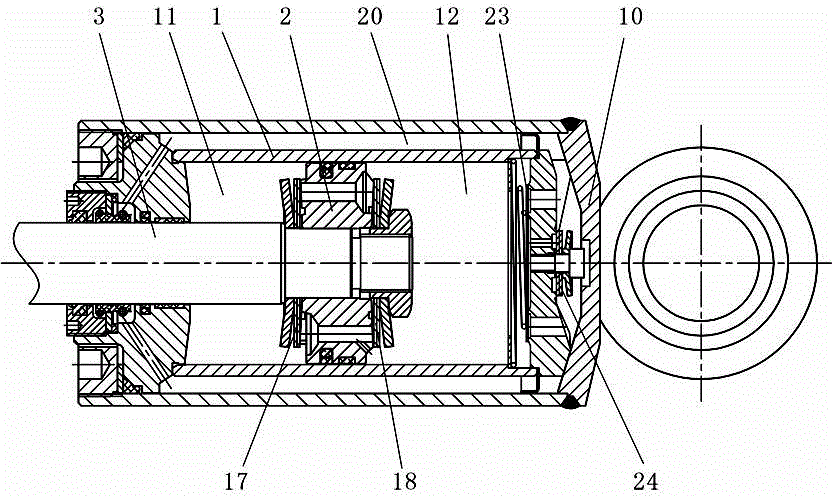

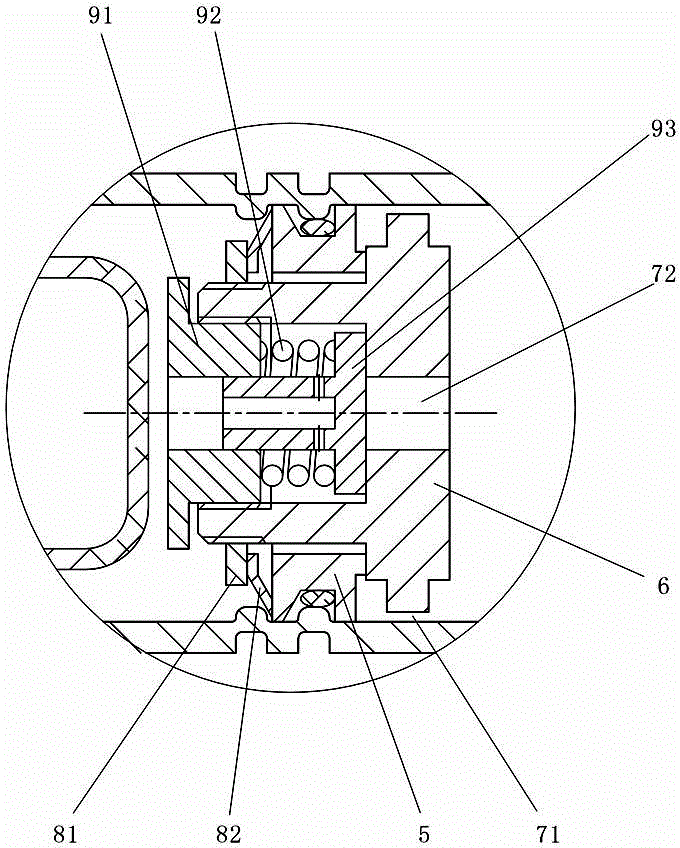

Integrated hydro-pneumatic spring device

InactiveCN102937159AImprove handling stabilityLose weightSpringsShock absorbersMechanical networkBall screw

The invention discloses an integrated hydro-pneumatic spring device. An inerter working chamber is coaxially arranged in a damping working cylinder, a piston portion in the inerter working chamber is arranged as a screw rod structure, a ball screw nut is arranged on the screw rod in the inerter working chamber according to a ball screw principle, a flywheel is coaxially fixed on the ball screw nut, the nut is limited in the middle section and can only rotate around the screw rod through two stop collars fixed at the top and bottom of the working cylinder, and ball circular grooves are arranged on contact surfaces of the stop collars with the nut. As an improvement, self-weight of a vehicle body is not increased when sprung mass of a suspension is improved, driving comfort and handling stability of vehicles are improved, complex mechanical network combined process is avoided, and spatial arrangement limitation is reduced due to coaxial parallel connection of the inerter and the damping.

Owner:JIANGSU UNIV

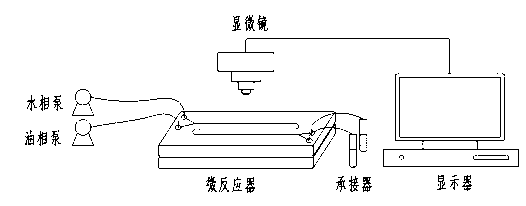

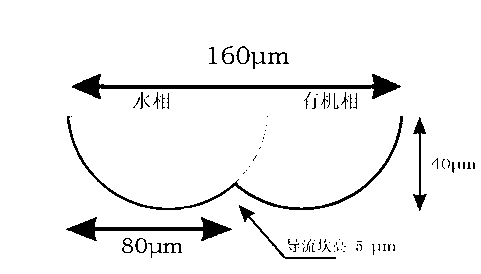

Microfluid extraction method for extracting and separating In, Fe and Zn

InactiveCN103060559ANo emulsificationImprove recycling efficiencyProcess efficiency improvementIndiumSolvent

The invention provides a microfluid extraction method for extracting and separating In, Fe and Zn. The microfluid extraction method comprises the steps of: using a sulfuric acid system solution containing indium, ferrum and zinc as a water phase and a P204 extracting agent diluted through solvent oil as an organic phase, which are respectively fed into two flow pumps, wherein the outlet end of the flow pump is connected with an inlet of a microreactor; simultaneously, observing a two-phase laminar flow phase interface formed inside a microchannel through an optical microscope, so that two phases flow in parallel and then begins to be separated when reaching a Y-type fork at the outlet of the microchannel, and the two phases flow out of the microreactor from outlets of the two phases; respectively collecting the two phases; and extracting indium to enter the organic phase and leaving ferrum and zinc in the water phase, so that the separation of indium, ferrum and zinc is realized. The extraction rate of In can be up to more than 90%, but ions of Fe and Zn are not extracted completely; moreover, no emulsion appears; and reaction time is greatly shortened, the using amount and consumption of the extracting agent can be reduced, the condition controllability is high, the safety is high, and extracted organic solvent is prevented from being exposed in the air.

Owner:KUNMING UNIV OF SCI & TECH

High concentration topical insecticide containing insect growth regulator

InactiveUS7132448B2Easy to useAvoids many common deleterious side effectsBiocideDead animal preservationHigh concentrationSide effect

A topical insecticide is provided which can be safe to use and avoids many common deleterious side effects of conventional topical insecticides. The insecticide contains an insecticide and an insect growth regulator effective for killing fleas, flea larvae and flea eggs. The insecticide is formulated by dissolving an insecticidal (tetrahydro-3-furanyl) methylamine derivative or a chloronicotinyl insecticide and an insect growth regulator (IGR) in a solvent containing a quaternary ammonium salt to increase the solvency of the IGR component, thereby providing an insecticide having high insecticidal activity.

Owner:CEVA ANIMAL HEALTH

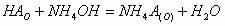

Process for enriching and preparing high-purity scandium by use of oxyl substituted acetic acid as extractant

InactiveCN1397653AGood chemical stabilityEasy to manufactureProcess efficiency improvementSodium bicarbonateSal ammoniac

A process for preparing scandium by using oxyl substituted acetic acid as extractant includes adding the said extractant, additive (alcohol mixture) and saponifier chosen from ammonia water, sodium hydroxide, dicarbonate and sodium carbonate to the Sc-contained rare-earth mixture liquid, extracting by 4-10 stages, washing with HCl or HNO3 by 2-8 stages, fraction distilling and mixing for 5-15 min, clarifying at 10-35 deg.C for 10-50 min to obtain Sc-enriched rare-earth, extracting by 5-15 stages and washing by 4-10 stages. Its advantages are high purity (99.99-99.999 wt.%) and high output rate (more than 90%).

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

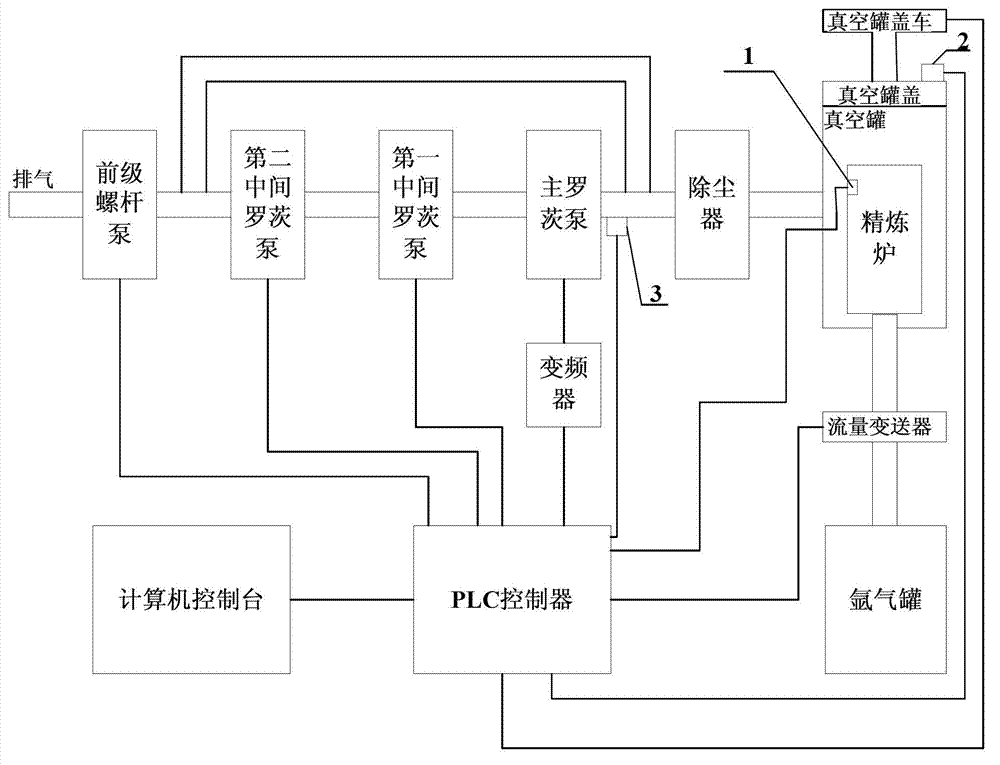

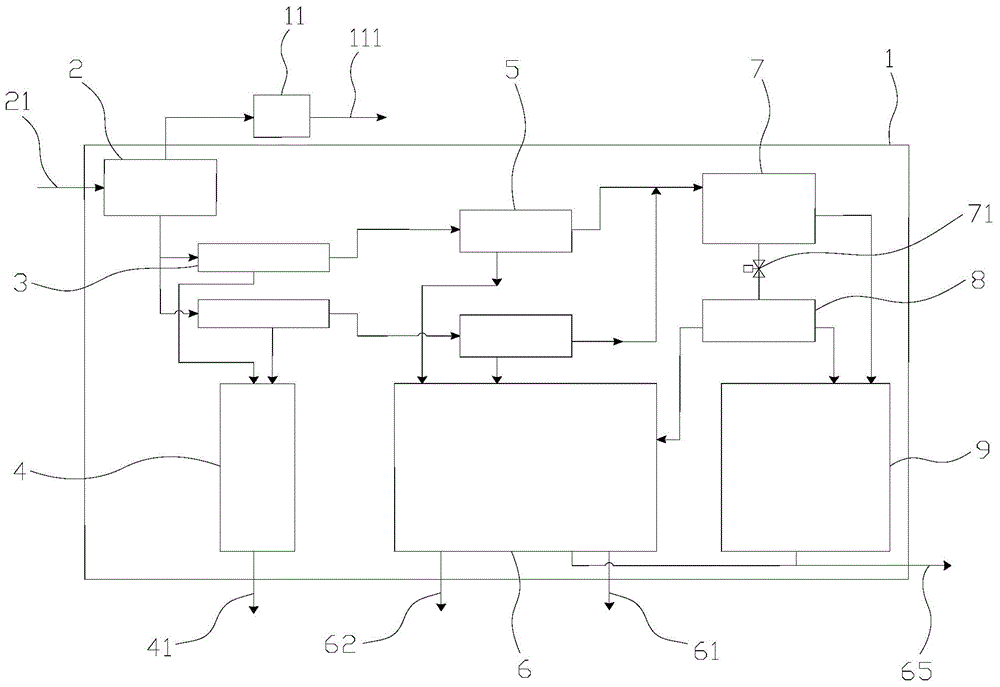

Molten steel vacuum refining system based on mechanical pump group

The invention discloses a molten steel vacuum refining system based on a mechanical pump group. The system comprises a vacuum tank, a deduster, a roots pump group and a pre-screw pump, wherein the roots pump group comprises a main roots pump, a first middle roots pump and a second middle roots pump; the deduster is also directly connected with the pre-screw pump through a pipeline; the bottom of the vacuum tank is connected with an argon system; the system also comprises a controller; the first middle roots pump, the second middle roots pump and the pre-screw pump are all electrically connected with the controller; the main roots pump is electrically connected with the controller through a frequency converter; a liquid level sensor is arranged at the upper part of the inner wall of a refining furnace of the vacuum tank; the liquid level sensor is electrically connected with the controller; a vacuum degree measuring device is mounted on a pipeline between the deduster and the main roots pump; and the vacuum degree measuring device is connected with the controller. The system disclosed by the invention can perform automatic control to realize stable liquid surface of the molten liquid in the refining furnace of the vacuum tank to prevent steel overflow, thereby avoiding production safety accident.

Owner:什邡市三裕锻件有限公司

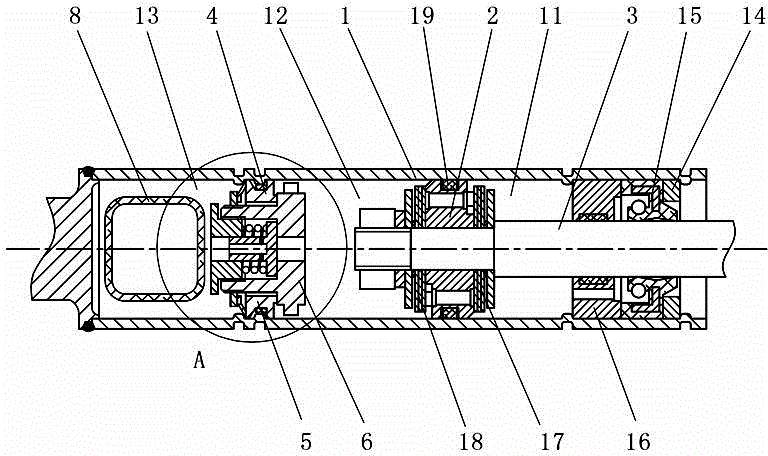

Hydraulic damper

InactiveCN104154167AReduce radial sizeReduce volumeSpringsShock absorbersEngineeringMechanical engineering

The invention discloses a hydraulic damper. The hydraulic damper comprises an oil cylinder barrel, a piston and a piston rod. A working cavity is arranged in the oil cylinder barrel. The piston is arranged in the working cavity. The working cavity is divided into a first working cavity and a second working cavity. One end of the piston rod is arranged on the piston. The other end of the piston rod penetrates through the first working cavity to be arranged outside the oil cylinder barrel. A compensation cavity is further arranged in the oil cylinder barrel. The compensation cavity is located at the end, far away from the first working cavity, of the second working cavity. A flow direction control assembly is arranged between the compensation cavity and the second working cavity. The hydraulic damper has the advantages of being simple in structure, small in size, high in reliability, long in service life, high in universality and the like.

Owner:ZHUZHOU TIMES EQUIP TECH

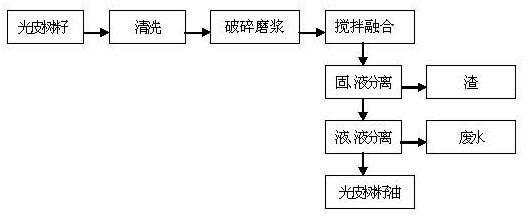

Extraction method of peanut germ oil

InactiveCN103451004ACompletely degradedHigh oil extraction rateFatty-oils/fats productionEdible oils/fatsAmylaseCellulase

The invention relates to the technical field of agricultural product processing, and particularly relates to an extraction method of peanut germ oil. The extraction method comprises the following steps: crushing peanut germs; firstly, carrying out enzymolysis by cellulase and amylase under a condition that pH is 4-6, wherein the vitality ratio of cellulase toand amylase is 5:3; then, adding acid proteinase for enzymolysis of the peanut germs and deactivating the enzymes to obtain peanut germ hydrolyzing slurry; separating the oil phase to obtain the peanut germ oil; superfine grinding the peanut germs to 300-400 meshes; processing the peanut germs crushed by steam for 18-20 minutes. By adopting compound enzymes, cell walls and intracellular network structures are degraded more thoroughly, so that the oil extraction rate is improved. By adopting superfine grinding treatment, the granularity of the germs is reduced, the surface area of the germs is increased, and the effect of the enzyme is improved. Meanwhile, the germs are effectively prevented from being emulsified. By adopting steam treatment, lipase in the germs is deactivated, and meanwhile, the cell walls are loosened to increase the permeability and facilitate effect of the enzyme, so that oil is more easily released.

Owner:张瑜

Production process for continuously producing high-hydrogen-content silicone oil

The invention discloses a production process for continuously producing high-hydrogen-content silicone oil. The production process comprises the following steps: performing hydrolysis reaction on raw materials including trimethylchlorosilane, methyldichlorosilane, diluted hydrochloric acid and low molecule, which are in proportion; separating an oil acid mixture obtained by the hydrolysis reaction, feeding a hydrolysate at the upper layer into a washing system for deacidification, feeding dilute acid at the lower layer into a hydrolysis reaction system for recycling; after the washed hydrolysate is dehydrated, feeding the dehydrated hydrolysate into a fixed bed reaction system filled with a catalyst, and performing telomeric reaction on hydrogen-containing silicone oil; performing decontaminating, low molecule removal and refining on the hydrogen-containing silicone oil subjected to the telomeric reaction to obtain the hydrogen-containing silicone oil of which the hydrogen content is 1.56-1.60wt%. The production process for the high-hydrogen-content silicone oil, provided by the invention, has the advantages of low energy consumption, high yield, low production cost, high product hydrogen content and the like.

Owner:HOSHINE SILICON IND CO LTD

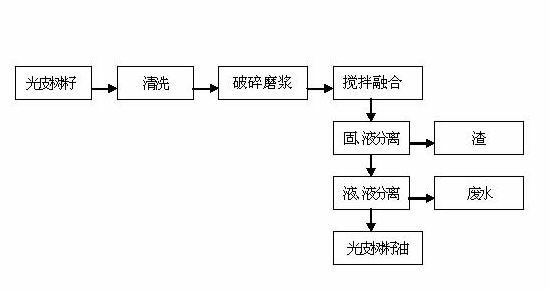

Method for extracting edible cornus wilsoniana seed oil from fresh cornus wilsoniana seed fruits at low temperature

InactiveCN102433217ALow extraction rateReduce colorFatty-oils/fats productionEdible oils/fatsVegetable oilNutrition

A method for extracting edible cornus wilsoniana seed oil from fresh cornus wilsoniana seed fruits at a low temperature comprises the following steps of: taking fresh mature cornus wilsoniana seeds as raw materials, cleaning the seeds, crushing and grinding the seeds into pulp by means of a crusher at a rotating speed of 10-100 r / min, adding water accounting for 30-200% of the weight of the raw materials to the pulp, performing stirring blending at a temperature ranging from 25 to 50 degrees centigrade for 10-120 r / min, and then performing solid-liquid separation through centrifuging to obtain solid residues and an oil-water mixture, and finally performing oil-water separation through centrifuging. The method for extracting edible cornus wilsoniana seed oil from fresh cornus wilsoniana seed fruits at the low temperature is to extract the oil at the low temperature, thereby effectively preventing the emulsification of oil and facilitating oil separation; the oil extraction ratio is greater than 97%; the obtained oil is low in tincture and acid value; the special flavor of the vegetable oil can be kept; the active components of the vegetable oil are not damaged; and the extracted cornus wilsoniana seed oil contains abundant nutrition components without benzo(a)pyrene and trans fatty acid; therefore, the oil can be directly eaten.

Owner:江西省粮油科学技术研究所

Process for treating oil by alkali washing

ActiveCN1693423ALow acid valueReduce the concentration of metal ionsRefining with aqueous alkaline solutionsAlcoholDispersed media

A process for alkali washing of oil to remove acid, salt and metal ions features that the raw oil is washed by the alcohol solution of sodium hydroxide in a mixer which is divided into upper and lower layers by the dispersing medium. The alcohol solution of sodium hydroxide in upper layer is dispersed into microdrops by said dispersing medium and then reacts on the raw oil in lower layer. After separation, the pure oil is obtained.

Owner:TSINGHUA UNIV

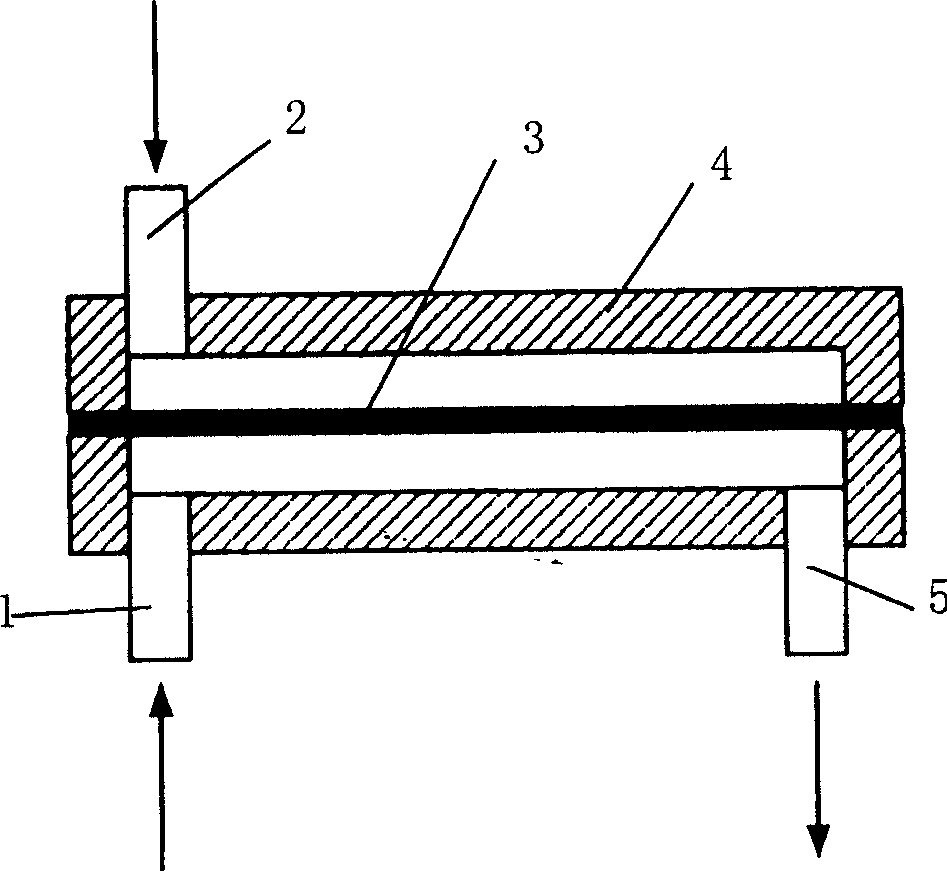

Propeller shaft sealing structure of ship propeller

InactiveCN104806736AAvoid enteringAvoid emulsificationGear lubrication/coolingWater acting propulsive elementsInterference fitThermal spraying

The invention relates to a shaft sealing structure of a ship propeller. A race is fixedly connected with a conical ring; the conical ring is arranged on a gearbox body; a thermal spraying bushing sleeves a propeller shaft in an interference way; four rotary skeleton oil seals are arranged on a ceramic area of the thermal spraying bushing; the outer diameter of each rotary skeleton oil seal is in interference fit with an inner hole of the race; a sealing lip of the inner diameter is in contact with the ceramic area of the thermal spraying bushing; the sealing lip of the outermost rotary skeleton oil seal faces outwards, the sealing lip of the innermost rotary skeleton oil seal faces inwards, a space ring is arranged between the two middle rotary skeleton oil seals, and the space ring, the two middle rotary skeleton oil seals and the thermal spraying bushing form a cavity; a communicated gravity oil passage is arranged in the gearbox body, the conical ring, the race and the space ring, and is communicated with the cavity; a sealing part sleeves the thermal spraying bushing; a sealing lip of the sealing part is in contact with the vertical end surface of a cover plate. The propeller shaft sealing structure has the advantage that gravity oil is filled into the gravity oil cavity through the oil passage, so the seawater is prevented from entering the gearbox, and the emulsifying of lubricating oil is avoided.

Owner:SMMC MARINE DRIVE SYST SUZHOU

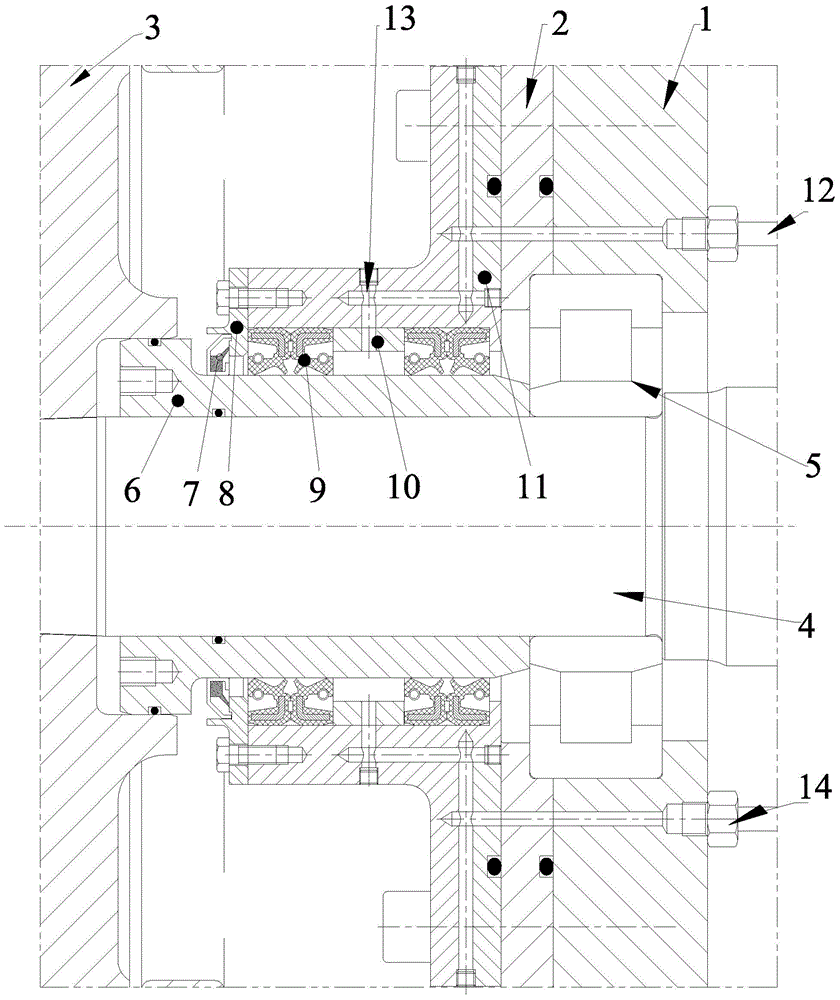

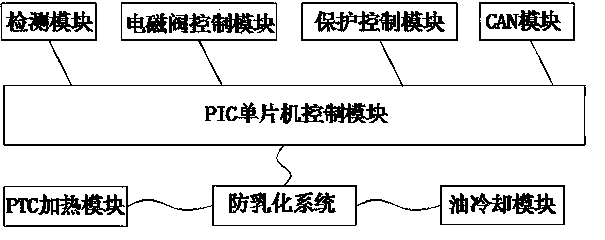

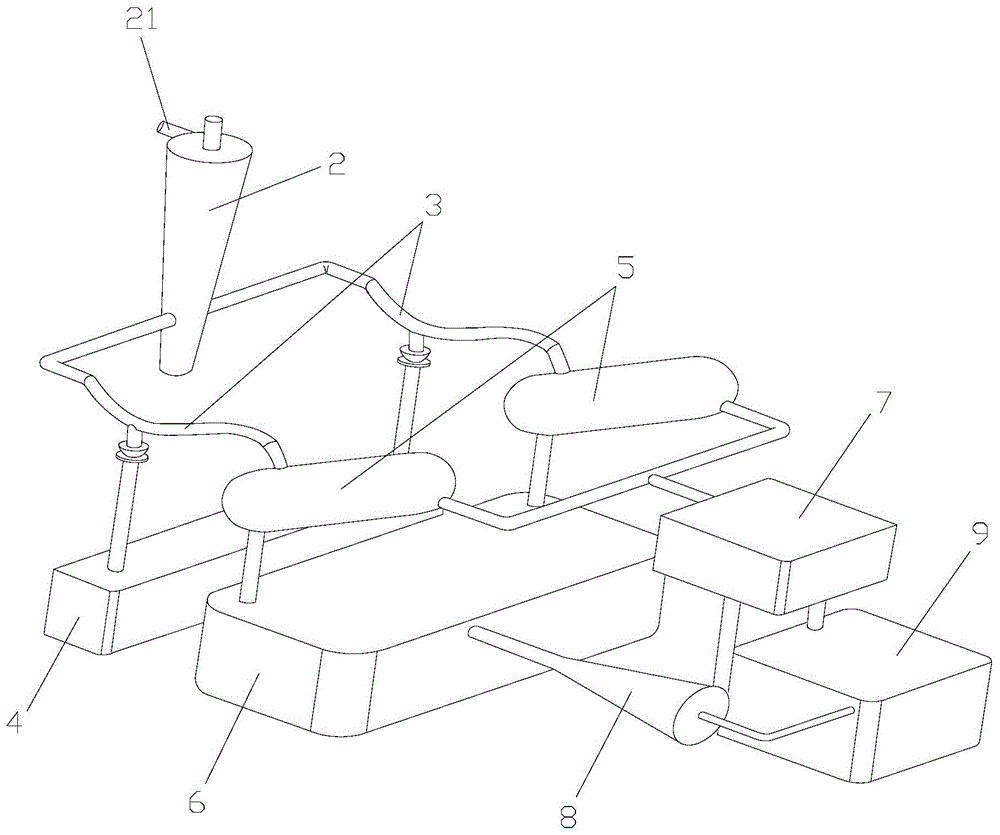

Novel anti-emulsifying system for electric automobile air compressor

InactiveCN104314791AAvoid emulsificationPositive displacement pump componentsPump controlArea networkComputer module

The invention discloses a novel anti-emulsifying system for an electric automobile air compressor, and relates to the technical field of electric automobile air compressors. The novel anti-emulsifying system comprises a PIC (peripheral interface controller) singlechip control module, a PTC (positive temperature coefficient) heating module and an oil cooling module; the PIC singlechip control module serves as a core and is divided into a detection module, an electromagnetic valve module, a protection control module and a CAN (controller area network) module. The anti-emulsifying system is unlikely to abrade a machine head and damage an oil filter and is high in oil emulsifying capability and low in maintenance cost.

Owner:合肥国骋新能源汽车技术有限公司

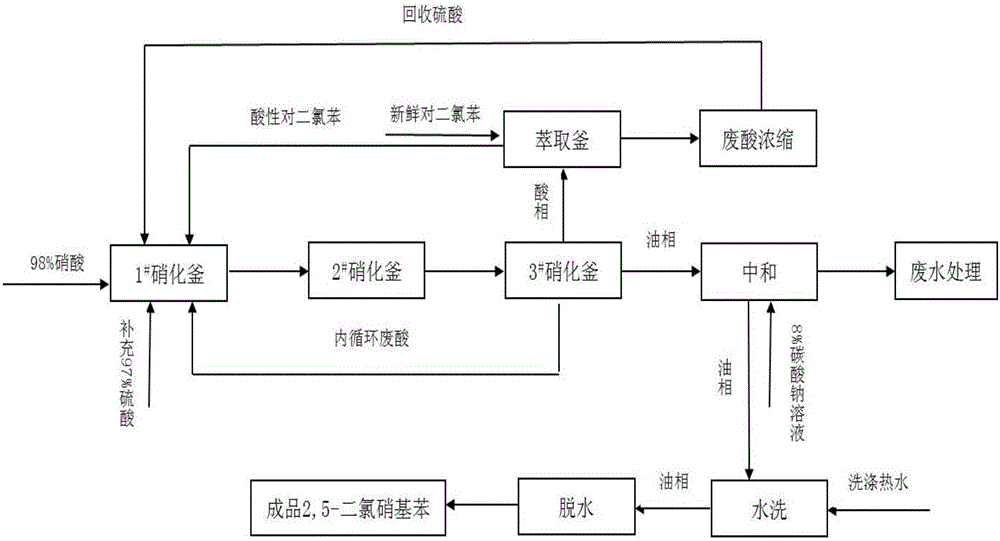

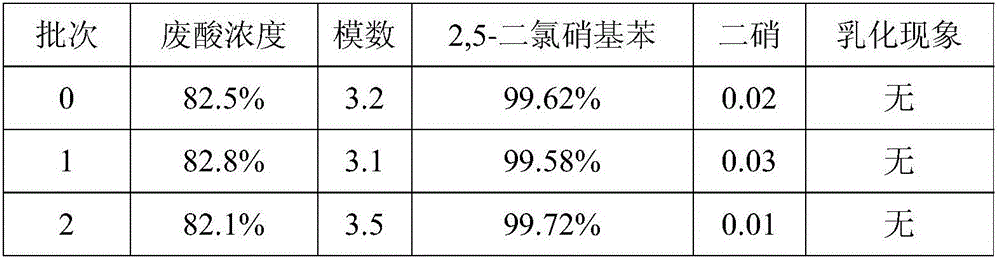

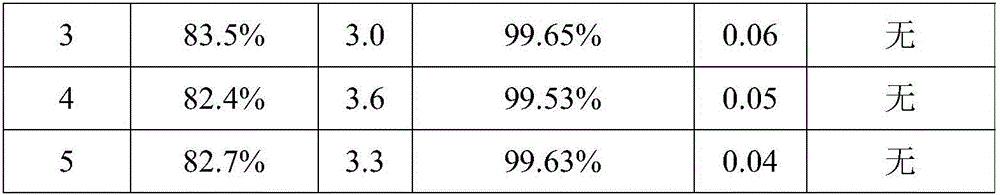

Method for preparation of 2, 5-dichloronitrobenzene by continuous nitration

ActiveCN106083596AOptimize process flowWith automatic separation functionNitro compound preparationNitrationOil phase

The invention discloses a method for preparation of 2, 5-dichloronitrobenzene by continuous nitration. The method comprises the steps of: adopting three-stage kettle type continuous reaction, adding sulfuric acid, nitric acid and p-dichlorobenzene in an extraction kettle into a first stage nitrification kettle simultaneously to carry out nitrification reaction, letting nitrification liquid enter a next stage nitrification kettle through self-carried raisers of all nitrification kettles in order to react, at the end of reaction in a third stage nitrification kettle, separating an oil phase and an acid phase, carrying out neutralization, washing and dehydration on the oil phase so as to obtain 2, 5-dichloronitrobenzene, internally recycling part of waste acid in the acid phase back to the first stage nitrification kettle, letting the residual waste acid enter an extraction kettle, and performing p-dichlorobenzene extraction, and then conducting separation to obtain acidic p-dichlorobenzene and extracted waste acid, concentrating the extracted waste acid into concentrated sulfuric acid, and making the concentrated sulfuric acid and acidic p-dichlorobenzene enter the first stage nitrification kettle for recycling. The method provided by the invention adopts automation control, cancels a mixed acid preparation procedure, simplifies the technological process, can realize continuous nitrification reaction, continuous nitrification liquid separation and continuous waste acid extraction.

Owner:江苏拓孚工程设计研究有限公司

Demulsification method in production processes for extracting tea-seed oil extraction with participation of water phase

InactiveCN103396879AAvoid emulsificationSimple methodFatty-oils/fats refiningFatty-oils/fats productionOil and greaseOil water

The invention discloses a demulsification method in production processes for extracting tea-seed oil extraction with the participation of a water phase, relates to a technology for breaking an oil-water emulsification state during tea-seed oil production, and in particular to a technology for breaking emulsification in production processes for extracting tea-seed oil extraction with the participation of a water phase, such as an aqueous enzymatic method, an aqueous solution method or an aqueous extraction method. The technical scheme is as follows: after tea seeds are moderately crushed, an appropriate amount of water phase is added, and the purpose of breaking an oil-water emulsification phenomenon is achieved by virtue of the comprehensive methods of increasing temperature, regulating pH value and centrifugally separating. The method provided by the invention is simple, feasible and strong in practicability, solves the problem of a low oil yield caused by the fact that oil and water are seriously emulsified and difficult to separate in a water-phase oil extraction process, and is beneficial to actual industrial application and popularization for the water-phase tea-seed oil extraction process technology.

Owner:CHANGSHA HAORUI BIOLOGICAL SCI & TECH

Method for extracting rare-earth elements through micro channels

InactiveCN105112658AShort staySmall footprintProcess efficiency improvementMicroreactorRare-earth element

The invention relates to a method for extracting rare-earth elements through micro channels, and belongs to the technical field of hydrometallurgy. The method comprises the steps that firstly, P507 or P204 is added into 260# solvent oil diluents according to the volume ratio of 3:10-10:3 to obtain an organic phase; a rare-earth salt solution serves as a water phase; the organic phase and the water phase are subjected to normal-temperature extraction through the micro channels in a microreactor according to the phase ratio of 5:1-1:5 and at the volume flowing speed of 5.55*10-10-4.17*10-8 m<3> / s; and finally, an extraction phase containing rare-earth elements and raffinate are obtained. In combination with the advantages that the micro channels are high in specific interfacial area, high in mass transfer rate, short in response time and the like, the purpose of achieving high-efficiency rare-earth extraction is realized through contact of two phase interfaces in the micro channels, and the method is safe, efficient and low in consumption.

Owner:KUNMING UNIV OF SCI & TECH

Method for comprehensively extracting polysaccharides, polyphenol and saponin from camellia oleifera abel defatted cakes

ActiveCN102993328AReduce solubilityEliminate the effects of purificationSugar derivativesSteroidsAcetic acidCamellia oleifera

The invention provides a method for comprehensively extracting polysaccharides, polyphenol and saponin from camellia oleifera abel defatted cakes. The method includes the following steps: obtaining polysaccharides through aqueous extraction, concentration, deproteinization and ethanol precipitation after the camellia oleifera abel defatted cakes are degreased; concentrating and adding salt into the supernatant after the ethanol precipitation of the polysaccharides, and performing extraction to obtain the polyphenol through ethyl acetate; and absorbing and analyzing the aqueous phase after extraction of the polyphenol through resin to obtain the saponin. According to the method, effects of substances such as the polysaccharides and the polyphenol during extraction of the saponin are overcome, and the purity of the saponin is improved; and the polysaccharides, the polyphenol and the saponin are obtained, and the defect of low utilization rate of camellia oleifera abel defatted cakes in the existing methods is overcome.

Owner:GUANGXI NORMAL UNIV

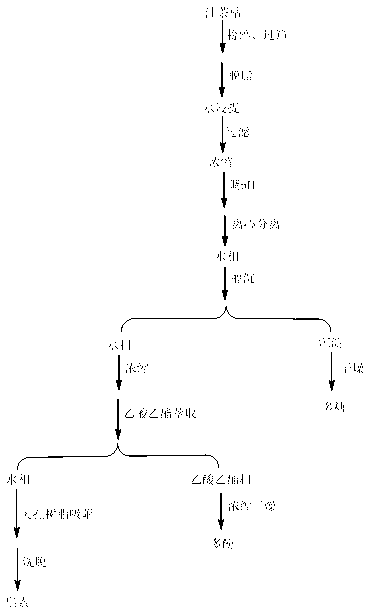

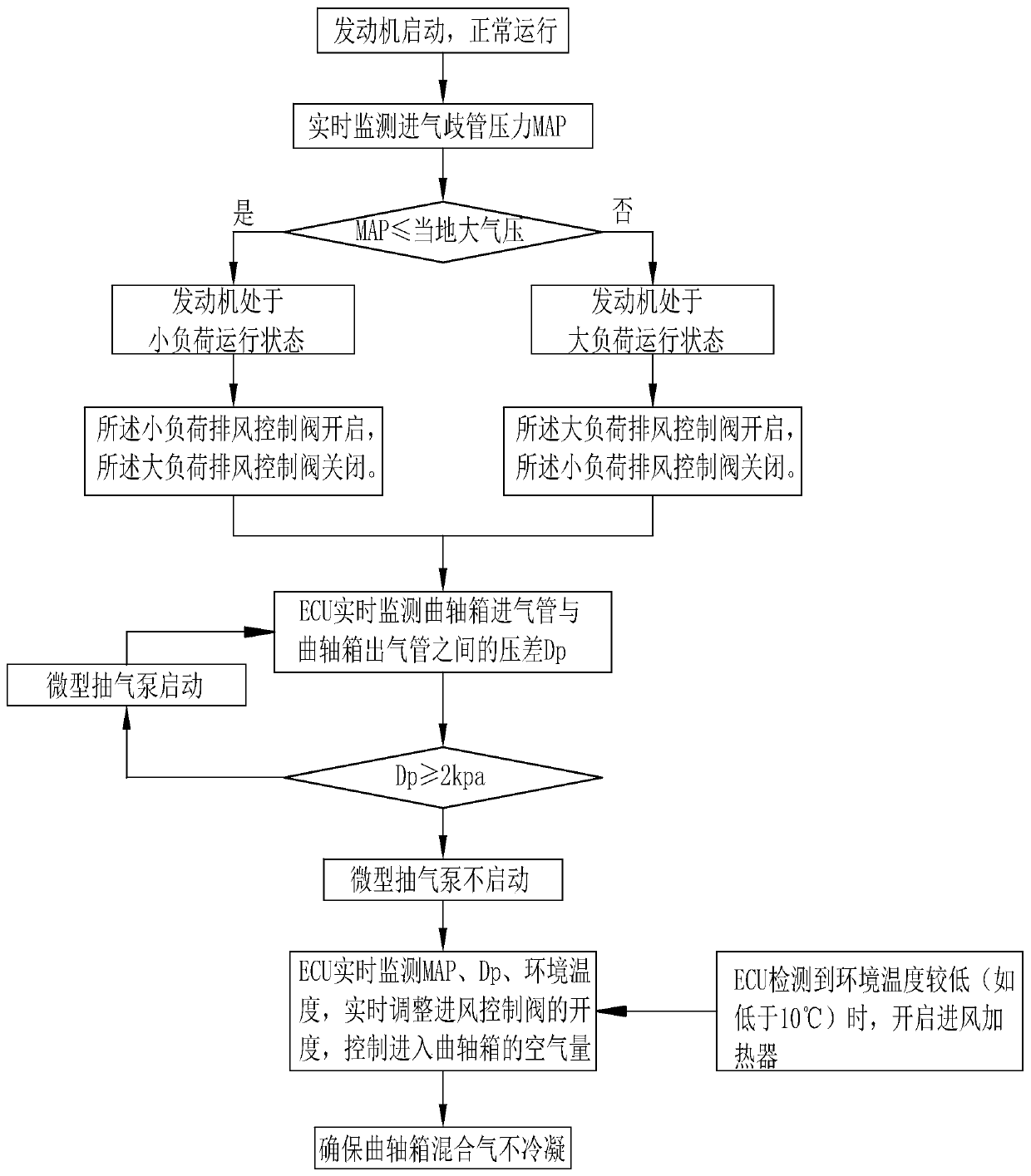

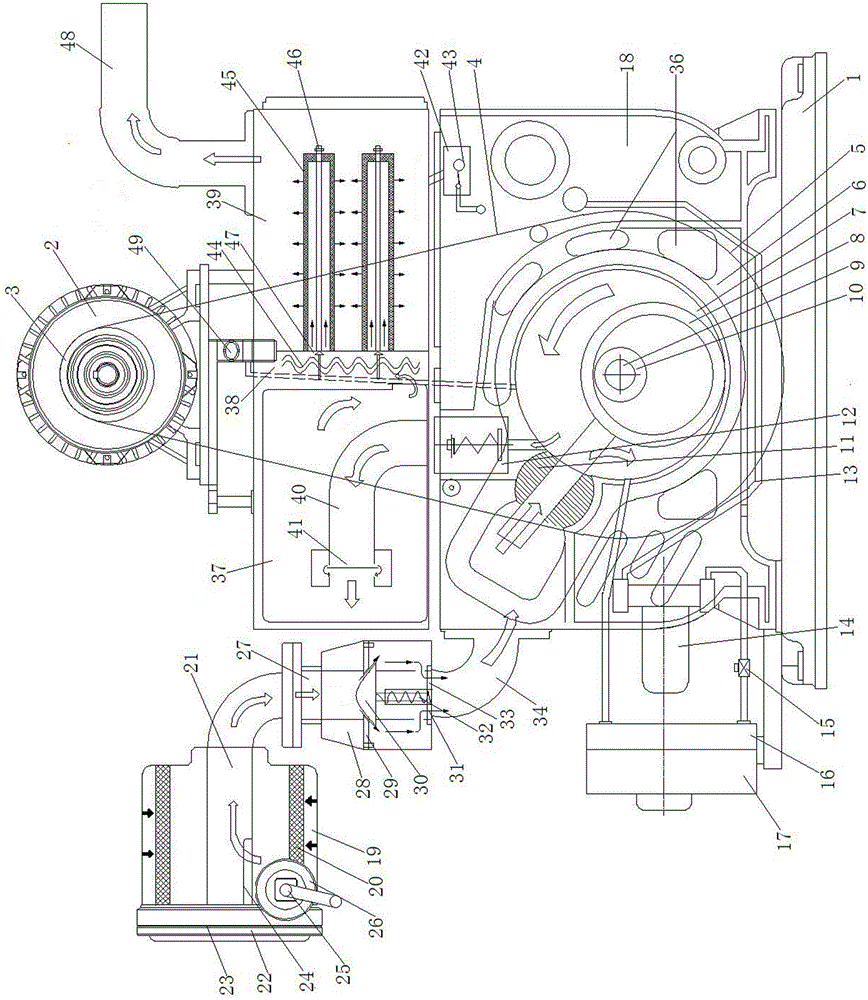

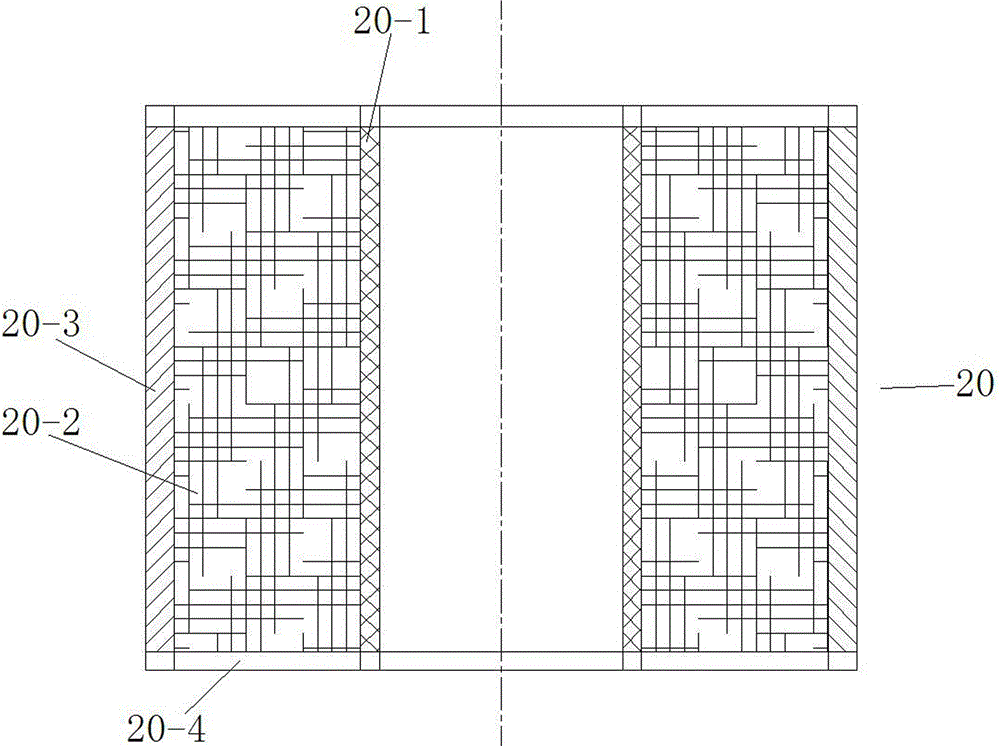

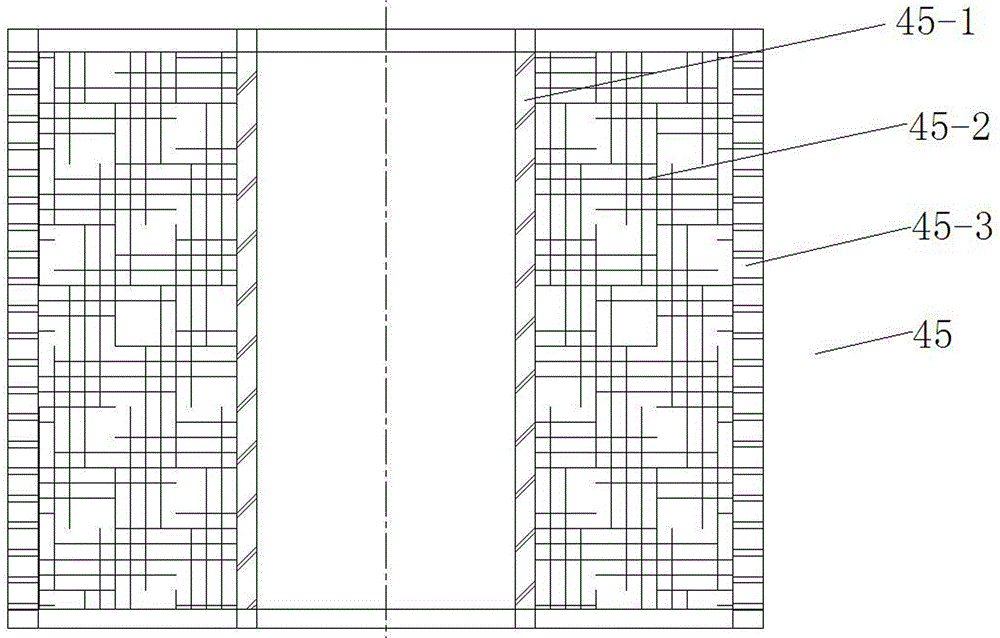

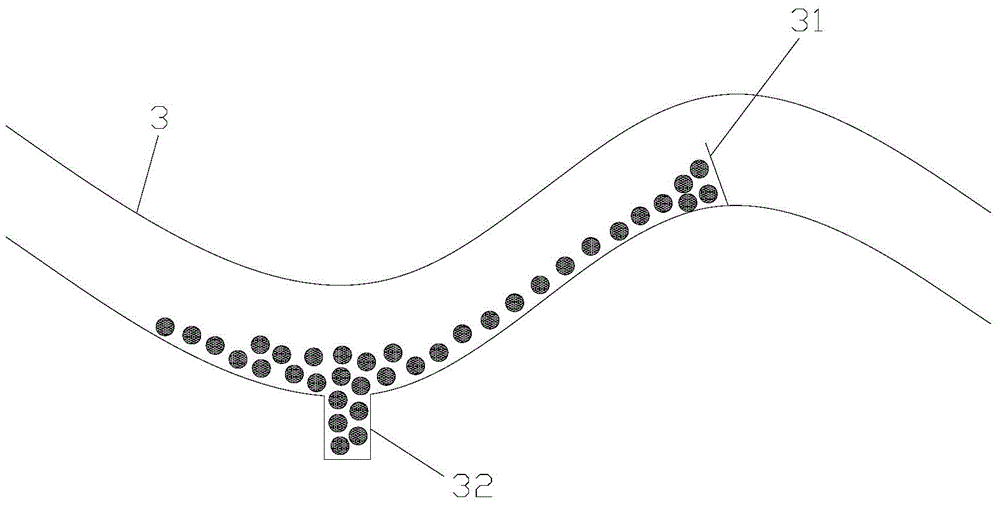

Crankcase ventilation system of supercharger front pre-mixing gas engine and ventilation method of crankcase ventilation system

PendingCN110593986AAchieving forced ventilationReduce percentage contentMachines/enginesCrankcase ventillationAir filterIntercooler

The invention discloses a crankcase ventilation system of a supercharger front pre-mixing gas engine. The crankcase ventilation system is used in cooperation with an ECU of the engine and comprises anair inlet branch pipe, a crankcase, an air inlet pipe, an air filter, a mixer, a supercharger, an intercooler and a throttle valve. The position between the air filter and the crankcase communicateswith an air inlet device, and the position between the crankcase and the air inlet branch pipe communicates with a small-load exhaust device. The small-load exhaust device is further connected with alarge-load exhaust device, and the large-load exhaust device and the air inlet branch pipe are arranged in parallel. The air outlet end of the large-load exhaust device is in communication with the part, between the mixer and the supercharger, of the air inlet pipe. A ventilation method of the system is further disclosed. Air is guided into the crankcase from a pipeline in front of the mixer, thecontent of moisture in the crankcase is reduced, accordingly, the dew point of the oil-gas mixer in the crankcase is reduced, the condensation phenomenon cannot happen, condensing and gathering of water steam into engine oil in an oil sump are eradicated, and it is ensured that damage of a lubricating component of the engine due to engine oil deterioration is avoided.

Owner:WEICHAI XIGANG NEW ENERGY POWER

Slide-valve vacuum pump suitable for vacuum extrusion of tiles

ActiveCN104481878ASolve the problem of lack of qualified cooling circulating waterAvoid failureRotary piston pumpsRotary piston liquid enginesExhaust valveVacuum extraction

The invention relates to a slide-valve vacuum pump suitable for a tile vacuum extruder, belongs to the technical field of vacuum pumps, is suitable for the industries of building materials, chemical engineering, medicines, electrons and ceramics as vacuum extraction equipment, and is especially suitable for the slide-valve vacuum pump used in the tile vacuum extruder. The slide-valve vacuum pump comprises an air inlet fine filter, a one-way check valve, a pump body, a one-piece slide bar and sliding sleeve, an eccentric wheel, a one-piece slide block, a main shaft, a belt pulley, a belt, a motor, an exhaust valve, a first exhaust oil-gas separation chamber, a second exhaust oil-gas separation chamber, a third exhaust oil-gas separation chamber, a pump oil cyclic cooling device and a base; the air inlet fine filter is arranged on a vacuum pump air inlet pipe on one side of the pump body through the one-way check valve; the air inlet fine filter comprises a shell, a fine filter filtering element, an air passing pipe, a cover board and a seal ring; and the one-way check valve comprises a valve body, a one-way check valve air inlet, a one-way check valve air outlet, a one-way check valve core, a valve core mounting base and a spring.

Owner:南通诺博特机器人制造有限公司

Oil-gas-water-solid three-level separation sled device

InactiveCN104150632ASimple structural designReasonable structural designWaste water treatment from quariesMultistage water/sewage treatmentThree levelCyclone

The invention relates to an Oil-gas-water-solid three-level separation sled device, comprising a sled shell, a cyclone bin, a sand settling diversion pipe, a sand settling bin, an inclined settling chamber, a water-gathering chamber, an oil-mixing bin, a cyclone and an oil-gathering chamber. The cyclone bin, the sand settling diversion pipe and the inclined settling chamber form a first separation system for primary separation of the oil-gas-water-solid four phases; the oil-mixing bin, a control valve and the cyclone form a second separation system for cyclone separation of oil-water two phases; and the oil-gathering chamber and the water-gathering chamber form a third separation system for gravity settling separation of the oil and water. Under a synergistic effect of the three separation systems, efficient separation of the oil, gas, water and solid is realized. The oil-gas-water-solid three-level separation sled device is simple and reasonable in structure design, has large processing capacity, occupies small floor area, is suitable for change of moisture content in a produced liquid of an oilfield, can separate oil, gas, water and solid phases in a liquid coming from the oilfield, is convenient for discharging the separated oil, gas, water and solid phases in time, has high efficiency and is simple to maintain.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com