Novel anti-emulsifying system for electric automobile air compressor

A technology of electric vehicles and air compressors, which is applied in the direction of machines/engines, mechanical equipment, liquid variable displacement machinery, etc., and can solve problems such as lubricating oil emulsification, increased maintenance costs, and easy wear of the machine head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

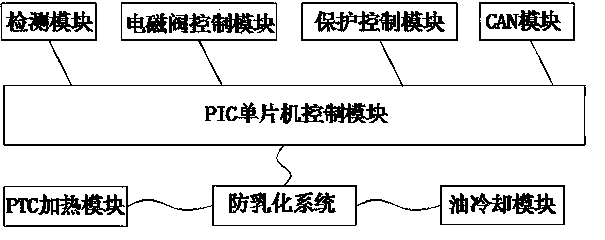

[0010] see figure 1 , a new type of anti-emulsification system for electric vehicle air compressors, which includes a PIC microcontroller control module, a PTC heating module and an oil cooling module, the core of which is the PIC microcontroller control module, which is divided into a detection module, a solenoid valve module, a protection control module and a CAN module; Both the PTC heating module and the oil cooling module are automatically controlled according to the oil temperature. This automatic control technology is mature and reduces the complexity of the PTC single-chip control.

[0011] 1. PIC microcontroller control module

[0012] The PIC single-chip microcomputer control module controls the solenoid valve according to the signals from the detection module and the CAN module. Once the pressure in the air compressor is too high or the outlet temperature is too high, the protection control module will immediately act and provide the VCU with the CAN bus. Alarm sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com