Oil-gas-water-solid three-level separation sled device

A three-stage separation, oil-gas-water technology, applied in water/sewage multi-stage treatment, mining wastewater treatment, water/sludge/sewage treatment, etc., can solve the problem of equipment treatment effect that affects pipeline transportation efficiency, oil-gas-water three-phase separator Reduced separation efficiency, inability to separate solid particles, etc., to achieve the effect of simple structure, small volume, and large daily processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

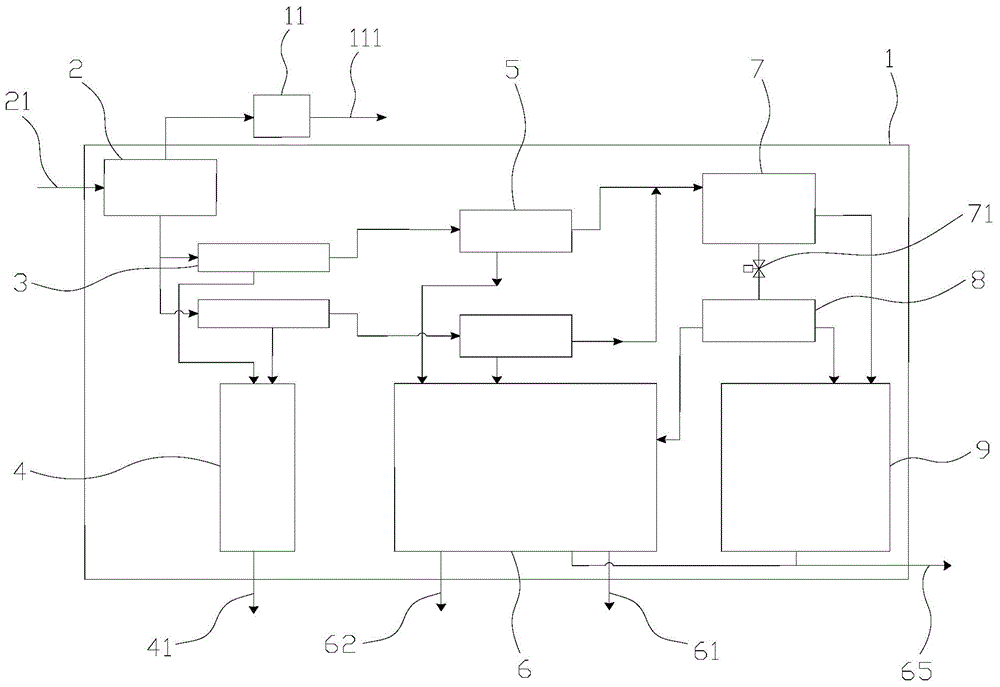

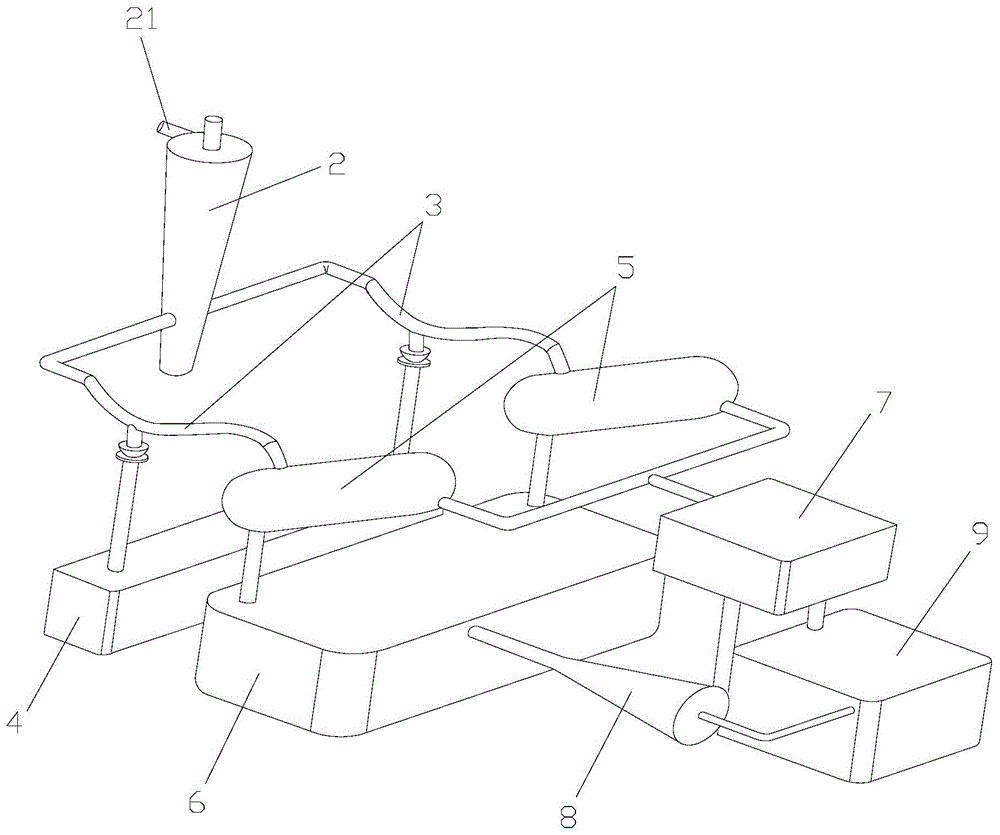

[0032] Such as Figures 1 to 8 As shown, the oil-gas-water-solid three-stage separation skid device of the present invention includes a skid shell 1 and a swirl chamber 2, a sand settling duct 3, a sand settling bin 4, and an inclined settling chamber 5 arranged inside the skid shell 1. , Water collecting chamber 6, oil mixing chamber 7, cyclone 8 and oil collecting chamber 9.

[0033] The outside of the top of the skid shell 1 is provided with a mist catcher 11, wherein one end of the mist catcher 11 is provided with an exhaust port 111, and the mist catcher 11 collects the liquid droplets in the separated gas, so as to achieve oil-gas-water Solid and efficient separation.

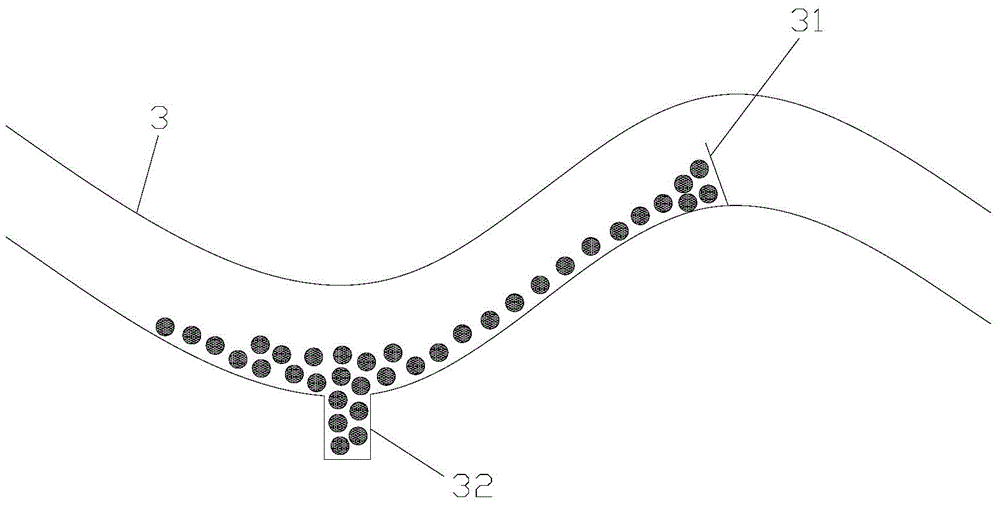

[0034]The swirl chamber 2 is used for gas phase separation and has a conical structure as a whole. There is a feed inlet 21 on one side of the top end, the top is connected to the mist catcher 11 outside the skid shell 1 through a pipe, and the bottom is through a sand settling guide tube. 3. Connect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com