Method for comprehensively extracting polysaccharides, polyphenol and saponin from camellia oleifera abel defatted cakes

A technology of camellia oleifera and camellia oleifera, which is applied in the field of comprehensive extraction of polysaccharides, polyphenols and saponins, can solve the problems of low purity of saponins and inability to separate and obtain active substances, and achieve a wide range of raw material sources, low production costs, and simple operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

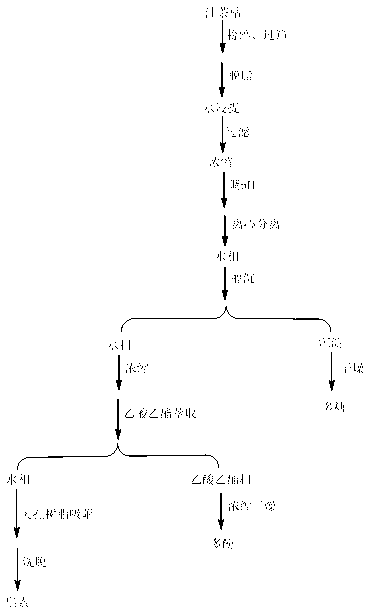

Image

Examples

Embodiment 1

[0025] Add 50 g of camellia oleifera powder to 450 ml of petroleum ether (boiling range 60-90°C), heat at 47°C for 2.5 h to remove fat and residual oil, recover petroleum ether, and dry to obtain defatted camellia oleifera powder. Water was added to the obtained degreased camellia oleifera powder, so that the mass volume ratio of camellia oleifera powder and water was 1:20 g / ml, leached continuously at 70 °C for 3.5 h, cooled, and centrifuged. Concentrate the water extract to 1 / 4 of the original volume, add 5% hydrochloric acid to adjust the pH of the solution to 4.0, centrifuge at a speed of 4500 rpm for 10 min, keep the supernatant, and then add 95% ethanol to it to make the ethanol The final concentration of the mixture was 75%, stirred, allowed to stand, and the precipitate obtained by centrifugation was freeze-dried to obtain camellia oleifera polysaccharide. The supernatant after the precipitation of polysaccharides was concentrated to 1 / 4 of the original volume, and eth...

Embodiment 2

[0028] Add 800 ml of petroleum ether (boiling range 60-90°C) to 100 g of camellia oleifera powder, heat at 50°C for 2 h to remove fat and residual oil, recover petroleum ether, and dry to obtain defatted camellia oleifera powder. Water was added to the obtained degreased Camellia oleifera powder, so that the mass volume ratio of Camellia oleifera powder and water was 1:15, the extraction was continued at 75 °C for 3 h, cooled, and centrifuged. Concentrate the water extract to 1 / 3 of the original volume, add 8% hydrochloric acid to adjust the pH of the solution to be 3.5, centrifuge at a speed of 3500 rpm for 15 min, keep the supernatant, and then add 95% ethanol to it to make the ethanol The final concentration was 80%, stirred, left standing, and the precipitate obtained by centrifugation was freeze-dried to obtain camellia oleifera polysaccharide. The supernatant after the polysaccharide precipitation was concentrated to 1 / 5 of the original volume, KCl solid was added to the...

Embodiment 3

[0031]Add 3000 ml of petroleum ether (boiling range 60-90°C) to 500 g of camellia oleifera powder, heat at 60°C for 2 h to remove fat and residual oil, recover petroleum ether, and dry to obtain defatted camellia oleifera powder. Water was added to the obtained degreased Camellia oleifera powder, so that the mass volume ratio of Camellia oleifera powder and water was 1:10, the extraction was continued at 80 °C for 2 h, cooled, and centrifuged. The water extract is concentrated to 1 / 2 of the original volume, adding 10% sulfuric acid to adjust the pH of the solution to be 3.0, centrifuging at a speed of 3000rpm for 15min, retaining the supernatant, and then adding 95% ethanol to it to make the final concentration of ethanol was 75%, stirred, left standstill, and the precipitate obtained by centrifugation was freeze-dried to obtain camellia oleifera polysaccharide. The supernatant after the polysaccharide precipitation was concentrated to 1 / 5 of the original volume, and NaCl soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com